Adjustment SUZUKI SWIFT 2008 2.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 691 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-47

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM memo ry by using scan tool.

3) Start engine and shift select lever to “D” range.

4) Start vehicle and increase vehicle speed to 40 km/h (25 mile/h) or more for 1 minutes.

5) Stop vehicle and turn ignition switch OFF.

6) Repeat Step 3) to 4) one time.

7) Stop vehicle and check DTC.

DTC Troubleshooting Step Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Do you have SUZUKI scan tool? Go to Step 3.Go to Step 4.

3 Check transmission range sensor (switch) circuit for

operation

Check by using SUZUKI scan tool:

1) Connect SUZUKI scan tool to DLC with ignition switch

OFF.

2) Turn ignition switch ON and check transmission range signal (P, R, N, D, 3, 2 or L) on display when shifting

select lever to each range.

Is applicable range indicated? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”

Go to Step 5.

4 Check transmission range sensor (switch) circuit for

operation

Check by not using SUZUKI scan tool:

1) Turn ignition switch ON.

2) Check voltage at terminals “C35-1”, “C35-7”, “C35-8”,

“C35-18”, “C35-19” and “C35-20” respectively with

select lever shifted to each range.

Taking terminal “C35-19” as an example, is battery

voltage indicated only when se lect lever is shifted to “2”

range and 0 V for other ranges as shown in the following

table.

Check voltage at other terminals likewise, referring to the

following table.

Are check results satisfactory? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 5.

5 1) Check select cable for adjustment referring to “Select Cable Adjustment”.

Is it adjusted correctly? Go to Step 6.

Adjust.

6 Check transmission range sensor (switch) for

installation position

1) Shift select lever to “N” range.

2) Check that “N” reference line on sensor and needle

direction shaped on lock washer are aligned.

Are they aligned? Go to Step 7.

Adjust.

Page 692 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-48 Automatic Transmission/Transaxle:

