ckp sensor SUZUKI SWIFT 2008 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 338 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-53 Engine Mechanical:

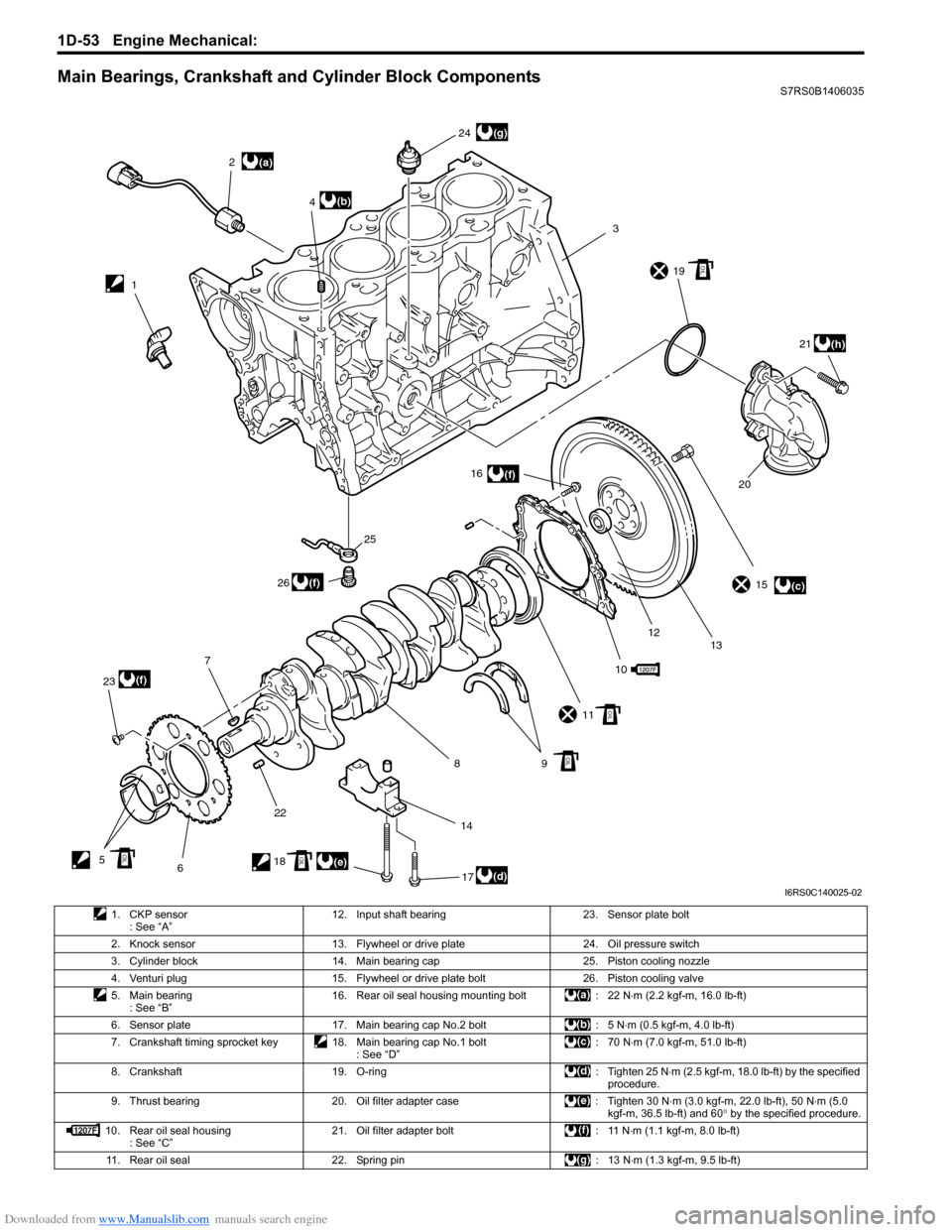

Main Bearings, Crankshaft and Cylinder Block ComponentsS7RS0B1406035

(a)

(c)

(d)(e)

(b)

(f)

(f)

(f)

(g)

(h)

12

3

4

5 67

8910

11 15

12 13

14 16

17

18 19

2021

22

23 24

25

26

OIL

OIL

OIL

OILOIL

I6RS0C140025-02

1. CKP sensor : See “A” 12. Input shaft bearing 23. Sensor plate bolt

2. Knock sensor 13. Flywheel or drive plate 24. Oil pressure switch 3. Cylinder block 14. Main bearing cap 25. Piston cooling nozzle

4. Venturi plug 15. Flywheel or drive plate bolt 26. Piston cooling valve

5. Main bearing : See “B” 16. Rear oil seal housing mounting bolt : 22 N

⋅m (2.2 kgf-m, 16.0 lb-ft)

6. Sensor plate 17. Main bearing cap No.2 bolt : 5 N ⋅m (0.5 kgf-m, 4.0 lb-ft)

7. Crankshaft timing sprocket key 18. Main bearing cap No.1 bolt : See “D”:70 N

⋅m (7.0 kgf-m, 51.0 lb-ft)

8. Crankshaft 19. O-ring : Tighten 25 N ⋅m (2.5 kgf-m, 18.0 lb-ft) by the specified

procedure.

9. Thrust bearing 20. Oil filter adapter case : Tighten 30 N ⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N⋅m (5.0

kgf-m, 36.5 lb-ft) and 60 ° by the specified procedure.

