100 SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 792 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-148 Automatic Transmission/Transaxle:

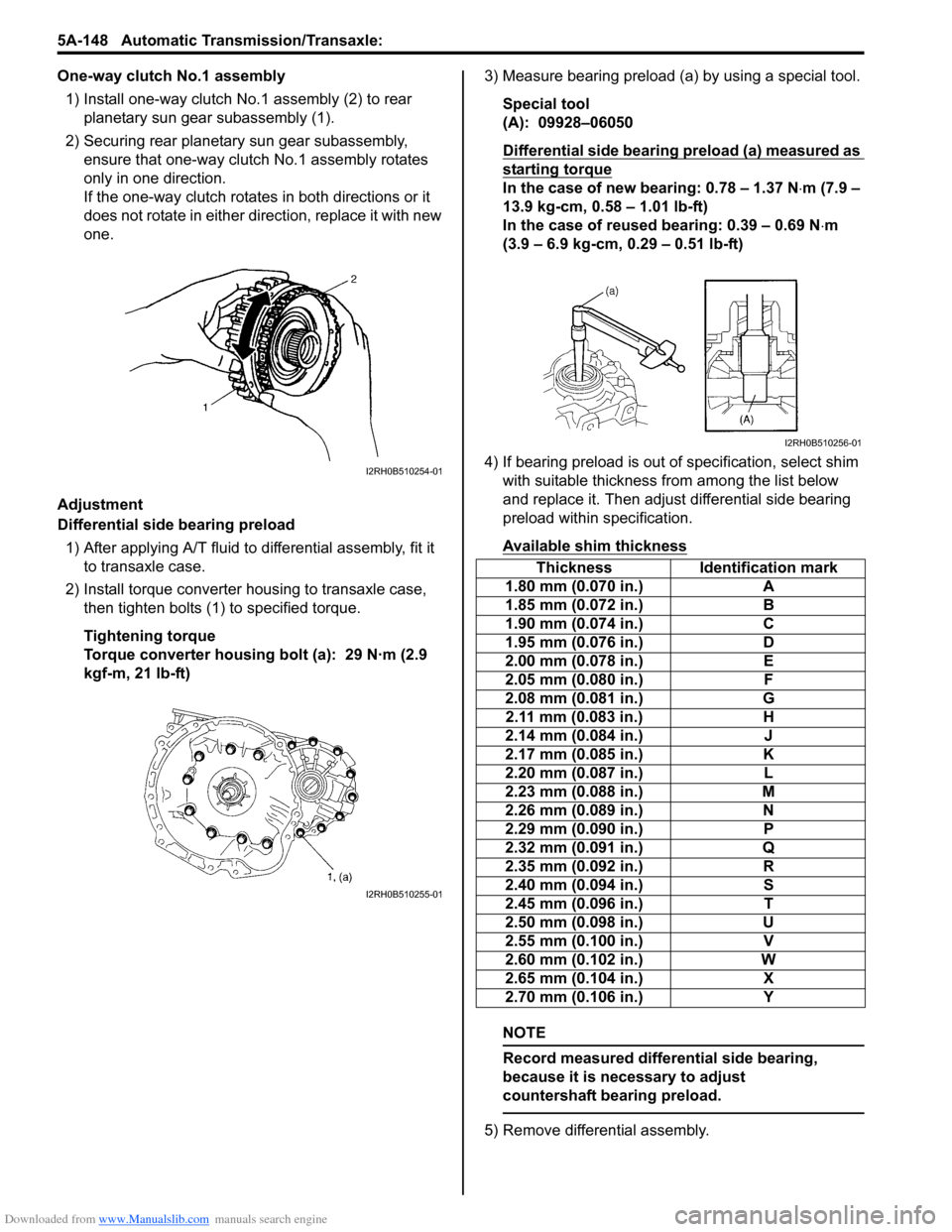

One-way clutch No.1 assembly1) Install one-way clutch No.1 assembly (2) to rear planetary sun gear subassembly (1).

2) Securing rear planetary sun gear subassembly, ensure that one-way clutch No.1 assembly rotates

only in one direction.

If the one-way clutch rotates in both directions or it

does not rotate in either direction, replace it with new

one.

Adjustment

Differential side bearing preload 1) After applying A/T fluid to differential assembly, fit it to transaxle case.

2) Install torque converter housing to transaxle case, then tighten bolts (1) to specified torque.

Tightening torque

Torque converter housing bolt (a): 29 N·m (2.9

kgf-m, 21 lb-ft) 3) Measure bearing preload (a) by using a special tool.

Special tool

(A): 09928–06050

Differential side bearing preload (a) measured as

starting torque

In the case of new bearing: 0.78 – 1.37 N ⋅m (7.9 –

13.9 kg-cm, 0.58 – 1.01 lb-ft)

In the case of reused bearing: 0.39 – 0.69 N ⋅m

(3.9 – 6.9 kg-cm, 0.29 – 0.51 lb-ft)

4) If bearing preload is out of specification, select shim with suitable thickness from among the list below

and replace it. Then adjust differential side bearing

preload within specification.

Available shim thickness

NOTE

Record measured differential side bearing,

because it is necessary to adjust

countershaft bearing preload.

5) Remove differential assembly.

I2RH0B510254-01

I2RH0B510255-01

Thickness Identification mark

1.80 mm (0.070 in.) A

1.85 mm (0.072 in.) B

1.90 mm (0.074 in.) C

1.95 mm (0.076 in.) D

2.00 mm (0.078 in.) E

2.05 mm (0.080 in.) F

2.08 mm (0.081 in.) G

2.11 mm (0.083 in.) H

2.14 mm (0.084 in.) J

2.17 mm (0.085 in.) K

2.20 mm (0.087 in.) L

2.23 mm (0.088 in.) M

2.26 mm (0.089 in.) N

2.29 mm (0.090 in.) P

2.32 mm (0.091 in.) Q

2.35 mm (0.092 in.) R

2.40 mm (0.094 in.) S

2.45 mm (0.096 in.) T

2.50 mm (0.098 in.) U

2.55 mm (0.100 in.) V

2.60 mm (0.102 in.) W

2.65 mm (0.104 in.) X

2.70 mm (0.106 in.) Y

I2RH0B510256-01

Page 793 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-149

Countershaft bearing preload1) After applying A/T fluid to countershaft assembly (1) and differential assembly (2), fit them.