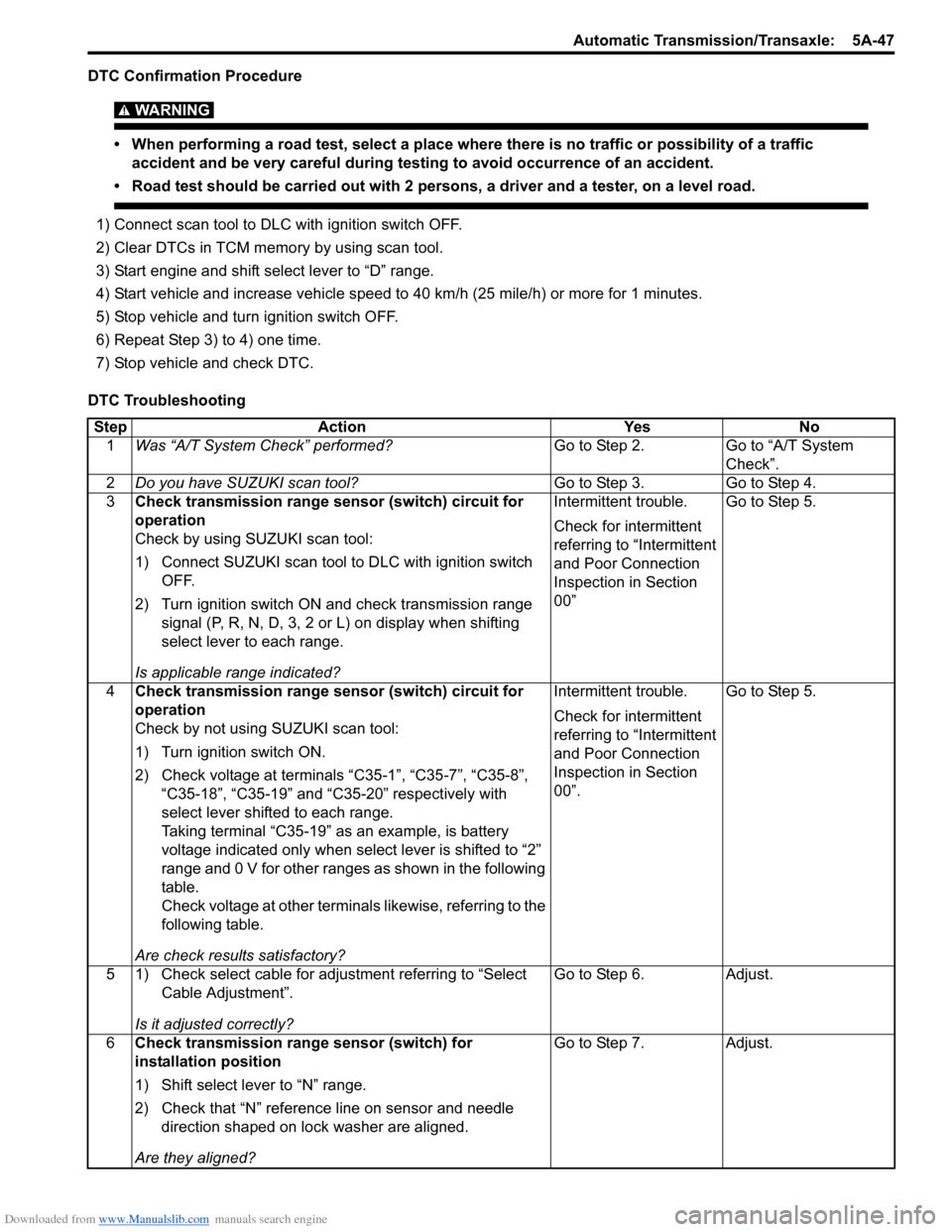

Table for Step 4

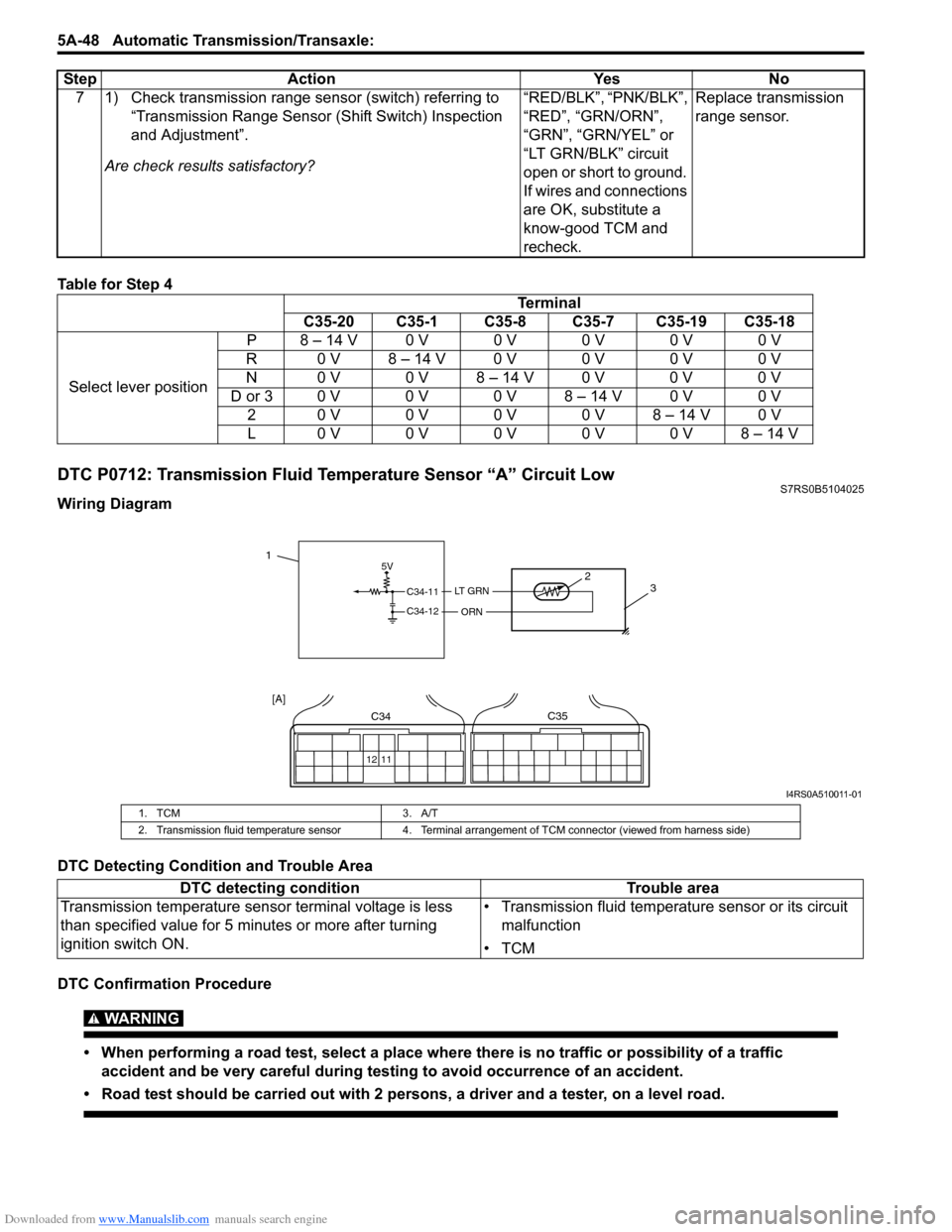

DTC P0712: Transmission Fluid Temperature Sensor “A” Circuit LowS7RS0B5104025

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

7 1) Check transmission range sensor (switch) referring to “Transmission Range Sensor (Shift Switch) Inspection

and Adjustment”.

Are check results satisfactory? “RED/BLK”, “PNK/BLK”,

“RED”, “GRN/ORN”,

“GRN”, “GRN/YEL” or

“LT GRN/BLK” circuit

open or short to ground.

If wires and connections

are OK, substitute a

know-good TCM and

recheck.Replace transmission

range sensor.

Step Action Yes No

Terminal

C35-20 C35-1 C35-8 C35-7 C35-19 C35-18

Select lever position P8 – 14 V0 V0 V0 V0 V0 V

R 0 V 8 – 14 V 0 V 0 V 0 V 0 V

N 0 V 0 V 8 – 14 V 0 V 0 V 0 V

D or 3 0 V 0 V 0 V 8 – 14 V 0 V 0 V 20 V0 V0 V0 V8 – 14 V0 V

L0 V0 V0 V0 V0 V8 – 14 V

5V

C34-11

C34-12

LT GRN

ORN

2 3

12 11

C34C35

[A]

1

I4RS0A510011-01

1. TCM 3. A/T

2. Transmission fluid temperature sensor 4. Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Transmission temperature sensor terminal voltage is less

than specified value for 5 minutes or more after turning

ignition switch ON. • Transmission fluid temperature sensor or its circuit

malfunction

•TCM

Page 734 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-90 Automatic Transmission/Transaxle:

