ACC SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1273 of 1496

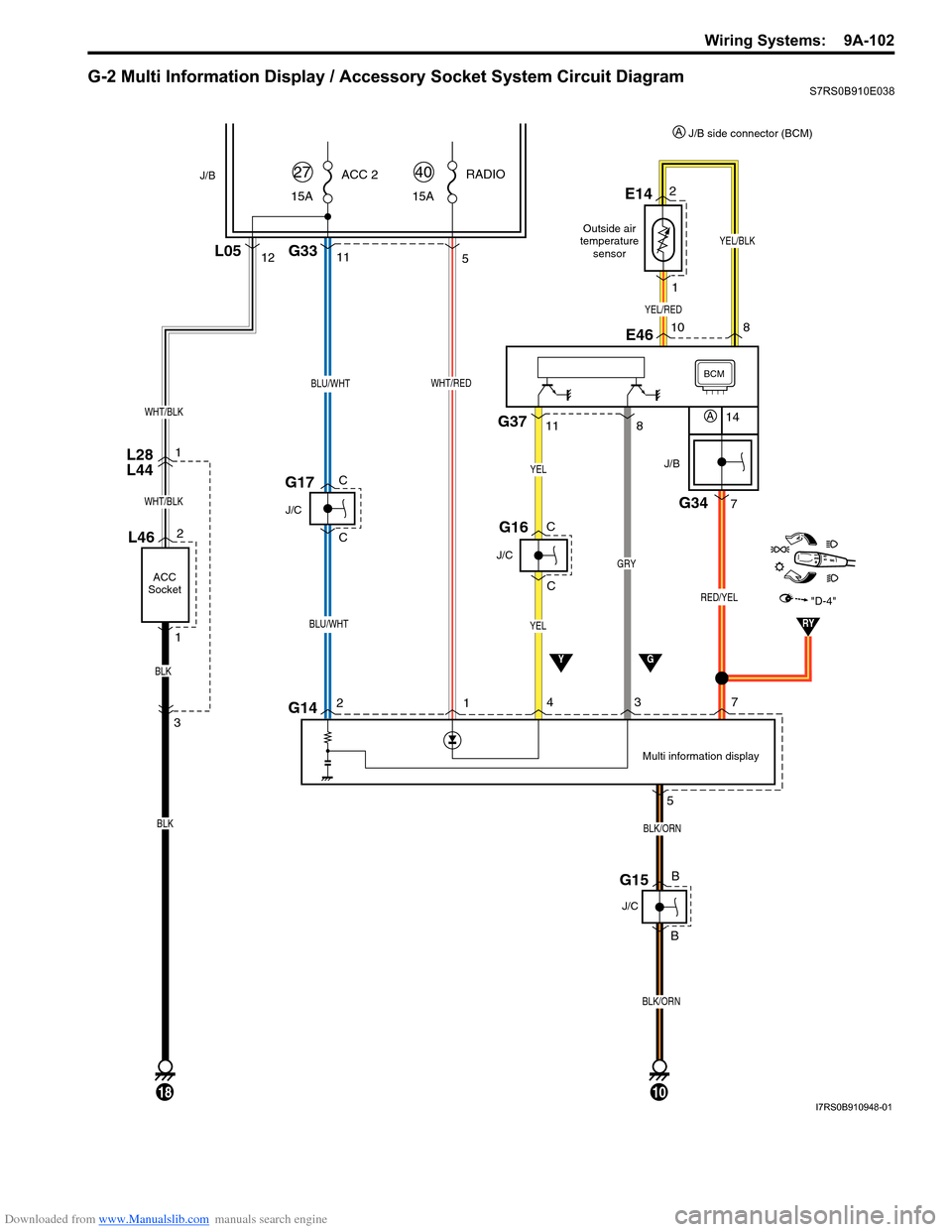

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-102

G-2 Multi Information Display / Accessory Socket System Circuit DiagramS7RS0B910E038

11

BLU/WHT

BLU/WHT

15AACC 2

27

J/C

G17

L28

L44

YG

Multi information display

J/B

BCM

J/B

G34

7

14

RED/YEL

10

BLK/ORN

2

BLK/ORN

15A RADIO

40

G335

WHT/RED

G141

3

J/C

YEL

YEL

G16

4

57

G15

J/C

12L05

WHT/BLK

L46

ACC

Socket

2

1

18

WHT/BLK

BLK

BLK

3 1

C

C

B

B

C

C

GRY

G378

11

"D-4"

RY

YEL/RED

YEL/BLK

2E14

1

8

10E46

A

J/B side connector (BCM)

