Turn SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 728 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-84 Automatic Transmission/Transaxle:

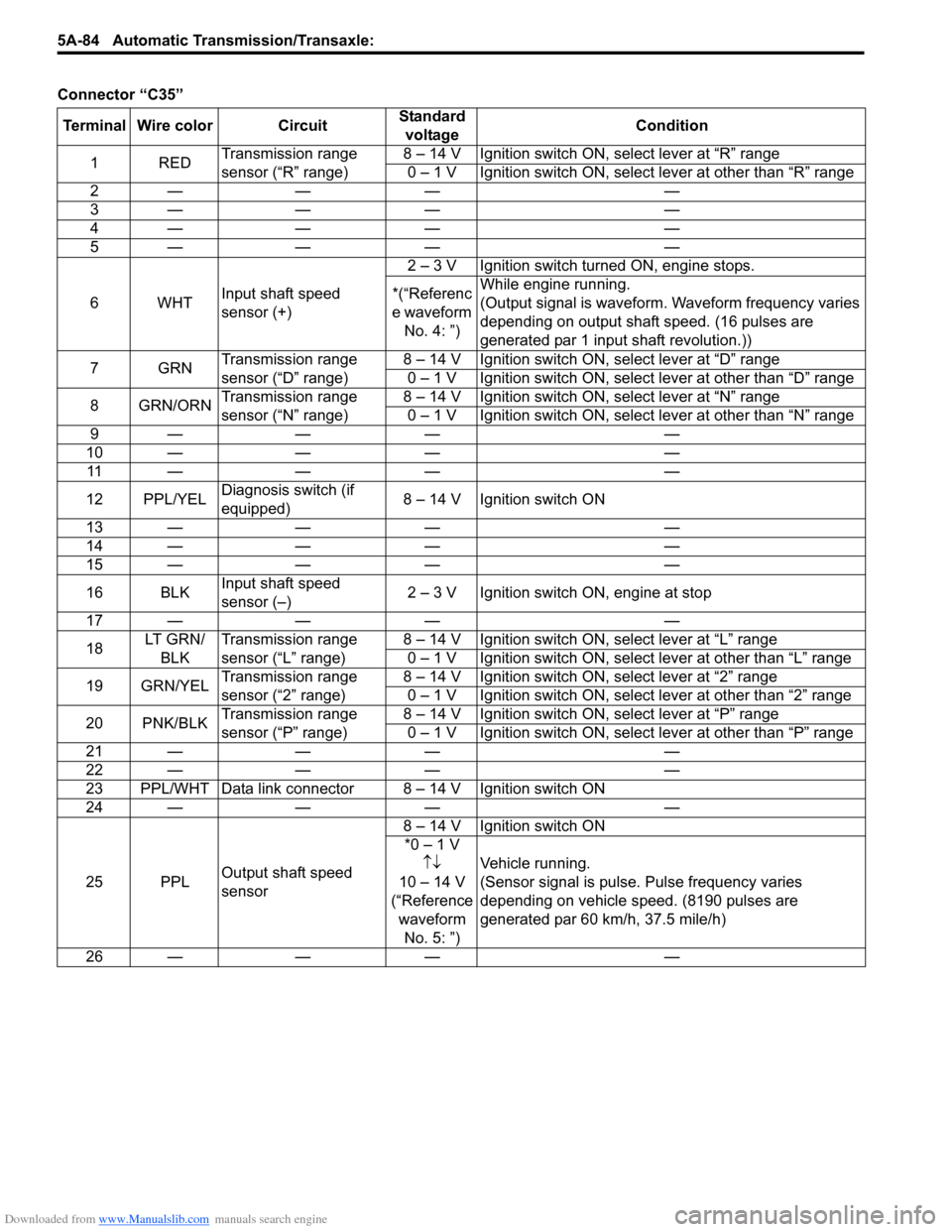

Connector “C35”

Terminal Wire color Circuit Standard

voltage Condition

1RED Transmission range

sensor (“R” range) 8 – 14 V Ignition switch ON, select lever at “R” range

0 – 1 V Ignition switch ON, select lever at other than “R” range

2— — — —

3— — — —

4— — — —

5— — — —

6WHT Input shaft speed

sensor (+) 2 – 3 V Ignition switch turned ON, engine stops.

*(“Referenc

e waveform No. 4: ”) While engine running.

(Output signal is waveform. Waveform frequency varies

depending on output shaft speed. (16 pulses are

generated par 1 input shaft revolution.))

7GRN Transmission range

sensor (“D” range) 8 – 14 V Ignition switch ON, select lever at “D” range

0 – 1 V Ignition switch ON, select lever at other than “D” range

8 GRN/ORN Transmission range

sensor (“N” range) 8 – 14 V Ignition switch ON, select lever at “N” range

0 – 1 V Ignition switch ON, select lever at other than “N” range

9— — — —

10 — — — — 11 — — — —

12 PPL/YEL Diagnosis switch (if

equipped) 8 – 14 V Ignition switch ON

13 — — — —

14 — — — —

15 — — — —

16 BLK Input shaft speed

sensor (–) 2 – 3 V Ignition switch ON, engine at stop

17 — — — —

18 LT G R N /

BLK Transmission range

sensor (“L” range) 8 – 14 V Ignition switch ON, select lever at “L” range

0 – 1 V Ignition switch ON, select lever at other than “L” range

19 GRN/YEL Transmission range

sensor (“2” range) 8 – 14 V Ignition switch ON, select lever at “2” range

0 – 1 V Ignition switch ON, select lever at other than “2” range

20 PNK/BLK Transmission range

sensor (“P” range) 8 – 14 V Ignition switch ON, select lever at “P” range

0 – 1 V Ignition switch ON, select lever at other than “P” range

21 — — — —

22 — — — —

23 PPL/WHT Data link connector 8 – 14 V Ignition switch ON

24 — — — —

25 PPL Output shaft speed

sensor 8 – 14 V Ignition switch ON

*0 – 1 V ↑↓

10 – 14 V

(“Reference waveform No. 5: ”) Vehicle running.

(Sensor signal is pulse. Pulse frequency varies

depending on vehicle speed. (8190 pulses are

generated par 60 km/h, 37.5 mile/h)

