Turn SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 506 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-8 Brake Control System and Diagnosis:

Excessive Pedal Travel InspectionS7RS0B4106003

1) Start engine.

2) Depress brake pedal a few times.

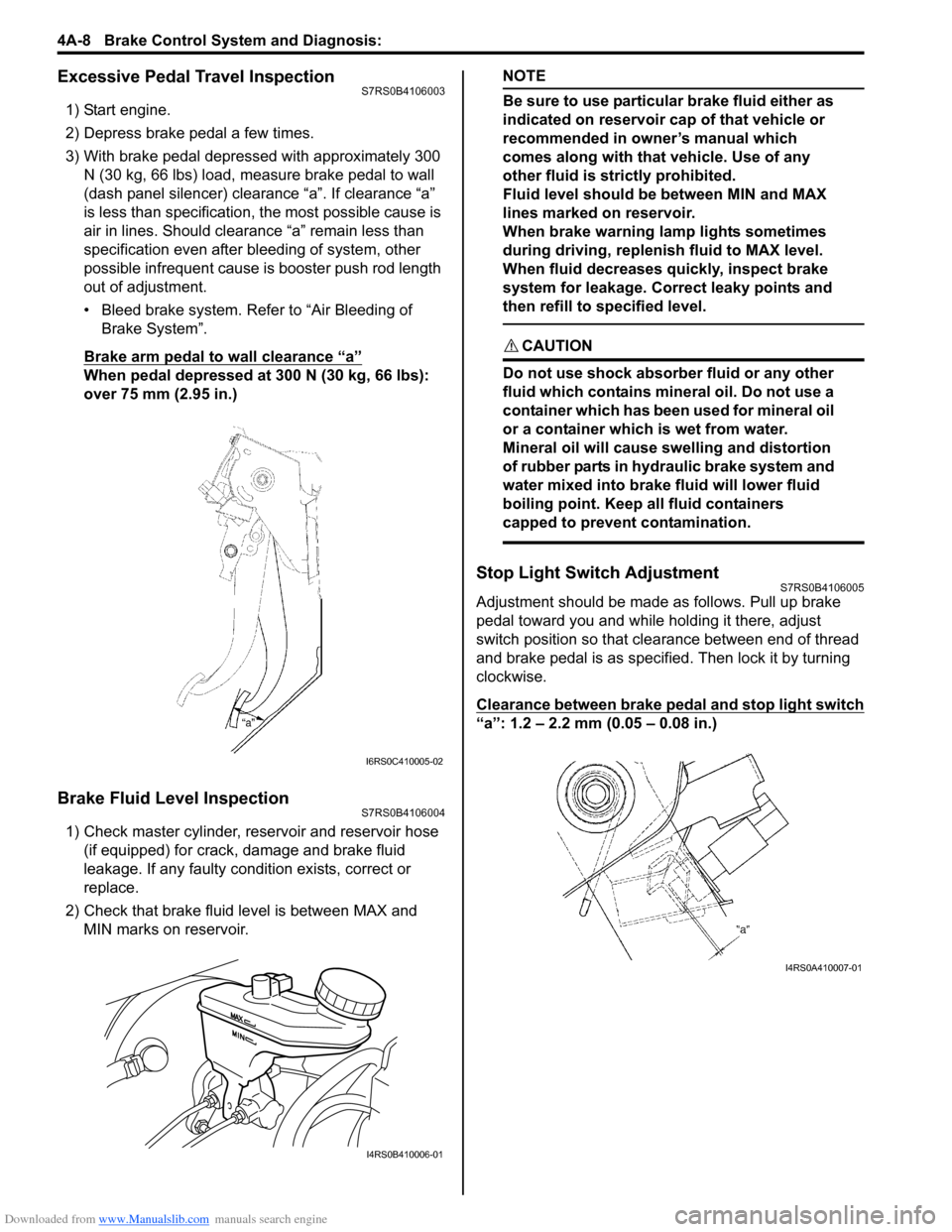

3) With brake pedal depressed with approximately 300 N (30 kg, 66 lbs) load, measure brake pedal to wall

(dash panel silencer) clearance “a”. If clearance “a”

is less than specification, the most possible cause is

air in lines. Should clearance “a” remain less than

specification even after bleeding of system, other

possible infrequent cause is booster push rod length

out of adjustment.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

Brake arm pedal to wall clearance “a”

When pedal depressed at 300 N (30 kg, 66 lbs):

over 75 mm (2.95 in.)

