Eps system SUZUKI SWIFT 2008 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1211 of 1496

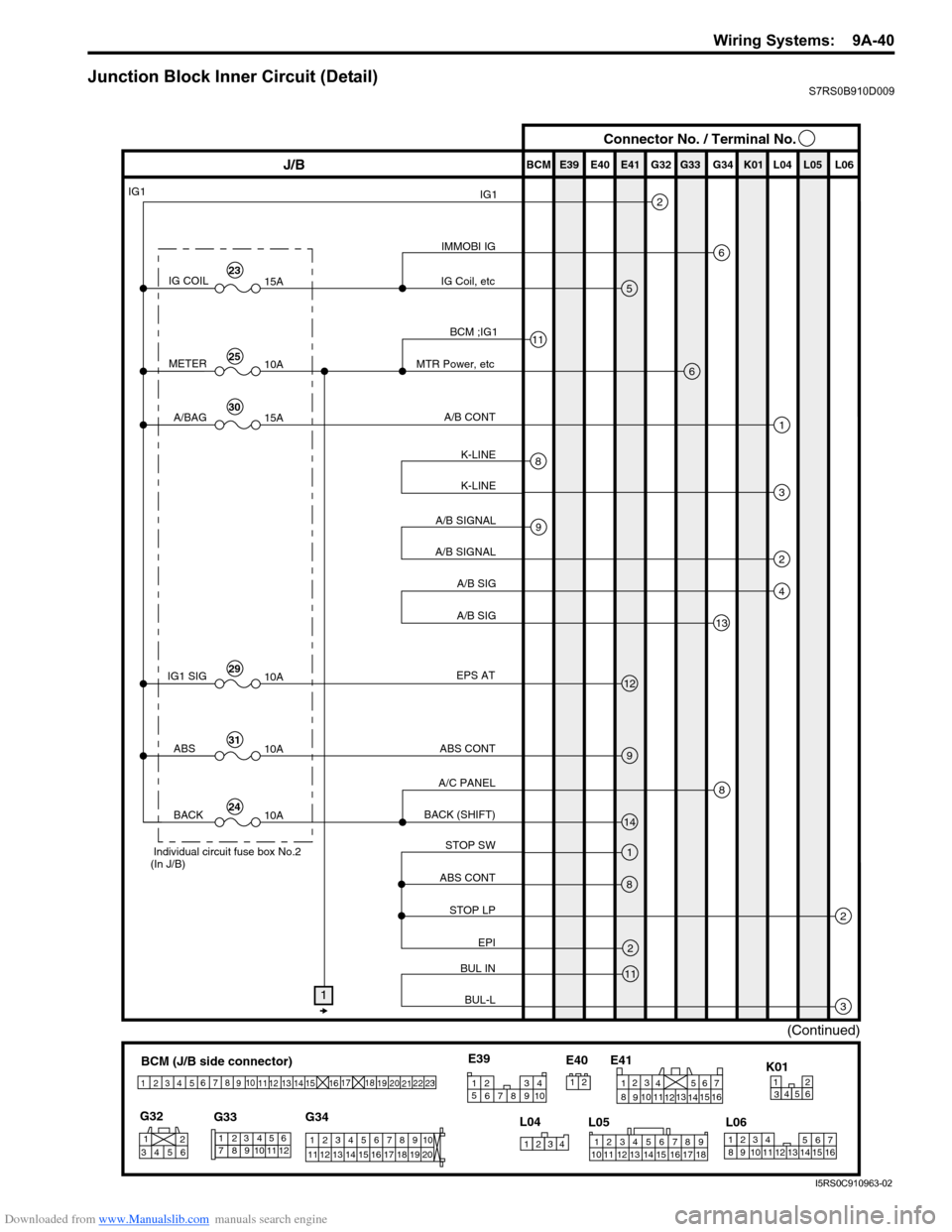

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-40

Junction Block Inner Circuit (Detail)S7RS0B910D009

BCM (J/B side connector)

34

1

2 5

15

14

12

13

10

11

9

8

6

7

17

161821 22

19

20

23

1234578 11 6

12

91034 6 52

1

G33

G32

G34

10

11 12 13 14 15 16 17 18 19 123456789

20

345612K01

23414

3

561214

11

10 157

2113 16

98

6

5

4

3

2

1

7

11

10

9

8

15

14

13

12 16

L04

L06

E41

21

123456789

15 16 17 18

1110 12 13 14

1

234

5 678 910

E39

L05

E40

IMMOBI IG

IG1

IG Coil, etc E39 E41E40

BCM G34G33G32 K01 L04 L05 L06

IG COIL

IG1

15A

METER10A

A/BAG15A

2

6

5

13

J/B Connector No. / Terminal No.

