section 9k SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 560 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-21 ABS:

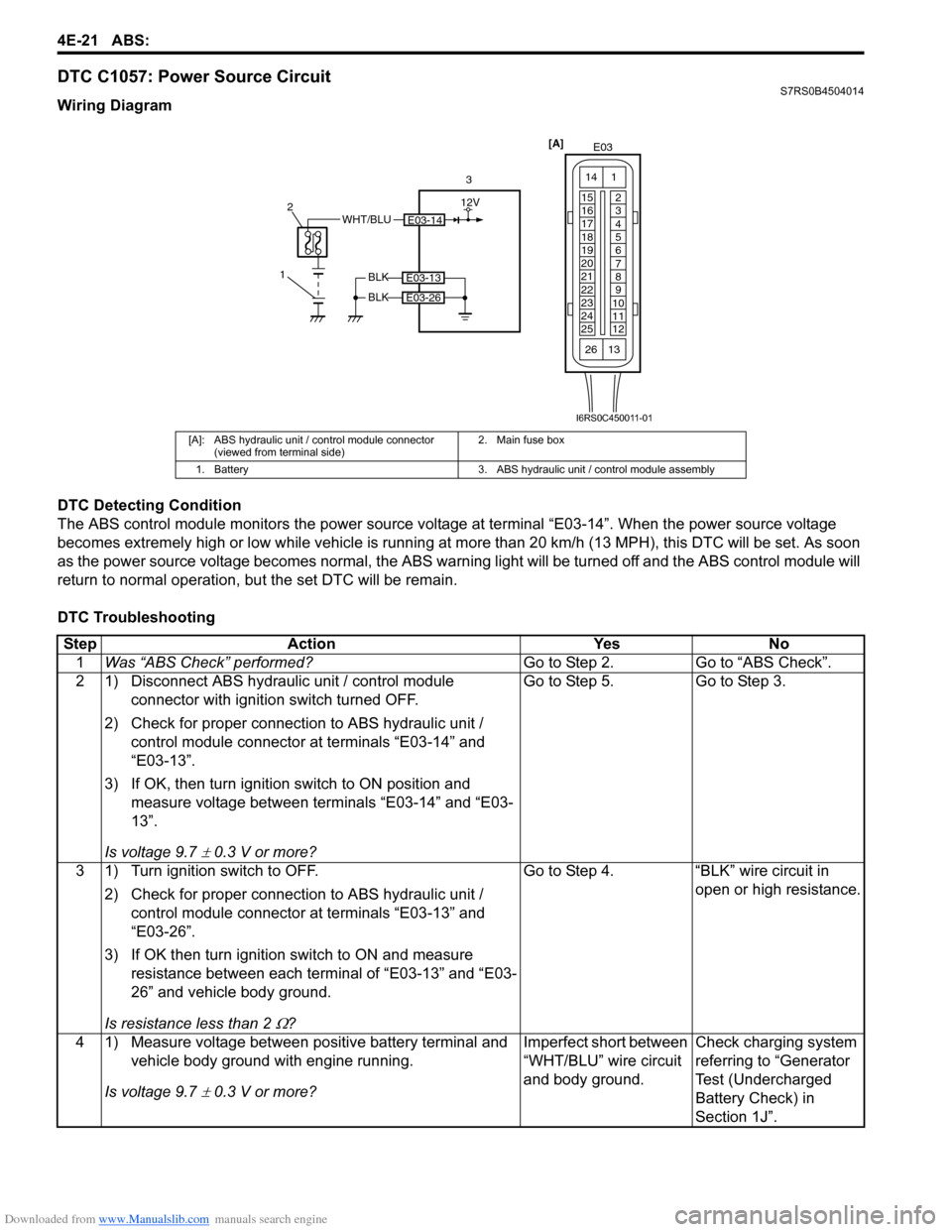

DTC C1057: Power Source CircuitS7RS0B4504014

Wiring Diagram

DTC Detecting Condition

The ABS control module monitors the power source voltage at terminal “E03-14”. When the power source voltage

becomes extremely high or low while vehicle is running at more than 20 km/h (13 MPH), this DTC will be set. As soon

as the power source volta ge becomes normal, the ABS warning light will be turned off and the ABS control module will

return to normal operation, bu t the set DTC will be remain.

DTC Troubleshooting

[A]: ABS hydraulic unit / control module connector (viewed from terminal side) 2. Main fuse box

1. Battery 3. ABS hydraulic unit / control module assembly

E03-14WHT/BLU

1 2

3

BLK

BLK

E03-13

E03-26

[A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

12V

I6RS0C450011-01

Step

Action YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 1) Disconnect ABS hydraulic unit / control module connector with ignition switch turned OFF.

2) Check for proper connection to ABS hydraulic unit / control module connector at terminals “E03-14” and

“E03-13”.

3) If OK, then turn ignition switch to ON position and measure voltage between terminals “E03-14” and “E03-

13”.

Is voltage 9.7

± 0.3 V or more? Go to Step 5. Go to Step 3.

3 1) Turn ignition switch to OFF. 2) Check for proper connection to ABS hydraulic unit / control module connector at terminals “E03-13” and

“E03-26”.

3) If OK then turn ignition switch to ON and measure resistance between each terminal of “E03-13” and “E03-

26” and vehicle body ground.

Is resistance less than 2

Ω? Go to Step 4. “BLK” wire circuit in

open or high resistance.

4 1) Measure voltage between positive battery terminal and vehicle body ground with engine running.

Is voltage 9.7

± 0.3 V or more? Imperfect short between

“WHT/BLU” wire circuit

and body ground.

Check charging system

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.

