hand rem SUZUKI SWIFT 2008 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 469 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-2

Lower than recommended pressure can cause:

• Tire squeal on turns

• Hard Steering

• Rapid and uneven wear on the edges of the tread

• Tire rim bruises and rupture

• Tire cord breakage

• High tire temperature

• Reduced handling

• High fuel consumption

Replacement Tires

When replacement is necessary, the original equipment

type tire should be used. Refer to the Tire Placard.

Replacement tires should be of the same size, load

range and construction as those originally on the vehicle.

Use of any other size or type tire may affect ride,

handling, speedometer / odometer calibration, vehicle

ground clearance and tire or snow chain clearance to the

body and chassis.

It is recommended that new tires be installed in pairs on

the same axle. If necessary to replace only one tire, it

should be paired with the tire having the most tread, to

equalize braking traction.

WARNING!

Do not mix different types of tires on the

same vehicle such as radial, bias and bias-

belted tires except in emergencies, because

handling may be seriously affected and may

result in loss of control.

The metric term for tire infl ation pressure is the kilo

pascal (kPa). Tire pressures is usually printed in both

kPa and kgf/cm

2 on the “Tire Placard”.

Metric tire gauges are available from tool suppliers.

The chart, shown the table, converts commonly used

inflation pressures from kPa to kgf/cm

2 and psi.

Wheels DescriptionS7RS0B2401002

Wheel Maintenance

Wheel repairs that use welding, heating, or peening are

not approved. All damaged wheels should be replaced.

Replacement Wheels

Wheels must be replaced if they are bent, dented, have

excessive lateral or radial runout, air leak through welds,

have elongated bolt holes, if lug wheel bolts won’t stay

tight, or if they are heavily rusted. Wheels with greater

runout than shown in the following may cause

objectional vibrations.

Replacement wheels must be equivalent to the original

equipment wheels in load capacity, diameter, rim with

offset and mounting configuration. A wheel of improper

size or type may affect wheel and bearing life, brake

cooling, speedometer / odometer calibration, vehicle

ground clearance and tire clearance to body and

chassis.

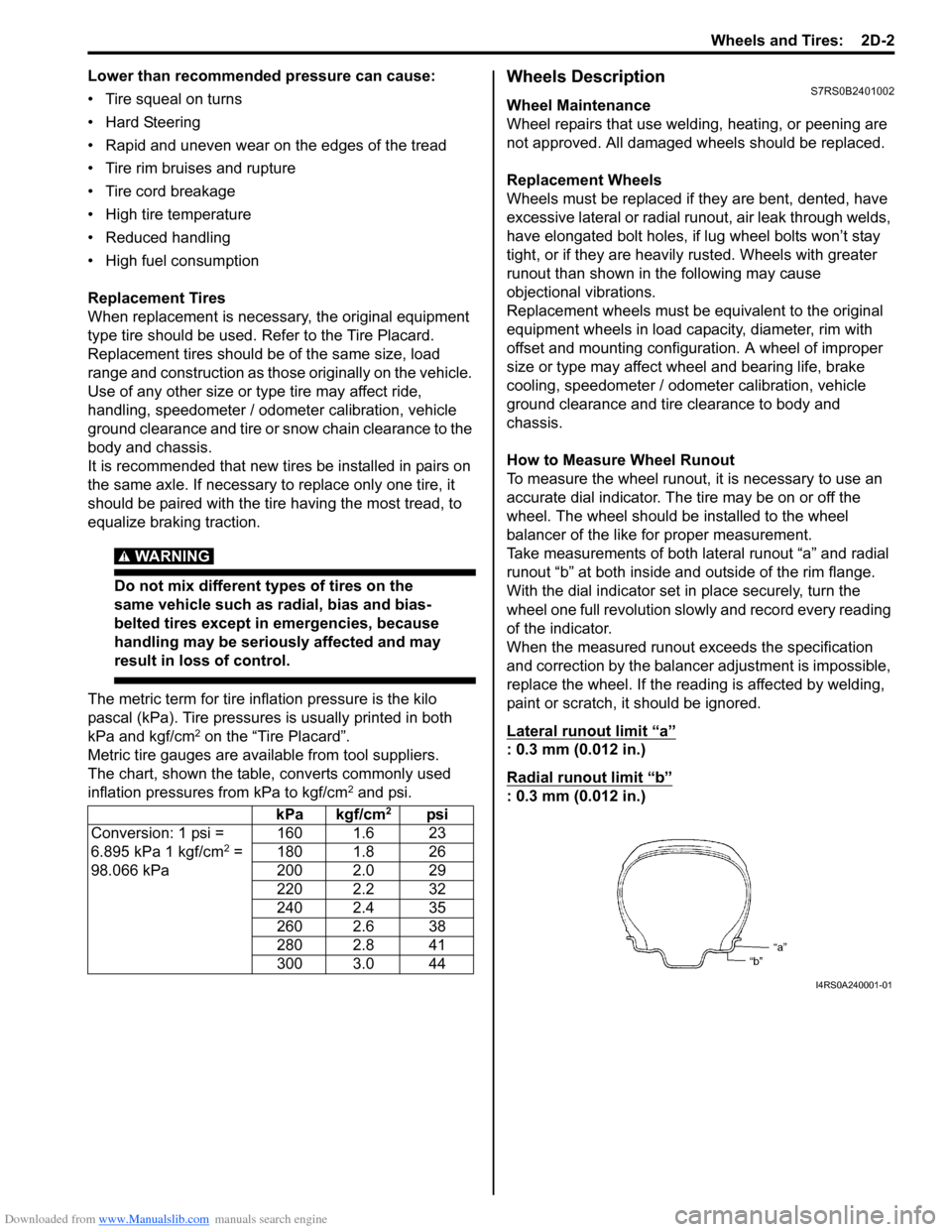

How to Measure Wheel Runout

To measure the wheel runout, it is necessary to use an

accurate dial indicator. The tire may be on or off the

wheel. The wheel should be installed to the wheel

balancer of the like for proper measurement.

Take measurements of both lateral runout “a” and radial

runout “b” at both inside an d outside of the rim flange.

With the dial indicator set in place securely, turn the

wheel one full revolution slowly and record every reading

of the indicator.

When the measured runout exceeds the specification

and correction by the balancer adjustment is impossible,

replace the wheel. If the reading is affected by welding,

paint or scratch, it should be ignored.

Lateral runout limit “a”

: 0.3 mm (0.012 in.)

Radial runout limit “b”

: 0.3 mm (0.012 in.)

kPa kgf/cm2psi

Conversion: 1 psi =

6.895 kPa 1 kgf/cm

2 =

98.066 kPa 160 1.6 23

180 1.8 26

200 2.0 29

220 2.2 32

240 2.4 35

260 2.6 38

280 2.8 41

300 3.0 44

I4RS0A240001-01

Page 475 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-8

Tire Mounting and DismountingS7RS0B2406004

CAUTION!

When installing tire which has arrow

indicating tire rotation direction to wheel,

make sure that this tire rotation direction is

same as actual tire rotation direction when

vehicle is moving forward. Otherwise, it is

not possible to install wheel with tire to

vehicle in specified direction.

Use a tire changing machine to mount or dismount tires.

