bolt SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 881 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-10

5) Tighten new bolts (1) until head of each bolt is broken off.

6) Turn ignition key to “ACC” or “ON” position and check to be sure that st eering shaft (2) rotates

smoothly. Also check for lock operation.

7) Install steering column. Re fer to “Steering Column

Removal and Installation”.

8) If steering lock assembly has replaced, after completing installation, register ignition key

transponder code in ECM referring to “Registration

of the Ignition Key in Section 10C”.

Steering Lower Shaft Removal and InstallationS7RS0B6206010

CAUTION!

Never turn steering wheel while steering

lower shaft is removed.

Should it have been turned and contact coil

have got out of its centered position, it needs

to be centered again. Also, turning steering

wheel more than about two and a half turns

will break contact coil.

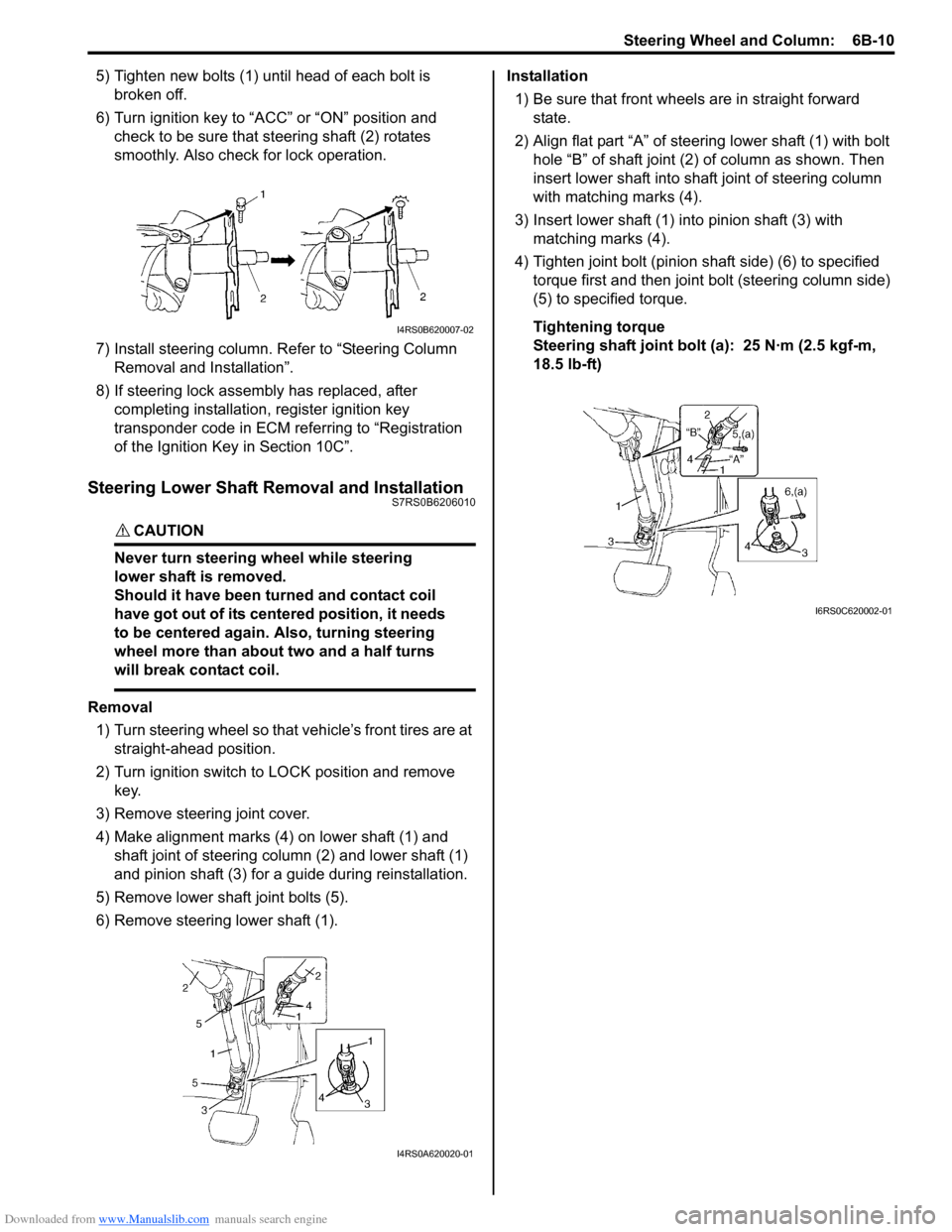

Removal

1) Turn steering wheel so that vehicle’s front tires are at straight-ahead position.

2) Turn ignition switch to LOCK position and remove key.

3) Remove steering joint cover.

4) Make alignment marks (4) on lower shaft (1) and shaft joint of steering colu mn (2) and lower shaft (1)

and pinion shaft (3) for a guide during reinstallation.

5) Remove lower shaf t joint bolts (5).

6) Remove steering lower shaft (1). Installation

1) Be sure that front wheels are in straight forward state.

2) Align flat part “A” of steering lower shaft (1) with bolt hole “B” of shaft joint (2) of column as shown. Then

insert lower shaft into shaf t joint of steering column

with matching marks (4).

3) Insert lower shaft (1) into pinion shaft (3) with matching marks (4).

4) Tighten joint bolt (pinion shaft side) (6) to specified

torque first and then joint bolt (steering column side)

(5) to specified torque.