2) Install torque converter housing to transaxle case, then tighten bolts to specified torque.

Tightening torque

Torque converter housing bolt: 29 N·m (2.9 kgf-

m, 21 lb-ft)

3) Measure bearing preload (b) by using special tool. Special tool

(A): 09928–06050

Countershaft bearing preload (b) measured as

starting torque

In the case of new bearing: 0.33 – 0.96 N⋅ m (3.3 –

9.8 kg-cm, 0.24 – 0.69 lb-ft)

In the case of reused bearing: 0.17 – 0.38 N ⋅m

(1.7 – 3.8 kg-cm, 0.12 – 0.28 lb-ft) 4) If bearing preload is out of specification, select shim

with suitable thickness from among the list below

and replace it. Then adjust countershaft bearing

preload within specification.

Available shim thickness

5) Remove differential assembly and countershaft assembly.

Countershaft bearing

preload =(b) – Differential side bearing

preload (a)

I2RH0B510257-01

I3RM0B510067-01

Thickness Identification mark

1.70 (0.066 in.) 1

1.75 (0.068 in.) 2

1.80 (0.070 in.) 3

1.85 (0.072 in.) 4

1.90 (0.074 in.) 5

1.93 (0.075 in.) 6

1.96 (0.077 in.) 7

1.99 (0.078 in.) A

2.02 (0.079 in.) B

2.05 (0.080 in.) C

2.08 (0.081 in.) D

2.11 (0.083 in.) E

2.14 (0.084 in.) F

2.17 (0.085 in.) G

2.20 (0.086 in.) H

2.25 (0.088 in.) K

2.30 (0.090 in.) L

2.35 (0.092 in.) M

2.40 (0.094 in.) N

2.45 (0.096 in.) P

2.50 (0.098 in.) Q

2.55 (0.100 in.) R

2.60 (0.102 in.) S

2.65 (0.104 in.) U

2.70 (0.106 in.) W

Page 797 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-153

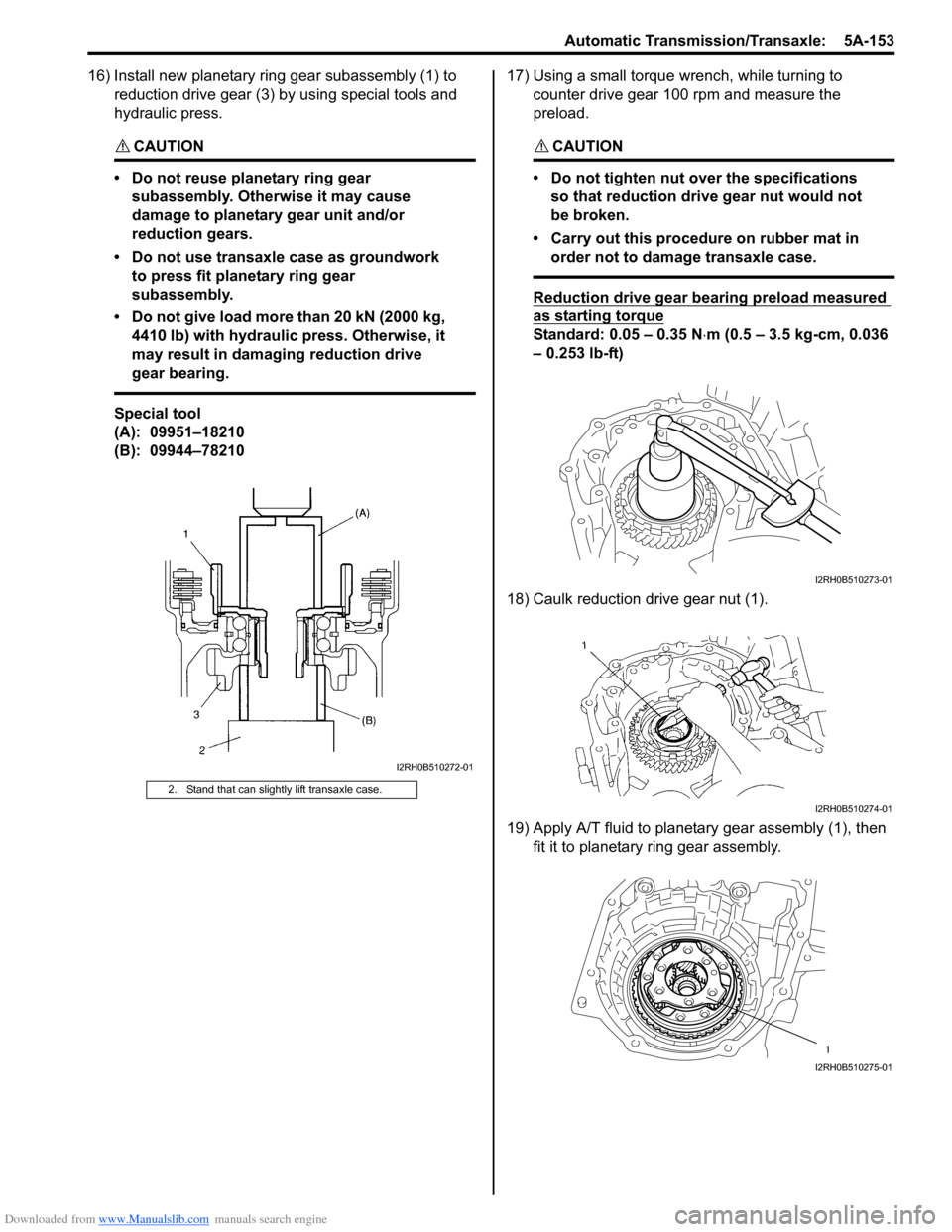

16) Install new planetary ring gear subassembly (1) to reduction drive gear (3) by using special tools and

hydraulic press.

CAUTION!

• Do not reuse planetary ring gear subassembly. Otherwise it may cause

damage to planetary gear unit and/or

reduction gears.

• Do not use transaxle case as groundwork to press fit planetary ring gear

subassembly.