Follow equipment manufacturer’s instructions. Do not

use hand tools or tire irons al one to change tires as they

may damage tire beads or wheel rim.

Rim bead seats should be cleaned with a wire brush or

coarse steel wool to remove lubricants, old rubber and

light rust. Before mounting or dismounting a tire, bead

area should be well lubricated with approved tire

lubricant.

After mounting, inflate to specified pressure shown on

tire placard so that beads are completely seated.

WARNING!

Do not stand over tire when inflating. Bead

may break when bead snaps over rim’s safety

hump and cause serious personal injury.

Do not exceed 330 kpa (47.9 psi) pressure

when inflating. If 330 kpa (47.9 psi) pressure

will not seat beads, deflate, re-lubricate and

reinflate.

Over inflation may cause bead to break and

cause serious personal injury.

Install valve core and inflate to proper pressure.

Tire RepairS7RS0B2406005

There are many different materials and techniques on

the market to repair tires. As not all of these work on all

types of tires, tire manufacturers have published detailed

instructions on how and when to repair tires. These

instructions can be obtained from each tire

manufacturer.

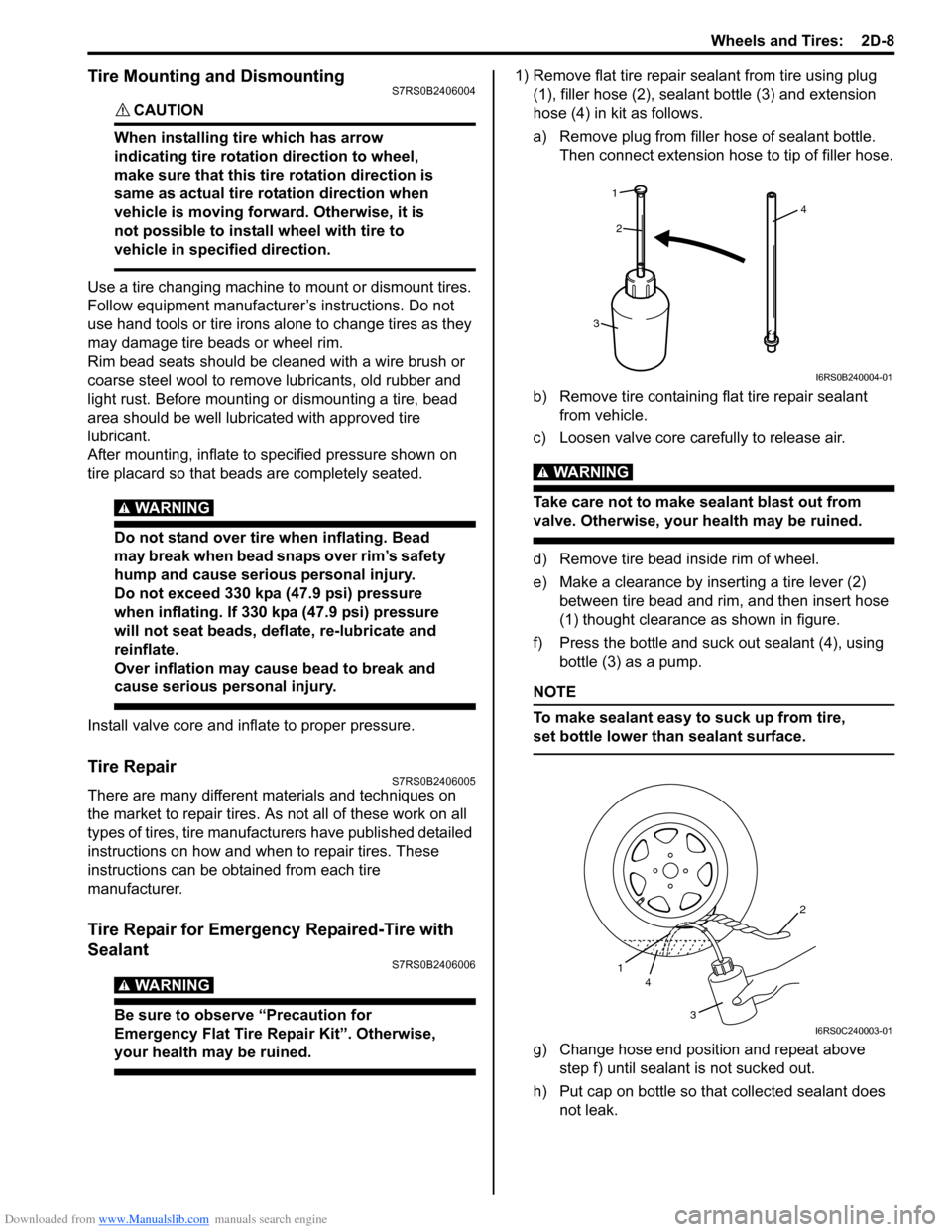

Tire Repair for Emergency Repaired-Tire with

Sealant

S7RS0B2406006

WARNING!

Be sure to observe “Precaution for

Emergency Flat Tire Repair Kit”. Otherwise,

your health may be ruined.

1) Remove flat tire repair sealant from tire using plug (1), filler hose (2), sealant bottle (3) and extension

hose (4) in kit as follows.

a) Remove plug from fille r hose of sealant bottle.

Then connect ext ension hose to tip of filler hose.

b) Remove tire containing flat tire repair sealant from vehicle.

c) Loosen valve core carefully to release air.

WARNING!

Take care not to make sealant blast out from

valve. Otherwise, your health may be ruined.

d) Remove tire bead inside rim of wheel.

e) Make a clearance by inserting a tire lever (2) between tire bead and rim, and then insert hose

(1) thought clearance as shown in figure.

f) Press the bottle and suck out sealant (4), using bottle (3) as a pump.

NOTE

To make sealant easy to suck up from tire,

set bottle lower than sealant surface.

g) Change hose end position and repeat above step f) until sealant is not sucked out.

h) Put cap on bottle so that collected sealant does not leak.

