Signal light SUZUKI SWIFT 2008 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 687 of 1496

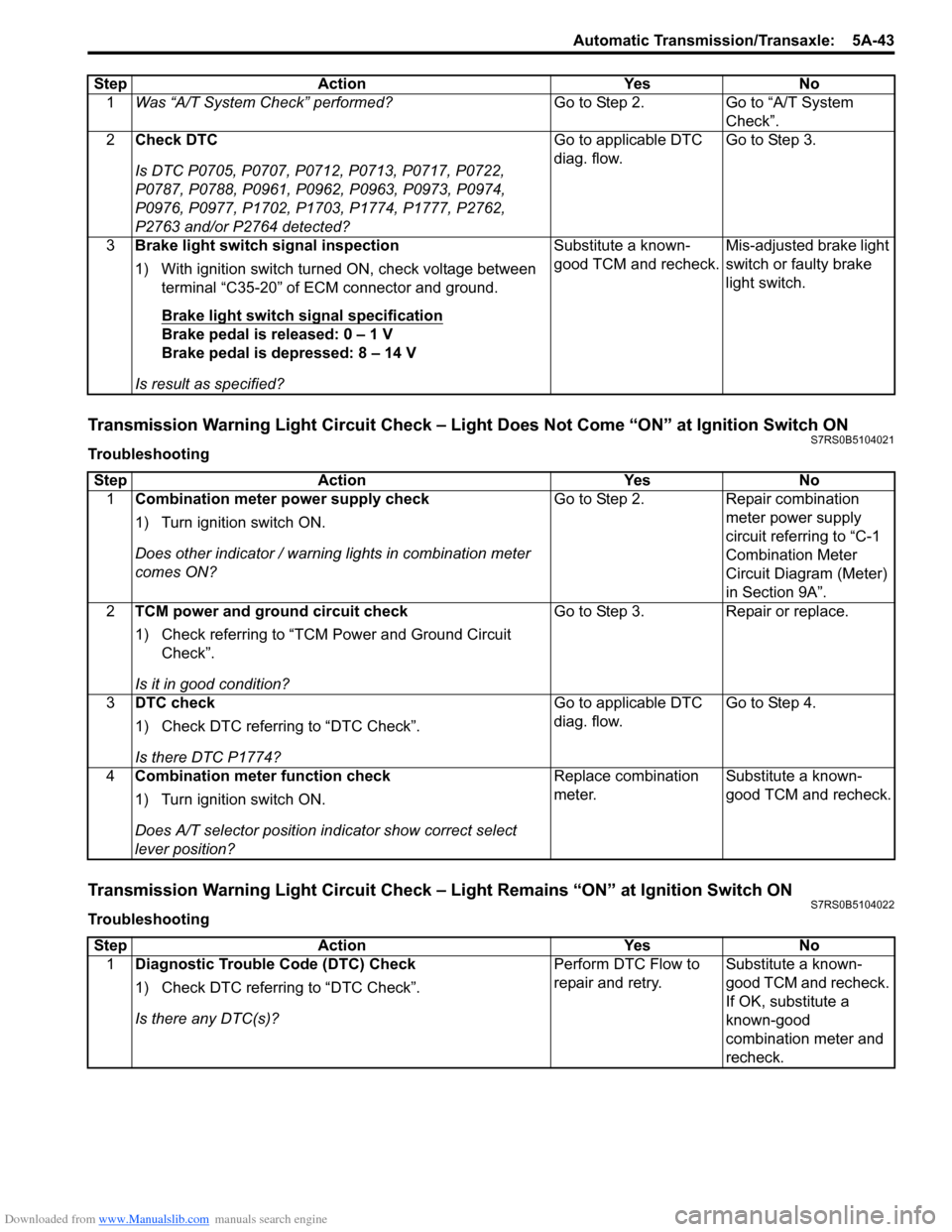

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-43

Transmission Warning Light Circuit Check – Light Does Not Come “ON” at Ignition Switch ONS7RS0B5104021

Troubleshooting

Transmission Warning Light Circuit Check – Light Remains “ON” at Ignition Switch ONS7RS0B5104022

TroubleshootingStep Action Yes No

1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

2 Check DTC

Is DTC P0705, P0707, P0712, P0713, P0717, P0722,

P0787, P0788, P0961, P0962, P0963, P0973, P0974,

P0976, P0977, P1702, P1703, P1774, P1777, P2762,

P2763 and/or P2764 detected? Go to applicable DTC

diag. flow.

Go to Step 3.

3 Brake light switch signal inspection

1) With ignition switch turned ON, check voltage between

terminal “C35-20” of ECM connector and ground.

Brake light switch signal specification

Brake pedal is released: 0 – 1 V

Brake pedal is depressed: 8 – 14 V

Is result as specified? Substitute a known-

good TCM and recheck.

Mis-adjusted brake light

switch or faulty brake

light switch.

Step

Action YesNo

1 Combination meter power supply check

1) Turn ignition switch ON.

Does other indicator / warnin g lights in combination meter

comes ON? Go to Step 2.

Repair combination

meter power supply

circuit referring to “C-1

Combination Meter

Circuit Diagram (Meter)

in Section 9A”.

2 TCM power and ground circuit check

1) Check referring to “TCM Power and Ground Circuit

Check”.

Is it in good condition? Go to Step 3.

Repair or replace.

3 DTC check

1) Check DTC referring to “DTC Check”.

Is there DTC P1774? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Combination meter function check

1) Turn ignition switch ON.

Does A/T selector position in dicator show correct select

lever position? Replace combination

meter.

Substitute a known-

good TCM and recheck.

Step

Action YesNo

1 Diagnostic Trouble Code (DTC) Check

1) Check DTC referring to “DTC Check”.

Is there any DTC(s)? Perform DTC Flow to

repair and retry.

Substitute a known-

good TCM and recheck.

If OK, substitute a

known-good

combination meter and

recheck.

