air con switch SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 952 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-4 Air Conditioning System: Manual Type

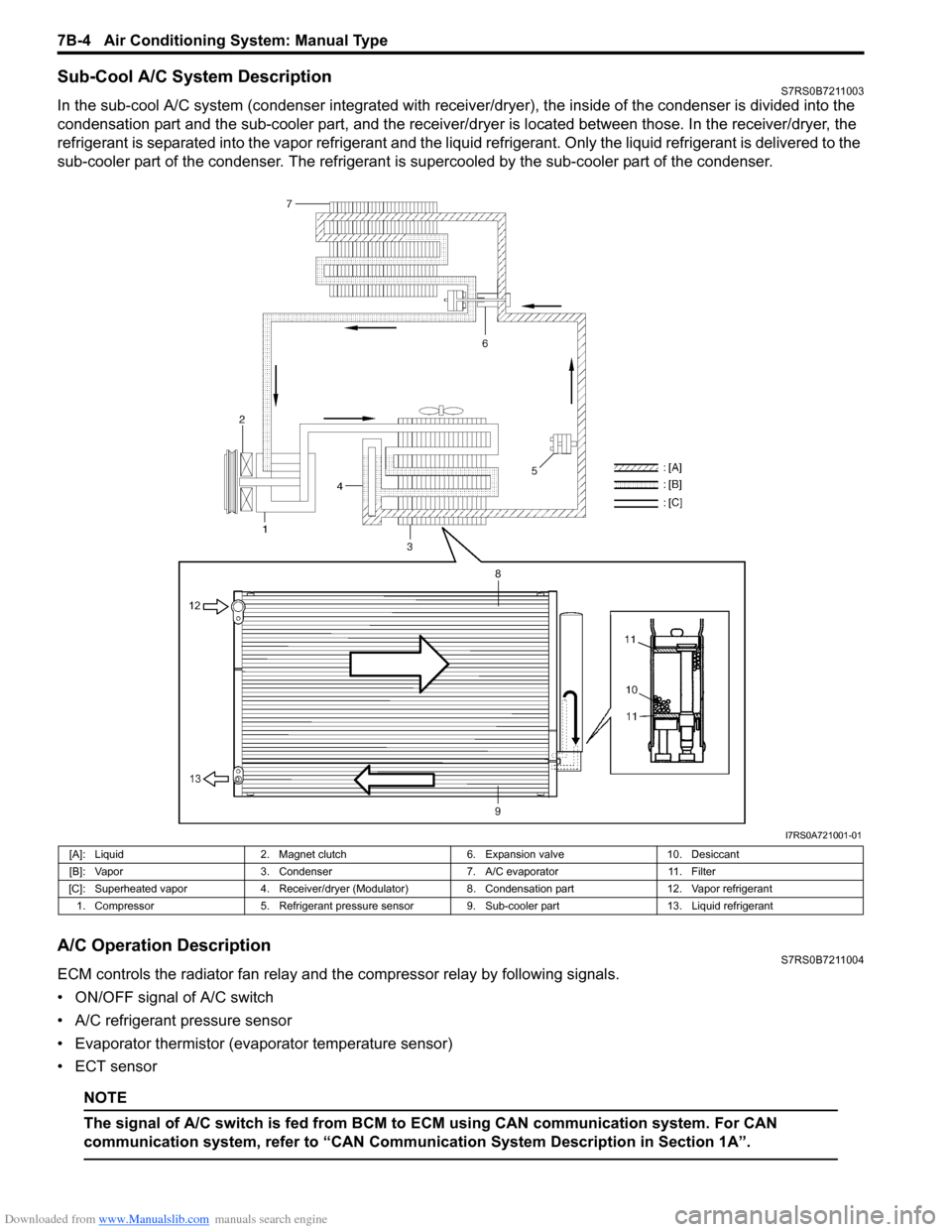

Sub-Cool A/C System DescriptionS7RS0B7211003

In the sub-cool A/C system (condenser integrated with receiver/dryer), the inside of the condenser is divided into the

condensation part and the sub-cooler part, and the receiver/dryer is located between those. In the receiver/dryer, the

refrigerant is separated into the vapor refrigerant and the liqui d refrigerant. Only the liquid refrigerant is delivered to the

sub-cooler part of the condenser. The refrigerant is supercooled by the sub-cooler part of the condenser.

A/C Operation DescriptionS7RS0B7211004

ECM controls the radiator fan relay and the compressor relay by following signals.

• ON/OFF signal of A/C switch

• A/C refrigerant pressure sensor

• Evaporator thermistor (evaporator temperature sensor)

• ECT sensor

NOTE

The signal of A/C swit ch is fed from BCM to ECM usin g CAN communication system. For CAN

communication system, refer to “CAN Communication System Description in Section 1A”.

I7RS0A721001-01

[A]: Liquid 2. Magnet clutch 6. Expansion valve10. Desiccant

[B]: Vapor 3. Condenser 7. A/C evaporator11. Filter

[C]: Superheated vapor 4. Receiver/dryer (Modulator) 8. Condensation part12. Vapor refrigerant

1. Compressor 5. Refrigerant pressure sensor 9. Sub-cooler part 13. Liquid refrigerant

Page 954 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-6 Air Conditioning System: Manual Type