4

1

2

3

I6RS0B240004-01

1 4

3 2

I6RS0C240003-01

Page 483 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-5

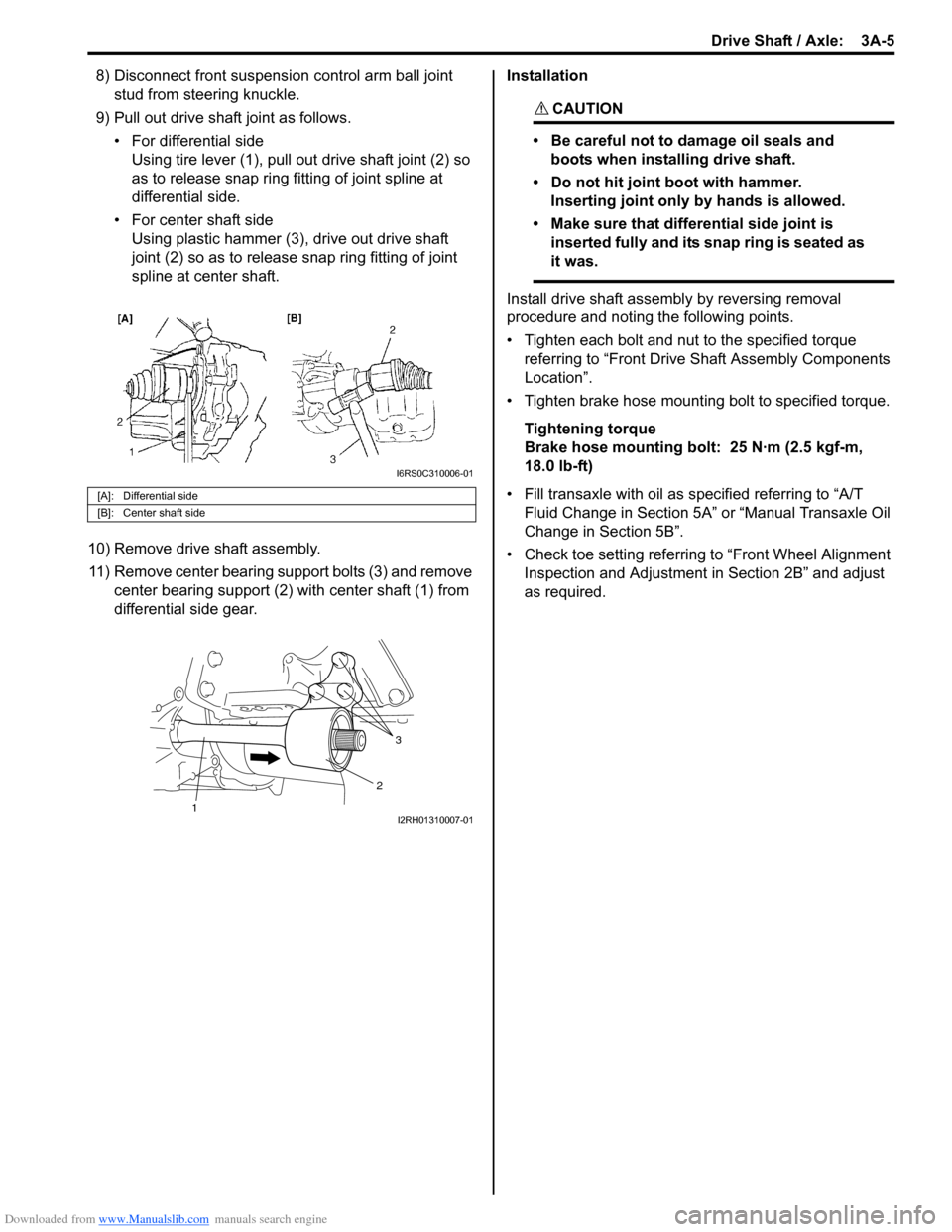

8) Disconnect front suspension control arm ball joint

stud from steering knuckle.

9) Pull out drive shaft joint as follows. • For differential sideUsing tire lever (1), pull out drive shaft joint (2) so

as to release snap ring fitting of joint spline at

differential side.

• For center shaft side Using plastic hammer (3), drive out drive shaft

joint (2) so as to release snap ring fitting of joint

spline at center shaft.

10) Remove drive shaft assembly. 11) Remove center bearing support bolts (3) and remove center bearing support (2) with center shaft (1) from

differential side gear. Installation

CAUTION!

• Be careful not to damage oil seals and

boots when installing drive shaft.

• Do not hit joint boot with hammer. Inserting joint only by hands is allowed.

• Make sure that differential side joint is inserted fully and its snap ring is seated as

it was.

Install drive shaft assemb ly by reversing removal

procedure and noting the following points.

• Tighten each bolt and nut to the specified torque referring to “Front Drive Shaft Assembly Components

Location”.

• Tighten brake hose mounting bolt to specified torque.

Tightening torque

Brake hose mounting bolt: 25 N·m (2.5 kgf-m,

18.0 lb-ft)

• Fill transaxle with oil as sp ecified referring to “A/T

Fluid Change in Section 5A” or “Manual Transaxle Oil

Change in Section 5B”.

• Check toe setting referring to “Front Wheel Alignment Inspection and Adjustment in Section 2B” and adjust

as required.

[A]: Differential side

[B]: Center shaft side

I6RS0C310006-01

3

2

1I2RH01310007-01

Page 519 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Brakes: 4B-3

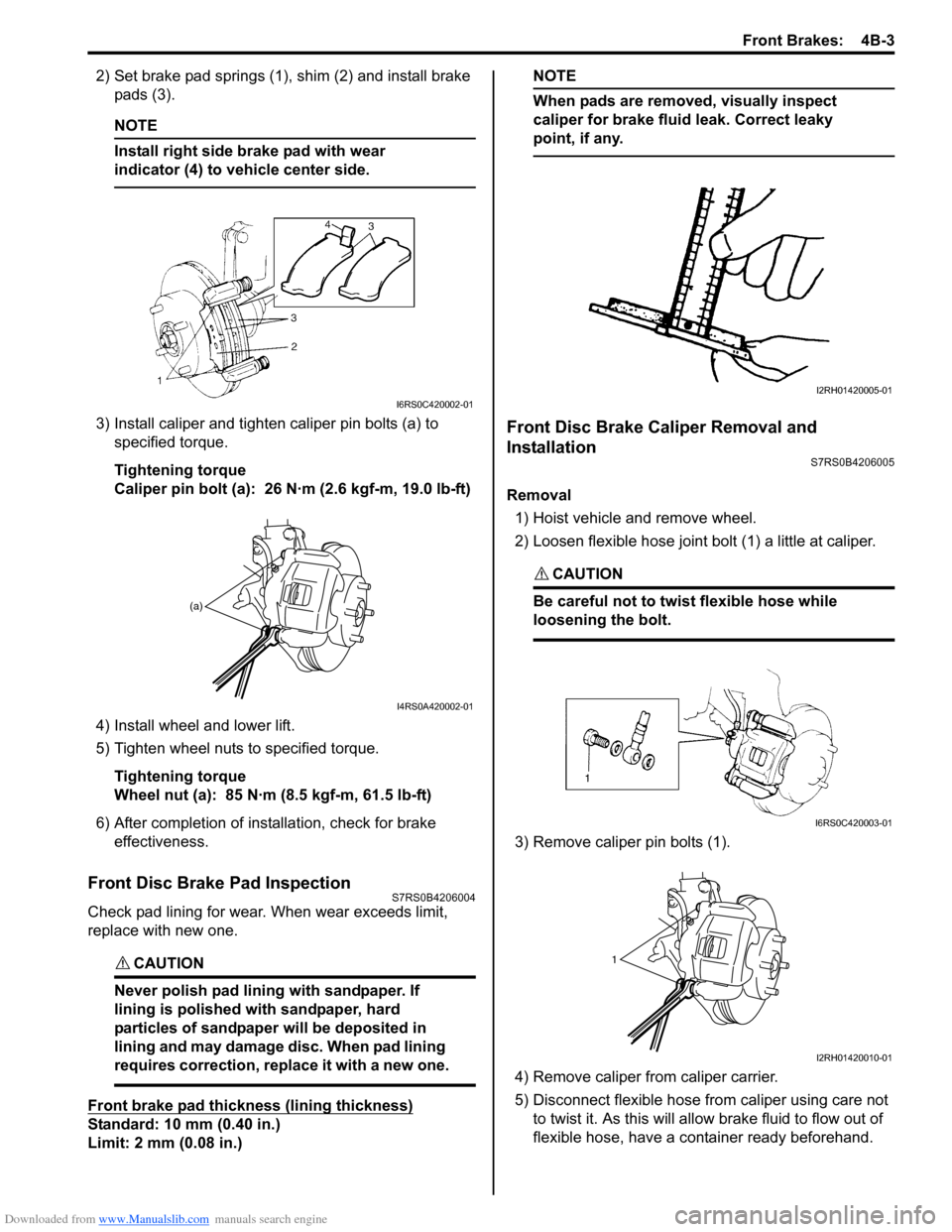

2) Set brake pad springs (1), shim (2) and install brake pads (3).