26 — — — —

Page 731 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-87

Troubleshooting

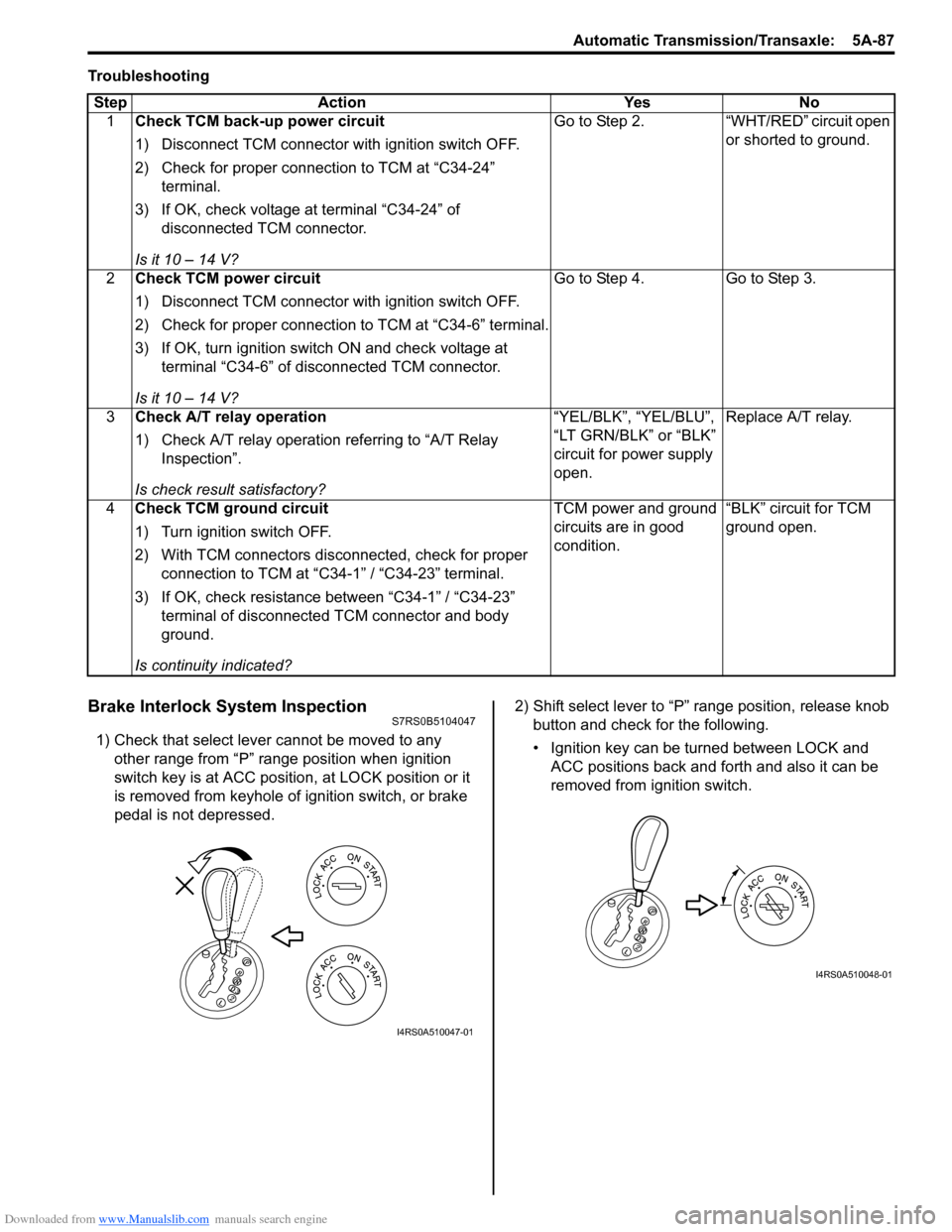

Brake Interlock System InspectionS7RS0B5104047

1) Check that select lever cannot be moved to any other range from “P” range position when ignition

switch key is at ACC position, at LOCK position or it

is removed from keyhole of ignition switch, or brake

pedal is not depressed. 2) Shift select lever to “P” range position, release knob

button and check for the following.

• Ignition key can be turned between LOCK and ACC positions back and forth and also it can be

removed from ignition switch.

Step Action Yes No

1 Check TCM back-up power circuit

1) Disconnect TCM connector with ignition switch OFF.

2) Check for proper connection to TCM at “C34-24”

terminal.

3) If OK, check voltage at terminal “C34-24” of disconnected TCM connector.

Is it 10 – 14 V? Go to Step 2. “WHT/RED” circuit open

or shorted to ground.

2 Check TCM power circuit

1) Disconnect TCM connector with ignition switch OFF.

2) Check for proper connection to TCM at “C34-6” terminal.

3) If OK, turn ignition switch ON and check voltage at

terminal “C34-6” of disconnected TCM connector.

Is it 10 – 14 V? Go to Step 4. Go to Step 3.

3 Check A/T relay operation

1) Check A/T relay operation referring to “A/T Relay

Inspection”.

Is check result satisfactory? “YEL/BLK”, “YEL/BLU”,

“LT GRN/BLK” or “BLK”

circuit for power supply

open.

Replace A/T relay.

4 Check TCM ground circuit

1) Turn ignition switch OFF.

2) With TCM connectors disconnected, check for proper

connection to TCM at “C34-1” / “C34-23” terminal.

3) If OK, check resistance between “C34-1” / “C34-23” terminal of disconnected TCM connector and body

ground.

Is continuity indicated? TCM power and ground

circuits are in good

condition.

“BLK” circuit for TCM

ground open.

I4RS0A510047-01

I4RS0A510048-01

Page 732 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-88 Automatic Transmission/Transaxle:

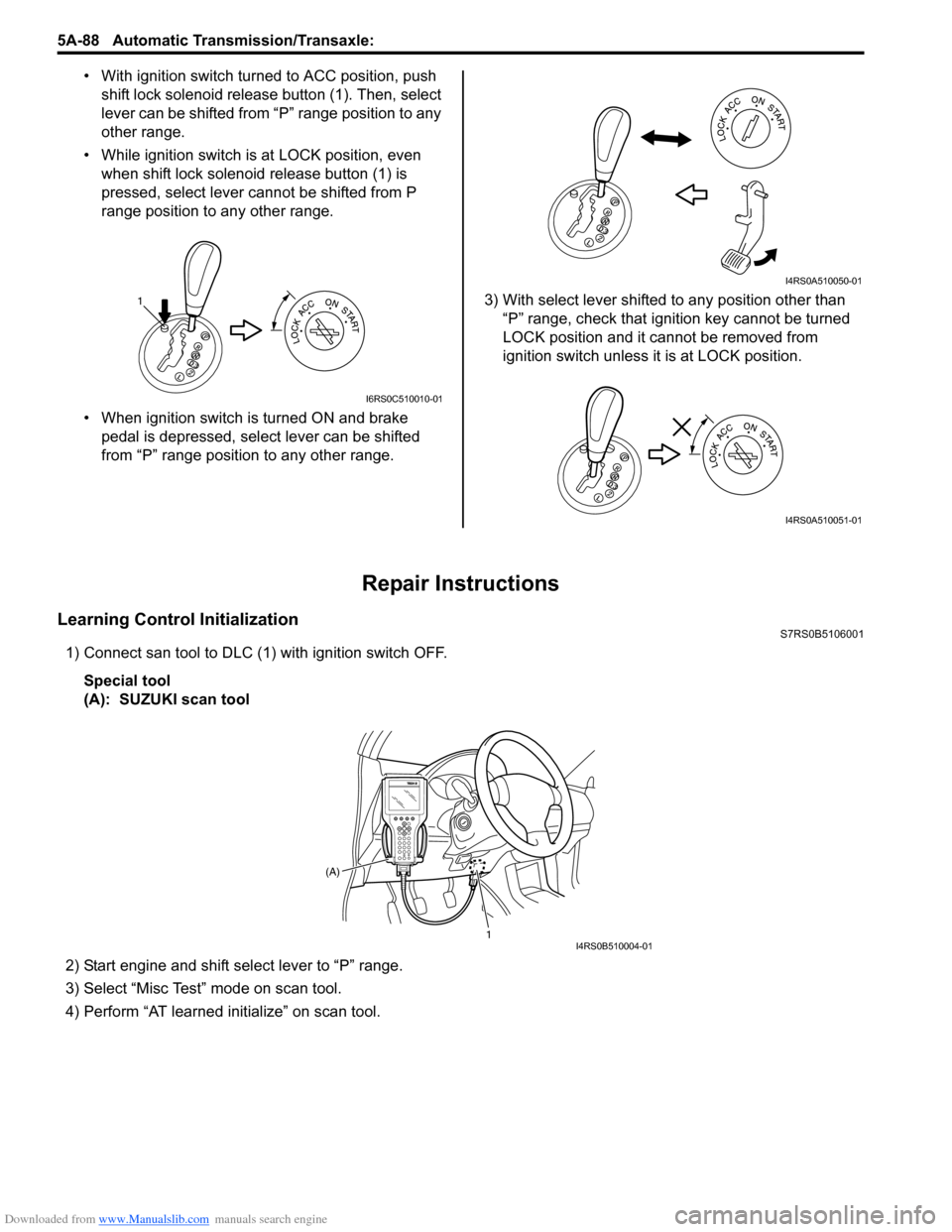

• With ignition switch turned to ACC position, push

shift lock solenoid release button (1). Then, select

lever can be shifted from “P” range position to any

other range.

• While ignition switch is at LOCK position, even when shift lock solenoid release button (1) is

pressed, select lever cannot be shifted from P

range position to any other range.

• When ignition switch is turned ON and brake pedal is depressed, select lever can be shifted

from “P” range position to any other range. 3) With select lever shifted to any position other than

“P” range, check that ignition key cannot be turned

LOCK position and it cannot be removed from

ignition switch unless it is at LOCK position.

Repair Instructions

Learning Control InitializationS7RS0B5106001

1) Connect san tool to DLC (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

2) Start engine and shift select lever to “P” range.

3) Select “Misc Test” mode on scan tool.

4) Perform “AT learned initialize” on scan tool.

1

I6RS0C510010-01

I4RS0A510050-01

I4RS0A510051-01

1

(A)I4RS0B510004-01

Page 734 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-90 Automatic Transmission/Transaxle:

A/T Fluid ChangeS7RS0B5106003

CAUTION!

Do not use any fluid other than the specified

ATF. Use of any fluid other than the specified

ATF may cause juddering or some other

faulty condition to occur.

1) Lift up vehicle.

2) When engine is cool, remove drain plug (1) from

transaxle housing (2) and drain A/T fluid.

3) Install drain plug (1).

Tightening torque

A/T fluid drain plug (a): 17 N·m (1.7 kgf-m, 12.5

lb-ft)

4) Lower vehicle and pour proper amount of SUZUKI ATF 3317 or Mobil ATF 3309.

5) Check fluid level referring to “A/T Fluid Level Check”.

Automatic transaxle fluid

: SUZUKI ATF 3317 or Mobil ATF 3309

Automatic transaxle fluid capacity

When draining from drai n plug hole: 3.3 liters

(6.97 / 5.81 US/Imp. pt.)

When overhauling: 5.6 liters (11.83 / 9.86 US/Imp.

pt.)

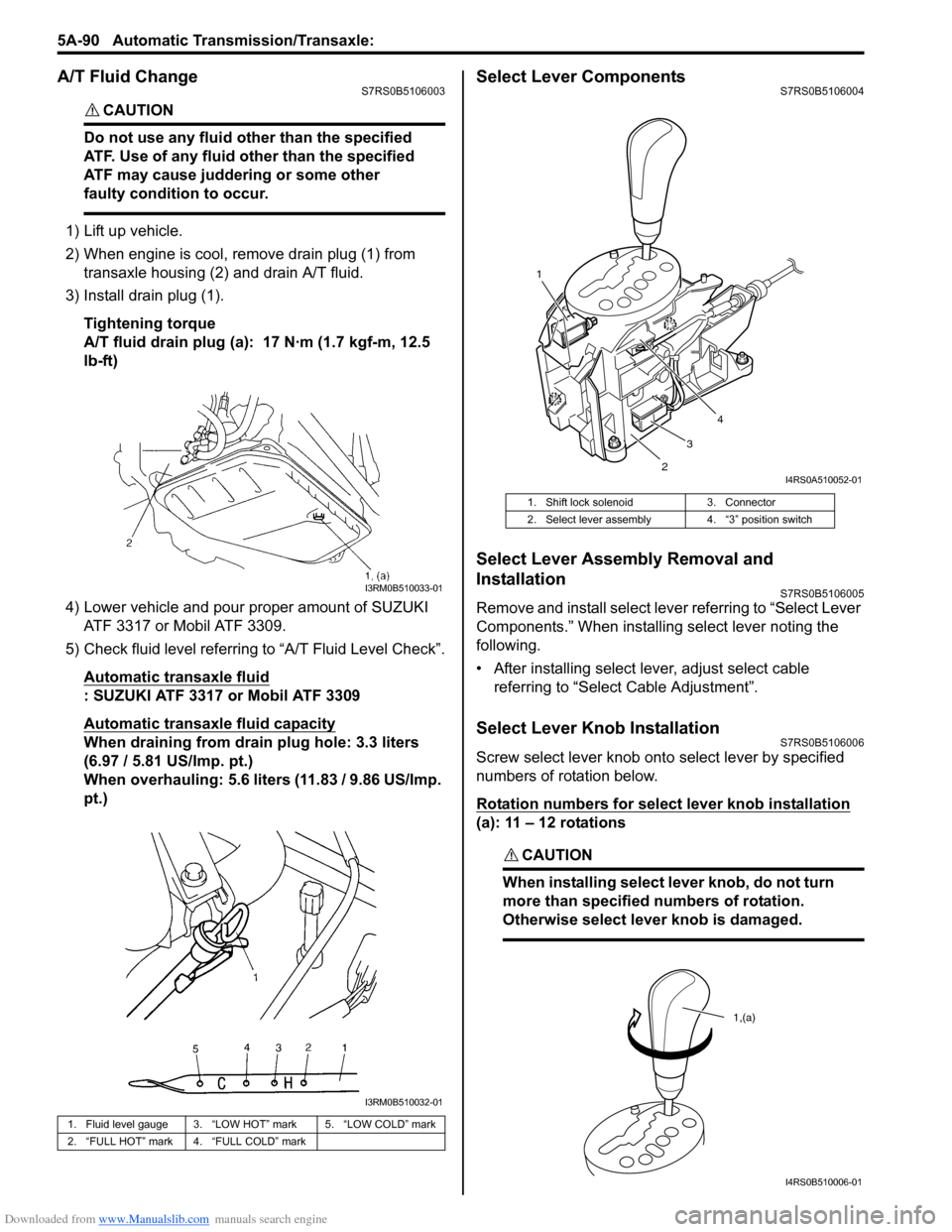

Select Lever ComponentsS7RS0B5106004

Select Lever Assembly Removal and

Installation

S7RS0B5106005

Remove and install select leve r referring to “Select Lever

Components.” When installing select lever noting the

following.

• After installing select lever, adjust select cable referring to “Select Cable Adjustment”.