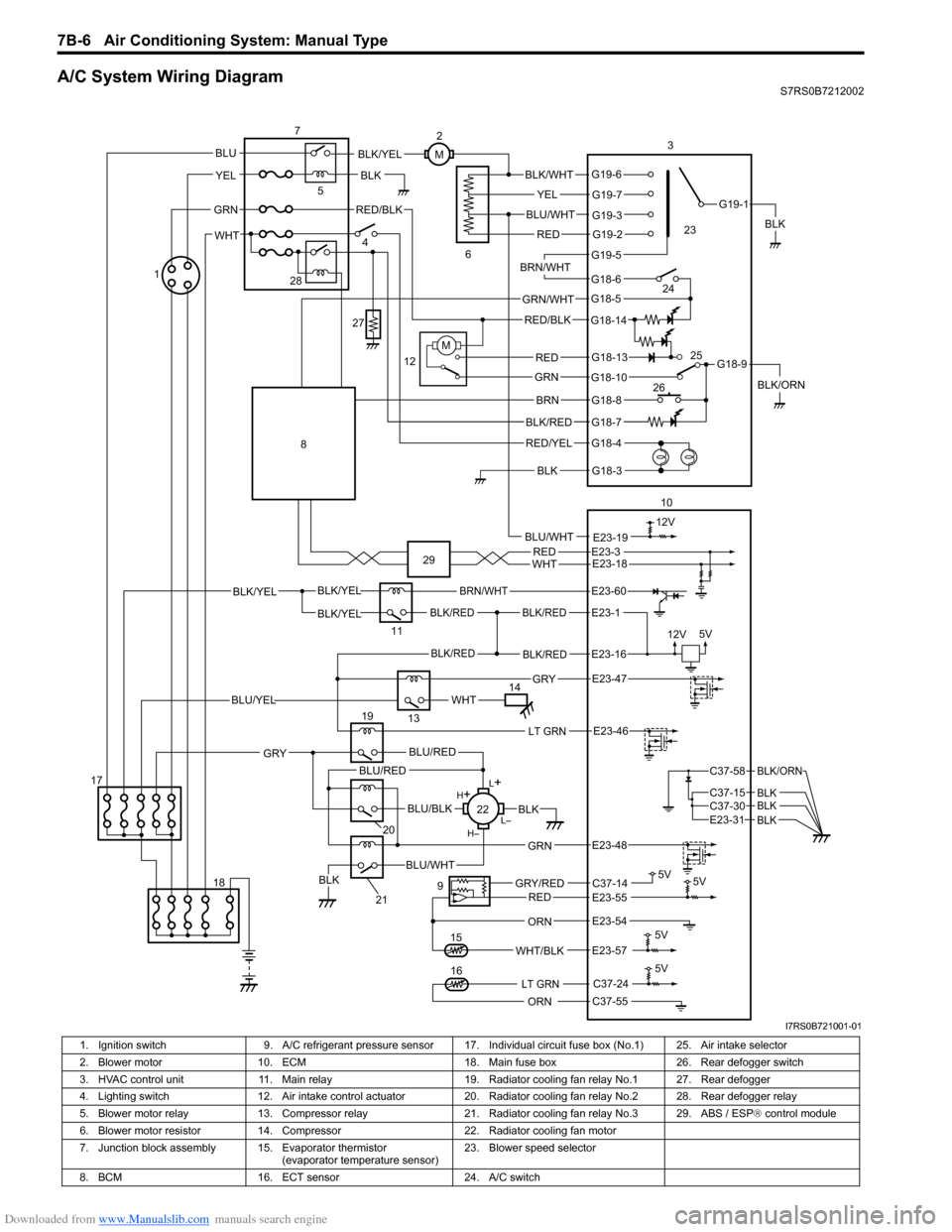

A/C System Wiring DiagramS7RS0B7212002

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

12V5V

5V 5V

5V11

E23-1

E23-60

BLK/REDBLK/REDE23-16

E23-57WHT/BLK

9

13

E23-55C37-14GRY/REDRED

BLK

ORN

E23-47 GRY

WHTBLU/YEL

RED/BLK

14 3

1

15

5

7

BLK

2

M

12VBLU/WHTE23-19

C37-24

C37-55ORN

5V

LT GRN16

G18-3

G18-4

G18-7

G18-8

G18-10

G18-13

G18-5

G18-6

G19-5

G19-2

G19-3

G19-7

G19-6

G19-1

G18-9

G18-14

BLK/WHT

YEL

BLU/WHT

RED

BRN/WHT

GRN/WHT

RED/BLK

RED

GRN

BRN

BLK/RED

RED/YEL

BLK

BLK/YEL

BLK/ORN

4

6

12

10

M

E23-54

REDWHTE23-3E23-18

17 18

LT GRNE23-46

L+

L–

H–

H

+

BLU/RED

BLK

BLU/WHTBLK

BLU/BLK

20

GRN

GRY

E23-48

19

21

22

BLU/REDC37-58

C37-15 C37-30

BLK/ORN

BLKBLKE23-31 BLK

BLU

YEL

GRN

WHT

23

24

26 25

28

27

8

29

I7RS0B721001-01

1. Ignition switch

9. A/C refrigerant pressure sensor 17. I ndividual circuit fuse box (No.1) 25. Air intake selector

2. Blower motor 10. ECM 18. Main fuse box 26. Rear defogger switch

3. HVAC control unit 11. Main relay 19. Radiator cooling fan relay No.1 27. Rear defogger

4. Lighting switch 12. Air intake control actuator 20. Radiator cooling fan relay No.2 28. Rear defogger relay

5. Blower motor relay 13. Compressor relay 21. Radiator cooling fan relay No.3 29. ABS / ESP ® control module

6. Blower motor resistor 14. Compressor 22. Radiator cooling fan motor

7. Junction block assembly 15. Evaporator thermistor (evaporator temperature sensor)23. Blower speed selector

8. BCM 16. ECT sensor 24. A/C switch

Page 955 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-7

Diagnostic Information and Procedures

A/C System Symptom DiagnosisS7RS0B7214001

ConditionPossible cause Correction / Reference Item

No cool air comes out (A/

C system does not

operate) No refrigerant

Perform recovery, evacuation and charge

referring to “Operation Procedure for

Refrigerant Charge”.

Fuse blown Check related fuses, and then check for short

circuit to ground.

A/C switch faulty Check A/C switch referring to “A/C Switch

Inspection”.

Blower speed selector faulty Check blower speed selector referring to

“Blower Speed Selector Inspection in Section

7A”.

Evaporator thermistor (Evaporator

temperature sensor) faulty Check evaporator thermistor (evaporator

temperature sensor) referring to “Evaporator

Thermistor (Evaporator Temperature Sensor)

Inspection”.

A/C refrigerant pressure sensor faulty Check A/C refrigerant pressure sensor

referring to “A/C Refrigerant Pressure Sensor

and Its Circuit Inspection”.

Wiring or grounding faulty Repair as necessary.

ECM faulty Check ECM referring to “A/C System

Inspection at ECM”.

Magnet clutch faulty Check magnet clutch referring to “Magnet

Clutch Inspection”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Compressor relay faulty Check compressor relay referring to

“Compressor Relay Inspection”.

BCM faulty Check BCM referring to “Inspection of BCM

and its Circuits in Section 10B”.

No cool air comes out

(radiator cooling fan

motor does not operate) Fuse blown

Check related fuses, and then check for short

circuit to ground.

Wiring or grounding faulty Repair as necessary.

Radiator cooling fan motor relay faulty Check radiator cooling fan motor relay

referring to “Radiator Cooling Fan Relay

Inspection in Section 1F”.

Radiator cooling fan motor faulty Check radiator cooling fan motor referring to

“Radiator Cooling Fan Removal and

Installation in Section 1F”.

ECM and/or its circuit faulty Check ECM and/or its circuit referring to “A/C

System Inspection at ECM”.

No cool air comes out

(blower motor does not

operate) Fuse blown

Check related fuses, and then check for short

circuit to ground.

Blower motor relay faulty Check blower motor relay referring to “Blower

Motor Relay Inspection in Section 7A”.

Blower motor resistor faulty Check blower motor resistor referring to

“Blower Motor Resistor Inspection in Section

7A”.

Blower speed selector faulty Check blower speed selector referring to

“Blower Speed Selector Inspection in Section

7A”.