A

Outside air

temperature sensor

I7RS0B910948-01

Page 1283 of 1496

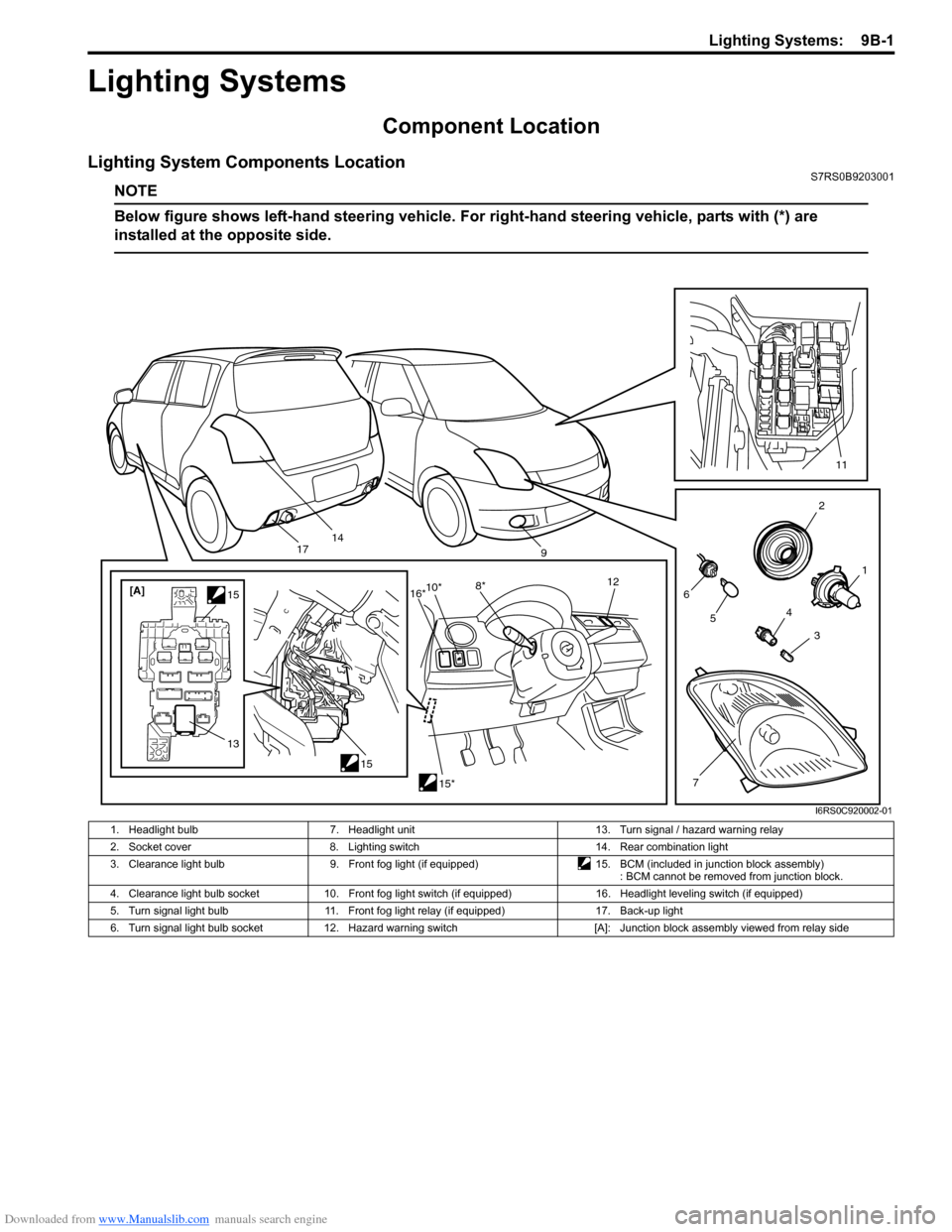

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-1

Body, Cab and Accessories

Lighting Systems

Component Location

Lighting System Components LocationS7RS0B9203001

NOTE

Below figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are

installed at the opposite side.

2

1

3

4

6

14

5

7

11

9

15

[A]

1515*

10*

8* 12

13

16*

17

I6RS0C920002-01

1. Headlight bulb 7. Headlight unit 13. Turn signal / hazard warning relay

2. Socket cover 8. Lighting switch 14. Rear combination light

3. Clearance light bulb 9. Front fog light (if equipped)15. BCM (included in junction block assembly)

: BCM cannot be removed from junction block.