NOTE

Install right side brake pad with wear

indicator (4) to vehicle center side.

3) Install caliper and tighten caliper pin bolts (a) to specified torque.

Tightening torque

Caliper pin bolt (a): 26 N·m (2.6 kgf-m, 19.0 lb-ft)

4) Install wheel and lower lift.

5) Tighten wheel nuts to specified torque. Tightening torque

Wheel nut (a): 85 N·m (8.5 kgf-m, 61.5 lb-ft)

6) After completion of installation, check for brake effectiveness.

Front Disc Brake Pad InspectionS7RS0B4206004

Check pad lining for wear. When wear exceeds limit,

replace with new one.

CAUTION!

Never polish pad lining with sandpaper. If

lining is polished with sandpaper, hard

particles of sandpaper will be deposited in

lining and may damage disc. When pad lining

requires correction, replace it with a new one.

Front brake pad thickness (lining thickness)

Standard: 10 mm (0.40 in.)

Limit: 2 mm (0.08 in.)

NOTE

When pads are removed, visually inspect

caliper for brake fluid leak. Correct leaky

point, if any.

Front Disc Brake Caliper Removal and

Installation

S7RS0B4206005

Removal

1) Hoist vehicle and remove wheel.

2) Loosen flexible hose joint bolt (1) a little at caliper.

CAUTION!

Be careful not to twist flexible hose while

loosening the bolt.

3) Remove caliper pin bolts (1).

4) Remove caliper fr om caliper carrier.

5) Disconnect flexible hose fr om caliper using care not

to twist it. As this will allow brake fluid to flow out of

flexible hose, have a container ready beforehand.

I6RS0C420002-01

(a)

I4RS0A420002-01

I2RH01420005-01

I6RS0C420003-01

1

I2RH01420010-01

Page 522 of 1496

Downloaded from www.Manualslib.com manuals search engine 4B-6 Front Brakes:

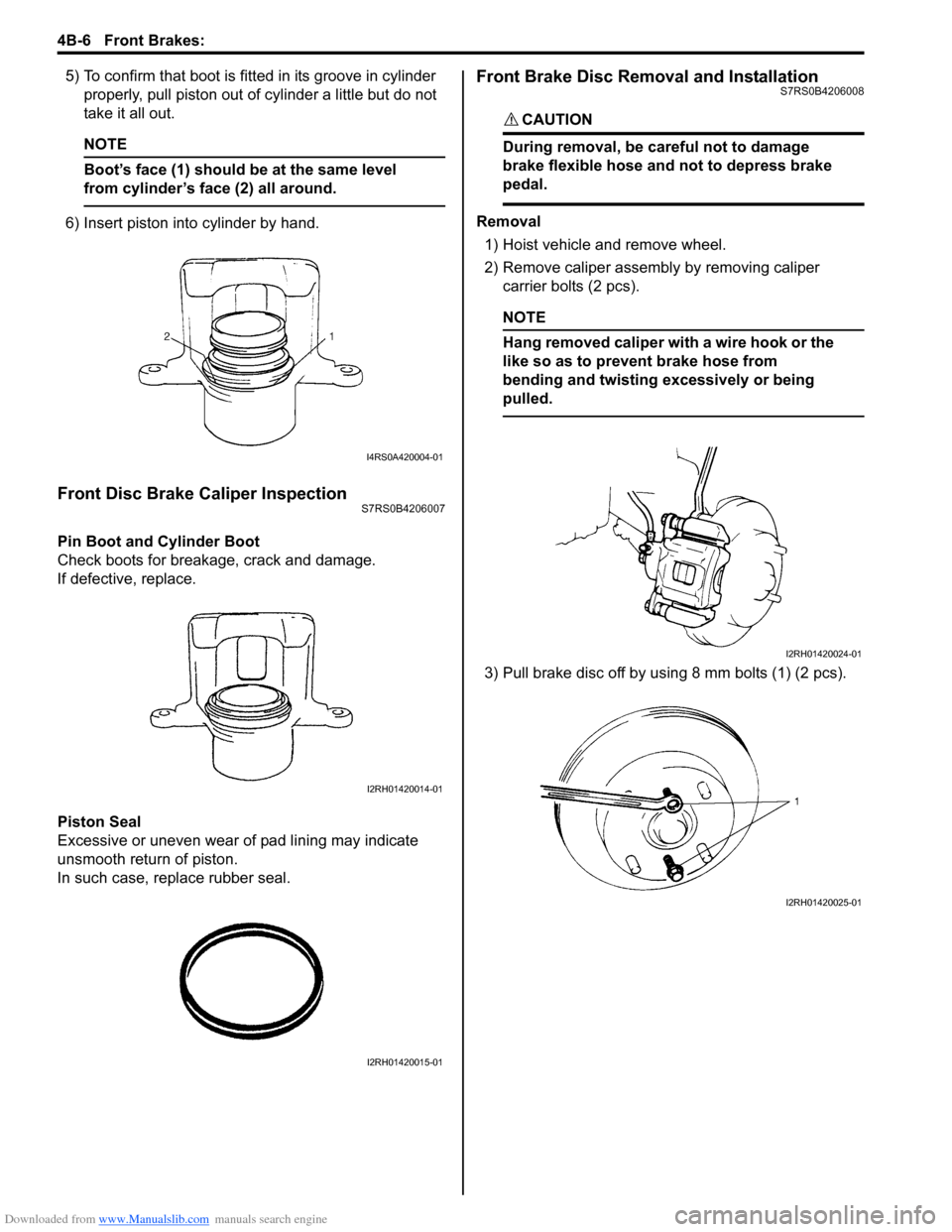

5) To confirm that boot is fitted in its groove in cylinder

properly, pull piston out of cylinder a little but do not

take it all out.

NOTE

Boot’s face (1) should be at the same level

from cylinder’s face (2) all around.

6) Insert piston into cylinder by hand.

Front Disc Brake Caliper InspectionS7RS0B4206007

Pin Boot and Cylinder Boot

Check boots for breakage, crack and damage.

If defective, replace.

Piston Seal

Excessive or uneven wear of pad lining may indicate

unsmooth return of piston.

In such case, replace rubber seal.

Front Brake Disc Removal and InstallationS7RS0B4206008

CAUTION!

During removal, be care ful not to damage

brake flexible hose and not to depress brake

pedal.

Removal

1) Hoist vehicle and remove wheel.

2) Remove caliper assembly by removing caliper carrier bolts (2 pcs).