10. Rear oil seal housing : See “C” 21. Oil filter adapter bolt : 11 N

⋅m (1.1 kgf-m, 8.0 lb-ft)

11. Rear oil seal 22. Spring pin : 13 N ⋅m (1.3 kgf-m, 9.5 lb-ft)

Page 339 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-54

Main Bearings, Crankshaft and Cylinder Block

Removal and Installation

S7RS0B1406036

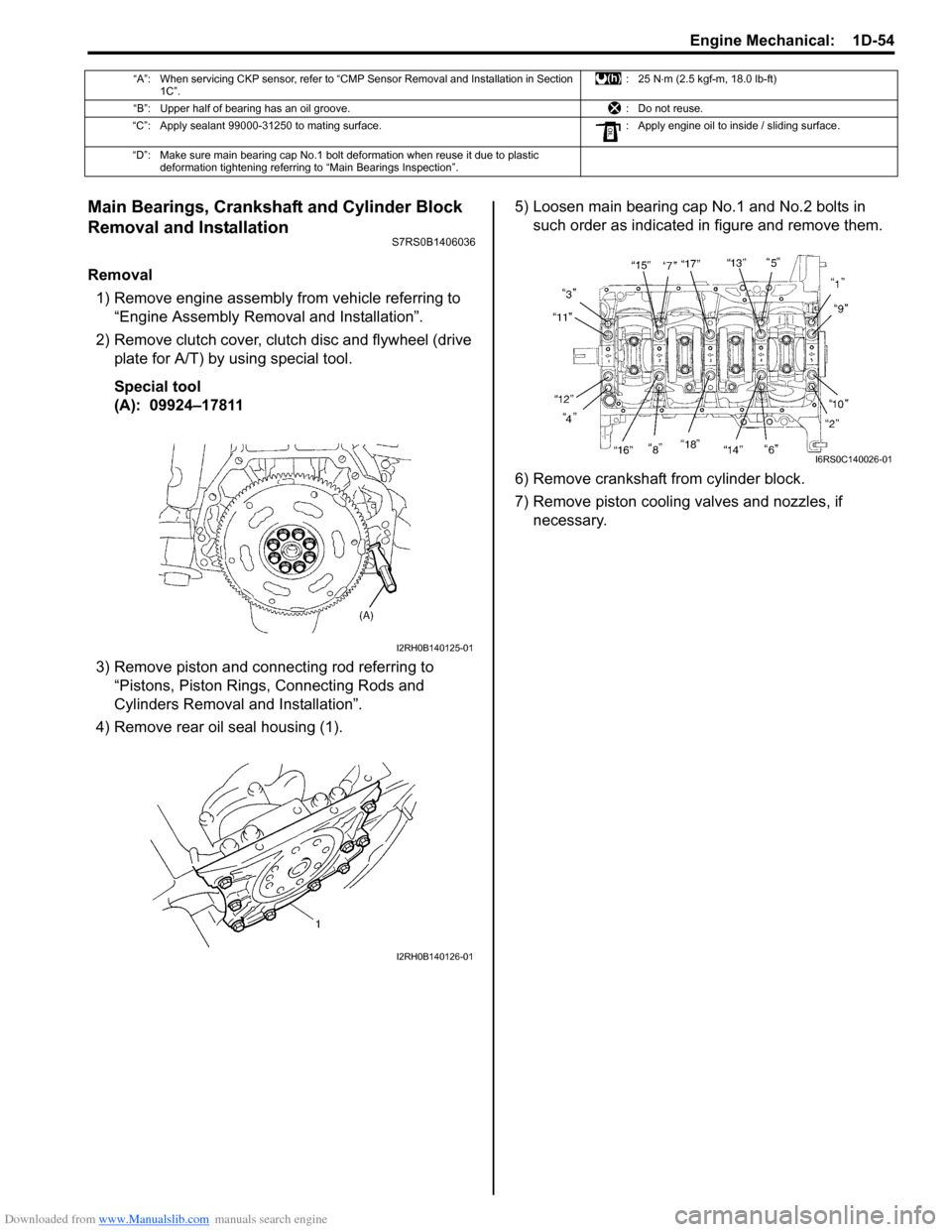

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove clutch cover, clut ch disc and flywheel (drive

plate for A/T) by using special tool.

Special tool

(A): 09924–17811

3) Remove piston and connecting rod referring to “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

4) Remove rear oil seal housing (1). 5) Loosen main bearing cap No.1 and No.2 bolts in

such order as indicated in figure and remove them.

6) Remove crankshaft from cylinder block.

7) Remove piston cooling valves and nozzles, if necessary.

“A”: When servicing CKP sensor, refer to “CMP Sensor Removal and Installation in Section 1C”. :25 N

⋅m (2.5 kgf-m, 18.0 lb-ft)

“B”: Upper half of bearing has an oil groove. : Do not reuse.

“C”: Apply sealant 99000-31250 to mating surface. : Apply engine oil to inside / sliding surface.

“D”: Make sure main bearing cap No.1 bolt deformation when reuse it due to plastic deformation tightening referring to “Main Bearings Inspection”.

I2RH0B140125-01

I2RH0B140126-01

I6RS0C140026-01

Page 393 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-1

Engine

Ignition System

General Description

Ignition System ConstructionS7RS0B1801001

The ignition system is an electronic (distributorless) ignition system. It consists of the parts as described below.

• ECM

It detects the engine and vehicle conditions through the si gnals from the sensors, determines the most suitable

ignition timing and time for electricity to flow to the primar y coil and sends a signal to the ignitor (power unit) in the

ignition coil assembly.

• Ignition coil assembly (including an ignitor)

The ignition coil assembly has a built -in ignitor which turns ON and OFF the current flow to the primary coil

according to the signal from ECM. When the current flow to the primary coil is turned OFF, a high voltage is induced

in the secondary coil.

• High-tension cords and spark plugs

• CMP sensor (Camshaft position sensor) and CKP sensor (Crankshaft position sensor)

Using signals from these sensors, ECM identifies the specific cylinder whose piston is in the compression stroke,

detects the crank angle and adjusts in itial ignition timing automatically.

• TP sensor, ECT sensor, MAP sensor, MAF sensor, IAT sensor, knock sensor and other sensors / switches

Although this ignition system does not have a distributor, it has two ignition coil assemblies (one is for No.1 and No.4

spark plugs and the other is for No.2 and No.3 spark plugs). W hen an ignition signal is sent from ECM to the ignitor in

the ignition coil assembly for No.1 and No.4 spark plugs, a high voltage is induced in the secondary coil and that

passes through the high-tension cords and causes No.1 and No.4 spark plugs to spark simultaneously. Likewise,

when an ignition signal is sent to the ignitor in the ot her ignition coil assembly, No.2 and No.3 spark plugs spark

simultaneously.