Page 867 of 1496

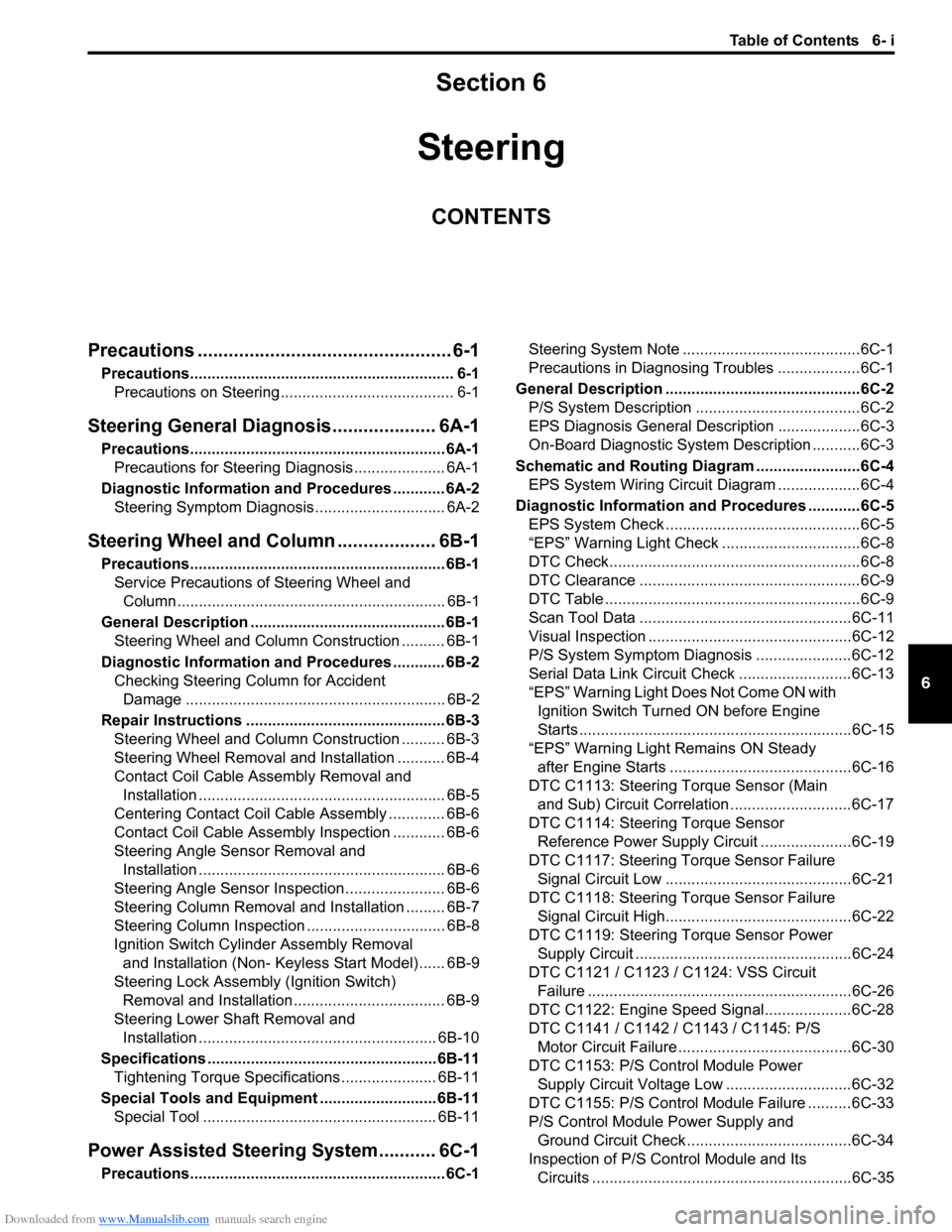

Downloaded from www.Manualslib.com manuals search engine Table of Contents 6- i

6

Section 6

CONTENTS

Steering

Precautions ................................................. 6-1

Precautions............................................................. 6-1

Precautions on Steering........................................ 6-1

Steering General Diagnosi s.................... 6A-1

Precautions........................................................... 6A-1

Precautions for Steering Diagnosis ..................... 6A-1

Diagnostic Information and Procedures ............ 6A-2 Steering Symptom Diagnosis .............................. 6A-2

Steering Wheel and Column ................... 6B-1

Precautions........................................................... 6B-1

Service Precautions of Steering Wheel and Column.............................................................. 6B-1

General Description ............................................. 6B-1 Steering Wheel and Column Construction .......... 6B-1

Diagnostic Information and Procedures ............ 6B-2 Checking Steering Column for Accident Damage ............................................................ 6B-2

Repair Instructions .............................................. 6B-3 Steering Wheel and Column Construction .......... 6B-3

Steering Wheel Removal and Installation ........... 6B-4

Contact Coil Cable Assembly Removal and Installation ......................................................... 6B-5

Centering Contact Coil Cable Assembly ............. 6B-6

Contact Coil Cable Assembly Inspection ............ 6B-6

Steering Angle Sensor Removal and Installation ......................................................... 6B-6

Steering Angle Sensor Inspection ....................... 6B-6

Steering Column Removal and Installation ......... 6B-7

Steering Column Inspecti on ................................ 6B-8

Ignition Switch Cylinder Assembly Removal and Installation (Non- Keyless Start Model)...... 6B-9

Steering Lock Assembly (Ignition Switch) Removal and Installation................................... 6B-9

Steering Lower Shaft Removal and Installation ....................................................... 6B-10

Specifications ..................................................... 6B-11

Tightening Torque Specifications ...................... 6B-11

Special Tools and Equipmen t ........................... 6B-11

Special Tool ...................................................... 6B-11

Power Assisted Steering System........... 6C-1

Precautions........................................................... 6C-1 Steering System Note .........................................6C-1

Precautions in Diagnosing Troubles ...................6C-1

General Description .............................................6C-2 P/S System Description ......................................6C-2

EPS Diagnosis General Descr iption ...................6C-3

On-Board Diagnostic System Description ...........6C-3

Schematic and Routing Diagram ........................6C-4 EPS System Wiring Circuit Diagram ...................6C-4

Diagnostic Information and Procedures ............6C-5 EPS System Check .............. ...............................6C-5

“EPS” Warning Light Check . ...............................6C-8

DTC Check..........................................................6C-8

DTC Clearance ...................................................6C-9

DTC Table ...........................................................6C-9

Scan Tool Data .................................................6C-11

Visual Inspection ...............................................6C-12

P/S System Symptom Diagnosis ......................6C-12

Serial Data Link Circuit Check ..........................6C-13

“EPS” Warning Light Do es Not Come ON with

Ignition Switch Turn ed ON before Engine

Starts ...............................................................6C-15

“EPS” Warning Light Remains ON Steady after Engine Starts ..........................................6C-16

DTC C1113: Steering Torque Sensor (Main and Sub) Circuit Correlation ............................6C-17

DTC C1114: Steering Torque Sensor Reference Power Supply Circuit .....................6C-19

DTC C1117: Steering Torque Sensor Failure Signal Circuit Low ...........................................6C-21

DTC C1118: Steering Torque Sensor Failure Signal Circuit High...........................................6C-22

DTC C1119: Steering Torque Sensor Power Supply Circuit ..................................................6C-24

DTC C1121 / C1123 / C1124: VSS Circuit

Failure .............................................................6C-26

DTC C1122: Engine Speed Signal....................6C-28

DTC C1141 / C1142 / C1143 / C1145: P/S Motor Circuit Failure ........................................6C-30

DTC C1153: P/S Control Module Power Supply Circuit Voltage Low .............................6C-32

DTC C1155: P/S Control Module Failure ..........6C-33

P/S Control Module Power Supply and Ground Circuit Check ......................................6C-34

Inspection of P/S Control Module and Its Circuits ............................................................6C-35

Page 887 of 1496

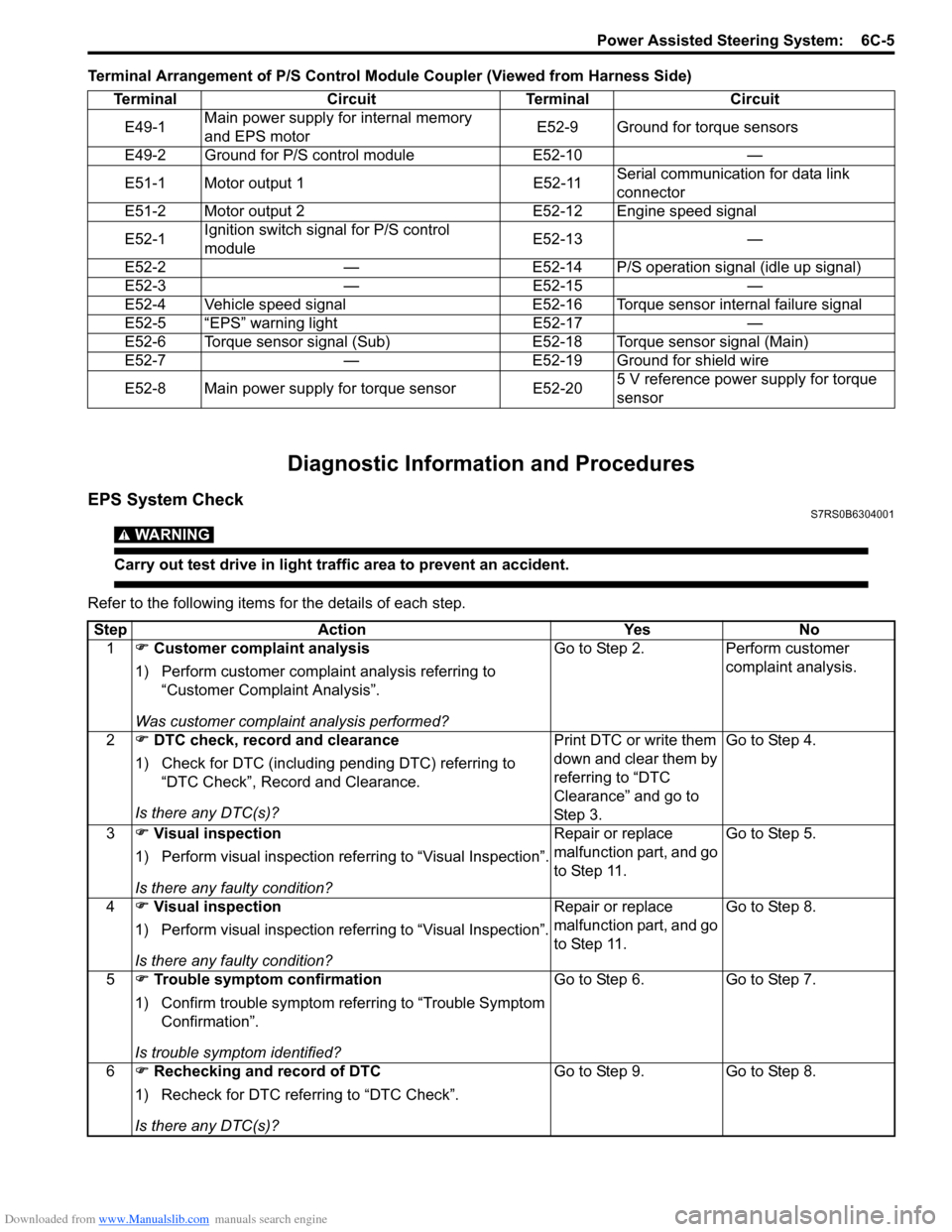

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-5

Terminal Arrangement of P/S Control Module Coupler (Viewed from Harness Side)

Diagnostic Information and Procedures

EPS System CheckS7RS0B6304001

WARNING!

