Speed sensor resistance SUZUKI SWIFT 2008 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 284 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-12 Engine Electrical Devices:

MAF and IAT Sensor InspectionS7RS0B1306020

CAUTION!

Do not heat up MAF and IAT sensor more

than 100 °C (212 °F). Otherwise, MAF and IAT

sensor will be damaged.

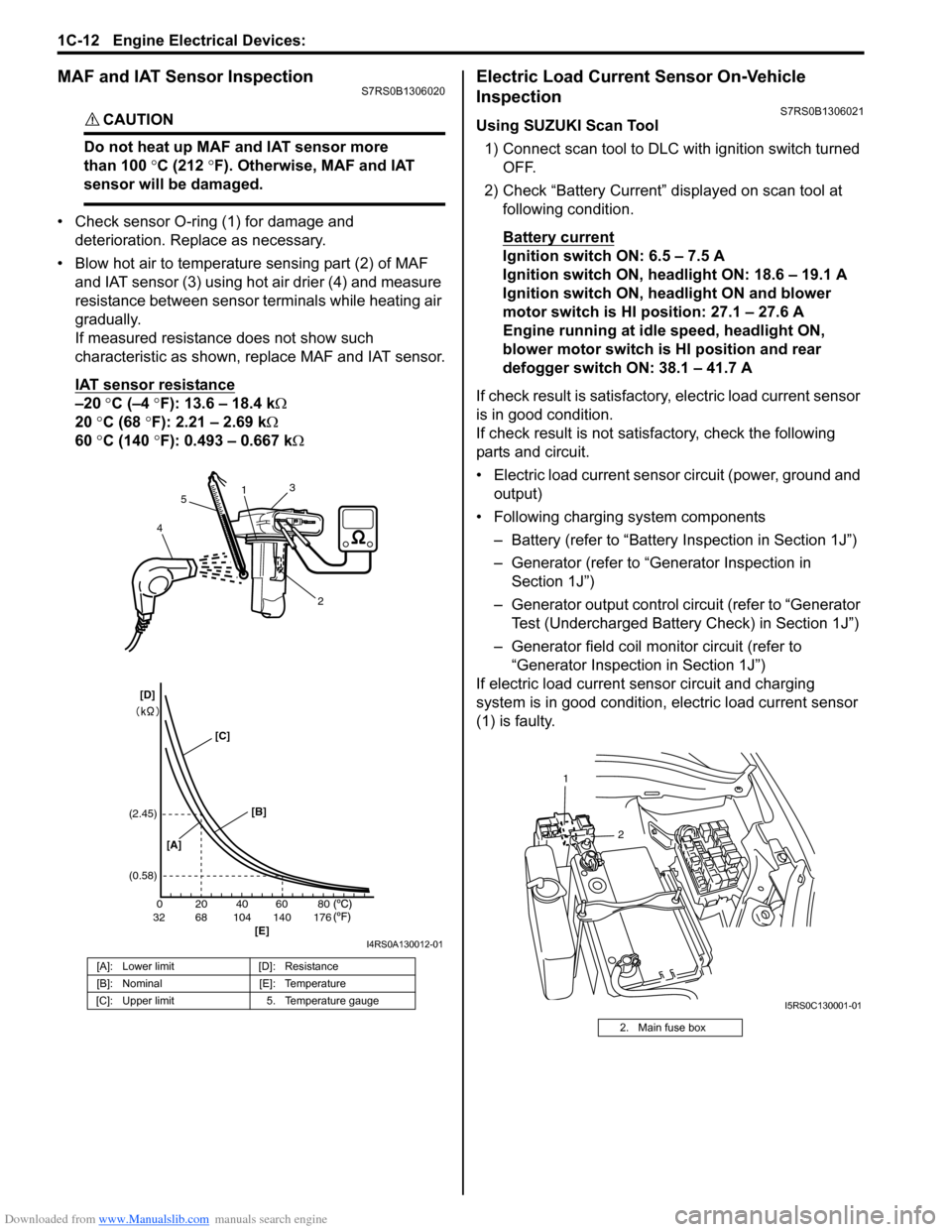

• Check sensor O-ring (1) for damage and deterioration. Replace as necessary.

• Blow hot air to temperature sensing part (2) of MAF and IAT sensor (3) using hot air drier (4) and measure

resistance between sensor terminals while heating air

gradually.

If measured resistance does not show such

characteristic as shown, replace MAF and IAT sensor.

IAT sensor resistance

–20 °C (–4 °F): 13.6 – 18.4 k Ω

20 °C (68 °F): 2.21 – 2.69 k Ω

60 °C (140 °F): 0.493 – 0.667 k Ω

Electric Load Current Sensor On-Vehicle

Inspection

S7RS0B1306021

Using SUZUKI Scan Tool

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Check “Battery Current” displayed on scan tool at following condition.

Battery current

Ignition switch ON: 6.5 – 7.5 A

Ignition switch ON, headlight ON: 18.6 – 19.1 A

Ignition switch ON, headlight ON and blower

motor switch is HI position: 27.1 – 27.6 A

Engine running at idle speed, headlight ON,

blower motor switch is HI position and rear

defogger switch ON: 38.1 – 41.7 A

If check result is satisfactory, electric load current sensor

is in good condition.

If check result is not satisf actory, check the following

parts and circuit.

• Electric load current sensor circuit (power, ground and output)

• Following charging system components

– Battery (refer to “Battery Inspection in Section 1J”)

– Generator (refer to “Generator Inspection in Section 1J”)

– Generator output control ci rcuit (refer to “Generator

Test (Undercharged Battery Check) in Section 1J”)

– Generator field coil monitor circuit (refer to “Generator Inspection in Section 1J”)

If electric load current sensor circuit and charging

system is in good condition, electric load current sensor

(1) is faulty.

[A]: Lower limit [D]: Resistance

[B]: Nominal [E]: Temperature

[C]: Upper limit 5. Temperature gauge

200

6832104 140 17640 60 80

(2.45)

(0.58)

1

2

3

4 5

[A] [B]

[E]

[C]

[D]

I4RS0A130012-01

2. Main fuse box

2

1

I5RS0C130001-01

Page 383 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-8

Installation1) Install clamps to marked location on pipes. If clamp is deformed, its claw is bent or broken, replace it with

new one.

