Electric load current sensor SUZUKI SWIFT 2008 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 669 of 1496

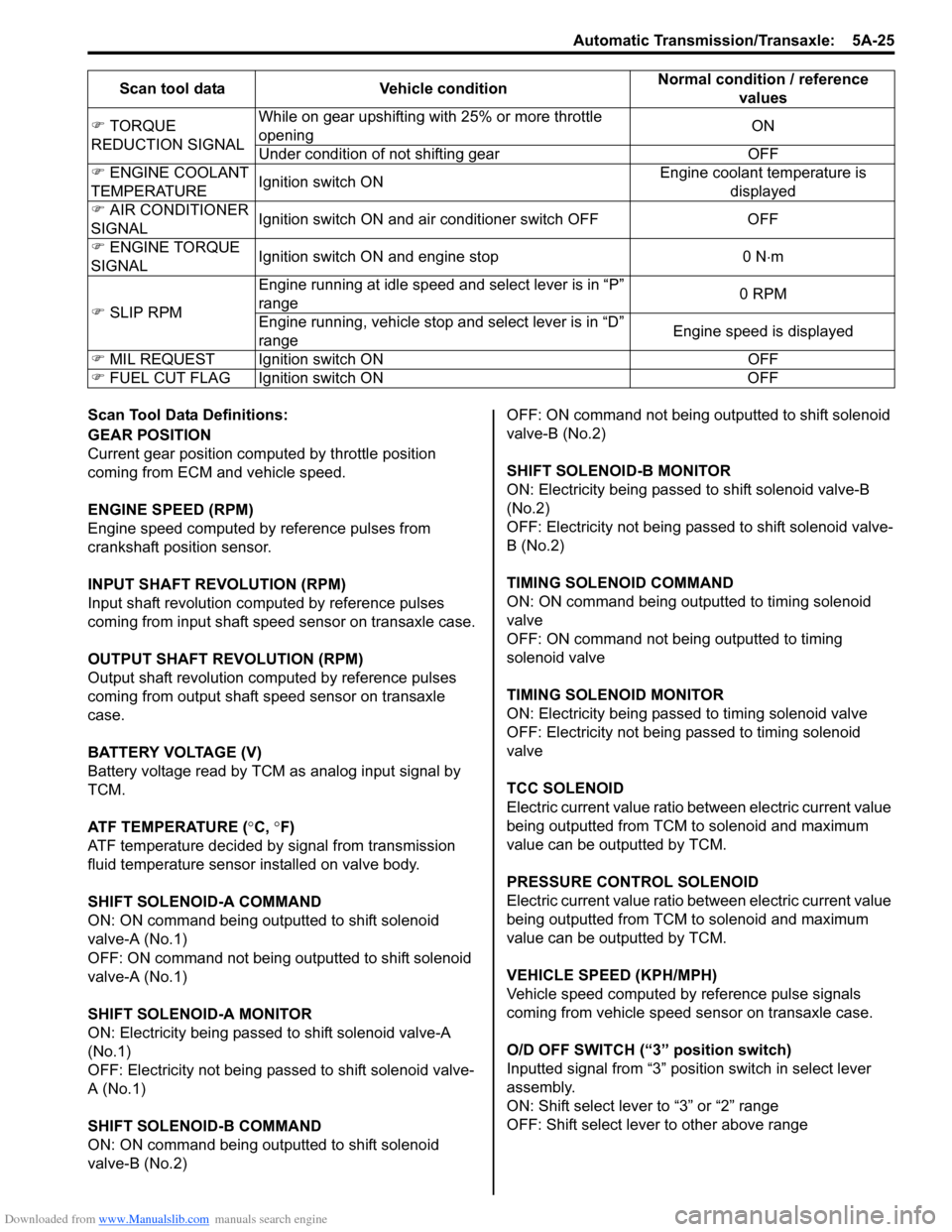

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-25

Scan Tool Data Definitions:

GEAR POSITION

Current gear position computed by throttle position

coming from ECM and vehicle speed.