Select Lever Knob InstallationS7RS0B5106006

Screw select lever knob onto select lever by specified

numbers of rotation below.

Rotation numbers for select lever knob installation

(a): 11 – 12 rotations

CAUTION!

When installing select lever knob, do not turn

more than specified numbers of rotation.

Otherwise select lever knob is damaged.

1. Fluid level gauge 3. “LOW HOT” mark 5. “LOW COLD” mark

2. “FULL HOT” mark 4. “FULL COLD” mark

I3RM0B510033-01

I3RM0B510032-01

1. Shift lock solenoid 3. Connector

2. Select lever assembly 4. “3” position switch

1

23 4

I4RS0A510052-01

1,(a)

I4RS0B510006-01

Page 737 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-93

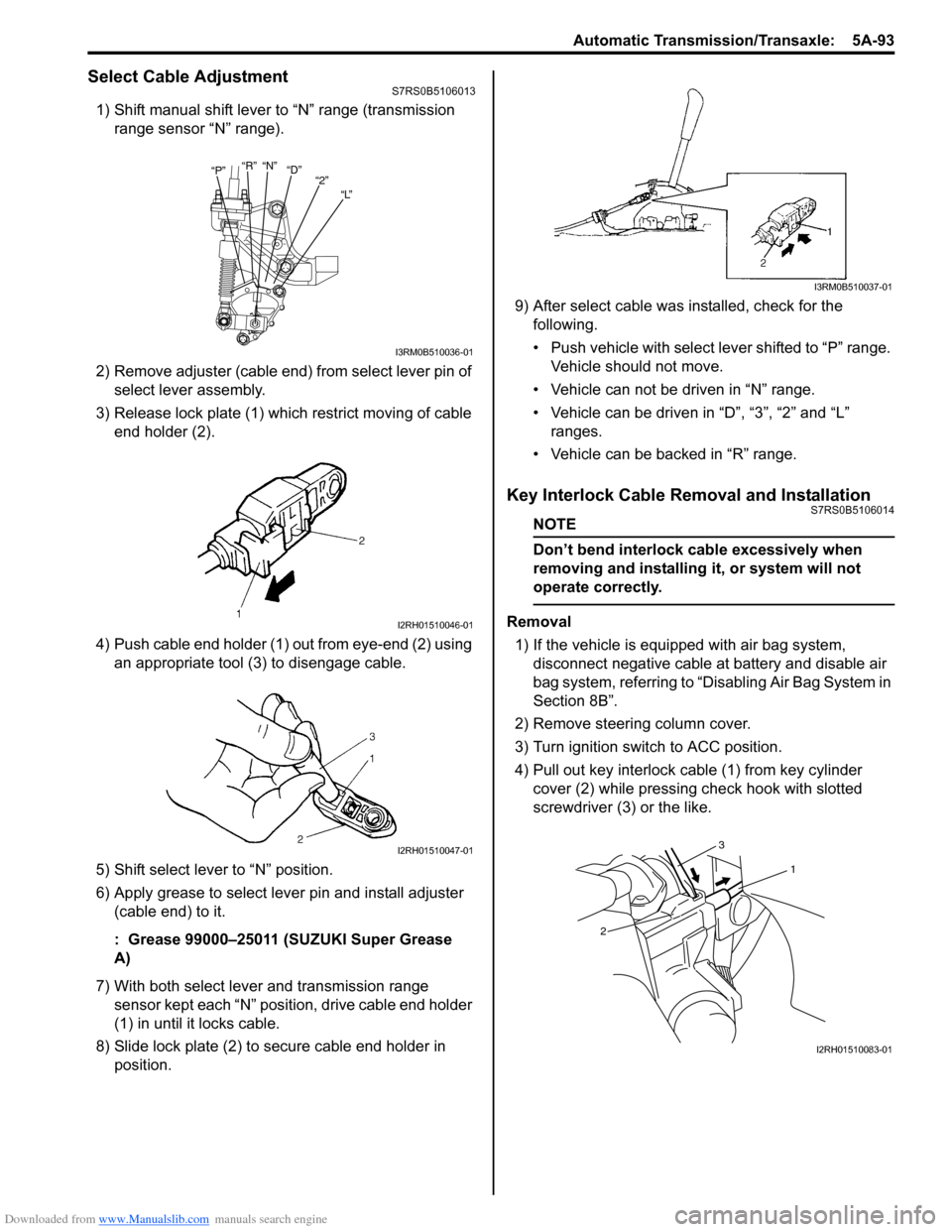

Select Cable AdjustmentS7RS0B5106013

1) Shift manual shift lever to “N” range (transmission range sensor “N” range).

2) Remove adjuster (cable end) from select lever pin of select lever assembly.

3) Release lock plate (1) which restrict moving of cable end holder (2).

4) Push cable end holder (1) out from eye-end (2) using an appropriate tool (3) to disengage cable.

5) Shift select lever to “N” position.

6) Apply grease to select lever pin and install adjuster (cable end) to it.

: Grease 99000–25011 (SUZUKI Super Grease

A)

7) With both select lever and transmission range sensor kept each “N” position, drive cable end holder

(1) in until it locks cable.

8) Slide lock plate (2) to secure cable end holder in position. 9) After select cable was

installed, check for the

following.

• Push vehicle with select lever shifted to “P” range. Vehicle should not move.

• Vehicle can not be driven in “N” range.

• Vehicle can be driven in “D”, “3”, “2” and “L” ranges.

• Vehicle can be backed in “R” range.

Key Interlock Cable Removal and InstallationS7RS0B5106014

NOTE

Don’t bend interlock cable excessively when

removing and installing it, or system will not

operate correctly.

Removal

1) If the vehicle is equipped with air bag system, disconnect negative cable at battery and disable air

bag system, referring to “Disabling Air Bag System in

Section 8B”.

2) Remove steering column cover.

3) Turn ignition switch to ACC position.

