abs sol SUZUKI SWIFT 2008 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 544 of 1496

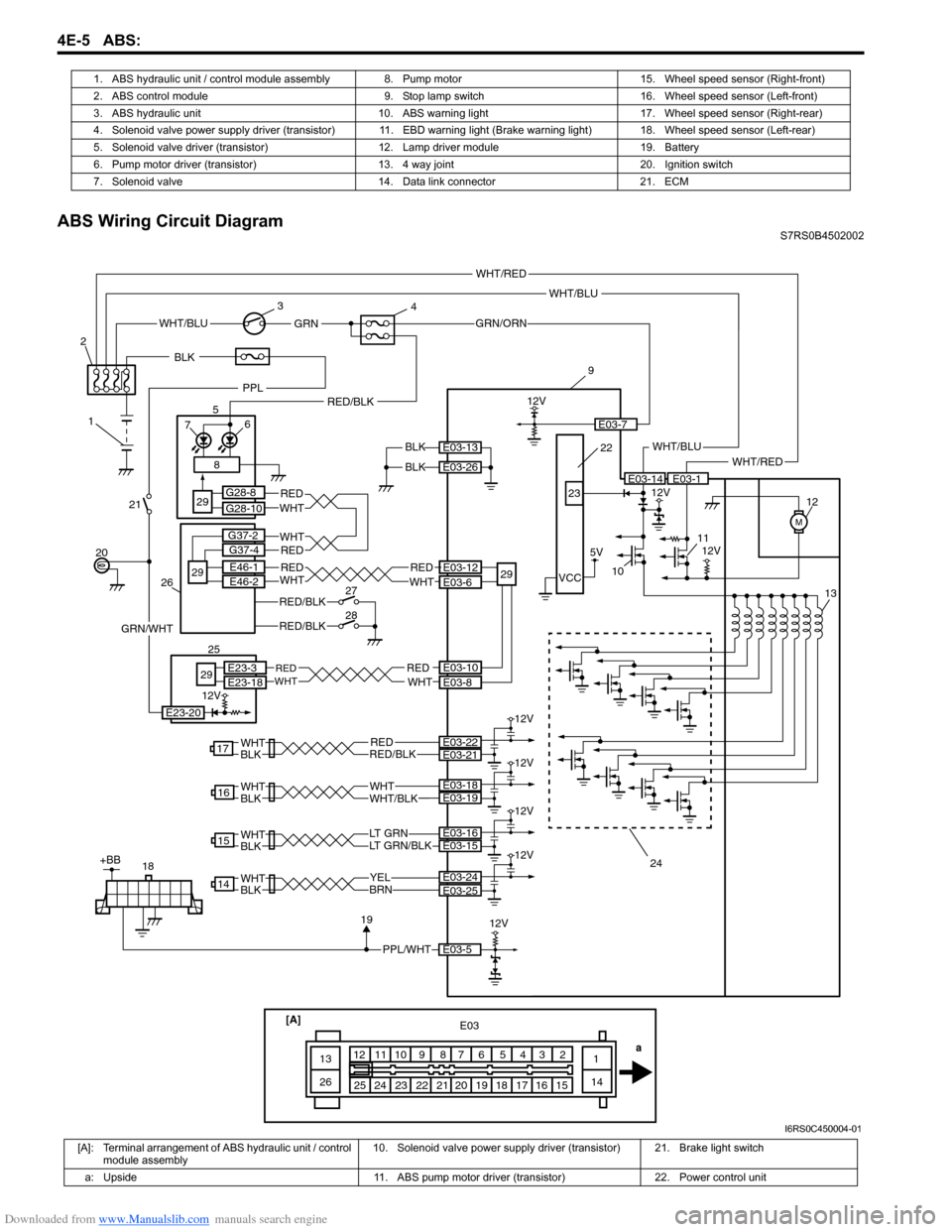

Downloaded from www.Manualslib.com manuals search engine 4E-5 ABS:

ABS Wiring Circuit DiagramS7RS0B4502002

1. ABS hydraulic unit / control module assembly 8.

Pump motor 15. Wheel speed sensor (Right-front)

2. ABS control module 9. Stop lamp switch 16. Wheel speed sensor (Left-front)

3. ABS hydraulic unit 10. ABS warning light 17. Wheel speed sensor (Right-rear)

4. Solenoid valve power supply driver (transistor) 11. EBD warnin g light (Brake warning light) 18. Wheel speed sensor (Left-rear)

5. Solenoid valve driver (transistor) 12. Lamp driver module 19. Battery

6. Pump motor driver (transistor) 13. 4 way joint 20. Ignition switch

7. Solenoid valve 14. Data link connector 21. ECM

[A]

14

1516171819202122232425 1

23456789101112

13

26 E03

a

WHT/BLU

BLKWHT/BLU

M

12V

9

10 11 12

13

BLKE03-14E03-1

E03-13

E03-26

YELBRN

14E03-24

LT GRN/BLKLT GRN

15

WHTWHT/BLK

16

RED

WHTBLK

WHTBLK

WHTBLK

WHTBLKRED/BLK

17

12V

PPL/WHT

18E03-5

1912V

5V

12V

23

24

VCC22

E03-25

E03-15E03-16

E03-19E03-18

E03-22E03-21

WHT/RED

WHT/RED

+BB

GRN/ORN

E03-7

WHT/BLUGRN

1

2

3

4

8

RED/BLK

E03-12

E03-6

RED

WHTE03-10E03-8

REDWHT

20 7

6

529

29

G28-8

G28-10

25

29

E23-3E23-18

GRN/WHT

21

PPL

12V

E23-20

12V

12V

12V

12V

REDWHTE46-1

E46-2

BLK

RED/BLK

RED/BLK

RED

RED

WHT

WHT

27

28

26

29

G37-2

G37-4

REDWHT

I6RS0C450004-01

[A]: Terminal arrangement of ABS hydraulic unit / control module assembly 10. Solenoid valve power supply driver

(transistor) 21. Brake light switch

a: Upside 11. ABS pump motor driver (transistor) 22. Power control unit

Page 545 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-6

1. Battery12. Pump motor23. Internal memory

2. Main fuse box 13. Solenoid valves24. Solenoid valve driver (transistor)

3. Ignition switch 14. Right-rear wheel speed sensor25. ECM

4. Circuit fuse box 15. Left-rear wheel speed sensor26. BCM

5. Combination meter 16. Right-front wheel speed sensor27. Brake fluid level switch

6. ABS warning light 17. Left-front wheel speed sensor28. Parking brake switch

7. EBD warning light (Brake warning light) 18. Data link connector29. CAN driver

8. Lamp driver module 19. To ECM, SDM and BCM

9. ABS hydraulic unit / control module assembly 20. Stop lamp

Terminal Wire color Circuit

E03 1

WHT/RED ABS pump motor driver (Transistor)