Wiring or grounding faulty Repair as necessary.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Page 959 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-11

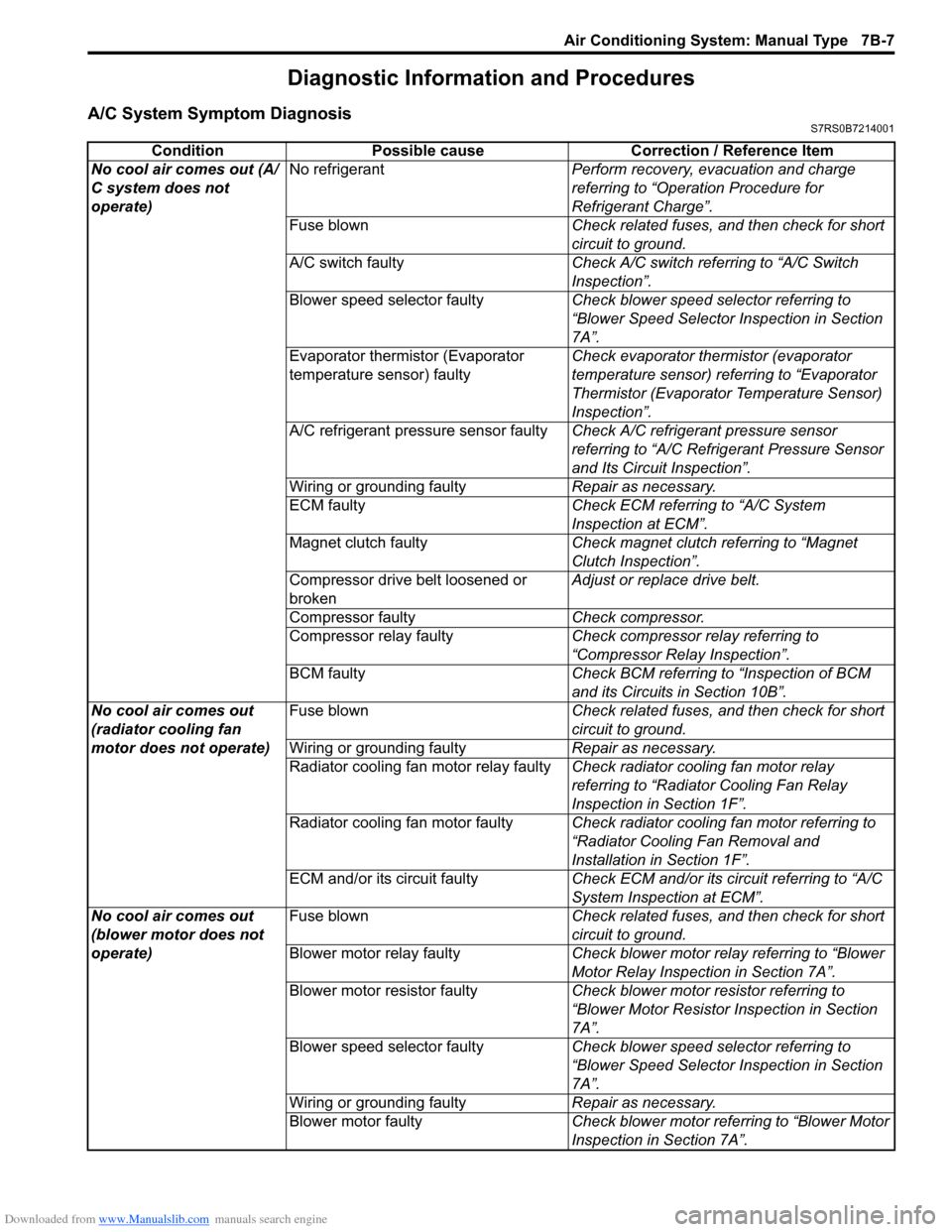

5) Warm up engine to the normal operating temperature and keep it at the specified idle speed.

6) Turn A/C switch ON, set blower speed selector at maximum speed position, temperature selector at

maximum cold position, airflow selector at face

position, and air intake switch at recirculation

position. (Confirm that A/C compressor and

condenser fans are working.)

7) Wait for ten minutes to stabilize the A/C operation.

8) Open front windows, front doors and engine hood.