4. Clearance light bulb socket 10. Front fog light switch (if equipped) 16. Headlight leveling switch (if equipped)

5. Turn signal light bulb 11. Front fog light relay (if equipped) 17. Back-up light

6. Turn signal light bulb socket 12. Hazard warning switch [A]: Junction block assembly viewed from relay side

Page 1287 of 1496

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-5

Interior Light Symptom DiagnosisS7RS0B9204008

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Repair Instructions

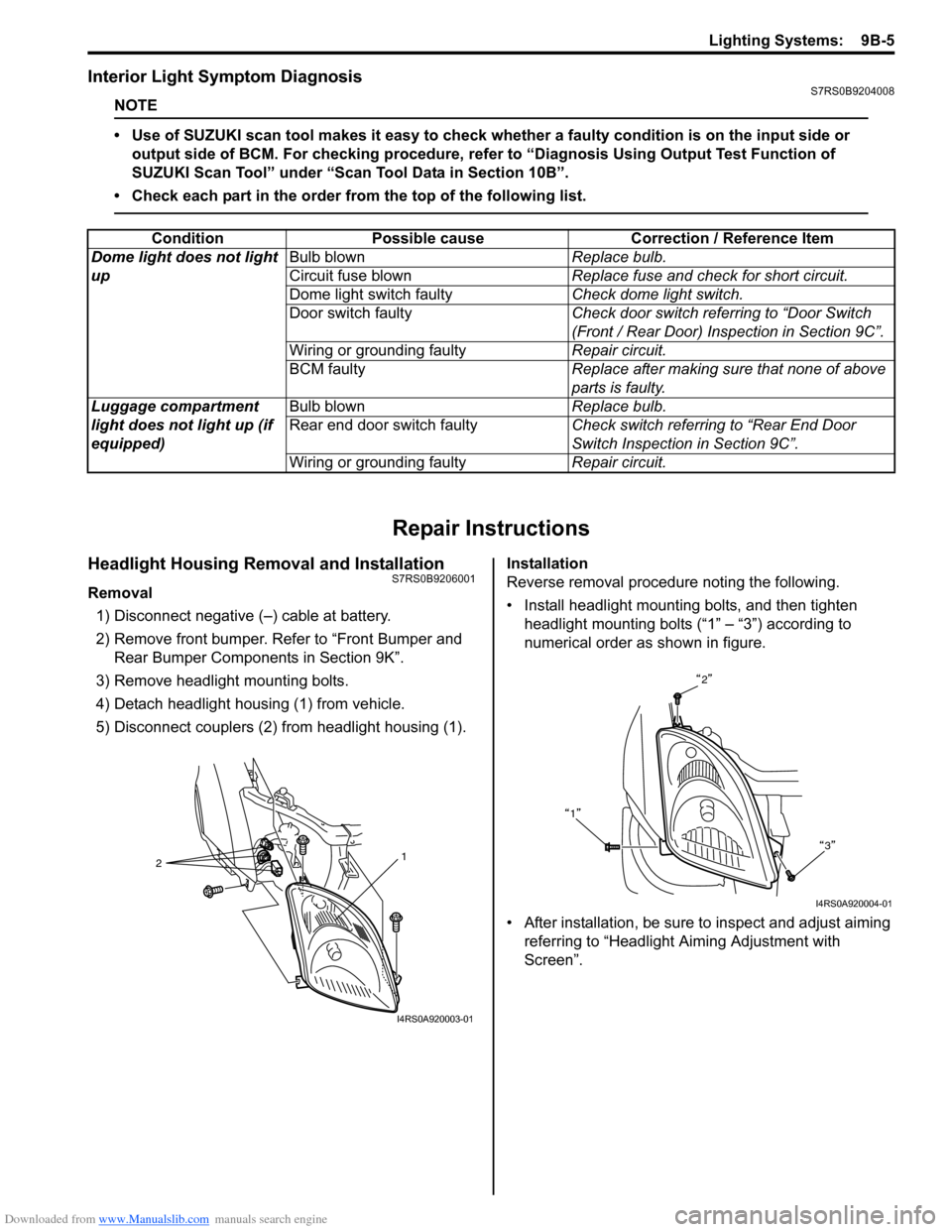

Headlight Housing Removal and InstallationS7RS0B9206001

Removal 1) Disconnect negative (–) cable at battery.

2) Remove front bumper. Refer to “Front Bumper and Rear Bumper Componen ts in Section 9K”.

3) Remove headlight mounting bolts.

4) Detach headlight housing (1) from vehicle.

5) Disconnect couplers (2) from headlight housing (1). Installation

Reverse removal procedure noting the following.

• Install headlight mounting bolts, and then tighten

headlight mounting bolts (“1” – “3”) according to

numerical order as shown in figure.

• After installation, be sure to inspect and adjust aiming referring to “Headlight Aiming Adjustment with

Screen”.

Condition Possible cause Correction / Reference Item

Dome light does not light

up Bulb blown

Replace bulb.

Circuit fuse blown Replace fuse and check for short circuit.

Dome light switch faulty Check dome light switch.

Door switch faulty Check door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Luggage compartment

light does not light up (if

equipped) Bulb blown

Replace bulb.

Rear end door switch faulty Check switch referring to “Rear End Door

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

2 1

I4RS0A920003-01

2

1 3

I4RS0A920004-01

Page 1288 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-6 Lighting Systems:

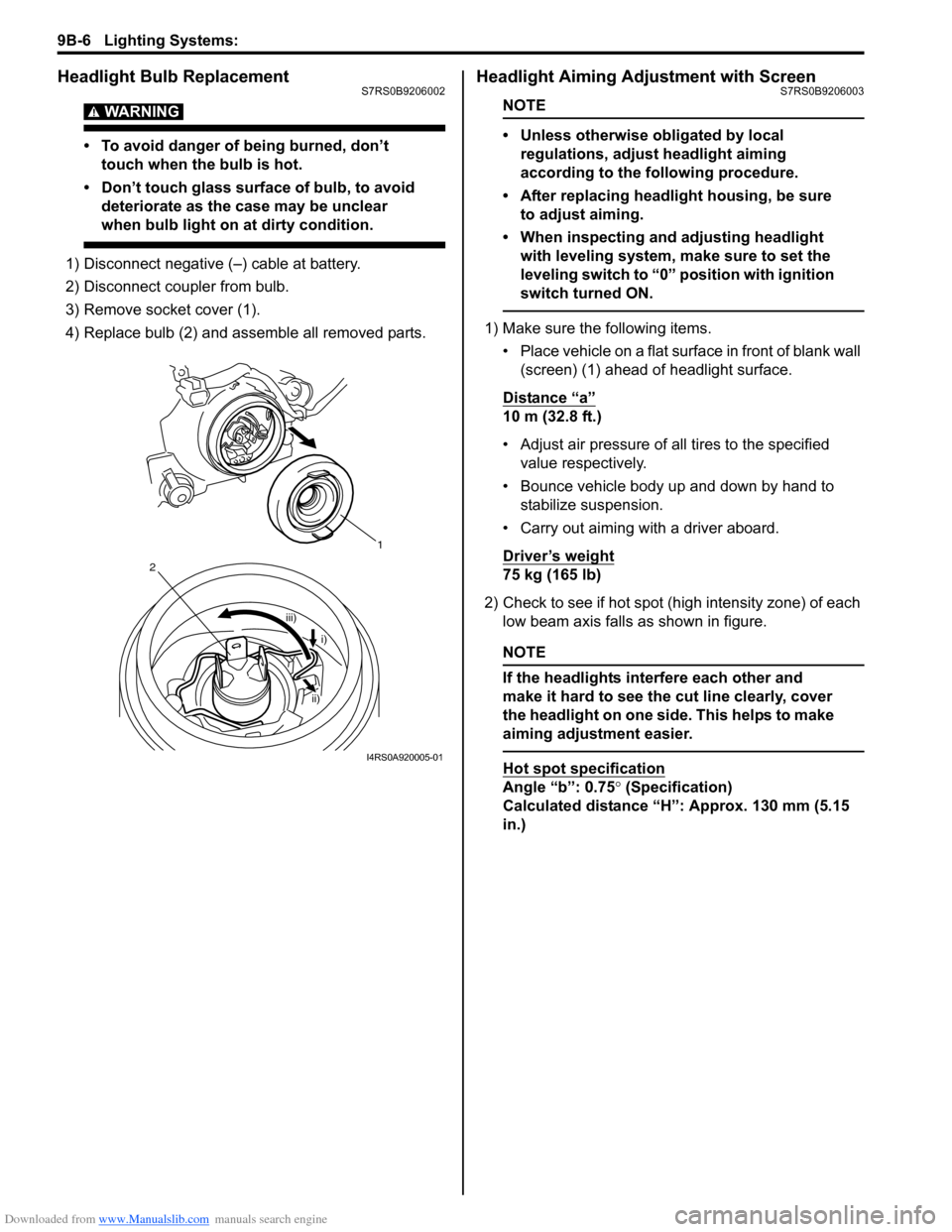

Headlight Bulb ReplacementS7RS0B9206002

WARNING!