2— —

3— —

4— —

5 PPL/WHT Data link connector

6 WHT CAN communication line (low) for BCM

7 GRN/ORN Ignition switch

8 WHT CAN communication line (low) for ECM

9— —

10 RED CAN communication line (high) for ECM

11 — —

12 RED CAN communication line (high) for BCM

13 BLK Ground

14 WHT/BLU Solenoid valve power supply driver (Transistor)

15 LT GRN/BLK Left–rear wheel speed sensor (–)

16 LT GRN Left–rear wheel speed sensor (+)

17 — —

18 WHT Right–front wheel speed sensor (+)

19 WHT/BLK Right–front wheel speed sensor (–)

20 — —

21 RED/BLK Left–front wheel speed sensor (–)

22 RED Left–front wheel speed sensor (+)

23 — —

24 YEL Right–rear wheel speed sensor (+)

25 BRN Right–rear wheel speed sensor (–)

26 BLK Ground

Page 550 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-11 ABS:

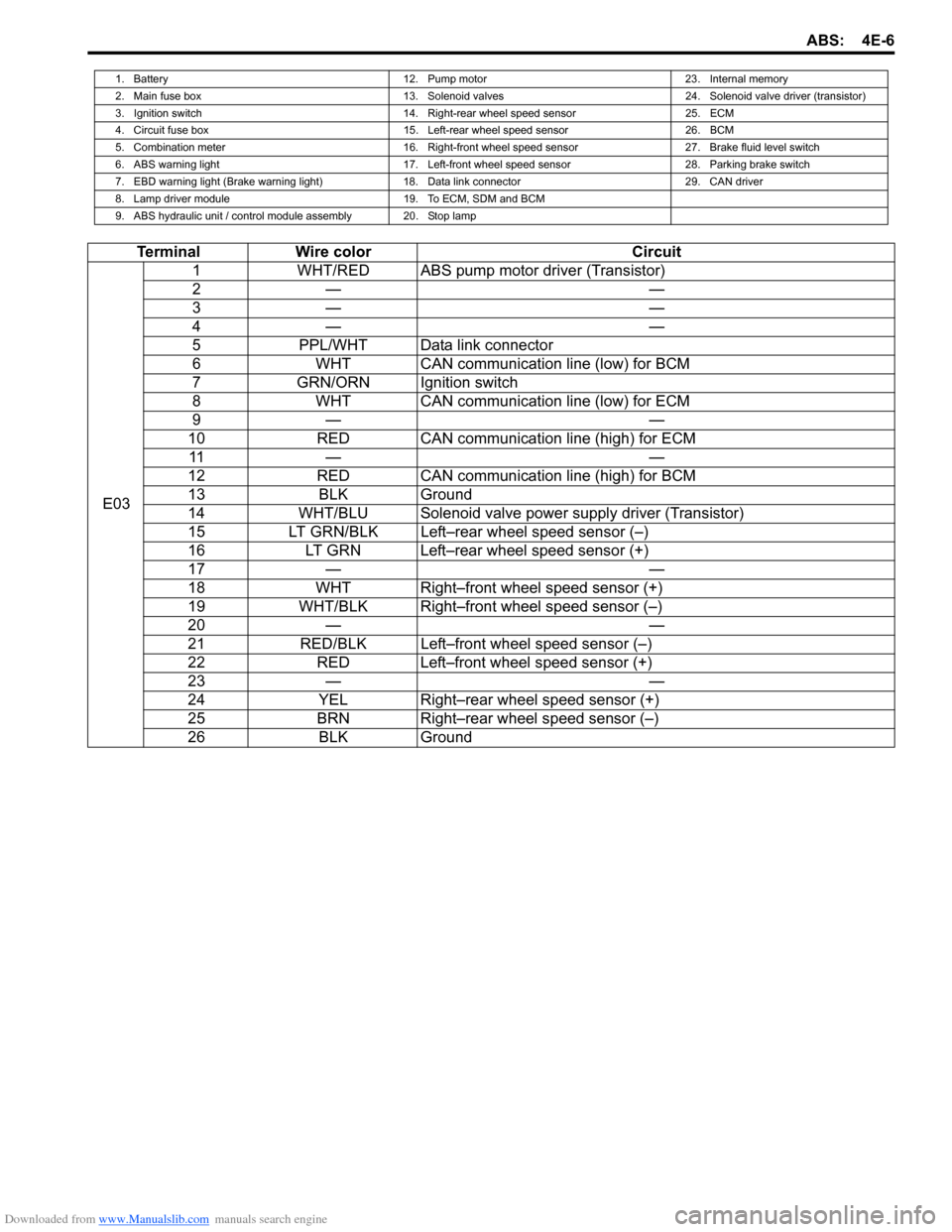

DTC CheckS7RS0B4504004

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (1).

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Read DTC according to instructions displayed on SUZUKI scan tool and print it or write it down. Refer

to SUZUKI scan tool operator’s manual for further

details.

NOTE

If SUZUKI scan tool can not communicate

ABS hydraulic unit / control module, perform

“Serial Data Link Circuit Check”.

5) After completing the check, turn ignition switch off and disconnect SUZUKI scan tool from DLC.

DTC TableS7RS0B4504005

CAUTION!

Be sure to perform “ABS Check” before

starting diagnosis.

1 (A)I4RS0A450009-01

DTC (displayed on

SUZUKI scan tool) Diagnostic Items

NO DTC Normal

�) C1021 RF

Wheel speed sensor circuit

�)

C1025 LF

�) C1031 RR

�) C1035 LR

�) C1022 RF

Wheel speed sensor circuit

or sensor ring

�)

C1026 LF

�) C1032 RR

�) C1036 LR

�) C1041

RFInlet solenoid valve circuit

�) C1042 Outlet solenoid valve circuit

�) C1045

LFInlet solenoid valve circuit

�) C1046 Outlet solenoid valve circuit

�) C1051

RRInlet solenoid valve circuit

�) C1052 Outlet solenoid valve circuit

�) C1055

LRInlet solenoid valve circuit

�) C1056 Outlet solenoid valve circuit

�) C1057 Power source

�) C1061 ABS pump motor and/or motor

driver circuit

�) C1063 Solenoid valve power supply driver

circuit

�) C1071 ABS control module

�) U1073 Control Module

Communication

Bus Off

�) U1100 Lost Communication with ECM

(Reception error)