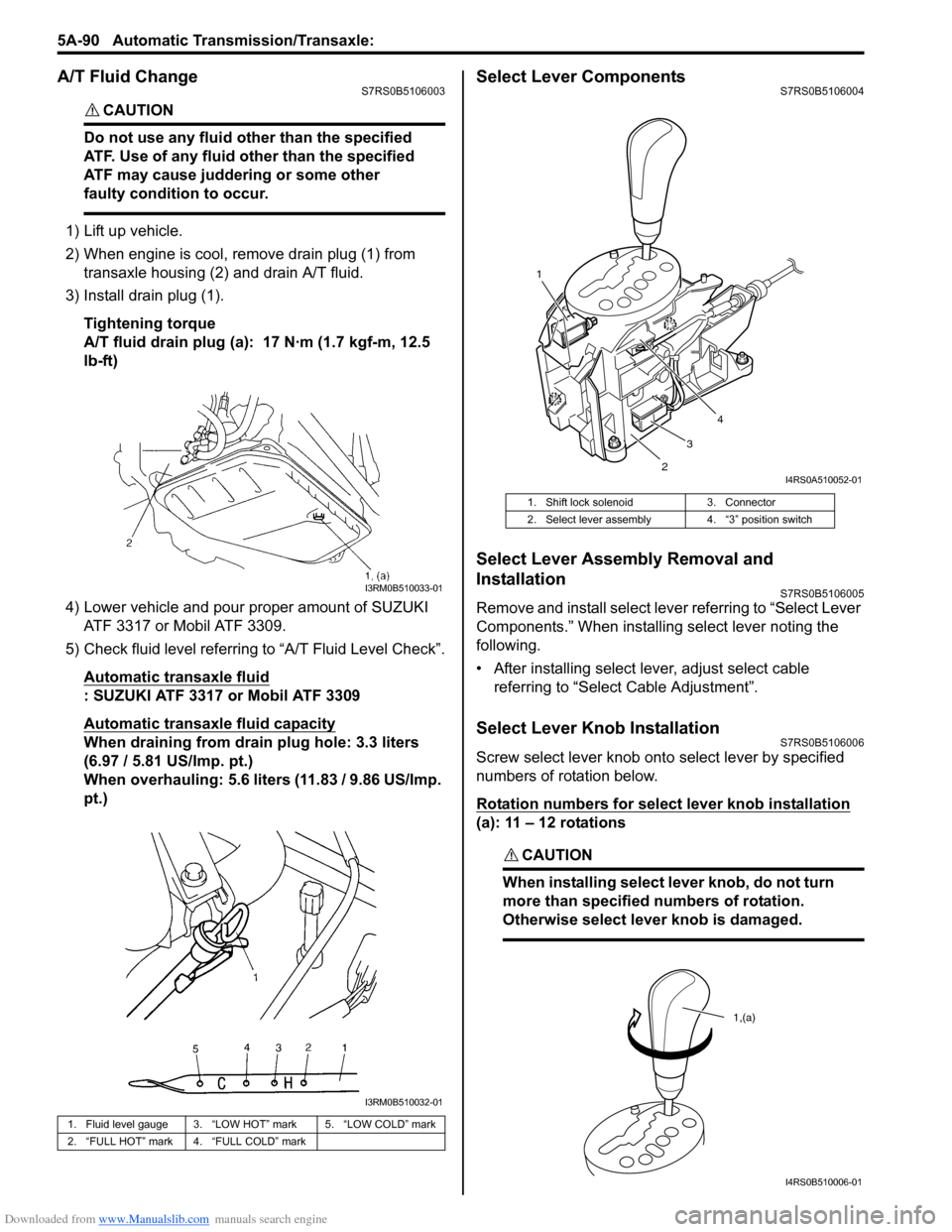

A/T Fluid ChangeS7RS0B5106003

CAUTION!

Do not use any fluid other than the specified

ATF. Use of any fluid other than the specified

ATF may cause juddering or some other

faulty condition to occur.

1) Lift up vehicle.

2) When engine is cool, remove drain plug (1) from

transaxle housing (2) and drain A/T fluid.

3) Install drain plug (1).

Tightening torque

A/T fluid drain plug (a): 17 N·m (1.7 kgf-m, 12.5

lb-ft)

4) Lower vehicle and pour proper amount of SUZUKI ATF 3317 or Mobil ATF 3309.

5) Check fluid level referring to “A/T Fluid Level Check”.

Automatic transaxle fluid

: SUZUKI ATF 3317 or Mobil ATF 3309

Automatic transaxle fluid capacity

When draining from drai n plug hole: 3.3 liters

(6.97 / 5.81 US/Imp. pt.)

When overhauling: 5.6 liters (11.83 / 9.86 US/Imp.

pt.)

Select Lever ComponentsS7RS0B5106004

Select Lever Assembly Removal and

Installation

S7RS0B5106005

Remove and install select leve r referring to “Select Lever

Components.” When installing select lever noting the

following.

• After installing select lever, adjust select cable referring to “Select Cable Adjustment”.

Select Lever Knob InstallationS7RS0B5106006

Screw select lever knob onto select lever by specified

numbers of rotation below.

Rotation numbers for select lever knob installation

(a): 11 – 12 rotations

CAUTION!

When installing select lever knob, do not turn

more than specified numbers of rotation.

Otherwise select lever knob is damaged.

1. Fluid level gauge 3. “LOW HOT” mark 5. “LOW COLD” mark

2. “FULL HOT” mark 4. “FULL COLD” mark

I3RM0B510033-01

I3RM0B510032-01

1. Shift lock solenoid 3. Connector

2. Select lever assembly 4. “3” position switch

1

23 4

I4RS0A510052-01

1,(a)

I4RS0B510006-01

Page 736 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-92 Automatic Transmission/Transaxle:

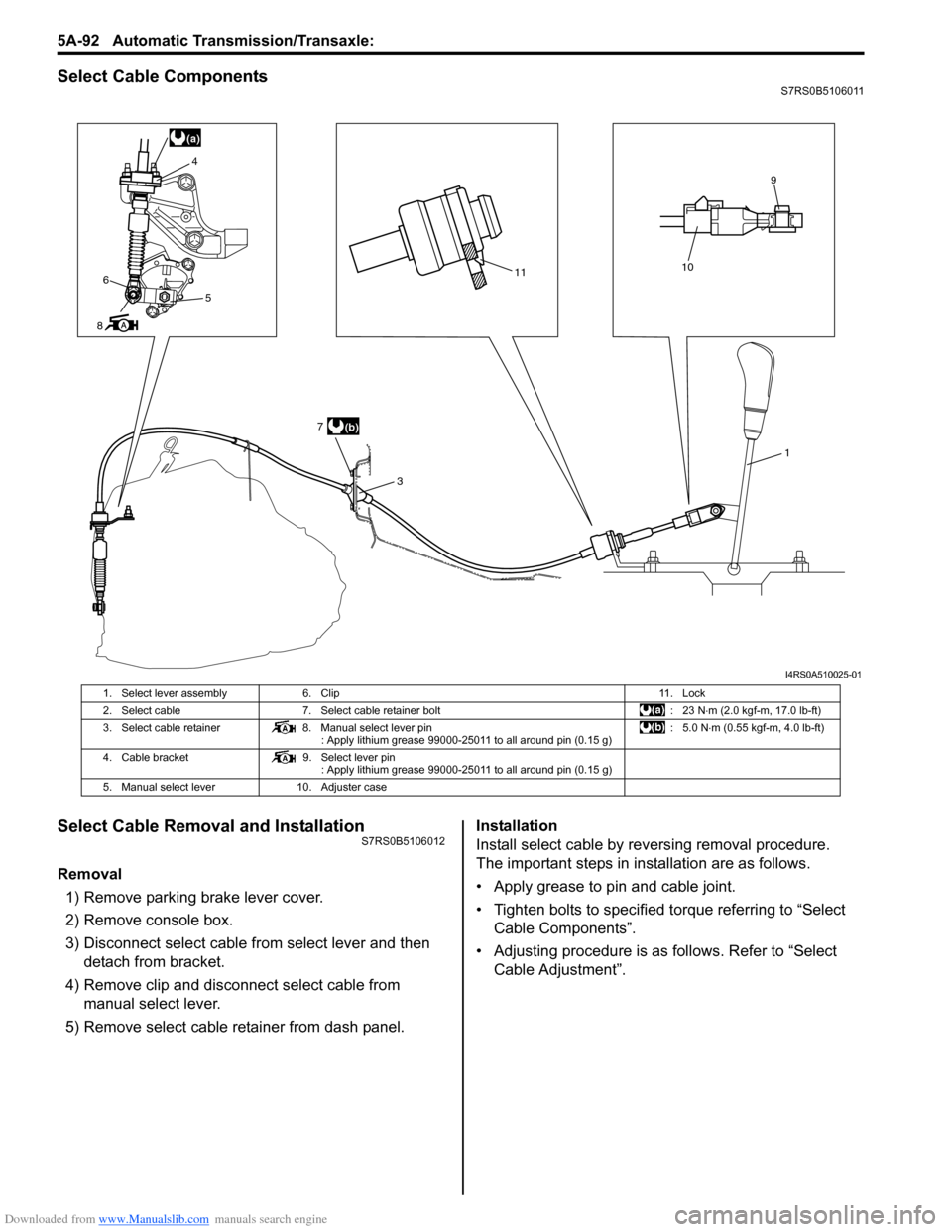

Select Cable ComponentsS7RS0B5106011

Select Cable Removal and InstallationS7RS0B5106012

Removal

1) Remove parking brake lever cover.