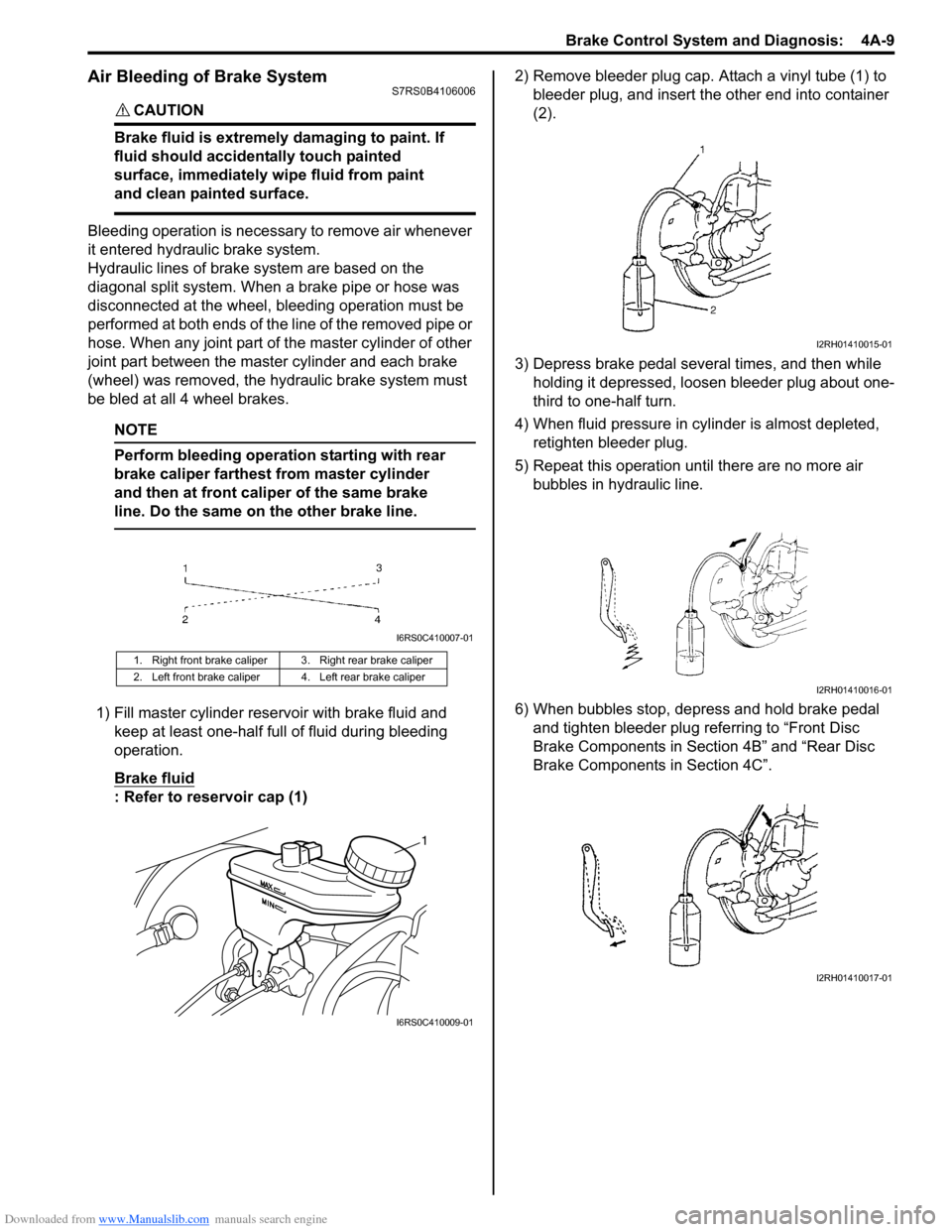

Brake Fluid Level InspectionS7RS0B4106004

1) Check master cylinder, reservoir and reservoir hose (if equipped) for crack, damage and brake fluid

leakage. If any faulty condition exists, correct or

replace.

2) Check that brake fluid level is between MAX and MIN marks on reservoir.

NOTE

Be sure to use particular brake fluid either as

indicated on reservoir cap of that vehicle or

recommended in owner’s manual which

comes along with that vehicle. Use of any

other fluid is strictly prohibited.

Fluid level should be between MIN and MAX

lines marked on reservoir.

When brake warning lamp lights sometimes

during driving, replenis h fluid to MAX level.

When fluid decreases quickly, inspect brake

system for leakage. Correct leaky points and

then refill to specified level.

CAUTION!

Do not use shock absorber fluid or any other

fluid which contains mineral oil. Do not use a

container which has been used for mineral oil

or a container which is wet from water.

Mineral oil will cause swelling and distortion

of rubber parts in hydraulic brake system and

water mixed into brake fluid will lower fluid

boiling point. Keep all fluid containers

capped to prevent contamination.

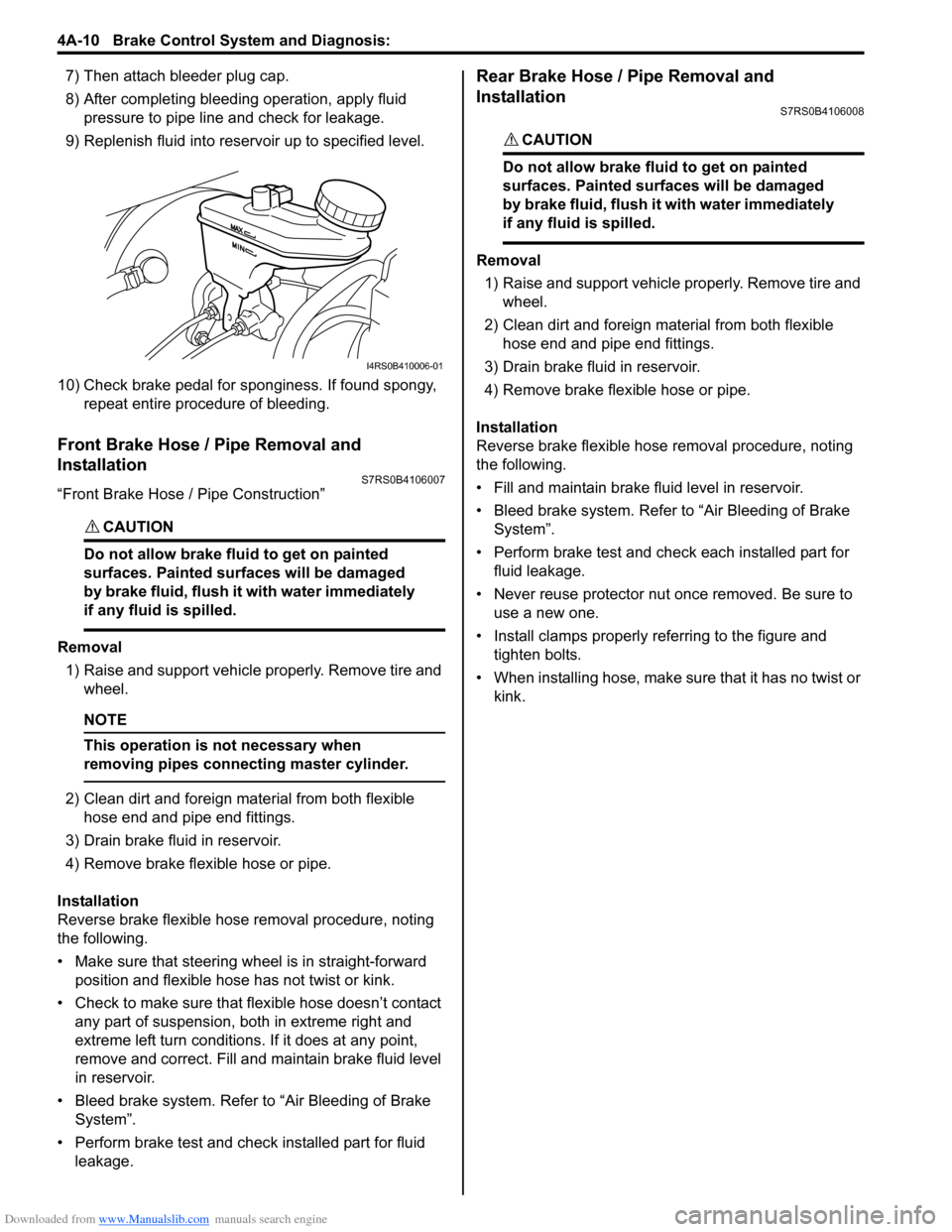

Stop Light Switch AdjustmentS7RS0B4106005

Adjustment should be made as follows. Pull up brake

pedal toward you and while holding it there, adjust

switch position so that clea rance between end of thread

and brake pedal is as specified. Then lock it by turning

clockwise.

Clearance between brake pedal and stop light switch

“a”: 1.2 – 2.2 mm (0.05 – 0.08 in.)

I6RS0C410005-02

I4RS0B410006-01

I4RS0A410007-01

Page 507 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-9

Air Bleeding of Brake SystemS7RS0B4106006

CAUTION!

Brake fluid is extremely damaging to paint. If

fluid should accidentally touch painted

surface, immediately wipe fluid from paint

and clean painted surface.

