Control system SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 928 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-46 Power Assisted Steering System:

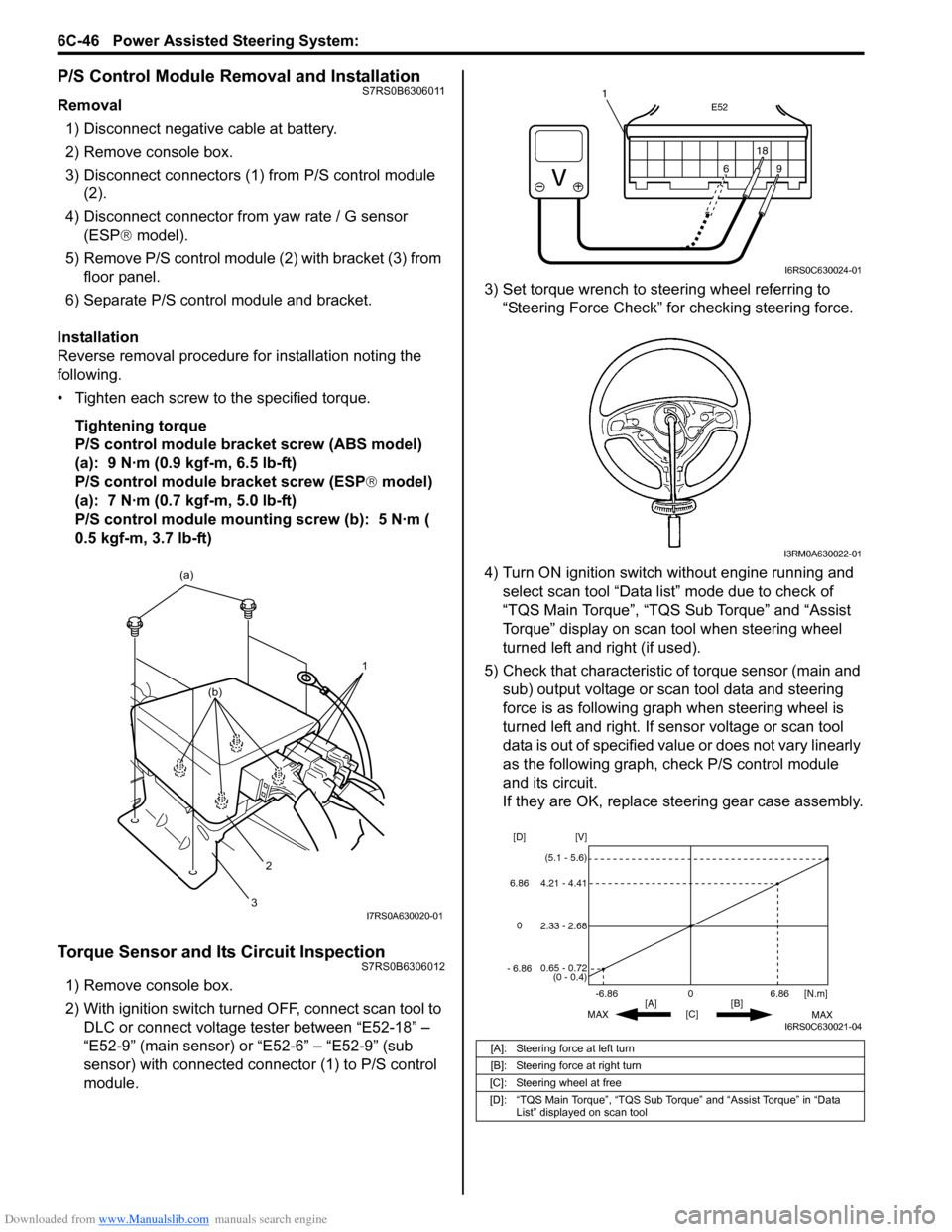

P/S Control Module Removal and InstallationS7RS0B6306011

Removal1) Disconnect negative cable at battery.

2) Remove console box.

3) Disconnect connectors (1) from P/S control module (2).

4) Disconnect connector from yaw rate / G sensor

(ESP ® model).

5) Remove P/S control module (2) with bracket (3) from floor panel.

6) Separate P/S control module and bracket.

Installation

Reverse removal procedure for installation noting the

following.

• Tighten each screw to the specified torque. Tightening torque

P/S control module bracket screw (ABS model)

(a): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

P/S control module bracket screw (ESP ® model)

(a): 7 N·m (0.7 kgf-m, 5.0 lb-ft)

P/S control module mounting screw (b): 5 N·m (

0.5 kgf-m, 3.7 lb-ft)