• Do not give load more than 20 kN (2000 kg, 4410 lb) with hydraulic press. Otherwise, it

may result in damaging reduction drive

gear bearing.

Special tool

(A): 09951–18210

(B): 09944–78210 17) Using a small torque

wrench, while turning to

counter drive gear 100 rpm and measure the

preload.

CAUTION!

• Do not tighten nut over the specifications so that reduction drive gear nut would not

be broken.

• Carry out this procedure on rubber mat in order not to damage transaxle case.

Reduction drive gear bearing preload measured

as starting torque

Standard: 0.05 – 0.35 N ⋅m (0.5 – 3.5 kg-cm, 0.036

– 0.253 lb-ft)

18) Caulk reduction drive gear nut (1).

19) Apply A/T fluid to planetary gear assembly (1), then fit it to planetary ring gear assembly.

2. Stand that can slightly lift transaxle case.

I2RH0B510272-01

I2RH0B510273-01

I2RH0B510274-01

1

I2RH0B510275-01

Page 803 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-159

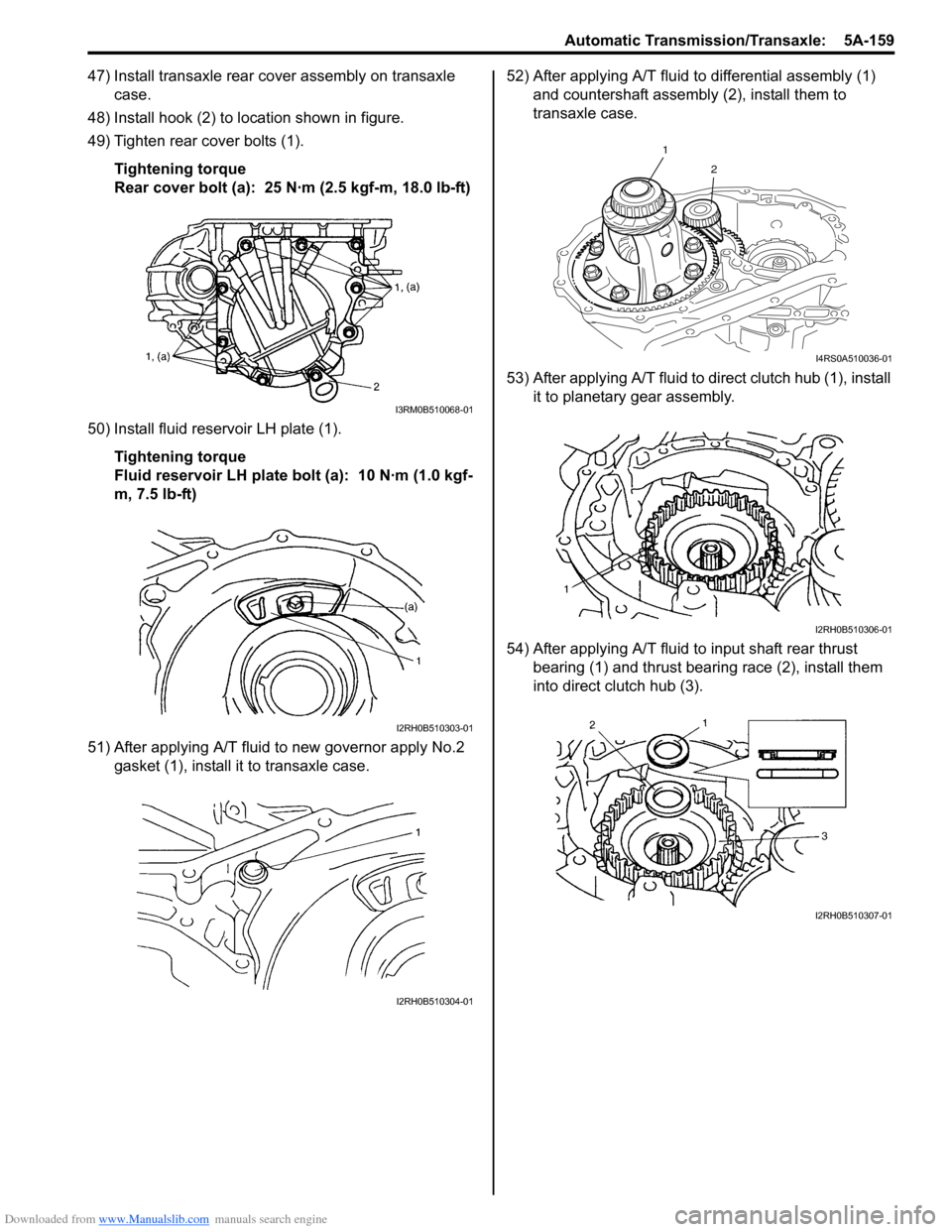

47) Install transaxle rear cover assembly on transaxle case.

48) Install hook (2) to location shown in figure.

49) Tighten rear cover bolts (1).

Tightening torque

Rear cover bolt (a): 25 N·m (2.5 kgf-m, 18.0 lb-ft)

50) Install fluid reservoir LH plate (1). Tightening torque

Fluid reservoir LH plate bolt (a): 10 N·m (1.0 kgf-

m, 7.5 lb-ft)

51) After applying A/T fluid to new governor apply No.2 gasket (1), install it to transaxle case. 52) After applying A/T fluid to differential assembly (1)

and countershaft assembly (2), install them to

transaxle case.

53) After applying A/T fluid to di rect clutch hub (1), install

it to planetary gear assembly.

54) After applying A/T fluid to input shaft rear thrust

bearing (1) and thrust bearing race (2), install them

into direct clutch hub (3).