2) Install pipes with pipe clamps to vehicle.

3) Connect fuel hoses and pipes to each pipe referring to “Fuel Hose Disconnecting and Reconnecting”.

4) Connect negative cable at battery.

5) With engine OFF, turn igniti on switch to ON position

and check for fuel leaks.

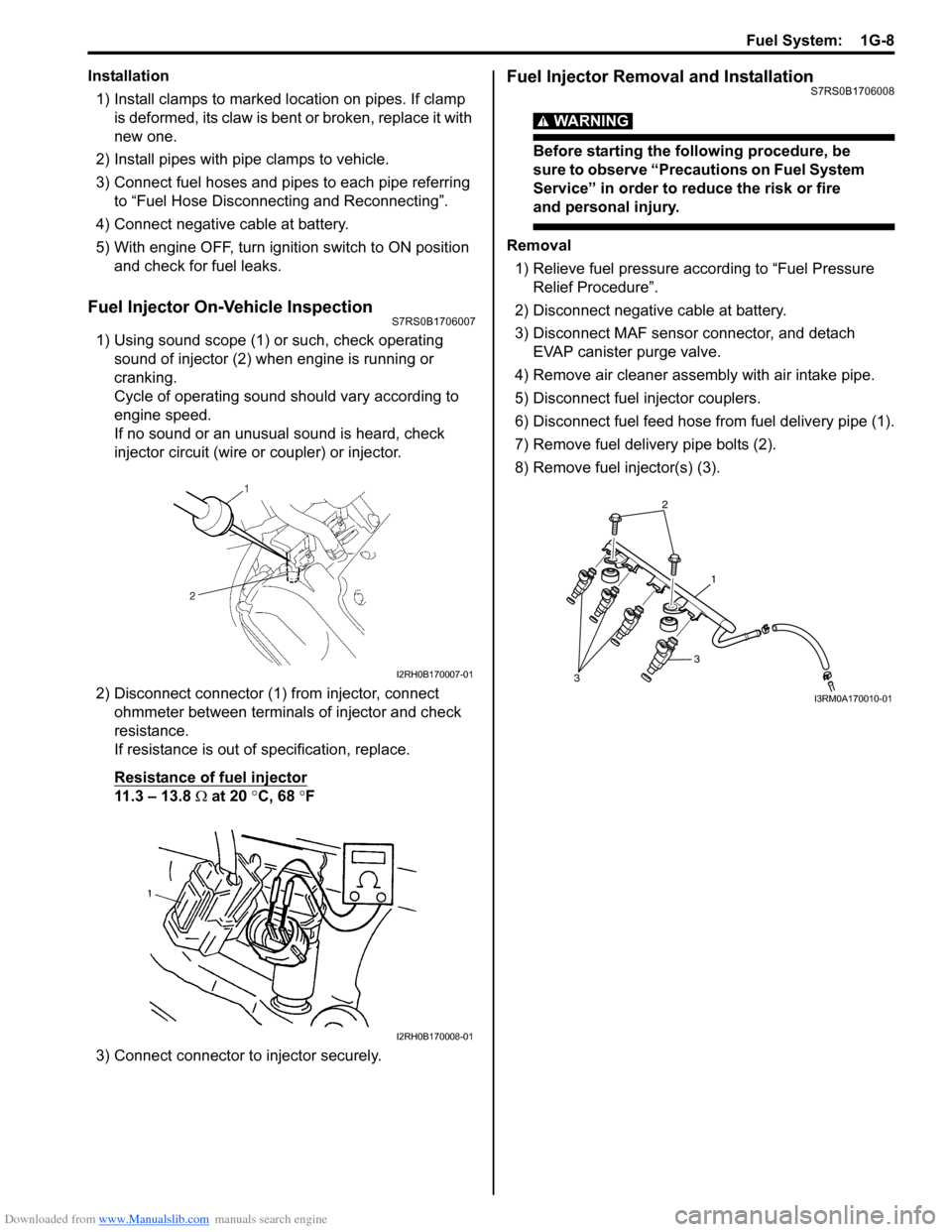

Fuel Injector On-Vehicle InspectionS7RS0B1706007

1) Using sound scope (1) or such, check operating sound of injector (2) when engine is running or

cranking.

Cycle of operating sound should vary according to

engine speed.

If no sound or an unusual sound is heard, check

injector circuit (wire or coupler) or injector.

2) Disconnect connector (1) from injector, connect ohmmeter between terminals of injector and check

resistance.

If resistance is out of specification, replace.

Resistance of fuel injector

11.3 – 13.8 Ω at 20 °C, 68 °F

3) Connect connector to injector securely.

Fuel Injector Removal and InstallationS7RS0B1706008

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal 1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure”.

2) Disconnect negative cable at battery.

3) Disconnect MAF sensor connector, and detach EVAP canister purge valve.

4) Remove air cleaner assembly with air intake pipe.

5) Disconnect fuel injector couplers.

6) Disconnect fuel feed hose from fuel delivery pipe (1).

7) Remove fuel delivery pipe bolts (2).

8) Remove fuel injector(s) (3).