Page 394 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-2 Ignition System:

Schematic and Routing Diagram

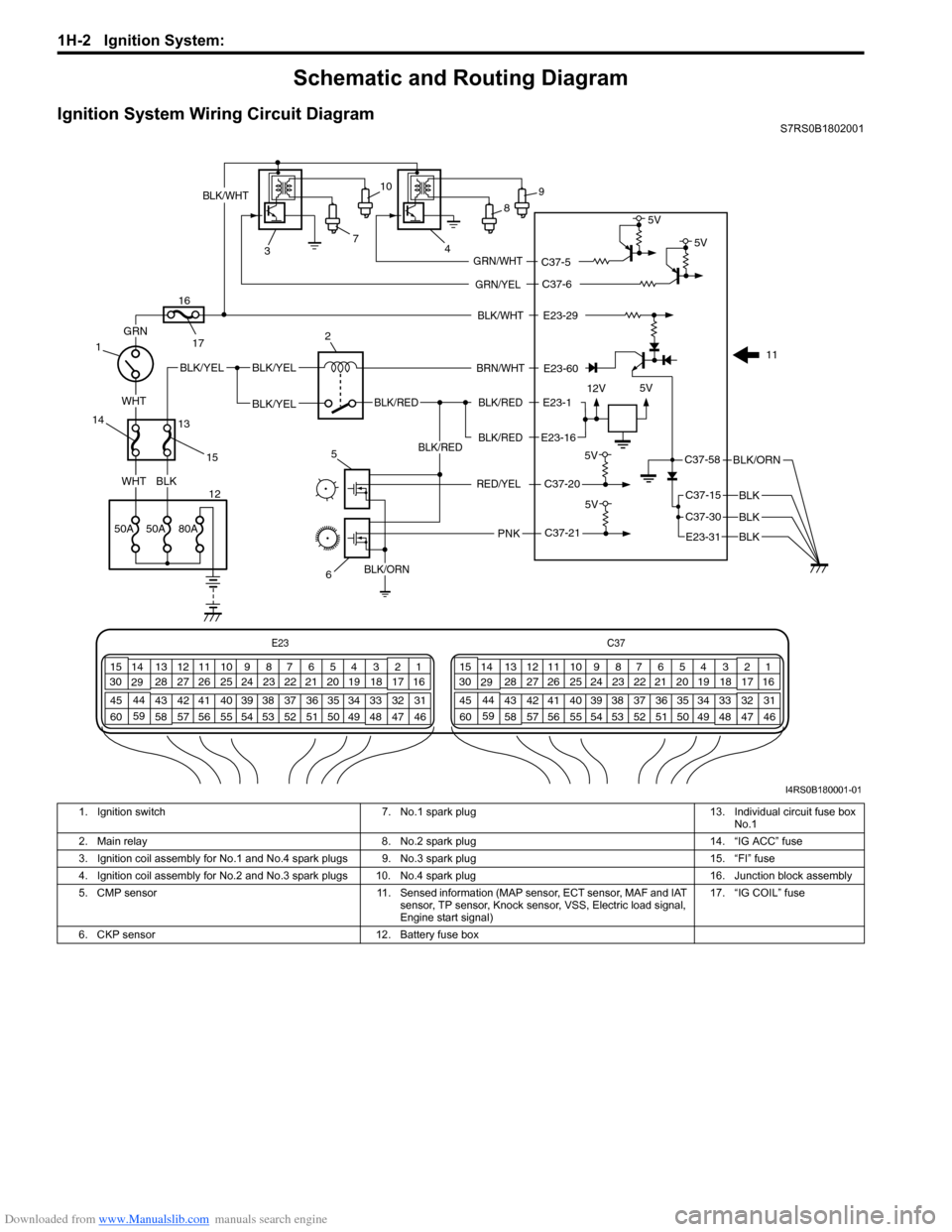

Ignition System Wiring Circuit DiagramS7RS0B1802001

E23-60

E23-29 12V 5V

5V

E23-1

E23-16

BLK/WHT

BLK/RED

BLK/RED BLK/RED

BLK/YELBLK/YEL

BLK/YEL

GRN

BLKWHT

WHT

BRN/WHT

BLK/ORN

BLK

BLK

C37-20

BLK/RED

PNK

5V

C37-21

BLK/WHT

7

3 4

1

12 5

6

2

11

8

9

10

GRN/YEL

GRN/WHT

C37-6

C37-5 5V

5V

RED/YEL

C37-58

C37-15

C37-30

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

13

14

15

16

17

50A50A80A

BLK/ORN

E23-31 BLK

I4RS0B180001-01

1. Ignition switch 7. No.1 spark plug 13. Individual circuit fuse box

No.1

2. Main relay 8. No.2 spark plug 14. “IG ACC” fuse

3. Ignition coil assembly for No.1 and No.4 spark plugs 9. No.3 spark plug 15. “FI” fuse

4. Ignition coil assembly for No.2 and No.3 spark plugs 10. No.4 spark plug 16. Junction block assembly