Bleeding operation is necessary to remove air whenever

it entered hydraulic brake system.

Hydraulic lines of brake system are based on the

diagonal split system. When a brake pipe or hose was

disconnected at the wheel, bleeding operation must be

performed at both ends of the line of the removed pipe or

hose. When any joint part of the master cylinder of other

joint part between the master cylinder and each brake

(wheel) was removed, the hydraulic brake system must

be bled at all 4 wheel brakes.

NOTE

Perform bleeding operation starting with rear

brake caliper farthest from master cylinder

and then at front caliper of the same brake

line. Do the same on the other brake line.

1) Fill master cylinder rese rvoir with brake fluid and

keep at least one-half full of fluid during bleeding

operation.

Brake fluid

: Refer to reservoir cap (1) 2) Remove bleeder plug cap. Attach a vinyl tube (1) to

bleeder plug, and insert the other end into container

(2).

3) Depress brake pedal several times, and then while holding it depressed, loosen bleeder plug about one-

third to one-half turn.

4) When fluid pressure in cy linder is almost depleted,

retighten bleeder plug.

5) Repeat this operation until there are no more air bubbles in hydraulic line.

6) When bubbles stop, depress and hold brake pedal and tighten bleeder plug referring to “Front Disc

Brake Components in Section 4B” and “Rear Disc

Brake Components in Section 4C”.

1. Right front brake caliper 3. Right rear brake caliper

2. Left front brake caliper 4. Left rear brake caliper

I6RS0C410007-01

1

I6RS0C410009-01

I2RH01410015-01

I2RH01410016-01

I2RH01410017-01

Page 508 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-10 Brake Control System and Diagnosis:

7) Then attach bleeder plug cap.

8) After completing bleeding operation, apply fluid pressure to pipe line and check for leakage.

9) Replenish fluid into reserv oir up to specified level.

10) Check brake pedal for sponginess. If found spongy, repeat entire procedure of bleeding.

Front Brake Hose / Pipe Removal and

Installation

S7RS0B4106007

“Front Brake Hose / Pipe Construction”

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Raise and support vehicle properly. Remove tire and wheel.

NOTE

This operation is not necessary when

removing pipes connecting master cylinder.

2) Clean dirt and foreign mate rial from both flexible

hose end and pipe end fittings.

3) Drain brake fluid in reservoir.

4) Remove brake flexible hose or pipe.

Installation

Reverse brake flexible hose removal procedure, noting

the following.

• Make sure that steering wh eel is in straight-forward

position and flexible hose has not twist or kink.

• Check to make sure that flexible hose doesn’t contact any part of suspension, both in extreme right and

extreme left turn conditions. If it does at any point,

remove and correct. Fill and maintain brake fluid level

in reservoir.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

• Perform brake test and check installed part for fluid leakage.

Rear Brake Hose / Pipe Removal and

Installation

S7RS0B4106008

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Raise and support vehicle properly. Remove tire and wheel.

2) Clean dirt and foreign material from both flexible hose end and pipe end fittings.

3) Drain brake fluid in reservoir.

4) Remove brake flexible hose or pipe.

Installation

Reverse brake flexible hose removal procedure, noting

the following.

• Fill and maintain brake fluid level in reservoir.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

• Perform brake test and check each installed part for fluid leakage.

• Never reuse protector nut once removed. Be sure to use a new one.

• Install clamps properly referring to the figure and tighten bolts.

• When installing hose, make sure that it has no twist or

kink.

I4RS0B410006-01

Page 512 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-14 Brake Control System and Diagnosis:

6) Fill reservoir with specified fluid.

7) After completing the work, bleed air from brake and clutch system referring to “Air Bleeding of Brake

System” and “Air Bleeding of Clutch System in

Section 5C” (M/T model).

8) Install cowl top panel referring to “Cowl Top Components in Section 9K”.

9) Install windshield wiper referring to “Windshield

Wiper Removal and Insta llation in Section 9D”.

10) Perform brake test and check each installed part for fluid leakage.

Master Cylinder Assembly Disassembly and

Assembly

S7RS0B4106013

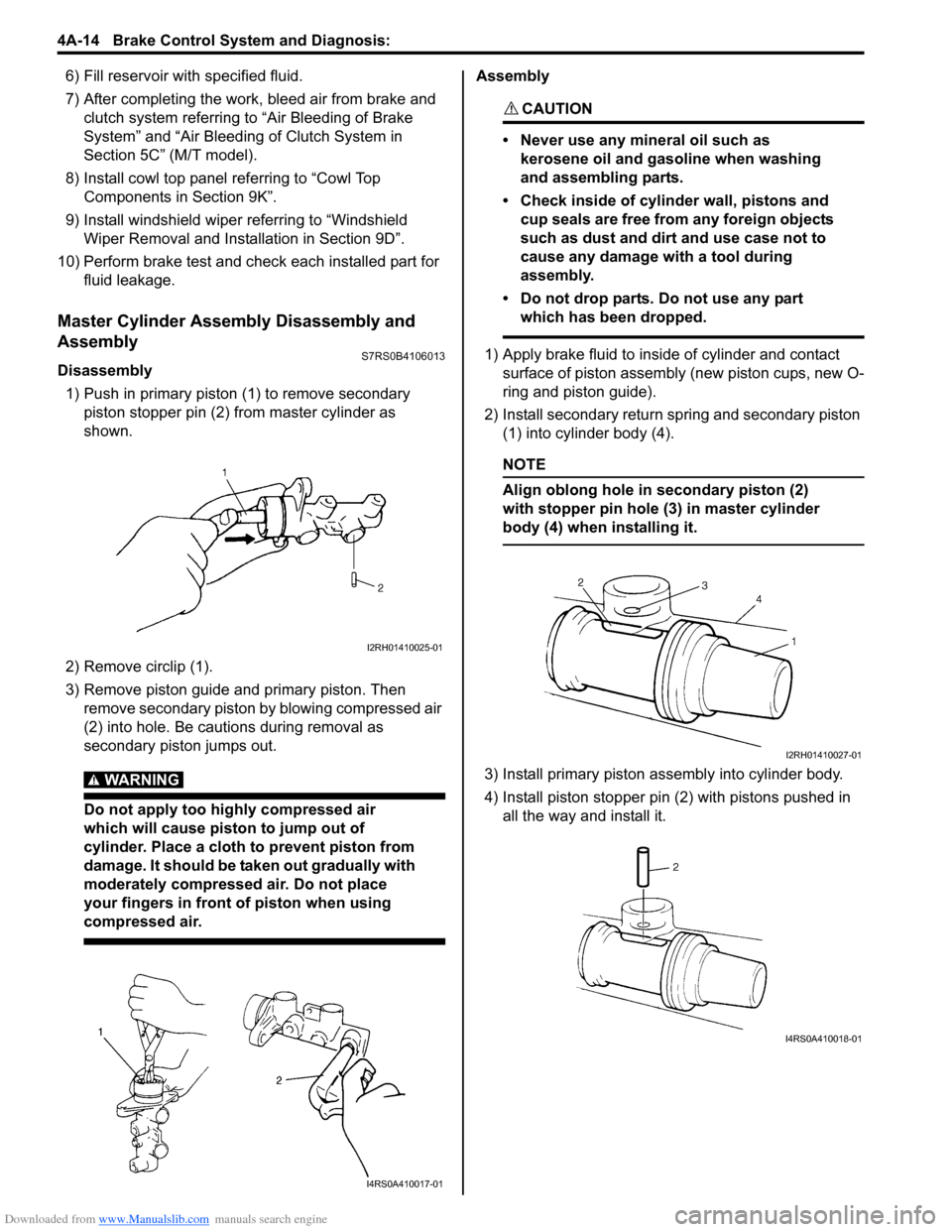

Disassembly

1) Push in primary piston (1) to remove secondary

piston stopper pin (2) from master cylinder as

shown.