Page 561 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-22

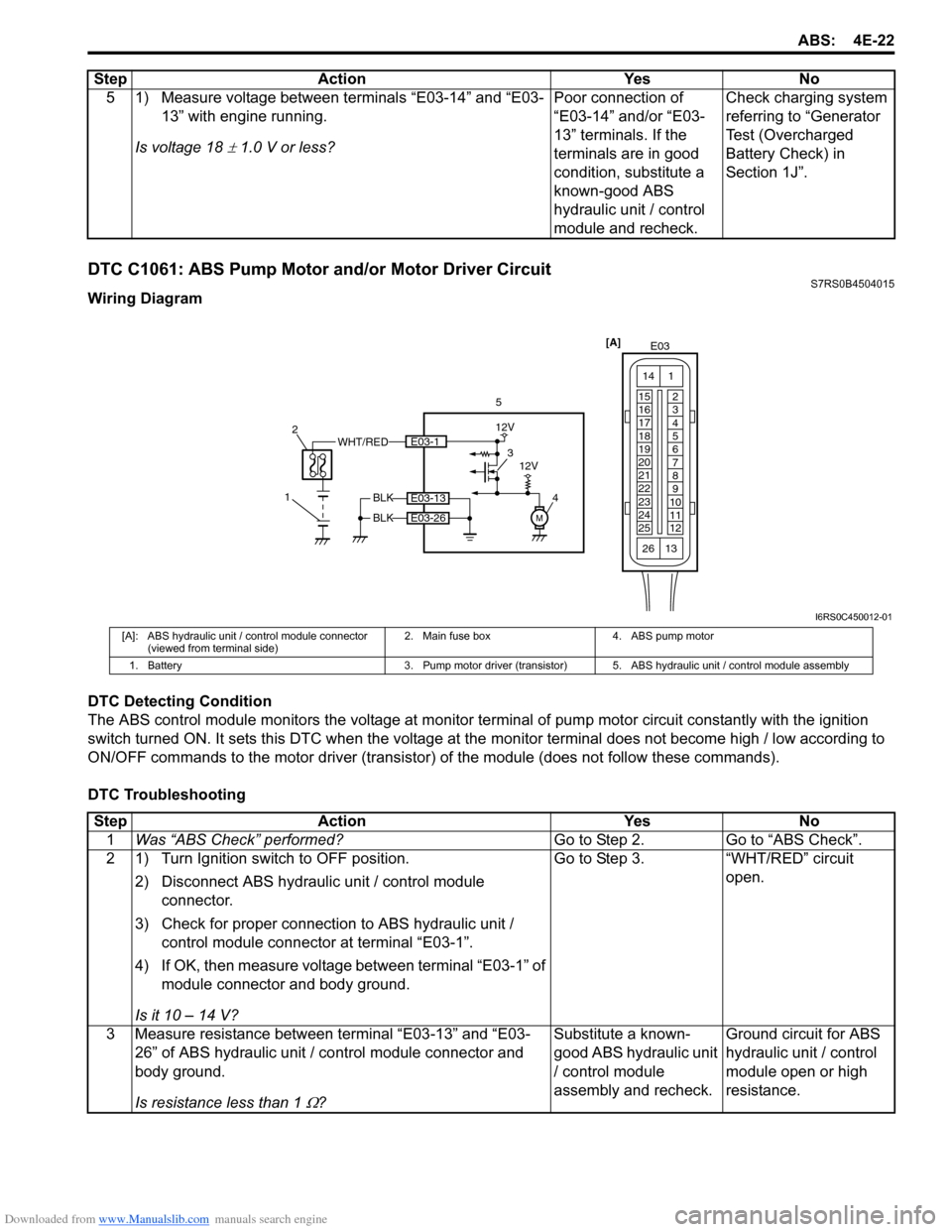

DTC C1061: ABS Pump Motor and/or Motor Driver CircuitS7RS0B4504015

Wiring Diagram

DTC Detecting Condition

The ABS control module monitors the voltage at monitor terminal of pump motor circuit constantly with the ignition

switch turned ON. It sets this DTC when the voltage at the monitor terminal does not become high / low according to

ON/OFF commands to the motor driver (transistor) of the module (does not follow these commands).

DTC Troubleshooting 5 1) Measure voltage between terminals “E03-14” and “E03-

13” with engine running.

Is voltage 18

± 1.0 V or less? Poor connection of

“E03-14” and/or “E03-

13” terminals. If the

terminals are in good

condition, substitute a

known-good ABS

hydraulic unit / control

module and recheck.Check charging system

referring to “Generator

Test (Overcharged

Battery Check) in

Section 1J”.

Step Action Yes No

WHT/RED

1 2

5

BLK

BLK

E03-13

E03-26

[A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

M

3

4E03-1

12V

12V

I6RS0C450012-01

[A]: ABS hydraulic unit / control module connector (viewed from terminal side) 2. Main fuse box 4. ABS pump motor

1. Battery 3. Pump motor driver (transistor) 5. ABS hydraulic unit / control module assembly

StepAction YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 1) Turn Ignition switch to OFF position.

2) Disconnect ABS hydraulic unit / control module connector.

3) Check for proper connection to ABS hydraulic unit / control module connector at terminal “E03-1”.

4) If OK, then measure voltage between terminal “E03-1” of module connector and body ground.

Is it 10 – 14 V? Go to Step 3.

“WHT/RED” circuit

open.

3 Measure resistance between terminal “E03-13” and “E03- 26” of ABS hydraulic unit / co ntrol module connector and

body ground.

Is resistance less than 1

Ω? Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

Ground circuit for ABS

hydraulic unit / control

module open or high

resistance.