ENGINE SPEED (RPM)

Engine speed computed by reference pulses from

crankshaft position sensor.

INPUT SHAFT REVOLUTION (RPM)

Input shaft revolution computed by reference pulses

coming from input shaft speed sensor on transaxle case.

OUTPUT SHAFT REVOLUTION (RPM)

Output shaft revolution computed by reference pulses

coming from output shaft speed sensor on transaxle

case.

BATTERY VOLTAGE (V)

Battery voltage read by TCM as analog input signal by

TCM.

ATF TEMPERATURE (°C, °F)

ATF temperature decided by signal from transmission

fluid temperature sensor installed on valve body.

SHIFT SOLENOID-A COMMAND

ON: ON command being outputted to shift solenoid

valve-A (No.1)

OFF: ON command not being outputted to shift solenoid

valve-A (No.1)

SHIFT SOLENOID-A MONITOR

ON: Electricity being passed to shift solenoid valve-A

(No.1)

OFF: Electricity not being passed to shift solenoid valve-

A (No.1)

SHIFT SOLENOID-B COMMAND

ON: ON command being outputted to shift solenoid

valve-B (No.2) OFF: ON command not being outputted to shift solenoid

valve-B (No.2)

SHIFT SOLENOID-B MONITOR

ON: Electricity being passed to shift solenoid valve-B

(No.2)

OFF: Electricity not being passed to shift solenoid valve-

B (No.2)

TIMING SOLENOID COMMAND

ON: ON command being outputted to timing solenoid

valve

OFF: ON command not being outputted to timing

solenoid valve

TIMING SOLENOID MONITOR

ON: Electricity being passed to timing solenoid valve

OFF: Electricity not being passed to timing solenoid

valve

TCC SOLENOID

Electric current value ratio between electric current value

being outputted from TCM to solenoid and maximum

value can be outputted by TCM.

PRESSURE CONTROL SOLENOID

Electric current value ratio between electric current value

being outputted from TCM to solenoid and maximum

value can be outputted by TCM.

VEHICLE SPEED (KPH/MPH)

Vehicle speed computed by reference pulse signals

coming from vehicle speed sensor on transaxle case.

O/D OFF SWITCH (“3” position switch)

Inputted signal from “3” position switch in select lever

assembly.

ON: Shift select lever to “3” or “2” range

OFF: Shift select lever to other above range

�)

TORQUE

REDUCTION SIGNAL While on gear upshifting with 25% or more throttle

opening

ON

Under condition of not shifting gear OFF

�) ENGINE COOLANT

TEMPERATURE Ignition switch ON Engine coolant temperature is

displayed

�) AIR CONDITIONER

SIGNAL Ignition switch ON and air conditioner switch OFF OFF

�) ENGINE TORQUE

SIGNAL Ignition switch ON and engine stop 0 N

⋅m

�) SLIP RPM Engine running at idle speed

and select lever is in “P”

range 0 RPM

Engine running, vehicle stop and select lever is in “D”