NOTE

Hang removed caliper with a wire hook or the

like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

3) Pull brake disc off by using 8 mm bolts (1) (2 pcs).

I4RS0A420004-01

I2RH01420014-01

I2RH01420015-01

I2RH01420024-01

I2RH01420025-01

Page 532 of 1496

Downloaded from www.Manualslib.com manuals search engine 4C-8 Rear Brakes:

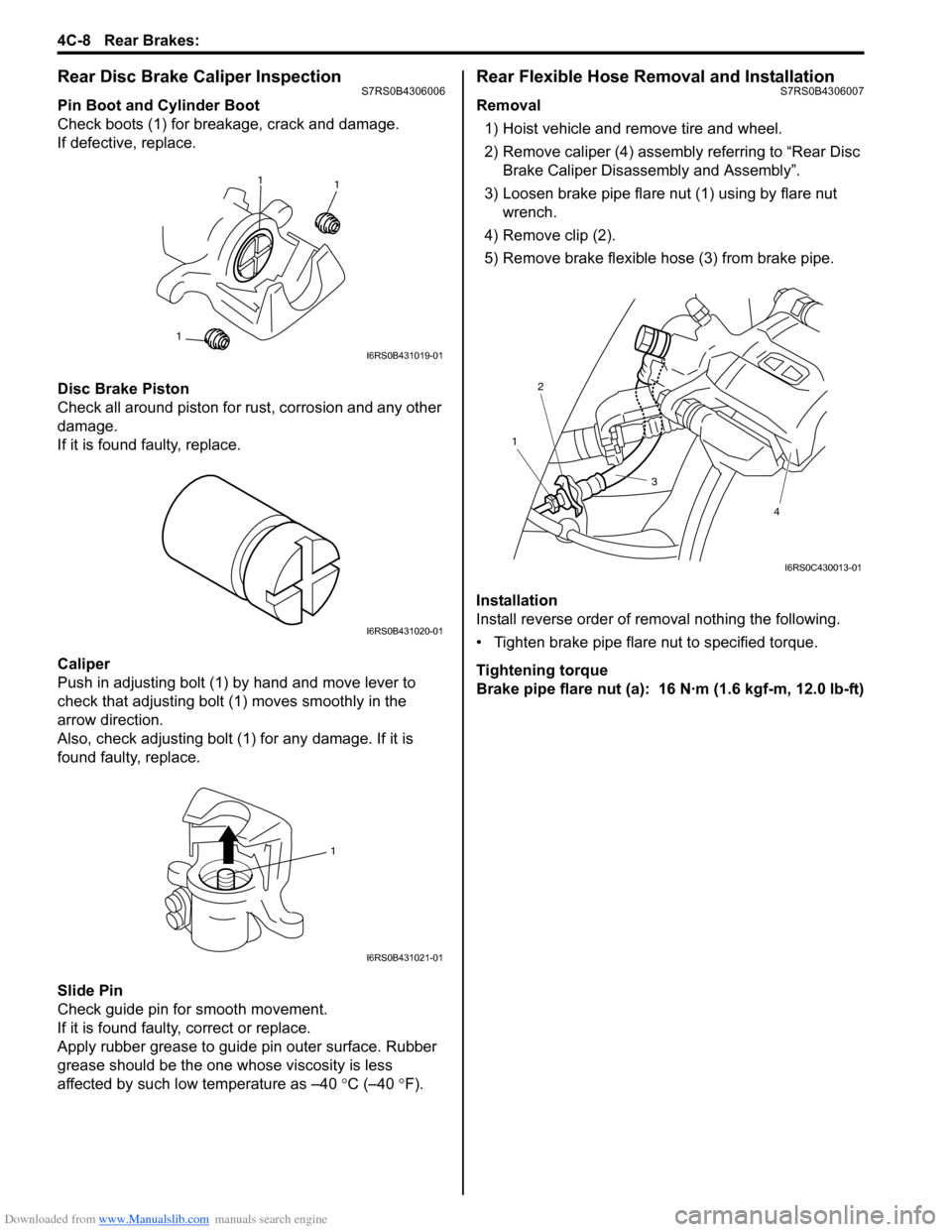

Rear Disc Brake Caliper InspectionS7RS0B4306006

Pin Boot and Cylinder Boot

Check boots (1) for breakage, crack and damage.

If defective, replace.

Disc Brake Piston

Check all around piston for rust, corrosion and any other

damage.

If it is found faulty, replace.

Caliper

Push in adjusting bolt (1) by hand and move lever to

check that adjusting bolt (1) moves smoothly in the

arrow direction.

Also, check adjusting bolt (1) for any damage. If it is

found faulty, replace.

Slide Pin

Check guide pin for smooth movement.

If it is found faulty, correct or replace.

Apply rubber grease to guide pin outer surface. Rubber

grease should be the one whose viscosity is less

affected by such low temperature as –40 °C (–40 ° F).

Rear Flexible Hose Removal and InstallationS7RS0B4306007

Removal

1) Hoist vehicle and remove tire and wheel.

2) Remove caliper (4) assembly referring to “Rear Disc Brake Caliper Disassembly and Assembly”.

3) Loosen brake pipe flare nut (1) using by flare nut wrench.

4) Remove clip (2).

5) Remove brake flexible hose (3) from brake pipe.

Installation

Install reverse order of removal nothing the following.

• Tighten brake pipe flare nut to specified torque.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 12.0 lb-ft)