Page 562 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-23 ABS:

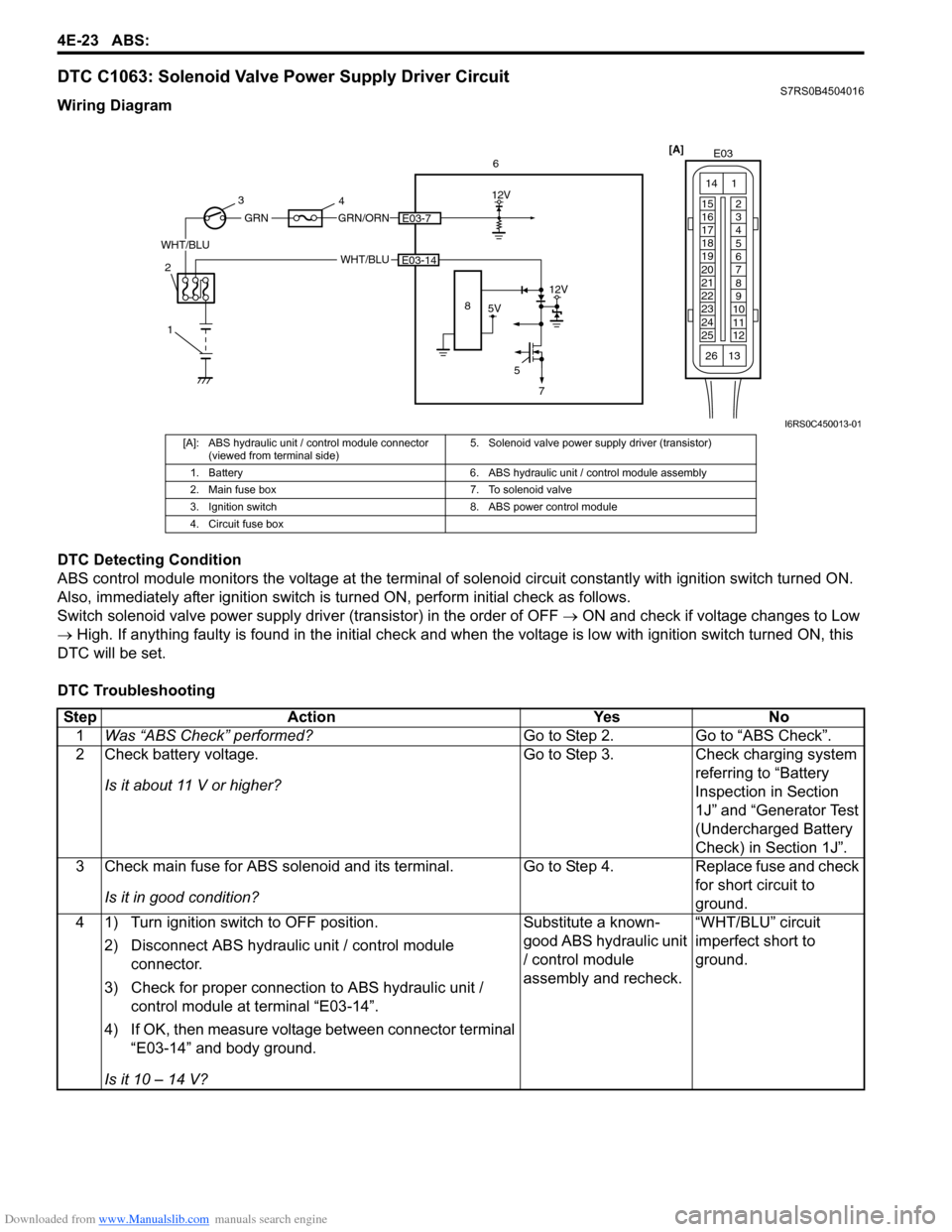

DTC C1063: Solenoid Valve Power Supply Driver CircuitS7RS0B4504016

Wiring Diagram

DTC Detecting Condition

ABS control module monitors the voltage at the terminal of solenoid circuit constantly with ignition switch turned ON.

Also, immediately after ignition switch is turned ON, perform initial check as follows.

Switch solenoid valve power supply driv er (transistor) in the order of OFF → ON and check if voltage changes to Low

→ High. If anything faulty is found in the initial check and when the voltage is low with ignition switch turned ON, this

DTC will be set.

DTC Troubleshooting

[A] E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

266

WHT/BLU

12V

5E03-14

5V

12V

8

GRN/ORNE03-7

WHT/BLU

GRN

1

2 3

4

7

I6RS0C450013-01

[A]: ABS hydraulic unit / control module connector

(viewed from terminal side) 5. Solenoid valve power supp

ly driver (transistor)

1. Battery 6. ABS hydraulic unit / control module assembly

2. Main fuse box 7. To solenoid valve

3. Ignition switch 8. ABS power control module

4. Circuit fuse box

Step Action YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 Check battery voltage.

Is it about 11 V or higher? Go to Step 3.

Check charging system

referring to “Battery

Inspection in Section

1J” and “Generator Test

(Undercharged Battery

Check) in Section 1J”.

3 Check main fuse for ABS solenoid and its terminal.

Is it in good condition? Go to Step 4.

Replace fuse and check

for short circuit to

ground.

4 1) Turn ignition switch to OFF position.

2) Disconnect ABS hydraulic unit / control module connector.

3) Check for proper connection to ABS hydraulic unit / control module at terminal “E03-14”.

4) If OK, then measure voltage between connector terminal “E03-14” and body ground.

Is it 10 – 14 V? Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

“WHT/BLU” circuit

imperfect short to

ground.

Page 565 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-26

DTC TroubleshootingStep Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Check connection of connectors of all control modules communicating by means of CAN.

2) Recheck DTC.

Is DTC U1073 indicated? Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00” in related manual.

3 1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 4. Repair insulation of

CAN communication

line circuit referring to

“Precaution for CAN

Communication System

in Section 00” in related

manual.

4 1) Turn ignition switch to OFF position.

2) Connect connector of disconnected control modules communicating by means of CAN.

3) Disconnect connector from any one of control modules other than BCM and ABS control module.

4) Recheck ABS contro l module for DTC.

IS DTC U1073 detected? Disconnected

connectors of control

modules other than the

one whose connector is

disconnected in Step 3)

one by one and check

that DTC U1073 is

detected by ABS control

module each time

connector is

disconnected.

When DTC U1073 is not

detected by ABS

module while checking

in this way, go to

description under “NO”

below. If DTC U1073 is

detected by ABS control

module, go to Step 5.Check power and

ground circuit of control

module disconnected in

Step 3) circuit is OK,

substitute a know-good

control module

disconnected in Step 3)

and recheck.

5 1) Substitute a know-good BCM and recheck ABS control module for DTC.

IS DTC U1073 detected? Substitute a know-good

ABS control module and

recheck.

End.