I2RH0B170007-01

I2RH0B170008-01

2

1

3

3

I3RM0A170010-01

Page 558 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-19 ABS:

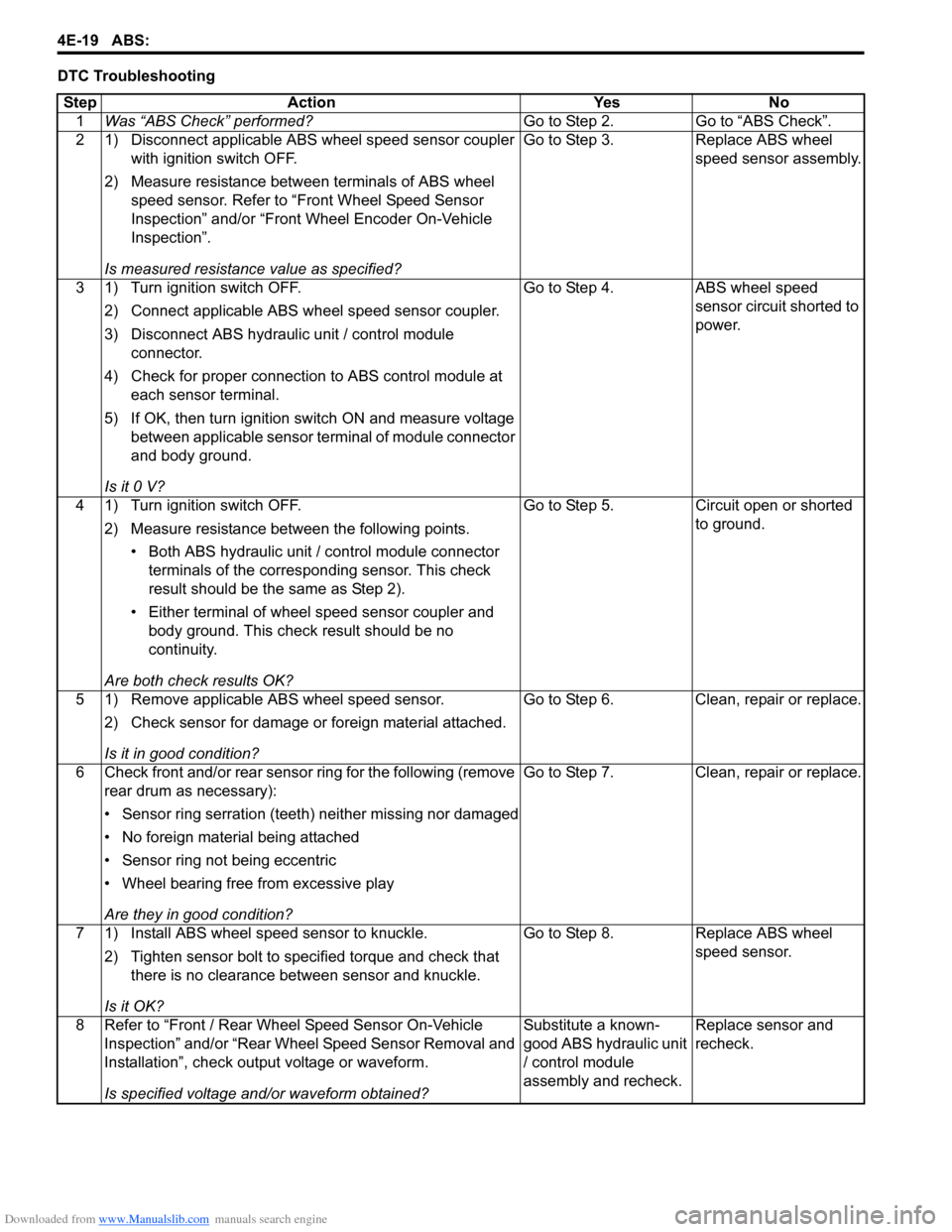

DTC TroubleshootingStep Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Disconnect applicable ABS wheel speed sensor coupler with ignition switch OFF.

2) Measure resistance betw een terminals of ABS wheel

speed sensor. Refer to “Front Wheel Speed Sensor

Inspection” and/or “Front Wheel Encoder On-Vehicle

Inspection”.

Is measured resistance value as specified? Go to Step 3. Replace ABS wheel

speed sensor assembly.

3 1) Turn ignition switch OFF. 2) Connect applicable ABS wh eel speed sensor coupler.

3) Disconnect ABS hydraulic unit / control module connector.

4) Check for proper connection to ABS control module at each sensor terminal.

5) If OK, then turn ignition switch ON and measure voltage between applicable sensor terminal of module connector

and body ground.

Is it 0 V? Go to Step 4. ABS wheel speed

sensor circuit shorted to

power.

4 1) Turn ignition switch OFF. 2) Measure resistance between the following points.• Both ABS hydraulic unit / control module connector terminals of the correspo nding sensor. This check

result should be the same as Step 2).

• Either terminal of wheel speed sensor coupler and body ground. This check result should be no

continuity.

Are both check results OK? Go to Step 5. Circuit open or shorted

to ground.

5 1) Remove applicable ABS wheel speed sensor. 2) Check sensor for damage or foreign material attached.

Is it in good condition? Go to Step 6. Clean, repair or replace.

6 Check front and/or rear sensor ring for the following (remove rear drum as necessary):

• Sensor ring serration (teeth) neither missing nor damaged

• No foreign material being attached

• Sensor ring not being eccentric

• Wheel bearing free from excessive play

Are they in good condition? Go to Step 7. Clean, repair or replace.

7 1) Install ABS wheel speed sensor to knuckle. 2) Tighten sensor bolt to specified torque and check that there is no clearance between sensor and knuckle.

Is it OK? Go to Step 8. Replace ABS wheel

speed sensor.

8 Refer to “Front / Rear Wheel Speed Sensor On-Vehicle Inspection” and/or “Rear Wheel Speed Sensor Removal and

Installation”, check output voltage or waveform.

Is specified voltage and/or waveform obtained? Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

Replace sensor and

recheck.

Page 570 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-31 ABS:

2) Bleed air from brake system referring to “Air Bleeding of Brake System in Section 4A”.

3) Check each installed part for fluid leakage and perform “ABS Hydraulic Un it Operation Check”.

NOTE

For new ABS hydraulic unit / control module

assembly, if “ABS Hydraulic Unit Operation

Check” has not been performed, ABS

warning light may flash when ignition switch

is turned ON position.

Accordingly preform “ABS Hydraulic Unit

Operation Check” to stop flashing of ABS

warning light.