9) With about 20 mm (0.8 in.) of dry bulb thermometer

(1) put right in front of center ventilation louver and a

wet and dry bulb thermometer (2) near air inlet of

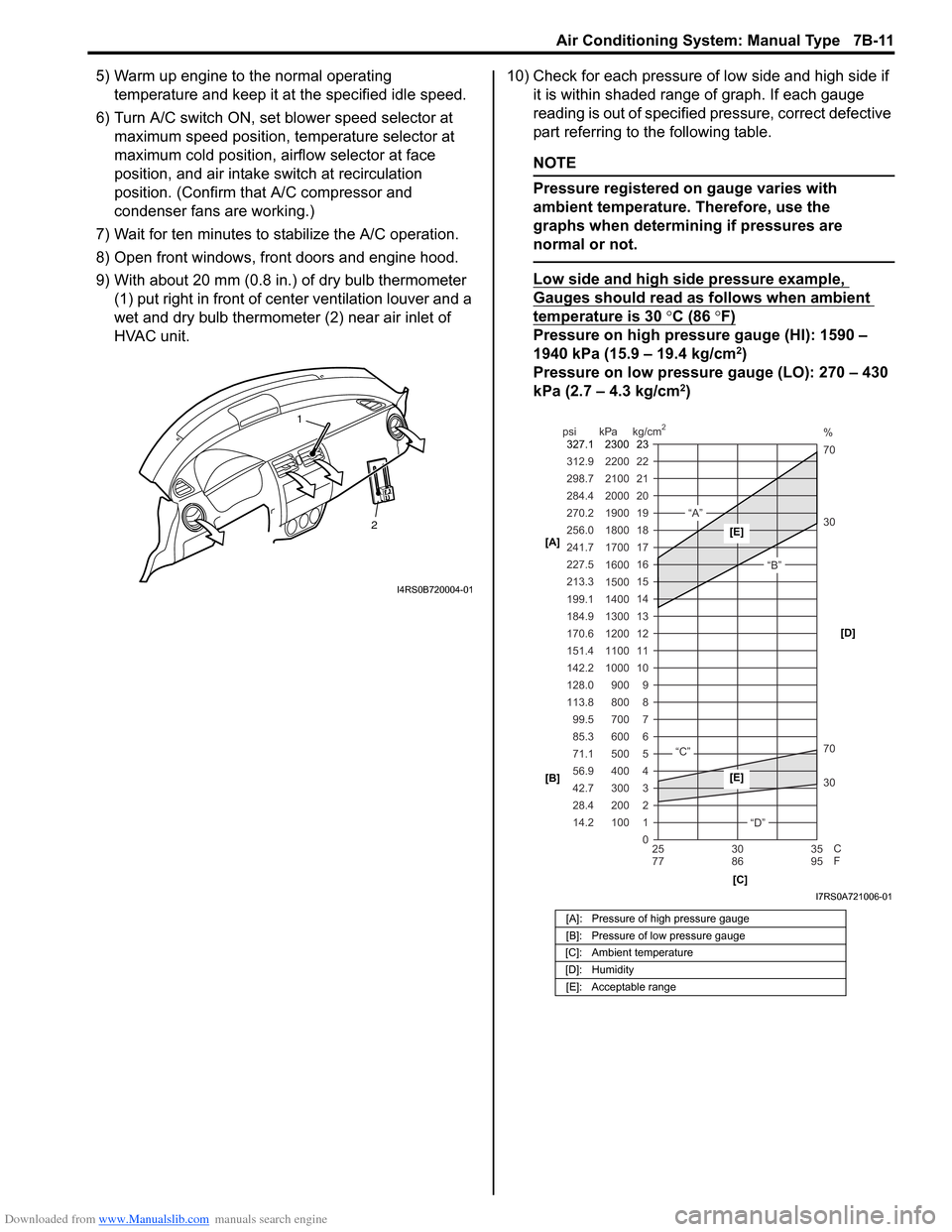

HVAC unit. 10) Check for each pressure of low side and high side if

it is within shaded range of graph. If each gauge

reading is out of specified pressure, correct defective

part referring to the following table.

NOTE

Pressure registered on gauge varies with

ambient temperature. Therefore, use the

graphs when determining if pressures are

normal or not.

Low side and high side pressure example,

Gauges should read as follows when ambient

temperature is 30 °C (86 °F)

Pressure on high pressure gauge (HI): 1590 –

1940 kPa (15.9 – 19.4 kg/cm2)

Pressure on low pressure gauge (LO): 270 – 430

kPa (2.7 – 4.3 kg/cm

2)

2

1

I4RS0B720004-01

[A]: Pressure of high pressure gauge

[B]: Pressure of low pressure gauge

[C]: Ambient temperature

[D]: Humidity [E]: Acceptable range

22

312.9 2200

0 1

2 3 30 70 30 70 %

4 5 6 7 8 9

10

11 12 13 14 15

16 17

18

19 21

298.7 2100

20

14.2 28.4 42.7 56.9 71.1 85.3 99.5

113.8 128.0 142.2

151.4

170.6

184.9 199.1

213.3 227.5

241.7

256.0

270.2

284.4

100 200 300 400 500 600 700 800 900

1000 1100 1200

1300

1400 1500 1600

1700 1800

1900

2000

25 30 35

77 86 95

psi kPa kg/cm

2

C

F

“A”

“B”

“C”

“D”

23

2300

327.1

[A]

[B]

[C][D][E]

[E]

I7RS0A721006-01

Page 961 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-13

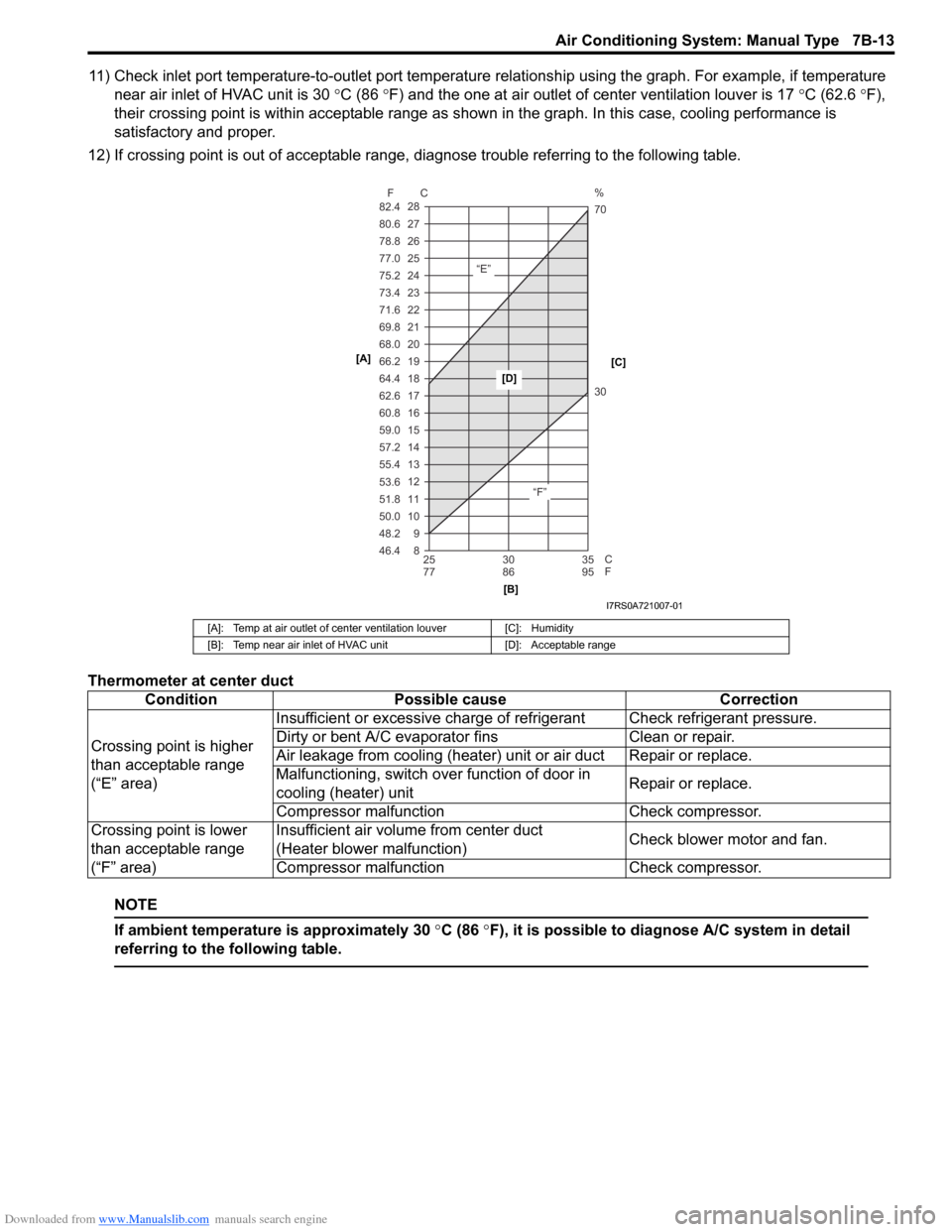

11) Check inlet port temperature-to-outlet port temperature relationship using the graph. For example, if temperature

near air inlet of HVAC unit is 30 °C (86 °F) and the one at air outlet of center ventilation louver is 17 °C (62.6 °F),

their crossing point is within acceptable range as shown in the graph. In this case, cooling performance is

satisfactory and proper.

12) If crossing point is out of acceptable range, diagnose trouble referring to the following table.

Thermometer at center duct

NOTE

If ambient temperature is approximately 30 °C (86 °F), it is possible to diagnose A/C system in detail

referring to the following table.