Page 566 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-27 ABS:

DTC U1100: Lost Communication with ECM (Reception Error)S7RS0B4504019

Wiring Diagram

Refer to “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition

Reception error of communication data for ECM is detected more than specified time continuously.

DTC Troubleshooting Step Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Check DTC for ABS.

Is DTC U1073 detected? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

3 1) Check DTC for ECM. Is DTC P1674 detected? Go to “DTC P1674:

CAN Communication

(Bus Off Error) in

Section 1A”.Go to Step 4.

4 1) Check connection of connectors of all control modules communicating by means of CAN.

2) Check DTC for ABS.

Is DTC U1100 detected? Go to Step 5. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00” in related manual.

5 1) Turn ignition switch to OFF position.

2) Disconnect connectors of ABS control module and ECM

communicating by means of CAN.

3) Check CAN communication circuit between ABS control module and ECM for open, short and high resistance.

Is CAN communication circuit in good condition? Go to Step 6. Repair or replace the

CAN communication

line.

6 1) Disconnect connectors of all control modules communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 5 for open, short and high

resistance.

Is each CAn communication circuit in good condition? Go to Step 7. Repair or replace the

CAN communication

line.

7 1) Turn ignition switch to OFF position. 2) Connect connector of disconnected control modules communicating by means of CAN.

3) Disconnect connector from any one of control modules other than BCM and ABS control module.

4) Recheck ABS contro l module for DTC

IS DTC U1100 detected? Disconnected

connectors of control

modules other than the

one whose connector is

disconnected in Step 3)

one by one and check

that DTC U1100 is

detected by ABS control

module each time

connector is

disconnected.

When DTC U1100 is not

detected by ABS

module while checking

in this way, go to

description under “NO”

below. If DTC U1100 is

detected by ABS control

module, go to Step 8.Check power and

ground circuit of control

module disconnected in

Step 3) circuit is OK,

substitute a know-good

control module

disconnected in Step 3)

and recheck.

Page 570 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-31 ABS:

2) Bleed air from brake system referring to “Air Bleeding of Brake System in Section 4A”.

3) Check each installed part for fluid leakage and perform “ABS Hydraulic Un it Operation Check”.

NOTE

For new ABS hydraulic unit / control module

assembly, if “ABS Hydraulic Unit Operation

Check” has not been performed, ABS

warning light may flash when ignition switch

is turned ON position.

Accordingly preform “ABS Hydraulic Unit

Operation Check” to stop flashing of ABS

warning light.

Front / Rear Wheel Speed Sensor On-Vehicle

Inspection

S7RS0B4506005

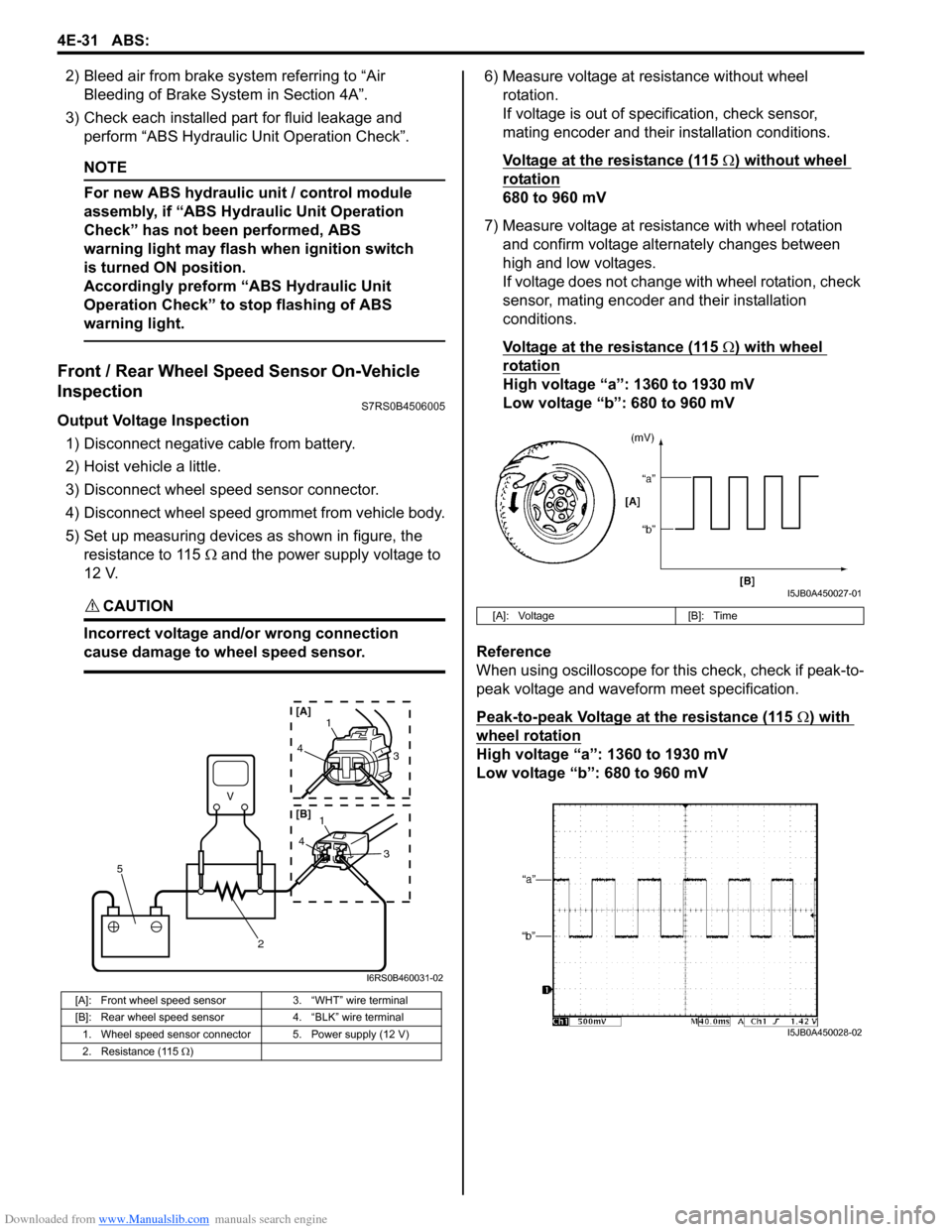

Output Voltage Inspection

1) Disconnect negative cable from battery.

