EVAP CANISTER SUZUKI SWIFT 2008 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 376 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-1 Fuel System:

Engine

Fuel System

Precautions

Precautions on Fuel System ServiceS7RS0B1700001

WARNING!

Before attempting service of any type on fuel system, the following should be always observed in

order to reduce the risk of fire and personal injury.

• Disconnect negative cable at battery.

• Do not smoke, and place no smoking signs near work area.

• Be sure to have CO

2 fire extinguisher handy.

• Be sure to perform work in a well-ventilated area and away from any open flames (such as gas hot heater).

• Wear safety glasses.

• To relieve fuel vapor pressure in fuel tank, remove fuel filler cap from fuel filler neck and then

reinstall it.

• As fuel feed line is still under high fuel pr essure even after stopping engine, loosening or

disconnecting fuel feed line directly may cause dangerous spout of fuel. Before loosening or

disconnecting fuel feed line, make sure to relieve fuel pressure referring to “Fuel Pressure Relief

Procedure”.

• A small amount of fuel may be released when the fuel line is disconnected. In order to reduce the risk of personal injury, cover a shop cloth to the fitting to be disconnected. Be sure to put that cloth

in an approved container after disconnecting.

• Never run engine with fuel pump relay disconnected when engine and exhaust system are hot.

• Note that fuel hose connection varies with each type of pipe. Be sure to connect and clamp each hose correctly referring to “Fuel Hose Disconnecting and Reconnecting”.

After connecting, make sure that it has no twist or kink.

• When installing inje ctor or fuel feed pipe, lubr icate its O-ring with gasoline.

General Description

Fuel System DescriptionS7RS0B1701001

CAUTION!

This engine requires the unleaded fuel only.

The leaded and/or low lead fuel can result in

engine damage and reduce the effectiveness

of the emission control system.

The main components of the fuel system are fuel tank,

fuel pump assembly (with fuel filter, fuel level gauge, fuel

pressure regulator, fuel feed line and fuel vapor line.

For the details of fuel flow, refer to “Fuel Delivery System

Diagram”.

Fuel Delivery System DescriptionS7RS0B1701002

The fuel delivery system consists of the fuel tank, fuel

pump assembly (with built-in f uel filter and fuel pressure

regulator), delivery pipe, injectors and fuel feed line.

The fuel in the fuel tank is pumped up by the fuel pump,

sent into delivery pipe and injected by the injectors.

As the fuel pump assembly is equipped with built-in fuel

filter and fuel pressure regulator, the fuel is filtered and

its pressure is regulated before being sent to the feed

pipe.

The excess fuel at fuel pressure regulation process is

returned back into the fuel tank.

Also, fuel vapor generated in fuel tank is led through the

fuel vapor line into the EVAP canister.

For system diagram, refer to “Fuel Delivery System

Diagram”.