Tightening torque

Steering shaft joint bolt (a ): 25 N·m (2.5 kgf-m,

18.5 lb-ft)

I4RS0B620007-02

I4RS0A620020-01

I6RS0C620002-01

Page 882 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-11 Steering Wheel and Column:

Specifications

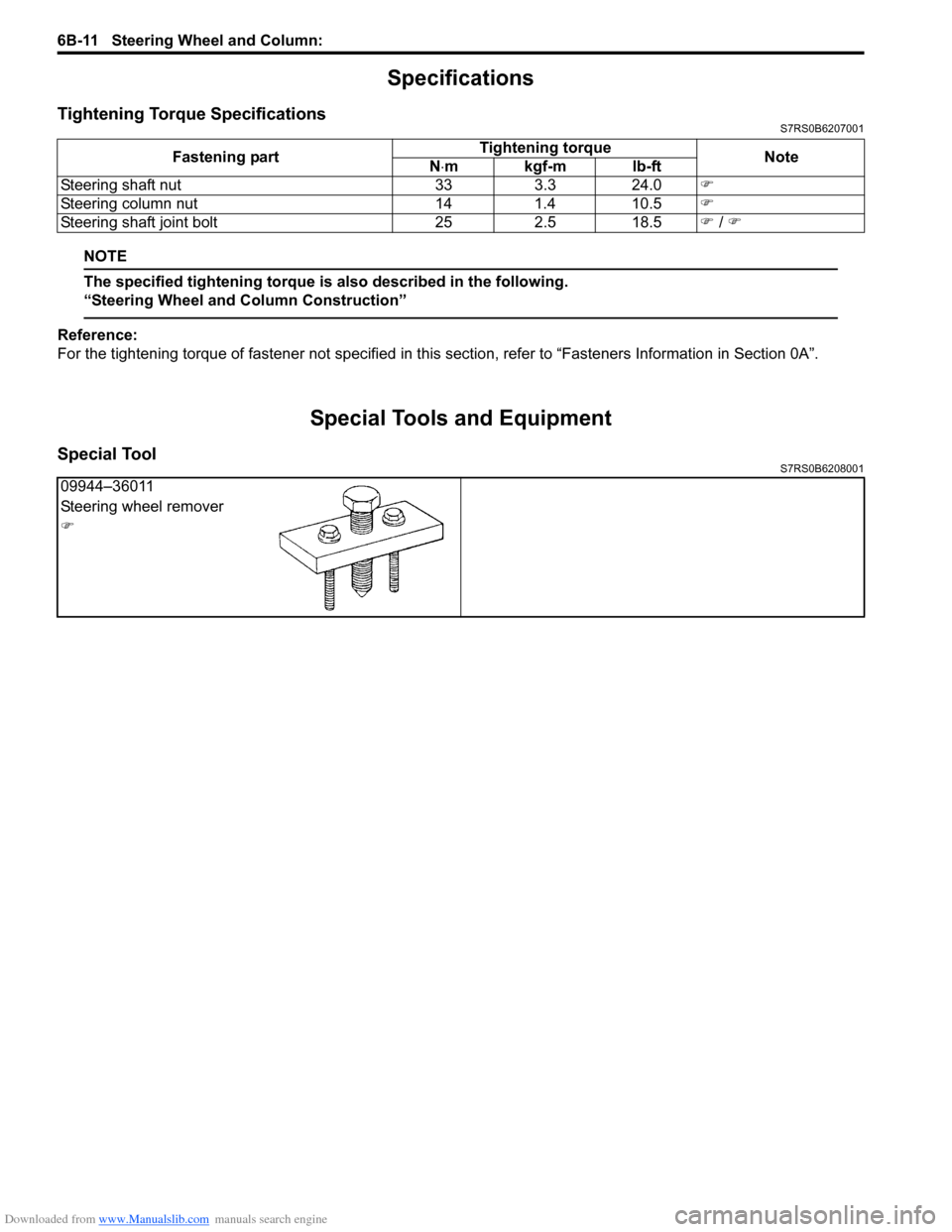

Tightening Torque SpecificationsS7RS0B6207001

NOTE

The specified tightening torque is also described in the following.

“Steering Wheel and Column Construction”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B6208001

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Steering shaft nut 33 3.3 24.0 �)

Steering column nut 14 1.4 10.5 �)

Steering shaft joint bolt 25 2.5 18.5 �) / �)

09944–36011

Steering wheel remover

�)

Page 922 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-40 Power Assisted Steering System:

Repair Instructions

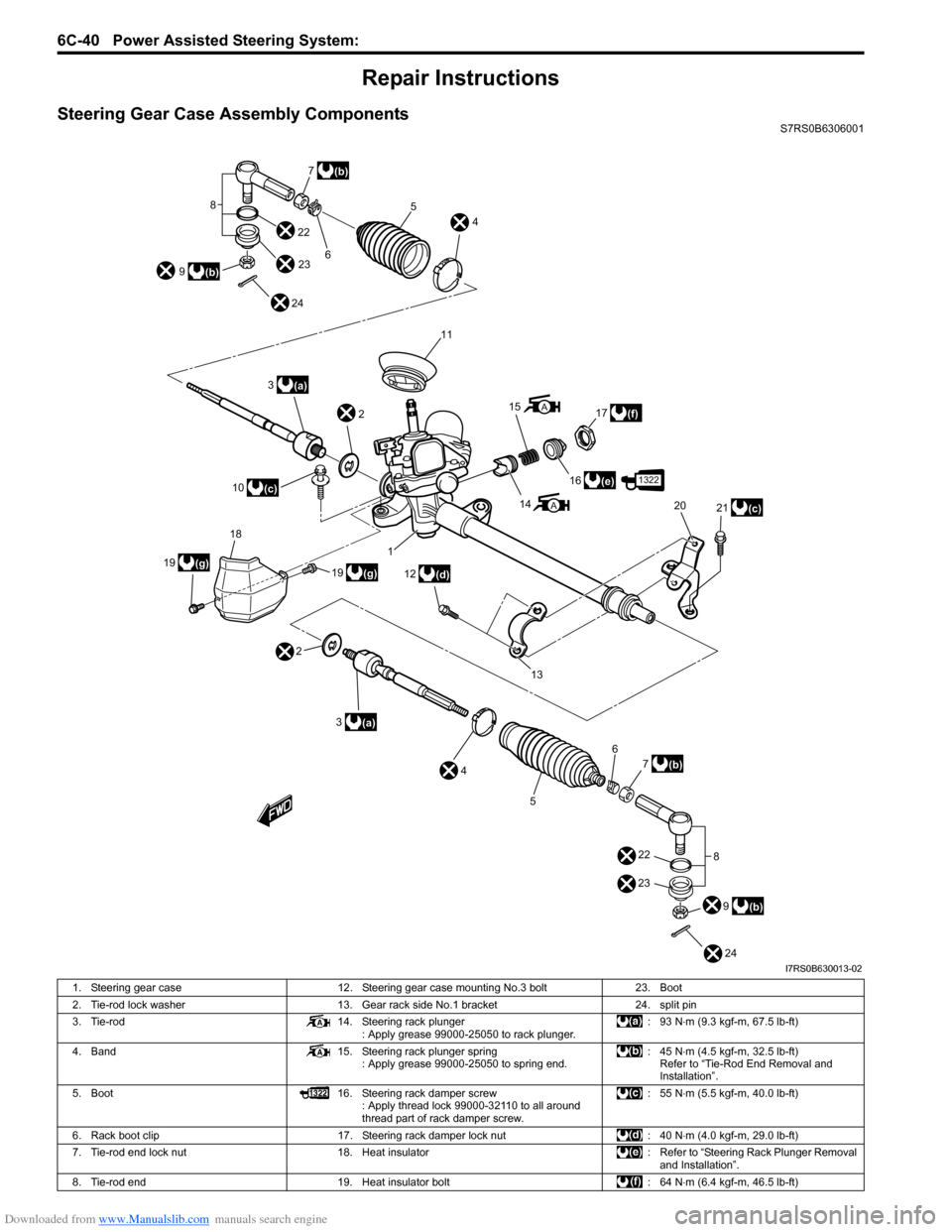

Steering Gear Case Assembly ComponentsS7RS0B6306001

3(a)

10

(c) 2

3

(a)

2 1

19

(g)

19 18(g) 6

11

8

9

(b) 7

(b)

22 23

24 4

5

14

15

16

(e)

17

(f)

12

(d) 21

(c)

20

4 6

5 7

(b)

9

(b)

8

13

22

23

24

A

A

1322

I7RS0B630013-02

1. Steering gear case 12. Steering gear case mounting No.3 bolt 23. Boot

2. Tie-rod lock washer 13. Gear rack side No.1 bracket 24. split pin

3. Tie-rod 14. Steering rack plunger

: Apply grease 99000-25050 to rack plunger. : 93 N

⋅m (9.3 kgf-m, 67.5 lb-ft)

4. Band 15. Steering rack plunger spring

: Apply grease 99000-25050 to spring end. : 45 N

⋅m (4.5 kgf-m, 32.5 lb-ft)

Refer to “Tie-Rod End Removal and

Installation”.

5. Boot 16. Steering rack damper screw

: Apply thread lock 99000-32110 to all around

thread part of rack damper screw. : 55 N

⋅m (5.5 kgf-m, 40.0 lb-ft)

6. Rack boot clip 17. Steering rack damper lock nut : 40 N⋅m (4.0 kgf-m, 29.0 lb-ft)

7. Tie-rod end lock nut 18. Heat insulator : Refer to “Steering Rack Plunger Removal

and Installation”.

8. Tie-rod end 19. Heat insulator bolt : 64 N⋅m (6.4 kgf-m, 46.5 lb-ft)

Page 923 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-41

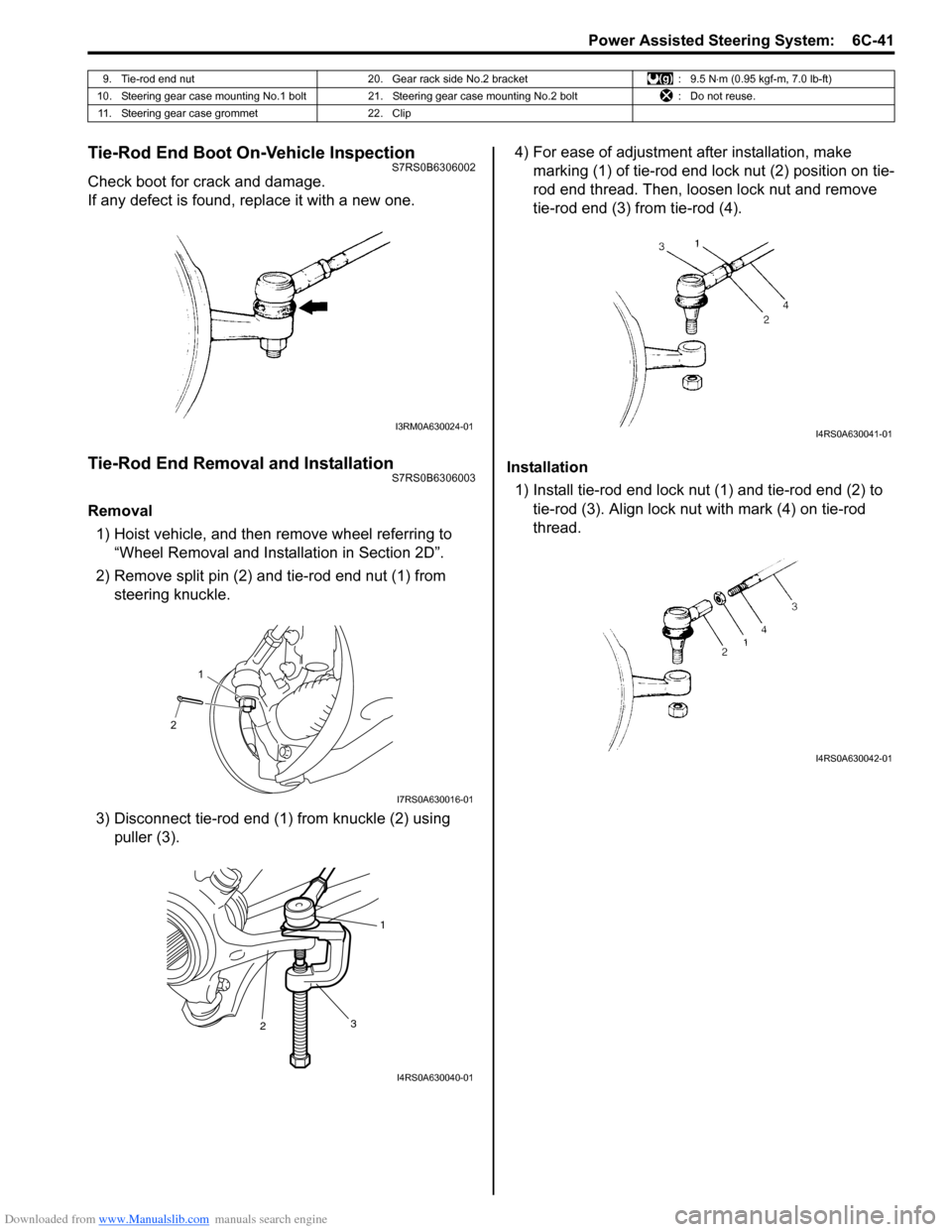

Tie-Rod End Boot On-Vehicle InspectionS7RS0B6306002

Check boot for crack and damage.