2) Hoist vehicle a little.

3) Disconnect wheel speed sensor connector.

4) Disconnect wheel speed grommet from vehicle body.

5) Set up measuring devices as shown in figure, the resistance to 115 Ω and the power supply voltage to

12 V.

CAUTION!

Incorrect voltage and/or wrong connection

cause damage to wheel speed sensor.

6) Measure voltage at resistance without wheel rotation.

If voltage is out of specification, check sensor,

mating encoder and their installation conditions.

Voltage at the resistance (115

Ω) without wheel

rotation

680 to 960 mV

7) Measure voltage at resistance with wheel rotation and confirm voltage alternately changes between

high and low voltages.

If voltage does not change with wheel rotation, check

sensor, mating encoder and their installation

conditions.

Voltage at the resistance (115

Ω) with wheel

rotation

High voltage “a”: 1360 to 1930 mV

Low voltage “b”: 680 to 960 mV

Reference

When using oscilloscope for this check, check if peak-to-

peak voltage and waveform meet specification.

Peak-to-peak Voltage at the resistance (115

Ω) with

wheel rotation

High voltage “a”: 1360 to 1930 mV

Low voltage “b”: 680 to 960 mV

[A]: Front wheel speed sensor 3. “WHT” wire terminal

[B]: Rear wheel speed sensor 4. “BLK” wire terminal

1. Wheel speed sensor connector 5. Power supply (12 V)

2. Resistance (115 Ω )

V

2

5

41

3

43

1

[A]

[B]

I6RS0B460031-02

[A]: Voltage [B]: Time

I5JB0A450027-01

I5JB0A450028-02

Page 572 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-33 ABS:

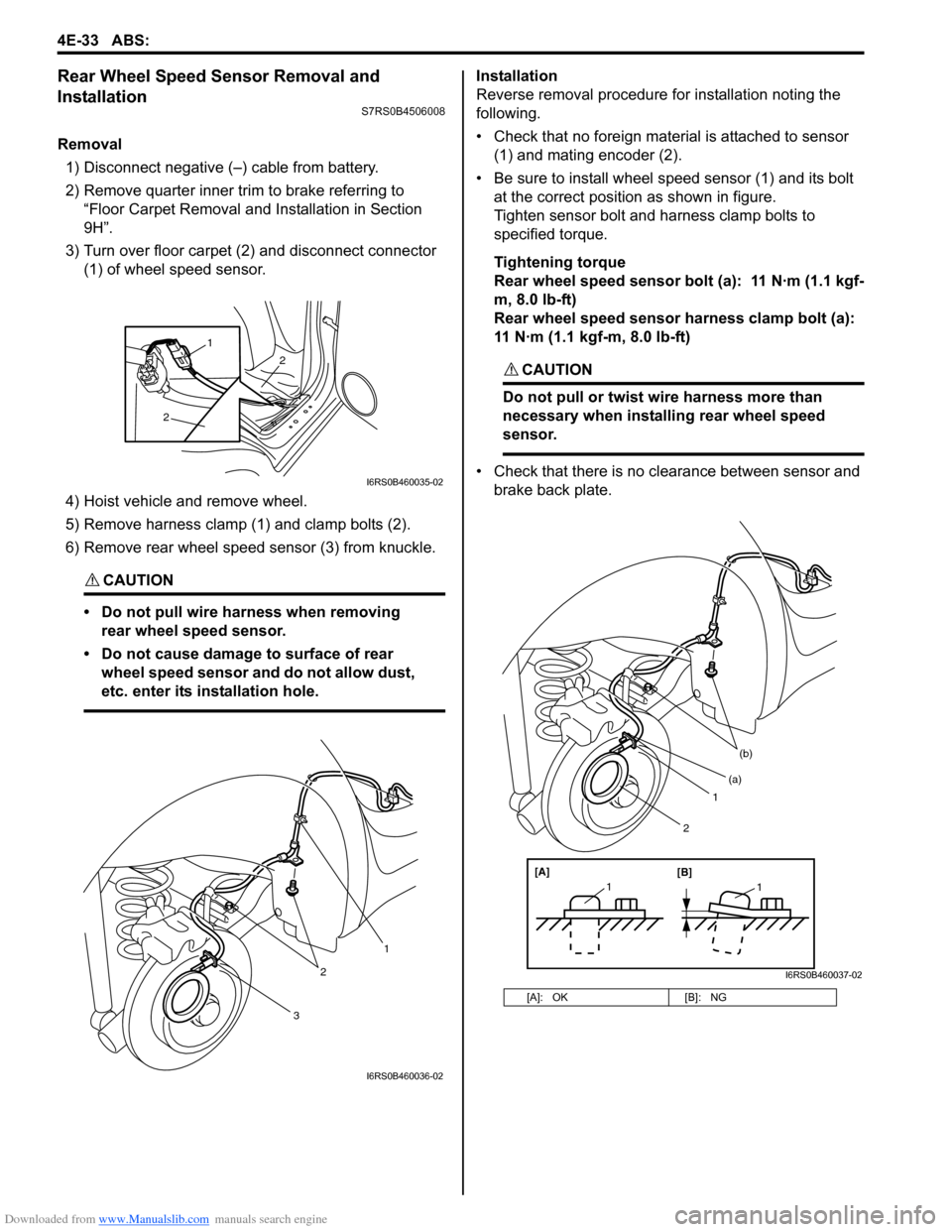

Rear Wheel Speed Sensor Removal and

Installation

S7RS0B4506008

Removal1) Disconnect negative (–) cable from battery.

2) Remove quarter inner trim to brake referring to “Floor Carpet Removal a nd Installation in Section

9H”.

3) Turn over floor carpet (2) and disconnect connector (1) of wheel speed sensor.

4) Hoist vehicle and remove wheel.

5) Remove harness clamp (1) and clamp bolts (2).