Carry out test drive in light traffic area to prevent an accident.

Refer to the following items for the details of each step.Terminal Circuit Terminal Circuit

E49-1 Main power supply for internal memory

and EPS motor E52-9 Ground for torque sensors

E49-2 Ground for P/S control module E52-10 —

E51-1 Motor output 1 E52-11 Serial communication for data link

connector

E51-2 Motor output 2 E52-12 Engine speed signal

E52-1 Ignition switch signal for P/S control

module E52-13 —

E52-2 — E52-14 P/S operation signal (idle up signal)

E52-3 — E52-15 —

E52-4 Vehicle speed signal E52-16 Torque sensor internal failure signal

E52-5 “EPS” warning light E52-17 —

E52-6 Torque sensor signal (Sub) E52-18 Torque sensor signal (Main)

E52-7 — E52-19 Ground for shield wire

E52-8 Main power supply for torque sensor E52-20 5 V reference power supply for torque

sensor

Step

Action YesNo

1 �) Customer complaint analysis

1) Perform customer complaint analysis referring to “Customer Complaint Analysis”.

Was customer complaint analysis performed? Go to Step 2.

Perform customer

complaint analysis.

2 �) DTC check, record and clearance

1) Check for DTC (including pending DTC) referring to “DTC Check”, Record and Clearance.

Is there any DTC(s)? Print DTC or write them

down and clear them by

referring to “DTC

Clearance” and go to

St ep 3 .Go to Step 4.

3 �) Visual inspection

1) Perform visual inspection referring to “Visual Inspection”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 11.

Go to Step 5.

4 �) Visual inspection

1) Perform visual inspection referring to “Visual Inspection”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 11.

Go to Step 8.

5 �) Trouble symptom confirmation

1) Confirm trouble symptom referring to “Trouble Symptom Confirmation”.

Is trouble symptom identified? Go to Step 6.

Go to Step 7.

6 �) Rechecking and record of DTC

1) Recheck for DTC referring to “DTC Check”.

Is there any DTC(s)? Go to Step 9.

Go to Step 8.

Page 908 of 1496

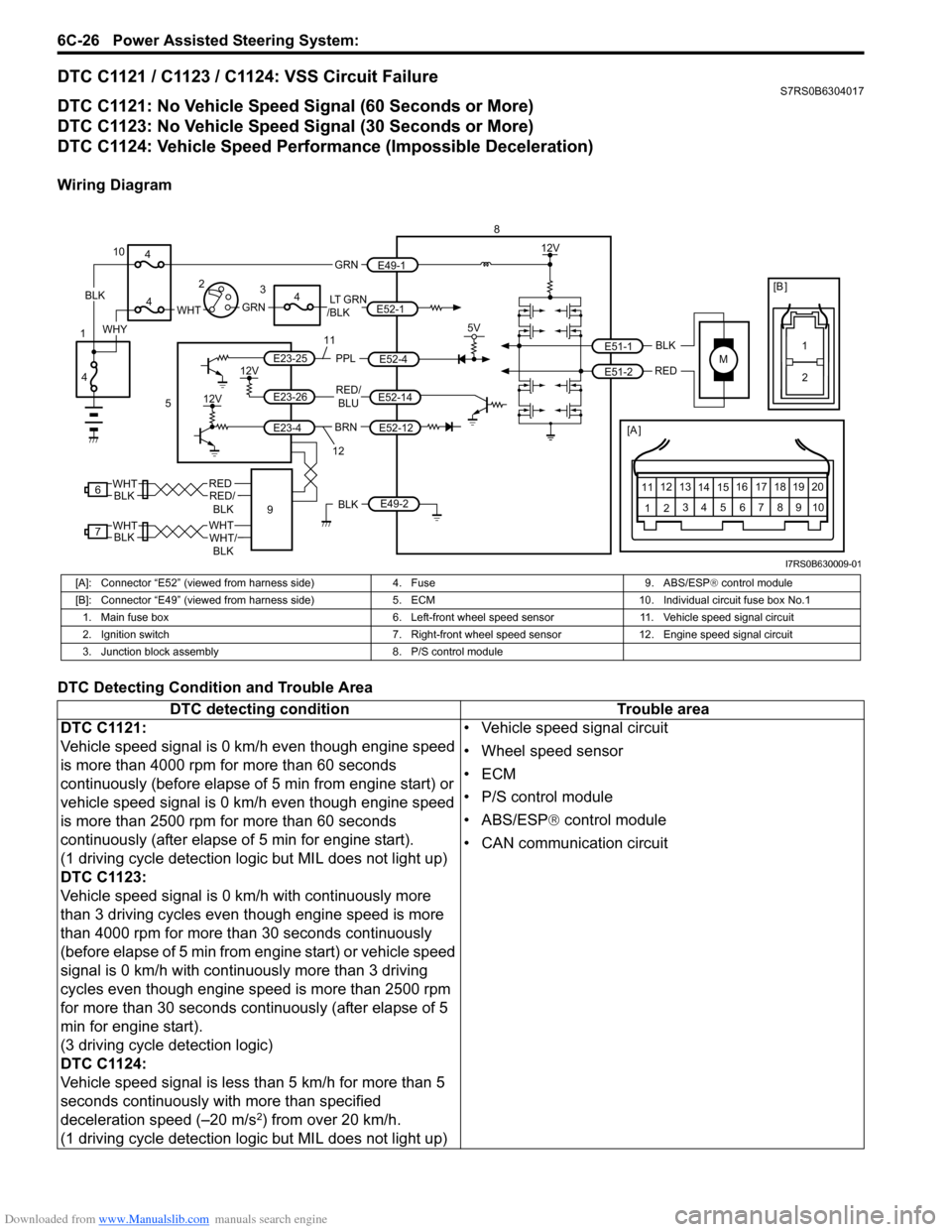

Downloaded from www.Manualslib.com manuals search engine 6C-26 Power Assisted Steering System:

DTC C1121 / C1123 / C1124: VSS Circuit FailureS7RS0B6304017

DTC C1121: No Vehicle Speed Signal (60 Seconds or More)

DTC C1123: No Vehicle Speed Signal (30 Seconds or More)

DTC C1124: Vehicle Speed Performance (Impossible Deceleration)

Wiring Diagram

DTC Detecting Condition and Trouble Area

M

BRNRED/

BLU

BLK

RED

E52-14

E52-12

E23-4

E23-26

E23-25 E51-1

E51-2

[A ]

12

3

4 5 67

89

11

10

12 13

141516

17 18 19 20

5V

PPL

E52-4

8

5

12V

E49-2BLK

12V

12V

6REDRED/ BLKWHT

7WHTWHT/BLKWHTBLK BLK

111

2

[B ]

9

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

10

3

4

4

4

4

1 2

12

I7RS0B630009-01

[A]: Connector “E52” (viewed from harness side)

4. Fuse9. ABS/ESP® control module

[B]: Connector “E49” (viewed from harness si de)5. ECM 10. Individual circuit fuse box No.1

1. Main fuse box 6. Left-front wheel speed sensor11. Vehicle speed signal circuit

2. Ignition switch 7. Right-front wheel speed sensor 12. Engine speed signal circuit

3. Junction block assembly 8. P/S control module

DTC detecting condition Trouble area

DTC C1121:

Vehicle speed signal is 0 km/h even though engine speed

is more than 4000 rpm for more than 60 seconds

continuously (before elapse of 5 min from engine start) or

vehicle speed signal is 0 km/h even though engine speed

is more than 2500 rpm for more than 60 seconds

continuously (after elapse of 5 min for engine start).