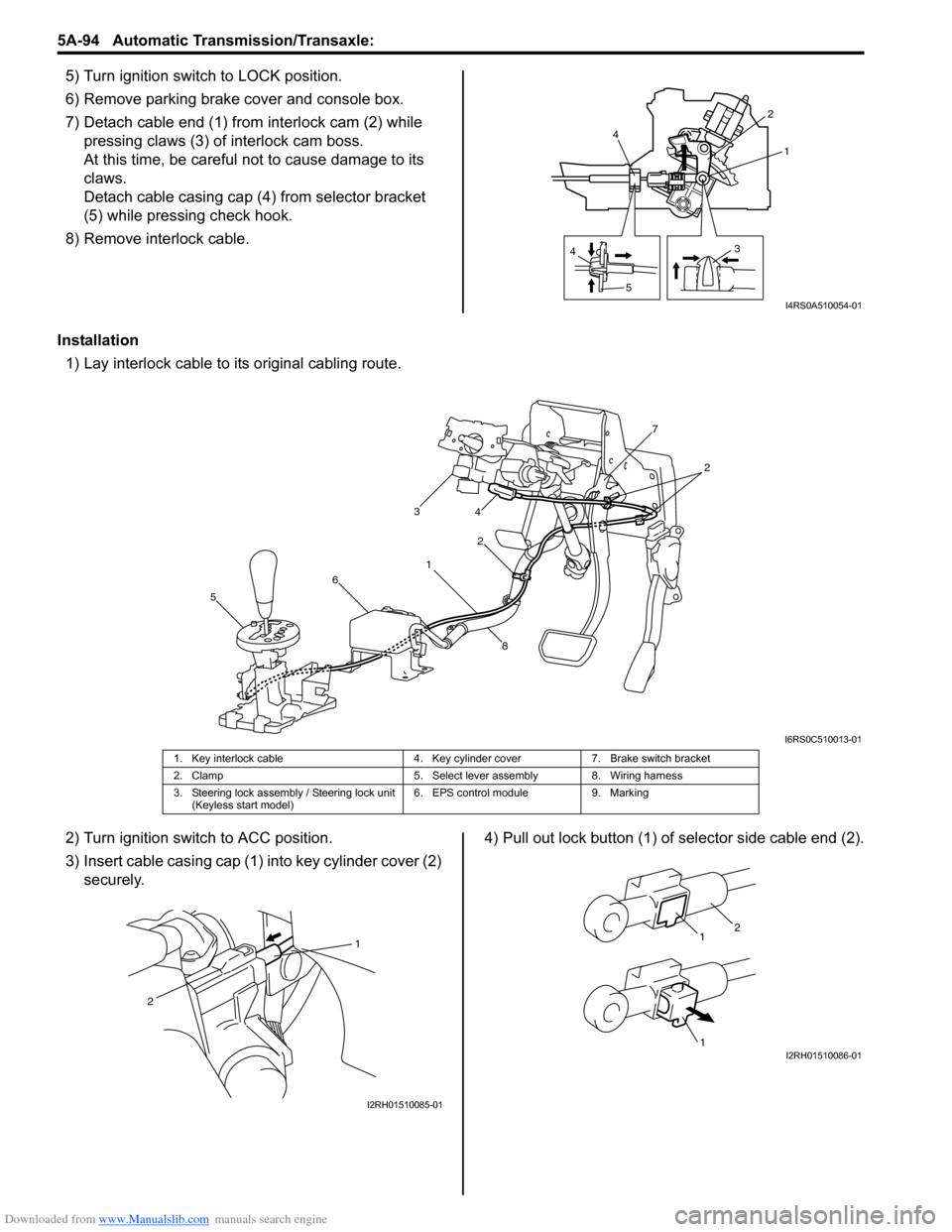

4) Pull out key interlock cable (1) from key cylinder cover (2) while pressing check hook with slotted

screwdriver (3) or the like.

“P” “R”

“N”

“D”

“2”

“L”

I3RM0B510036-01

I2RH01510046-01

I2RH01510047-01

I3RM0B510037-01

1

2 3

I2RH01510083-01

Page 738 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-94 Automatic Transmission/Transaxle:

5) Turn ignition switch to LOCK position.

6) Remove parking brake cover and console box.

7) Detach cable end (1) from interlock cam (2) while

pressing claws (3) of interlock cam boss.

At this time, be careful no t to cause damage to its

claws.

Detach cable casing cap (4 ) from selector bracket

(5) while pressing check hook.

8) Remove interlock cable.

Installation 1) Lay interlock cable to its original cabling route.

2) Turn ignition switch to ACC position.

3) Insert cable casing cap (1) into key cylinder cover (2) securely. 4) Pull out lock button (1) of selector side cable end (2).

4

5 31

2

4

I4RS0A510054-01

1 2

3

4

5 6 7

8

2

I6RS0C510013-01

1. Key interlock cable 4. Key cylinder cover7. Brake switch bracket

2. Clamp 5. Select lever assembly 8. Wiring harness

3. Steering lock assembly / Steering lock unit (Keyless start model) 6. EPS control module

9. Marking

1

2

I2RH01510085-01

1

1

2

I2RH01510086-01

Page 739 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-95

5) Shift select lever to “N” position.

NOTE

If select lever is in “P” position, shift select

lever referring to “Select Lever Inspection”.

6) Install cable casing cap (3) to selector bracket (4).

7) Connect cable end (1) to interlock cam (2) with ignition switch turned to ACC position.

8) Drive lock button (5) in cable end until it locks cable expansion and contraction.

9) With select lever set at “P ” position, turn ignition key

to ACC position and then check for the following

conditions.

• With knob button released, ignition key can be turned from ACC position to LOCK position.

• With knob button pressed, ignition key cannot be

turned from ACC position to LOCK position.

10) Install steering column cover. 11) If the vehicle is equipped with air bag system, connect negative cable at battery and enable air bag

system, referring to “Enabling Air Bag System in

Section 8B”.