range Engine speed is displayed

�) MIL REQUEST Ignition switch ON OFF

�) FUEL CUT FLAG Ignition switch ON OFFScan tool data Vehicle condition

Normal condition / reference

values

Page 894 of 1496

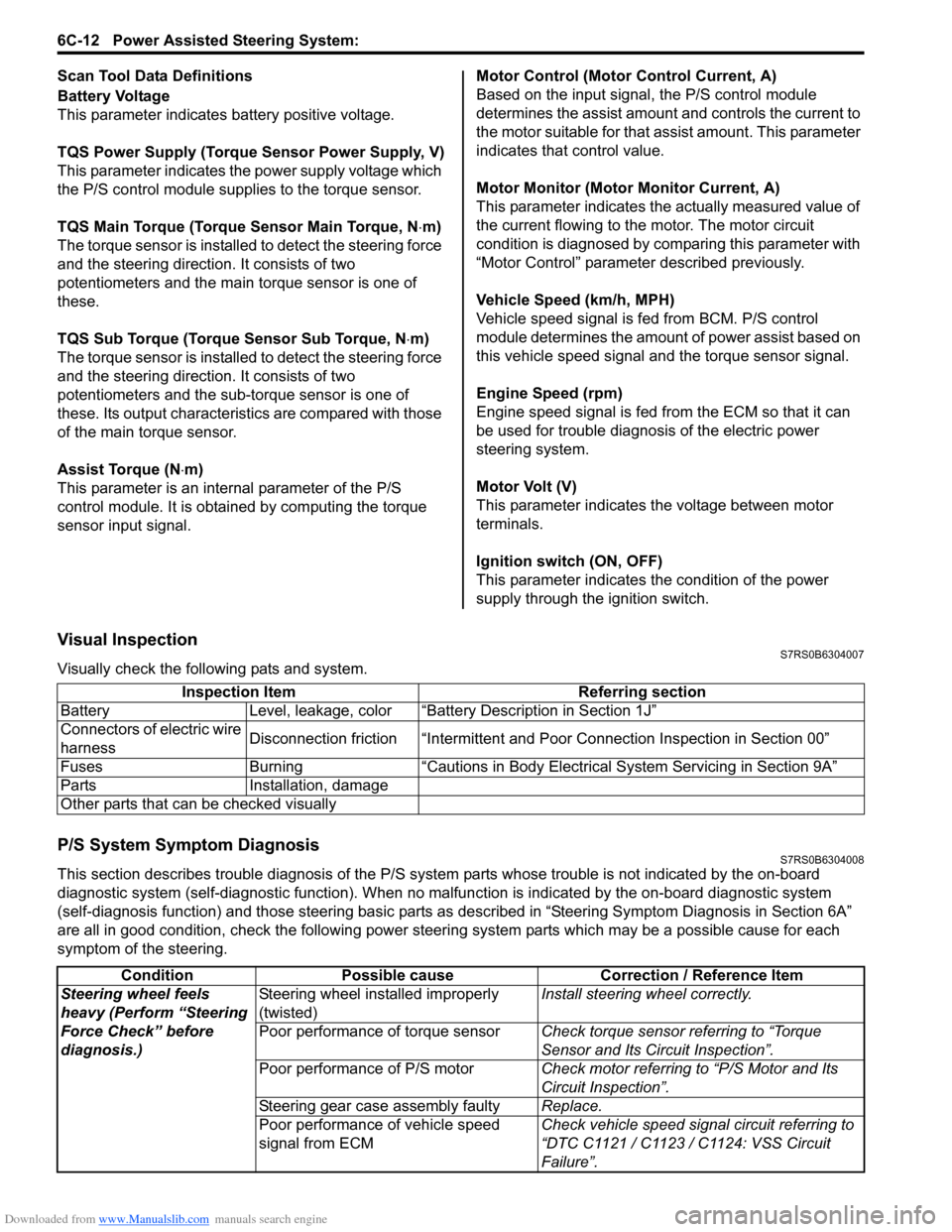

Downloaded from www.Manualslib.com manuals search engine 6C-12 Power Assisted Steering System:

Scan Tool Data Definitions

Battery Voltage

This parameter indicates battery positive voltage.

TQS Power Supply (Torque Sensor Power Supply, V)

This parameter indicates the power supply voltage which

the P/S control module supplies to the torque sensor.

TQS Main Torque (Torque Sensor Main Torque, N ⋅m)

The torque sensor is installed to detect the steering force

and the steering directio n. It consists of two

potentiometers and the main torque sensor is one of

these.

TQS Sub Torque (Torque Sensor Sub Torque, N ⋅m)

The torque sensor is installed to detect the steering force

and the steering directio n. It consists of two

potentiometers and the sub-torque sensor is one of

these. Its output characteristics are compared with those

of the main torque sensor.