(1 driving cycle detection logic but MIL does not light up)

DTC C1123:

Vehicle speed signal is 0 km/h with continuously more

than 3 driving cycles even though engine speed is more

than 4000 rpm for more than 30 seconds continuously

(before elapse of 5 min from engine start) or vehicle speed

signal is 0 km/h with continuously more than 3 driving

cycles even though engine speed is more than 2500 rpm

for more than 30 seconds continuously (after elapse of 5

min for engine start).

(3 driving cycle detection logic)

DTC C1124:

Vehicle speed signal is less than 5 km/h for more than 5

seconds continuously with more than specified

deceleration speed (–20 m/s

2) from over 20 km/h.

(1 driving cycle detection logic but MIL does not light up) • Vehicle speed signal circuit

• Wheel speed sensor

•ECM

• P/S control module

• ABS/ESP®

control module

• CAN communication circuit

Page 918 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-36 Power Assisted Steering System:

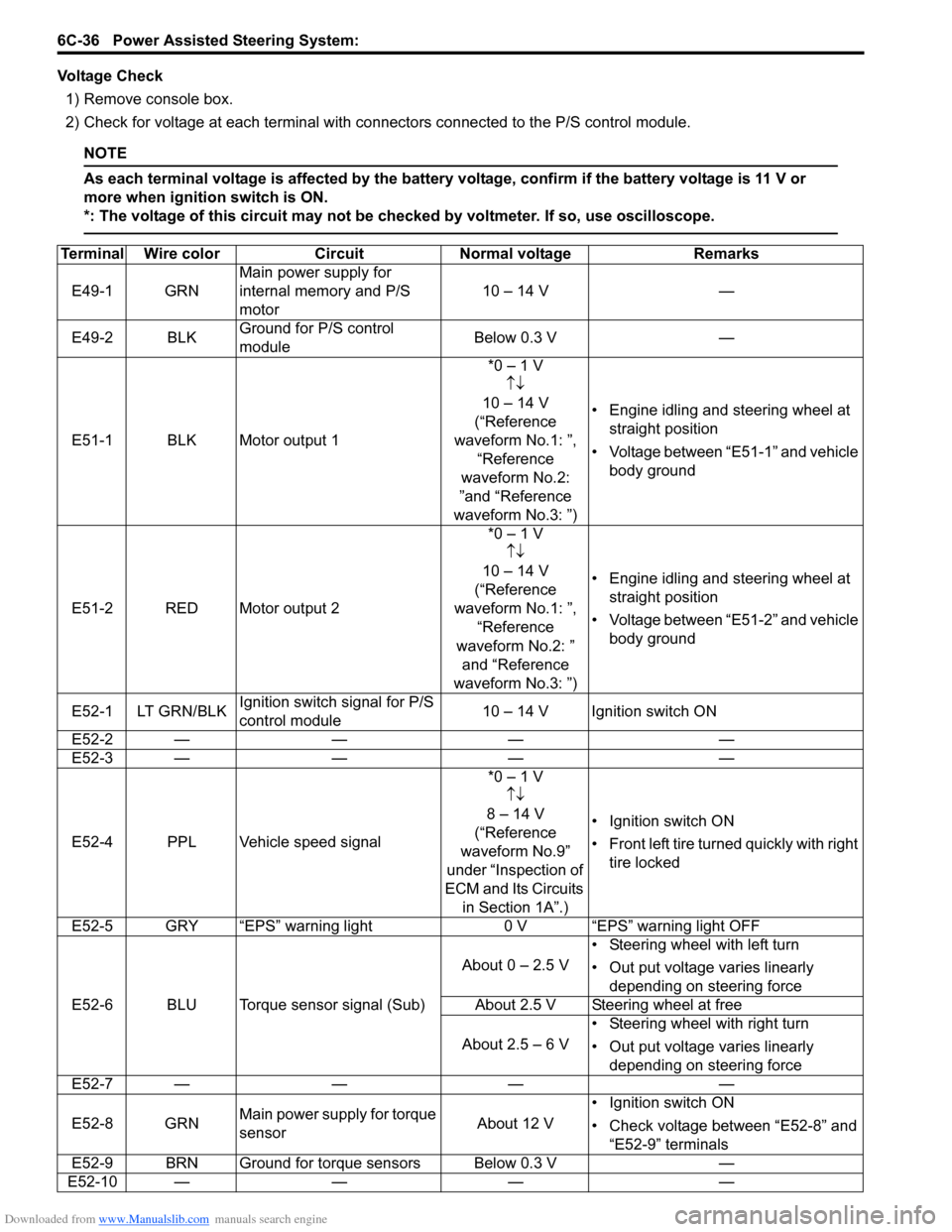

Voltage Check1) Remove console box.

2) Check for voltage at each terminal with co nnectors connected to the P/S control module.

NOTE

As each terminal voltage is affected by the battery voltage, confirm if the battery voltage is 11 V or

more when ignition switch is ON.

*: The voltage of this circuit may not be checked by voltmeter. If so, use oscilloscope.

Terminal Wire colorCircuit Normal voltage Remarks

E49-1 GRN Main power supply for

internal memory and P/S

motor 10 – 14 V

—

E49-2 BLK Ground for P/S control

module Below 0.3 V

—

E51-1 BLK Motor output 1 *0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.1: ”, “Reference

waveform No.2:

”and “Reference

waveform No.3: ”) • Engine idling and steering wheel at

straight position

• Voltage between “E51-1” and vehicle body ground

E51-2 RED Motor output 2 *0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.1: ”, “Reference

waveform No.2: ” and “Reference

waveform No.3: ”) • Engine idling and steering wheel at

straight position

• Voltage between “E51-2” and vehicle body ground

E52-1 LT GRN/BLK Ignition switch signal for P/S

control module 10 – 14 V Ignition switch ON

E52-2 — —— —

E52-3 — —— —

E52-4 PPL Vehicle speed signal *0 – 1 V

↑↓

8 – 14 V

(“Reference

waveform No.9”

under “Inspection of

ECM and Its Circuits in Section 1A”.) • Ignition switch ON

•Front left tire tu

rned quickly with right

tire locked

E52-5 GRY “EPS” warning light 0 V “EPS” warning light OFF

E52-6 BLU Torque sensor signal (Sub) About 0 – 2.5 V

• Steering wheel with left turn

• Out put voltage varies linearly

depending on steering force

About 2.5 V Steering wheel at free

About 2.5 – 6 V • Steering wheel with right turn

• Out put voltage varies linearly

depending on steering force

E52-7 — —— —

E52-8 GRN Main power supply for torque

sensor About 12 V• Ignition switch ON

• Check voltage between “E52-8” and

“E52-9” terminals

E52-9 BRN Ground for torque sensors Below 0.3 V —

E52-10 — —— —

Page 992 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-44 Air Conditioning System: Automatic Type

3) Light over sunload sensor vertically with an incandescent lamp approximately 100 W apart from

about 100 mm (3.94 in.).

NOTE

If sunload sensor is not lighted over with an

incandescent lamp, DTC B1504 is detected

as current DTC even though there is not any

malfunction.

4) Turn ignition switch to ON position.

5) Erase DTC according to instructions displayed on SUZUKI scan tool.

NOTE

To know how to use SUZUKI scan tool, refer

to operator’s manual for SUZUKI scan tool.

6) After completing the clearance, turn ignition switch to OFF position, and then di sconnect SUZUKI scan

tool from DLC.