[A]: Temp at air outlet of center ventilation louver [C]: Humidity

[B]: Temp near air inlet of HVAC unit [D]: Acceptable range

ConditionPossible cause Correction

Crossing point is higher

than acceptable range

(“E” area) Insufficient or excessive charge of refrigerant Check refrigerant pressure.

Dirty or bent A/C evaporator fins

Clean or repair.

Air leakage from cooling (heater) unit or air duct Repair or replace.

Malfunctioning, switch over function of door in

cooling (heater) unit Repair or replace.

Compressor malfunct ion Check compressor.

Crossing point is lower

than acceptable range

(“F” area) Insufficient air volume from center duct

(Heater blower malfunction)

Check blower motor and fan.

Compressor malfunct ion Check compressor.

8 9

10 11 12 13 14

15 16 17 18 19

20

21

22

23

24

25 26

27

28

46.4 48.2 50.0 51.8 53.6 55.4 57.2 59.0 60.8 62.6 64.4

66.2 68.0

69.8

71.6

73.4

75.2

77.0

78.8 80.6

82.4

25 30 35

77 86 95

F C

C

F

“E”

“F”30 70 %

[A]

[B][C]

[D]

I7RS0A721007-01

Page 974 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-26 Air Conditioning System: Manual Type

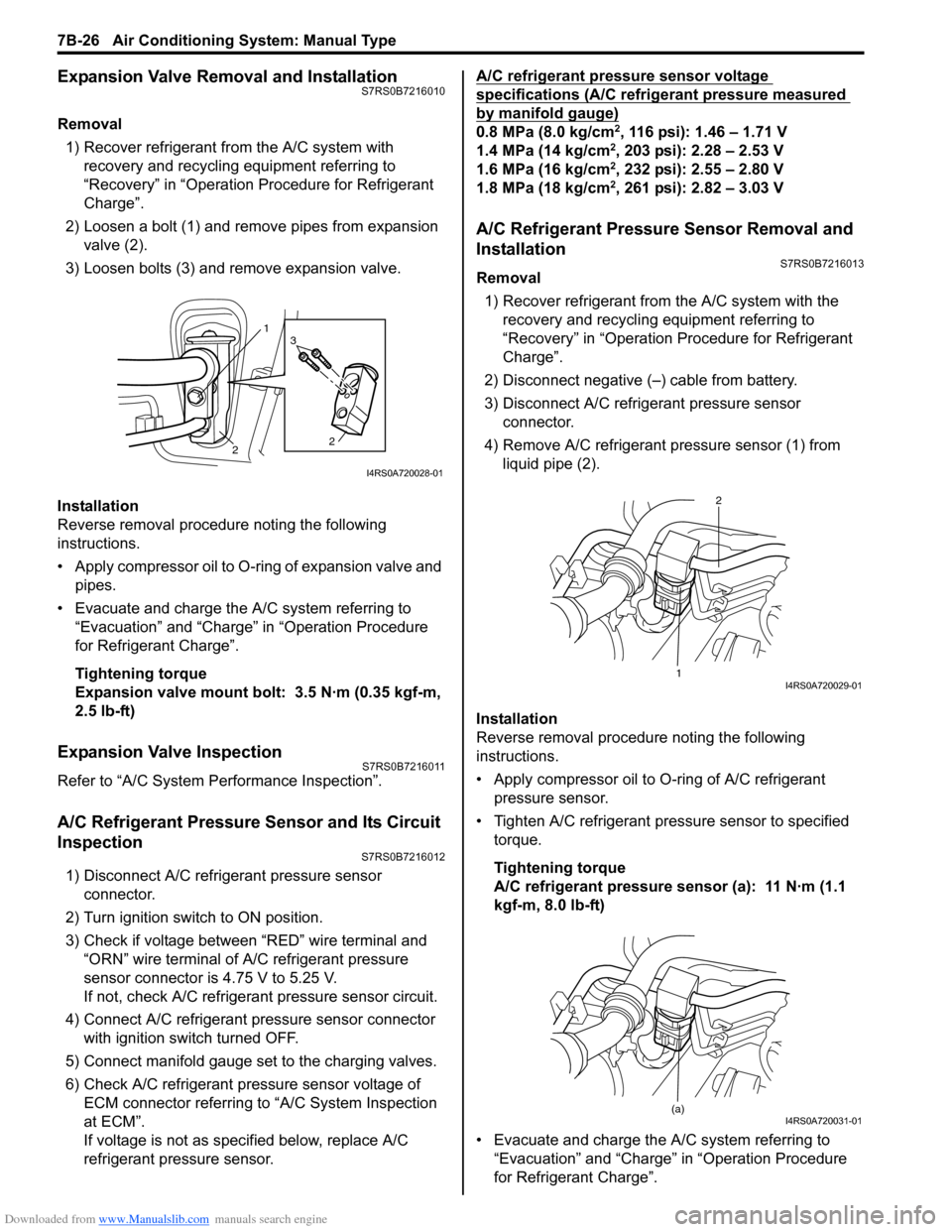

Expansion Valve Removal and InstallationS7RS0B7216010

Removal1) Recover refrigerant fr om the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Loosen a bolt (1) and remove pipes from expansion valve (2).

3) Loosen bolts (3) and remove expansion valve.

Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of expansion valve and pipes.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

Tightening torque

Expansion valve mount bolt: 3.5 N·m (0.35 kgf-m,

2.5 lb-ft)

Expansion Valve InspectionS7RS0B7216011

Refer to “A/C System Performance Inspection”.

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S7RS0B7216012

1) Disconnect A/C refrigerant pressure sensor connector.

2) Turn ignition switch to ON position.

3) Check if voltage between “RED” wire terminal and “ORN” wire terminal of A/C refrigerant pressure

sensor connector is 4.75 V to 5.25 V.

If not, check A/C refrigerant pressure sensor circuit.

4) Connect A/C refrigerant pressure sensor connector with ignition switch turned OFF.

5) Connect manifold gauge set to the charging valves.

6) Check A/C refrigerant pressure sensor voltage of ECM connector referring to “A/C System Inspection

at ECM”.

If voltage is not as specified below, replace A/C

refrigerant pressure sensor. A/C refrigerant pressure sensor voltage

specifications (A/C refrigerant pressure measured

by manifold gauge)

0.8 MPa (8.0 kg/cm2, 116 psi): 1.46 – 1.71 V

1.4 MPa (14 kg/cm2, 203 psi): 2.28 – 2.53 V

1.6 MPa (16 kg/cm2, 232 psi): 2.55 – 2.80 V

1.8 MPa (18 kg/cm2, 261 psi): 2.82 – 3.03 V

A/C Refrigerant Pressure Sensor Removal and

Installation

S7RS0B7216013

Removal

1) Recover refrigerant from the A/C system with the recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Disconnect negative (–) cable from battery.

3) Disconnect A/C refrigerant pressure sensor connector.