5. CMP sensor 11. Sensed information (MAP sensor, ECT sensor, MAF and IAT

sensor, TP sensor, Knock sensor, VSS, Electric load signal,

Engine start signal) 17. “IG COIL” fuse

6. CKP sensor 12. Battery fuse box

Page 395 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-3

Component Location

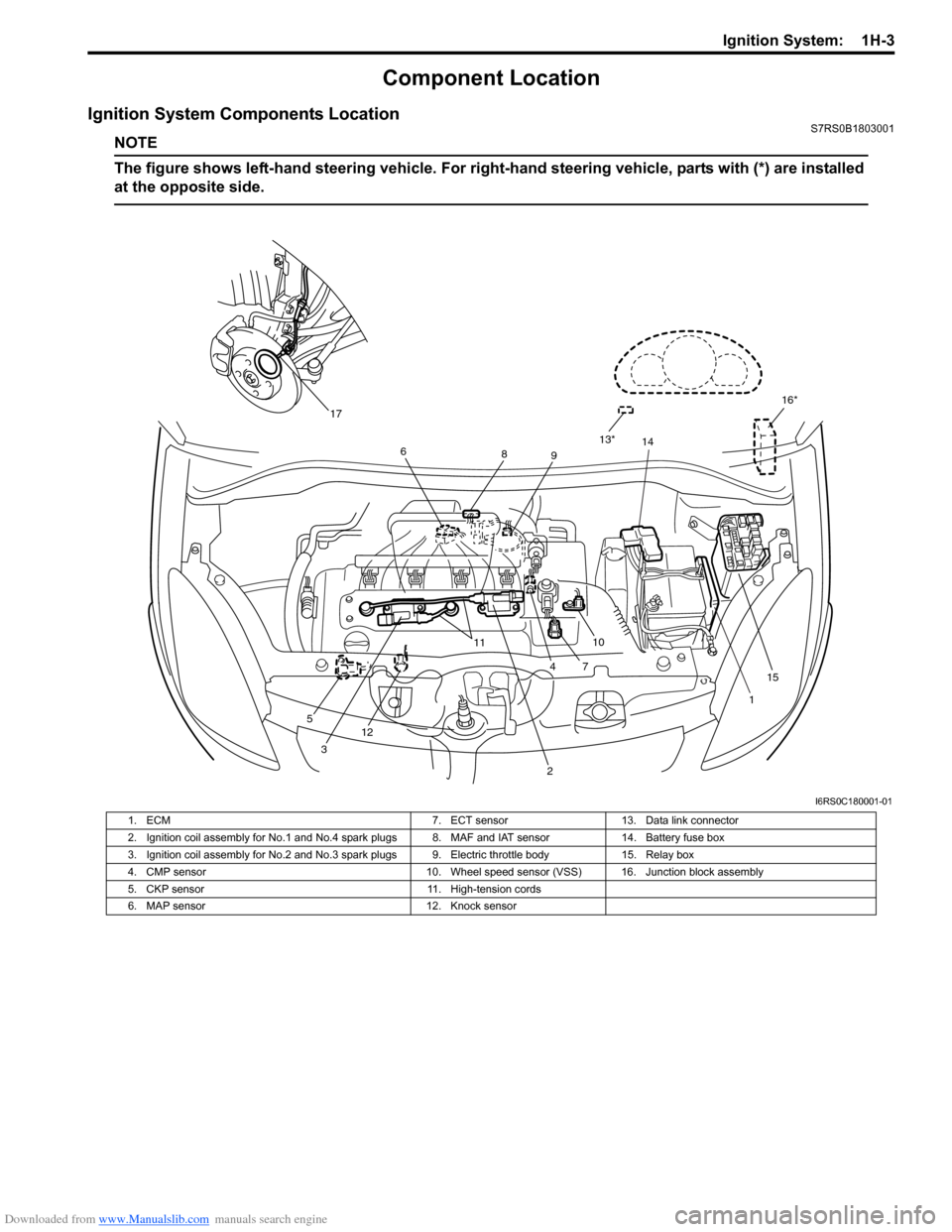

Ignition System Components LocationS7RS0B1803001

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

16*

1

2

14

7

5 12 11

410

6

89

3 13*

15

17

I6RS0C180001-01

1. ECM 7. ECT sensor13. Data link connector

2. Ignition coil assembly for No.1 and No.4 spark plugs 8. MAF and IAT sensor 14. Battery fuse box

3. Ignition coil assembly for No.2 and No.3 spark plugs 9. Electric throttle body 15. Relay box

4. CMP sensor 10. Wheel speed sensor (VSS) 16. Junction block assembly

5. CKP sensor 11. High-tension cords

6. MAP sensor 12. Knock sensor

Page 396 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-4 Ignition System:

Diagnostic Information and Procedures

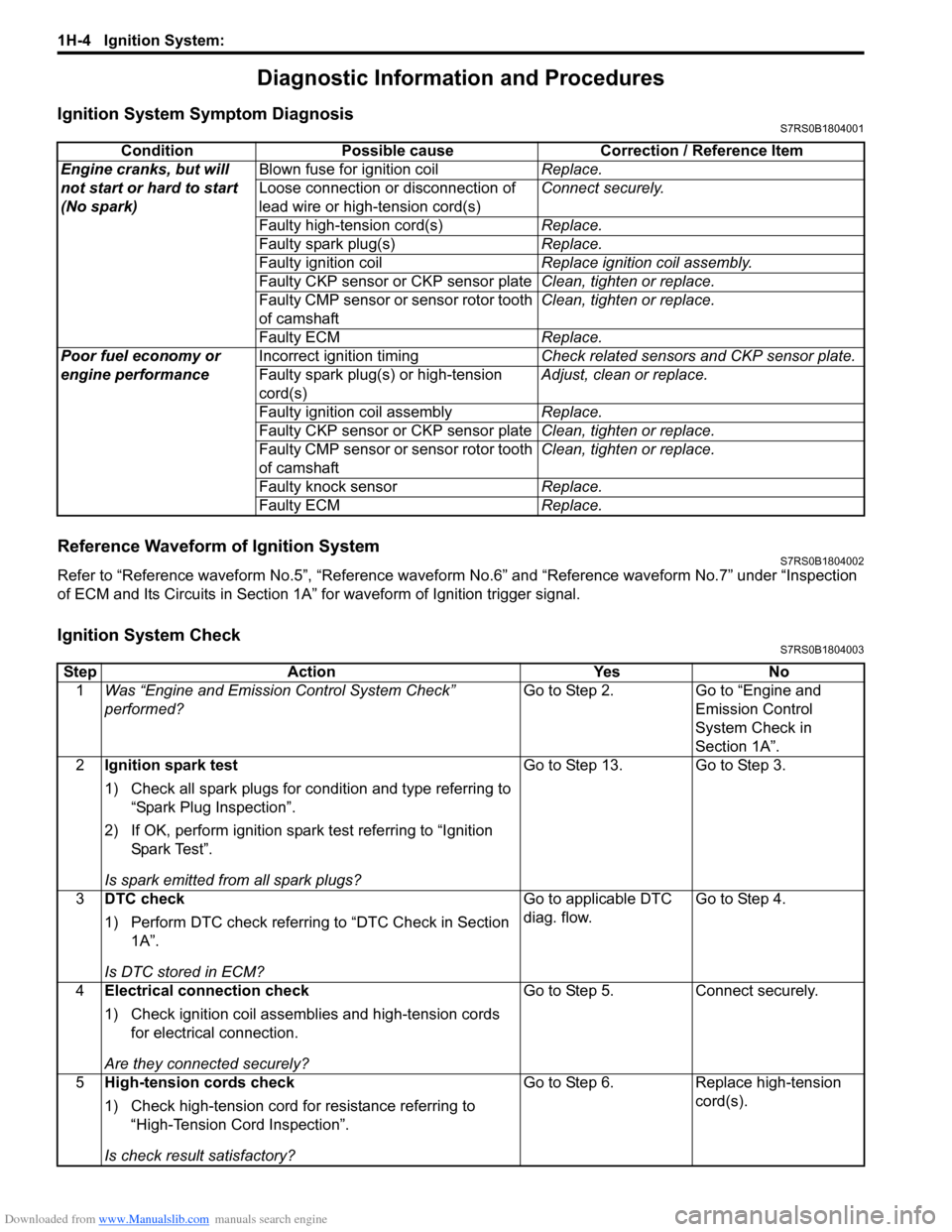

Ignition System Symptom DiagnosisS7RS0B1804001

Reference Waveform of Ignition SystemS7RS0B1804002

Refer to “Reference waveform No.5”, “Reference waveform No.6” and “Reference waveform No.7” under “Inspection

of ECM and Its Circuits in Section 1A” for waveform of Ignition trigger signal.

Ignition System CheckS7RS0B1804003

Condition Possible cause Correction / Reference Item

Engine cranks, but will

not start or hard to start

(No spark) Blown fuse for ignition coil

Replace.

Loose connection or disconnection of

lead wire or high-tension cord(s) Connect securely.

Faulty high-tension cord(s) Replace.

Faulty spark plug(s) Replace.

Faulty ignition coil Replace ignition coil assembly.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty ECM Replace.

Poor fuel economy or

engine performance Incorrect ignition timing

Check related sensors and CKP sensor plate.

Faulty spark plug(s) or high-tension

cord(s) Adjust, clean or replace.

Faulty ignition coil assembly Replace.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty knock sensor Replace.

Faulty ECM Replace.

StepAction YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check in

Section 1A”.

2 Ignition spark test

1) Check all spark plugs for condition and type referring to

“Spark Plug Inspection”.

2) If OK, perform ignition spark test referring to “Ignition Spar k Tes t”.

Is spark emitted from all spark plugs? Go to Step 13. Go to Step 3.

3 DTC check

1) Perform DTC check referring to “DTC Check in Section

1A”.

Is DTC stored in ECM? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Electrical connection check

1) Check ignition coil assemblies and high-tension cords

for electrical connection.

Are they connected securely? Go to Step 5.

Connect securely.

5 High-tension cords check

1) Check high-tension cord for resistance referring to

“High-Tension Cord Inspection”.

Is check result satisfactory? Go to Step 6.

Replace high-tension

cord(s).