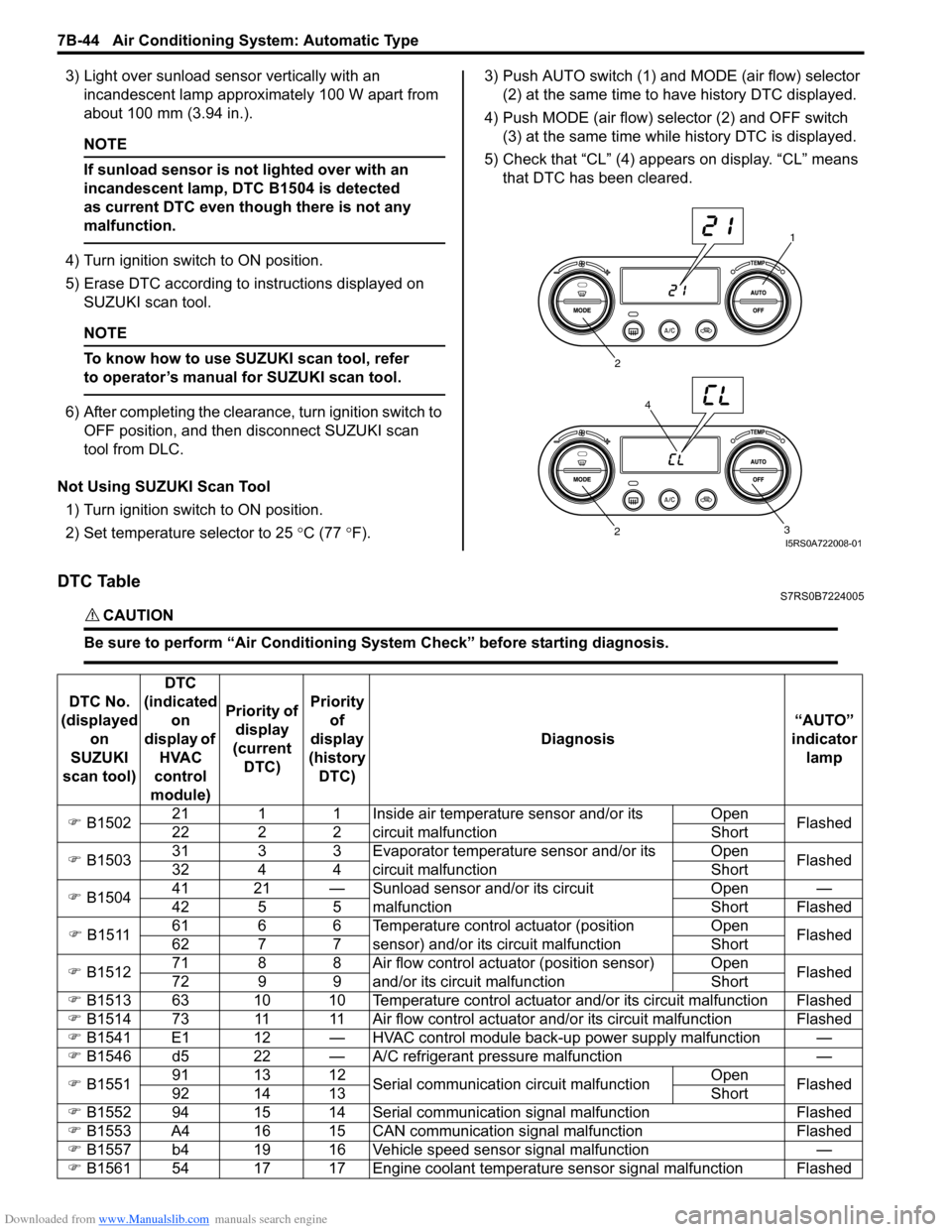

Not Using SUZUKI Scan Tool 1) Turn ignition switch to ON position.

2) Set temperature selector to 25 °C (77 °F). 3) Push AUTO switch (1) and

MODE (air flow) selector

(2) at the same time to have history DTC displayed.

4) Push MODE (air flow) selector (2) and OFF switch (3) at the same time while history DTC is displayed.

5) Check that “CL” (4) appears on display. “CL” means that DTC has been cleared.

DTC TableS7RS0B7224005

CAUTION!

Be sure to perform “Air Conditioning Sy stem Check” before starting diagnosis.

1

2

3

2

4

I5RS0A722008-01

DTC No.

(displayed on

SUZUKI

scan tool) DTC

(indicated on

display of HVAC

control

module) Priority of

display

(current DTC) Priority

of

display

(history DTC) Diagnosis

“AUTO”

indicator lamp

�) B1502 21 1 1 Inside air temperature sensor and/or its

circuit malfunction Open

Flashed

22 2 2 Short

�) B1503 31 3 3 Evaporator temperature sensor and/or its

circuit malfunction Open

Flashed

32 4 4 Short

�) B1504 41 21 — Sunload sensor and/or its circuit

malfunction Open —

42 5 5 Short Flashed

�) B1511 61 6 6 Temperature control actuator (position

sensor) and/or its circuit malfunction Open

Flashed

62 7 7 Short

�) B1512 71 8 8 Air flow control actuator (position sensor)

and/or its circuit malfunction Open

Flashed

72 9 9 Short

�) B1513 63 10 10 Temperature control actuator and/or its circuit malfunction Flashed

�) B1514 73 11 11 Air flow control actuator and/or its circuit malfunction Flashed

�) B1541 E1 12 — HVAC control module back-up power supply malfunction —

�) B1546 d5 22 — A/C refrigerant pressure malfunction —

�) B1551 91 13 12

Serial communication circuit malfunction Open

Flashed

92 14 13 Short

�) B1552 94 15 14 Serial communication signal malfunction Flashed

�) B1553 A4 16 15 CAN communication signal malfunction Flashed

�) B1557 b4 19 16 Vehicle speed sensor signal malfunction —

�) B1561 54 17 17 Engine coolant temperature sensor signal malfunction Flashed

Page 993 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-45

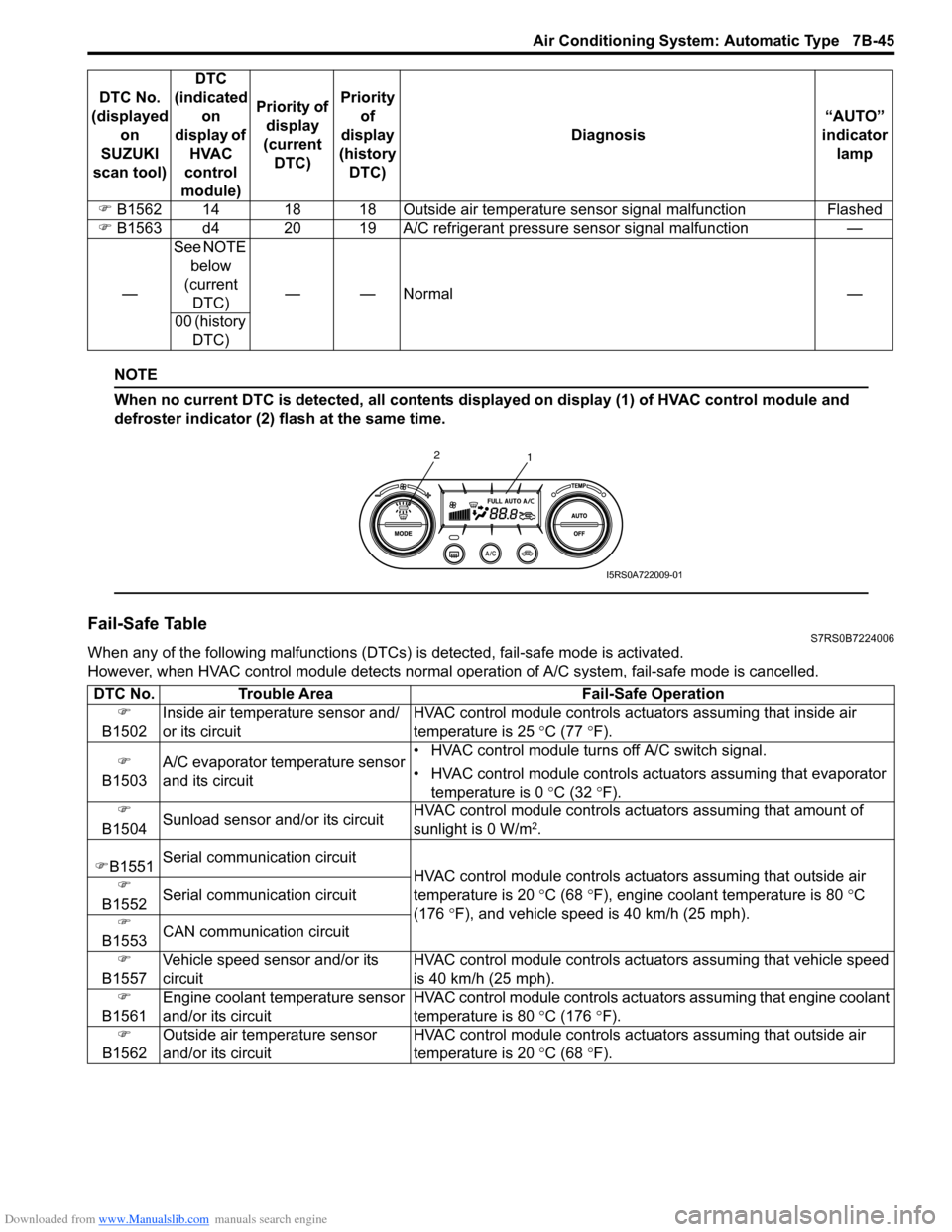

NOTE

When no current DTC is detected, all contents displayed on display (1) of HVAC control module and

defroster indicator (2) flash at the same time.