If any defect is found, replace it with a new one.

Tie-Rod End Removal and InstallationS7RS0B6306003

Removal1) Hoist vehicle, and then remove wheel referring to “Wheel Removal and Installation in Section 2D”.

2) Remove split pin (2) and tie-rod end nut (1) from steering knuckle.

3) Disconnect tie-rod end (1) from knuckle (2) using puller (3). 4) For ease of adjustment after installation, make

marking (1) of tie-rod end lock nut (2) position on tie-

rod end thread. Then, loosen lock nut and remove

tie-rod end (3) from tie-rod (4).

Installation 1) Install tie-rod end lock nut (1) and tie-rod end (2) to tie-rod (3). Align lock nut with mark (4) on tie-rod

thread.

9. Tie-rod end nut 20. Gear rack side No.2 bracket : 9.5 N⋅m (0.95 kgf-m, 7.0 lb-ft)

10. Steering gear case mounting No.1 bolt 21. Steering gear case mounting No.2 bolt : Do not reuse.

11. Steering gear case grommet 22. Clip

I3RM0A630024-01

21

I7RS0A630016-01

2 1

3

I4RS0A630040-01

I4RS0A630041-01

I4RS0A630042-01

Page 924 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-42 Power Assisted Steering System:

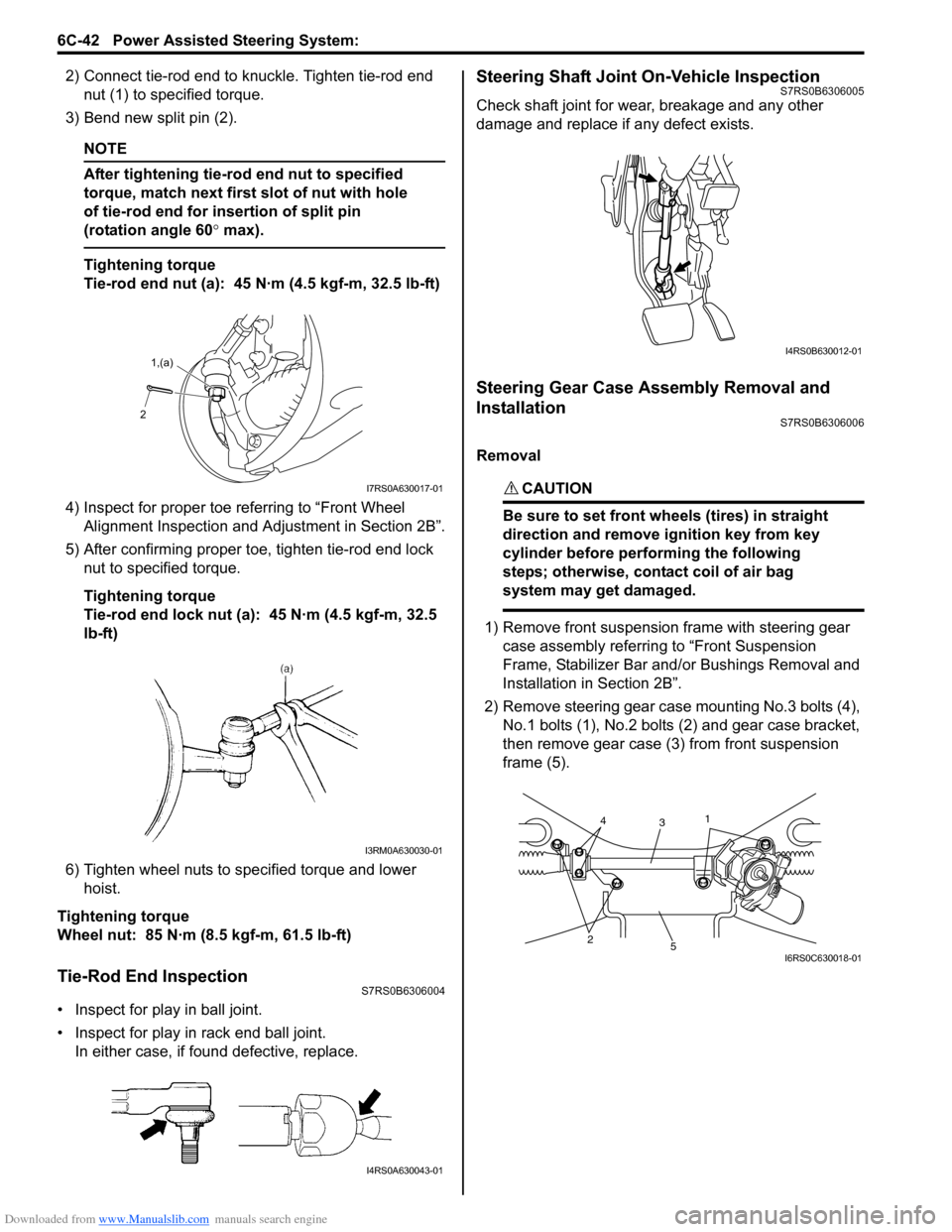

2) Connect tie-rod end to knuckle. Tighten tie-rod end nut (1) to spec ified torque.

3) Bend new split pin (2).

NOTE

After tightening tie-rod end nut to specified

torque, match next first slot of nut with hole

of tie-rod end for insertion of split pin

(rotation angle 60 ° max).

Tightening torque

Tie-rod end nut (a): 45 N·m (4.5 kgf-m, 32.5 lb-ft)

4) Inspect for proper toe re ferring to “Front Wheel

Alignment Inspection and Adjustment in Section 2B”.

5) After confirming proper toe, tighten tie-rod end lock nut to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5

lb-ft)

6) Tighten wheel nuts to specified torque and lower hoist.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

Tie-Rod End InspectionS7RS0B6306004

• Inspect for play in ball joint.

• Inspect for play in rack end ball joint. In either case, if found defective, replace.

Steering Shaft Joint On-Vehicle InspectionS7RS0B6306005

Check shaft joint for wear, breakage and any other

damage and replace if any defect exists.

Steering Gear Case Assembly Removal and

Installation

S7RS0B6306006

Removal

CAUTION!

Be sure to set front wheels (tires) in straight

direction and remove ignition key from key

cylinder before performing the following

steps; otherwise, contact coil of air bag

system may get damaged.