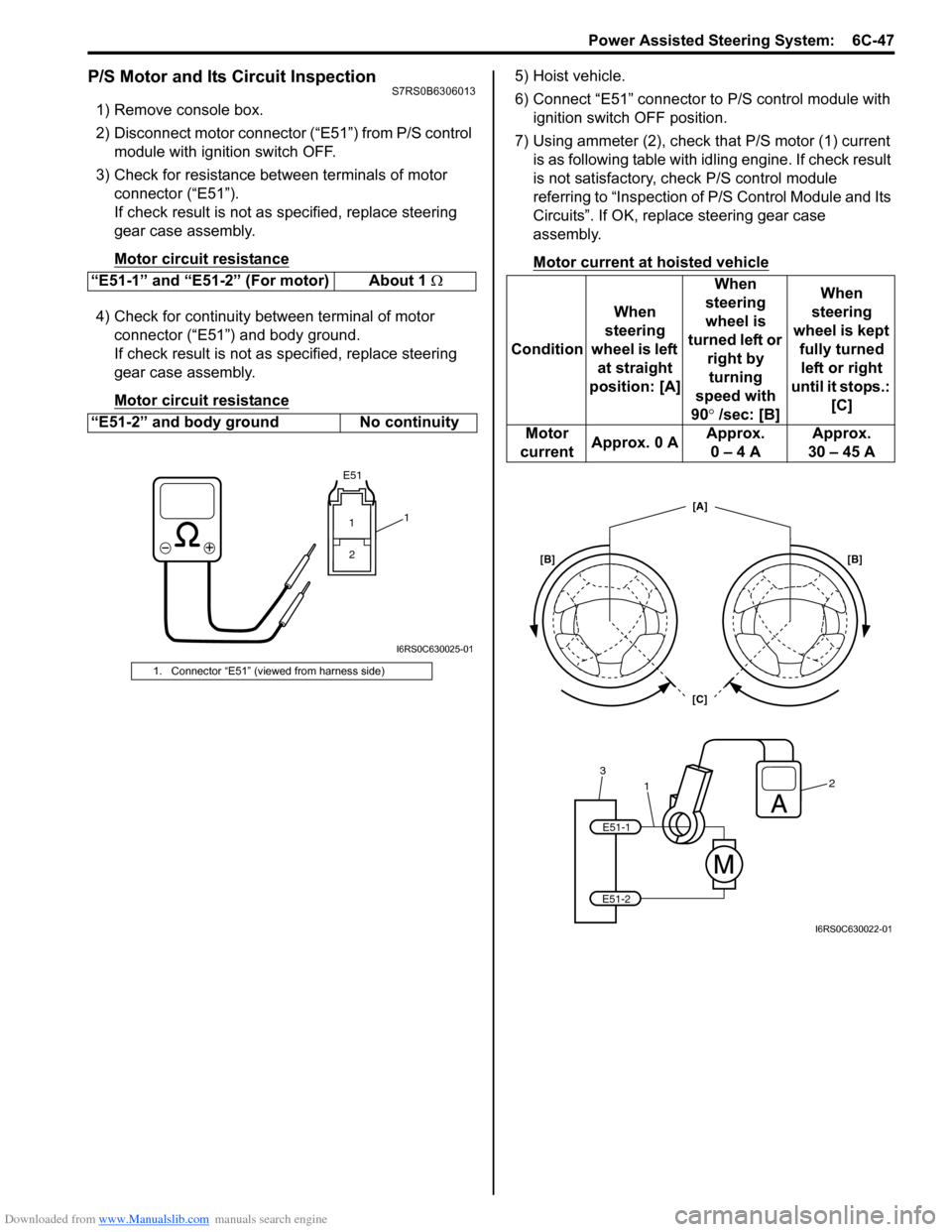

Torque Sensor and Its Circuit InspectionS7RS0B6306012

1) Remove console box.

2) With ignition switch turned OFF, connect scan tool to DLC or connect voltage tester between “E52-18” –

“E52-9” (main sensor) or “E52-6” – “E52-9” (sub

sensor) with connected connector (1) to P/S control

module. 3) Set torque wrench to stee

ring wheel referring to

“Steering Force Check” for checking steering force.

4) Turn ON ignition switch without engine running and select scan tool “Data list” mode due to check of

“TQS Main Torque”, “TQS Sub Torque” and “Assist

Torque” display on scan tool when steering wheel

turned left and right (if used).

5) Check that characteristic of torque sensor (main and sub) output voltage or scan tool data and steering

force is as following graph when steering wheel is

turned left and right. If sensor voltage or scan tool

data is out of specified value or does not vary linearly

as the following graph, check P/S control module

and its circuit.

If they are OK, replace steering gear case assembly.

1

(a)

2

3

(b)

I7RS0A630020-01

[A]: Steering force at left turn

[B]: Steering force at right turn

[C]: Steering wheel at free

[D]: “TQS Main Torque”, “TQS Sub Torque” and “Assist Torque” in “Data List” displayed on scan tool

E52

18

9

6

9

6 18

1

I6RS0C630024-01

I3RM0A630022-01

0

[C] [N.m]

MAX MAX

[B]

[A]

2.33 - 2.68 [V]

[D]

0.65 - 0.72

(0 - 0.4)

4.21 - 4.41

(5.1 - 5.6)