Fail-Safe TableS7RS0B7224006

When any of the following malfunctions (DTCs) is detected, fail-safe mode is activated.

However, when HVAC control module detects normal ope ration of A/C system, fail-safe mode is cancelled.

�)

B1562 14 18 18 Outside air temperatur e sensor signal malfunction Flashed

�) B1563 d4 20 19 A/C refrigerant pressure sensor signal malfunction —

— See NOTE

below

(current DTC) ——Normal —

00 (history DTC)

DTC No.

(displayed on

SUZUKI

scan tool) DTC

(indicated on

display of HVAC

control

module) Priority of

display

(current DTC) Priority

of

display

(history DTC) Diagnosis

“AUTO”

indicator lamp

1

2

I5RS0A722009-01

DTC No.

Trouble Area Fail-Safe Operation

�)

B1502 Inside air temperature sensor and/

or its circuit HVAC control module controls actu

ators assuming that inside air

temperature is 25 ° C (77 °F).

�)

B1503 A/C evaporator temperature sensor

and its circuit • HVAC control module turn

s off A/C switch signal.

• HVAC control module controls actu ators assuming that evaporator

temperature is 0 ° C (32 °F).

�)

B1504 Sunload sensor and/or its circuit HVAC control module controls actu

ators assuming that amount of

sunlight is 0 W/m

2.

�) B1551 Serial communication circuit

HVAC control module controls actuators assuming that outside air

temperature is 20 ° C (68 °F), engine coolant temperature is 80 °C

(176 °F), and vehicle speed is 40 km/h (25 mph).

�)

B1552 Serial communication circuit

�)

B1553 CAN communication circuit

�)

B1557 Vehicle speed sensor and/or its

circuit HVAC control module controls act

uators assuming that vehicle speed

is 40 km/h (25 mph).

�)

B1561 Engine coolant temperature sensor

and/or its circuit HVAC control module controls act

uators assuming that engine coolant

temperature is 80 ° C (176 °F).

�)

B1562 Outside air temperature sensor

and/or its circuit HVAC control module controls actu

ators assuming that outside air

temperature is 20 ° C (68 °F).

Page 995 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-47

Scan Tool Data Definitions

TEMP CONT SWITCH (TEMPERATURE SELECTOR): Position of temperature control

selector of HVAC control module

CABIN TEMPERATURE: In-car temperature detected

by inside air temperature sensor installed in HVAC

control module

OUTSIDE AIR TEMP (OUTSIDE AIR TEMPERATURE): Outside air temperature

detected by outside air temperature sensor installed

in front bumper member

EVAPORATOR TEMP (EVAPORATOR TEMPERATURE): Temperature of air passed

through evaporator

COOLANT TEMP (ENGINE COOLANT TEMPERATURE): Engine coolant temperature

detected by engine coolant temperature sensor

SUN LOAD: Amount of sunlight detected by sunload

sensor installed on the driver side on the dashboard

MODE CONT SWITCH (MODE (AIR FLOW) SELECTOR): Position of air flow selector of HVAC

control module

FAN CONT SWITCH (BLOWER SPEED SELECTOR): Position of blower speed selector of HVAC control

module

FAN DESIRED VOLT: Voltage for blower motor AIR MIX POS SEN (TEMPERATURE CONTROL

ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in temperature control actuator

MODE POS SENSOR (AIR FLOW CONTROL ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in air flow control actuator

A/C CONT SIG (A/C SWITCH SIGNAL, ON or OFF): State of A/C switch

BLOWER LOAD SIG (BLO WER FAN LOAD SIGNAL,

ON or OFF): ON: Position of blower speed selector

is 1st position or more / OFF: Position of blower

speed selector is OFF position.

AIR INTAKE MODE (AUTO, FRE or REC): State of air

intake mode

REFRIGERANT PRESSURE (A/C REFRIGERANT ABSOLUTE PRESSURE): This parameter

indicates A/C refrigerant absolute pressure

calculated by ECM

A/C COMP CLUTCH (A/C COMPRESSOR MAGNET CLUTCH, ON or OFF): This parameter indicates

the state of the A/C switch

DFR INDICATOR (DEFROSTER INDICATOR LAMP, ON or OFF): State of defroster indicator lamp

VEHICLE SPEED: It is computed based on pulse

signals from vehicle speed sensor

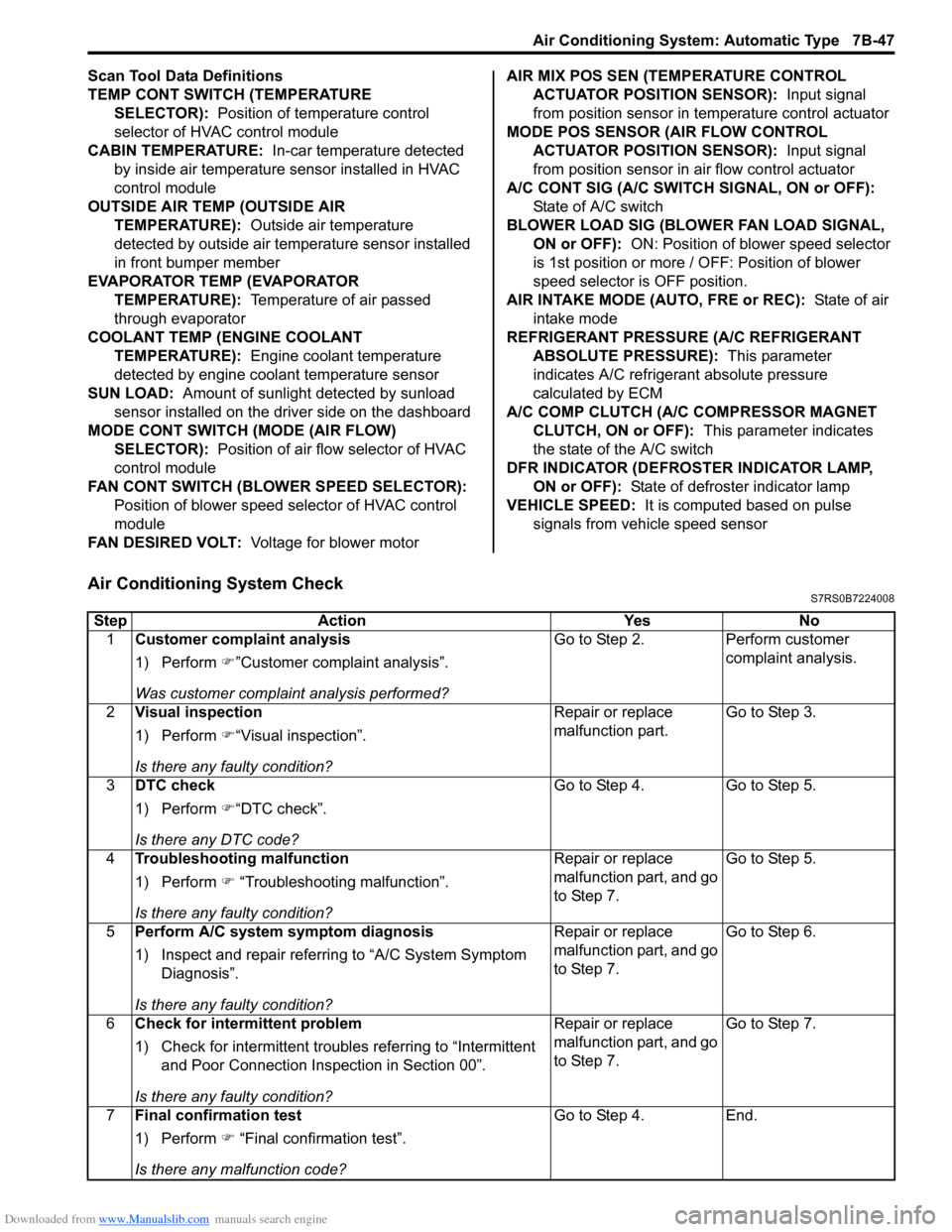

Air Conditioning System CheckS7RS0B7224008

Step Action YesNo

1 Customer complaint analysis

1) Perform �)”Customer complaint analysis”.