1) Remove front suspension frame with steering gear case assembly referrin g to “Front Suspension

Frame, Stabilizer Bar and/ or Bushings Removal and

Installation in Section 2B”.

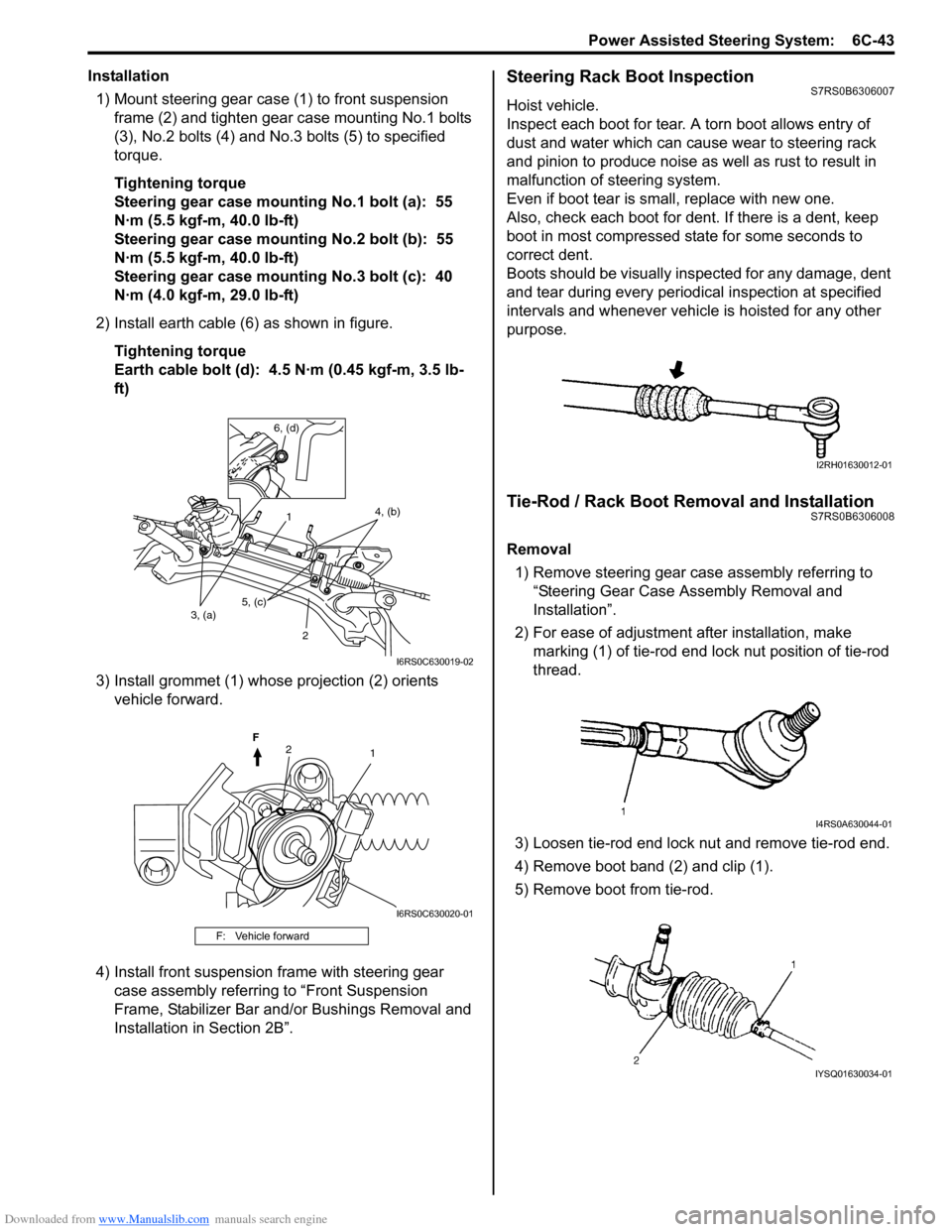

2) Remove steering gear case mounting No.3 bolts (4), No.1 bolts (1), No.2 bolts (2) and gear case bracket,

then remove gear case (3) from front suspension

frame (5).

2 1,(a)

I7RS0A630017-01

I3RM0A630030-01

I4RS0A630043-01

I4RS0B630012-01

25

3

14

I6RS0C630018-01

Page 925 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-43

Installation1) Mount steering gear case (1) to front suspension frame (2) and tighten gear case mounting No.1 bolts

(3), No.2 bolts (4) and No .3 bolts (5) to specified

torque.

Tightening torque

Steering gear case mounting No.1 bolt (a): 55

N·m (5.5 kgf-m, 40.0 lb-ft)

Steering gear case mounting No.2 bolt (b): 55

N·m (5.5 kgf-m, 40.0 lb-ft)

Steering gear case mounting No.3 bolt (c): 40

N·m (4.0 kgf-m, 29.0 lb-ft)

2) Install earth cable (6) as shown in figure. Tightening torque

Earth cable bolt (d): 4.5 N·m (0.45 kgf-m, 3.5 lb-

ft)

3) Install grommet (1) whose projection (2) orients vehicle forward.

4) Install front suspension frame with steering gear case assembly referring to “Front Suspension

Frame, Stabilizer Bar and/or Bushings Removal and

Installation in Section 2B”.Steering Rack Boot InspectionS7RS0B6306007

Hoist vehicle.

Inspect each boot for tear. A torn boot allows entry of

dust and water which can cause wear to steering rack

and pinion to produce noise as well as rust to result in

malfunction of steering system.

Even if boot tear is small, replace with new one.

Also, check each boot for dent. If there is a dent, keep

boot in most compressed st ate for some seconds to

correct dent.

Boots should be visually inspected for any damage, dent

and tear during every periodical inspection at specified

intervals and whenever vehicle is hoisted for any other

purpose.

Tie-Rod / Rack Boot Removal and InstallationS7RS0B6306008

Removal

1) Remove steering gear case assembly referring to

“Steering Gear Case Assembly Removal and

Installation”.

2) For ease of adjustment after installation, make marking (1) of tie-rod end lock nut position of tie-rod

thread.

3) Loosen tie-rod end lock nut and remove tie-rod end.

4) Remove boot band (2) and clip (1).

5) Remove boot from tie-rod.