Page 553 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-14

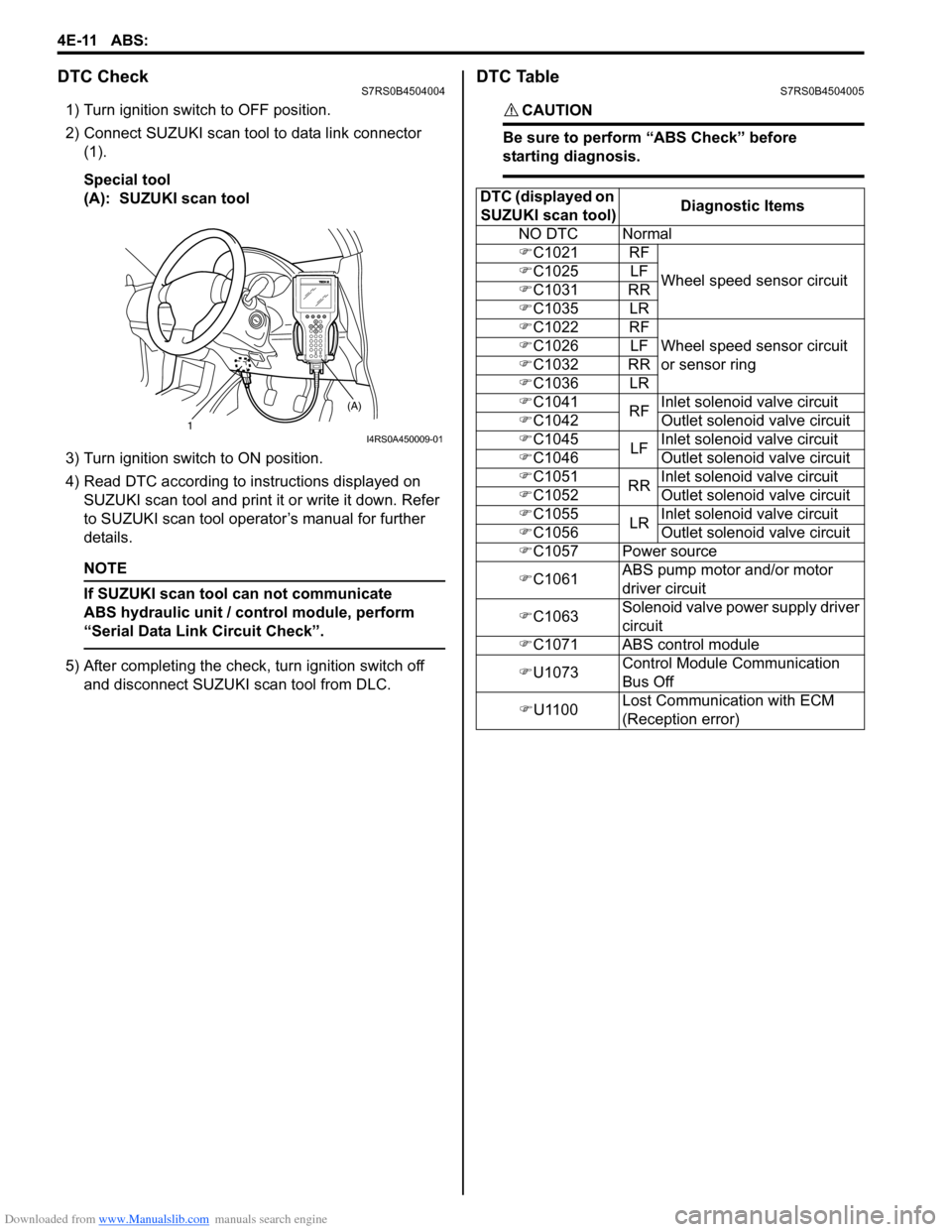

ABS Warning Light Comes ON SteadyS7RS0B4504009

Wiring Diagram

Refer to “ABS Warning Light Does Not Come ON at Ignition Switch ON”.

Circuit Description

Operation (ON/OFF) of ABS wa rning light is controlled by ABS contro l module through lamp driver module in

combination meter.

If the Antilock brake system is in good condition, ABS control module turns ABS warning lig ht ON at the ignition switch

ON, keeps it ON for 2 seconds and then turns it OFF. If an abnormality in the system is detected, ABS warning light is

turned ON continuously by ABS c ontrol module. Also, it is turned ON continuously by la mp driver module when the

connector of ABS control module is disconnected.

Troubleshooting 4 Check CAN communication circuit between combination

meter and ABS control module referring to “DTC U1073:

Control Module Communication Bus Off”.

Is CAN communication circuit in good condition? Go to Step 5.

Repair or replace.

5 1) Remove combination meter wit h ignition switch turned

OFF.

2) Check for proper connection to “RED/BLK” and “BLK/ ORN” wire of combinat ion meter connector.

3) If OK, turn ON ignition switch and measure voltage at “PPL/RED” wire of combi nation meter connector and

vehicle body ground.

Is it 10 – 14 V? Go to Step 6.

Repair power supply

circuit for combination

meter.

6 1) Measure resistance between “BLK/ORN” wire of combination meter connector and vehicle body ground.

Is resistance less than 2

Ω? Replace combination

meter.

“BLK/ORN” circuit open

or high resistance.

Step Action Yes No

Step

Action YesNo

1 1) Perform diagnostic trouble code check.

Is there any DTC(s)? Go to applicable DTC

diag. flow.

Go to Step 2.

2 Are main fuses for ABS pump motor and ABS solenoid in

good condition? Go to Step 3.

Replace fuse and check

circuit for short to

ground.

3 1) Turn ignition switch to OFF.

2) Disconnect ABS control module connector.

3) Check for proper connection to ABS control module connector at terminals “E03-7”, “E03-13” and “E03-26”.

4) If OK then turn ignition switch to ON position and measure voltage between terminal “E03-7” and vehicle

body ground.

Is it 10 – 14 V? Go to Step 4.

“GRN/ORN” circuit

open.

4 1) Turn ignition switch to OFF position. 2) Check for proper connection to ABS control module connector at terminals “E03-1” and “E03-14”.

3) If OK then turn ignition switch to ON position and measure voltage between each terminal of “E03-1”,

“E03-14” and vehicle body ground.

Are they 10 – 14 V? Go to Step 5.

“WHT/RED” and/or

“WHT/BLU” circuit

open.