Assist Torque (N ⋅m)

This parameter is an internal parameter of the P/S

control module. It is obtained by computing the torque

sensor input signal. Motor Control (Motor Control Current, A)

Based on the input signal, the P/S control module

determines the assist amount

and controls the current to

the motor suitable for that a ssist amount. This parameter

indicates that control value.

Motor Monitor (Motor Monitor Current, A)

This parameter indicates the actually measured value of

the current flowing to the motor. The motor circuit

condition is diagnosed by co mparing this parameter with

“Motor Control” parameter described previously.

Vehicle Speed (km/h, MPH)

Vehicle speed signal is fed from BCM. P/S control

module determines the amount of power assist based on

this vehicle speed signal and the torque sensor signal.

Engine Speed (rpm)

Engine speed signal is fed from the ECM so that it can

be used for trouble diagnos is of the electric power

steering system.

Motor Volt (V)

This parameter indicates the voltage between motor

terminals.

Ignition switch (ON, OFF)

This parameter indicates the condition of the power

supply through the ignition switch.

Visual InspectionS7RS0B6304007

Visually check the following pats and system.

P/S System Symptom DiagnosisS7RS0B6304008

This section describes trouble diagnosis of the P/S system parts whose trouble is not indicated by the on-board

diagnostic system (self-diagnostic functi on). When no malfunction is indicated by the on-board diagnostic system

(self-diagnosis function) and those stee ring basic parts as described in “Steering Symptom Diagnosis in Section 6A”

are all in good condition, check the following power steer ing system parts which may be a possible cause for each

symptom of the steering. Inspection Item Referring section

Battery Level, leakage, color “Batte ry Description in Section 1J”

Connectors of electric wire

harness Disconnection friction “Intermittent and Poor

Connection Inspection in Section 00”

Fuses Burning “Cautions in Body Electric al System Servicing in Section 9A”

Parts Installation, damage

Other parts that can be checked visually

Condition Possible cause Correction / Reference Item

Steering wheel feels

heavy (Perform “Steering

Force Check” before

diagnosis.) Steering wheel installed improperly

(twisted)

Install steering wheel correctly.

Poor performance of torque sensor Check torque sensor referring to “Torque

Sensor and Its Circuit Inspection”.

Poor performance of P/S motor Check motor referring to “P/S Motor and Its

Circuit Inspection”.

Steering gear case assembly faulty Replace.

Poor performance of vehicle speed

signal from ECM Check vehicle speed signal circuit referring to

“DTC C1121 / C1123 / C1124: VSS Circuit

Failure”.