F: Vehicle forward

1 2

3, (a) 4, (b)

6, (d)

5, (c)

I6RS0C630019-02

12

F

I6RS0C630020-01

I2RH01630012-01

I4RS0A630044-01

IYSQ01630034-01

Page 930 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-48 Power Assisted Steering System:

Specifications

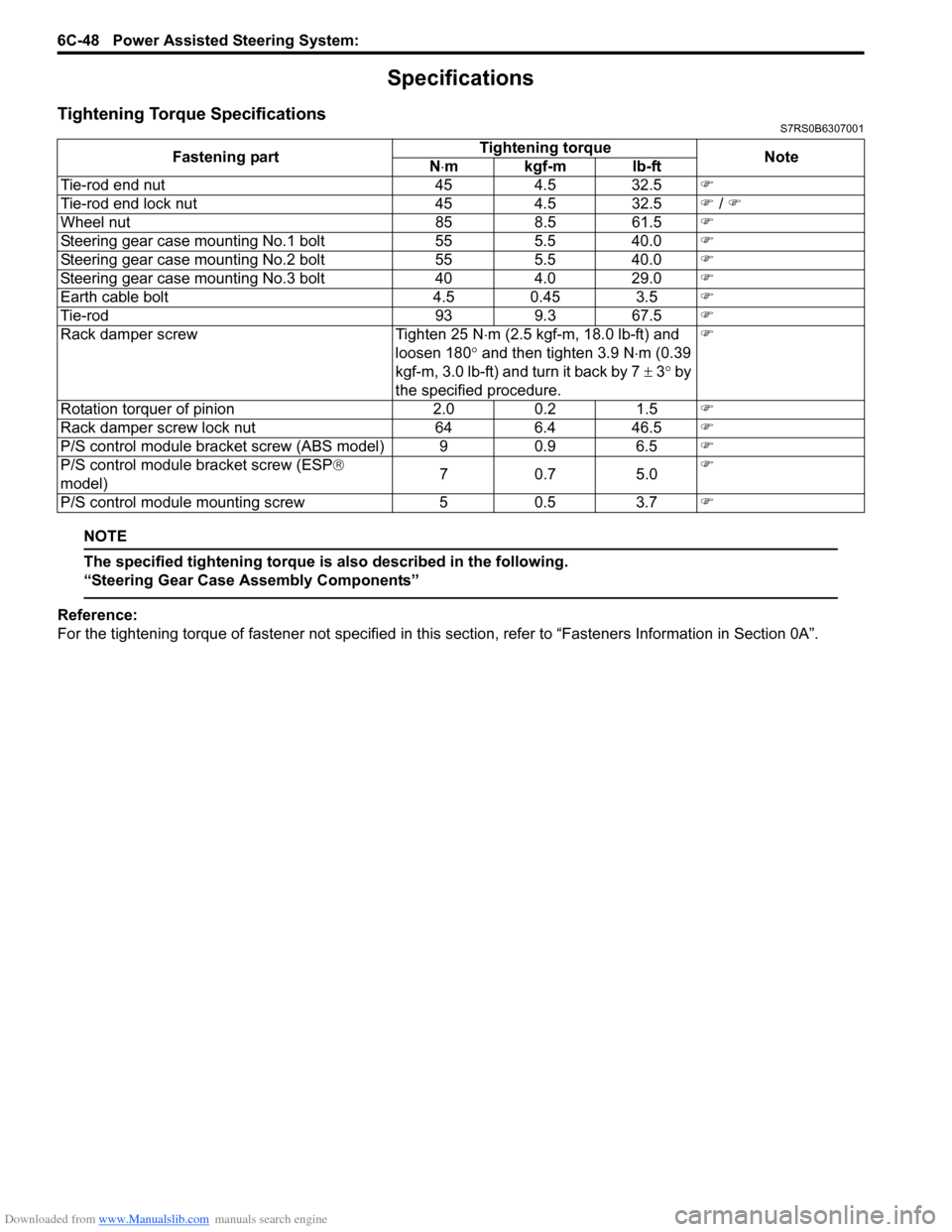

Tightening Torque SpecificationsS7RS0B6307001

NOTE

The specified tightening torque is also described in the following.

“Steering Gear Case Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Tie-rod end nut 454.5 32.5 �)

Tie-rod end lock nut 454.5 32.5 �) / �)

Wheel nut 858.5 61.5 �)

Steering gear case mounting No.1 bolt 555.5 40.0 �)

Steering gear case mounting No.2 bolt 555.5 40.0 �)

Steering gear case mounting No.3 bolt 404.0 29.0 �)

Earth cable bolt 4.5 0.45 3.5�)

Tie-rod 939.3 67.5 �)

Rack damper screw Tighten 25 N⋅m (2.5 kgf-m, 18.0 lb-ft) and

loosen 180 ° and then tighten 3.9 N ⋅m (0.39

kgf-m, 3.0 lb-ft) and turn it back by 7 ± 3° by

the specified procedure. �)

Rotation torquer of pinion 2.00.2 1.5 �)

Rack damper screw lock nut 646.4 46.5 �)

P/S control module bracket screw (ABS model) 9 0.9 6.5�)

P/S control module bracket screw (ESP ®

model) 70

.7 5 .0 �)

P/S control module mounting screw 50.5 3.7 �)

Page 941 of 1496

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-5

• Check for operation and current.a. Put blower motor (1) in a soft-jawed vise.

b. Connect battery to blower motor as shown.

c. Check if blower motor operates smoothly without noise.

d. Check if ammeter indicates the specified current. If measured current is out of specification, replace

blower motor.