4) Remove A/C refrigerant pressure sensor (1) from liquid pipe (2).

Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of A/C refrigerant

pressure sensor.

• Tighten A/C refrigerant pressure sensor to specified torque.

Tightening torque

A/C refrigerant pressure sensor (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

1

2 2

3

I4RS0A720028-01

1 2I4RS0A720029-01

(a)I4RS0A720031-01

Page 975 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-27

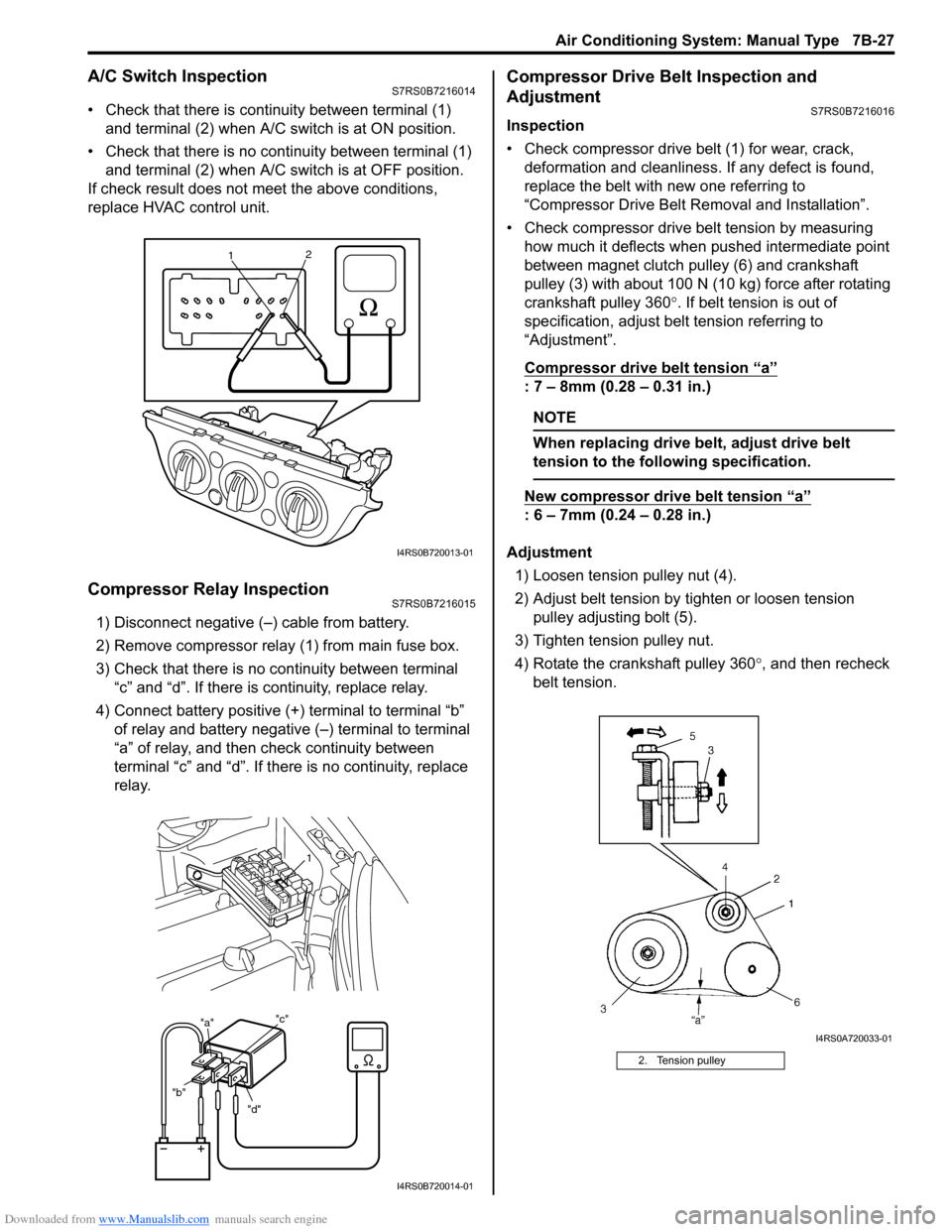

A/C Switch InspectionS7RS0B7216014

• Check that there is continuity between terminal (1) and terminal (2) when A/C s witch is at ON position.

• Check that there is no continuity between terminal (1) and terminal (2) when A/C s witch is at OFF position.

If check result does not meet the above conditions,

replace HVAC control unit.

Compressor Relay InspectionS7RS0B7216015

1) Disconnect negative (–) cable from battery.

2) Remove compressor relay (1) from main fuse box.

3) Check that there is no continuity between terminal “c” and “d”. If there is continuity, replace relay.

4) Connect battery positive (+ ) terminal to terminal “b”

of relay and battery negative (–) terminal to terminal

“a” of relay, and then check continuity between

terminal “c” and “d”. If there is no continuity, replace

relay.

Compressor Drive Belt Inspection and

Adjustment

S7RS0B7216016

Inspection

• Check compressor drive belt (1) for wear, crack, deformation and cleanliness. If any defect is found,

replace the belt with new one referring to

“Compressor Drive Belt Re moval and Installation”.

• Check compressor drive belt tension by measuring how much it deflects when pushed intermediate point

between magnet clutch pulley (6) and crankshaft

pulley (3) with about 100 N (10 kg) force after rotating

crankshaft pulley 360 °. If belt tension is out of

specification, adjust belt tension referring to

“Adjustment”.

Compressor drive belt tension

“a”

: 7 – 8mm (0.28 – 0.31 in.)

NOTE

When replacing drive belt, adjust drive belt

tension to the following specification.

New compressor dr ive belt tension “a”

: 6 – 7mm (0.24 – 0.28 in.)

Adjustment 1) Loosen tension pulley nut (4).

2) Adjust belt tension by ti ghten or loosen tension

pulley adjusting bolt (5).

3) Tighten tension pulley nut.

4) Rotate the crankshaft pulley 360 °, and then recheck

belt tension.