1 1

1

I6RS0B431019-01

I6RS0B431020-01

1

I6RS0B431021-01

1

2

3

4

I6RS0C430013-01

Page 569 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-30

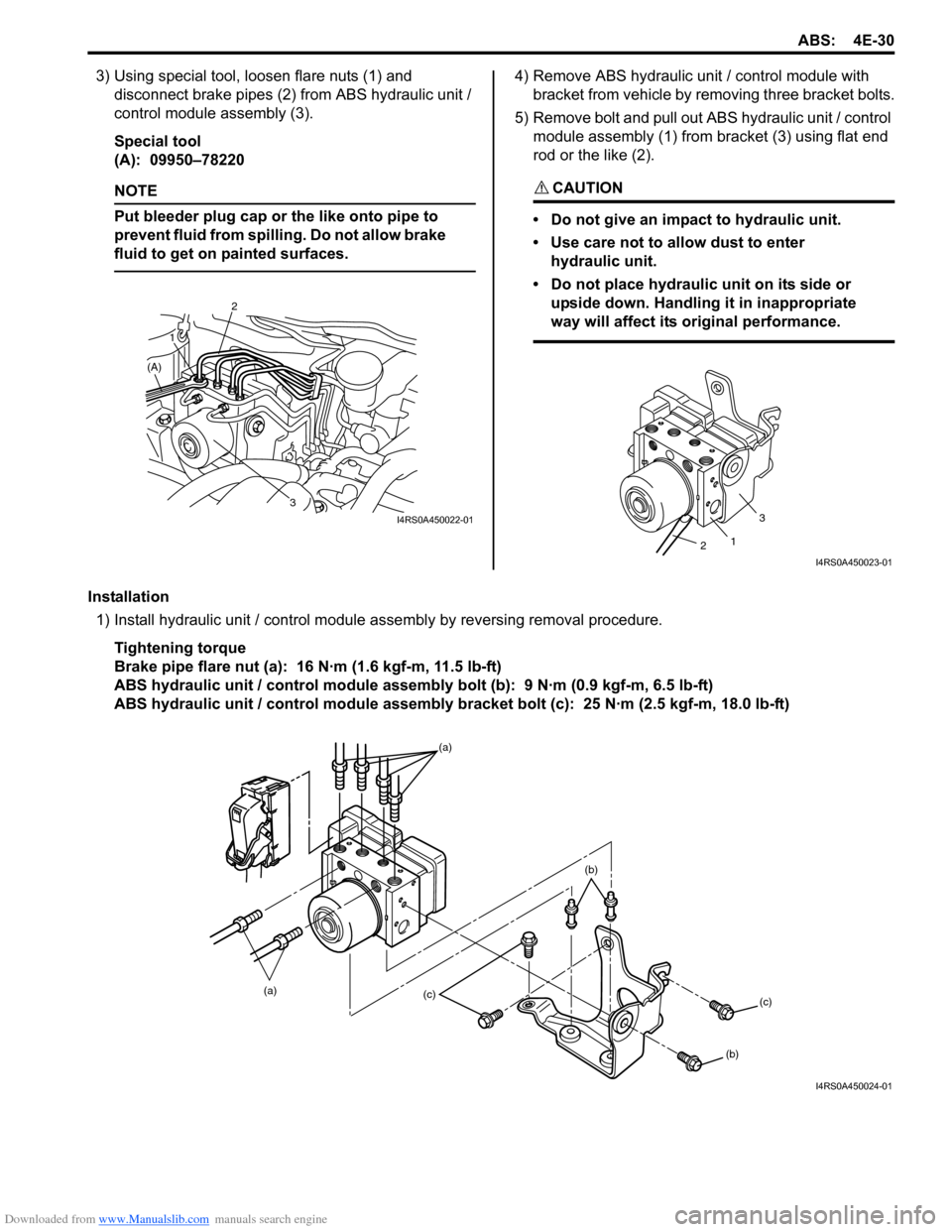

3) Using special tool, loosen flare nuts (1) and disconnect brake pipes (2) from ABS hydraulic unit /

control module assembly (3).

Special tool

(A): 09950–78220

NOTE

Put bleeder plug cap or the like onto pipe to

prevent fluid from spilli ng. Do not allow brake

fluid to get on painted surfaces.

4) Remove ABS hydraulic unit / control module with

bracket from vehicle by removing three bracket bolts.

5) Remove bolt and pull out ABS hydraulic unit / control module assembly (1) from bracket (3) using flat end

rod or the like (2).

CAUTION!

• Do not give an impact to hydraulic unit.

• Use care not to allow dust to enter hydraulic unit.

• Do not place hydraulic unit on its side or upside down. Handling it in inappropriate

way will affect its original performance.

Installation

1) Install hydraulic unit / control module assembly by reversing removal procedure.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 11.5 lb-ft)

ABS hydraulic unit / control module assembly bolt (b): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

ABS hydraulic unit / control module assembly bracket bolt (c): 25 N·m (2.5 kgf-m, 18.0 lb-ft)

3

2

1

(A)

I4RS0A450022-01

1

3

2

I4RS0A450023-01

(a) (a)(c)

(c)

(b)

(b)

I4RS0A450024-01

Page 594 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-20 Electronic Stability Program:

NOTE

•�{: Activated

• X: Deactivated

• *1: If two or more wheel speed sensor are defective, ABS warning lamp, EBD warning lamp and ESP ® warning lamp are lit and all the control functions are deactivated. If one wheel speed sensor is

defective, ABS warning lamp and ESP ® warning lamp are lit and ABS and TCS / stability control are

deactivated.

• *2: ESP ® OFF mode is cancelled and all control functions are activated.

• *3: EBD control function is activated only if po wer supply circuit is little low voltage malfunction.

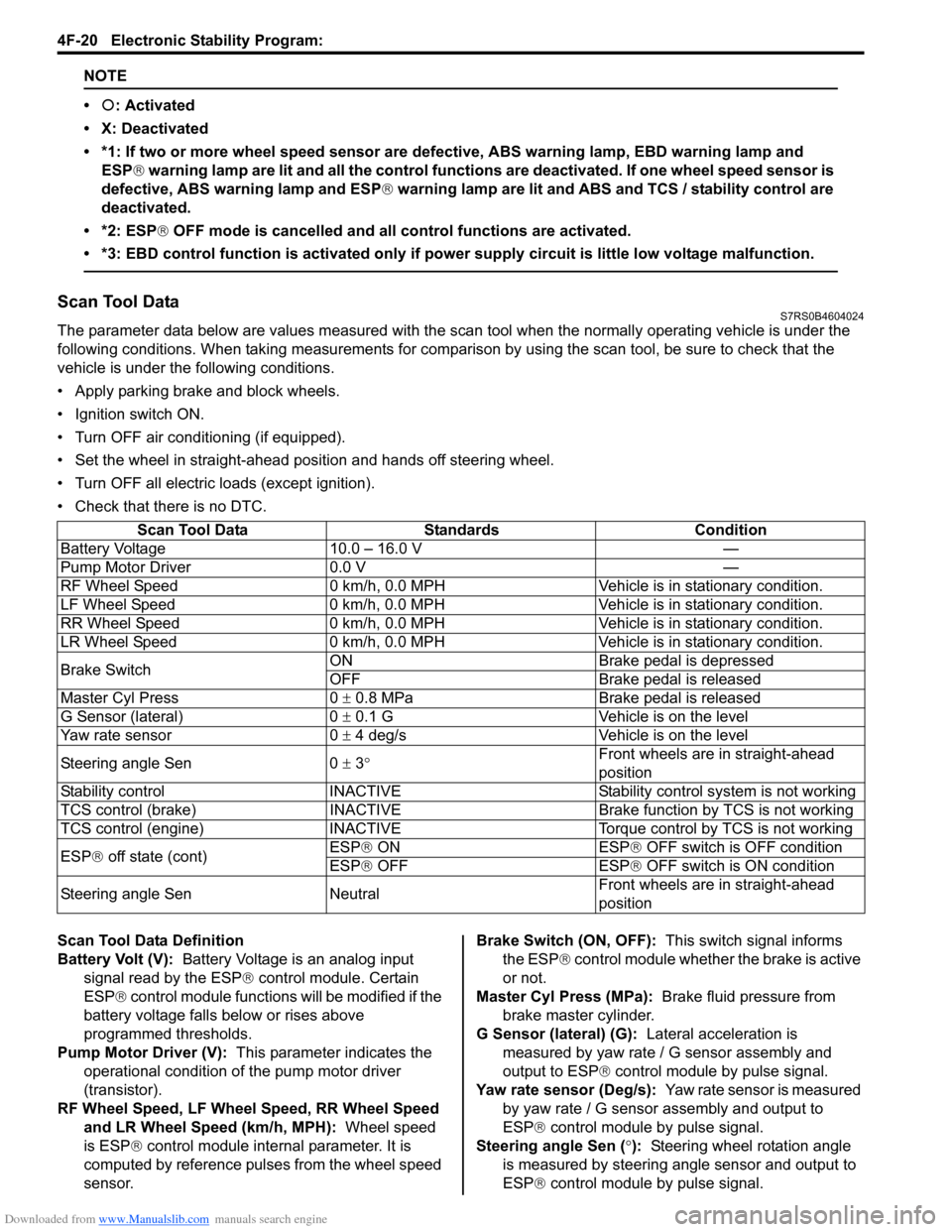

Scan Tool DataS7RS0B4604024

The parameter data below are values measured with the scan tool when the normally operating vehicle is under the

following conditions. When taking measurements for comparis on by using the scan tool, be sure to check that the

vehicle is under the following conditions.