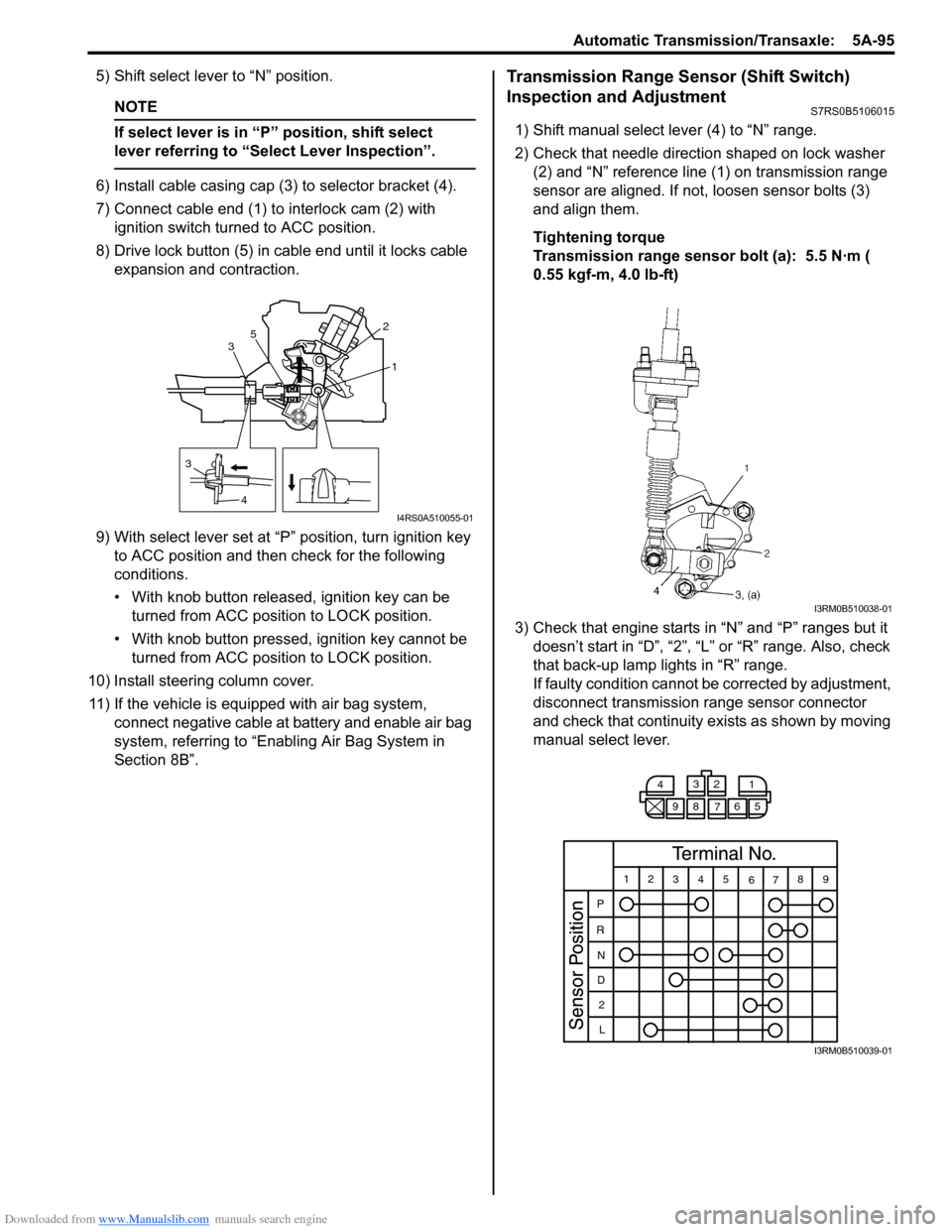

Transmission Range Sensor (Shift Switch)

Inspection and Adjustment

S7RS0B5106015

1) Shift manual select lever (4) to “N” range.

2) Check that needle direction shaped on lock washer (2) and “N” reference line (1) on transmission range

sensor are aligned. If not, loosen sensor bolts (3)

and align them.

Tightening torque

Transmission range sensor bolt (a): 5.5 N·m (

0.55 kgf-m, 4.0 lb-ft)

3) Check that engine starts in “N” and “P” ranges but it doesn’t start in “D”, “2”, “L” or “R” range. Also, check

that back-up lamp lights in “R” range.

If faulty condition cannot be corrected by adjustment,

disconnect transmission range sensor connector

and check that continuity ex ists as shown by moving

manual select lever.

3

4 1

2

3 5

I4RS0A510055-01

I3RM0B510038-01

4

3

2

1

98 76 5

12 345

6789

P

R N

D 2

L

I3RM0B510039-01

Page 744 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-100 Automatic Transmission/Transaxle:

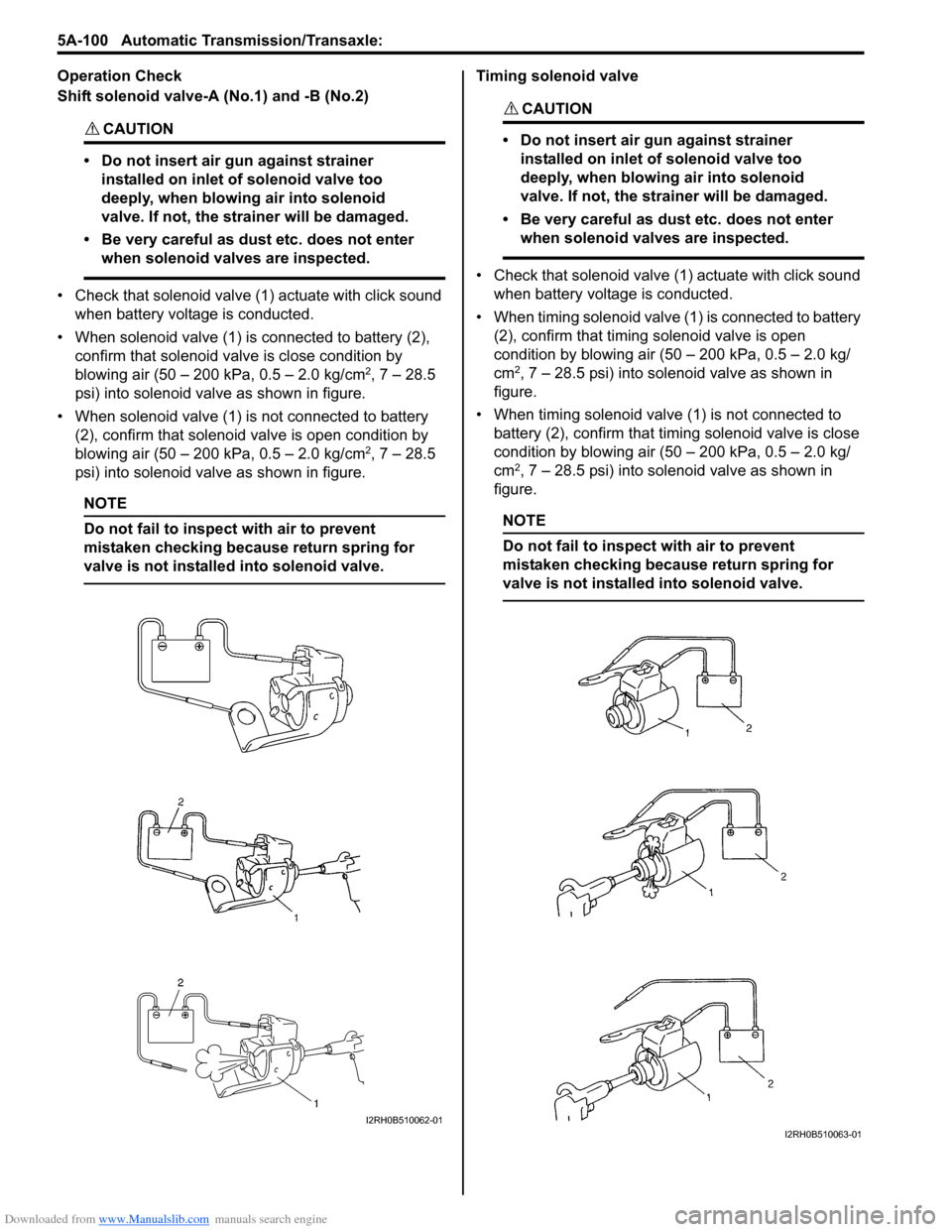

Operation Check

Shift solenoid valve-A (No.1) and -B (No.2)

CAUTION!

• Do not insert air gun against strainer installed on inlet of solenoid valve too

deeply, when blowing air into solenoid

valve. If not, the strainer will be damaged.

• Be very careful as dust etc. does not enter when solenoid valves are inspected.

• Check that solenoid valve (1) actuate with click sound when battery voltage is conducted.

• When solenoid valve (1) is connected to battery (2), confirm that solenoid valve is close condition by

blowing air (50 – 200 kPa, 0.5 – 2.0 kg/cm

2, 7 – 28.5

psi) into solenoid valve as shown in figure.

• When solenoid valve (1) is not connected to battery (2), confirm that solenoid valve is open condition by

blowing air (50 – 200 kPa, 0.5 – 2.0 kg/cm

2, 7 – 28.5

psi) into solenoid valve as shown in figure.

NOTE

Do not fail to inspect with air to prevent

mistaken checking because return spring for

valve is not installe d into solenoid valve.

Timing solenoid valve

CAUTION!

• Do not insert air gun against strainer

installed on inlet of solenoid valve too

deeply, when blowing air into solenoid

valve. If not, the strainer will be damaged.

• Be very careful as dust etc. does not enter when solenoid valves are inspected.