Was customer complaint analysis performed? Go to Step 2.

Perform customer

complaint analysis.

2 Visual inspection

1) Perform �)“Visual inspection”.

Is there any faulty condition? Repair or replace

malfunction part.

Go to Step 3.

3 DTC check

1) Perform �)“DTC check”.

Is there any DTC code? Go to Step 4.

Go to Step 5.

4 Troubleshooting malfunction

1) Perform �) “Troubleshooting malfunction”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 5.

5 Perform A/C system symptom diagnosis

1) Inspect and repair referri ng to “A/C System Symptom

Diagnosis”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 6.

6 Check for intermittent problem

1) Check for intermittent troubles referring to “Intermittent

and Poor Connection Inspection in Section 00”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 7.

7 Final confirmation test

1) Perform �) “Final confirmation test”.

Is there any malfunction code? Go to Step 4.

End.

Page 1016 of 1496

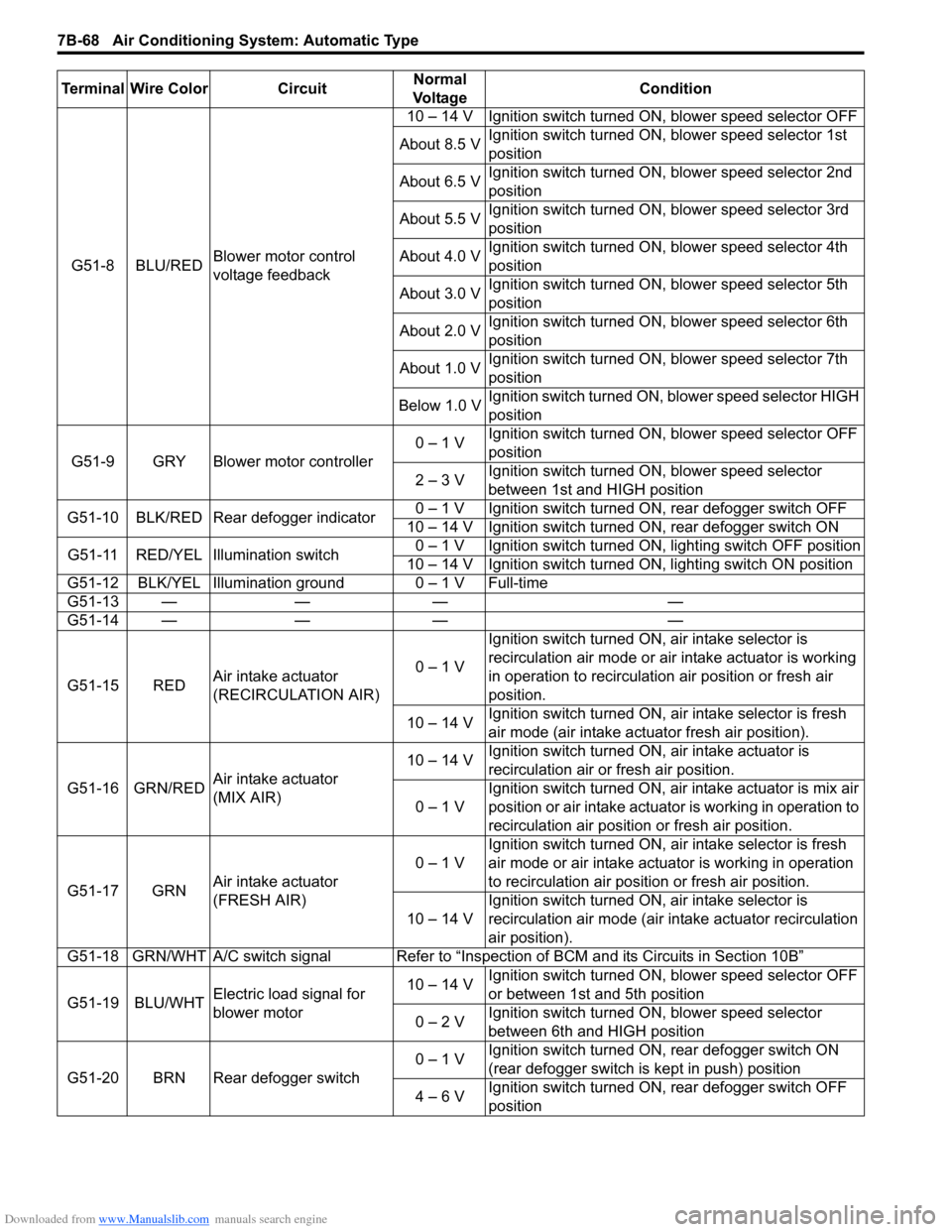

Downloaded from www.Manualslib.com manuals search engine 7B-68 Air Conditioning System: Automatic Type

G51-8 BLU/REDBlower motor control

voltage feedback 10 – 14 V Ignition switch turned ON, blower speed selector OFF

About 8.5 V Ignition switch turned ON, blower speed selector 1st

position

About 6.5 V Ignition switch turned ON, blower speed selector 2nd

position

About 5.5 V Ignition switch turned ON, blower speed selector 3rd

position

About 4.0 V Ignition switch turned ON, blower speed selector 4th

position

About 3.0 V Ignition switch turned ON, blower speed selector 5th

position

About 2.0 V Ignition switch turned ON, blower speed selector 6th

position

About 1.0 V Ignition switch turned ON, blower speed selector 7th

position

Below 1.0 V Ignition switch turned ON, blower speed selector HIGH

position

G51-9 GRY Blower motor controller 0 – 1 V

Ignition switch turned ON, blower speed selector OFF

position

2 – 3 V Ignition switch turned ON, blower speed selector

between 1st and HIGH position

G51-10 BLK/RED Rear defogger indicator 0 – 1 V Ignition switch turned ON, rear defogger switch OFF

10 – 14 V Ignition switch turned ON, rear defogger switch ON

G51-11 RED/YEL Illumination switch 0 – 1 V Ignition switch turned ON, lighting switch OFF position

10 – 14 V Ignition switch turned ON, lighting switch ON position

G51-12 BLK/YEL Illumination ground 0 – 1 V Full-time

G51-13 — — — —

G51-14 — — — —

G51-15 RED Air intake actuator

(RECIRCULATION AIR) 0 – 1 VIgnition switch turned ON, air intake selector is

recirculation air mode or air intake actuator is working

in operation to recirculation air position or fresh air

position.

10 – 14 V Ignition switch turned ON, ai

r intake selector is fresh

air mode (air intake actuator fresh air position).

G51-16 GRN/RED Air intake actuator

(MIX AIR) 10 – 14 V

Ignition switch turned ON, air intake actuator is

recirculation air or fresh air position.

0 – 1 V Ignition switch turned ON, air intake actuator is mix air

position or air intake actuator is working in operation to

recirculation air position or fresh air position.

G51-17 GRN Air intake actuator

(FRESH AIR) 0 – 1 V

Ignition switch turned ON, ai

r intake selector is fresh

air mode or air intake actuator is working in operation

to recirculation air position or fresh air position.

10 – 14 V Ignition switch turned ON, air intake selector is

recirculation air mode (air intake actuator recirculation

air position).