• Apply parking brake and block wheels.

• Ignition switch ON.

• Turn OFF air conditioning (if equipped).

• Set the wheel in straight-ahead position and hands off steering wheel.

• Turn OFF all electric loads (except ignition).

• Check that there is no DTC.

Scan Tool Data Definition

Battery Volt (V): Battery Voltage is an analog input

signal read by the ESP ® control module. Certain

ESP ® control module functions will be modified if the

battery voltage falls below or rises above

programmed thresholds.

Pump Motor Driver (V): This parameter indicates the

operational condition of the pump motor driver

(transistor).

RF Wheel Speed, LF Wheel Speed, RR Wheel Speed and LR Wheel Speed (km/h, MPH): Wheel speed

is ESP ® control module internal parameter. It is

computed by reference puls es from the wheel speed

sensor. Brake Switch (ON, OFF):

This switch signal informs

the ESP ® control module whether the brake is active

or not.

Master Cyl Press (MPa): Brake fluid pressure from

brake master cylinder.

G Sensor (lateral) (G): Lateral acceleration is

measured by yaw rate / G sensor assembly and

output to ESP ® control module by pulse signal.

Yaw rate sensor (Deg/s): Yaw rate sensor is measured

by yaw rate / G sensor assembly and output to

ESP® control module by pulse signal.

Steering angle Sen ( °): Steering wheel rotation angle

is measured by steering angle sensor and output to

ESP® control module by pulse signal.

Scan Tool Data Standards Condition

Battery Voltage 10.0 – 16.0 V —

Pump Motor Driver 0.0 V —

RF Wheel Speed 0 km/h, 0.0 MPH Veh icle is in stationary condition.

LF Wheel Speed 0 km/h, 0.0 MPH Veh icle is in stationary condition.

RR Wheel Speed 0 km/h, 0.0 MPH Vehic le is in stationary condition.

LR Wheel Speed 0 km/h, 0.0 MPH Veh icle is in stationary condition.

Brake Switch ON Brake pedal is depressed

OFF Brake pedal is released

Master Cyl Press 0 ± 0.8 MPa Brake pedal is released

G Sensor (lateral) 0 ± 0.1 G Vehicle is on the level

Yaw rate sensor 0 ± 4 deg/s Vehicle is on the level

Steering angle Sen 0 ± 3 ° Front wheels are in straight-ahead

position

Stability control INACTIVE Stability control system is not working

TCS control (brake) INACTIVE Brake function by TCS is not working

TCS control (engine) INACTIVE Torque control by TCS is not working

ESP ® off state (cont) ESP®

ON ESP

® OF

F switch is OFF condition

ESP® OFF ESP ® OFF switch is ON condition

Steering angle Sen Neutral Front wheels are in straight-ahead

position

Page 628 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-54 Electronic Stability Program:

Repair Instructions

ESP® Hydraulic Unit Operation CheckS7RS0B4606025

1) Check that basic brake system other than ESP ® is

in good condition.

2) Check that battery voltage is 11 V or higher.

3) Lift up vehicle.

4) Set transmission to neutral and release parking brake.

5) Turn each wheel gradually by hand to check if braked ragging occurs. If it does, correct.

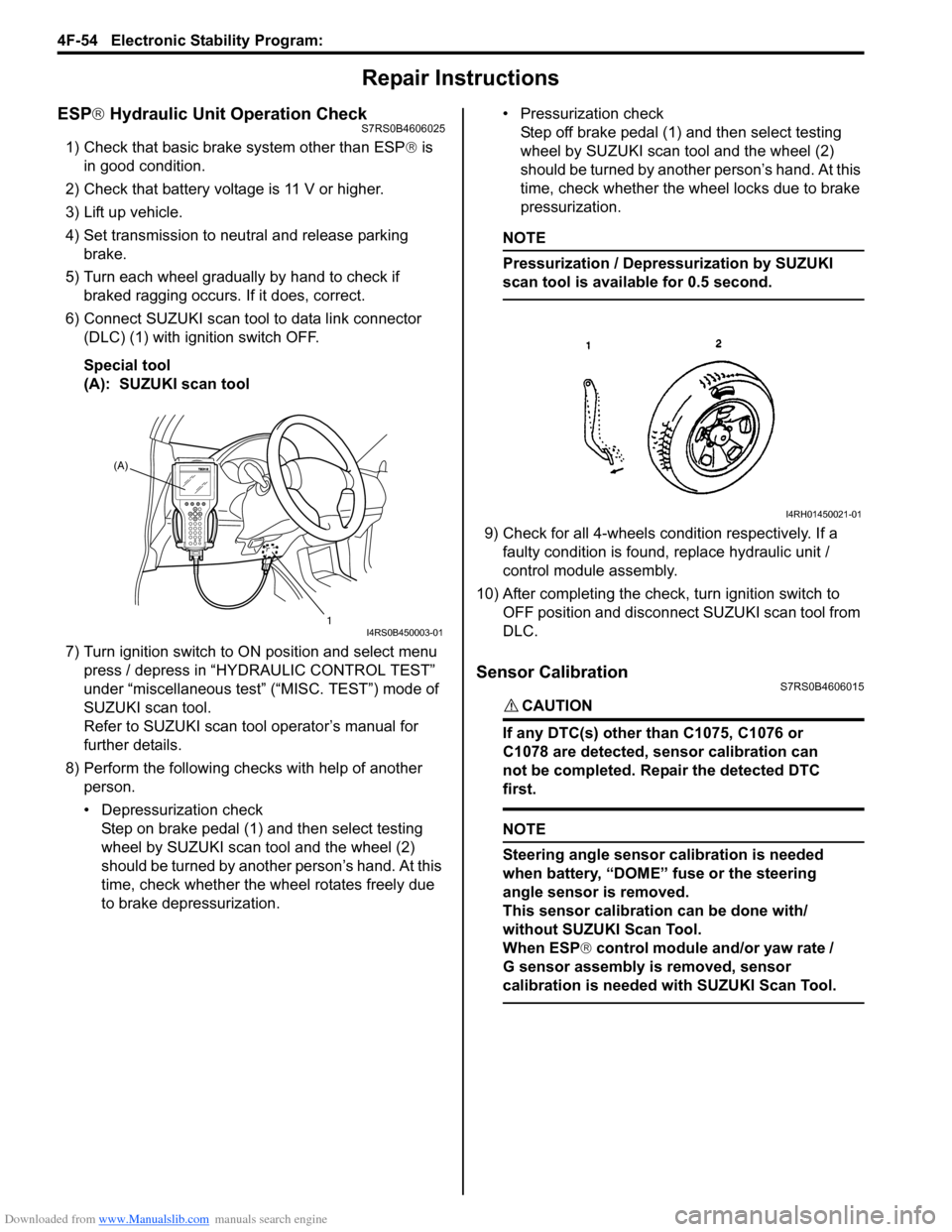

6) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

7) Turn ignition switch to ON position and select menu press / depress in “HYDRAULIC CONTROL TEST”

under “miscellaneous test” (“MISC. TEST”) mode of

SUZUKI scan tool.