• Check that solenoid valve (1) actuate with click sound

when battery voltage is conducted.

• When timing solenoid valve (1 ) is connected to battery

(2), confirm that timing solenoid valve is open

condition by blowing air (50 – 200 kPa, 0.5 – 2.0 kg/

cm

2, 7 – 28.5 psi) into solenoid valve as shown in

figure.

• When timing solenoid valve (1) is not connected to battery (2), confirm that timi ng solenoid valve is close

condition by blowing air (50 – 200 kPa, 0.5 – 2.0 kg/

cm

2, 7 – 28.5 psi) into solenoid valve as shown in

figure.

NOTE

Do not fail to inspect with air to prevent

mistaken checking because return spring for

valve is not installed into solenoid valve.

I2RH0B510062-01I2RH0B510063-01

Page 746 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-102 Automatic Transmission/Transaxle:

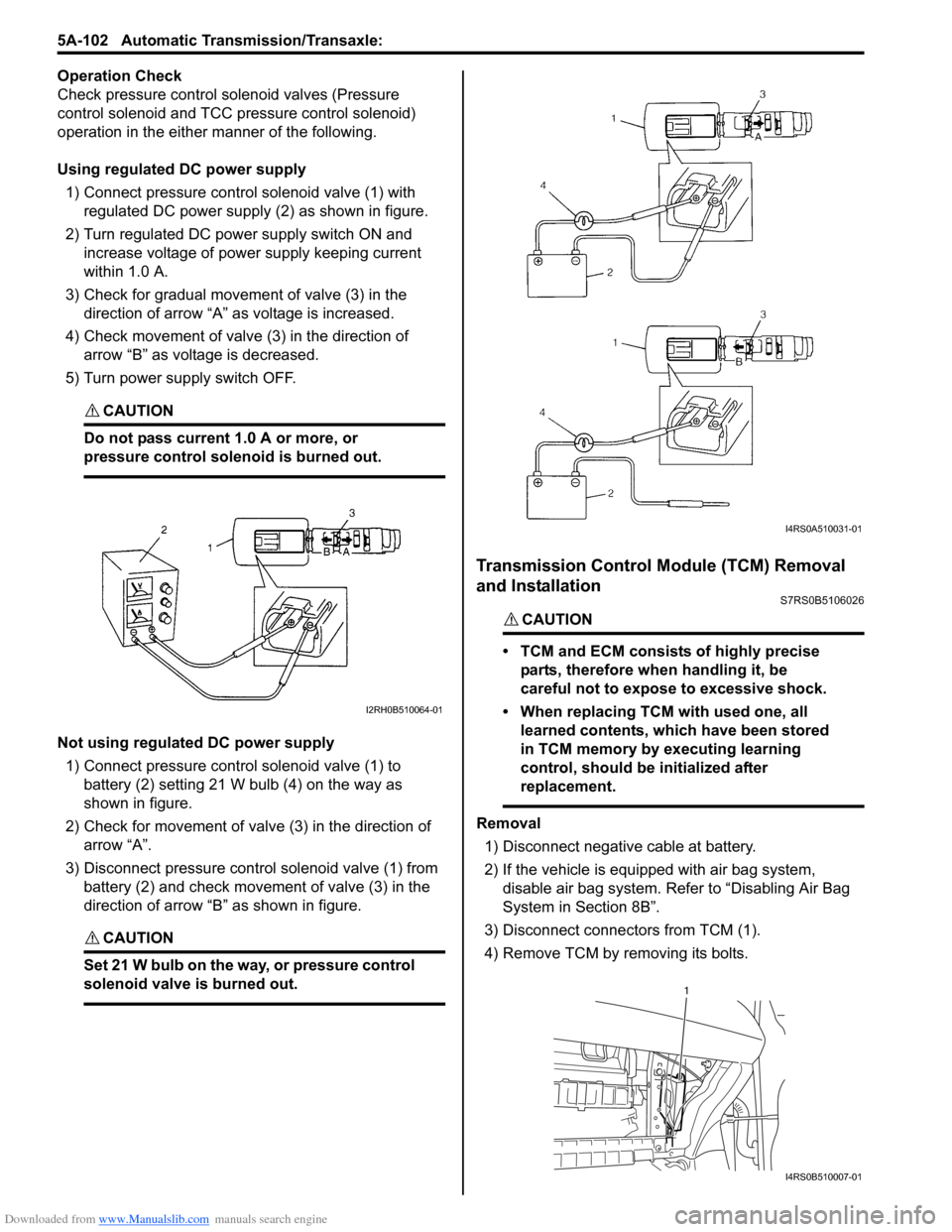

Operation Check

Check pressure control solenoid valves (Pressure

control solenoid and TCC pressure control solenoid)

operation in the either manner of the following.

Using regulated DC power supply

1) Connect pressure contro l solenoid valve (1) with

regulated DC power supply (2) as shown in figure.

2) Turn regulated DC power supply switch ON and increase voltage of power supply keeping current

within 1.0 A.

3) Check for gradual movement of valve (3) in the direction of arrow “A” as voltage is increased.

4) Check movement of valve (3) in the direction of arrow “B” as voltage is decreased.

5) Turn power supply switch OFF.

CAUTION!

Do not pass current 1.0 A or more, or

pressure control solenoid is burned out.

Not using regulated DC power supply 1) Connect pressure control solenoid valve (1) to battery (2) setting 21 W bulb (4) on the way as

shown in figure.

2) Check for movement of valve (3) in the direction of arrow “A”.

3) Disconnect pressure control solenoid valve (1) from battery (2) and check movement of valve (3) in the

direction of arrow “B” as shown in figure.

CAUTION!

Set 21 W bulb on the way, or pressure control

solenoid valve is burned out.

Transmission Control Module (TCM) Removal

and Installation

S7RS0B5106026

CAUTION!

• TCM and ECM consists of highly precise

parts, therefore when handling it, be

careful not to expose to excessive shock.

• When replacing TCM with used one, all learned contents, which have been stored

in TCM memory by executing learning

control, should be initialized after

replacement.

Removal

1) Disconnect negative cable at battery.

2) If the vehicle is equipped with air bag system, disable air bag system. Refer to “Disabling Air Bag

System in Section 8B”.

3) Disconnect connectors from TCM (1).

4) Remove TCM by removing its bolts.