2) Remove console box.

3) Disconnect select cable from select lever and then detach from bracket.

4) Remove clip and disconnect select cable from manual select lever.

5) Remove select cable retainer from dash panel. Installation

Install select cable by reversing removal procedure.

The important steps in inst

allation are as follows.

• Apply grease to pin and cable joint.

• Tighten bolts to specified torque referring to “Select Cable Components”.

• Adjusting procedure is as follows. Refer to “Select Cable Adjustment”.

(a)

11

3

10

9

6

8 4

5

(b)

7

1

I4RS0A510025-01

1. Select lever assembly

6. Clip 11. Lock

2. Select cable 7. Select cable retainer bolt : 23 N⋅m (2.0 kgf-m, 17.0 lb-ft)

3. Select cable retainer 8. Manual select lever pin

: Apply lithium grease 99000-25011 to all around pin (0.15 g) :5.0 N

⋅m (0.55 kgf-m, 4.0 lb-ft)

4. Cable bracket 9. Select lever pin

: Apply lithium grease 99000-25011 to all around pin (0.15 g)

5. Manual select lever 10. Adjuster case

Page 737 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-93

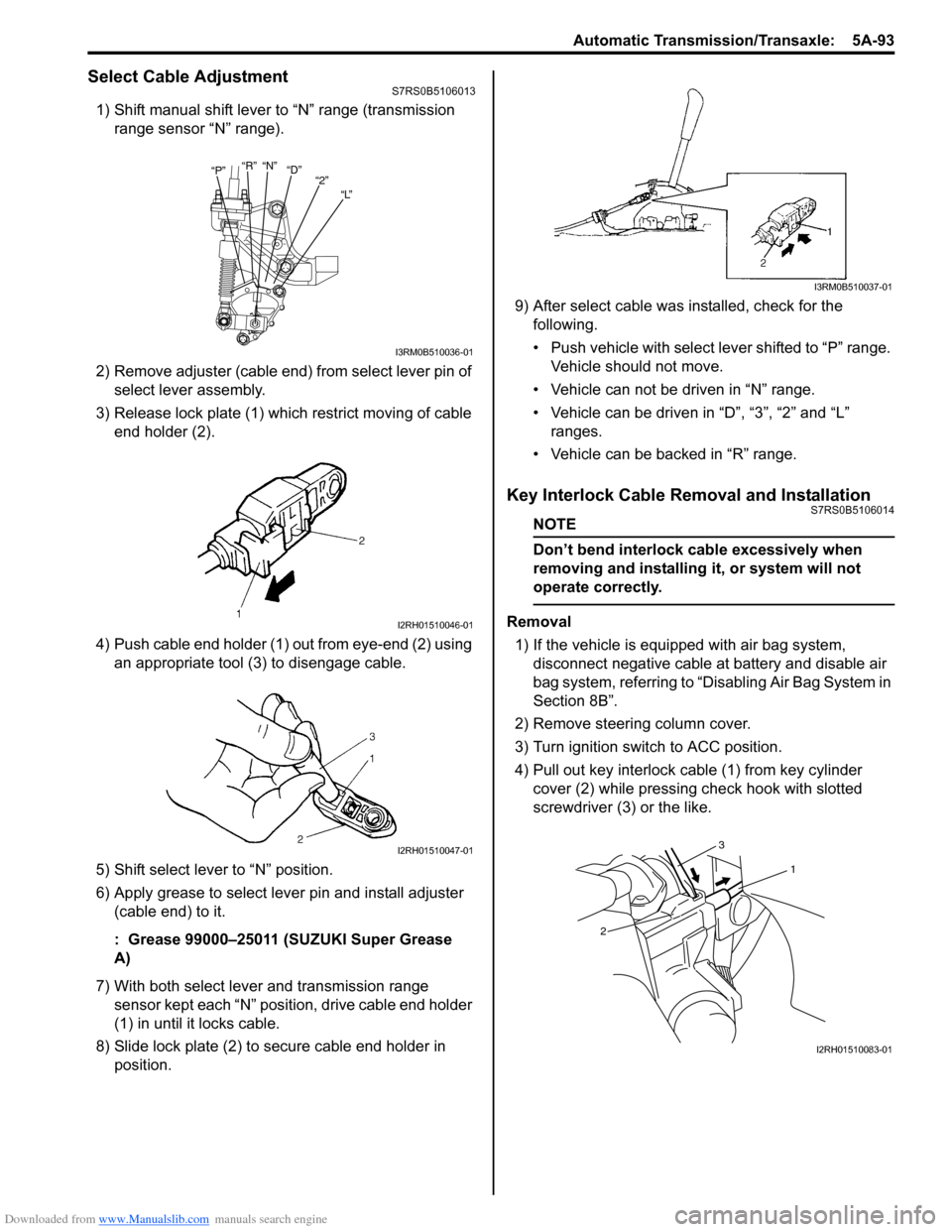

Select Cable AdjustmentS7RS0B5106013

1) Shift manual shift lever to “N” range (transmission range sensor “N” range).

2) Remove adjuster (cable end) from select lever pin of select lever assembly.

3) Release lock plate (1) which restrict moving of cable end holder (2).

4) Push cable end holder (1) out from eye-end (2) using an appropriate tool (3) to disengage cable.

5) Shift select lever to “N” position.

6) Apply grease to select lever pin and install adjuster (cable end) to it.

: Grease 99000–25011 (SUZUKI Super Grease

A)

7) With both select lever and transmission range sensor kept each “N” position, drive cable end holder

(1) in until it locks cable.

8) Slide lock plate (2) to secure cable end holder in position. 9) After select cable was

installed, check for the

following.

• Push vehicle with select lever shifted to “P” range. Vehicle should not move.

• Vehicle can not be driven in “N” range.

• Vehicle can be driven in “D”, “3”, “2” and “L” ranges.

• Vehicle can be backed in “R” range.

Key Interlock Cable Removal and InstallationS7RS0B5106014

NOTE

Don’t bend interlock cable excessively when

removing and installing it, or system will not

operate correctly.

Removal

1) If the vehicle is equipped with air bag system, disconnect negative cable at battery and disable air

bag system, referring to “Disabling Air Bag System in

Section 8B”.

2) Remove steering column cover.

3) Turn ignition switch to ACC position.

4) Pull out key interlock cable (1) from key cylinder cover (2) while pressing check hook with slotted

screwdriver (3) or the like.

“P” “R”

“N”

“D”

“2”

“L”

I3RM0B510036-01

I2RH01510046-01

I2RH01510047-01

I3RM0B510037-01

1

2 3

I2RH01510083-01

Page 739 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-95

5) Shift select lever to “N” position.