6) Remove rear wheel speed sensor (3) from knuckle.

CAUTION!

• Do not pull wire harness when removing rear wheel speed sensor.

• Do not cause damage to surface of rear wheel speed sensor and do not allow dust,

etc. enter its installation hole.

Installation

Reverse removal procedure for installation noting the

following.

• Check that no foreign material is attached to sensor (1) and mating encoder (2).

• Be sure to install wheel speed sensor (1) and its bolt at the correct position as shown in figure.

Tighten sensor bolt and harness clamp bolts to

specified torque.

Tightening torque

Rear wheel speed sensor bolt (a): 11 N·m (1.1 kgf-

m, 8.0 lb-ft)

Rear wheel speed sensor harness clamp bolt (a):

11 N·m (1.1 kgf-m, 8.0 lb-ft)

CAUTION!

Do not pull or twist wire harness more than

necessary when installing rear wheel speed

sensor.

• Check that there is no clearance between sensor and brake back plate.

2

2

1

I6RS0B460035-02

3

2

1

I6RS0B460036-02

[A]: OK [B]: NG

1

(b)

[A][B]

11

(a)

2

I6RS0B460037-02

Page 573 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-34

Rear Wheel Speed Sensor InspectionS7RS0B4506009

Refer to “Front Wheel Speed Sensor Inspection” since

rear wheel speed sensor is the same as front wheel

speed sensor.

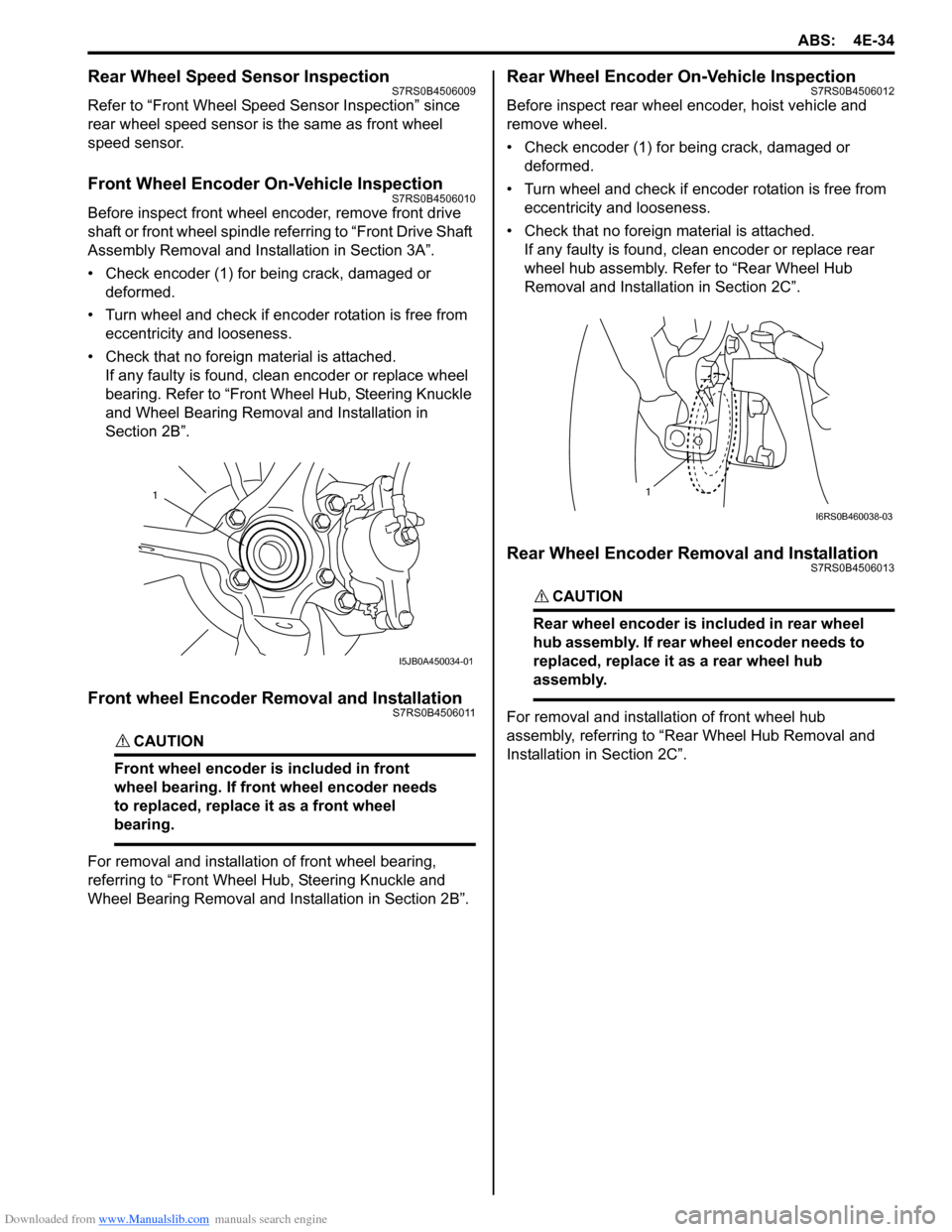

Front Wheel Encoder On-Vehicle InspectionS7RS0B4506010

Before inspect front wheel encoder, remove front drive

shaft or front wheel spindle referring to “Front Drive Shaft

Assembly Removal and Installation in Section 3A”.

• Check encoder (1) for being crack, damaged or deformed.

• Turn wheel and check if encoder rotation is free from eccentricity and looseness.

• Check that no foreign material is attached. If any faulty is found, cl ean encoder or replace wheel

bearing. Refer to “Front Wheel Hub, Steering Knuckle

and Wheel Bearing Removal and Installation in

Section 2B”.

Front wheel Encoder Removal and InstallationS7RS0B4506011

CAUTION!

Front wheel encoder is included in front

wheel bearing. If front wheel encoder needs

to replaced, replace it as a front wheel

bearing.

For removal and installation of front wheel bearing,

referring to “Front Wheel Hub, Steering Knuckle and

Wheel Bearing Removal and Installation in Section 2B”.