BCM ;IG1

MTR Power, etc

A/B CONT

K-LINE K-LINE

A/B SIGNAL

A/B SIGNAL

A/B SIG

A/B SIG

IG1 SIG 10AEPS AT

ABS CONT

STOP SW

ABS CONT

STOP LP EPI

BUL IN

BUL-L

BACK (SHIFT)

A/C PANEL

6

1

3

2

4

8

11

9

12

9

14

1

2

3

8

2

11

8

ABS

10A

BACK10A

1

(Continued)

Individual circuit fuse box No.2

(In J/B)

23

25

30

29

31

24

I5RS0C910963-02

Page 1246 of 1496

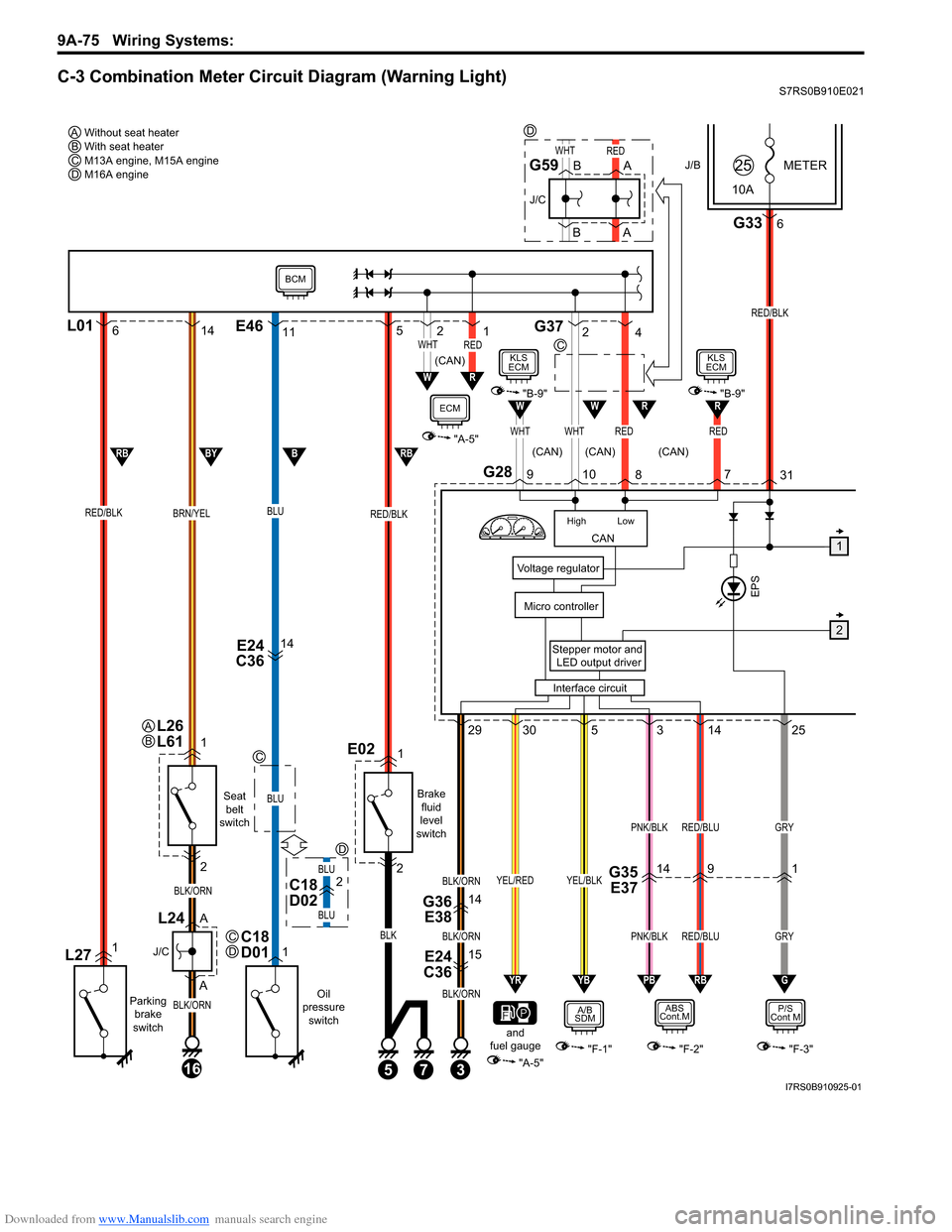

Downloaded from www.Manualslib.com manuals search engine 9A-75 Wiring Systems:

C-3 Combination Meter Circuit Diagram (Warning Light)S7RS0B910E021

J/BMETER

10A25

G2831

3

E24

C3615

G36 E3814

Stepper motor and

LED output driver

Voltage regulator

Interface circuit

Micro controllerEPS

G336

RED/BLK

145293025

PNK/BLKGRY

GRY

RED/BLU

PNK/BLK

BLK/ORN

BLK/ORN

BLK/ORN

RED/BLU

P/S

Cont M

"F-3"

RBPBYBYR

YEL/BLKYEL/RED

A/B

SDM

"F-1""A-5"

ABS

Cont.M

"F-2"

G

CAN

High Low

WHTWHTRED

WHTRED

RED

RW

109 8

6L0114

RED/BLKBRN/YEL

L271

Parking

brake

switch

1

2

A

A

16

BLK/ORN

BLK/ORN

J/C

L24

Seat belt

switch

Oil

pressure switch

E24

C3614

BLU

BLU

1C18

D01

RED/BLK

E021

Brake

fluid

level

switch

and

fuel gauge

2

53

BLK

11 5E46G372

4

RW

W

21WHTRED

"A-5"