2) Remove circlip (1).

3) Remove piston guide and primary piston. Then remove secondary piston by blowing compressed air

(2) into hole. Be cautions during removal as

secondary piston jumps out.

WARNING!

Do not apply too highly compressed air

which will cause piston to jump out of

cylinder. Place a cloth to prevent piston from

damage. It should be taken out gradually with

moderately compressed air. Do not place

your fingers in front of piston when using

compressed air.

Assembly

CAUTION!

• Never use any mineral oil such as kerosene oil and gasoline when washing

and assembling parts.

• Check inside of cylinder wall, pistons and cup seals are free from any foreign objects

such as dust and dirt and use case not to

cause any damage with a tool during

assembly.

• Do not drop parts. Do not use any part which has been dropped.

1) Apply brake fluid to inside of cylinder and contact surface of piston assembly (new piston cups, new O-

ring and piston guide).

2) Install secondary return spring and secondary piston (1) into cylinder body (4).

NOTE

Align oblong hole in secondary piston (2)

with stopper pin hole (3) in master cylinder

body (4) when installing it.

3) Install primary piston assembly into cylinder body.

4) Install piston stopper pin (2) with pistons pushed in all the way and install it.

I2RH01410025-01

I4RS0A410017-01

I2RH01410027-01

I4RS0A410018-01

Page 522 of 1496

Downloaded from www.Manualslib.com manuals search engine 4B-6 Front Brakes:

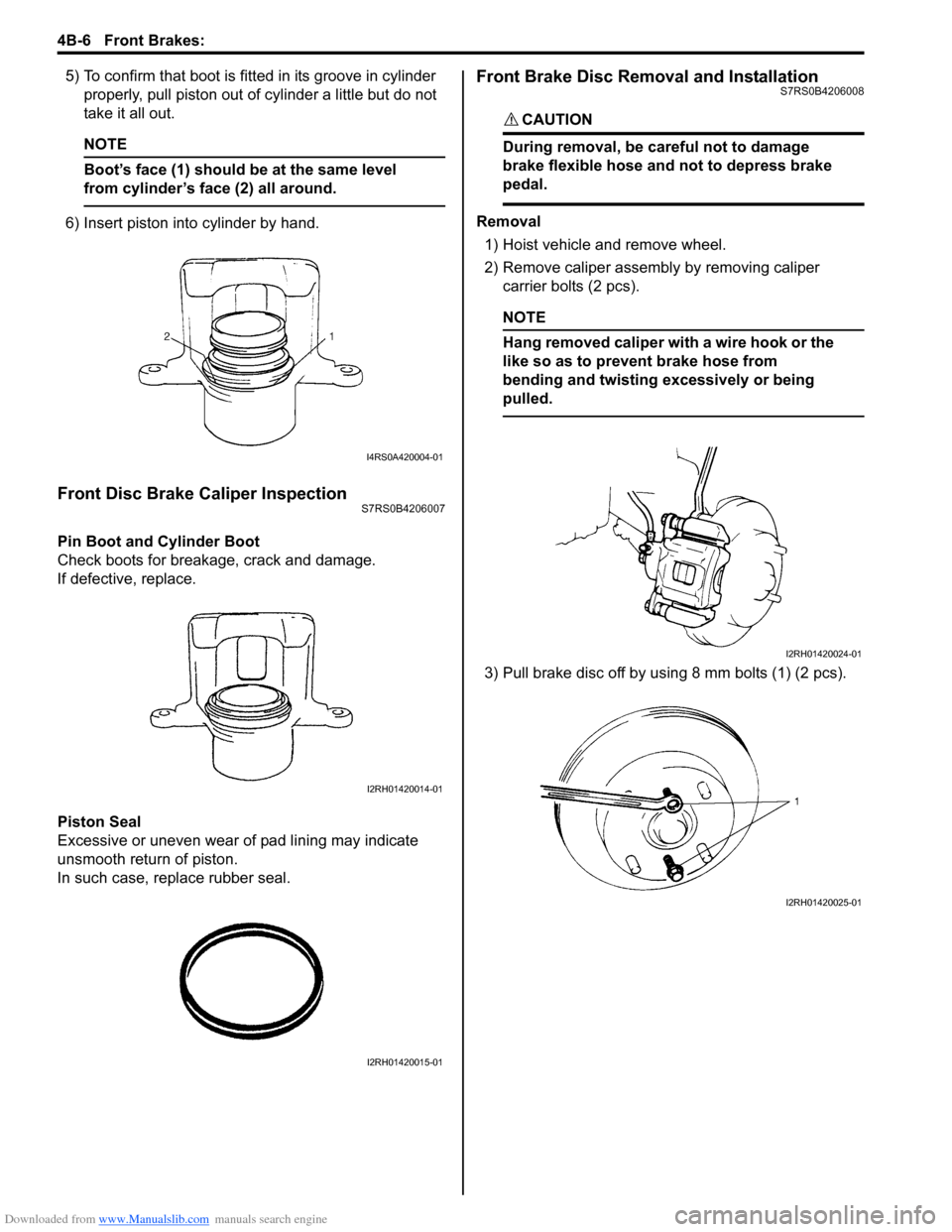

5) To confirm that boot is fitted in its groove in cylinder

properly, pull piston out of cylinder a little but do not

take it all out.

NOTE

Boot’s face (1) should be at the same level

from cylinder’s face (2) all around.

6) Insert piston into cylinder by hand.

Front Disc Brake Caliper InspectionS7RS0B4206007

Pin Boot and Cylinder Boot

Check boots for breakage, crack and damage.

If defective, replace.

Piston Seal

Excessive or uneven wear of pad lining may indicate

unsmooth return of piston.

In such case, replace rubber seal.

Front Brake Disc Removal and InstallationS7RS0B4206008

CAUTION!

During removal, be care ful not to damage

brake flexible hose and not to depress brake

pedal.