Page 555 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-16

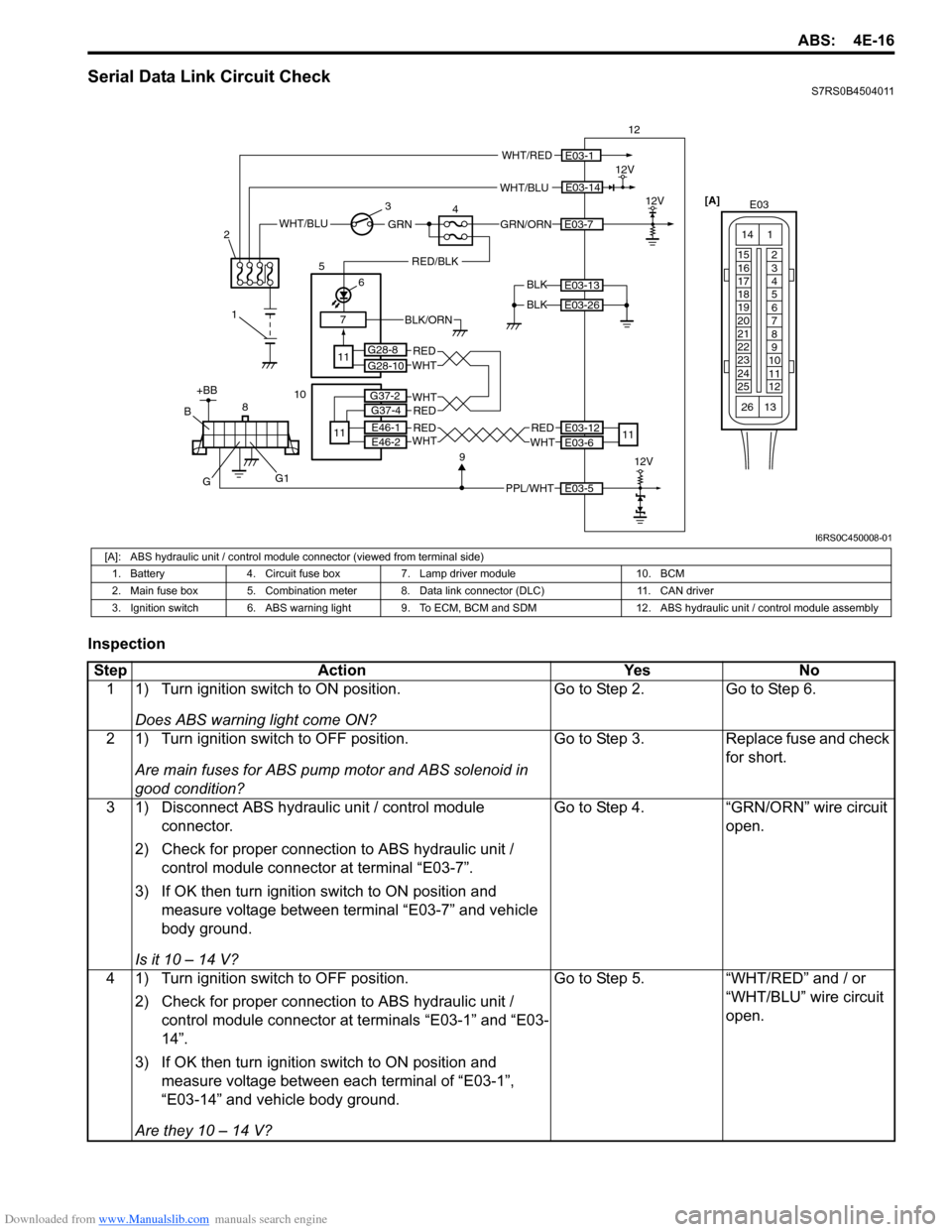

Serial Data Link Circuit CheckS7RS0B4504011

Inspection

WHT/BLU

BLK12V

12

BLK

E03-14

E03-13

E03-26

WHT/RED

GRN/ORNE03-7WHT/BLUGRN

1

2

3

47

RED/BLK

6

5

11

E03-112V

[A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

BLK/ORN

PPL/WHT

8E03-5

912V

+BB

G

B

G1

E03-12

E03-6

REDWHT

11

G28-8

G28-10

REDWHTE46-1

E46-2RED

RED

WHT

WHT

10

11

G37-2

G37-4

I6RS0C450008-01

[A]: ABS hydraulic unit / control module connector (viewed from terminal side)

1. Battery 4. Circuit fuse box 7. Lamp driver module 10. BCM

2. Main fuse box 5. Combination meter 8. Data link connector (DLC) 11. CAN driver

3. Ignition switch 6. ABS warning light 9. To ECM, BCM and SDM 12. ABS hydraulic unit / control module assembly

Step Action YesNo

1 1) Turn ignition switch to ON position.

Does ABS warning light come ON? Go to Step 2.

Go to Step 6.

2 1) Turn ignition switch to OFF position. Are main fuses for ABS pump motor and ABS solenoid in

good condition? Go to Step 3.

Replace fuse and check

for short.

3 1) Disconnect ABS hydraulic unit / control module connector.

2) Check for proper connection to ABS hydraulic unit / control module connector at terminal “E03-7”.

3) If OK then turn ignition switch to ON position and measure voltage between terminal “E03-7” and vehicle

body ground.

Is it 10 – 14 V? Go to Step 4.

“GRN/ORN” wire circuit

open.

4 1) Turn ignition switch to OFF position. 2) Check for proper connection to ABS hydraulic unit / control module connector at terminals “E03-1” and “E03-

14”.

3) If OK then turn ignition switch to ON position and measure voltage between each terminal of “E03-1”,

“E03-14” and vehicle body ground.

Are they 10 – 14 V? Go to Step 5.

“WHT/RED” and / or

“WHT/BLU” wire circuit

open.