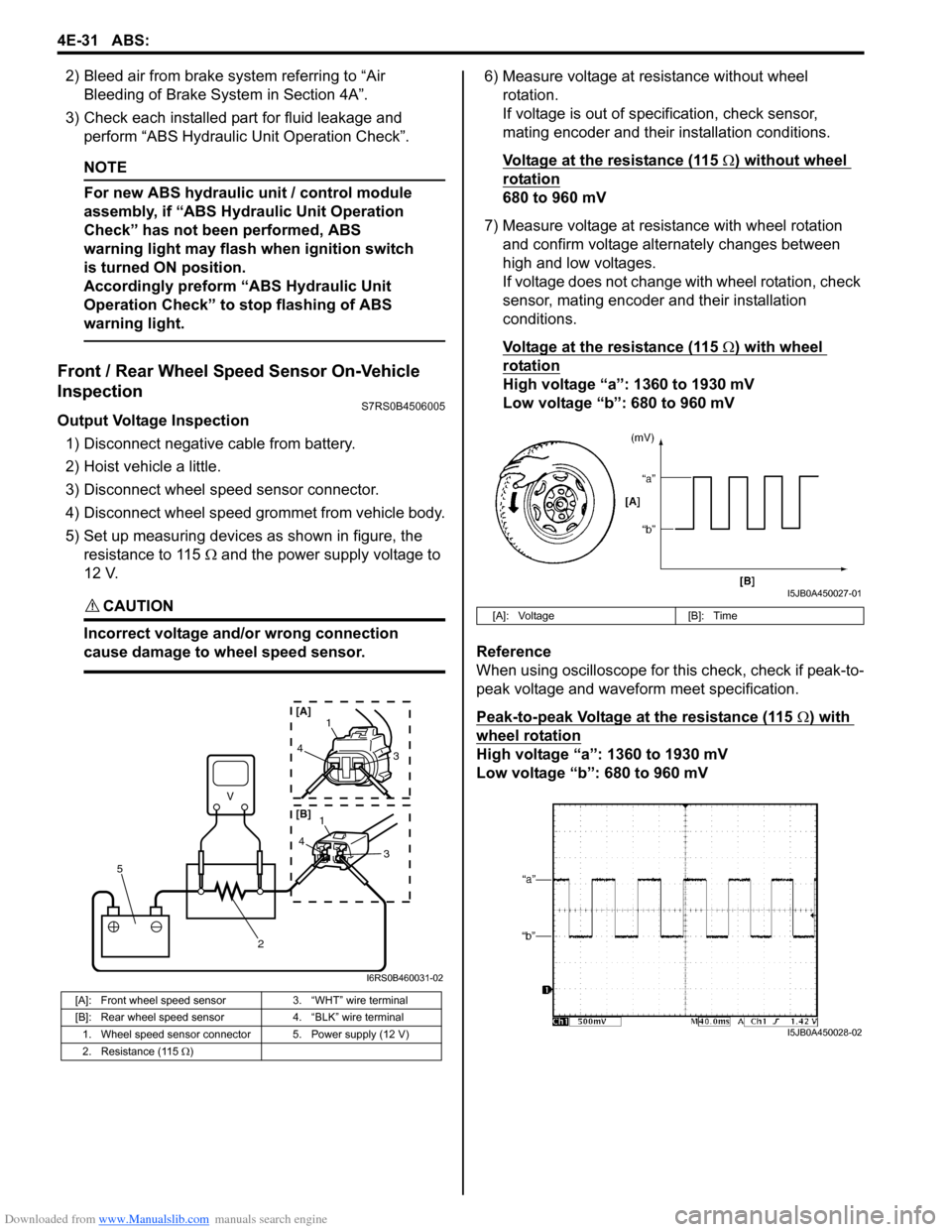

Front / Rear Wheel Speed Sensor On-Vehicle

Inspection

S7RS0B4506005

Output Voltage Inspection

1) Disconnect negative cable from battery.

2) Hoist vehicle a little.

3) Disconnect wheel speed sensor connector.

4) Disconnect wheel speed grommet from vehicle body.

5) Set up measuring devices as shown in figure, the resistance to 115 Ω and the power supply voltage to

12 V.

CAUTION!

Incorrect voltage and/or wrong connection

cause damage to wheel speed sensor.

6) Measure voltage at resistance without wheel rotation.

If voltage is out of specification, check sensor,

mating encoder and their installation conditions.

Voltage at the resistance (115

Ω) without wheel

rotation

680 to 960 mV

7) Measure voltage at resistance with wheel rotation and confirm voltage alternately changes between

high and low voltages.

If voltage does not change with wheel rotation, check

sensor, mating encoder and their installation

conditions.

Voltage at the resistance (115

Ω) with wheel

rotation

High voltage “a”: 1360 to 1930 mV

Low voltage “b”: 680 to 960 mV

Reference

When using oscilloscope for this check, check if peak-to-

peak voltage and waveform meet specification.

Peak-to-peak Voltage at the resistance (115

Ω) with

wheel rotation

High voltage “a”: 1360 to 1930 mV

Low voltage “b”: 680 to 960 mV

[A]: Front wheel speed sensor 3. “WHT” wire terminal

[B]: Rear wheel speed sensor 4. “BLK” wire terminal

1. Wheel speed sensor connector 5. Power supply (12 V)

2. Resistance (115 Ω )

V

2

5

41

3

43

1

[A]

[B]