6.86

-6.86

0

6.86

- 6.86

I6RS0C630021-04

Page 929 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-47

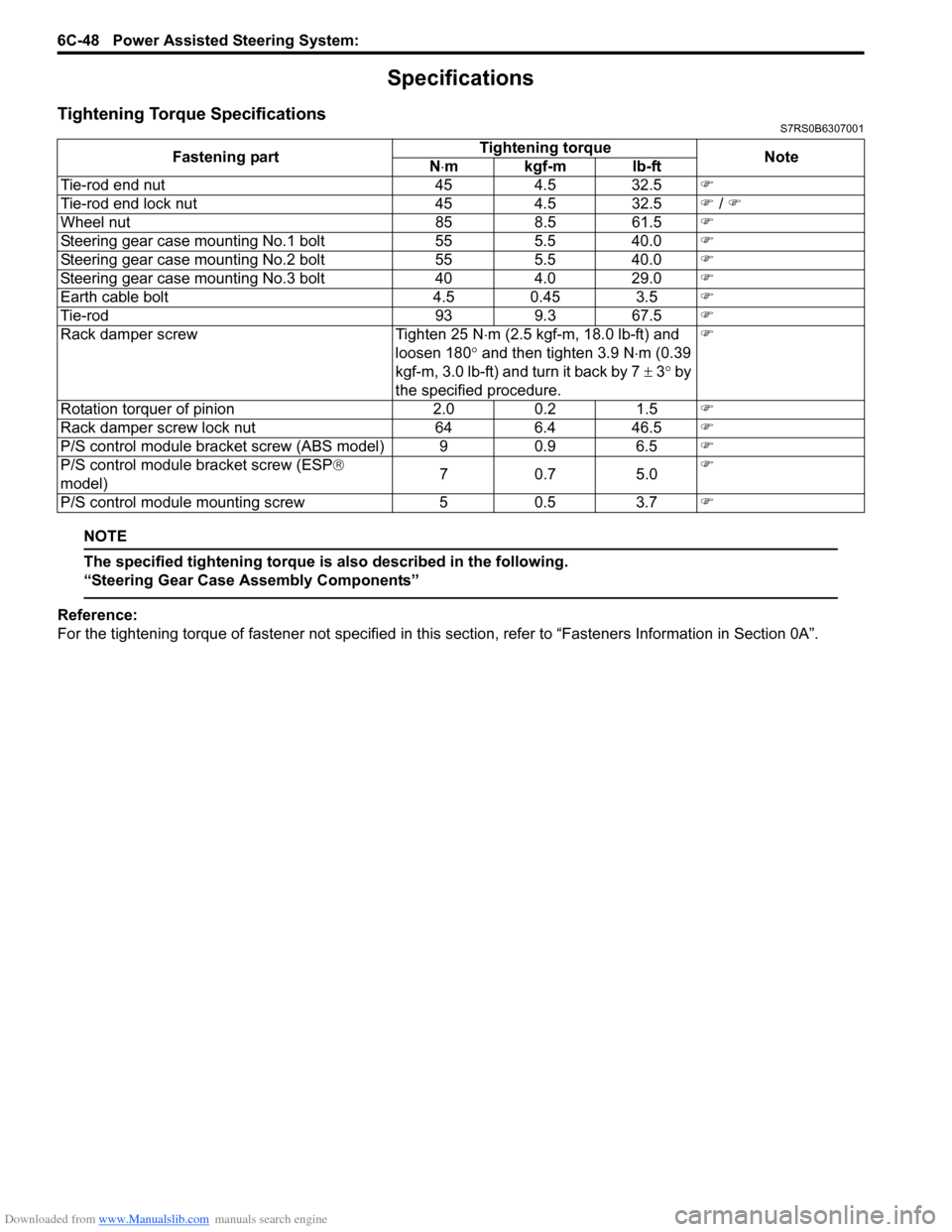

P/S Motor and Its Circuit InspectionS7RS0B6306013

1) Remove console box.

2) Disconnect motor connector (“E51”) from P/S control module with ignition switch OFF.

3) Check for resistance between terminals of motor connector (“E51”).

If check result is not as specified, replace steering

gear case assembly.

Motor circuit resistance

4) Check for continuity between terminal of motor connector (“E51”) and body ground.

If check result is not as specified, replace steering

gear case assembly.

Motor circuit resistance

5) Hoist vehicle.

6) Connect “E51” connector to P/S control module with ignition switch OFF position.

7) Using ammeter (2), check that P/S motor (1) current is as following table with id ling engine. If check result

is not satisfactory, check P/S control module

referring to “Inspection of P/S Control Module and Its

Circuits”. If OK, replace steering gear case

assembly.

Motor current at hoisted vehicle

“E51-1” and “E51-2” (For motor) About 1 Ω

“E51-2” and body ground No continuity

1. Connector “E51” (viewed from harness side)

E51

11 2

I6RS0C630025-01

Condition When

steering

wheel is left at straight

position: [A] When

steering

wheel is

turned left or right by turning

speed with

90° /sec: [B] When

steering

wheel is kept fully turned left or right

until it stops.: [C]

Motor

current Approx. 0 A Approx.

0 – 4 A Approx.

30 – 45 A

1

32

E51-1

E51-2

[C] [A]

[B] [B]

I6RS0C630022-01

Page 930 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-48 Power Assisted Steering System:

Specifications

Tightening Torque SpecificationsS7RS0B6307001

NOTE

The specified tightening torque is also described in the following.

“Steering Gear Case Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Tie-rod end nut 454.5 32.5 �)

Tie-rod end lock nut 454.5 32.5 �) / �)

Wheel nut 858.5 61.5 �)

Steering gear case mounting No.1 bolt 555.5 40.0 �)

Steering gear case mounting No.2 bolt 555.5 40.0 �)

Steering gear case mounting No.3 bolt 404.0 29.0 �)

Earth cable bolt 4.5 0.45 3.5�)

Tie-rod 939.3 67.5 �)

Rack damper screw Tighten 25 N⋅m (2.5 kgf-m, 18.0 lb-ft) and

loosen 180 ° and then tighten 3.9 N ⋅m (0.39

kgf-m, 3.0 lb-ft) and turn it back by 7 ± 3° by

the specified procedure. �)

Rotation torquer of pinion 2.00.2 1.5 �)

Rack damper screw lock nut 646.4 46.5 �)

P/S control module bracket screw (ABS model) 9 0.9 6.5�)

P/S control module bracket screw (ESP ®

model) 70

.7 5 .0 �)

P/S control module mounting screw 50.5 3.7 �)

Page 933 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 7- i

7

Section 7

CONTENTS

HVAC

Precautions ................................................. 7-1

Precautions............................................................. 7-1

Precautions on HVAC ........................................... 7-1

Heater and Ventilation.... ......................... 7A-1

General Description ............................................. 7A-1

Heater and Ventilation Construction ................... 7A-1

Schematic and Routing Diagram ........................ 7A-2 Heater and Ventilation Wiring Circuit Diagram .... 7A-2

Diagnostic Information and Procedures ............ 7A-3 Heater and Ventilation Symptom Diagnosis........ 7A-3

Repair Instructions .............................................. 7A-4 HVAC Unit Components ..................................... 7A-4

HVAC Unit Removal and Installation .................. 7A-4

Blower Motor Removal and Installation............... 7A-4

Blower Motor Inspection ..................................... 7A-4

Blower Motor Resistor Removal and Installation ......................................................... 7A-5

Blower Motor Resistor Inspection ....................... 7A-5

Blower Motor Relay Inspection ........................... 7A-6

HVAC Control Unit Components ......................... 7A-6

HVAC Control Unit Remova l and Installation ...... 7A-7

Blower Speed Selector In spection ...................... 7A-9

Air Intake Selector Inspec tion ............................. 7A-9

Air Intake Control Actuator Removal and Installation ......................................................... 7A-9

Air Intake Control Actuator Inspection .............. 7A-10

Center Ventilation Louver Removal and Installation ....................................................... 7A-10

Side Ventilation Louver Removal and Installation ....................................................... 7A-11

HVAC Air Filter Removal and Installation (If Equipped)........................................................ 7A-12

HVAC Air Filter Inspection (If Equipped) ........... 7A-12

Air Conditioning System... ...................... 7B-1

Manual Type ............................................................ 7B-1

Precautions........................................................... 7B-1A/C System Caution ............................................ 7B-1

Precautions on Servicing A/C System ................ 7B-1

General Description ............................................. 7B-3 Refrigerant Type Identifica tion ............................ 7B-3

Sub-Cool A/C System Description ...................... 7B-4

A/C Operation Description .................................. 7B-4 Schematic and Routing Diagram ........................7B-5

Major Components of A/C System ...................... 7B-5

A/C System Wiring Diagram ............................... 7B-6

Diagnostic Information and Procedures ............7B-7 A/C System Symptom Diagnosis ........................ 7B-7