Page 377 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-2

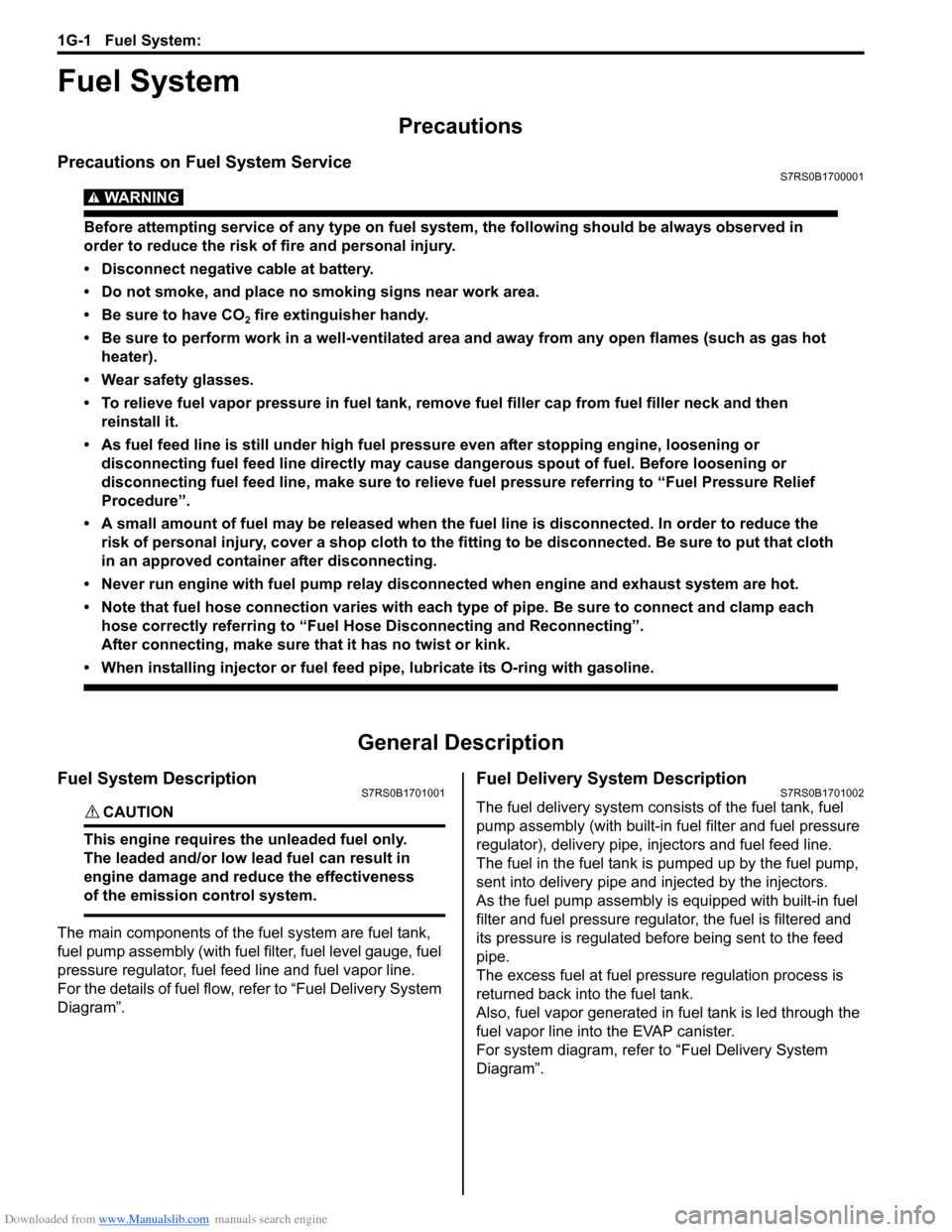

Fuel Pump DescriptionS7RS0B1701003

The fuel pump (1) is an in-tank type electric pump.

Incorporated in the pump assembly are;

a fuel filter (2) and a fuel pressure regulator (3) are

included and a fuel level gauge (4) is attached.

Addition of the fuel pressure regulator to the fuel pump

makes it possible to mainta in the fuel pressure at

constant level and ECM controls compensation for

variation in the intake manifold pressure.