• To avoid danger of being burned, don’t touch when the bulb is hot.

• Don’t touch glass surface of bulb, to avoid deteriorate as the case may be unclear

when bulb light on at dirty condition.

1) Disconnect negative (–) cable at battery.

2) Disconnect coupler from bulb.

3) Remove socket cover (1).

4) Replace bulb (2) and assemble all removed parts.

Headlight Aiming Adjustment with ScreenS7RS0B9206003

NOTE

• Unless otherwise obligated by local regulations, adjust headlight aiming

according to the following procedure.

• After replacing headlight housing, be sure to adjust aiming.

• When inspecting and adjusting headlight with leveling system, make sure to set the

leveling switch to “0 ” position with ignition

switch turned ON.

1) Make sure the following items.

• Place vehicle on a flat surface in front of blank wall (screen) (1) ahead of headlight surface.

Distance “a”

10 m (32.8 ft.)

• Adjust air pressure of all tires to the specified value respectively.

• Bounce vehicle body up and down by hand to stabilize suspension.

• Carry out aiming with a driver aboard.

Driver’s weight

75 kg (165 lb)

2) Check to see if hot spot (high intensity zone) of each low beam axis falls as shown in figure.

NOTE

If the headlights interfere each other and

make it hard to see the cut line clearly, cover

the headlight on one side. This helps to make

aiming adjustment easier.

Hot spot specification

Angle “b”: 0.75 ° (Specification)

Calculated distance “H”: Approx. 130 mm (5.15

in.)

1

iii)

2

i)

ii)

I4RS0A920005-01

Page 1290 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-8 Lighting Systems:

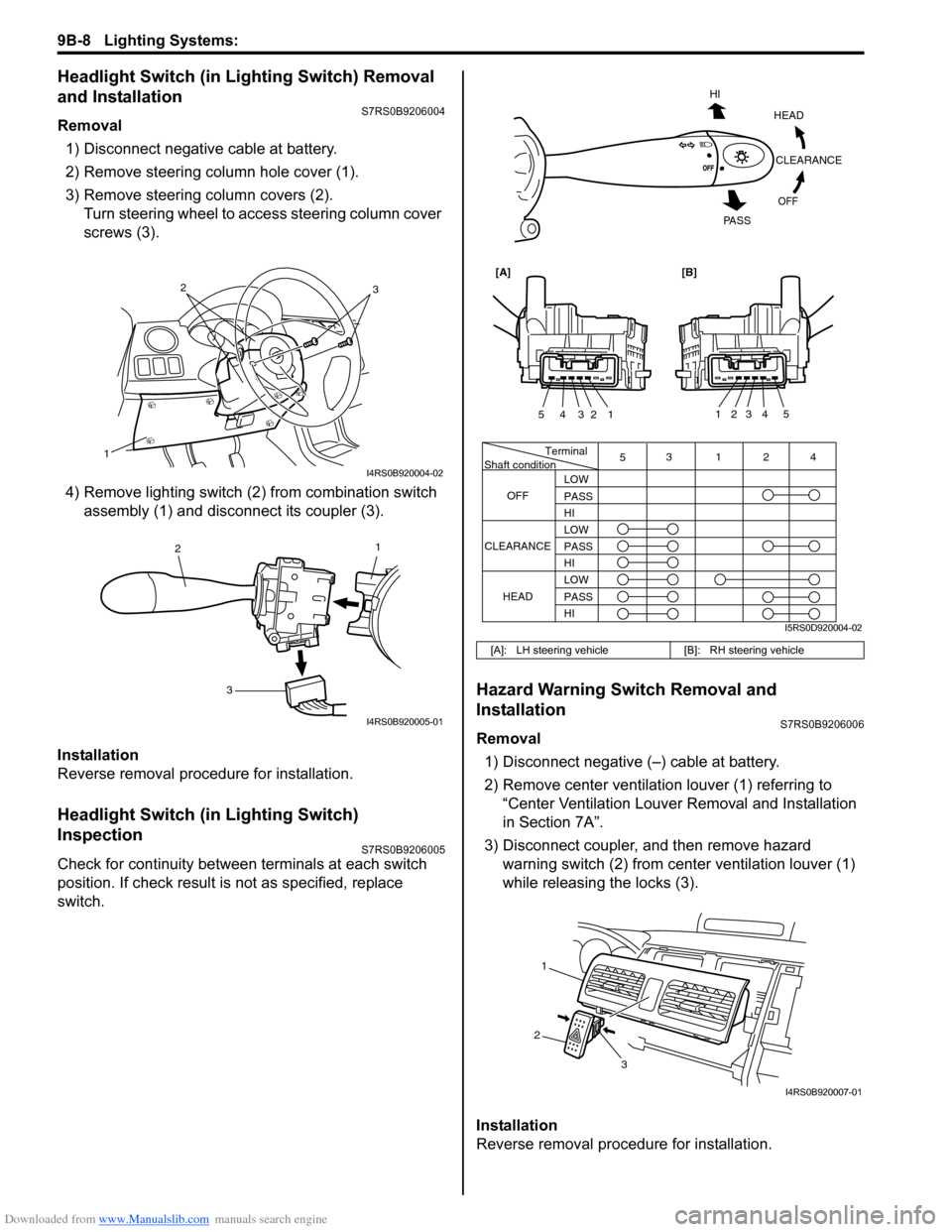

Headlight Switch (in Lighting Switch) Removal

and Installation

S7RS0B9206004

Removal1) Disconnect negative cable at battery.