Page 397 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-5

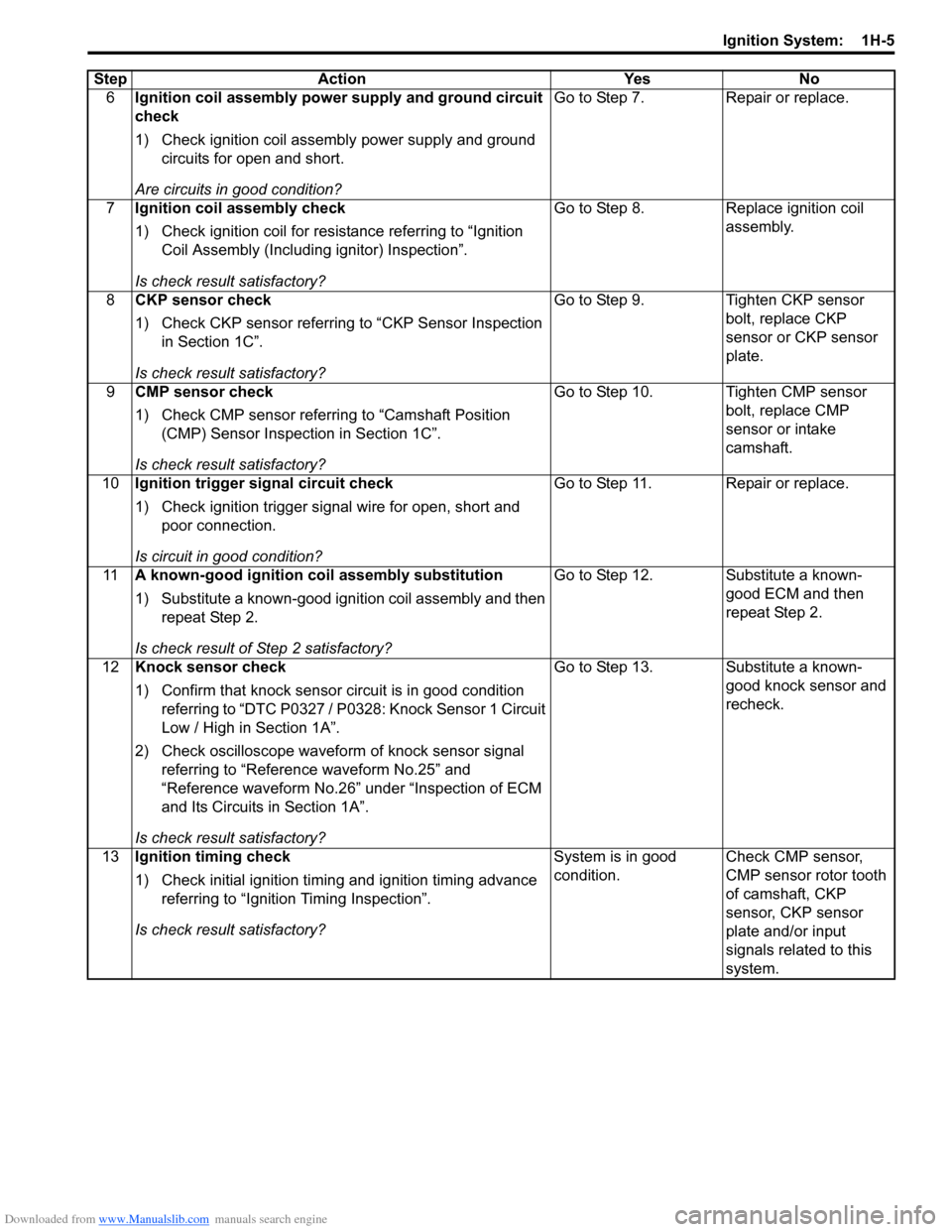

6Ignition coil assembly power supply and ground circuit

check

1) Check ignition coil assembly power supply and ground

circuits for open and short.

Are circuits in good condition? Go to Step 7.

Repair or replace.

7 Ignition coil assembly check

1) Check ignition coil for resistance referring to “Ignition

Coil Assembly (Including ignitor) Inspection”.

Is check result satisfactory? Go to Step 8.

Replace ignition coil

assembly.

8 CKP sensor check

1) Check CKP sensor referring to “CKP Sensor Inspection

in Section 1C”.

Is check result satisfactory? Go to Step 9.

Tighten CKP sensor

bolt, replace CKP

sensor or CKP sensor

plate.

9 CMP sensor check

1) Check CMP sensor referring to “Camshaft Position

(CMP) Sensor Inspection in Section 1C”.

Is check result satisfactory? Go to Step 10. Tighten CMP sensor

bolt, replace CMP

sensor or intake

camshaft.

10 Ignition trigger signal circuit check

1) Check ignition trigger signal wire for open, short and

poor connection.

Is circuit in good condition? Go to Step 11. Repair or replace.

11 A known-good ignition coil assembly substitution

1) Substitute a known-good ignition coil assembly and then

repeat Step 2.

Is check result of Step 2 satisfactory? Go to Step 12. Substitute a known-

good ECM and then

repeat Step 2.

12 Knock sensor check

1) Confirm that knock sensor circuit is in good condition

referring to “DTC P0327 / P0328: Knock Sensor 1 Circuit

Low / High in Section 1A”.

2) Check oscilloscope waveform of knock sensor signal

referring to “Reference waveform No.25” and

“Reference waveform No.26” under “Inspection of ECM

and Its Circuits in Section 1A”.

Is check result satisfactory? Go to Step 13. Substitute a known-

good knock sensor and

recheck.

13 Ignition timing check

1) Check initial ignition timing and ignition timing advance

referring to “Ignition Timing Inspection”.

Is check result satisfactory? System is in good

condition.

Check CMP sensor,

CMP sensor rotor tooth

of camshaft, CKP

sensor, CKP sensor

plate and/or input

signals related to this

system.