Rear Wheel Encoder On-Vehicle InspectionS7RS0B4506012

Before inspect rear wheel encoder, hoist vehicle and

remove wheel.

• Check encoder (1) for being crack, damaged or deformed.

• Turn wheel and check if encoder rotation is free from eccentricity and looseness.

• Check that no foreign material is attached. If any faulty is found, clean encoder or replace rear

wheel hub assembly. Refer to “Rear Wheel Hub

Removal and Installati on in Section 2C”.

Rear Wheel Encoder Removal and InstallationS7RS0B4506013

CAUTION!

Rear wheel encoder is included in rear wheel

hub assembly. If rear wheel encoder needs to

replaced, replace it as a rear wheel hub

assembly.

For removal and installation of front wheel hub

assembly, referring to “Rear Wheel Hub Removal and

Installation in Section 2C”.

1

I5JB0A450034-01

1

I6RS0B460038-03

Page 574 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-35 ABS:

Specifications

Tightening Torque SpecificationsS7RS0B4507001

NOTE

The specified tightening torque is also described in the following.

“Front Wheel Speed Sensor Components Location”

“Rear Wheel Speed Sensor Components Location”

“ABS Hydraulic Unit / Control Module Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B4508001

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Brake pipe flare nut 16 1.6 11.5 �)

ABS hydraulic unit / c ontrol module assembly

bolt 90.9 6.5�)

ABS hydraulic unit / c ontrol module assembly

bracket bolt 25 2.5 18.0�)

Front wheel speed sensor bolt 25 2.5 18.0 �)

Front wheel speed sensor harness clamp bolt 11 1.1 8.0 �)

Rear wheel speed sensor bolt 11 1.1 8.0 �)

Rear wheel speed sensor har ness clamp bolt 11 1.1 8.0 �)

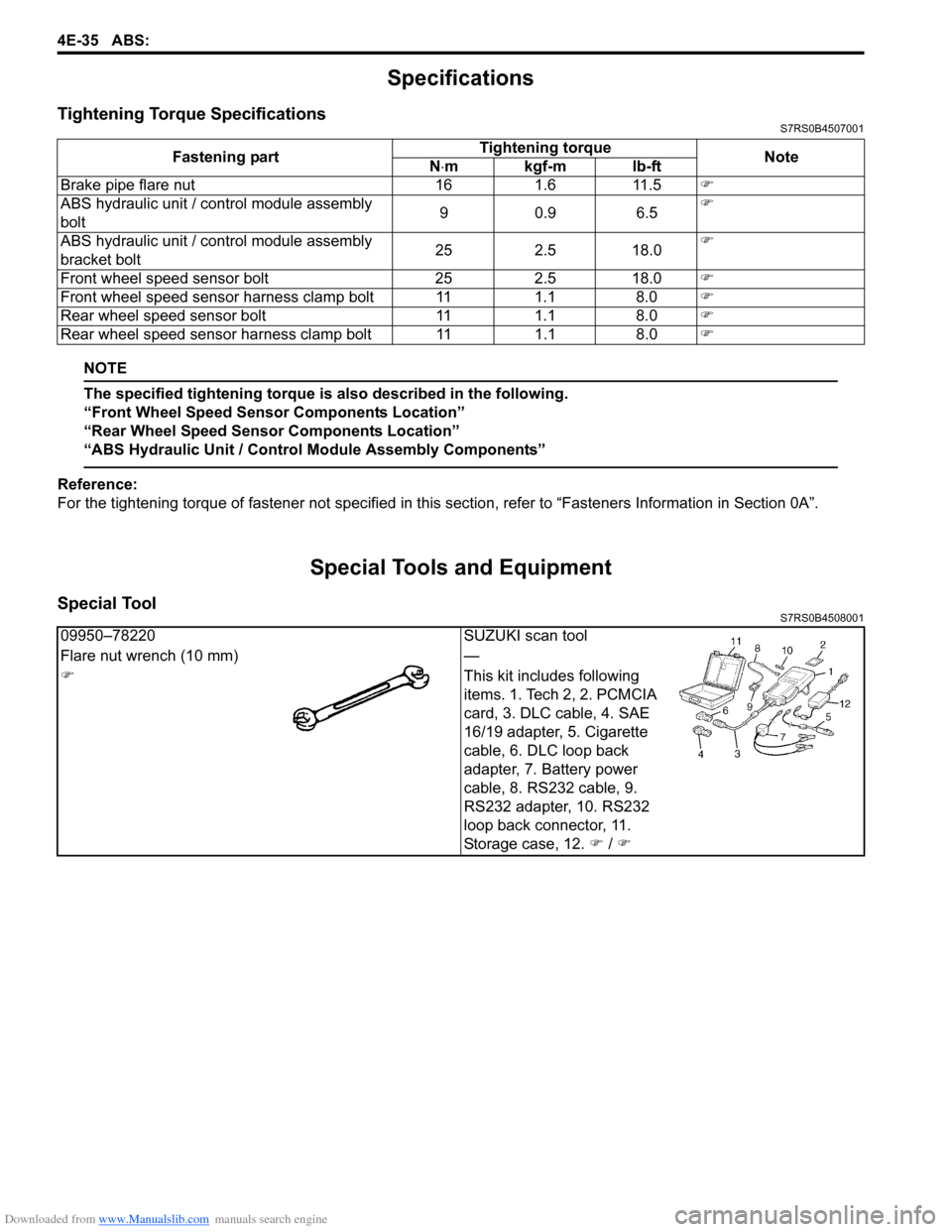

09950–78220SUZUKI scan tool

Flare nut wrench (10 mm) —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �) / �)

Page 575 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-1

Brakes

Electronic Stability Program

Precautions

Precautions in Diagnosing TroublesS7RS0B4600001

To ensure that the trouble diagnosis is done accurately

and smoothly, observe the following and follow

“Electronic Stability Program System Check”.

• Diagnostic information stored in ESP® control module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before us ing scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• If the vehicles was operated in any of the following ways, ESP ® warning lamp may light momentarily but

this does not indicate anything abnormal in ESP ®.