Schematic and Routing Diagram

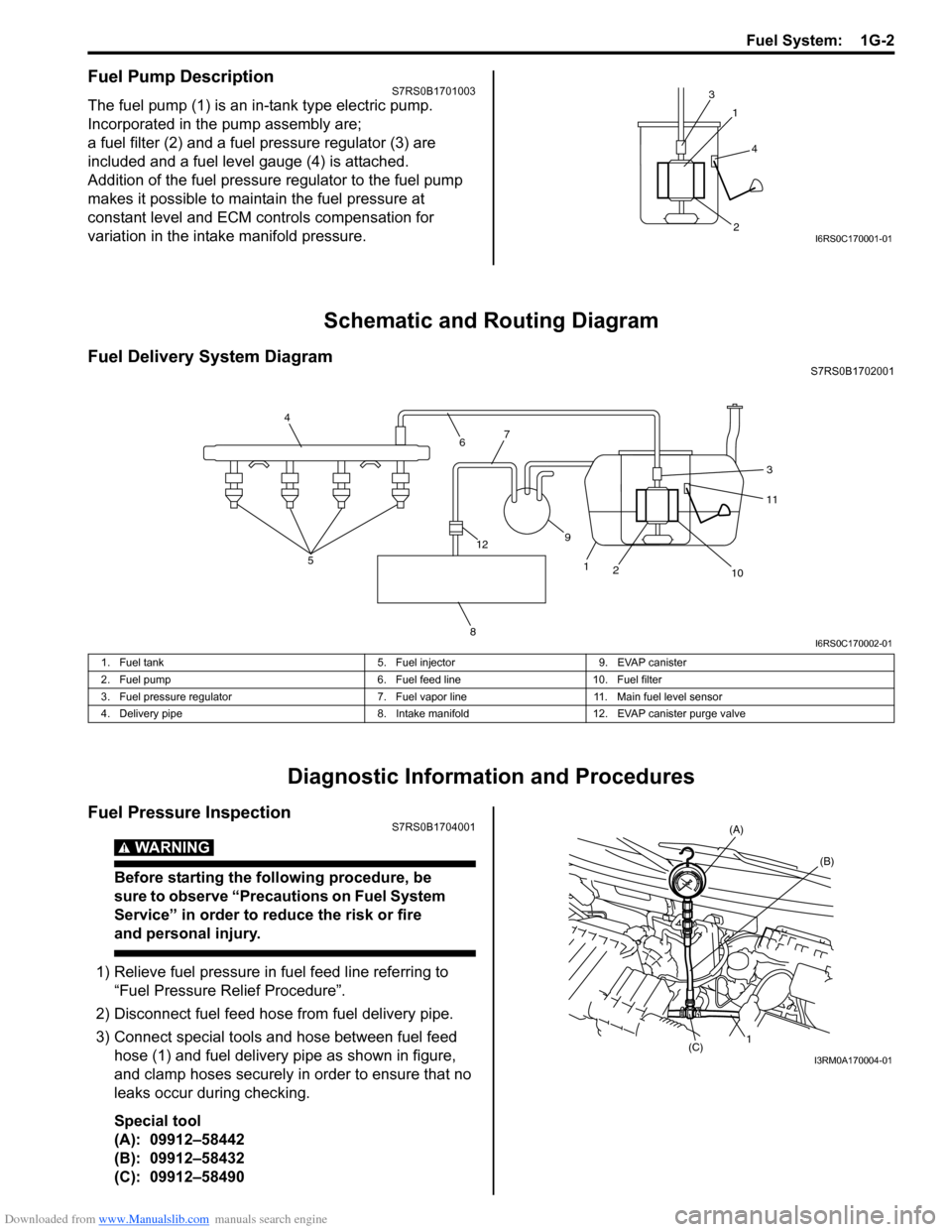

Fuel Delivery System DiagramS7RS0B1702001

Diagnostic Information and Procedures

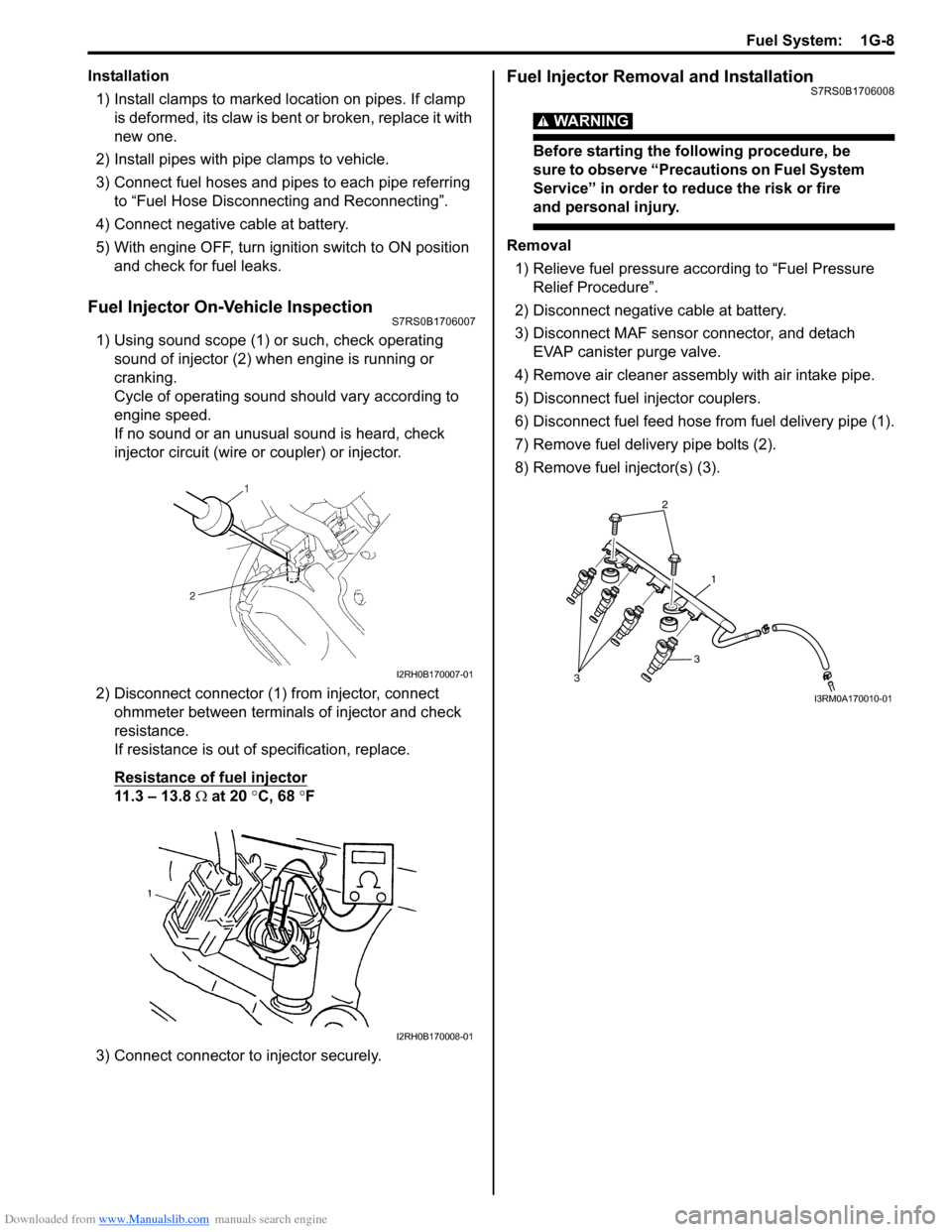

Fuel Pressure InspectionS7RS0B1704001

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

1) Relieve fuel pressure in fuel feed line referring to

“Fuel Pressure Relief Procedure”.

2) Disconnect fuel feed hose from fuel delivery pipe.

3) Connect special tools and hose between fuel feed hose (1) and fuel delivery pipe as shown in figure,

and clamp hoses securely in order to ensure that no

leaks occur during checking.

Special tool

(A): 09912–58442

(B): 09912–58432

(C): 09912–58490

1

3

2

4

I6RS0C170001-01

4

6 7

8

12

2 3

11

10

5

1

9

I6RS0C170002-01

1. Fuel tank

5. Fuel injector9. EVAP canister

2. Fuel pump 6. Fuel feed line10. Fuel filter

3. Fuel pressure regulator 7. Fuel vapor line 11. Main fuel level sensor

4. Delivery pipe 8. Intake manifold12. EVAP canister purge valve

1

(C) (B)

(A)

I3RM0A170004-01

Page 383 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-8

Installation1) Install clamps to marked location on pipes. If clamp is deformed, its claw is bent or broken, replace it with

new one.

2) Install pipes with pipe clamps to vehicle.

3) Connect fuel hoses and pipes to each pipe referring to “Fuel Hose Disconnecting and Reconnecting”.

4) Connect negative cable at battery.

5) With engine OFF, turn igniti on switch to ON position

and check for fuel leaks.

Fuel Injector On-Vehicle InspectionS7RS0B1706007

1) Using sound scope (1) or such, check operating sound of injector (2) when engine is running or

cranking.

Cycle of operating sound should vary according to

engine speed.

If no sound or an unusual sound is heard, check

injector circuit (wire or coupler) or injector.

2) Disconnect connector (1) from injector, connect ohmmeter between terminals of injector and check

resistance.

If resistance is out of specification, replace.

Resistance of fuel injector

11.3 – 13.8 Ω at 20 °C, 68 °F

3) Connect connector to injector securely.

Fuel Injector Removal and InstallationS7RS0B1706008

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal 1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure”.