Step

Action YesNo

Page 401 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-9

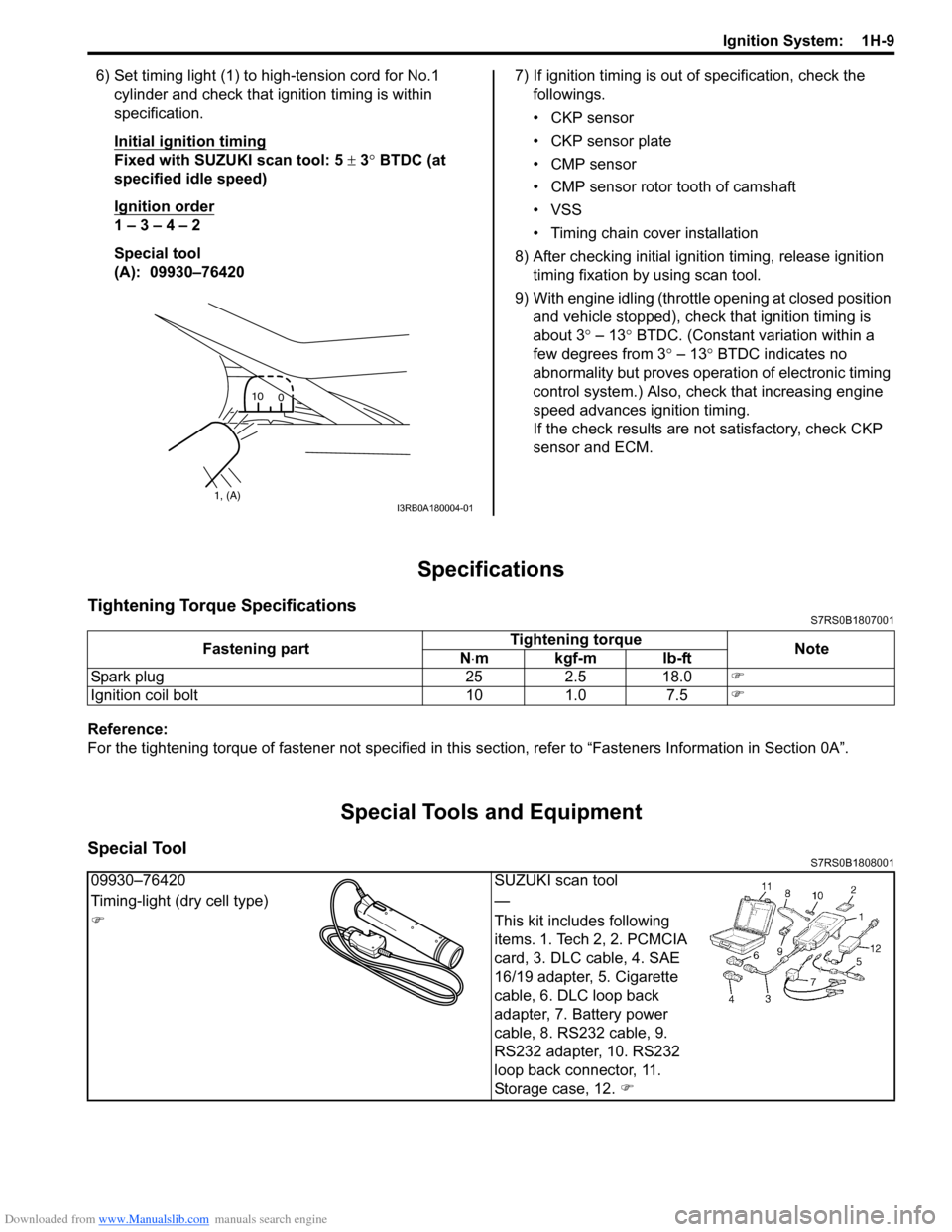

6) Set timing light (1) to high-tension cord for No.1 cylinder and check that ignition timing is within

specification.

Initial ignition timing

Fixed with SUZUKI scan tool: 5 ± 3° BTDC (at

specified idle speed)

Ignition order

1 – 3 – 4 – 2

Special tool

(A): 09930–76420 7) If ignition timing is out

of specification, check the

followings.

• CKP sensor

• CKP sensor plate

• CMP sensor

• CMP sensor rotor tooth of camshaft

• VSS

• Timing chain cover installation

8) After checking initial igniti on timing, release ignition

timing fixation by using scan tool.

9) With engine idling (throttl e opening at closed position

and vehicle stopped), check that ignition timing is

about 3 ° – 13° BTDC. (Constant variation within a

few degrees from 3 ° – 13° BTDC indicates no

abnormality but proves operation of electronic timing

control system.) Also, check that increasing engine

speed advances ignition timing.

If the check results are not satisfactory, check CKP

sensor and ECM.

Specifications

Tightening Torque SpecificationsS7RS0B1807001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B1808001

1, (A)10

0I3RB0A180004-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Spark plug 25 2.5 18.0 �)

Ignition coil bolt 10 1.0 7.5 �)

09930–76420SUZUKI scan tool

Timing-light (dry cell type) —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �)

Page 678 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-34 Automatic Transmission/Transaxle:

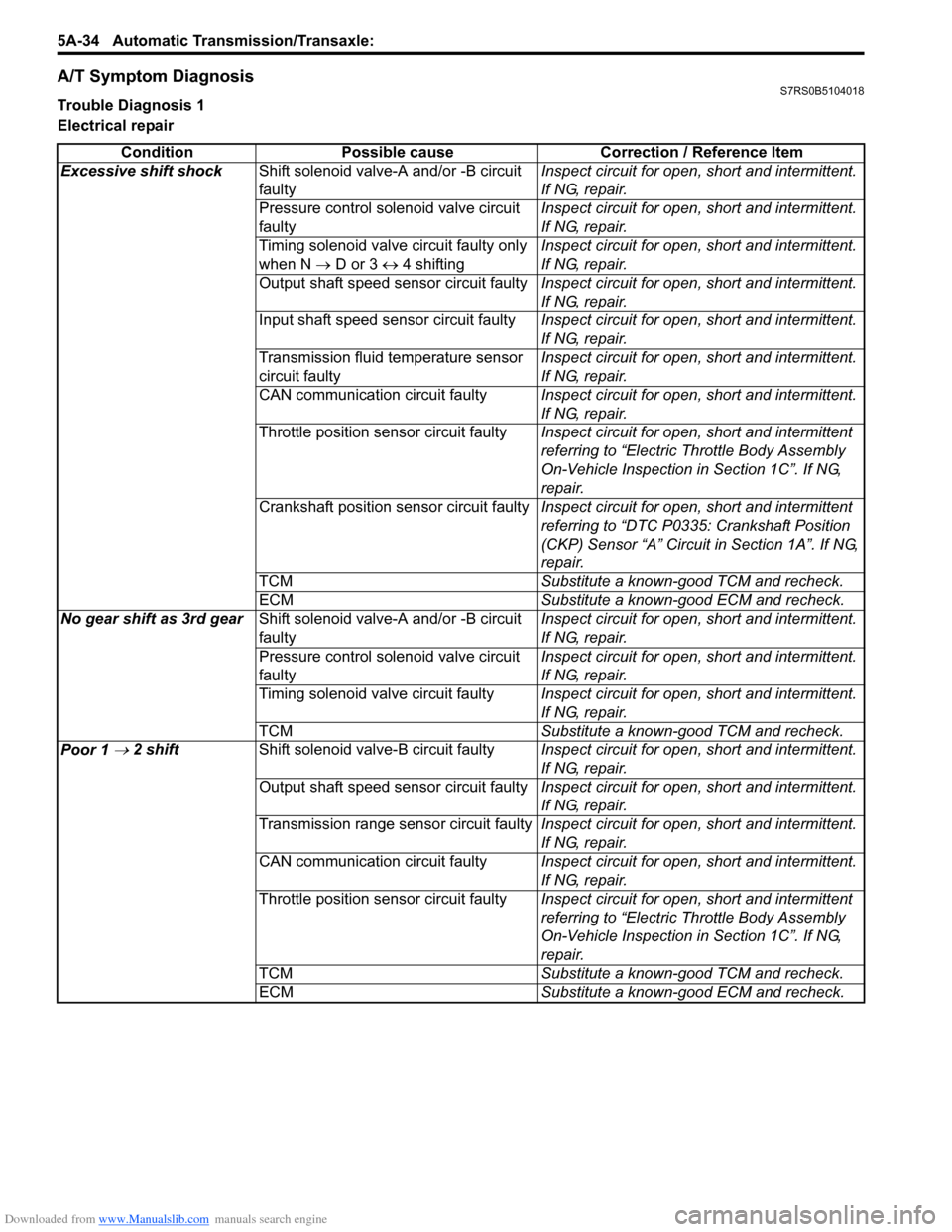

A/T Symptom DiagnosisS7RS0B5104018

Trouble Diagnosis 1

Electrical repair

Condition Possible cause Correction / Reference Item

Excessive shift shock Shift solenoid valve-A and/or -B circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Timing solenoid valve circuit faulty only

when N → D or 3 ↔ 4 shifting Inspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Input shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission fluid temperature sensor

circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “Electric Throttle Body Assembly

On-Vehicle Inspection in Section 1C”. If NG,

repair.