Page 1184 of 1496

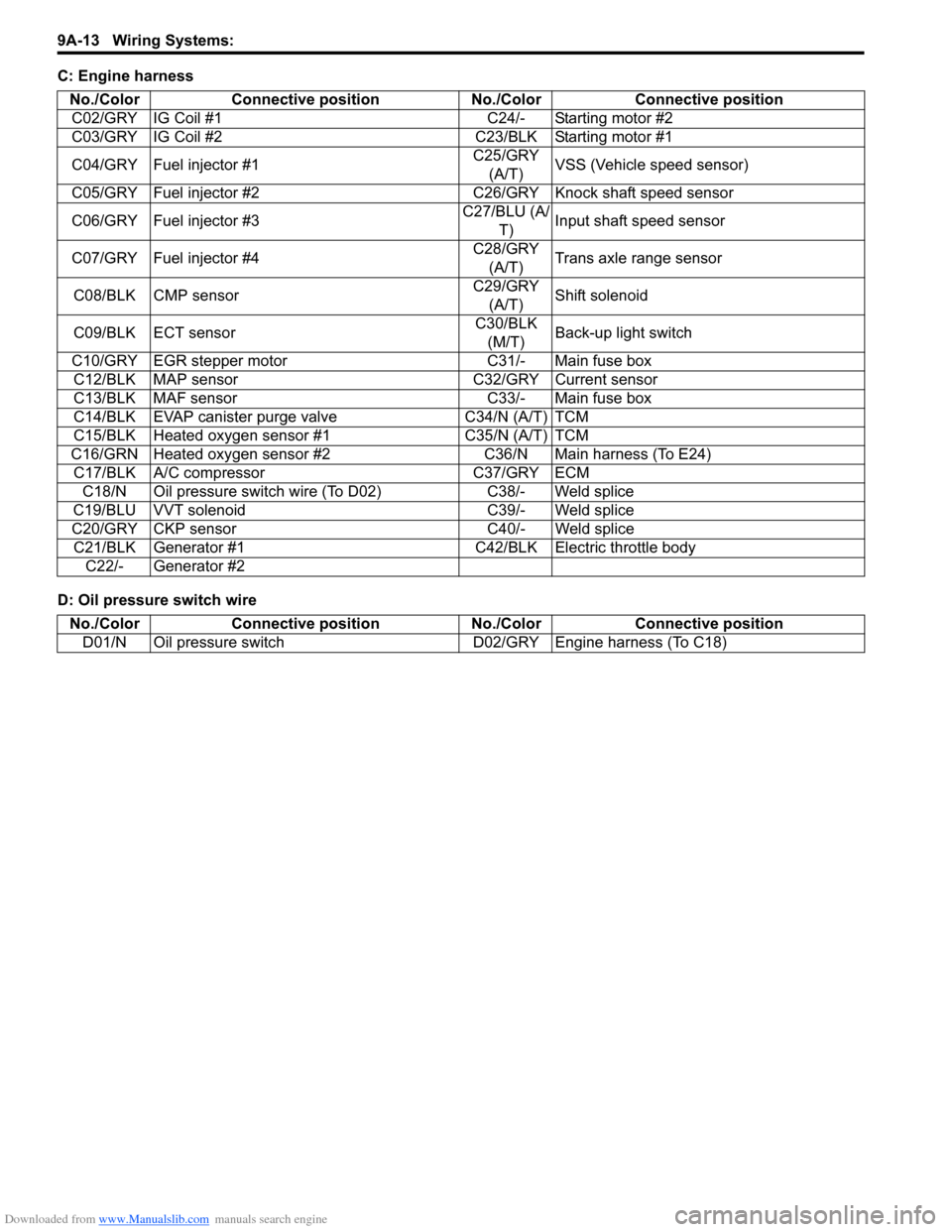

Downloaded from www.Manualslib.com manuals search engine 9A-13 Wiring Systems:

C: Engine harness

D: Oil pressure switch wireNo./Color Connective position No./Color Connective position

C02/GRY IG Coil #1 C24/- Starting motor #2

C03/GRY IG Coil #2 C23/BLK Starting motor #1

C04/GRY Fuel injector #1 C25/GRY

(A/T) VSS (Vehicle speed sensor)

C05/GRY Fuel injector #2 C26/GRY Knock shaft speed sensor

C06/GRY Fuel injector #3 C27/BLU (A/

T) Input shaft speed sensor

C07/GRY Fuel injector #4 C28/GRY

(A/T) Trans axle range sensor

C08/BLK CMP sensor C29/GRY

(A/T) Shift solenoid

C09/BLK ECT sensor C30/BLK

(M/T) Back-up light switch

C10/GRY EGR stepper motor C31/- Main fuse box C12/BLK MAP sensor C32/GRY Current sensor

C13/BLK MAF sensor C33/- Main fuse box

C14/BLK EVAP canister purge valve C34/N (A/T) TCM

C15/BLK Heated oxygen sensor #1 C35/N (A/T) TCM

C16/GRN Heated oxygen sensor #2 C36/N Main harness (To E24) C17/BLK A/C compressor C37/GRY ECM C18/N Oil pressure switch wire (To D02) C38/- Weld splice

C19/BLU VVT solenoid C39/- Weld splice

C20/GRY CKP sensor C40/- Weld splice C21/BLK Generator #1 C42/BLK Electric throttle body C22/- Generator #2

No./Color Connective position No./ColorConnective position

D01/N Oil pressure switch D02/GRY Engine harness (To C18)