Abnormal Noise Sympto m Diagnosis of A/C

System .............................................................. 7B-9

A/C System Performance Inspection ................ 7B-10

A/C System Inspection at ECM ......................... 7B-15

Repair Instructions ........... .................................7B-16

Operation Procedure for Re frigerant Charge .... 7B-16

Condenser Assembly On-Vehicle Inspection .... 7B-21

Condenser Assembly Removal and Installation ....................................................... 7B-21

Receiver/Dryer Removal and Installation .......... 7B-22

HVAC Unit Components ................................... 7B-23

HVAC Unit Removal and In stallation ................ 7B-24

Evaporator Inspection ....................................... 7B-24

Evaporator Thermistor (Evaporator Temperature Sensor) Removal and

Installation ....................................................... 7B-25

Evaporator Thermistor (Evaporator Temperature Sensor) Inspec tion..................... 7B-25

Expansion Valve Removal and Installation ....... 7B-26

Expansion Valve Inspection .............................. 7B-26

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-26

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-26

A/C Switch Inspection ....................................... 7B-27

Compressor Relay Inspection ........................... 7B-27

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-27

Compressor Drive Belt Removal and Installation ....................................................... 7B-28

Compressor Assembly Removal and Installation ....................................................... 7B-28

Compressor Assembly Components................. 7B-29

Magnet Clutch Inspection.................................. 7B-29

Magnet Clutch Removal and Installation........... 7B-29

Relief Valve Inspection...................................... 7B-31

Relief Valve Removal and Installation............... 7B-32

Specifications .................... .................................7B-32

Tightening Torque Specifications ...................... 7B-32

Special Tools and Equipmen t ...........................7B-33

Page 934 of 1496

Downloaded from www.Manualslib.com manuals search engine 7-ii Table of Contents

Recommended Service Material ....................... 7B-33

Special Tool ...................................................... 7B-33

Automatic Type .................... .................................7B-34

Precautions.........................................................7B-34 A/C System Caution .......................................... 7B-34

Precautions in Diagnosing Trouble ................... 7B-34

Precautions on Servicing A/C System .............. 7B-34

General Description .......... .................................7B-34

Auto A/C System Descript ion ............................ 7B-34

HVAC Control Module Operation Description ... 7B-36

Refrigerant Type Identifica tion .......................... 7B-36

Sub-Cool A/C System Description .................... 7B-36

A/C Operation Description ................................ 7B-36

On-Board Diagnostic System Description ......... 7B-37

Schematic and Routing Diagram ......................7B-37 Major Components of A/C System .................... 7B-37

A/C System Wiring Diagra m ............................. 7B-38

Diagnostic Information and Procedures ..........7B-39 A/C System Symptom Diagnosis ...................... 7B-39

Abnormal Noise Sympto m Diagnosis of A/C

System ............................................................ 7B-42

DTC Check........................................................ 7B-42

DTC Clearance ................................................. 7B-43

DTC Table ......................................................... 7B-44

Fail-Safe Table ................. ................................. 7B-45

Scan Tool Data ................................................. 7B-46

Air Conditioning System Check......................... 7B-47

Visual Inspection ............................................... 7B-49

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit Malfunction .......................... 7B-49

DTC B1503: A/C Evaporator Air Temperature Sensor and/or Its Circuit Malfunction .............. 7B-50

DTC B1504: Sunload Sensor and/or Its Circuit Malfunction ......... ................................. 7B-52

DTC B1511: Temperature Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-53

DTC B1512: Air flow Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-55

DTC B1513: Temperature Control Actuator and/or Its Circuit Malfunction .......................... 7B-57

DTC B1514: Air Flow Co ntrol Actuator and/or

Its Circuit Malfunction ...................................... 7B-60

DTC B1541: HVAC Control Module Back-Up Power Supply Malfunction .............................. 7B-62

DTC B1546: A/C Refrigerant Pressure Malfunction ...................................................... 7B-63

DTC B1551: Serial Communication Circuit Malfunction ...................................................... 7B-63

DTC B1552: Serial Communication Signal Malfunction ...................................................... 7B-64

DTC B1553: CAN Communication Signal Malfunction ...................................................... 7B-65

DTC B1557: Vehicle Speed Sensor Signal Malfunction ...................................................... 7B-65

DTC B1561: Engine Coolant Temperature Sensor Signal Malfunctio n .............................. 7B-66 DTC B1562: Outside Air Temperature Sensor

Signal Malfunction ........................................... 7B-66

DTC B1563: A/C Refr igerant Pressure

Sensor Signal Malfunction .............................. 7B-66

Inspection of HVAC Control Module and Its Circuit .............................................................. 7B-67

A/C System Performance Inspection ................ 7B-70

A/C System Inspection at ECM ......................... 7B-70

Repair Instructions ............ ................................7B-71

Operation Procedure for Refrigerant Charge .... 7B-71

HVAC Unit Components ................................... 7B-72

HVAC Unit Removal and In stallation ................ 7B-73

Temperature Control Actuator Removal and Installation ....................................................... 7B-73

Temperature Control Actuat or Inspection ......... 7B-73

Air Flow Control Actuator Removal and Installation ....................................................... 7B-74

Air Flow Control Actuator Inspection ................. 7B-74

Air Intake Control Actuator Removal and Installation ....................................................... 7B-75

Air Intake Control Actuator Inspection............... 7B-75

Actuator Linkage Inspection .............................. 7B-76

Blower Motor Controller Removal and Installation ....................................................... 7B-76

Blower Motor Controller Inspection ................... 7B-76

HVAC Control Module Removal and Installation ....................................................... 7B-77

Sunload Sensor Removal and Installation ........ 7B-77

Sunload Sensor Inspection ............................... 7B-77

Outside Air Temperature Sensor Removal and Installation ................................................ 7B-77

Outside Air Temperature Sensor Inspection ..... 7B-77

Inside Air Temperature Sensor Removal and Installation ....................................................... 7B-78

Inside Air Temperature Sens or Inspection ........ 7B-78

Condenser Assembly On-Vehicle Inspection .... 7B-78

Condenser Assembly Removal and Installation ....................................................... 7B-78

Receiver/Dryer Removal and Installation .......... 7B-78

Evaporator Inspection ....................................... 7B-78

Evaporator Temperature Sensor Removal and Installation ................................................ 7B-78

Evaporator Temperature Se nsor Inspection ..... 7B-78

Expansion Valve Removal an d Installation ....... 7B-78

Expansion Valve Inspection .............................. 7B-78

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-78

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-78

Compressor Relay Inspection .