2) Disconnect negative cable at battery.

3) Disconnect MAF sensor connector, and detach EVAP canister purge valve.

4) Remove air cleaner assembly with air intake pipe.

5) Disconnect fuel injector couplers.

6) Disconnect fuel feed hose from fuel delivery pipe (1).

7) Remove fuel delivery pipe bolts (2).

8) Remove fuel injector(s) (3).

I2RH0B170007-01

I2RH0B170008-01

2

1

3

3

I3RM0A170010-01

Page 1182 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-11 Wiring Systems:

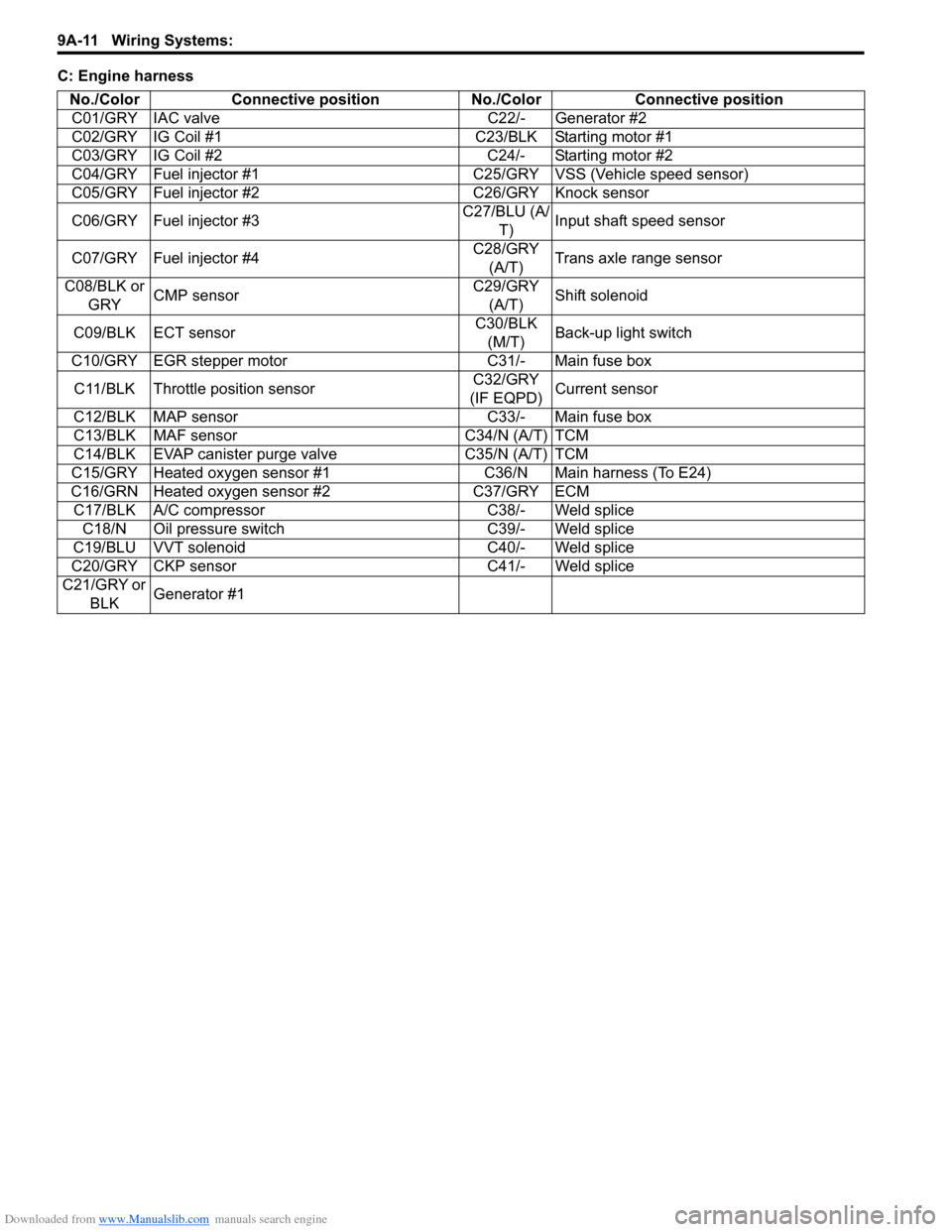

C: Engine harnessNo./Color Connective position No./Color Connective positionC01/GRY IAC valve C22/- Generator #2