I6RS0B460031-02

[A]: Voltage [B]: Time

I5JB0A450027-01

I5JB0A450028-02

Page 607 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-33

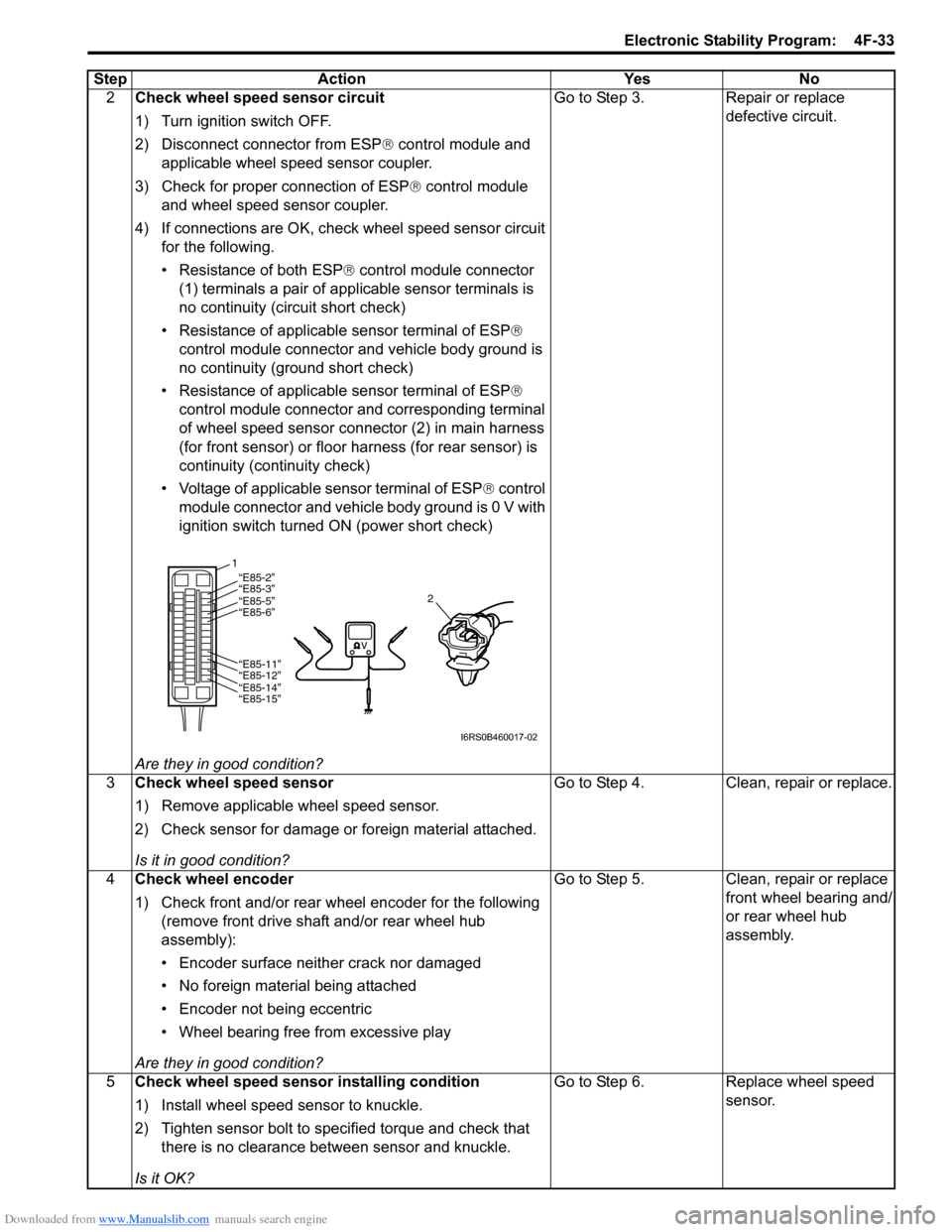

2Check wheel speed sensor circuit

1) Turn ignition switch OFF.

2) Disconnect connector from ESP ® control module and

applicable wheel speed sensor coupler.

3) Check for proper connection of ESP ® control module

and wheel speed sensor coupler.

4) If connections are OK, che ck wheel speed sensor circuit

for the following.

• Resistance of both ESP ® control module connector

(1) terminals a pair of app licable sensor terminals is

no continuity (circuit short check)

• Resistance of applicable sensor terminal of ESP ®

control module connector and vehicle body ground is

no continuity (ground short check)

• Resistance of applicable sensor terminal of ESP ®

control module connector and corresponding terminal

of wheel speed sensor connector (2) in main harness

(for front sensor) or floor harness (for rear sensor) is

continuity (continuity check)

• Voltage of applicable sensor terminal of ESP ® control

module connector and vehicle body ground is 0 V with

ignition switch turned ON (power short check)

Are they in good condition? Go to Step 3. Repair or replace

defective circuit.

3 Check wheel speed sensor

1) Remove applicable wheel speed sensor.

2) Check sensor for damage or foreign material attached.

Is it in good condition? Go to Step 4. Clean, repair or replace.

4 Check wheel encoder

1) Check front and/or rear wheel encoder for the following

(remove front drive shaft and/or rear wheel hub

assembly):

• Encoder surface neither crack nor damaged

• No foreign material being attached

• Encoder not being eccentric

• Wheel bearing free from excessive play

Are they in good condition? Go to Step 5. Clean, repair or replace

front wheel bearing and/

or rear wheel hub

assembly.

5 Check wheel speed sensor installing condition

1) Install wheel speed sensor to knuckle.

2) Tighten sensor bolt to specified torque and check that

there is no clearance between sensor and knuckle.

Is it OK? Go to Step 6. Replace wheel speed

sensor.

Step Action Yes No

1

2“E85-2”“E85-3”“E85-5”

“E85-6”

“E85-11”

“E85-12”

“E85-14”

“E85-15”

I6RS0B460017-02

Page 631 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-57

3) Remove front brake pipe referring to “Front Brake Hose / Pipe Removal and In stallation in Section 4A”.

4) Remove ESP ® hydraulic unit / control module with

bracket from vehicle by removing bracket bolts.

5) Remove bolt (4) and pull out ESP ® hydraulic unit /

control module assembly (1) from bracket (3) using

flat end rod or the like (2).

Installation 1) Install hydraulic unit / co ntrol module assembly and

by reversing removal procedure.

Tightening torque

Brake pipe flare nut: 16 N·m (1.6 kgf-m, 11.5 lb-

ft)

ESP ® hydraulic unit / control module assembly

bolt: 9 N·m (0.9 kgf-m, 6.5 lb-ft)

ESP ® hydraulic unit / control module assembly

bracket bolt: 25 N·m (2.5 kgf-m, 18.0 lb-ft)

2) Bleed air from brake system referring to “Air Bleeding of Brake System in Section 4A”.