Page 559 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-20

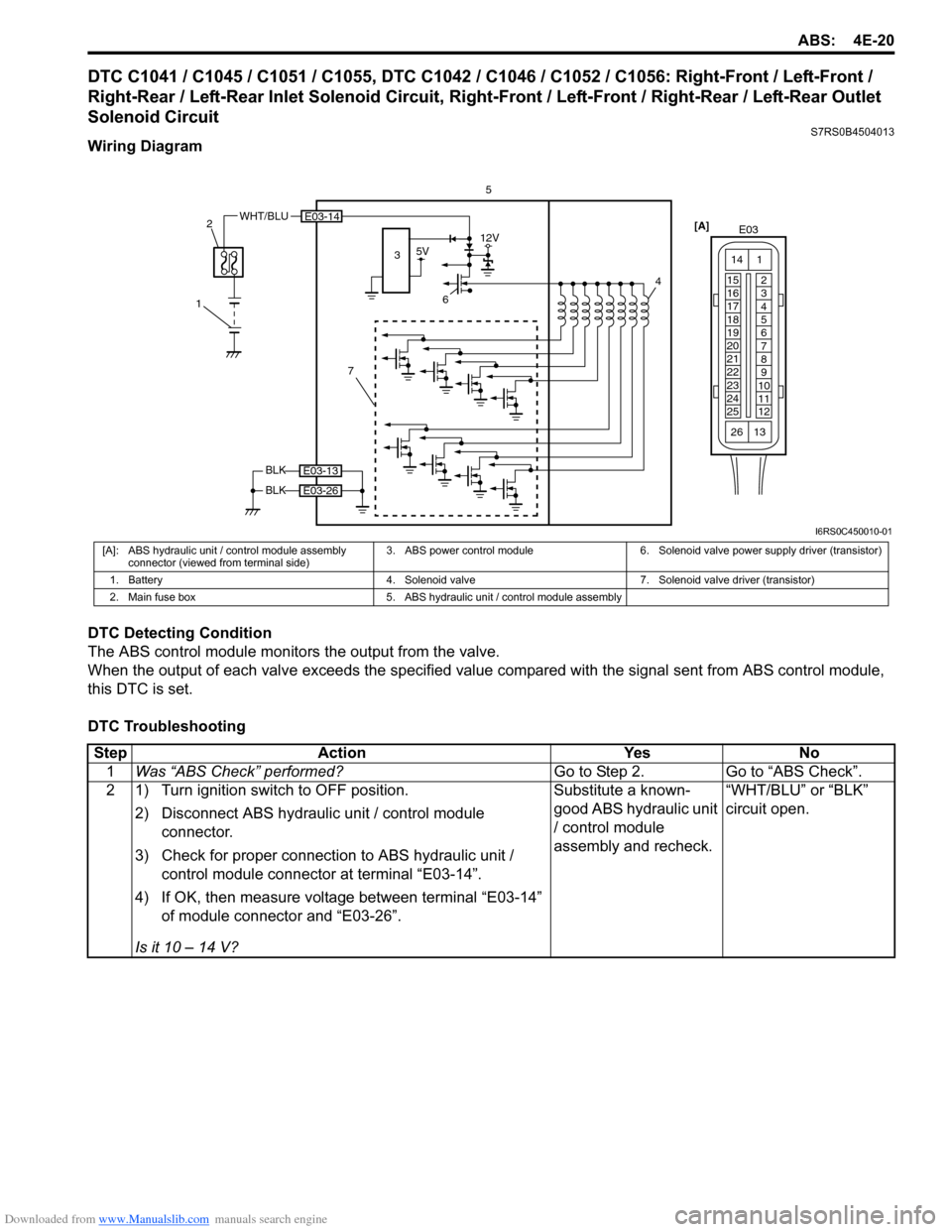

DTC C1041 / C1045 / C1051 / C1055, DTC C1042 / C1046 / C1052 / C1056: Right-Front / Left-Front /

Right-Rear / Left-Rear Inlet Solenoid Circuit, Right-Front / Left-Front / Right-Rear / Left-Rear Outlet

Solenoid Circuit

S7RS0B4504013

Wiring Diagram

DTC Detecting Condition

The ABS control module monitors the output from the valve.

When the output of each valve exceeds the specified value compared with the signal sent from ABS control module,

this DTC is set.

DTC Troubleshooting

6 4

E03-14

5V12V

7

3

WHT/BLU

1 2

5

BLK

BLK

E03-13

E03-26

[A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

I6RS0C450010-01

[A]: ABS hydraulic unit / control module assembly

connector (viewed from terminal side) 3. ABS power control module 6. Solenoid valve power supply driver (transistor)

1. Battery 4. Solenoid valve 7. Solenoid valve driver (transistor)

2. Main fuse box 5. ABS hydraulic unit / control module assembly

Step Action YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 1) Turn ignition switch to OFF position.

2) Disconnect ABS hydraulic unit / control module connector.

3) Check for proper connection to ABS hydraulic unit / control module connector at terminal “E03-14”.

4) If OK, then measure voltage between terminal “E03-14” of module connector and “E03-26”.

Is it 10 – 14 V? Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

“WHT/BLU” or “BLK”

circuit open.

Page 562 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-23 ABS:

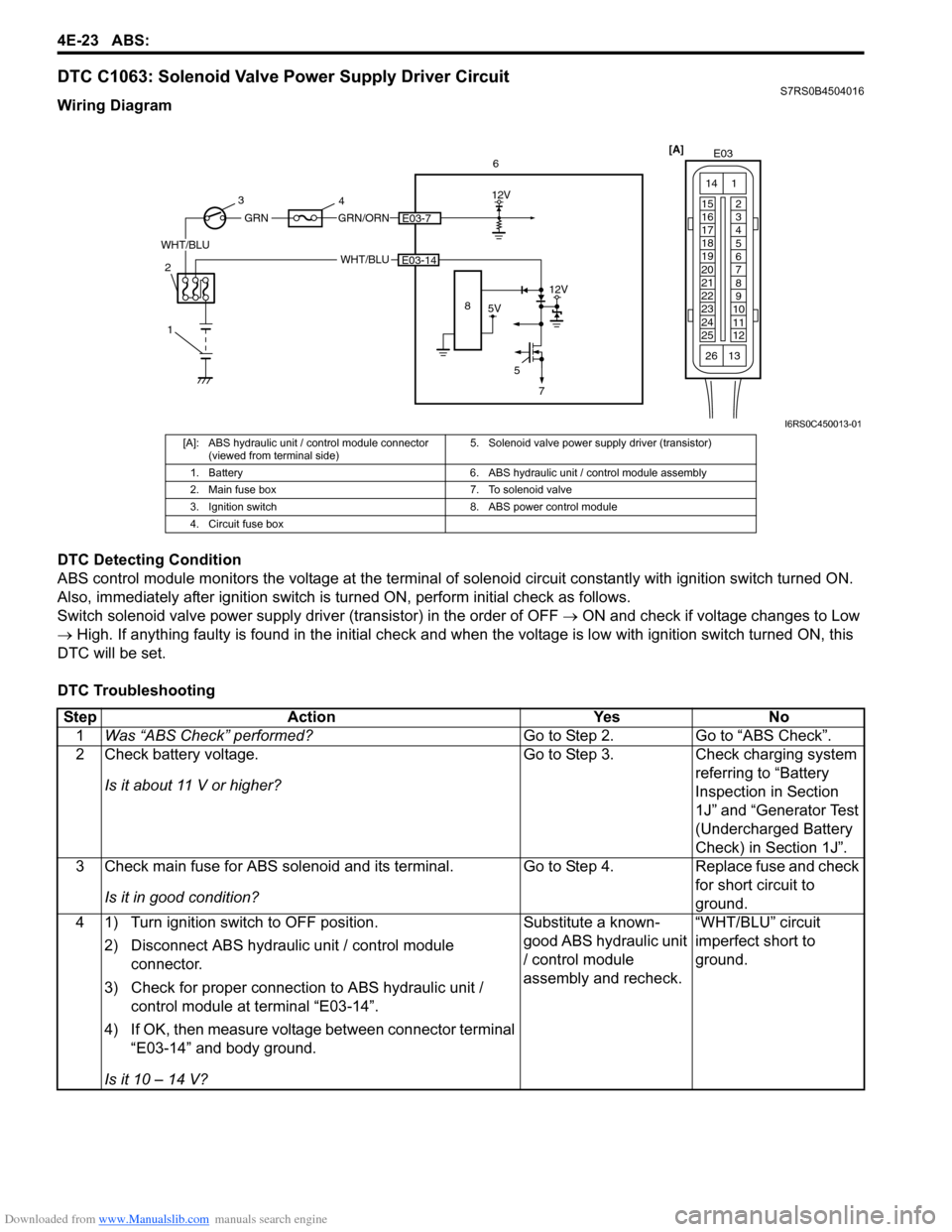

DTC C1063: Solenoid Valve Power Supply Driver CircuitS7RS0B4504016

Wiring Diagram

DTC Detecting Condition

ABS control module monitors the voltage at the terminal of solenoid circuit constantly with ignition switch turned ON.

Also, immediately after ignition switch is turned ON, perform initial check as follows.

Switch solenoid valve power supply driv er (transistor) in the order of OFF → ON and check if voltage changes to Low

→ High. If anything faulty is found in the initial check and when the voltage is low with ignition switch turned ON, this

DTC will be set.

DTC Troubleshooting

[A] E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

266

WHT/BLU

12V

5E03-14

5V

12V

8

GRN/ORNE03-7

WHT/BLU

GRN

1

2 3

4

7

I6RS0C450013-01

[A]: ABS hydraulic unit / control module connector

(viewed from terminal side) 5. Solenoid valve power supp

ly driver (transistor)

1. Battery 6. ABS hydraulic unit / control module assembly

2. Main fuse box 7. To solenoid valve

3. Ignition switch 8. ABS power control module

4. Circuit fuse box

Step Action YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 Check battery voltage.

Is it about 11 V or higher? Go to Step 3.

Check charging system

referring to “Battery

Inspection in Section

1J” and “Generator Test

(Undercharged Battery

Check) in Section 1J”.

3 Check main fuse for ABS solenoid and its terminal.

Is it in good condition? Go to Step 4.

Replace fuse and check

for short circuit to

ground.

4 1) Turn ignition switch to OFF position.

2) Disconnect ABS hydraulic unit / control module connector.

3) Check for proper connection to ABS hydraulic unit / control module at terminal “E03-14”.

4) If OK, then measure voltage between connector terminal “E03-14” and body ground.

Is it 10 – 14 V? Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

“WHT/BLU” circuit

imperfect short to

ground.

Page 567 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-28

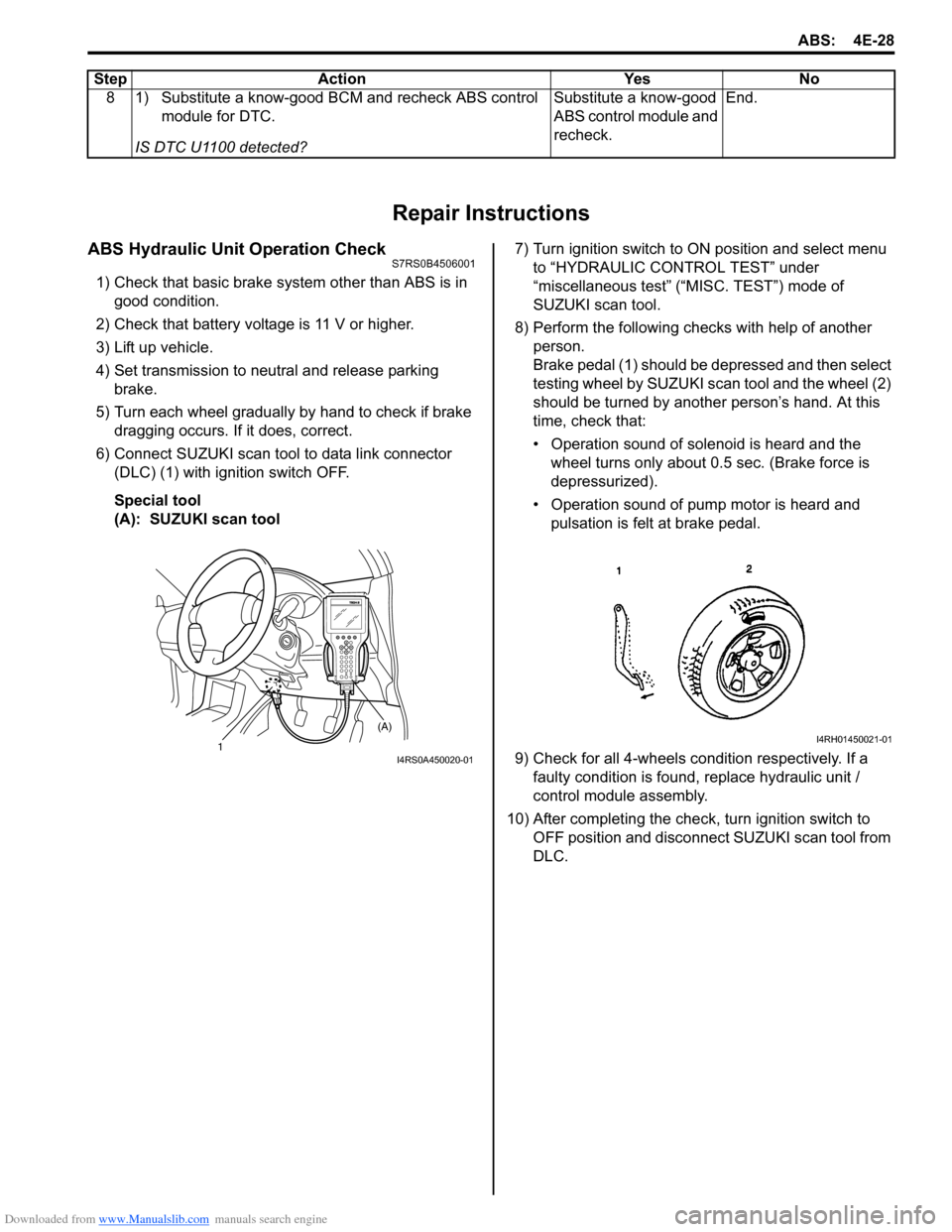

Repair Instructions

ABS Hydraulic Unit Operation CheckS7RS0B4506001

1) Check that basic brake system other than ABS is in good condition.