C02/GRY IG Coil #1 C23/BLK Starting motor #1

C03/GRY IG Coil #2 C24/- Starting motor #2

C04/GRY Fuel injector #1 C25/GR Y VSS (Vehicle speed sensor)

C05/GRY Fuel injector #2 C26/GRY Knock sensor

C06/GRY Fuel injector #3 C27/BLU (A/

T) Input shaft speed sensor

C07/GRY Fuel injector #4 C28/GRY

(A/T) Trans axle range sensor

C08/BLK or GRY CMP sensor C29/GRY

(A/T) Shift solenoid

C09/BLK ECT sensor C30/BLK

(M/T) Back-up light switch

C10/GRY EGR stepper motor C31/- Main fuse box C11/BLK Throttle position sensor C32/GRY

(IF EQPD) Current sensor

C12/BLK MAP sensor C33/- Main fuse box

C13/BLK MAF sensor C34/N (A/T) TCM

C14/BLK EVAP canister purge valve C35/N (A/T) TCM

C15/GRY Heated oxygen sensor #1 C36/N Main harness (To E24)

C16/GRN Heated oxygen sensor #2 C37/GRY ECM C17/BLK A/C compressor C38/- Weld splice C18/N Oil pressure switch C39/- Weld splice

C19/BLU VVT solenoid C40/- Weld splice

C20/GRY CKP sensor C41/- Weld splice

C21/GRY or BLK Generator #1

Page 1184 of 1496

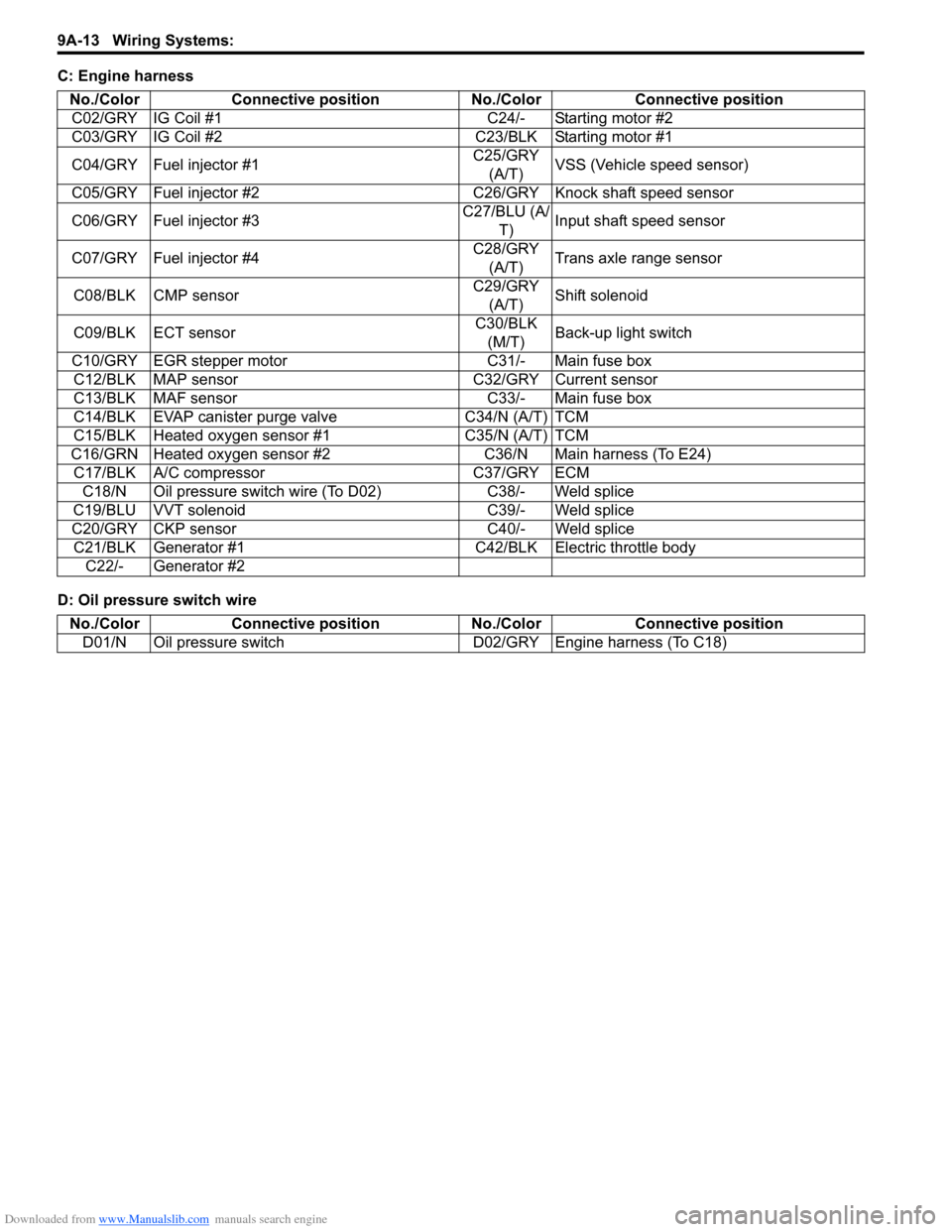

Downloaded from www.Manualslib.com manuals search engine 9A-13 Wiring Systems:

C: Engine harness