NOTE

If select lever is in “P” position, shift select

lever referring to “Select Lever Inspection”.

6) Install cable casing cap (3) to selector bracket (4).

7) Connect cable end (1) to interlock cam (2) with ignition switch turned to ACC position.

8) Drive lock button (5) in cable end until it locks cable expansion and contraction.

9) With select lever set at “P ” position, turn ignition key

to ACC position and then check for the following

conditions.

• With knob button released, ignition key can be turned from ACC position to LOCK position.

• With knob button pressed, ignition key cannot be

turned from ACC position to LOCK position.

10) Install steering column cover. 11) If the vehicle is equipped with air bag system, connect negative cable at battery and enable air bag

system, referring to “Enabling Air Bag System in

Section 8B”.

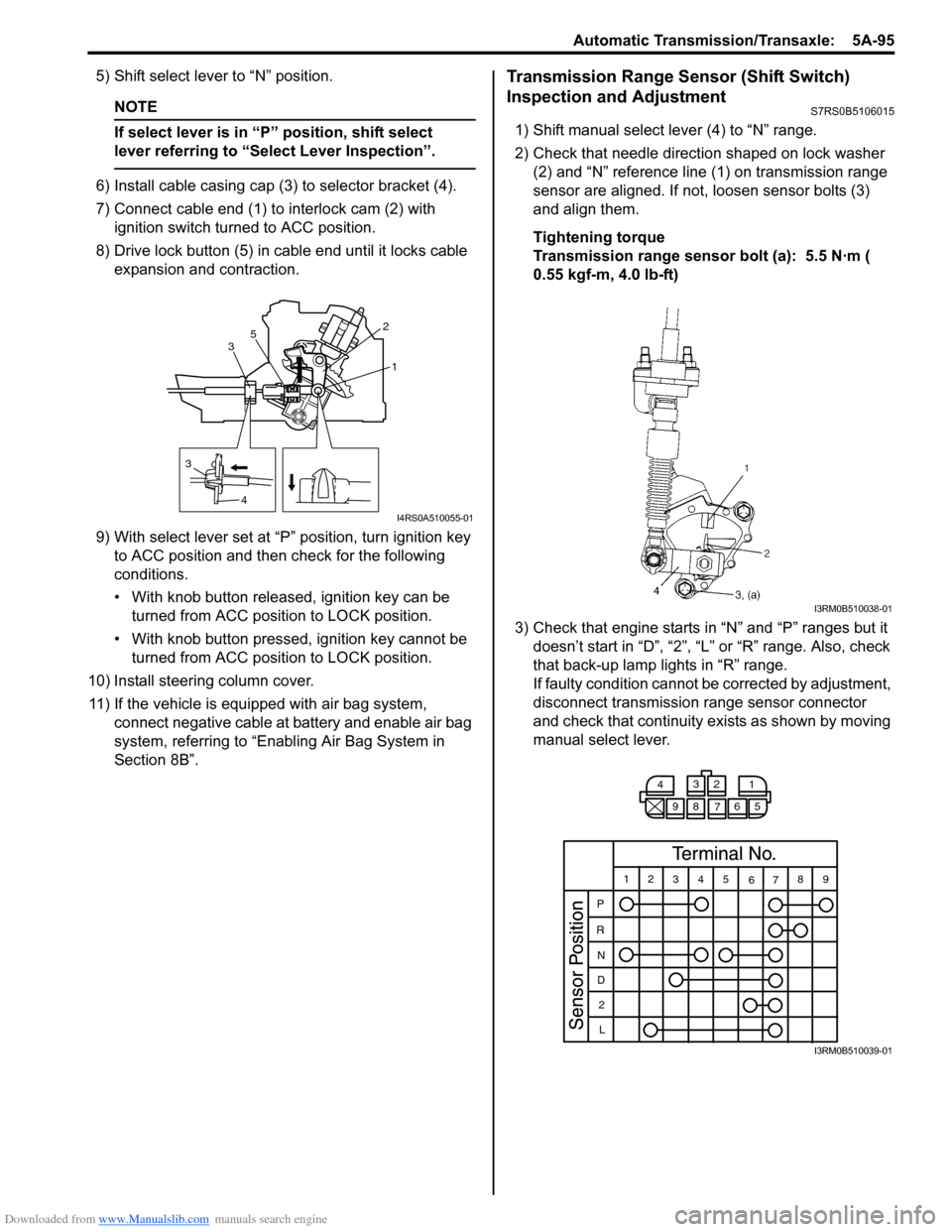

Transmission Range Sensor (Shift Switch)

Inspection and Adjustment

S7RS0B5106015

1) Shift manual select lever (4) to “N” range.

2) Check that needle direction shaped on lock washer (2) and “N” reference line (1) on transmission range

sensor are aligned. If not, loosen sensor bolts (3)

and align them.

Tightening torque

Transmission range sensor bolt (a): 5.5 N·m (

0.55 kgf-m, 4.0 lb-ft)

3) Check that engine starts in “N” and “P” ranges but it doesn’t start in “D”, “2”, “L” or “R” range. Also, check

that back-up lamp lights in “R” range.

If faulty condition cannot be corrected by adjustment,

disconnect transmission range sensor connector

and check that continuity ex ists as shown by moving

manual select lever.