2) Check that battery voltage is 11 V or higher.

3) Lift up vehicle.

4) Set transmission to neutral and release parking brake.

5) Turn each wheel gradually by hand to check if brake dragging occurs. If it does, correct.

6) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool 7) Turn ignition switch to ON position and select menu

to “HYDRAULIC CONTROL TEST” under

“miscellaneous test” (“MISC. TEST”) mode of

SUZUKI scan tool.

8) Perform the following checks with help of another person.

Brake pedal (1) should be depressed and then select

testing wheel by SUZUKI scan tool and the wheel (2)

should be turned by another person’s hand. At this

time, check that:

• Operation sound of solenoid is heard and the wheel turns only about 0.5 sec. (Brake force is

depressurized).

• Operation sound of pump motor is heard and pulsation is felt at brake pedal.

9) Check for all 4-wheels co ndition respectively. If a

faulty condition is found, replace hydraulic unit /

control module assembly.

10) After completing the check, turn ignition switch to OFF position and disconnect SUZUKI scan tool from

DLC.

8 1) Substitute a know-good BCM and recheck ABS control

module for DTC.

IS DTC U1100 detected? Substitute a know-good

ABS control module and

recheck.

End.

Step Action Yes No

1 (A)I4RS0A450020-01

I4RH01450021-01

Page 578 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-4 Electronic Stability Program:

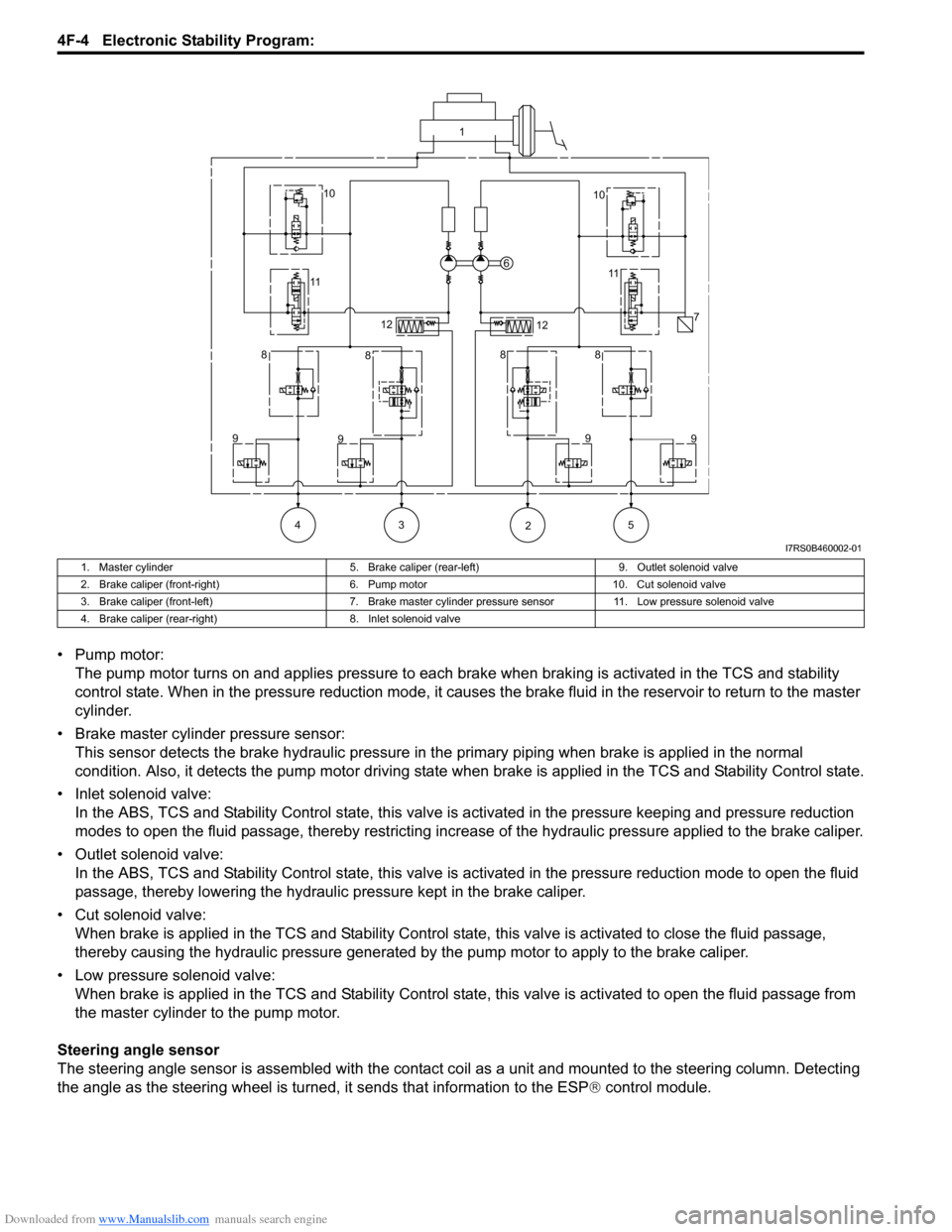

• Pump motor:The pump motor turns on and applies pressure to each brake when braking is activated in the TCS and stability

control state. When in the pressure reduction mode, it causes the brake fluid in the reservoir to return to the master

cylinder.

• Brake master cylinder pressure sensor: This sensor detects the brake hydraulic pressure in th e primary piping when brake is applied in the normal

condition. Also, it detects the pump motor driving state wh en brake is applied in the TCS and Stability Control state.

• Inlet solenoid valve: In the ABS, TCS and Stability Control stat e, this valve is activated in the pressure keeping and pressure reduction

modes to open the fluid passage, thereby restricting increase of the hydraulic pressure applied to the brake caliper.

• Outlet solenoid valve: In the ABS, TCS and Stability Control state, this valve is activated in the pressure reduction mode to open the fluid

passage, thereby lowering the hydraulic pressure kept in the brake caliper.

• Cut solenoid valve: When brake is applied in the TCS and Stability Control state, this valve is activated to close the fluid passage,

thereby causing the hydraulic pressure generated by the pump motor to apply to the brake caliper.

• Low pressure solenoid valve: When brake is applied in the TCS and Stab ility Control state, this valve is activated to open the fluid passage from

the master cylinder to the pump motor.

Steering angle sensor

The steering angle sensor is assembled with the contact co il as a unit and mounted to the steering column. Detecting

the angle as the steering wheel is turned, it sends that information to the ESP ® control module.