Removal

1) Hoist vehicle and remove wheel.

2) Remove caliper assembly by removing caliper carrier bolts (2 pcs).

NOTE

Hang removed caliper with a wire hook or the

like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

3) Pull brake disc off by using 8 mm bolts (1) (2 pcs).

I4RS0A420004-01

I2RH01420014-01

I2RH01420015-01

I2RH01420024-01

I2RH01420025-01

Page 525 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Brakes: 4C-1

Brakes

Rear Brakes

Repair Instructions

Rear Disc Brake ComponentsS7RS0B4306001

(d)

(c)

(a)

(a)

(a)16171413

2

1

15 2 19

12

117

7

3

7

4

20 20

5

10

9

8

(b)

18

6

24

23

22

21

I7RS0B430001-01

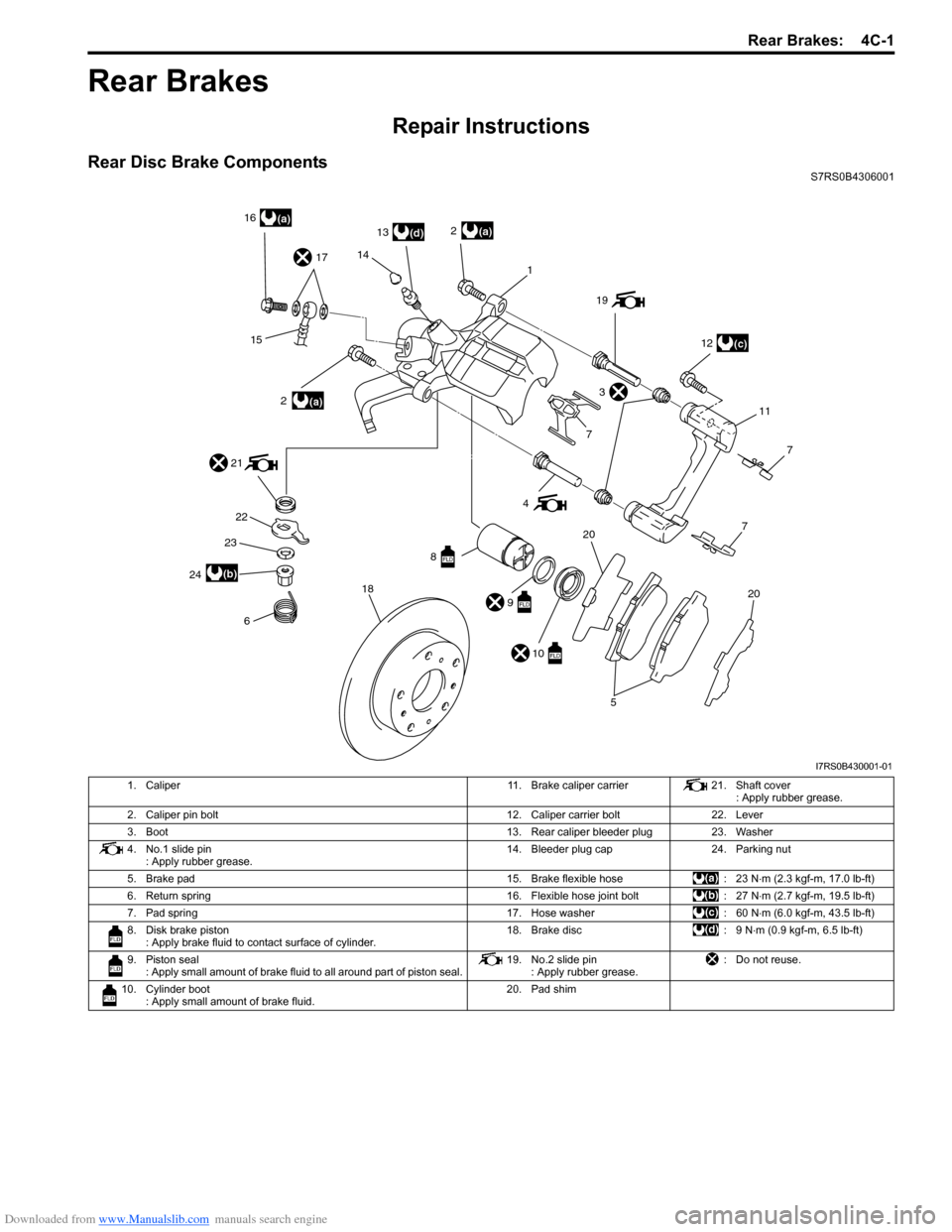

1. Caliper

11. Brake caliper carrier21. Shaft cover

: Apply rubber grease.

2. Caliper pin bolt 12. Caliper carrier bolt22. Lever

3. Boot 13. Rear caliper bleeder plug23. Washer

4. No.1 slide pin : Apply rubber grease. 14. Bleeder plug cap

24. Parking nut

5. Brake pad 15. Brake flexible hose: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

6. Return spring 16. Flexible hose joint bolt: 27 N⋅m (2.7 kgf-m, 19.5 lb-ft)

7. Pad spring 17. Hose washer: 60 N⋅m (6.0 kgf-m, 43.5 lb-ft)

8. Disk brake piston : Apply brake fluid to contact surface of cylinder. 18. Brake disc

: 9 N⋅m (0.9 kgf-m, 6.5 lb-ft)

9. Piston seal : Apply small amount of brake fluid to all around part of piston seal. 19. No.2 slide pin

: Apply rubber grease. : Do not reuse.

10. Cylinder boot : Apply small amount of brake fluid. 20. Pad shim

Page 526 of 1496

Downloaded from www.Manualslib.com manuals search engine 4C-2 Rear Brakes:

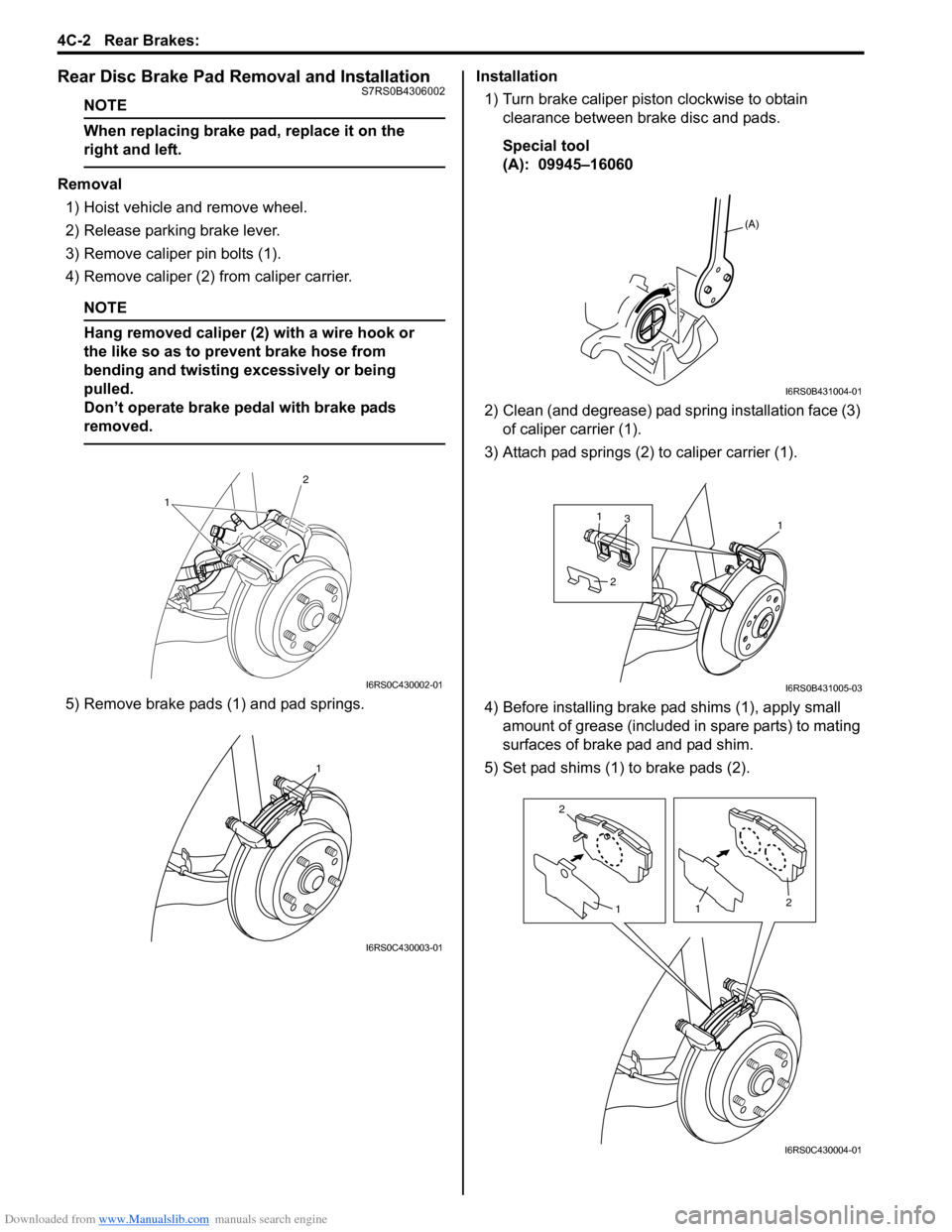

Rear Disc Brake Pad Removal and InstallationS7RS0B4306002

NOTE

When replacing brake pad, replace it on the

right and left.

Removal1) Hoist vehicle and remove wheel.

2) Release parking brake lever.

3) Remove caliper pin bolts (1).

4) Remove caliper (2) from caliper carrier.

NOTE

Hang removed caliper (2) with a wire hook or

the like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

Don’t operate brake pedal with brake pads

removed.

5) Remove brake pads (1) and pad springs. Installation

1) Turn brake caliper piston clockwise to obtain clearance between brake disc and pads.

Special tool

(A): 09945–16060

2) Clean (and degrease) pad spring installation face (3) of caliper carrier (1).

3) Attach pad springs (2) to caliper carrier (1).

4) Before installing brake p ad shims (1), apply small

amount of grease (included in spare parts) to mating

surfaces of brake pad and pad shim.

5) Set pad shims (1) to brake pads (2).

1 2

I6RS0C430002-01

1

I6RS0C430003-01

(A)

I6RS0B431004-01

113

2

I6RS0B431005-03

2

1

1 2

I6RS0C430004-01

Page 530 of 1496

Downloaded from www.Manualslib.com manuals search engine 4C-6 Rear Brakes:

Rear Disc Brake Pad InspectionS7RS0B4306004

Check pad lining for wear. When wear exceeds limit,

replace with new one.

CAUTION!

Never polish pad lining with sandpaper. If

lining is polished with sandpaper, hard

particles of sandpaper will be deposited in

lining and may damage disc. When pad lining

requires correction, replace it with a new one.

Rear brake pad thickness (lining thickness)

Standard: 9.0 mm (0.354 in.)

Limit: 1.0 mm (0.039 in.)

NOTE

When pads are removed, visually inspect

caliper for brake fluid leak. Correct leaky

point, if any.