I3RM0B510068-01

I2RH0B510303-01

I2RH0B510304-01

1

2

I4RS0A510036-01

I2RH0B510306-01

I2RH0B510307-01

Page 805 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-161

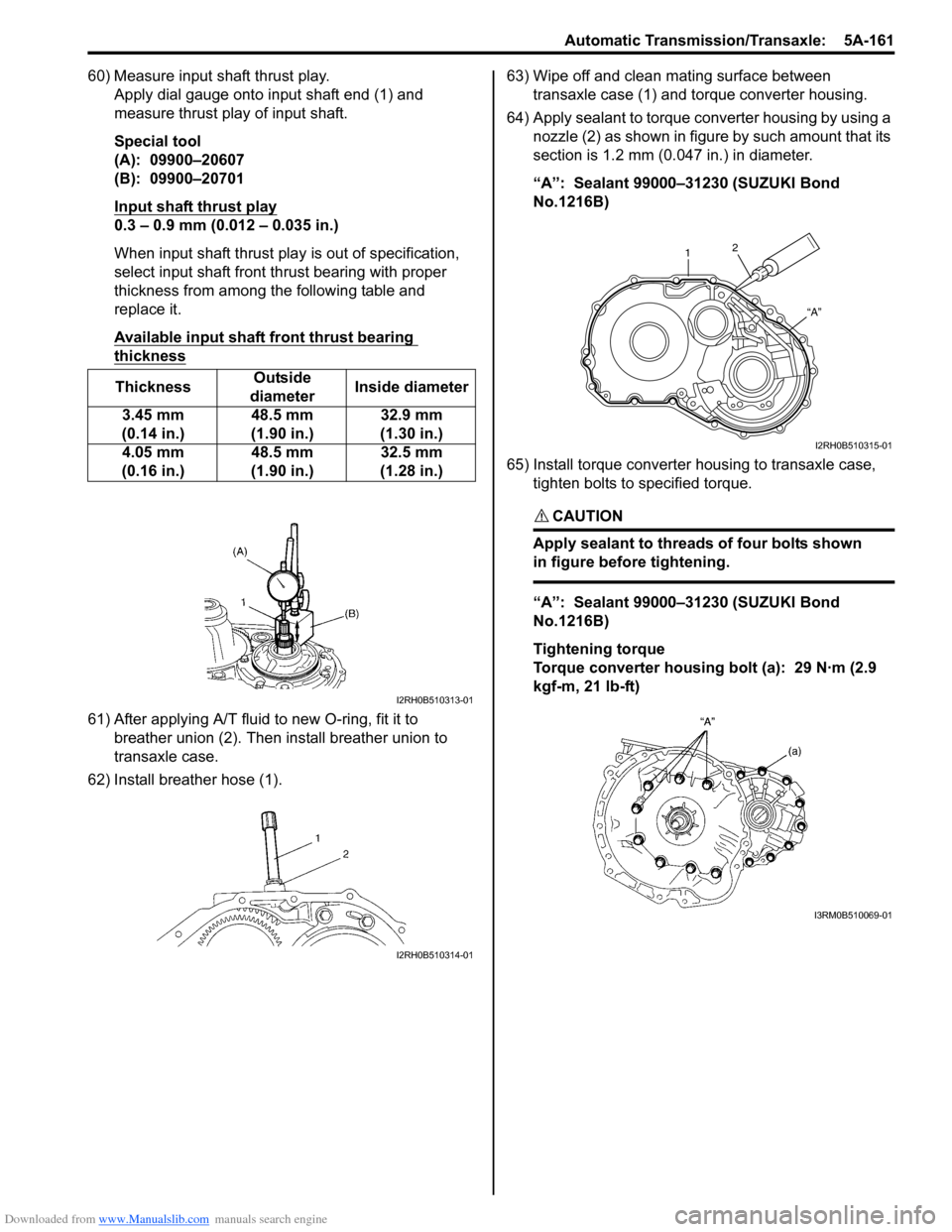

60) Measure input shaft thrust play.Apply dial gauge onto input shaft end (1) and

measure thrust play of input shaft.

Special tool

(A): 09900–20607

(B): 09900–20701

Input shaft thrust play

0.3 – 0.9 mm (0.012 – 0.035 in.)

When input shaft thrust play is out of specification,

select input shaft front th rust bearing with proper

thickness from among the following table and

replace it.

Available input shaft front thrust bearing

thickness

61) After applying A/T fluid to new O-ring, fit it to breather union (2). Then install breather union to

transaxle case.

62) Install breather hose (1). 63) Wipe off and clean mating surface between

transaxle case (1) and torque converter housing.

64) Apply sealant to torque converter housing by using a nozzle (2) as shown in figure by such amount that its

section is 1.2 mm (0.047 in.) in diameter.

“A”: Sealant 99000–31230 (SUZUKI Bond

No.1216B)

65) Install torque converter housing to transaxle case, tighten bolts to specified torque.

CAUTION!

Apply sealant to threads of four bolts shown

in figure before tightening.

“A”: Sealant 99000–31230 (SUZUKI Bond

No.1216B)

Tightening torque

Torque converter housing bolt (a): 29 N·m (2.9

kgf-m, 21 lb-ft)

Thickness

Outside

diameter Inside diameter

3.45 mm

(0.14 in.) 48.5 mm

(1.90 in.) 32.9 mm

(1.30 in.)

4.05 mm

(0.16 in.) 48.5 mm

(1.90 in.) 32.5 mm

(1.28 in.)

I2RH0B510313-01

I2RH0B510314-01

1 2

“A”

I2RH0B510315-01

I3RM0B510069-01

Page 808 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-164 Automatic Transmission/Transaxle:

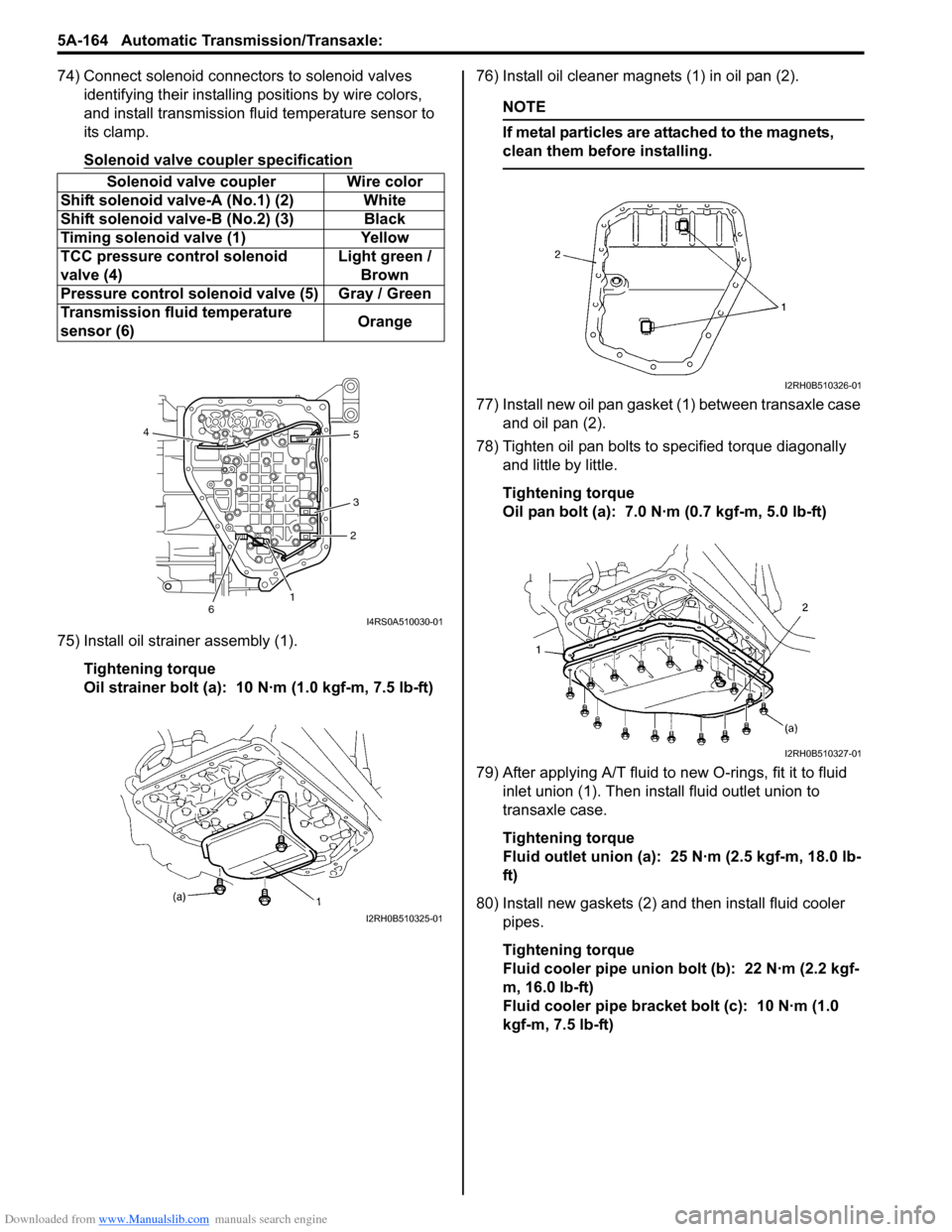

74) Connect solenoid connectors to solenoid valves identifying their installing positions by wire colors,

and install transmission fluid temperature sensor to

its clamp.

Solenoid valve coupler specification

75) Install oil strainer assembly (1).

Tightening torque

Oil strainer bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft) 76) Install oil cleaner magnets (1) in oil pan (2).

NOTE

If metal particles are attached to the magnets,

clean them before installing.

77) Install new oil pan gasket (1) between transaxle case

and oil pan (2).

78) Tighten oil pan bolts to specified torque diagonally and little by little.

Tightening torque

Oil pan bolt (a): 7.0 N·m (0.7 kgf-m, 5.0 lb-ft)

79) After applying A/T fluid to new O-rings, fit it to fluid inlet union (1). Then inst all fluid outlet union to

transaxle case.

Tightening torque

Fluid outlet union (a): 25 N·m (2.5 kgf-m, 18.0 lb-

ft)

80) Install new gaskets (2) and then install fluid cooler pipes.

Tightening torque

Fluid cooler pipe union bolt (b): 22 N·m (2.2 kgf-

m, 16.0 lb-ft)

Fluid cooler pipe bracket bolt (c): 10 N·m (1.0

kgf-m, 7.5 lb-ft)