.......................... 7B-78

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-78

Compressor Drive Belt Removal and Installation ....................................................... 7B-79

Compressor Assembly Removal and Installation ....................................................... 7B-79

Compressor Assembly Components................. 7B-79

Magnet Clutch Removal and Installation........... 7B-79

Magnet Clutch Inspection.................................. 7B-79

Relief Valve Inspection...................................... 7B-79

Page 940 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-4 Heater and Ventilation:

Repair Instructions

HVAC Unit ComponentsS7RS0B7106001

For manual type A/C, refer to “HVAC Unit Components

in Section 7B”.

For automatic type A/C, refer to “HVAC Unit

Components in Section 7B”.

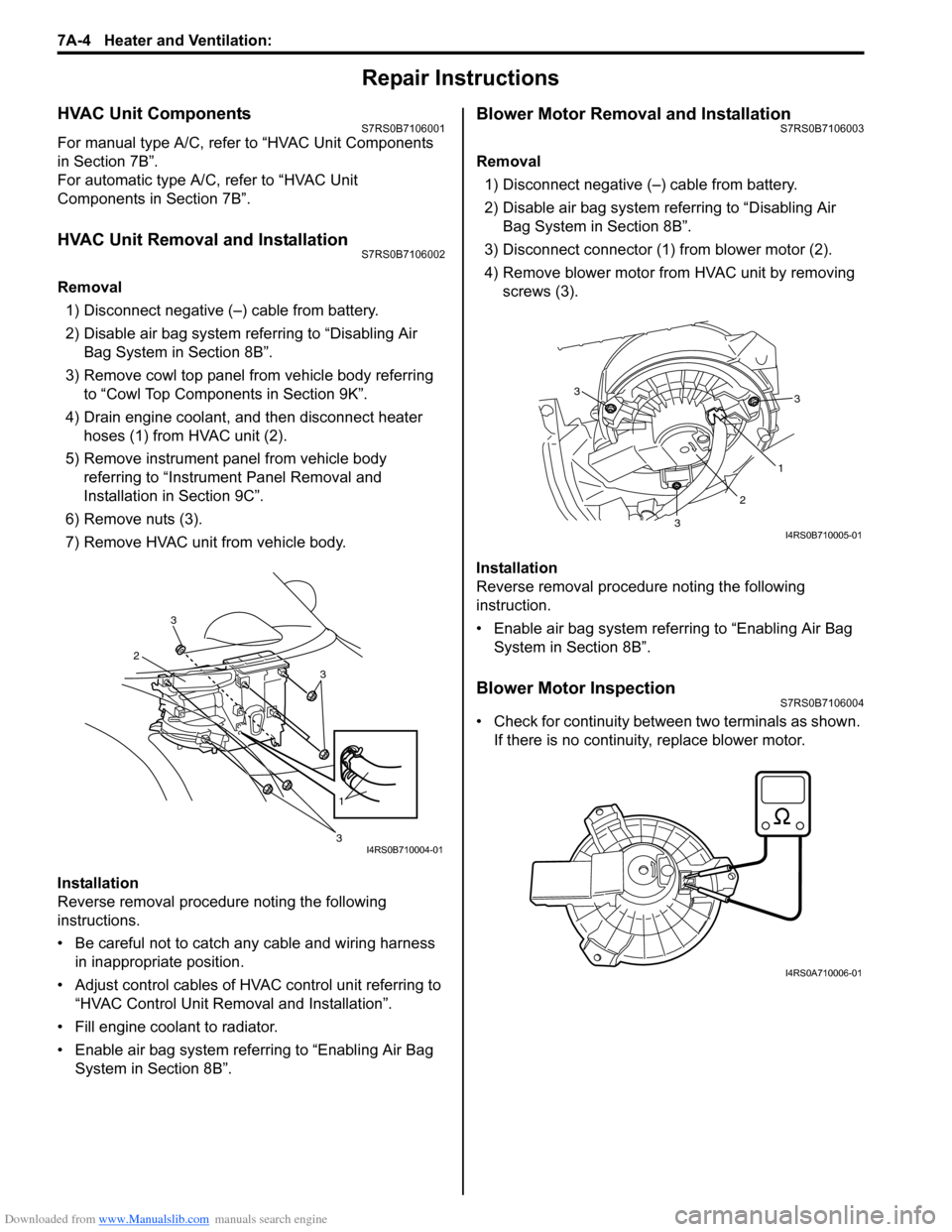

HVAC Unit Removal and InstallationS7RS0B7106002

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove cowl top panel from vehicle body referring to “Cowl Top Components in Section 9K”.

4) Drain engine coolant, and then disconnect heater hoses (1) from HVAC unit (2).

5) Remove instrument panel from vehicle body referring to “Instrument Panel Removal and

Installation in Section 9C”.

6) Remove nuts (3).

7) Remove HVAC unit from vehicle body.

Installation

Reverse removal procedure noting the following

instructions.

• Be careful not to catch any cable and wiring harness in inappropriate position.

• Adjust control cables of HVAC control unit referring to “HVAC Control Unit Remo val and Installation”.

• Fill engine coolant to radiator.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Blower Motor Removal and InstallationS7RS0B7106003

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Disconnect connector (1) from blower motor (2).

4) Remove blower motor from HVAC unit by removing screws (3).

Installation

Reverse removal procedure noting the following

instruction.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Blower Motor InspectionS7RS0B7106004

• Check for continuity between two terminals as shown. If there is no continuity, replace blower motor.