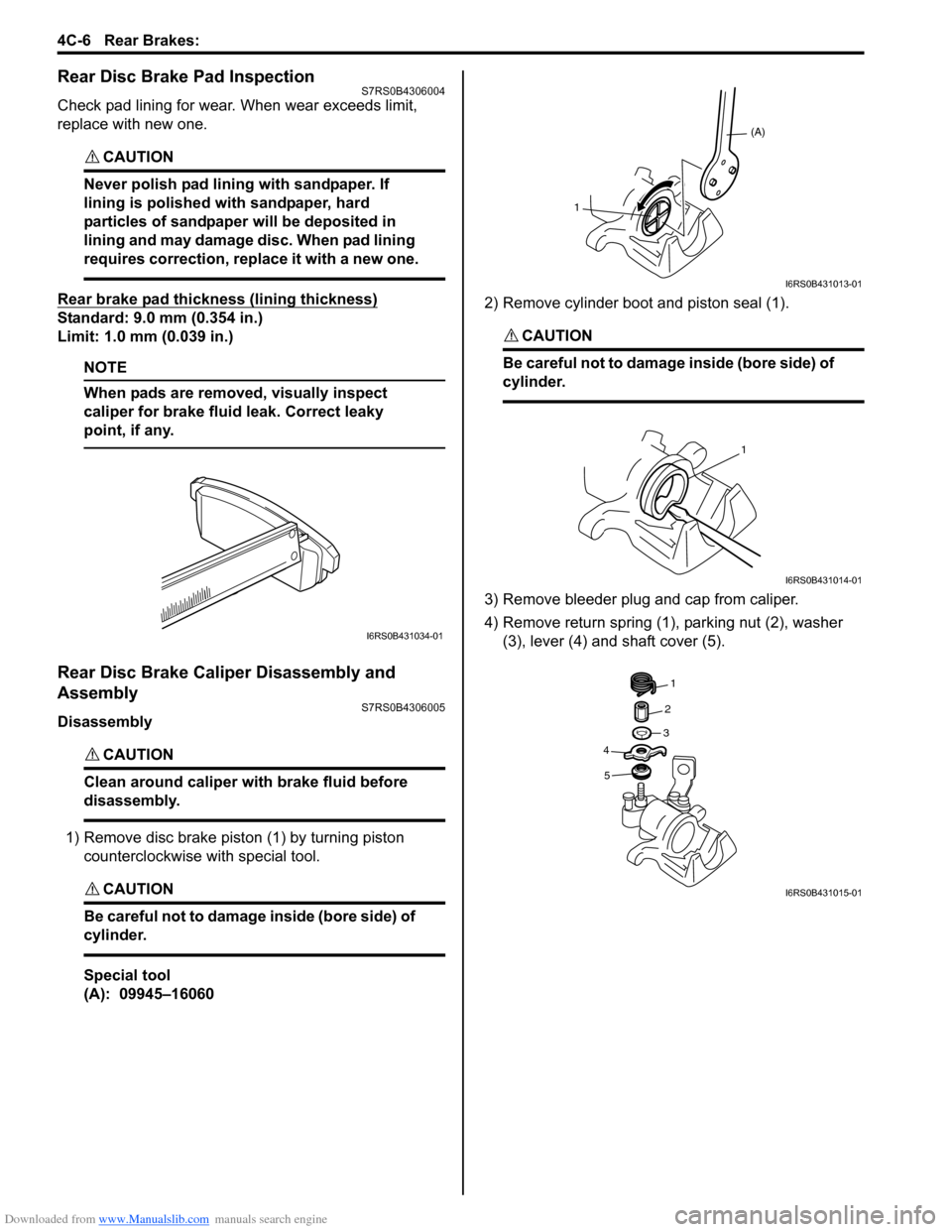

Rear Disc Brake Caliper Disassembly and

Assembly

S7RS0B4306005

Disassembly

CAUTION!

Clean around caliper with brake fluid before

disassembly.

1) Remove disc brake piston (1) by turning piston counterclockwise with special tool.

CAUTION!

Be careful not to damage inside (bore side) of

cylinder.

Special tool

(A): 09945–16060 2) Remove cylinder boot and piston seal (1).

CAUTION!

Be careful not to damage inside (bore side) of

cylinder.

3) Remove bleeder plug and cap from caliper.

4) Remove return spring (1), parking nut (2), washer

(3), lever (4) and shaft cover (5).

I6RS0B431034-01

(A)

1

I6RS0B431013-01

1

I6RS0B431014-01

1

2

3

4

5

I6RS0B431015-01

Page 531 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Brakes: 4C-7

Assembly

CAUTION!

• Wash each part cleanly before installation in the same fluid as the one used in master

cylinder reservoir.

• Never use other fluid or thinner.

• Before installing caliper to brake caliper carrier, install slide pins with grease

applied into carrier hole and check for its

smooth movement in thrust direction.

• Before installing piston seal to cylinder, apply fluid to them.

• Install a piston seal into groove in cylinder securely making sure that it is not twisted.

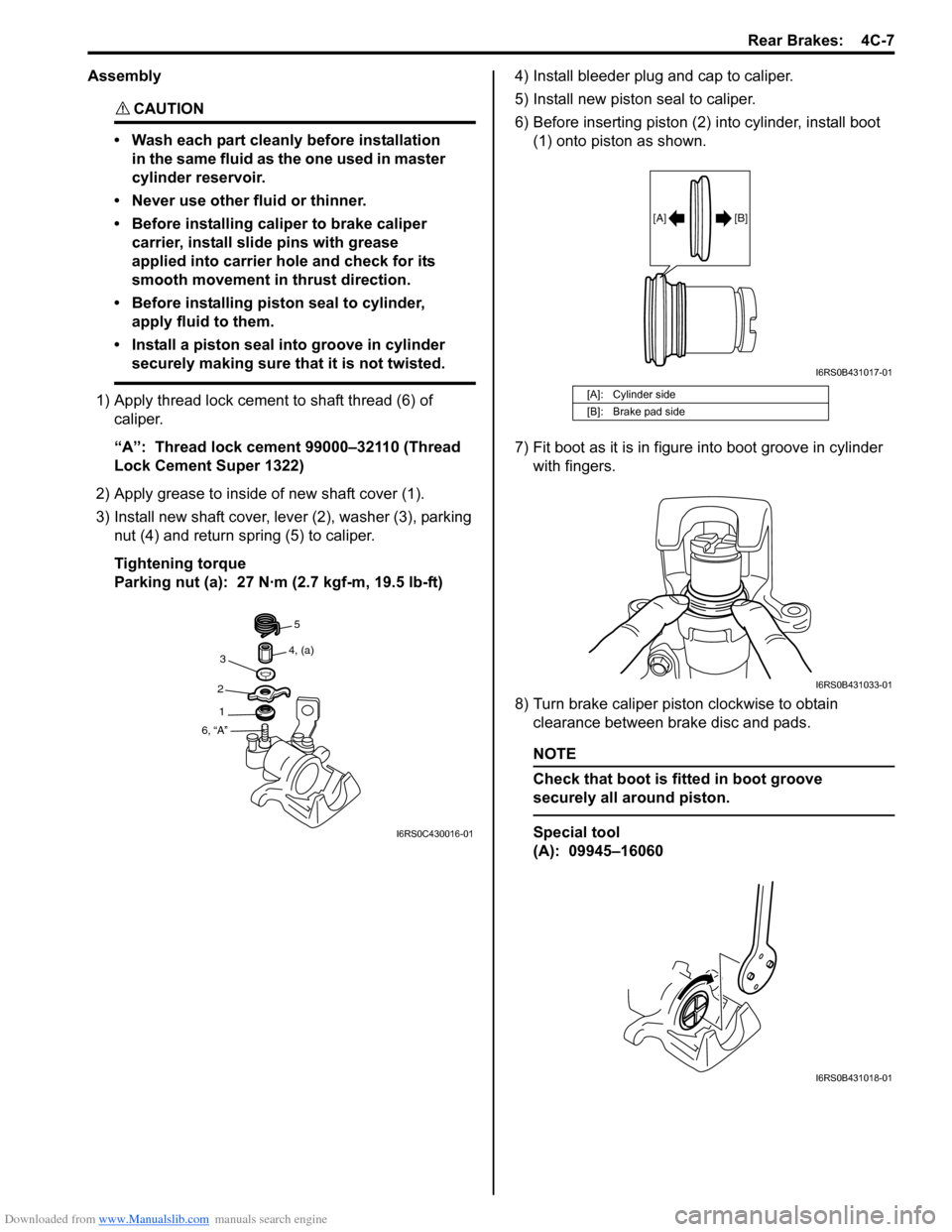

1) Apply thread lock cement to shaft thread (6) of caliper.

“A”: Thread lock cement 99000–32110 (Thread

Lock Cement Super 1322)

2) Apply grease to inside of new shaft cover (1).

3) Install new shaft cover, leve r (2), washer (3), parking

nut (4) and return spring (5) to caliper.

Tightening torque

Parking nut (a): 27 N·m (2.7 kgf-m, 19.5 lb-ft) 4) Install bleeder plug and cap to caliper.

5) Install new piston seal to caliper.

6) Before inserting piston (2) into cylinder, install boot

(1) onto piston as shown.