3) Check each installed part for fluid leakage.

4) Connect SUZUKI Scan Tool.

5) Turn ignition switch to ON position. And SLIP indicator lamp flush. (Other than replace with new

one) If other than SLIP indicator lamp light, check

DTC and repair it.

6) Turn ignition switch to ON position. And ESP®

warning lamp, SLIP indicator lamp, ESP ® OFF

lamp, Brake warning lamp lights and ABS warning

lamp flush. (Replace new one)

7) Check DTC.

NOTE

If any DTC(s) other than C1075, C1076 or

C1078 are detected, sensor calibration can

not be completed. Repair the detected it(s)

first.

8) Perform “Sensor Calibration”.

9) Perform “ESP ® Hydraulic Unit Operation Check”.

10) Turn ignition switch to OFF position once and then

ON position. In this state, make sure that indicator

light and warning light turns off.

11) Check DTC(s) are not stored in hydraulic unit / control module.

Front / Rear Wheel Speed Sensor On-Vehicle

Inspection

S7RS0B4606028

CAUTION!

Incorrect voltage and/or wrong connection

cause damage to wheel speed sensor.

Output Voltage Inspection

1) Disconnect negative (–) cable from battery.

2) Hoist vehicle a little.

3) Disconnect wheel speed sensor connector.

4) Disconnect wheel speed grommet from vehicle body.

5) Set up measuring devices as shown in figure, the resistance to 115 Ω and the power supply voltage

to12 V.

4

1

2 3

I6RS0B460030-02

[A]: Front wheel speed sensor 3. “WHT” wire terminal

[B]: Rear wheel speed sensor 4. “BLK” wire terminal

1. Wheel speed sensor connector 5. Power supply (12 V)

2. Resistance (115 Ω)

V

2

5

4 1

3

43

1

[A]

[B]

I6RS0B460031-02

Page 632 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-58 Electronic Stability Program:

6) Measure voltage at resistance without wheel rotation.

If voltage is out of specification, check sensor,

mating encoder and their installation conditions.

Voltage at the resistance (115

Ω) without wheel

rotation

680 to 960 mV

7) Measure voltage at resistance with wheel rotation and confirm voltage alternately changes between

high and low voltages.

If voltage does not change with wheel rotation, check

sensor, mating encoder and their installation

conditions.

Voltage at the resistance (115

Ω) with wheel

rotation

High voltage “a”: 1360 to 1930 mV

Low voltage “b”: 680 to 960 mV

Reference

When using oscilloscope for this check, check if peak-to-

peak voltage and waveform meet specification.

Peak-to-peak Voltage at the resistance (115

Ω) with

wheel rotation

High voltage “a”: 1360 to 1930 mV

Low voltage “b”: 680 to 960 mV

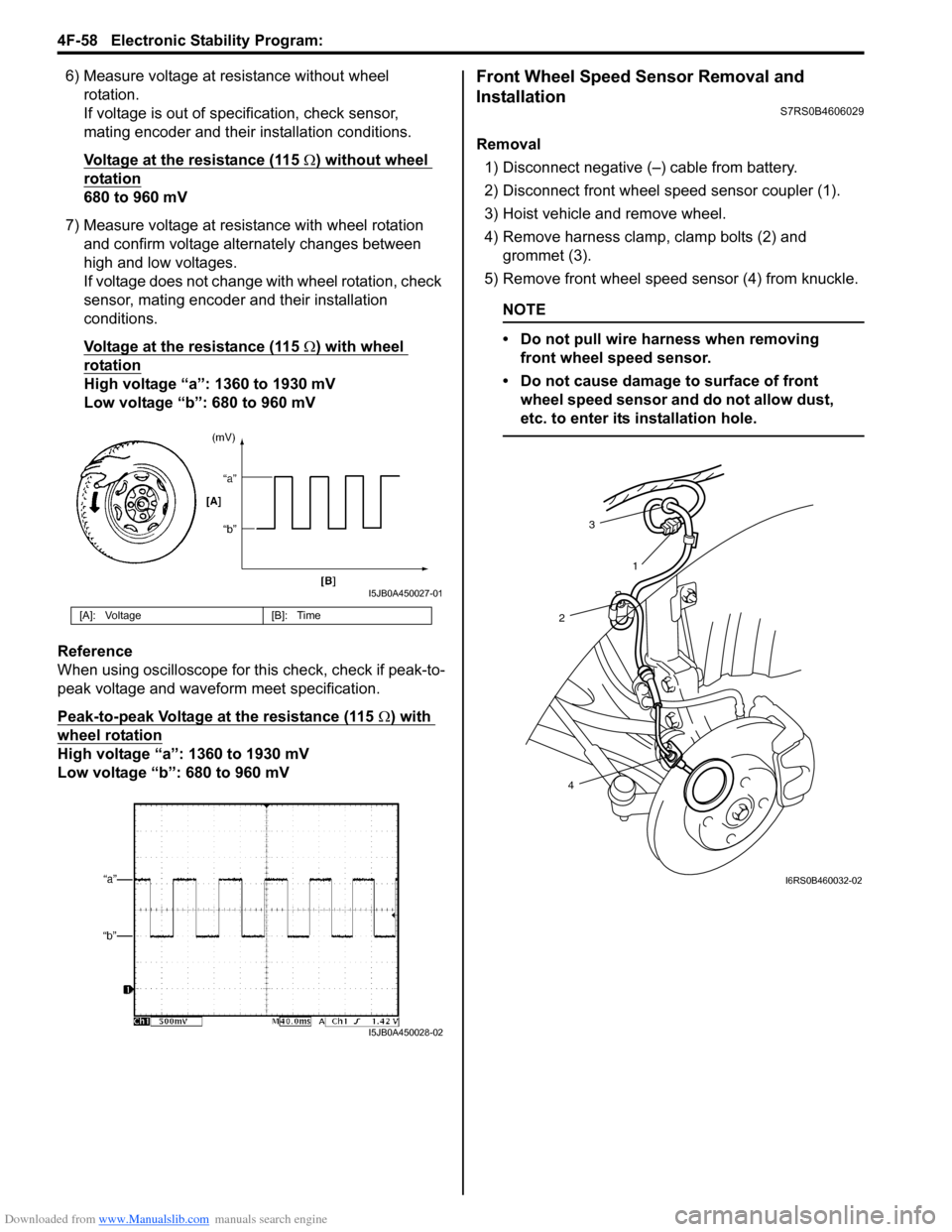

Front Wheel Speed Sensor Removal and

Installation

S7RS0B4606029

Removal

1) Disconnect negative (–) cable from battery.