3

4 1

2

3 5

I4RS0A510055-01

I3RM0B510038-01

4

3

2

1

98 76 5

12 345

6789

P

R N

D 2

L

I3RM0B510039-01

Page 791 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-147

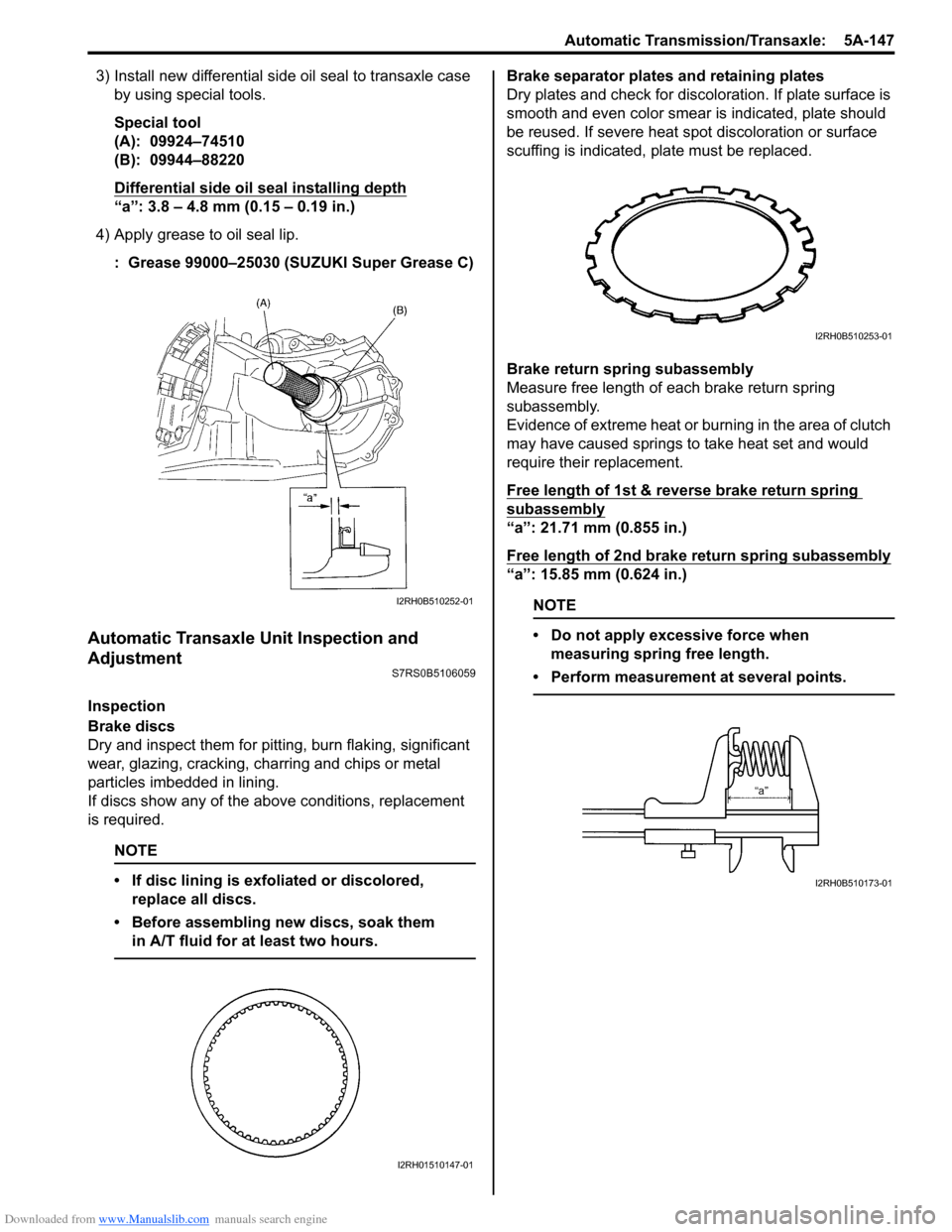

3) Install new differential side oil seal to transaxle case by using special tools.

Special tool

(A): 09924–74510

(B): 09944–88220

Differential side oil seal installing depth

“a”: 3.8 – 4.8 mm (0.15 – 0.19 in.)

4) Apply grease to oil seal lip. : Grease 99000–25030 (SUZUKI Super Grease C)

Automatic Transaxle Unit Inspection and

Adjustment

S7RS0B5106059

Inspection

Brake discs

Dry and inspect them for pitting, burn flaking, significant

wear, glazing, cracking, charring and chips or metal

particles imbedded in lining.

If discs show any of the ab ove conditions, replacement

is required.

NOTE

• If disc lining is exfoliated or discolored, replace all discs.

• Before assembling new discs, soak them in A/T fluid for at least two hours.

Brake separator plates and retaining plates

Dry plates and check for discol oration. If plate surface is

smooth and even color smear is indicated, plate should

be reused. If severe heat spot discoloration or surface

scuffing is indicated, plate must be replaced.

Brake return spring subassembly

Measure free length of each brake return spring

subassembly.

Evidence of extreme heat or burning in the area of clutch

may have caused springs to take heat set and would

require their replacement.

Free length of 1st & reverse brake return spring

subassembly

“a”: 21.71 mm (0.855 in.)

Free length of 2nd brake return spring subassembly

“a”: 15.85 mm (0.624 in.)

NOTE

• Do not apply excessive force when measuring spring free length.

• Perform measurement at several points.

I2RH0B510252-01

I2RH01510147-01

I2RH0B510253-01

I2RH0B510173-01

Page 792 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-148 Automatic Transmission/Transaxle:

One-way clutch No.1 assembly1) Install one-way clutch No.1 assembly (2) to rear planetary sun gear subassembly (1).

2) Securing rear planetary sun gear subassembly, ensure that one-way clutch No.1 assembly rotates

only in one direction.

If the one-way clutch rotates in both directions or it

does not rotate in either direction, replace it with new

one.