Refer to SUZUKI scan tool operator’s manual for

further details.

8) Perform the following checks with help of another person.

• Depressurization checkStep on brake pedal (1) and then select testing

wheel by SUZUKI scan tool and the wheel (2)

should be turned by another person’s hand. At this

time, check whether the wheel rotates freely due

to brake depressurization. • Pressurization check

Step off brake pedal (1) and then select testing

wheel by SUZUKI scan tool and the wheel (2)

should be turned by another person’s hand. At this

time, check whether the wheel locks due to brake

pressurization.

NOTE

Pressurization / Depressurization by SUZUKI

scan tool is available for 0.5 second.

9) Check for all 4-wheels condition respectively. If a faulty condition is found, replace hydraulic unit /

control module assembly.

10) After completing the check, turn ignition switch to OFF position and disconnect SUZUKI scan tool from

DLC.

Sensor CalibrationS7RS0B4606015

CAUTION!

If any DTC(s) other than C1075, C1076 or

C1078 are detected, sensor calibration can

not be completed. Repair the detected DTC

first.

NOTE

Steering angle sensor calibration is needed

when battery, “DOME” fuse or the steering

angle sensor is removed.

This sensor calibration can be done with/

without SUZUKI Scan Tool.

When ESP ® control module and/or yaw rate /

G sensor assembly is removed, sensor

calibration is needed with SUZUKI Scan Tool.

(A)

1

I4RS0B450003-01

I4RH01450021-01

Page 630 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-56 Electronic Stability Program:

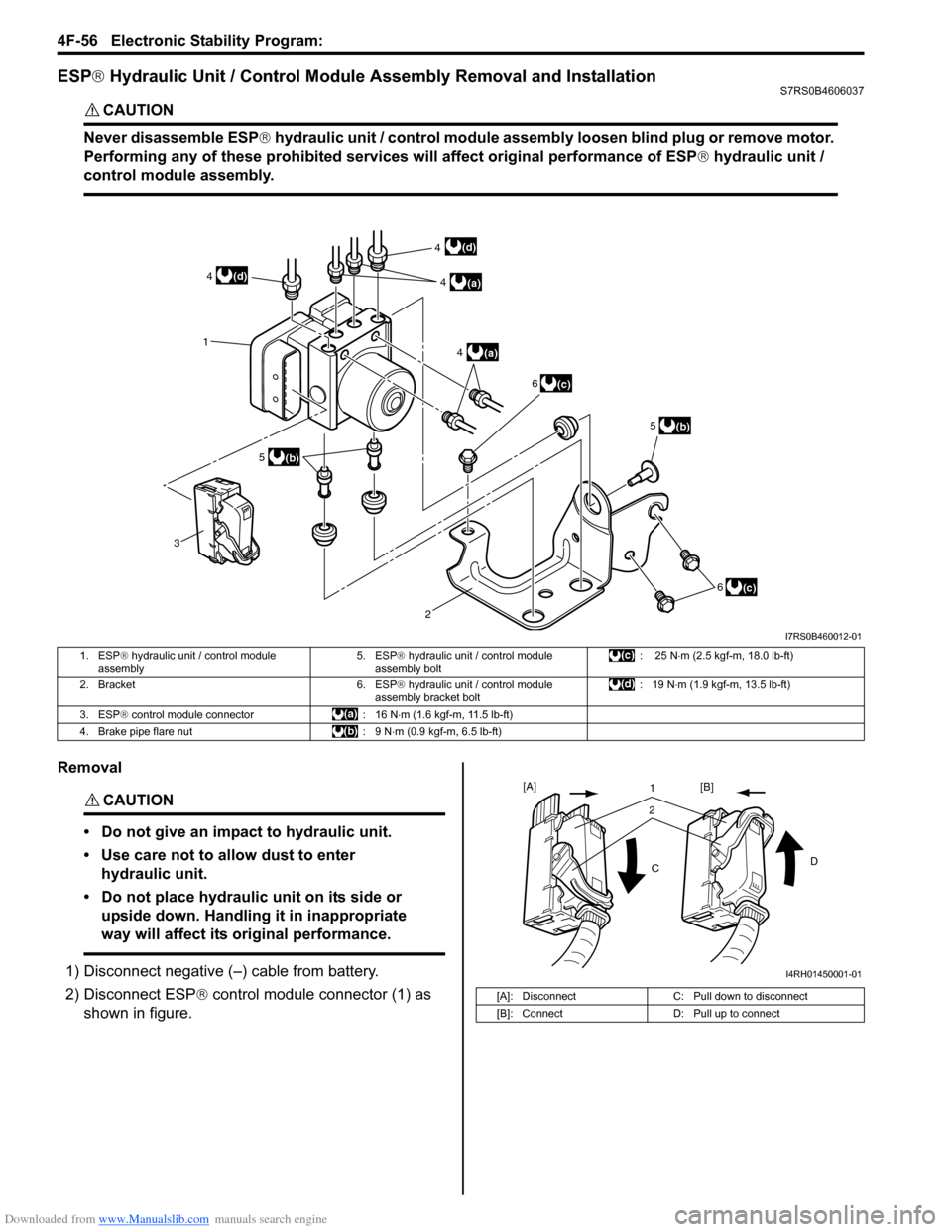

ESP® Hydraulic Unit / Control Module Assembly Removal and InstallationS7RS0B4606037

CAUTION!

Never disassemble ESP ® hydraulic unit / control module assembly loosen blind plug or remove motor.

Performing any of these proh ibited services will affect original performance of ESP ® hydraulic unit /

control module assembly.

Removal

CAUTION!

• Do not give an impact to hydraulic unit.

• Use care not to allow dust to enter hydraulic unit.

• Do not place hydraulic unit on its side or upside down. Handling it in inappropriate

way will affect its original performance.

1) Disconnect negative (–) cable from battery.

2) Disconnect ESP ® control module connector (1) as

shown in figure.

3 1

(c)

2

(b)

(a)4

(a)

4

5

6

(b)

5

(c)

6

(d)

(d) 4

4

I7RS0B460012-01

1. ESP ® hydraulic unit / control module

assembly 5. ESP

® hydraulic unit / control module

assembly bolt : 25 N

⋅m (2.5 kgf-m, 18.0 lb-ft)

2. Bracket 6. ESP ® hydraulic unit / control module

assembly bracket bolt : 19 N

⋅m (1.9 kgf-m, 13.5 lb-ft)

3. ESP ® control module connector : 16 N ⋅m (1.6 kgf-m, 11.5 lb-ft)

4. Brake pipe flare nut : 9 N ⋅m (0.9 kgf-m, 6.5 lb-ft)

[A]: DisconnectC: Pull down to disconnect

[B]: Connect D: Pull up to connect

21

C D

[A]

[B]

I4RH01450001-01