3

2

3

1

3I4RS0B710004-01

3

1

2

3

3

I4RS0B710005-01

I4RS0A710006-01

Page 943 of 1496

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-7

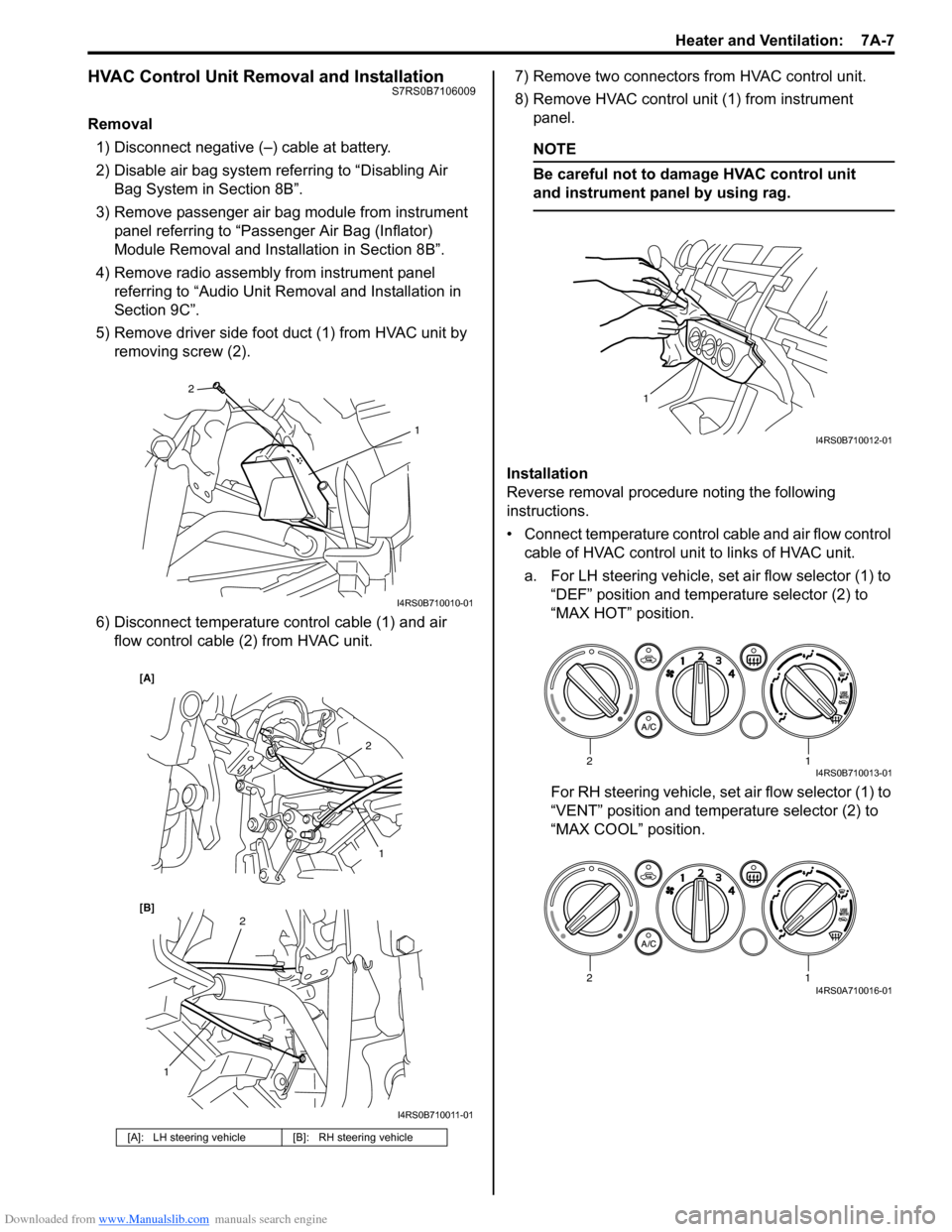

HVAC Control Unit Removal and InstallationS7RS0B7106009

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Audio Unit Re moval and Installation in

Section 9C”.

5) Remove driver side foot duct (1) from HVAC unit by removing screw (2).

6) Disconnect temperature control cable (1) and air flow control cable (2) from HVAC unit. 7) Remove two connectors from HVAC control unit.

8) Remove HVAC control unit (1) from instrument

panel.

NOTE

Be careful not to damage HVAC control unit

and instrument panel by using rag.

Installation

Reverse removal procedure noting the following

instructions.

• Connect temperature control cable and air flow control

cable of HVAC control unit to links of HVAC unit.

a. For LH steering vehicle, set air flow selector (1) to “DEF” position and temperature selector (2) to

“MAX HOT” position.

For RH steering vehicle, set air flow selector (1) to

“VENT” position and temperature selector (2) to

“MAX COOL” position.

[A]: LH steering vehicle [B]: RH steering vehicle

2

1

I4RS0B710010-01

2

1

1

2

[B] [A]

I4RS0B710011-01

1

I4RS0B710012-01

12I4RS0B710013-01

12I4RS0A710016-01

Page 944 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-8 Heater and Ventilation:

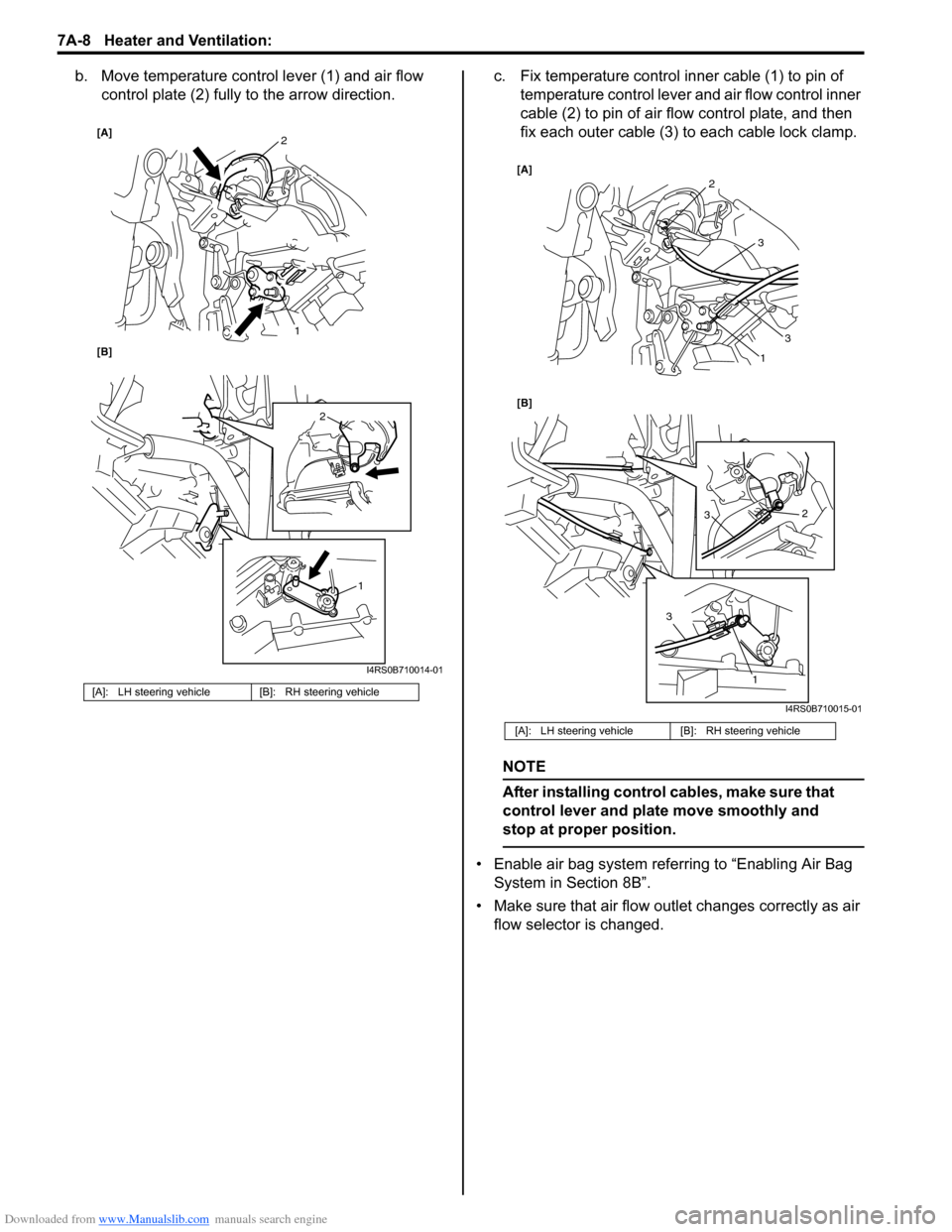

b. Move temperature control lever (1) and air flow control plate (2) fully to the arrow direction. c. Fix temperature control inner cable (1) to pin of

temperature control lever and air flow control inner

cable (2) to pin of air fl ow control plate, and then

fix each outer cable (3) to each cable lock clamp.

NOTE

After installing control cables, make sure that

control lever and plate move smoothly and

stop at proper position.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

• Make sure that air flow outlet changes correctly as air flow selector is changed.

[A]: LH steering vehicle [B]: RH steering vehicle

1

2

[A]

[B]

1

2

I4RS0B710014-01

[A]: LH steering vehicle [B]: RH steering vehicle

1

2

[B] [A] 3

3

1

3

23

I4RS0B710015-01

Page 946 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-10 Heater and Ventilation:

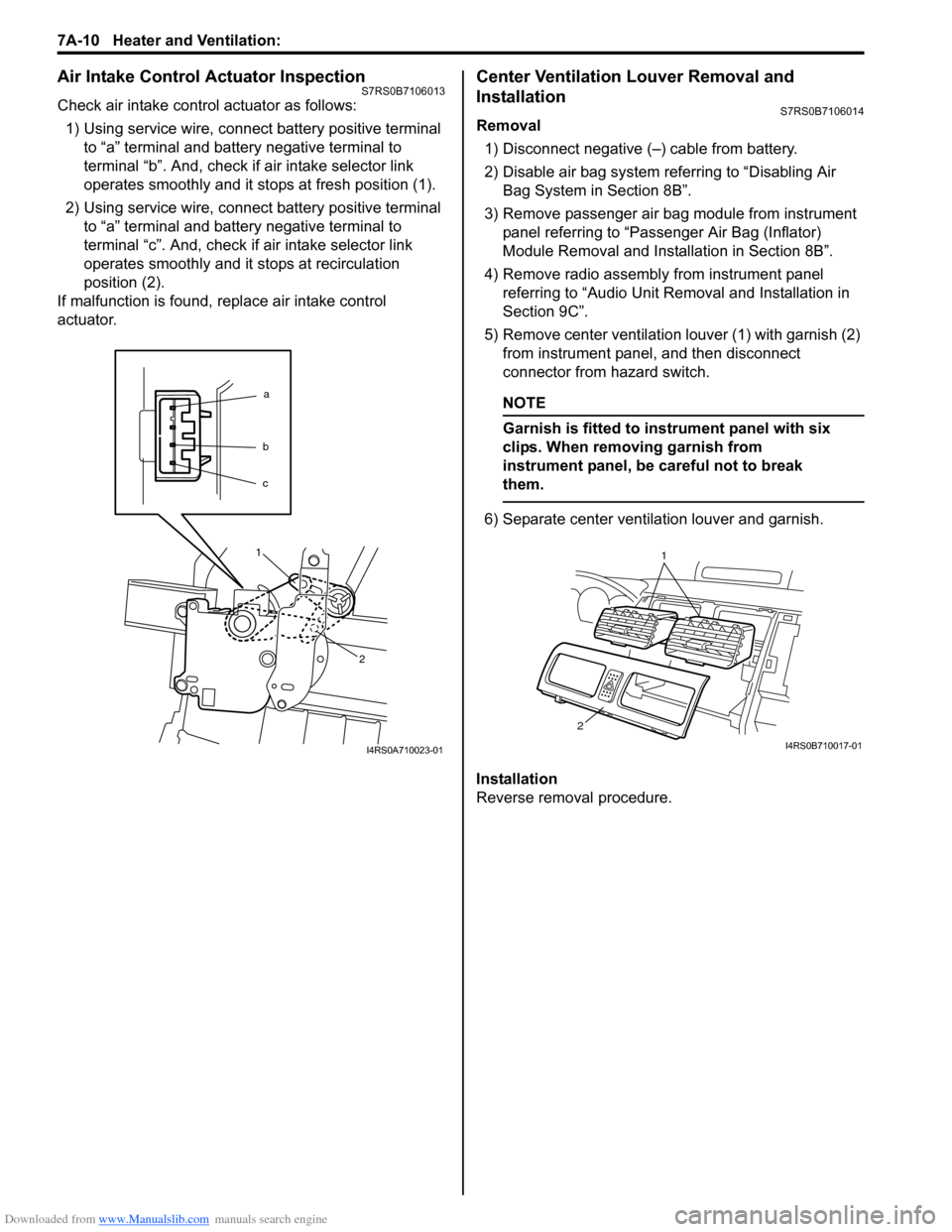

Air Intake Control Actuator InspectionS7RS0B7106013

Check air intake control actuator as follows:1) Using service wire, connect battery positive terminal to “a” terminal and battery negative terminal to

terminal “b”. And, check if air intake selector link

operates smoothly and it st ops at fresh position (1).