I2RH0B510064-01

I4RS0A510031-01

1

I4RS0B510007-01

Page 753 of 1496

Downloaded from www.Manualslib.com manuals search engine A u to m a tic Tra n s m is s io n /Tra n s a x le : 5 A -1 0 9

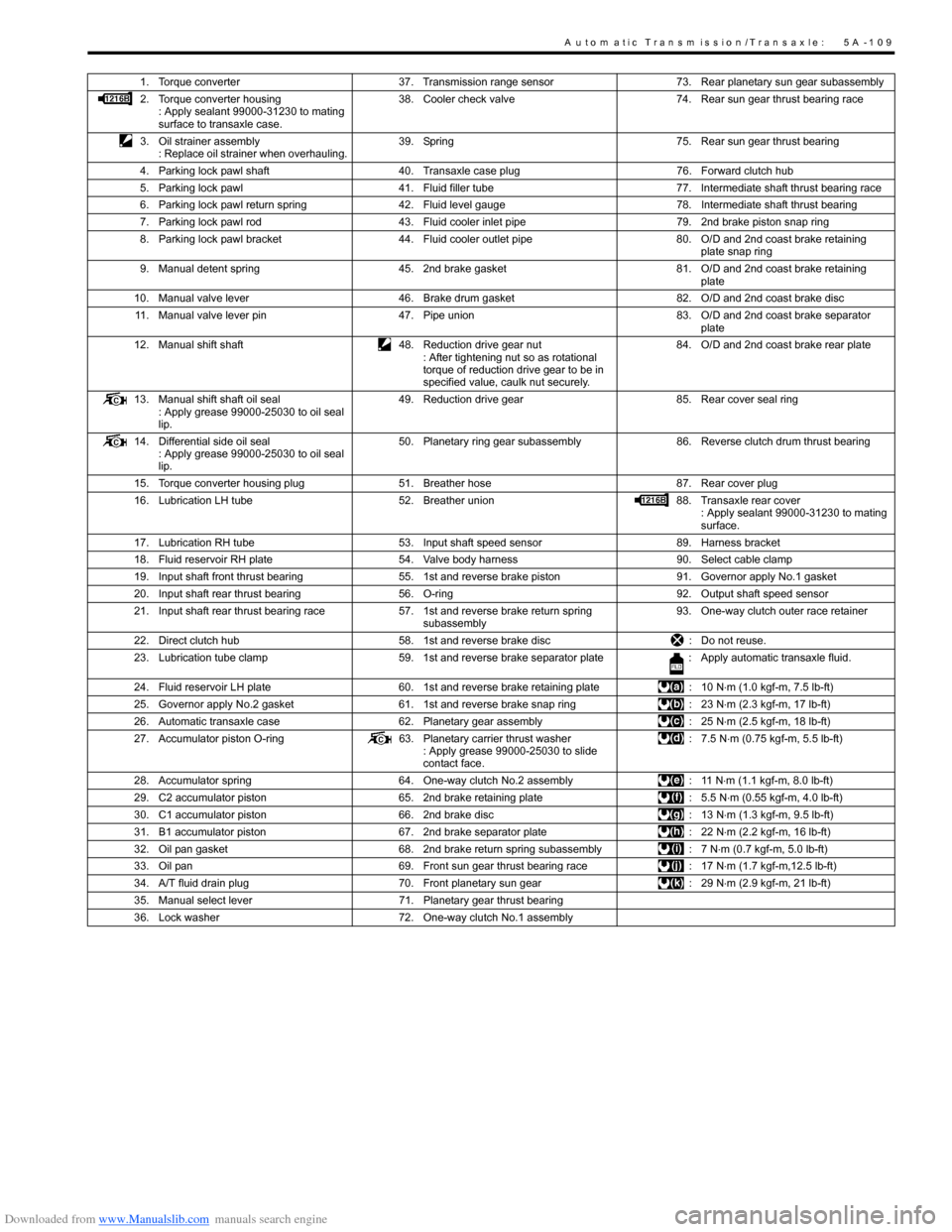

1. Torque converter37. Transmission range sensor 73. Rear planetary sun gear subassembly

2. Torque converter housing : Apply sealant 99000-31230 to mating

surface to transaxle case. 38. Cooler check valve

74. Rear sun gear thrust bearing race

3. Oil strainer assembly : Replace oil strainer when overhauling. 39. Spring

75. Rear sun gear thrust bearing

4. Parking lock pawl shaft 40. Transaxle case plug 76. Forward clutch hub

5. Parking lock pawl 41. Fluid filler tube 77. Intermediate shaft thrust bearing race

6. Parking lock pawl return spring 42. Fluid level gauge 78. Intermediate shaft thrust bearing

7. Parking lock pawl rod 43. Fluid cooler inlet pipe 79. 2nd brake piston snap ring

8. Parking lock pawl bracket 44. Fluid cooler outlet pipe 80. O/D and 2nd coast brake retaining

plate snap ring

9. Manual detent spring 45. 2nd brake gasket 81. O/D and 2nd coast brake retaining

plate

10. Manual valve lever 46. Brake drum gasket 82. O/D and 2nd coast brake disc

11. Manual valve lever pin 47. Pipe union 83. O/D and 2nd coast brake separator

plate

12. Manual shift shaft 48. Reduction drive gear nut

: After tightening nut so as rotational

torque of reduction drive gear to be in

specified value, caulk nut securely. 84. O/D and 2nd coast brake rear plate

13. Manual shift shaft oil seal : Apply grease 99000-25030 to oil seal

lip. 49. Reduction drive gear

85. Rear cover seal ring

14. Differential side oil seal : Apply grease 99000-25030 to oil seal

lip. 50. Planetary ring gear subassembly

86. Reverse clutch drum thrust bearing

15. Torque converter housing plug 51. Breather hose 87. Rear cover plug

16. Lubrication LH tube 52. Breather union 88. Transaxle rear cover

: Apply sealant 99000-31230 to mating

surface.

17. Lubrication RH tube 53. Input shaft speed sensor 89. Harness bracket

18. Fluid reservoir RH plate 54. Valve body harness 90. Select cable clamp

19. Input shaft front thrust bearing 55. 1st and reverse brake piston 91. Governor apply No.1 gasket

20. Input shaft rear thrust bearing 56. O-ring 92. Output shaft speed sensor

21. Input shaft rear thrust bearing race 57. 1st and reverse brake return spring

subassembly 93. One-way clutch outer race retainer

22. Direct clutch hub 58. 1st and reverse brake disc : Do not reuse.

23. Lubrication tube clamp 59. 1st and reverse brake separator plate : Apply automatic transaxle fluid.

24. Fluid reservoir LH plate 60. 1st and reverse brake retaining plate : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

25. Governor apply No.2 gasket 61. 1st and reverse brake snap ring : 23 N⋅m (2.3 kgf-m, 17 lb-ft)

26. Automatic transaxle case 62. Planetary gear assembly : 25 N⋅m (2.5 kgf-m, 18 lb-ft)

27. Accumulator piston O-ring 63. Planetary carrier thrust washer

: Apply grease 99000-25030 to slide

contact face. : 7.5 N

⋅m (0.75 kgf-m, 5.5 lb-ft)

28. Accumulator spring 64. One-way clutch No.2 assembly : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

29. C2 accumulator piston 65. 2nd brake retaining plate : 5.5 N⋅m (0.55 kgf-m, 4.0 lb-ft)

30. C1 accumulator piston 66. 2nd brake disc : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

31. B1 accumulator piston 67. 2nd brake separator plate : 22 N⋅m (2.2 kgf-m, 16 lb-ft)

32. Oil pan gasket 68. 2nd brake return spring subassembly : 7 N⋅m (0.7 kgf-m, 5.0 lb-ft)

33. Oil pan 69. Front sun gear thrust bearing race : 17 N⋅m (1.7 kgf-m,12.5 lb-ft)

34. A/T fluid drain plug 70. Front planetary sun gear : 29 N⋅m (2.9 kgf-m, 21 lb-ft)

35. Manual select lever 71. Planetary gear thrust bearing

36. Lock washer 72. One-way clutch No.1 assembly