7) Fit boot as it is in figure into boot groove in cylinder with fingers.

8) Turn brake caliper piston clockwise to obtain clearance between brake disc and pads.

NOTE

Check that boot is fitted in boot groove

securely all around piston.

Special tool

(A): 09945–16060

5

4, (a)

2

3

1

6, “A”

I6RS0C430016-01

[A]: Cylinder side

[B]: Brake pad side

[A] [B]

I6RS0B431017-01

I6RS0B431033-01

I6RS0B431018-01

Page 541 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-2

General Description

ABS DescriptionS7RS0B4501001

The ABS (Antilock Brake System) controls the fluid

pressure applied to the wheel cylinder of each brake

from the master cylinder so that each wheel is not locked

even when hard braking is applied.

This ABS has also the following function.

While braking is applied, but before ABS control

becomes effective, braking force is distributed between

the front and rear so as to prevent the rear wheels from

being locked too early for better stability of the vehicle.

The main component parts of this ABS include the

following parts in addition to those of the conventional

brake system.

• Wheel speed sensor which senses revolution speed of each wheel and outputs its signal.

• ABS warning light which light s to inform abnormality

when system fails to operate properly.

• ABS hydraulic unit / cont rol module assembly is

incorporated ABS co ntrol module, ABS hydraulic unit

(actuator assembly), solenoid valve power supply

driver (transistor), solenoid valve driver (transistor),

pump motor driver (transistor).

– ABS control module which sends operation signal to ABS hydraulic unit to control fluid pressure

applied to each wheel cylinder based on signal

from each wheel speed sensor so as to prevent

wheel from locking.

– ABS hydraulic unit which operates according to signal from ABS control module to control fluid

pressure applied to wheel cylinder of each 4

wheels.

– Solenoid valve power supp ly driver (transistor)

which supplies power to solenoid valve in ABS

hydraulic unit.

– Solenoid valve driver (transistor) which controls each solenoid valves in ABS hydraulic unit.

– Pump motor driver (transistor) which supplies power to pump motor in ABS hydraulic unit.

This ABS is equipped with Electronic Brake force

Distribution (EBD) system that controls a fluid pressure

of rear wheels to best condition, which is the same

function as that of proportion ing valve, by the signal from

wheel sensor independently of change of load due to

load capacity and so on. An d if the EBD system fails to

operate properly, the brake warning light lights to inform

abnormality.

ABS Hydraulic Unit / Control Module Assembly

Description

S7RS0B4501002

ABS control module is a component of ABS hydraulic

unit / control module asse mbly and has the following

functions.

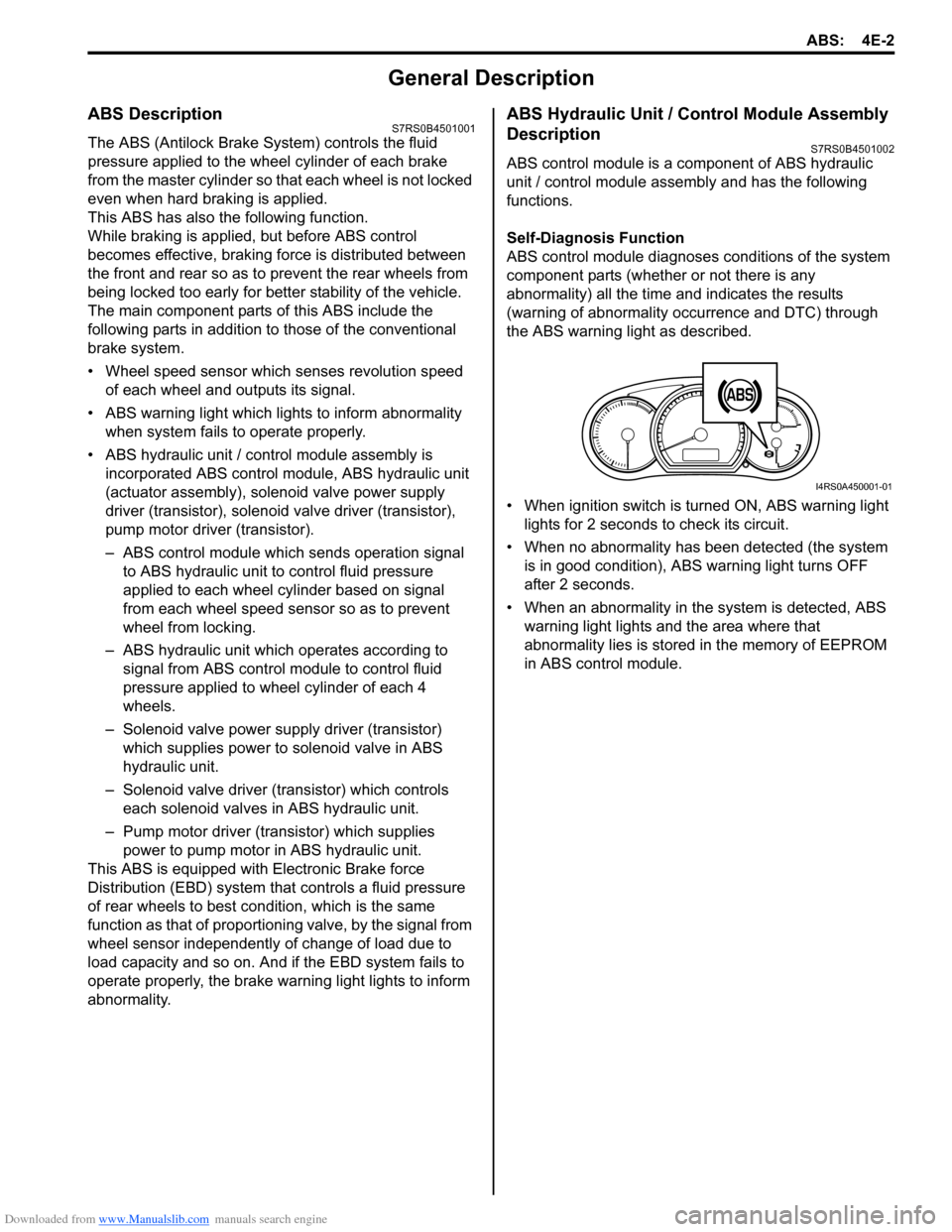

Self-Diagnosis Function

ABS control module diagnose s conditions of the system

component parts (whether or not there is any

abnormality) all the time and indicates the results

(warning of abnormality occurrence and DTC) through

the ABS warning light as described.

• When ignition switch is turned ON, ABS warning light lights for 2 seconds to check its circuit.

• When no abnormality has been detected (the system is in good condition), ABS warning light turns OFF

after 2 seconds.

• When an abnormality in th e system is detected, ABS

warning light lights and the area where that

abnormality lies is stored in the memory of EEPROM

in ABS control module.

1

I4RS0A450001-01