2) Remove steering column hole cover (1).

3) Remove steering column covers (2). Turn steering wheel to acce ss steering column cover

screws (3).

4) Remove lighting switch (2 ) from combination switch

assembly (1) and disconnect its coupler (3).

Installation

Reverse removal procedure for installation.

Headlight Switch (in Lighting Switch)

Inspection

S7RS0B9206005

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Hazard Warning Switch Removal and

Installation

S7RS0B9206006

Removal 1) Disconnect negative (–) cable at battery.

2) Remove center ventilation louver (1) referring to

“Center Ventilation Louver Removal and Installation

in Section 7A”.

3) Disconnect coupler, and then remove hazard warning switch (2) from center ventilation louver (1)

while releasing the locks (3).

Installation

Reverse removal procedure for installation.

1

32

I4RS0B920004-02

1

2

3

I4RS0B920005-01

[A]: LH steering vehicle [B]: RH steering vehicle

Terminal

Shaft condition

OFF 5

3124

LOW

PASS

HI

LOW

PASS

HI LOW

PASS

HI

CLEARANCE

HEAD

HEADCLEARANCE

OFF

HI

PA S S

54321

54321

[A][B]

I5RS0D920004-02

1

2 3

I4RS0B920007-01

Page 1294 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-12 Lighting Systems:

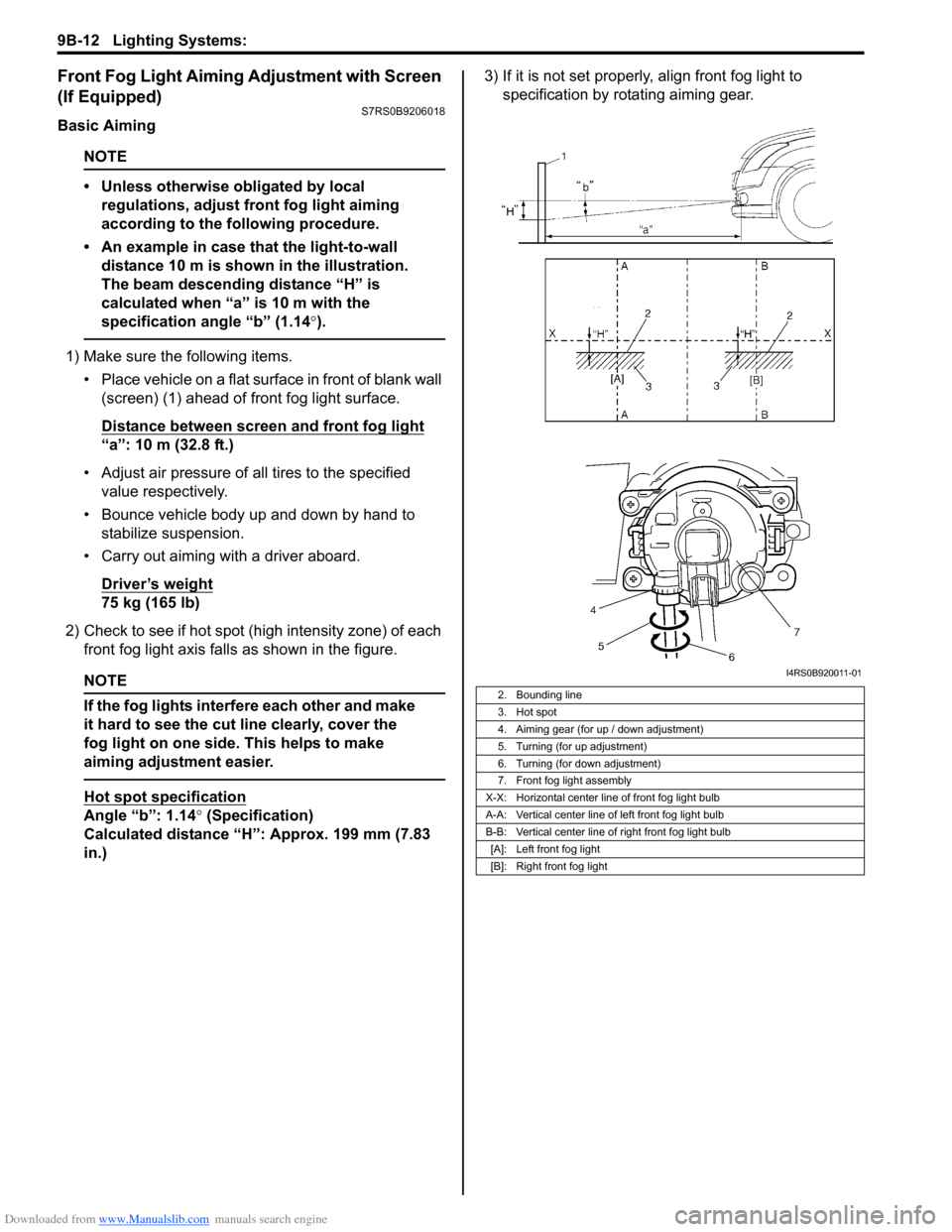

Front Fog Light Aiming Adjustment with Screen

(If Equipped)

S7RS0B9206018

Basic Aiming

NOTE

• Unless otherwise obligated by local regulations, adjust front fog light aiming

according to the following procedure.

• An example in case that the light-to-wall distance 10 m is shown in the illustration.

The beam descending distance “H” is

calculated when “a” is 10 m with the

specification angle “b” (1.14 °).

1) Make sure the following items.