D: Oil pressure switch wireNo./Color Connective position No./Color Connective position

C02/GRY IG Coil #1 C24/- Starting motor #2

C03/GRY IG Coil #2 C23/BLK Starting motor #1

C04/GRY Fuel injector #1 C25/GRY

(A/T) VSS (Vehicle speed sensor)

C05/GRY Fuel injector #2 C26/GRY Knock shaft speed sensor

C06/GRY Fuel injector #3 C27/BLU (A/

T) Input shaft speed sensor

C07/GRY Fuel injector #4 C28/GRY

(A/T) Trans axle range sensor

C08/BLK CMP sensor C29/GRY

(A/T) Shift solenoid

C09/BLK ECT sensor C30/BLK

(M/T) Back-up light switch

C10/GRY EGR stepper motor C31/- Main fuse box C12/BLK MAP sensor C32/GRY Current sensor

C13/BLK MAF sensor C33/- Main fuse box

C14/BLK EVAP canister purge valve C34/N (A/T) TCM

C15/BLK Heated oxygen sensor #1 C35/N (A/T) TCM

C16/GRN Heated oxygen sensor #2 C36/N Main harness (To E24) C17/BLK A/C compressor C37/GRY ECM C18/N Oil pressure switch wire (To D02) C38/- Weld splice

C19/BLU VVT solenoid C39/- Weld splice

C20/GRY CKP sensor C40/- Weld splice C21/BLK Generator #1 C42/BLK Electric throttle body C22/- Generator #2

No./Color Connective position No./ColorConnective position

D01/N Oil pressure switch D02/GRY Engine harness (To C18)