2) Disconnect front wheel speed sensor coupler (1).

3) Hoist vehicle and remove wheel.

4) Remove harness clamp, clamp bolts (2) and grommet (3).

5) Remove front wheel speed sensor (4) from knuckle.

NOTE

• Do not pull wire harness when removing front wheel speed sensor.

• Do not cause damage to surface of front wheel speed sensor and do not allow dust,

etc. to enter its installation hole.

[A]: Voltage [B]: Time

I5JB0A450027-01

I5JB0A450028-02

3

2

4 1

I6RS0B460032-02

Page 695 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-51

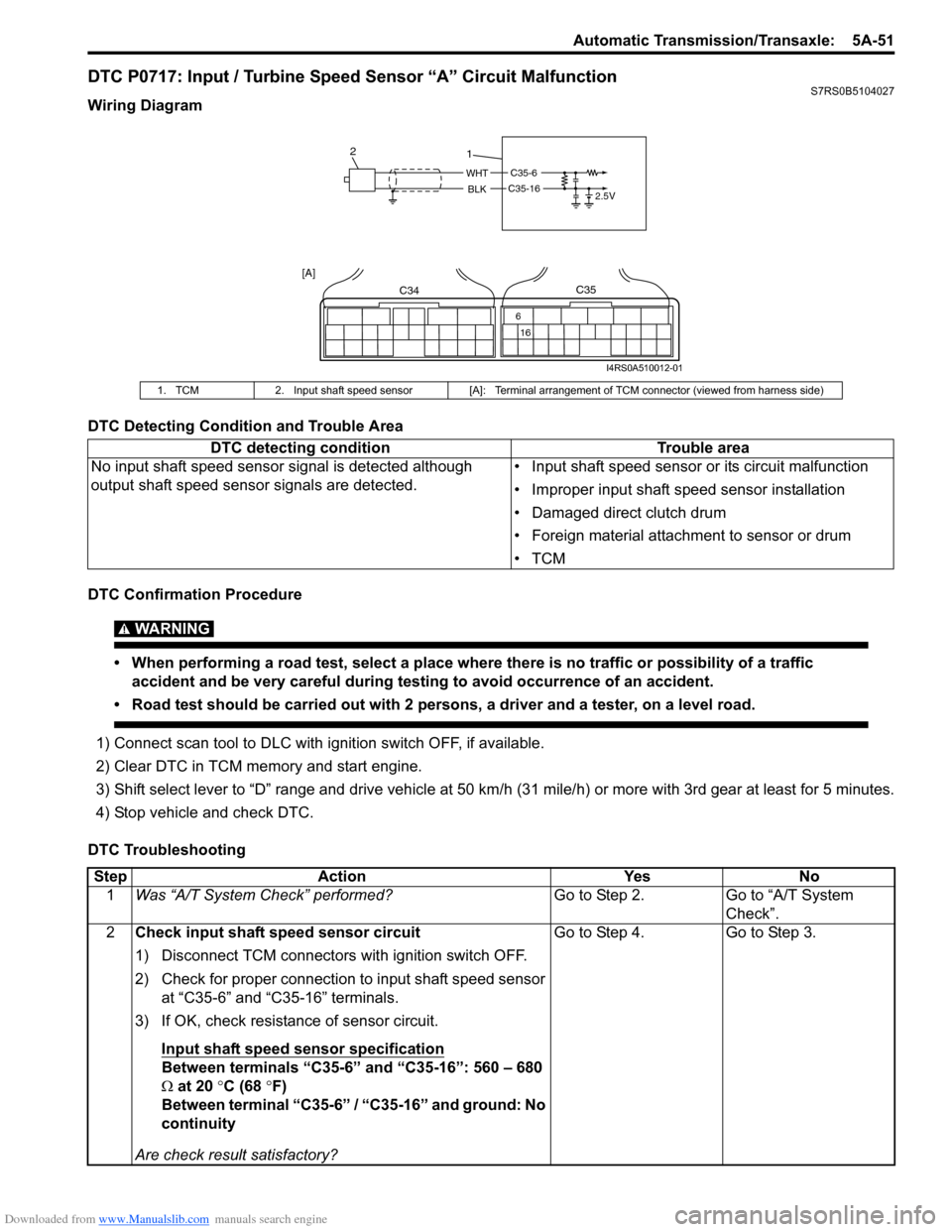

DTC P0717: Input / Turbine Speed Sensor “A” Circuit MalfunctionS7RS0B5104027

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory and start engine.

3) Shift select lever to “D” range and drive vehicle at 50 km /h (31 mile/h) or more with 3rd gear at least for 5 minutes.

4) Stop vehicle and check DTC.

DTC Troubleshooting

1. TCM 2. Input shaft speed sensor [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

No input shaft speed sensor signal is detected although

output shaft speed sens or signals are detected. • Input shaft speed sensor or its circuit malfunction

• Improper input shaft speed sensor installation

• Damaged direct clutch drum

• Foreign material attachment to sensor or drum

•TCM

C35-6

2.5VWHT

BLKC35-16

1

2

C34

16

6

C35

[A]

I4RS0A510012-01

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Check input shaft speed sensor circuit

1) Disconnect TCM connectors with ignition switch OFF.

2) Check for proper connection to input shaft speed sensor

at “C35-6” and “C35-16” terminals.

3) If OK, check resistance of sensor circuit.

Input shaft speed sensor specification

Between terminals “C35-6” and “C35-16”: 560 – 680

Ω at 20 °C (68 °F)

Between terminal “C35-6” / “C35-16” and ground: No

continuity

Are check result satisfactory? Go to Step 4. Go to Step 3.