1

10 10

11 11

6

7

12 12

8 8 88

9 9 9

9

43 5 2

I7RS0B460002-01

1. Master cylinder 5. Brake caliper (rear-left)9. Outlet solenoid valve

2. Brake caliper (front-right) 6. Pump motor10. Cut solenoid valve

3. Brake caliper (front-left) 7. Brake master cylinder pressure sensor 11. Low pressure solenoid valve

4. Brake caliper (rear-right) 8. Inlet solenoid valve

Page 579 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-5

Yaw rate / G sensor

The yaw rate / G sensor consists of the yaw rate (angular velocity in the vehicle turning direction) sensor and right-left

G (acceleration in right-left direction) sensor and is mounted to the P/S controller B/K at the lower part of the center

console. It detects the angular velocity in the vehicle turn ing direction and movement in the right-left direction, and

then it sends that information to ESP ® control module.

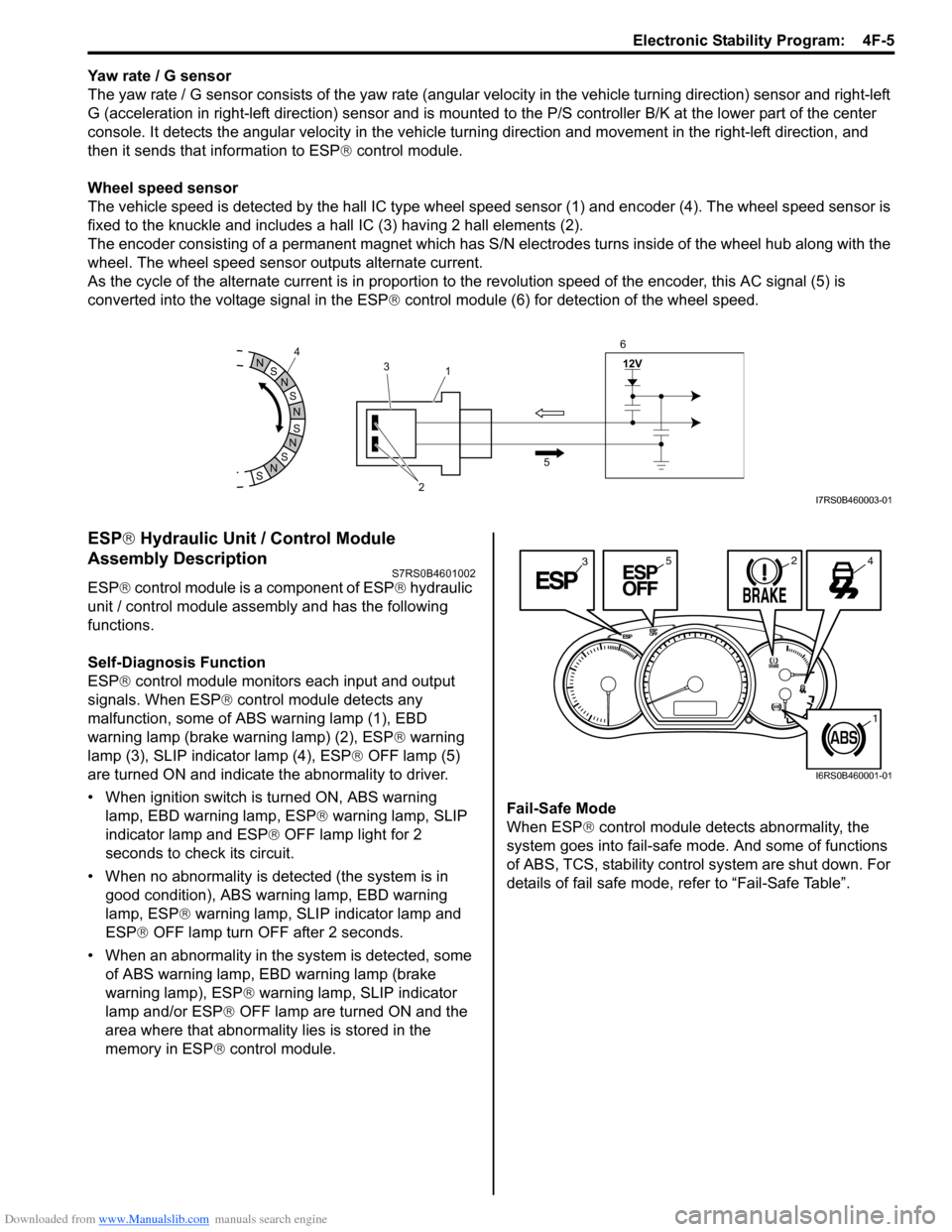

Wheel speed sensor

The vehicle speed is detected by the hall IC type wheel speed sensor (1) and encoder (4). The wheel speed sensor is

fixed to the knuckle and includes a hall IC (3) having 2 hall elements (2).

The encoder consisting of a permanent ma gnet which has S/N electrodes turns inside of the wheel hub along with the

wheel. The wheel speed sensor outputs alternate current.

As the cycle of the alternate current is in proportion to the revolution speed of the encoder, this AC signal (5) is

converted into the voltage signal in the ESP ® control module (6) for detection of the wheel speed.

ESP ® Hydraulic Unit / Control Module

Assembly Description

S7RS0B4601002

ESP ® control module is a component of ESP ® hydraulic

unit / control module assembly and has the following

functions.

Self-Diagnosis Function

ESP ® control module monitors each input and output

signals. When ESP ® control module detects any

malfunction, some of ABS warning lamp (1), EBD

warning lamp (brake warning lamp) (2), ESP ® warning

lamp (3), SLIP indicator lamp (4), ESP ® OFF lamp (5)

are turned ON and indicate the abnormality to driver.

• When ignition switch is turned ON, ABS warning lamp, EBD warning lamp, ESP ® warning lamp, SLIP

indicator lamp and ESP ® OFF lamp light for 2

seconds to check its circuit.

• When no abnormality is detected (the system is in good condition), ABS warning lamp, EBD warning

lamp, ESP ® warning lamp, SLIP indicator lamp and

ESP ® OFF lamp turn OFF after 2 seconds.

• When an abnormality in the system is detected, some of ABS warning lamp, EBD warning lamp (brake

warning lamp), ESP ® warning lamp, SLIP indicator

lamp and/or ESP ® OFF lamp are turned ON and the

area where that abnormality lies is stored in the

memory in ESP ® control module. Fail-Safe Mode

When ESP

® control module detects abnormality, the

system goes into fail-safe mode. And some of functions

of ABS, TCS, stability control system are shut down. For

details of fail safe mode, re fer to “Fail-Safe Table”.

S

N

S

N

S

N

N

S

N

S

12V

2

3

1

5

4

6I7RS0B460003-01

3245

1

I6RS0B460001-01