Page 1222 of 1496

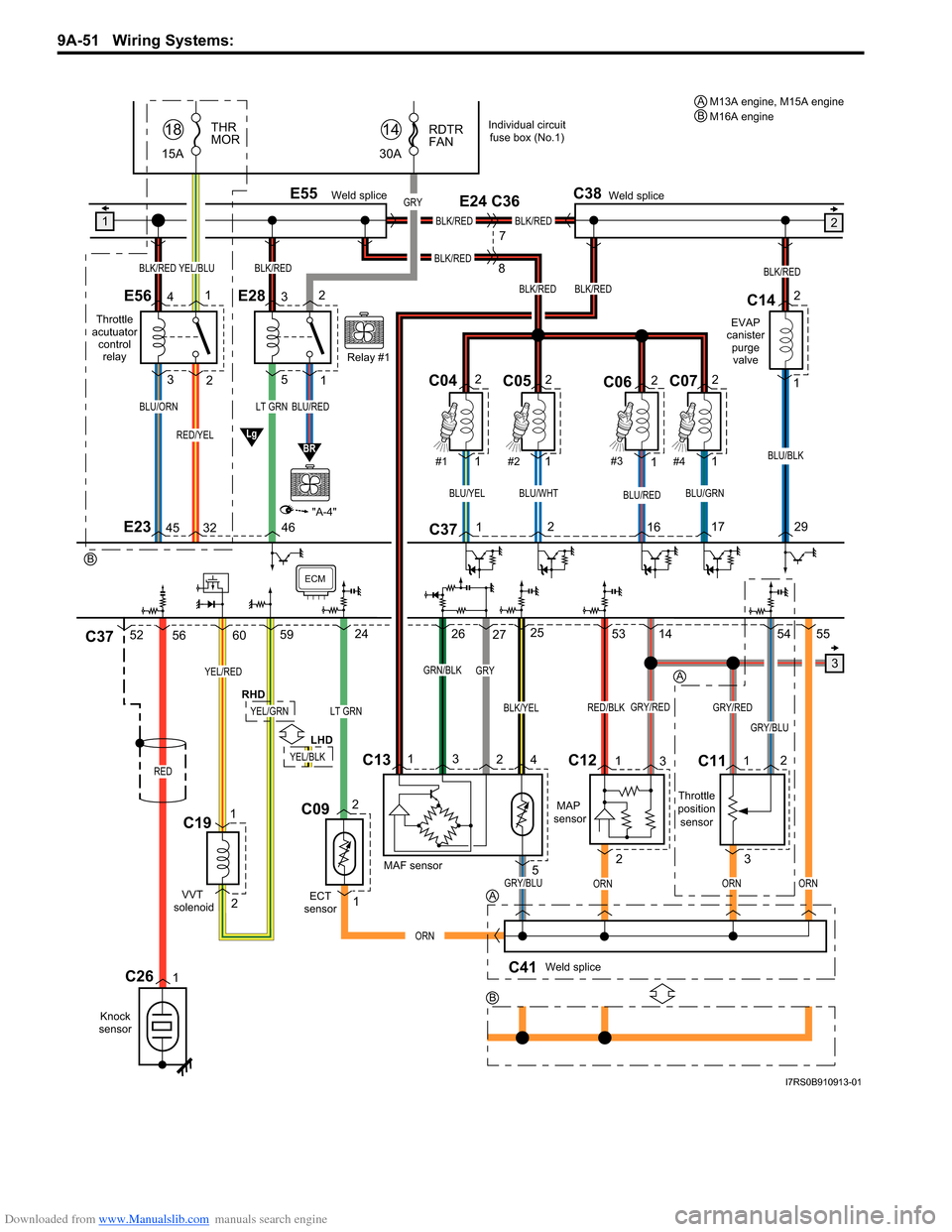

Downloaded from www.Manualslib.com manuals search engine 9A-51 Wiring Systems:

Throttle

acutuator controlrelay

4532

BLK/REDYEL/BLU

1

243E562

135E28

15A THR

MOR

18

M13A engine, M15A engine

M16A engine

A

B

A

A

B

B

2C09

LT GRN

1

C12

C13

C11

E23

C37

C37

Knock

sensor

C19

ECM

C042

1C052

1C062

1C072

1

#2

#1 #3

#4

BLU/REDBLU/WHTBLU/YELBLU/GRN

BLK/RED

BLU/BLK

EVAP

canister purgevalve

C14

ECT

sensor

ORN

MAF sensor

MAP

sensorThrottle

position sensor

Weld spliceC41

ORNORNORN

LT GRNBLU/REDBLU/ORN

RED/YEL

GRY

"A-4"

Lg

30A RDTR

FAN

14

Relay #1

BR

46

1

2

1

29

17

16

2

1

2425

26 27

4

3

2

1

5

1

2 3

1

32

2

3

54 55

RED/BLKGRY/REDGRY/RED

GRY/BLU

53 14

E24 C36

8

7

C26

RED

1

56

VVT

solenoid

1

2

60 59

BLK/RED

E55Weld spliceC38Weld splice

BLK/REDBLK/RED

BLK/REDBLK/RED

BLK/RED

GRN/BLKGRY

BLK/YEL

GRY/BLU

52

YEL/RED

Individual circuit

fuse box (No.1)

YEL/GRN

YEL/BLK

RHD

LHD

I7RS0B910913-01