• Place vehicle on a flat surface in front of blank wall (screen) (1) ahead of front fog light surface.

Distance between screen and front fog light

“a”: 10 m (32.8 ft.)

• Adjust air pressure of all tires to the specified value respectively.

• Bounce vehicle body up and down by hand to stabilize suspension.

• Carry out aiming with a driver aboard.

Driver’s weight

75 kg (165 lb)

2) Check to see if hot spot (h igh intensity zone) of each

front fog light axis falls as shown in the figure.

NOTE

If the fog lights interfere each other and make

it hard to see the cut line clearly, cover the

fog light on one side. This helps to make

aiming adjustment easier.

Hot spot specification

Angle “b”: 1.14° (Specification)

Calculated distance “H”: Approx. 199 mm (7.83

in.) 3) If it is not set properly

, align front fog light to

specification by rotating aiming gear.

2. Bounding line

3. Hot spot

4. Aiming gear (for up / down adjustment)

5. Turning (for up adjustment)

6. Turning (for down adjustment)

7. Front fog light assembly

X-X: Horizontal center line of front fog light bulb

A-A: Vertical center line of left front fog light bulb

B-B: Vertical center line of right front fog light bulb [A]: Left front fog light

[B]: Right front fog light

I4RS0B920011-01

Page 1296 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-1 Instrumentation / Driver Info. / Horn:

Body, Cab and Accessories

Instrumentation / Driver Info. / Horn

Precautions

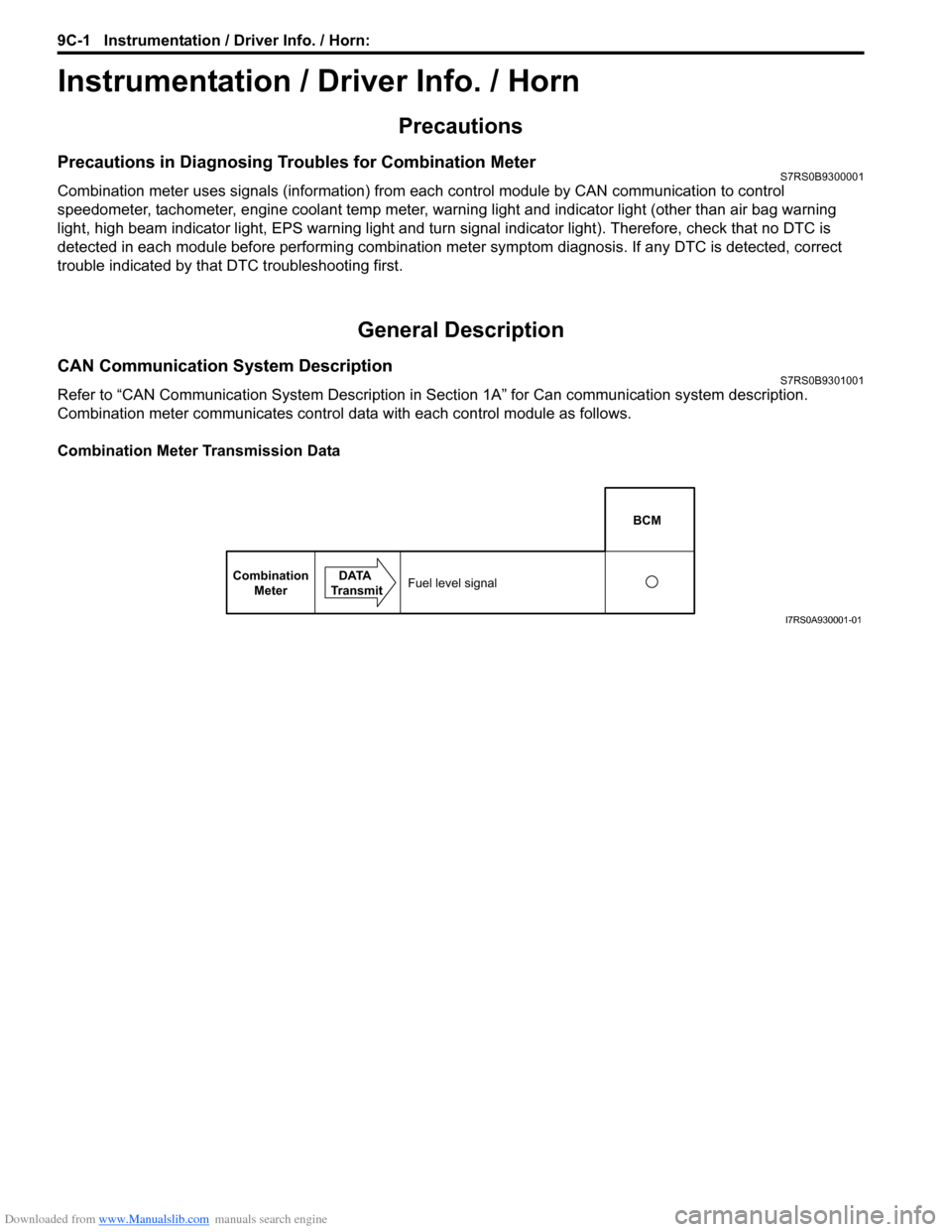

Precautions in Diagnosing Troubles for Combination MeterS7RS0B9300001

Combination meter uses signals (information) from each control module by CAN communication to control

speedometer, tachometer, engine coolant temp meter, warning light and indicator light (other than air bag warning

light, high beam indicator light, EPS warn ing light and turn signal indicator light). Therefore, check that no DTC is

detected in each module before performing combination me ter symptom diagnosis. If any DTC is detected, correct

trouble indicated by that DTC troubleshooting first.

General Description

CAN Communication System DescriptionS7RS0B9301001

Refer to “CAN Communication System Description in Section 1A” for Can communication system description.

Combination meter communicates control data with each control module as follows.