1 2

I4RS0B720013-01

"d"

"b" "a"

"c"

1

I4RS0B720014-01

2. Tension pulley

I4RS0A720033-01

Page 977 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-29

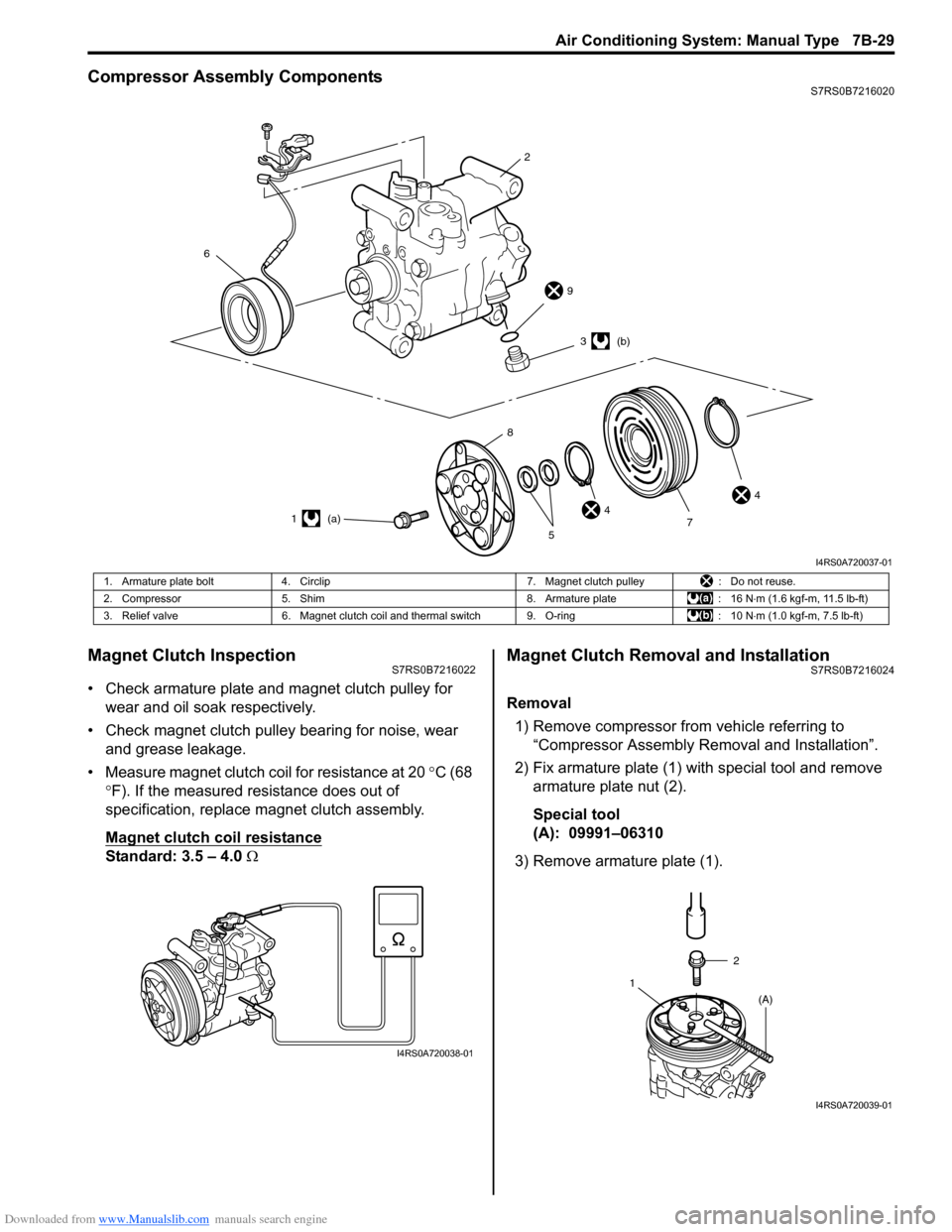

Compressor Assembly ComponentsS7RS0B7216020

Magnet Clutch InspectionS7RS0B7216022

• Check armature plate and magnet clutch pulley for wear and oil soak respectively.

• Check magnet clutch pulley bearing for noise, wear and grease leakage.

• Measure magnet clutch coil for resistance at 20 °C (68

° F). If the measured resistance does out of

specification, replace magnet clutch assembly.

Magnet clutch coil resistance

Standard: 3.5 – 4.0 Ω

Magnet Clutch Removal and InstallationS7RS0B7216024

Removal

1) Remove compressor from vehicle referring to “Compressor Assembly Re moval and Installation”.

2) Fix armature plate (1) with special tool and remove armature plate nut (2).

Special tool

(A): 09991–06310

3) Remove armature plate (1).

6

2

9

44

3 (b)

1 (a) 7

5

8

I4RS0A720037-01

1. Armature plate bolt

4. Circlip 7. Magnet clutch pulley: Do not reuse.

2. Compressor 5. Shim 8. Armature plate: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. Relief valve 6. Magnet clutch coil and thermal switch 9. O-ring : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

I4RS0A720038-01

2

1 (A)

I4RS0A720039-01

Page 978 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-30 Air Conditioning System: Manual Type