Solenoid valve coupler Wire color

Shift solenoid valve-A (No.1) (2) White

Shift solenoid val ve-B (No.2) (3) Black

Timing solenoid valve (1) Yellow

TCC pressure control solenoid

valve (4) Light green /

Brown

Pressure control solenoid valve (5) Gray / Green

Transmission fluid temperature

sensor (6) Orange

12

3 5

4

6

I4RS0A510030-01

I2RH0B510325-01

I2RH0B510326-01

I2RH0B510327-01

Page 809 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-165

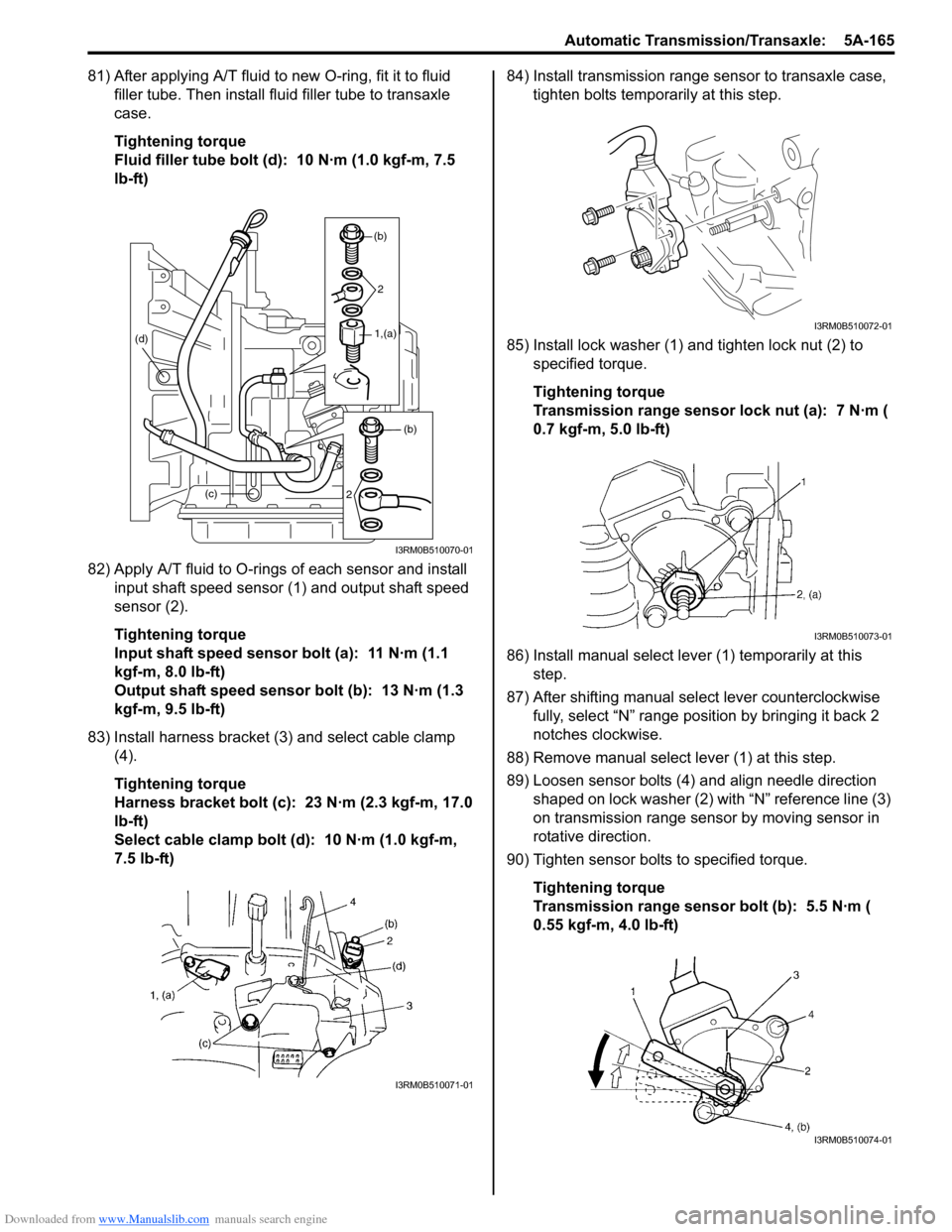

81) After applying A/T fluid to new O-ring, fit it to fluid filler tube. Then install fl uid filler tube to transaxle

case.

Tightening torque

Fluid filler tube bolt (d): 10 N·m (1.0 kgf-m, 7.5

lb-ft)

82) Apply A/T fluid to O-rings of each sensor and install input shaft speed sensor (1) and output shaft speed

sensor (2).

Tightening torque

Input shaft speed sensor bolt (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

Output shaft speed sensor bolt (b): 13 N·m (1.3

kgf-m, 9.5 lb-ft)

83) Install harness bracket (3) and select cable clamp (4).

Tightening torque

Harness bracket bolt (c): 23 N·m (2.3 kgf-m, 17.0

lb-ft)

Select cable clamp bolt (d): 10 N·m (1.0 kgf-m,

7.5 lb-ft) 84) Install transmission range sensor to transaxle case,

tighten bolts temporarily at this step.

85) Install lock washer (1) and tighten lock nut (2) to specified torque.

Tightening torque

Transmission range sensor lock nut (a): 7 N·m (

0.7 kgf-m, 5.0 lb-ft)

86) Install manual select leve r (1) temporarily at this

step.

87) After shifting manual se lect lever counterclockwise

fully, select “N” range position by bringing it back 2

notches clockwise.

88) Remove manual select lever (1) at this step.

89) Loosen sensor bolts (4) and align needle direction shaped on lock washer (2) with “N” reference line (3)

on transmission range sensor by moving sensor in

rotative direction.

90) Tighten sensor bolts to specified torque.

Tightening torque

Transmission range sensor bolt (b): 5.5 N·m (

0.55 kgf-m, 4.0 lb-ft)

(c)

(d)

(b)

2

1,(a)

(b)

2

I3RM0B510070-01

I3RM0B510071-01

I3RM0B510072-01

I3RM0B510073-01

I3RM0B510074-01

Page 810 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-166 Automatic Transmission/Transaxle:

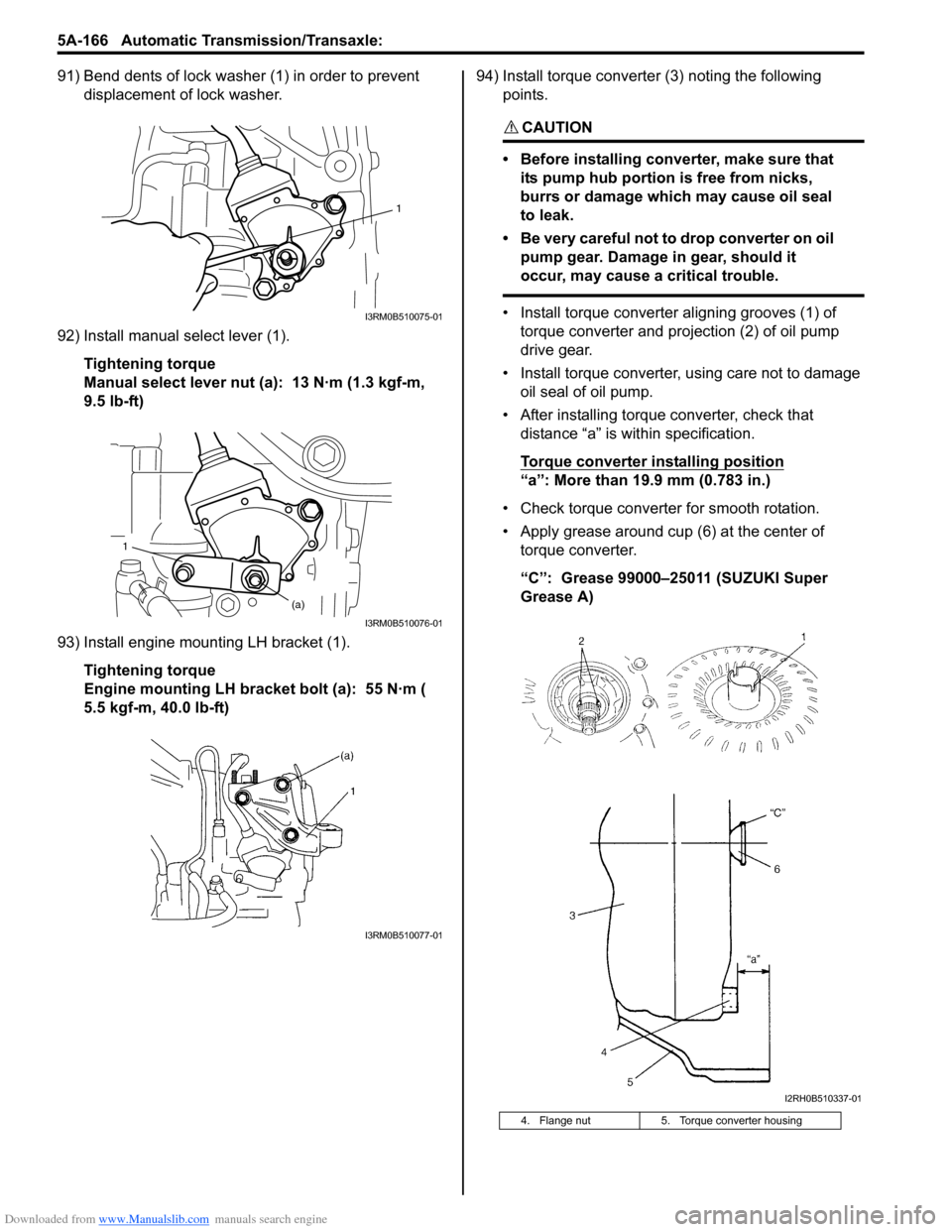

91) Bend dents of lock washer (1) in order to prevent displacement of lock washer.

92) Install manual select lever (1). Tightening torque

Manual select lever nut (a): 13 N·m (1.3 kgf-m,

9.5 lb-ft)

93) Install engine mounting LH bracket (1). Tightening torque

Engine mounting LH bracket bolt (a): 55 N·m (

5.5 kgf-m, 40.0 lb-ft) 94) Install torque converter (3) noting the following

points.

CAUTION!

• Before installing converter, make sure that its pump hub portion is free from nicks,

burrs or damage which may cause oil seal

to leak.

• Be very careful not to drop converter on oil pump gear. Damage in gear, should it

occur, may cause a critical trouble.

• Install torque converter aligning grooves (1) of torque converter and projection (2) of oil pump

drive gear.

• Install torque converter, using care not to damage oil seal of oil pump.

• After installing torque converter, check that distance “a” is within specification.

Torque converter installing position

“a”: More than 19.9 mm (0.783 in.)

• Check torque converter for smooth rotation.

• Apply grease around cup (6) at the center of torque converter.

“C”: Grease 99000–25011 (SUZUKI Super

Grease A)

1

I3RM0B510075-01

1

(a)

I3RM0B510076-01

I3RM0B510077-01

4. Flange nut 5. Torque converter housing

I2RH0B510337-01

Page 812 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-168 Automatic Transmission/Transaxle:

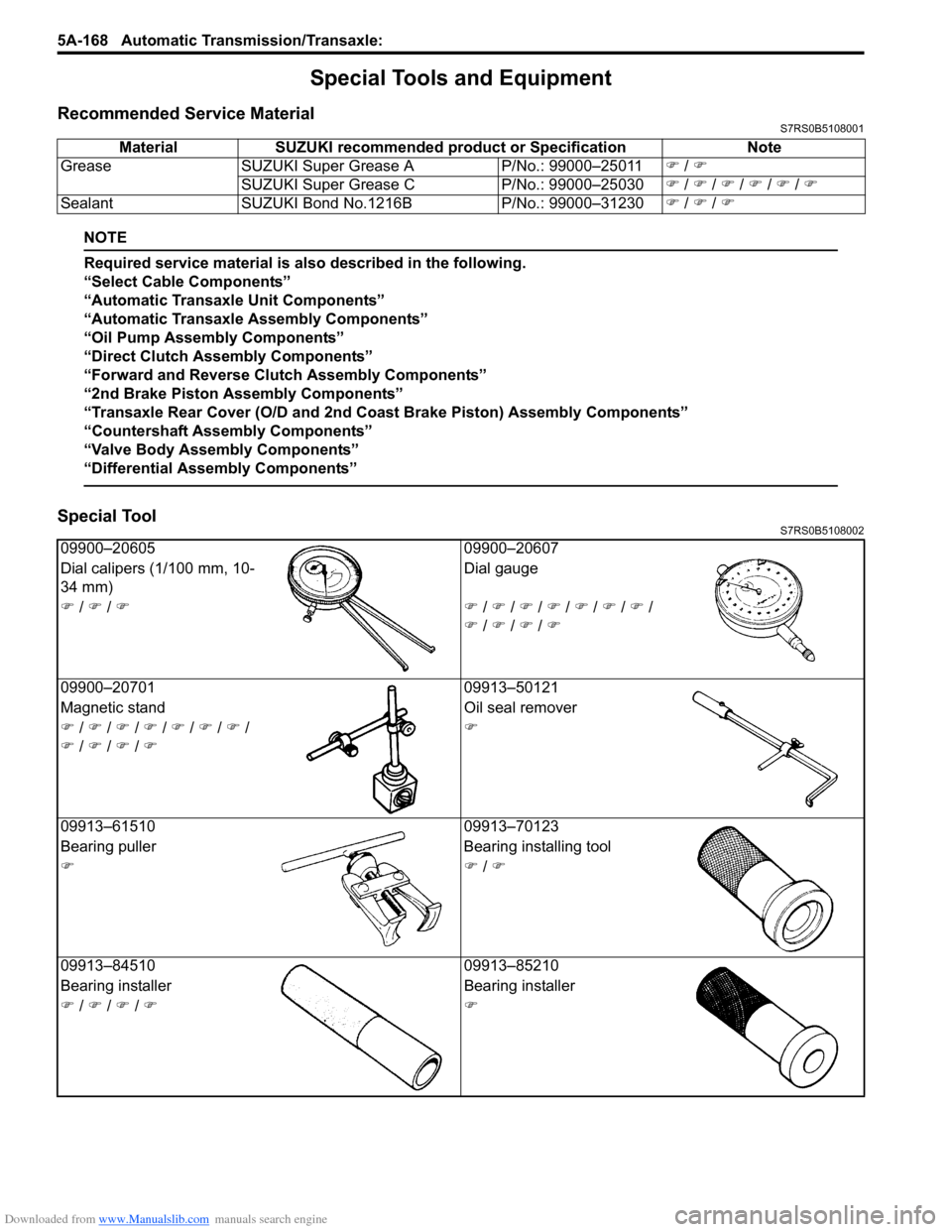

Special Tools and Equipment

Recommended Service MaterialS7RS0B5108001

NOTE

Required service material is also described in the following.