Combination Meter Transmission Data

BCM

Combination Meter DATA

TransmitFuel level signal

I7RS0A930001-01

Page 1298 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-3 Instrumentation / Driver Info. / Horn:

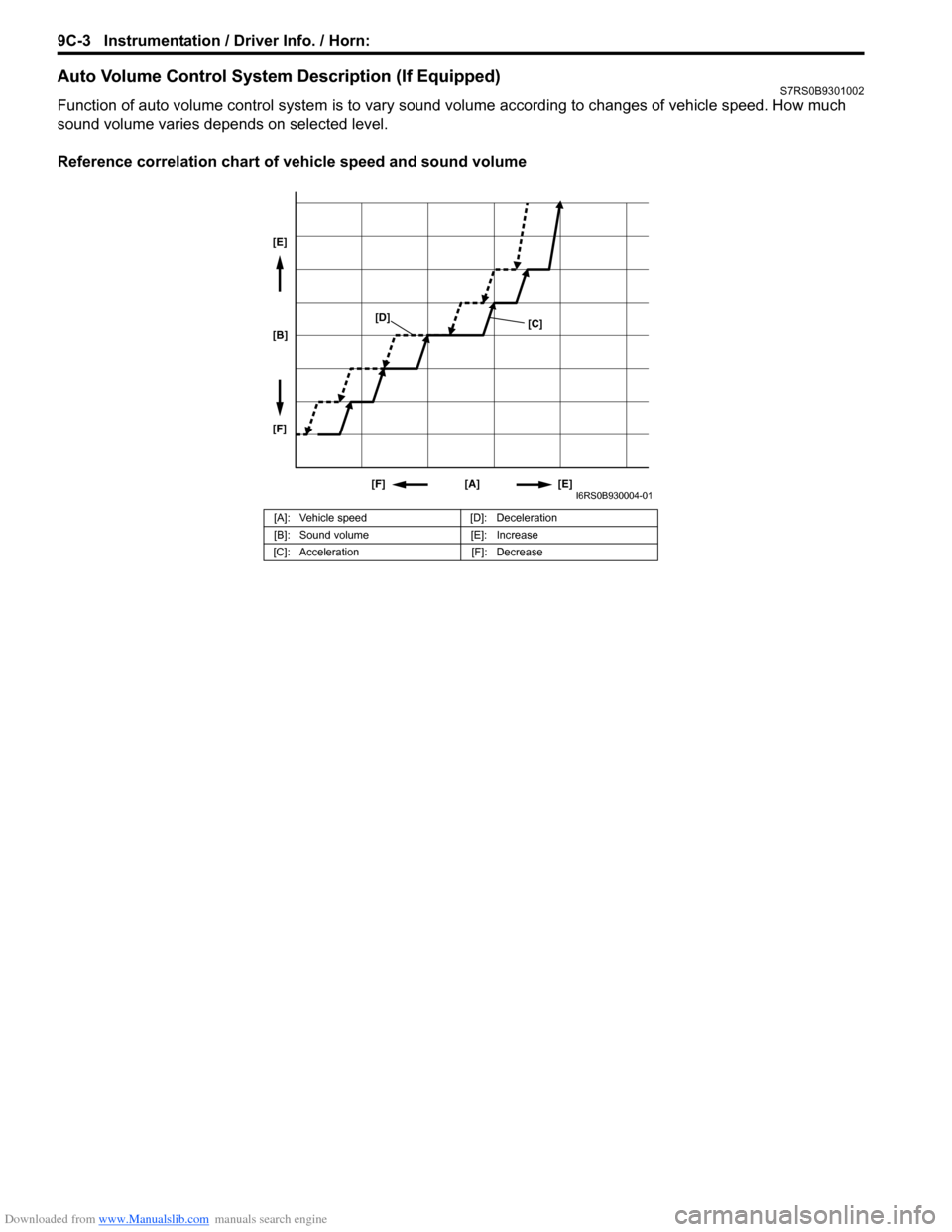

Auto Volume Control System Description (If Equipped)S7RS0B9301002

Function of auto volume control system is to vary sound volume according to changes of vehicle speed. How much

sound volume varies depends on selected level.

Reference correlation chart of vehicle speed and sound volume

[A]: Vehicle speed [D]: Deceleration

[B]: Sound volume [E]: Increase

[C]: Acceleration [F]: Decrease

[A][E]

[F]

[B] [E]

[F]

[C]

[D]

I6RS0B930004-01

Page 1308 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-13 Instrumentation / Driver Info. / Horn:

CD Player

Auto Volume Control System

Remote Audio Control Switch Symptom Diagnosis (If Equipped)S7RS0B9304018

ConditionPossible cause Correction / Reference Item

CD-ROM does not insert Another CD-ROM already inserted Eject CD-ROM.

Circuit fuse blown Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Extraneous material come to be mixed

CD player Clear extraneous material from CD player or

replace radio assembly.

Radio assembly faulty Replace radio assembly.

CD-ROM does not eject Circuit fuse blown Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Extraneous material come to be mixed

in CD player Clear extraneous material from CD player or

replace radio assembly.

Radio assembly faulty Replace radio assembly.

CD player does not load

CD-ROM CD-ROM faulty

—

CD-ROM inserted wit h incorrect side upInsert correctly.

Temperature in cabin is too hot —

Water droplets form on internal lens Dry about 1 hour with power on.

Radio assembly faulty Replace radio assembly.

Sound skips or is noisy CD-ROM faulty —

Driving vibration —

Water droplets form on internal lens Dry about 1 hour with power on.

Radio assembly installed incorrectly Install correctly.

Radio assembly faulty Replace radio assembly.

CD player is operative,

but all speakers does not

sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Individual speaker is

noisy or inoperative Wiring and/or grounding faulty

Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.

Sound quality or volume

is poor CD-ROM faulty

—

Wiring and/or grounding faulty Repair as necessary.