2) Using service wire, connect battery positive terminal to “a” terminal and battery negative terminal to

terminal “c”. And, check if air intake selector link

operates smoothly and it stops at recirculation

position (2).

If malfunction is found, replace air intake control

actuator.

Center Ventilation Louver Removal and

Installation

S7RS0B7106014

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Audio Unit Re moval and Installation in

Section 9C”.

5) Remove center ventilation louver (1) with garnish (2) from instrument panel, and then disconnect

connector from hazard switch.

NOTE

Garnish is fitted to in strument panel with six

clips. When removing garnish from

instrument panel, be careful not to break

them.

6) Separate center ventilation louver and garnish.

Installation

Reverse removal procedure.

a

b

c

1

2

I4RS0A710023-01

1

2

I4RS0B710017-01

Page 952 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-4 Air Conditioning System: Manual Type

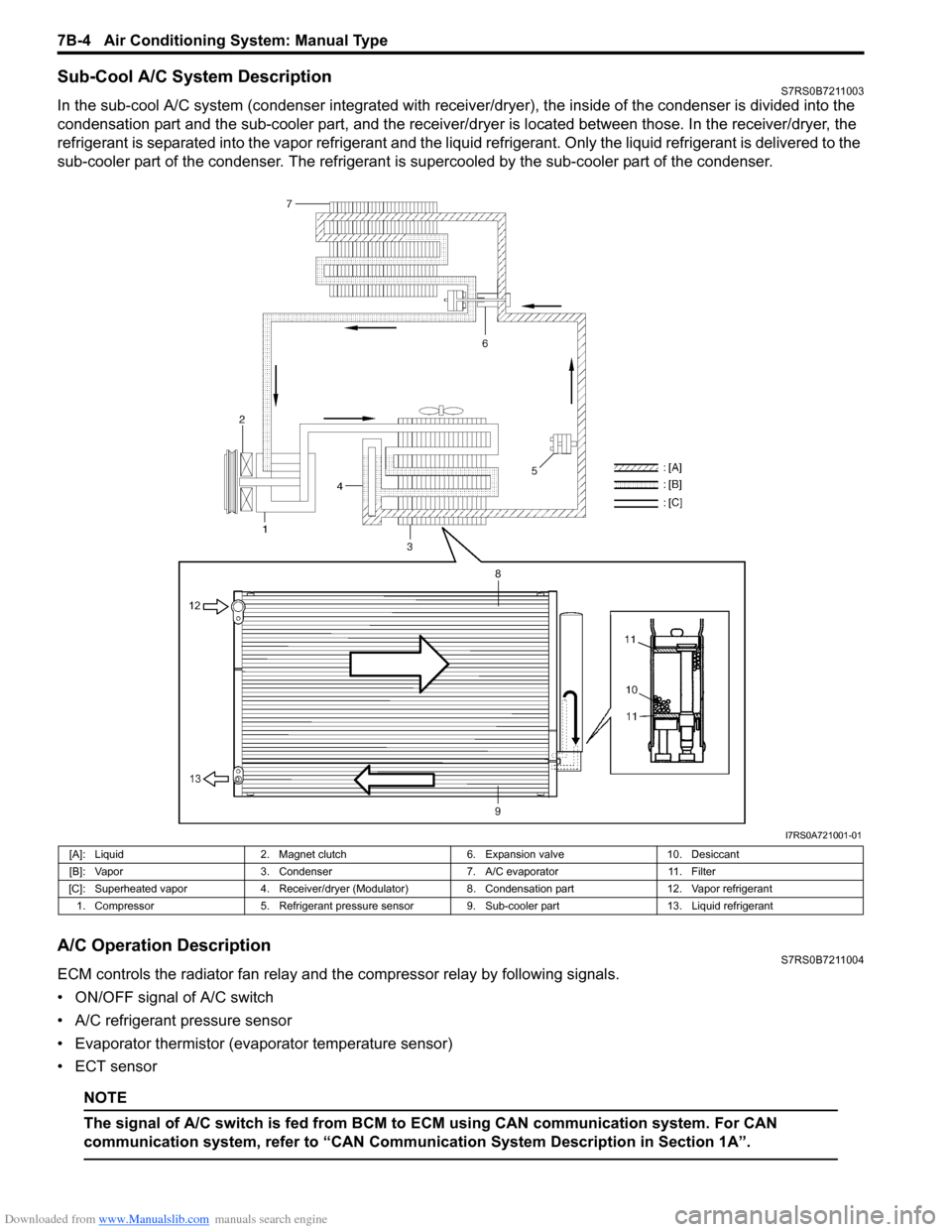

Sub-Cool A/C System DescriptionS7RS0B7211003

In the sub-cool A/C system (condenser integrated with receiver/dryer), the inside of the condenser is divided into the

condensation part and the sub-cooler part, and the receiver/dryer is located between those. In the receiver/dryer, the

refrigerant is separated into the vapor refrigerant and the liqui d refrigerant. Only the liquid refrigerant is delivered to the

sub-cooler part of the condenser. The refrigerant is supercooled by the sub-cooler part of the condenser.

A/C Operation DescriptionS7RS0B7211004

ECM controls the radiator fan relay and the compressor relay by following signals.

• ON/OFF signal of A/C switch

• A/C refrigerant pressure sensor

• Evaporator thermistor (evaporator temperature sensor)

• ECT sensor

NOTE

The signal of A/C swit ch is fed from BCM to ECM usin g CAN communication system. For CAN

communication system, refer to “CAN Communication System Description in Section 1A”.

I7RS0A721001-01

[A]: Liquid 2. Magnet clutch 6. Expansion valve10. Desiccant

[B]: Vapor 3. Condenser 7. A/C evaporator11. Filter

[C]: Superheated vapor 4. Receiver/dryer (Modulator) 8. Condensation part12. Vapor refrigerant

1. Compressor 5. Refrigerant pressure sensor 9. Sub-cooler part 13. Liquid refrigerant