Page 741 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-97

Installation1) Apply A/T fluid to input shaft speed sensor O-ring.

2) Install input shaft speed se nsor (1) to A/T case and

tighten bolt to specified torque.

Tightening torque

Input shaft speed sensor bolt (a): 5.5 N·m (0.55

kgf-m, 4.0 lb-ft)

3) Connect input shaft speed sensor connector (2) to input shaft speed sensor (1).

4) Connect negative cable to battery.

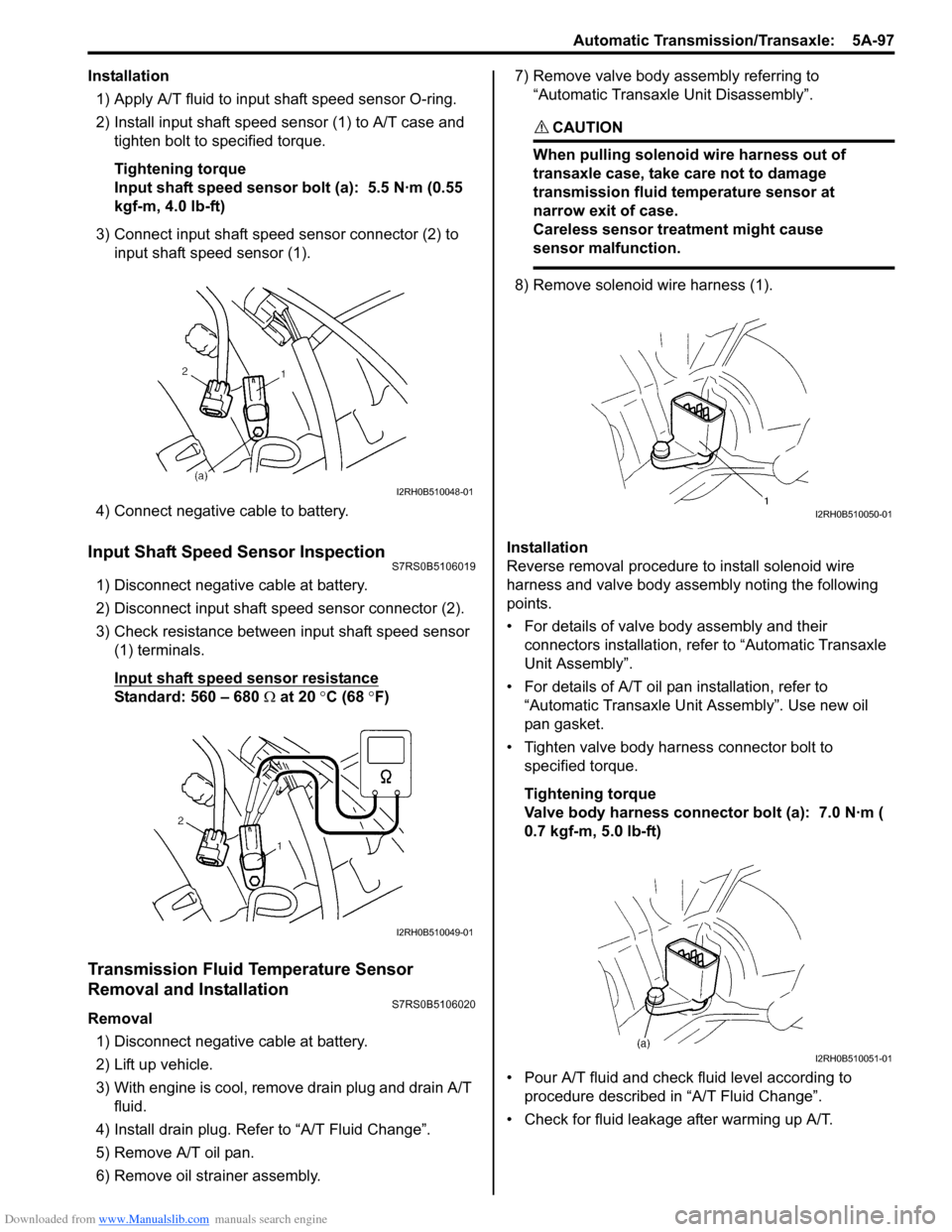

Input Shaft Speed Sensor InspectionS7RS0B5106019

1) Disconnect negative cable at battery.

2) Disconnect input shaft speed sensor connector (2).

3) Check resistance between input shaft speed sensor (1) terminals.

Input shaft speed sensor resistance

Standard: 560 – 680 Ω at 20 °C (68 °F)

Transmission Fluid Temperature Sensor

Removal and Installation

S7RS0B5106020

Removal

1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) With engine is cool, remove drain plug and drain A/T fluid.

4) Install drain plug. Refer to “A/T Fluid Change”.

5) Remove A/T oil pan.

6) Remove oil stra iner assembly. 7) Remove valve body assembly referring to

“Automatic Transaxl e Unit Disassembly”.

CAUTION!

When pulling solenoid wire harness out of

transaxle case, take care not to damage

transmission fluid temperature sensor at

narrow exit of case.

Careless sensor treatment might cause

sensor malfunction.

8) Remove solenoid wire harness (1).

Installation

Reverse removal procedure to install solenoid wire

harness and valve body assembly noting the following

points.

• For details of valve body assembly and their connectors installation, refer to “Automatic Transaxle

Unit Assembly”.

• For details of A/T oil pa n installation, refer to

“Automatic Transaxle Unit Assembly”. Use new oil

pan gasket.

• Tighten valve body harness connector bolt to specified torque.

Tightening torque

Valve body harness connector bolt (a): 7.0 N·m (

0.7 kgf-m, 5.0 lb-ft)

• Pour A/T fluid and check fluid level according to procedure described in “A/T Fluid Change”.

• Check for fluid leakage after warming up A/T.

I2RH0B510048-01

I2RH0B510049-01

I2RH0B510050-01

I2RH0B510051-01