Speaker installed incorrectly Install correctly.

Speaker faulty Replace speaker.

ConditionPossible cause Correction / Reference Item

Sound volume does not

vary according to

changes of vehicle speed Auto volume control system is “OFF”

mode

Select auto volume control.

Vehicle speed signal faulty Check vehicle speed signal referring to

“Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped)”.

Wiring and/or grounding faulty Repair as necessary.

ECM faulty Check input and output signal of ECM referring

to “Inspection of ECM and Its Circuits in

Section 1A”

Radio assembly faulty Replace radio assembly.

ConditionPossible cause Correction / Reference Item

Audio system is

operative, but remote

control switch does not

control audio system Remote audio control switch faulty

Check remote audio control switch referring to

“Remote Audio Control Switch Inspection (If

Equipped)”.

Contact coil faulty Replace contact coil.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Page 1309 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-14

Navigation Symptom Diagnosis (If Equipped)S7RS0B9304019

Repair Instructions

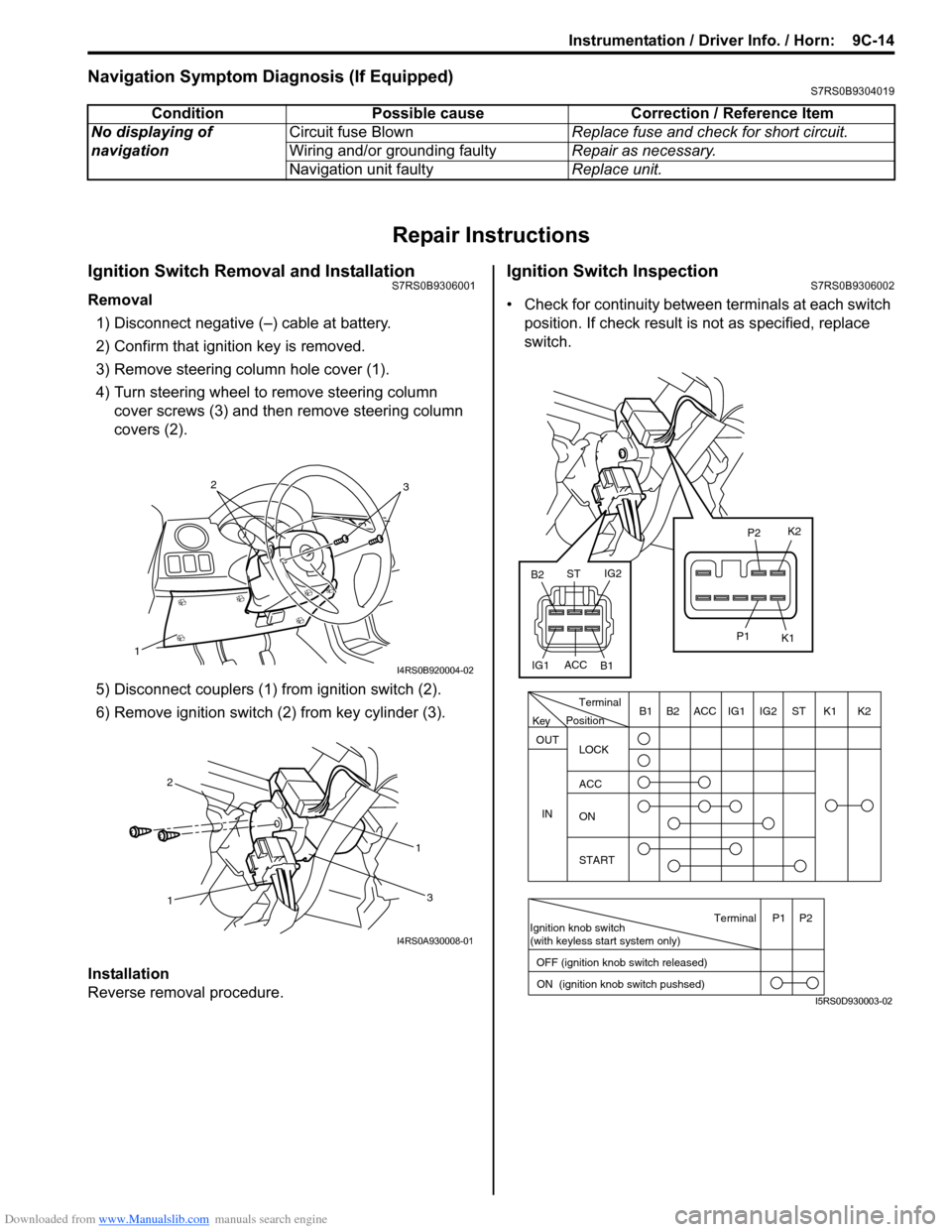

Ignition Switch Removal and InstallationS7RS0B9306001

Removal

1) Disconnect negative (–) cable at battery.

2) Confirm that ignition key is removed.

3) Remove steering column hole cover (1).

4) Turn steering wheel to remove steering column cover screws (3) and then remove steering column

covers (2).

5) Disconnect couplers (1) from ignition switch (2).

6) Remove ignition switch (2) from key cylinder (3).

Installation

Reverse removal procedure.

Ignition Switch InspectionS7RS0B9306002

• Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Condition Possible cause Correction / Reference Item

No displaying of

navigation Circuit fuse Blown

Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Navigation unit faulty Replace unit.

1

32

I4RS0B920004-02

1 1

2

3

I4RS0A930008-01

PositionTerminal

LOCK

ACC

ON

START

OUT

INK2K1ST

IG2

IG1

ACC

B1 B2

Ignition knob switch

(with keyless start system only)

ACC

IG1 IG2

ST

B2

B1 K2

K1

P2

P1

Terminal

OFF (ignition knob switch released) ON (ignition knob switch pushsed)P1 P2

Key

I5RS0D930003-02