Crankshaft position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “DTC P0335: Crankshaft Position

(CKP) Sensor “A” Circuit in Section 1A”. If NG,

repair.

TCM Substitute a known-good TCM and recheck.

ECM Substitute a known-good ECM and recheck.

No gear shift as 3rd gear Shift solenoid valve-A and/or -B circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Timing solenoid valve circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

TCM Substitute a known-good TCM and recheck.

Poor 1

→ 2 shift Shift solenoid valve-B circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission range sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “Electric Throttle Body Assembly

On-Vehicle Inspection in Section 1C”. If NG,

repair.

TCM Substitute a known-good TCM and recheck.

ECM Substitute a known-good ECM and recheck.

Page 679 of 1496

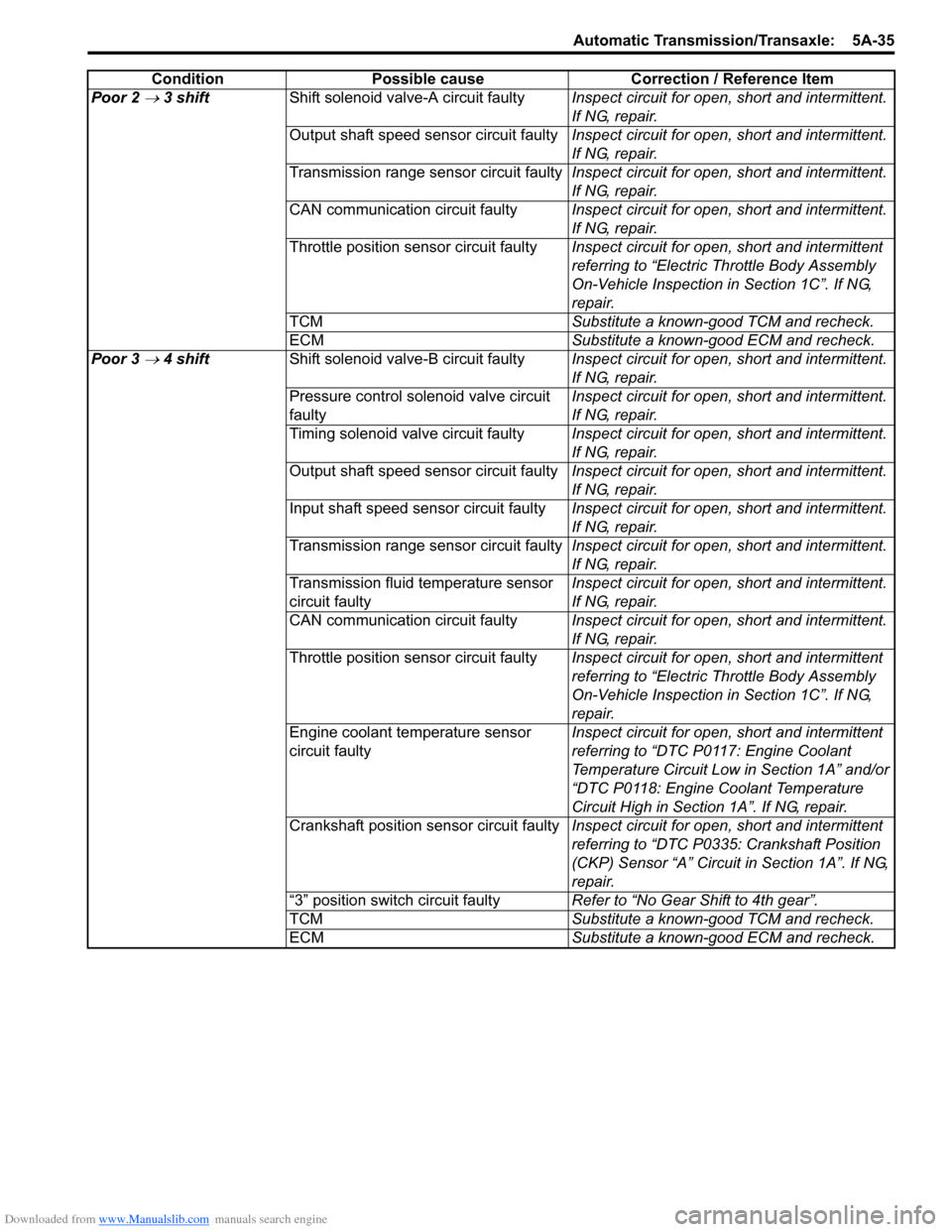

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-35

Poor 2 → 3 shiftShift solenoid valve-A circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission range sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “Electric Throttle Body Assembly

On-Vehicle Inspection in Section 1C”. If NG,

repair.

TCM Substitute a known-good TCM and recheck.

ECM Substitute a known-good ECM and recheck.

Poor 3

→ 4 shift Shift solenoid valve-B circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Timing solenoid valve circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Input shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission range sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission fluid temperature sensor

circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “Electric Throttle Body Assembly

On-Vehicle Inspection in Section 1C”. If NG,

repair.

Engine coolant temperature sensor

circuit faulty Inspect circuit for open, short and intermittent

referring to “DTC P0117: Engine Coolant

Temperature Circuit Low

in Section 1A” and/or

“DTC P0118: Engine Coolant Temperature

Circuit High in Section 1A”. If NG, repair.

Crankshaft position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “DTC P0335: Crankshaft Position

(CKP) Sensor “A” Circuit in Section 1A”. If NG,

repair.

“3” position switch circuit faulty Refer to “No Gear Shift to 4th gear”.

TCM Substitute a known-good TCM and recheck.

ECM Substitute a known-good ECM and recheck.

Condition Possible cause Correction / Reference Item