“Select Cable Components”

“Automatic Transaxle Unit Components”

“Automatic Transaxle Assembly Components”

“Oil Pump Assembly Components”

“Direct Clutch Assembly Components”

“Forward and Reverse Clutch Assembly Components”

“2nd Brake Piston Assembly Components”

“Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Components”

“Countershaft Assembly Components”

“Valve Body Assembly Components”

“Differential Assembly Components”

Special ToolS7RS0B5108002

Material SUZUKI recommended product or Specification Note

Grease SUZUKI Super Grease A P/No.: 99000–25011�) / �)

SUZUKI Super Grease C P/No.: 99000–25030�) / �) / �) / �) / �) / �)

Sealant SUZUKI Bond No.1216B P/No.: 99000–31230�) / �) / �)

09900–20605 09900–20607

Dial calipers (1/100 mm, 10-

34 mm) Dial gauge

�) / �) / �)�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �)

09900–20701 09913–50121

Magnetic stand Oil seal remover

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) �)

09913–61510 09913–70123

Bearing puller Bearing installing tool

�)�) / �)

09913–84510 09913–85210

Bearing installer Bearing installer

�) / �) / �) / �)�)

Page 813 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-169

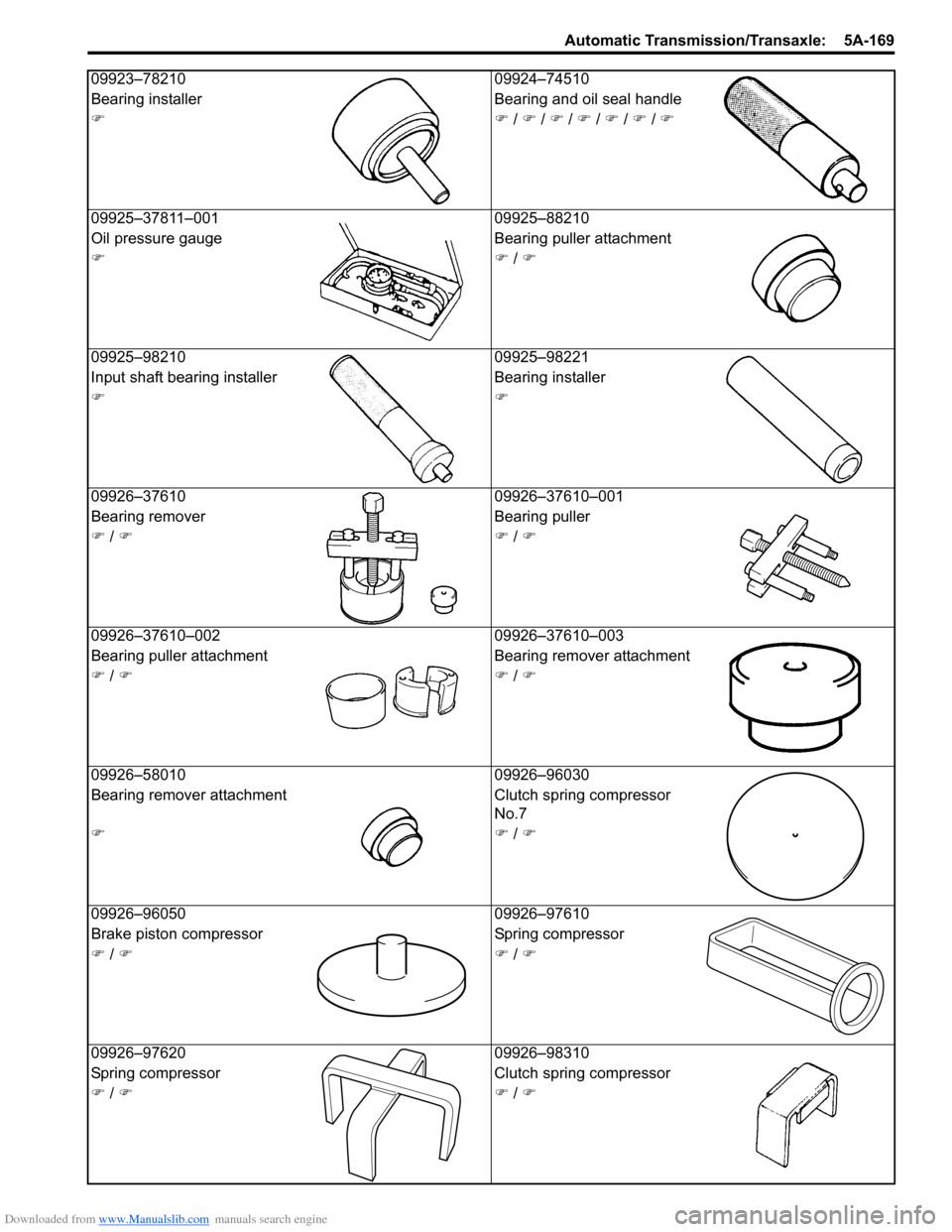

09923–7821009924–74510

Bearing installer Bearing and oil seal handle

�)�) / �) / �) / �) / �) / �) / �)

09925–37811–001 09925–88210

Oil pressure gauge Bearing puller attachment

�)�) / �)

09925–98210 09925–98221

Input shaft bearing inst aller Bearing installer

�)�)

09926–37610 09926–37610–001

Bearing remover Bearing puller

�) / �)�) / �)

09926–37610–002 09926–37610–003

Bearing puller attachment Bearing remover attachment

�) / �)�) / �)

09926–58010 09926–96030

Bearing remover attachment Clutch spring compressor

No.7

�)�) / �)

09926–96050 09926–97610

Brake piston compressor Spring compressor

�) / �)�) / �)

09926–97620 09926–98310

Spring compressor Clutch spring compressor

�) / �)�) / �)