– The vehicle was driven with parking brake pulled.

– The vehicle was driven with brake dragging.

– The vehicle was stuck in mud, sand, etc.

– Wheel spin occurred while driving.

– Wheel(s) was rotated while the vehicle was jacked up.

• Be sure to use the trouble diagnosis procedure as described in “Electronic Stability Program System

Check”. Failure to follow it may resu lt in incorrect

diagnosis. (Some other diagnosis trouble code may

be stored by mistake in the memory of ESP ® control

module during inspection.)

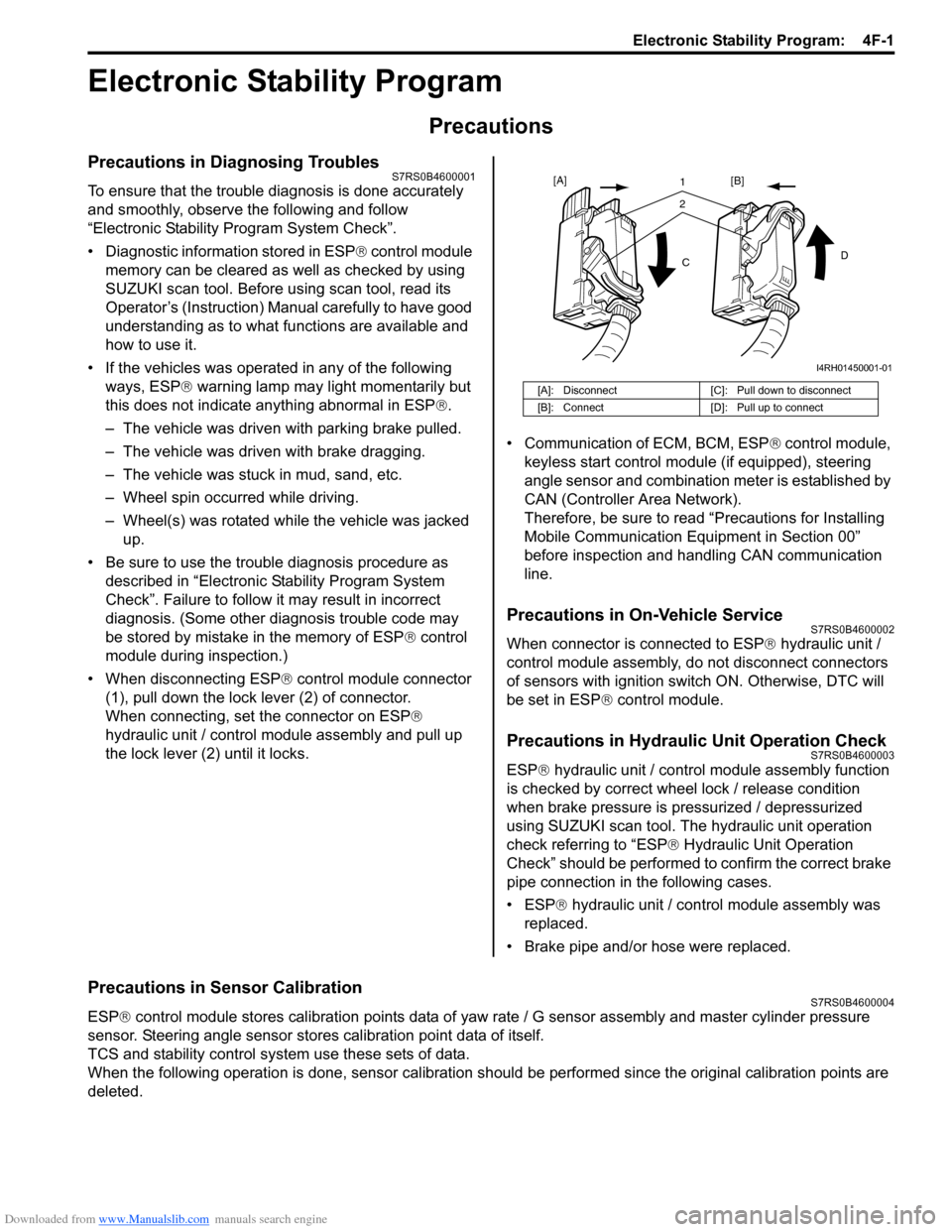

• When disconnecting ESP ® control module connector

(1), pull down the lock lever (2) of connector.

When connecting, set the connector on ESP ®

hydraulic unit / control module assembly and pull up

the lock lever (2) until it locks. • Communication of ECM, BCM, ESP

® control module,

keyless start control module (if equipped), steering

angle sensor and combination meter is established by

CAN (Controller Area Network).

Therefore, be sure to read “Precautions for Installing

Mobile Communication Equipment in Section 00”

before inspection and handling CAN communication

line.

Precautions in On-Vehicle ServiceS7RS0B4600002

When connector is connected to ESP ® hydraulic unit /

control module assembly, do not disconnect connectors

of sensors with ignition switch ON. Otherwise, DTC will

be set in ESP ® control module.

Precautions in Hydraulic Unit Operation CheckS7RS0B4600003

ESP® hydraulic unit / control module assembly function

is checked by correct wheel lock / release condition

when brake pressure is pressurized / depressurized

using SUZUKI scan tool. The hydraulic unit operation

check referring to “ESP ® Hydraulic Unit Operation

Check” should be performed to confirm the correct brake

pipe connection in the following cases.

• ESP® hydraulic unit / contro l module assembly was

replaced.

• Brake pipe and/or hose were replaced.

Precautions in Sensor CalibrationS7RS0B4600004

ESP ® control module stores calibration points data of yaw rate / G sensor assembly and master cylinder pressure

sensor. Steering angle sensor stores calibration point data of itself.

TCS and stability control system use these sets of data.

When the following operation is done, sensor calibration should be performed since the original calibration points are

deleted.

[A]: Disconnect [C]: Pull down to disconnect

[B]: Connect [D]: Pull up to connect

21

C D

[A]

[B]

I4RH01450001-01