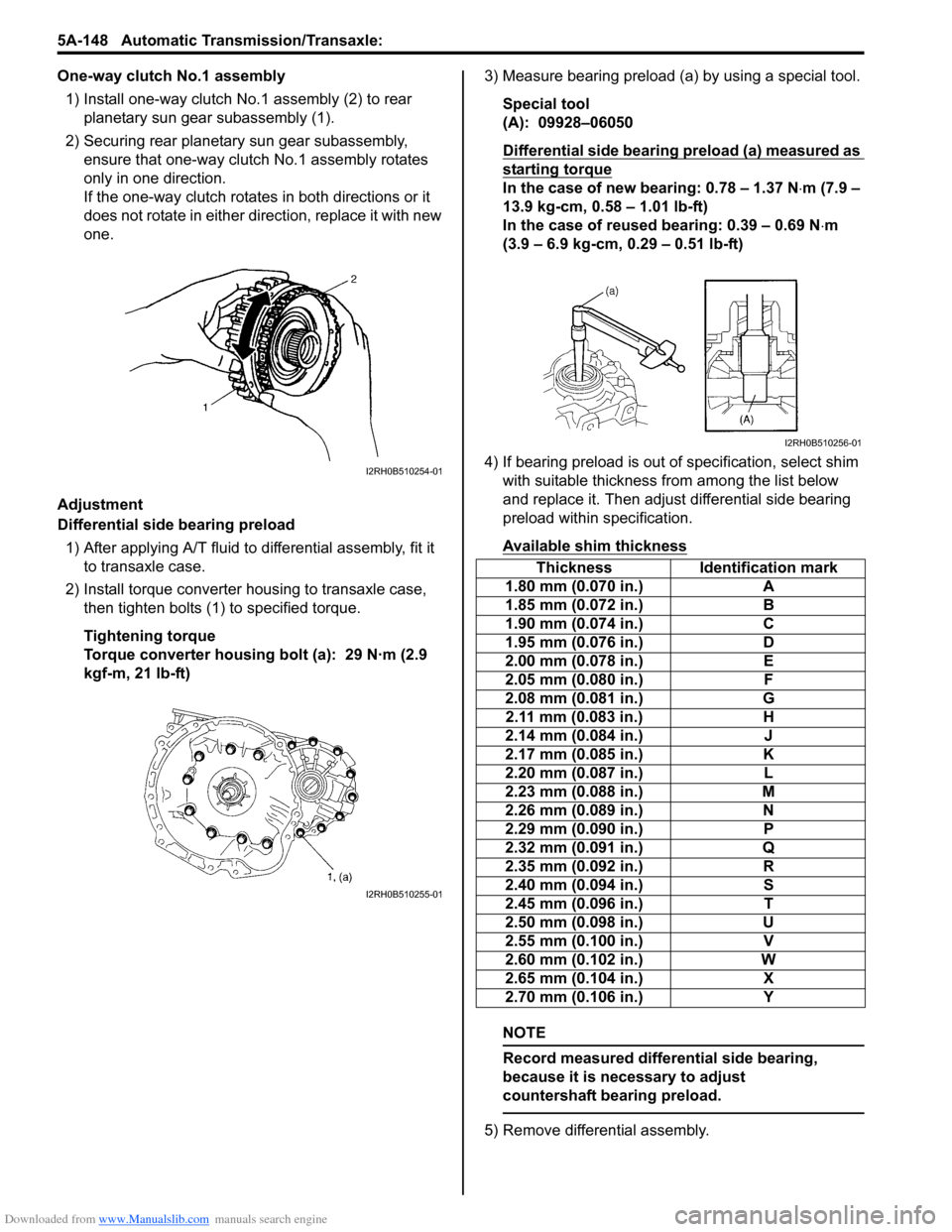

Adjustment

Differential side bearing preload 1) After applying A/T fluid to differential assembly, fit it to transaxle case.

2) Install torque converter housing to transaxle case, then tighten bolts (1) to specified torque.

Tightening torque

Torque converter housing bolt (a): 29 N·m (2.9

kgf-m, 21 lb-ft) 3) Measure bearing preload (a) by using a special tool.

Special tool

(A): 09928–06050

Differential side bearing preload (a) measured as

starting torque

In the case of new bearing: 0.78 – 1.37 N ⋅m (7.9 –

13.9 kg-cm, 0.58 – 1.01 lb-ft)

In the case of reused bearing: 0.39 – 0.69 N ⋅m

(3.9 – 6.9 kg-cm, 0.29 – 0.51 lb-ft)

4) If bearing preload is out of specification, select shim with suitable thickness from among the list below

and replace it. Then adjust differential side bearing

preload within specification.

Available shim thickness

NOTE

Record measured differential side bearing,

because it is necessary to adjust

countershaft bearing preload.

5) Remove differential assembly.

I2RH0B510254-01

I2RH0B510255-01

Thickness Identification mark

1.80 mm (0.070 in.) A

1.85 mm (0.072 in.) B

1.90 mm (0.074 in.) C

1.95 mm (0.076 in.) D

2.00 mm (0.078 in.) E

2.05 mm (0.080 in.) F

2.08 mm (0.081 in.) G

2.11 mm (0.083 in.) H

2.14 mm (0.084 in.) J

2.17 mm (0.085 in.) K

2.20 mm (0.087 in.) L

2.23 mm (0.088 in.) M

2.26 mm (0.089 in.) N

2.29 mm (0.090 in.) P

2.32 mm (0.091 in.) Q

2.35 mm (0.092 in.) R

2.40 mm (0.094 in.) S

2.45 mm (0.096 in.) T

2.50 mm (0.098 in.) U

2.55 mm (0.100 in.) V

2.60 mm (0.102 in.) W

2.65 mm (0.104 in.) X

2.70 mm (0.106 in.) Y

I2RH0B510256-01

Page 820 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-6 Manual Transmission/Transaxle:

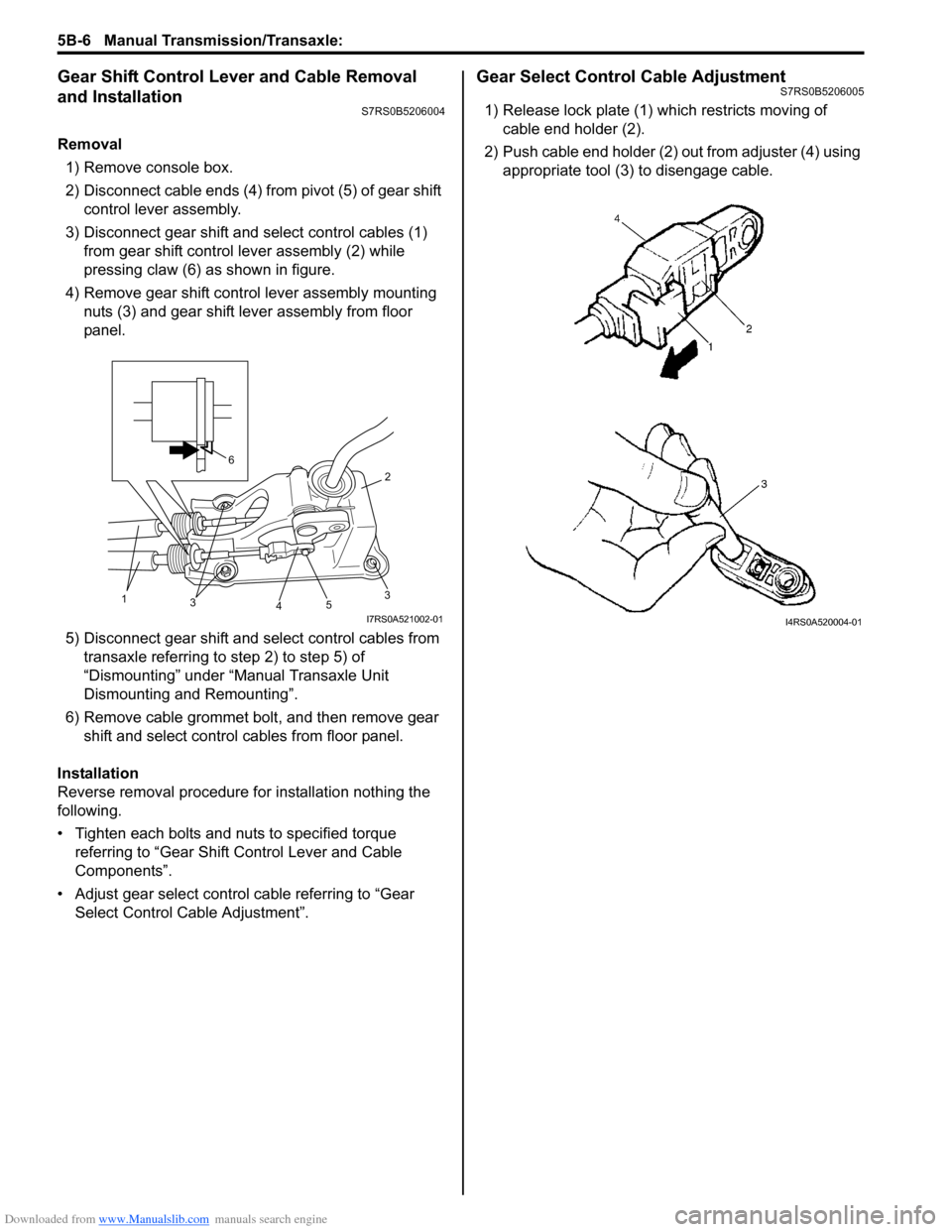

Gear Shift Control Lever and Cable Removal

and Installation

S7RS0B5206004

Removal1) Remove console box.