G51-18 GRN/WHT A/C switch signal Refer to “Inspe ction of BCM and its Circuits in Section 10B”

G51-19 BLU/WHT Electric load signal for

blower motor 10 – 14 V

Ignition switch turned ON, blower speed selector OFF

or between 1st and 5th position

0 – 2 V Ignition switch turned ON, blower speed selector

between 6th and HIGH position

G51-20 BRN Rear defogger switch 0 – 1 V

Ignition switch turned ON, rear defogger switch ON

(rear defogger switch is kept in push) position

4 – 6 V Ignition switch turned ON, rear defogger switch OFF

position

Terminal Wire Color Circuit

Normal

Vo l ta g e Condition

Page 1167 of 1496

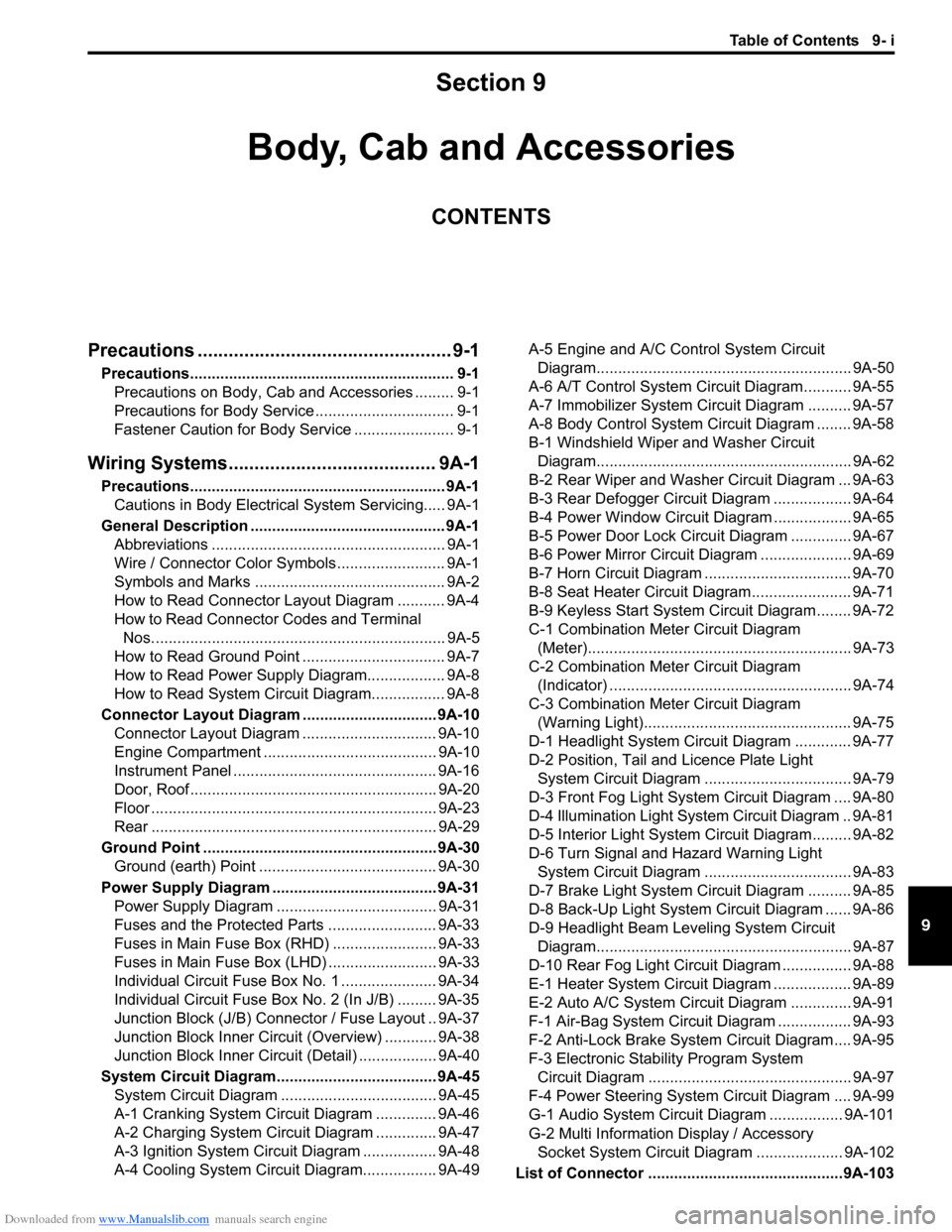

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9- i

9

Section 9

CONTENTS

Body, Cab and Accessories

Precautions ................................................. 9-1

Precautions............................................................. 9-1

Precautions on Body, Cab and Accessories ......... 9-1

Precautions for Body Service ................................ 9-1

Fastener Caution for Body Service ....................... 9-1

Wiring Systems............... ......................... 9A-1

Precautions........................................................... 9A-1

Cautions in Body Electrical System Servicing..... 9A-1

General Description ............................................. 9A-1 Abbreviations ...................................................... 9A-1

Wire / Connector Color Sy mbols ......................... 9A-1

Symbols and Marks ............................................ 9A-2

How to Read Connector Layout Diagram ........... 9A-4

How to Read Connector Codes and Terminal Nos.................................................................... 9A-5

How to Read Ground Point ................................. 9A-7

How to Read Power Supply Diagram.................. 9A-8

How to Read System Circuit Diagram................. 9A-8

Connector Layout Diagram . .............................. 9A-10

Connector Layout Diagram ............................... 9A-10

Engine Compartment .......... .............................. 9A-10

Instrument Panel ............................................... 9A-16

Door, Roof......................................................... 9A-20

Floor .................................................................. 9A-23

Rear .................................................................. 9A-29

Ground Point ...................................................... 9A-30 Ground (earth) Point ......................................... 9A-30

Power Supply Diagram ........ .............................. 9A-31

Power Supply Diagram ....... .............................. 9A-31

Fuses and the Protected Parts ......................... 9A-33

Fuses in Main Fuse Box (RHD) ........................ 9A-33

Fuses in Main Fuse Box (LHD) ......................... 9A-33

Individual Circuit Fuse Box No. 1 ...................... 9A-34

Individual Circuit Fuse Box No. 2 (In J/B) ......... 9A-35

Junction Block (J/B) Connector / Fuse Layout .. 9A-37

Junction Block Inner Circuit (Overview) ............ 9A-38

Junction Block Inner Circuit (Detail) .................. 9A-40

System Circuit Diagram... .................................. 9A-45

System Circuit Diagram .. .................................. 9A-45

A-1 Cranking System Circ uit Diagram .............. 9A-46

A-2 Charging System Circu it Diagram .............. 9A-47

A-3 Ignition System Circu it Diagram ................. 9A-48

A-4 Cooling System Circuit Diagram................. 9A-49 A-5 Engine and A/C Control System Circuit

Diagram........................................................... 9A-50

A-6 A/T Control System Circuit Diagram........... 9A-55

A-7 Immobilizer System Circuit Diagram .......... 9A-57

A-8 Body Control System Circuit Diagram ........ 9A-58

B-1 Windshield Wiper and Washer Circuit Diagram........................................................... 9A-62

B-2 Rear Wiper and Washer Circuit Diagram ... 9A-63

B-3 Rear Defogger Circuit Diagram .................. 9A-64

B-4 Power Window Circuit Diagram .................. 9A-65

B-5 Power Door Lock Circu it Diagram .............. 9A-67

B-6 Power Mirror Circuit Diagram ..................... 9A-69

B-7 Horn Circuit Diagram .................................. 9A-70

B-8 Seat Heater Circuit Diagram....................... 9A-71

B-9 Keyless Start System Circuit Diagram........ 9A-72

C-1 Combination Mete r Circuit Diagram

(Meter)............................................................. 9A-73

C-2 Combination Mete r Circuit Diagram

(Indicator) ........................................................ 9A-74

C-3 Combination Mete r Circuit Diagram

(Warning Light)................................................ 9A-75

D-1 Headlight System Circuit Diagram ............. 9A-77

D-2 Position, Tail and Licence Plate Light System Circuit Diagram .................................. 9A-79

D-3 Front Fog Light System Circuit Diagram .... 9A-80

D-4 Illumination Light System Circuit Diagram .. 9A-81

D-5 Interior Light System Circuit Diagram......... 9A-82

D-6 Turn Signal and Hazard Warning Light System Circuit Diagram .................................. 9A-83

D-7 Brake Light System Circuit Diagram .......... 9A-85

D-8 Back-Up Light System Circuit Diagram ...... 9A-86

D-9 Headlight Beam Leveling System Circuit Diagram........................................................... 9A-87

D-10 Rear Fog Light Circuit Diagram ................ 9A-88

E-1 Heater System Circuit Diagram .................. 9A-89

E-2 Auto A/C System Circuit Diagram .............. 9A-91

F-1 Air-Bag System Circuit Diagram ................. 9A-93

F-2 Anti-Lock Brake System Circuit Diagram.... 9A-95

F-3 Electronic Stab ility Program System

Circuit Diagram .................. ............................. 9A-97

F-4 Power Steering System Circuit Diagram .... 9A-99

G-1 Audio System Circuit Diagram ................. 9A-101

G-2 Multi Information Display / Accessory Socket System Circuit Diagram .................... 9A-102

List of Connector .............................................9A-103