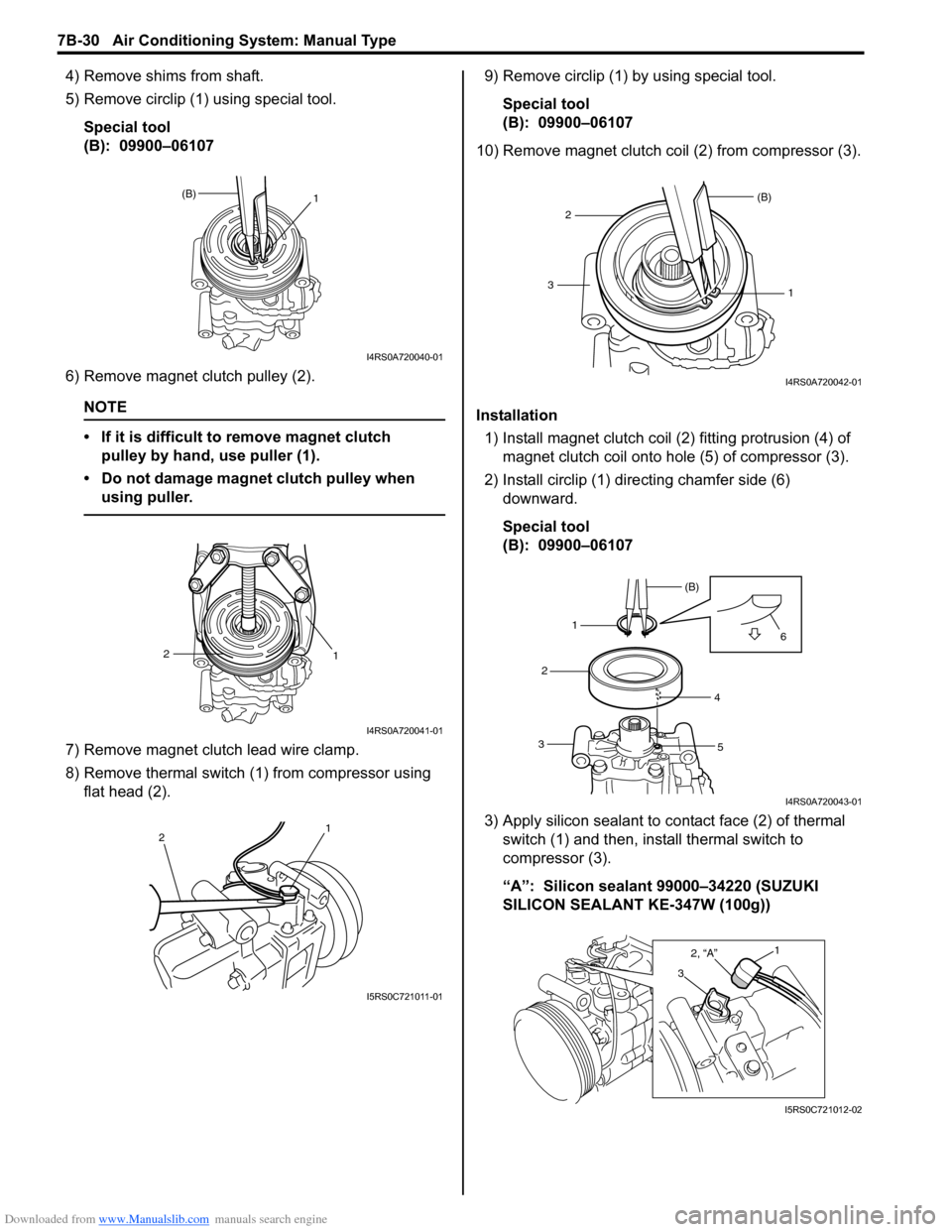

4) Remove shims from shaft.

5) Remove circlip (1) using special tool.Special tool

(B): 09900–06107

6) Remove magnet clutch pulley (2).

NOTE

• If it is difficult to remove magnet clutch pulley by hand, use puller (1).

• Do not damage magnet clutch pulley when using puller.

7) Remove magnet clutch lead wire clamp.

8) Remove thermal switch (1) from compressor using flat head (2). 9) Remove circlip (1) by using special tool.

Special tool

(B): 09900–06107

10) Remove magnet clutch coil (2) from compressor (3).

Installation 1) Install magnet clutch coil (2) fitting protrusion (4) of magnet clutch coil onto hole (5) of compressor (3).

2) Install circlip (1) dire cting chamfer side (6)

downward.

Special tool

(B): 09900–06107

3) Apply silicon sealant to co ntact face (2) of thermal

switch (1) and then, inst all thermal switch to

compressor (3).

“A”: Silicon sealant 99000–34220 (SUZUKI

SILICON SEALANT KE-347W (100g))

(B) 1

I4RS0A720040-01

1

2

I4RS0A720041-01

2 1

I5RS0C721011-01

1

(B)

23

I4RS0A720042-01

1 (B)

2

3 4

5 6

I4RS0A720043-01

3

2, “A”1

I5RS0C721012-02

Page 983 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-35

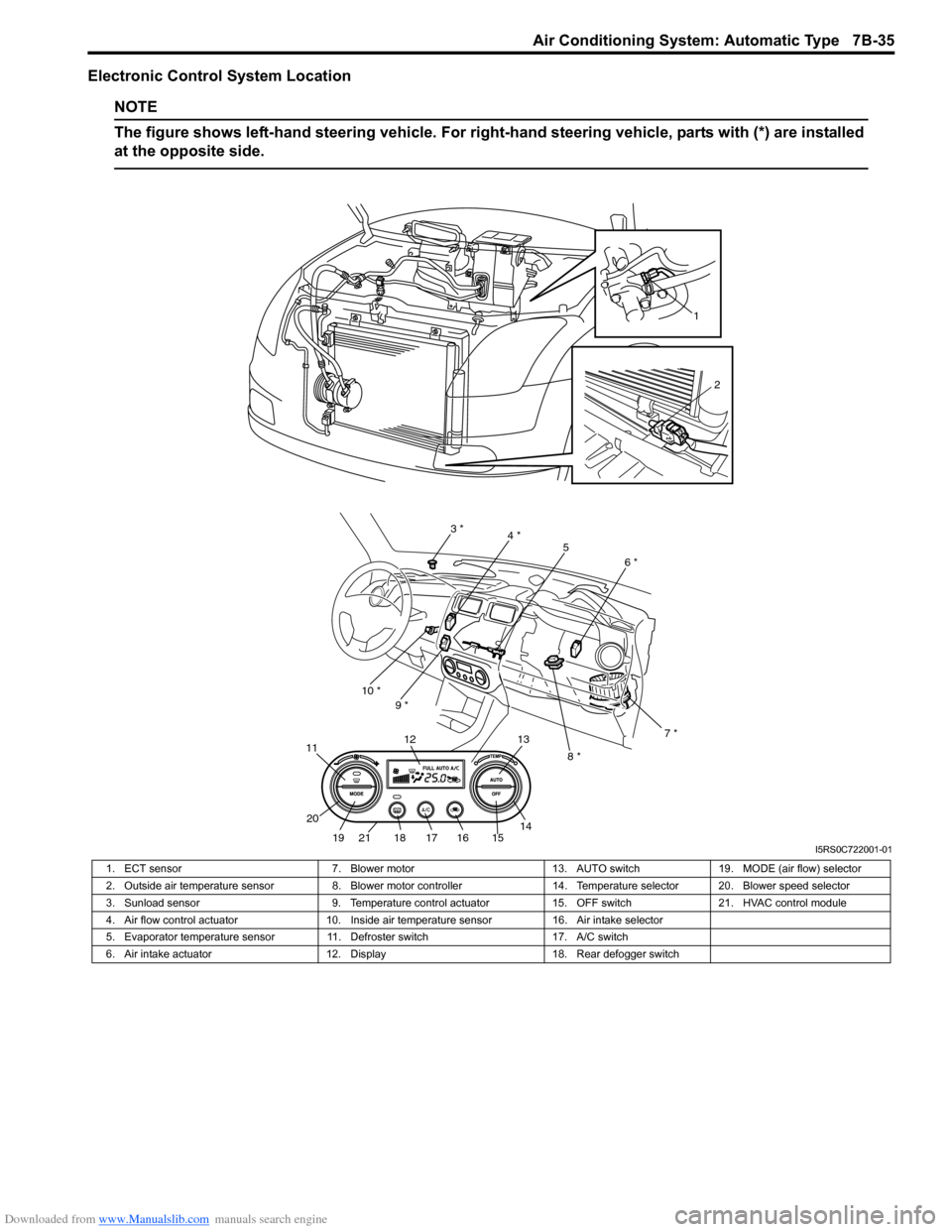

Electronic Control System Location

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

1

2

3 * 4 *

5

6 *

7 *

8 *

9 *

10 *

21

11

12 13

14

15161718

19

20

I5RS0C722001-01

1. ECT sensor

7. Blower motor13. AUTO switch19. MODE (air flow) selector

2. Outside air temperature sensor 8. Blower motor controller 14. Temperature selector 20. Blower speed selector

3. Sunload sensor 9. Temperature control actuator15. OFF switch21. HVAC control module

4. Air flow control actuator 10. Inside air temperature sensor 16. Air intake selector

5. Evaporator temperature sensor 11. Defroster switch 17. A/C switch

6. Air intake actuator 12. Display 18. Rear defogger switch