2) Disconnect cable ends (4) from pivot (5) of gear shift control lever assembly.

3) Disconnect gear shift and select control cables (1) from gear shift control lever assembly (2) while

pressing claw (6) as shown in figure.

4) Remove gear shift control lever assembly mounting nuts (3) and gear shift lever assembly from floor

panel.

5) Disconnect gear shift and select control cables from transaxle referring to step 2) to step 5) of

“Dismounting” under “Manual Transaxle Unit

Dismounting and Remounting”.

6) Remove cable grommet bolt, and then remove gear shift and select control cables from floor panel.

Installation

Reverse removal procedure for installation nothing the

following.

• Tighten each bolts and nuts to specified torque referring to “Gear Shift Control Lever and Cable

Components”.

• Adjust gear select control cable referring to “Gear Select Control Cable Adjustment”.

Gear Select Control Cable AdjustmentS7RS0B5206005

1) Release lock plate (1) which restricts moving of cable end holder (2).

2) Push cable end holder (2) out from adjuster (4) using appropriate tool (3) to disengage cable.

35

4

2

31

6

I7RS0A521002-01I4RS0A520004-01

Page 856 of 1496

Downloaded from www.Manualslib.com manuals search engine 5C-4 Clutch:

3) Depress clutch pedal several times, and then release clutch pedal, push snap ring (2) and pull pipe

connector (1) one notch.

4) When fluid pressure in cylinder is almost depleted, push pipe connector.

5) Repeat this operation until there are no more air bubbles in hydraulic line.

6) When bubbles stop, depress and hold clutch pedal, push pipe connector, and pull snap ring.

7) Then attach bleeder plug cap.

8) After completing bleeding operation, apply fluid pressure to pipe line and check for leakage.

9) Replenish fluid into reserv oir up to specified level.

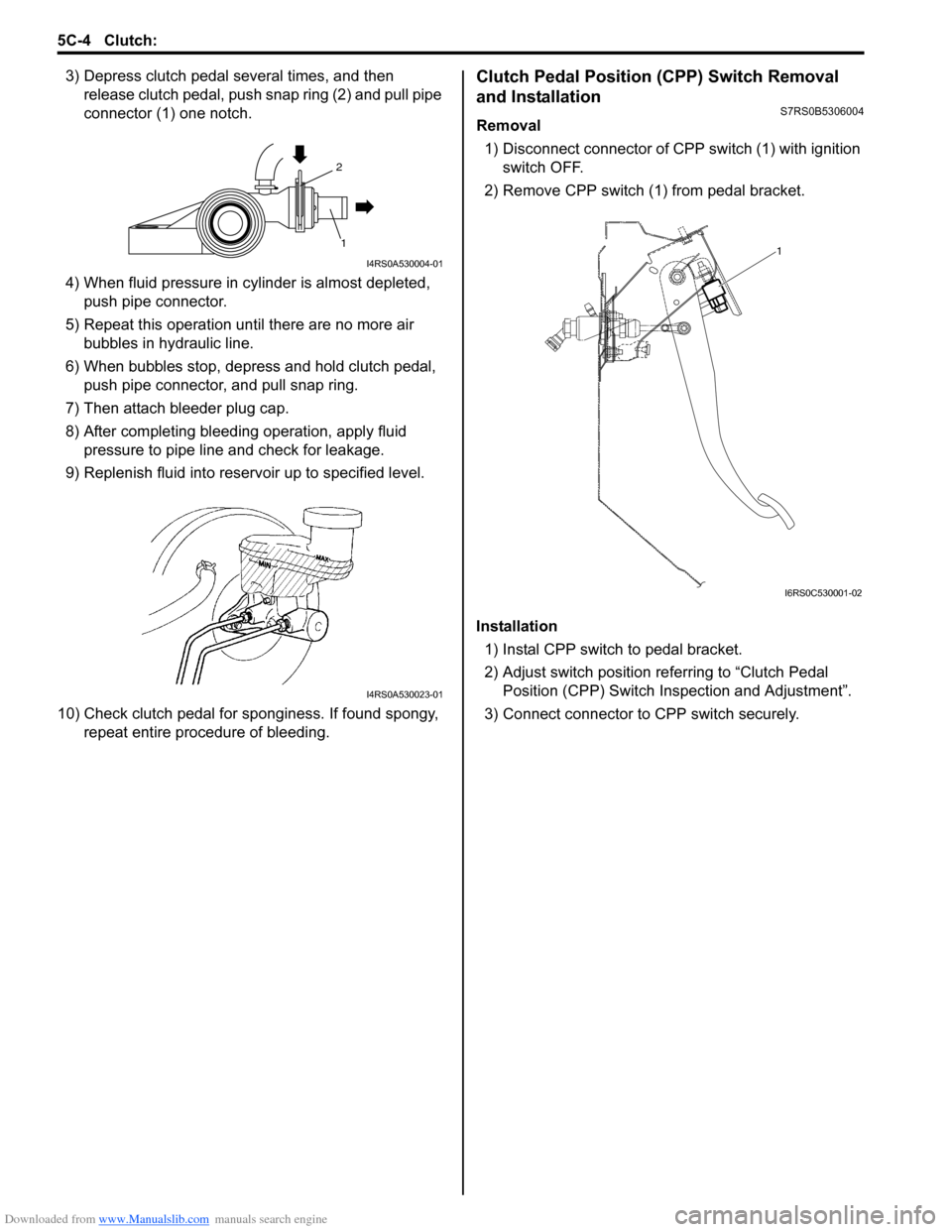

10) Check clutch pedal for sponginess. If found spongy, repeat entire procedure of bleeding.Clutch Pedal Position (CPP) Switch Removal

and Installation

S7RS0B5306004

Removal

1) Disconnect connector of C PP switch (1) with ignition

switch OFF.

2) Remove CPP switch (1 ) from pedal bracket.

Installation 1) Instal CPP switch to pedal bracket.

2) Adjust switch position re ferring to “Clutch Pedal

Position (CPP) Switch Inspection and Adjustment”.

3) Connect connector to CPP switch securely.

2

1

I4RS0A530004-01

I4RS0A530023-01

1

I6RS0C530001-02