Blower motor specified current at 12 V

16 A maximum

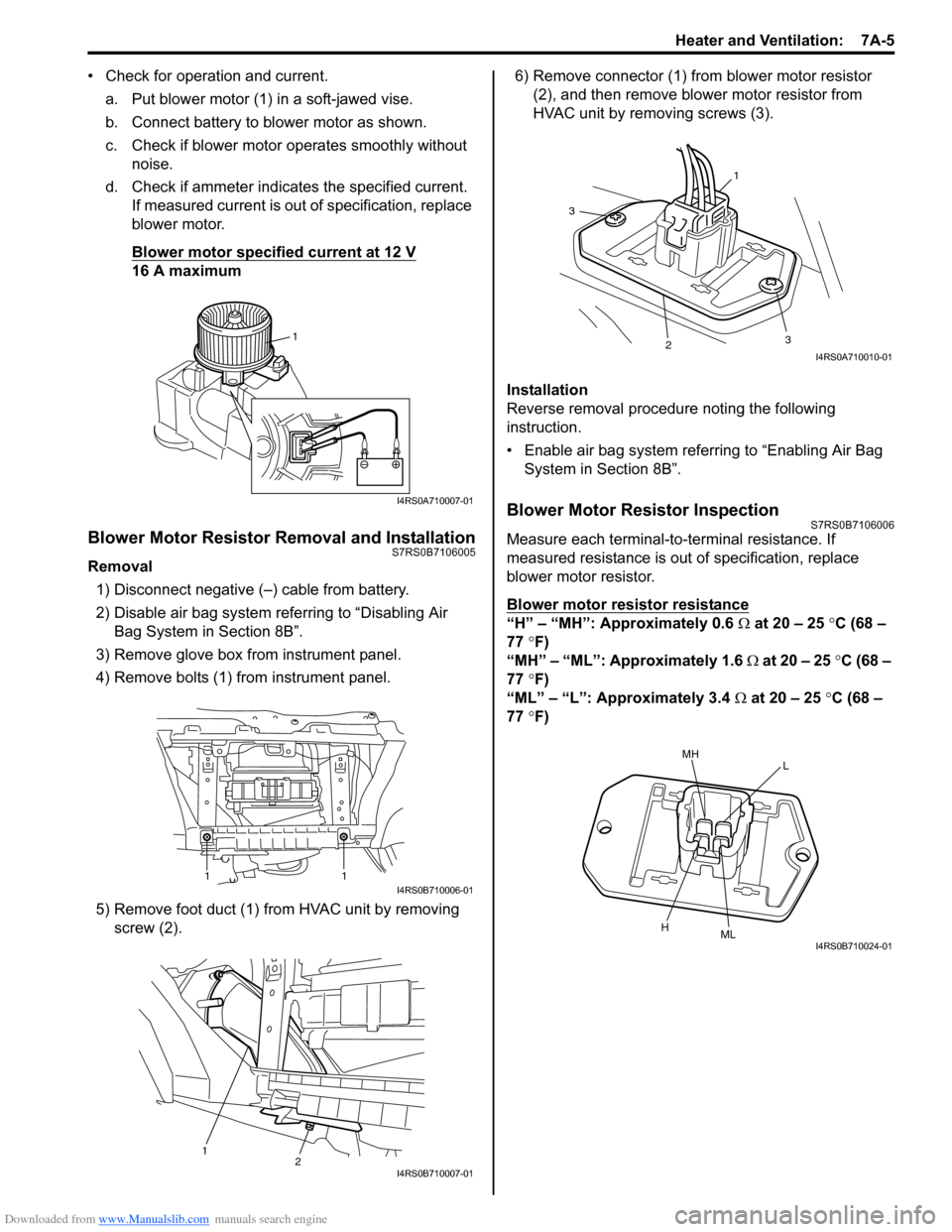

Blower Motor Resistor Removal and InstallationS7RS0B7106005

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove glove box from instrument panel.

4) Remove bolts (1) from instrument panel.

5) Remove foot duct (1) from HVAC unit by removing screw (2). 6) Remove connector (1) from blower motor resistor

(2), and then remove blower motor resistor from

HVAC unit by removing screws (3).

Installation

Reverse removal procedure noting the following

instruction.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Blower Motor Resistor InspectionS7RS0B7106006

Measure each terminal-to-terminal resistance. If

measured resistance is out of specification, replace

blower motor resistor.

Blower motor resistor resistance

“H” – “MH”: Approximately 0.6 Ω at 20 – 25 °C (68 –

77 °F)

“MH” – “ML”: Approximately 1.6 Ω at 20 – 25 °C (68 –

77 °F)

“ML” – “L”: Approximately 3.4 Ω at 20 – 25 °C (68 –

77 °F)

1

I4RS0A710007-01

11I4RS0B710006-01

12I4RS0B710007-01

1

3

23

I4RS0A710010-01

MHL

HMLI4RS0B710024-01

Page 957 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-9

Abnormal Noise Symptom Diagnosis of A/C SystemS7RS0B7214002

Abnormal Noise from Compressor

Abnormal Noise from Magnetic Clutch

Abnormal Noise from Tubing

Abnormal Noise from Condenser Assembly

Abnormal Noise from Crankshaft PulleyInsufficient airflow of

cooled air

A/C evaporator clogged or frosted

Check A/C evaporator and evaporator

thermistor (evaporator temperature sensor)

referring to “Evaporator Inspection” and

“Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Air leaking from HVAC unit or air duct Repair as necessary.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Wiring or grounding faulty Repair as necessary.

Condition Possible cause Correction / Reference Item

Condition

Possible cause Correction / Reference Item

During compressor

operation, a rumbling

noise is heard

proportional to engine

revolutions Inadequate clearance in scroll area

Replace compressor.

A loud noise is heard at a

certain rpm,

disproportionately to

engine revolution Loose or faulty compressor drive belt

Adjust drive belt tension or replace drive belt.

Loose compressor mounting bolts Retighten mounting bolts.

A loud rattle is heard at

low engine rpm Loose compressor clutch plate bolt

Retighten clutch plate bolt.

Replace compressor if it was operated in this

condition for a long time.

Condition Possible cause Correction / Reference Item

A rumbling noise is heard

when compressor is not

in operation Worn or damaged bearings

Replace magnet clutch assembly.

A chattering noise is

heard when compressor

is in operation Faulty magnet clutch clearance

(excessive clearance)

Adjust magnet clutch clearance.

Worn magnet clutch friction surface Replace magnet clutch assembly.

Compressor oil leaked from shaft seal,

contaminating the friction surface Replace compressor body assembly.

Condition

Possible cause Correction / Reference Item

A droning noise is heard

from inside of the vehicle,

but not particularly

noticeable in engine

compartment Faulty tubing clamps

Reposition clamps or increase the number of

clamps.

Resonance caused by pulsation from

variations in re frigerant pressure Attach a silencer to tubing, or modify its

position and length.

Condition

Possible cause Correction / Reference Item

Considerable vibration in

condenser assembly Resonance from condenser assembly

bracket and body Firmly insert a silenc

er between condenser

assembly bracket and body.

Condition Possible cause Correction / Reference Item

A large rattling noise is

heard at idle or sudden

acceleration Loosen crankshaft pulley bolt

Retighten bolt.

Page 969 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-21

Removal of Manifold Gauge Set

WARNING!

High pressure side is under high pressure.

Therefore, be careful not to get injured

especially on your eyes and skin.

For the A/C system charged with the specified amount of

refrigerant, remove manifold gauge set as follows:

1) Close low pressure side valve of manifold gauge set. (The high pressure side valve is closed continuously

during the process of charging.)

2) Close refrigerant container valve.

3) Stop engine.

4) Using shop rag, remove charging hoses from service valves. This operation must be performed quickly.

5) Put caps on service valves.

Check A/C System for Refrigerant Leaks

Whenever a refrigerant leak is suspected in the system

or any service operation has been performed which may

result in malfunction of lines and connections, it is

advisable to check for leaks.

Common sense should be used during refrigerant leak

test, since the need and extent of any such test will, in

general, depend upon the nature of a complaint and the

type of a service performed on the system.

Liquid leak detector

WARNING!

• To prevent explosions and fires, make sure that there are no flammables in the vicinity.

• When the refrigerant exposed to fire, it turns into a poisonous gas (phosgene). Do

not inhale this gas.

There is a number of fittings and places throughout the

A/C system where a liquid leak detector solution may be

used to pinpoint refrigerant leaks.

By merely applying the solution to the area in question

with a swab, such as attached to the cap of a vial,

bubbles will form within seconds if there is a leak.

For confined areas, such as sections of the evaporator

and condenser, an electronic (refrigerant) leak detector

is more practical fo r determining leaks.

Special tool

(A): 09990–86012

Condenser Assembly On-Vehicle InspectionS7RS0B7216002

Check the followings.

• Clog of condenser fins If any clog is found, cond enser fins should be washed

with water and should be dried with compressed air.

• Condenser fins for leakage and breakage If any defects are found, repair or replace condenser.

• Condenser fittings for leakage. If any defects are found, repair or replace condenser.

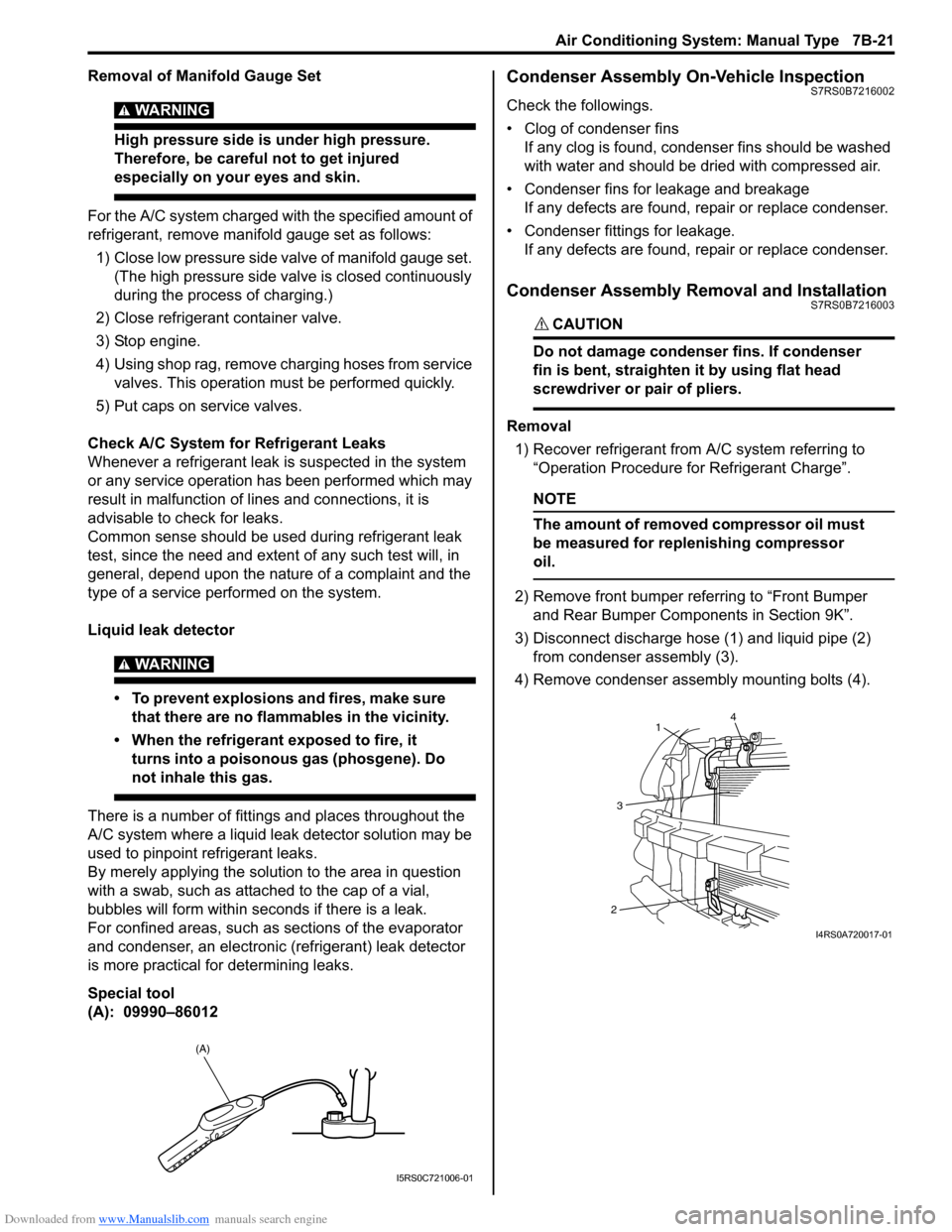

Condenser Assembly Removal and InstallationS7RS0B7216003

CAUTION!

Do not damage condenser fins. If condenser

fin is bent, straighten it by using flat head

screwdriver or pair of pliers.

Removal

1) Recover refrigerant from A/C system referring to “Operation Procedure for Refrigerant Charge”.

NOTE

The amount of removed compressor oil must

be measured for replenishing compressor

oil.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect discharge hose (1) and liquid pipe (2) from condenser assembly (3).

4) Remove condenser assembly mounting bolts (4).

(A)

I5RS0C721006-01

4

1

3

2

I4RS0A720017-01