1

2

RBBBYRB

7

BCM

ECM"B-9"

KLS

ECM

7

R"B-9"

KLS

ECM

Without seat heater

AWith seat heater

BM13A engine, M15A engine

CM16A engine

D

C

C

C

D

(CAN)

(CAN) (CAN)

(CAN)

L26

L61AB

B

BA

A

J/C

G59

BLU

BLU

D

C18

D022G35 E371419

D

I7RS0B910925-01

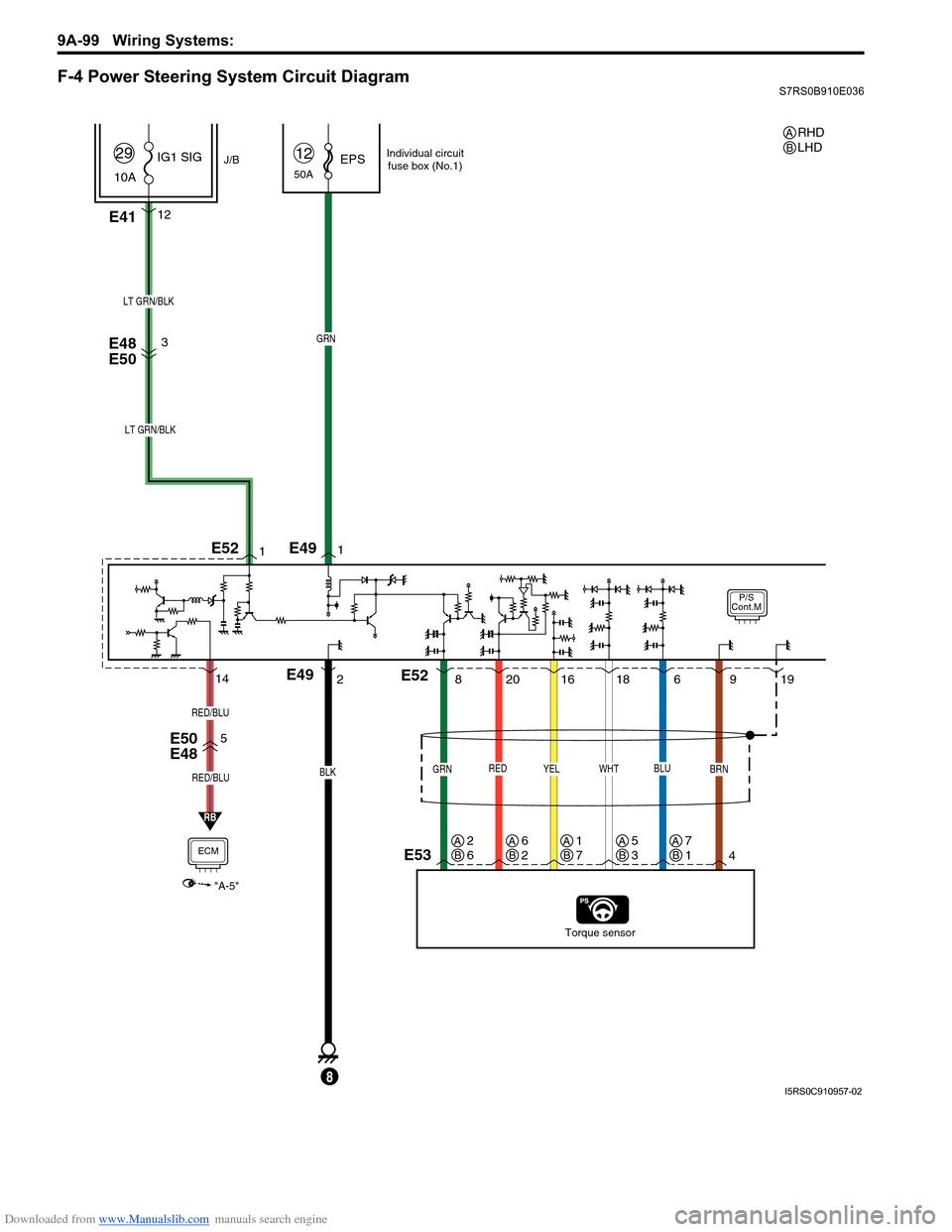

Page 1270 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-99 Wiring Systems:

F-4 Power Steering System Circuit DiagramS7RS0B910E036

P/S

Cont.M

50AEPS12

E4112

J/B

10A IG1 SIG

29

RED

20

E48

E50

E50

E48

Torque sensor

BLK

E49

8

GRN

LT GRN/BLK

YEL

16

GRN

8

BRN

49

WHT

18

BLU

619

1

21

LT GRN/BLK

3

E53

E49

E52

E52

RB

5

ECM

"A-5"

RED/BLU

RED/BLU

14

Individual circuit

fuse box (No.1)

RHD

LHDAB

AB2

6AB6

2AB1

7AB5

3AB7

1

I5RS0C910957-02

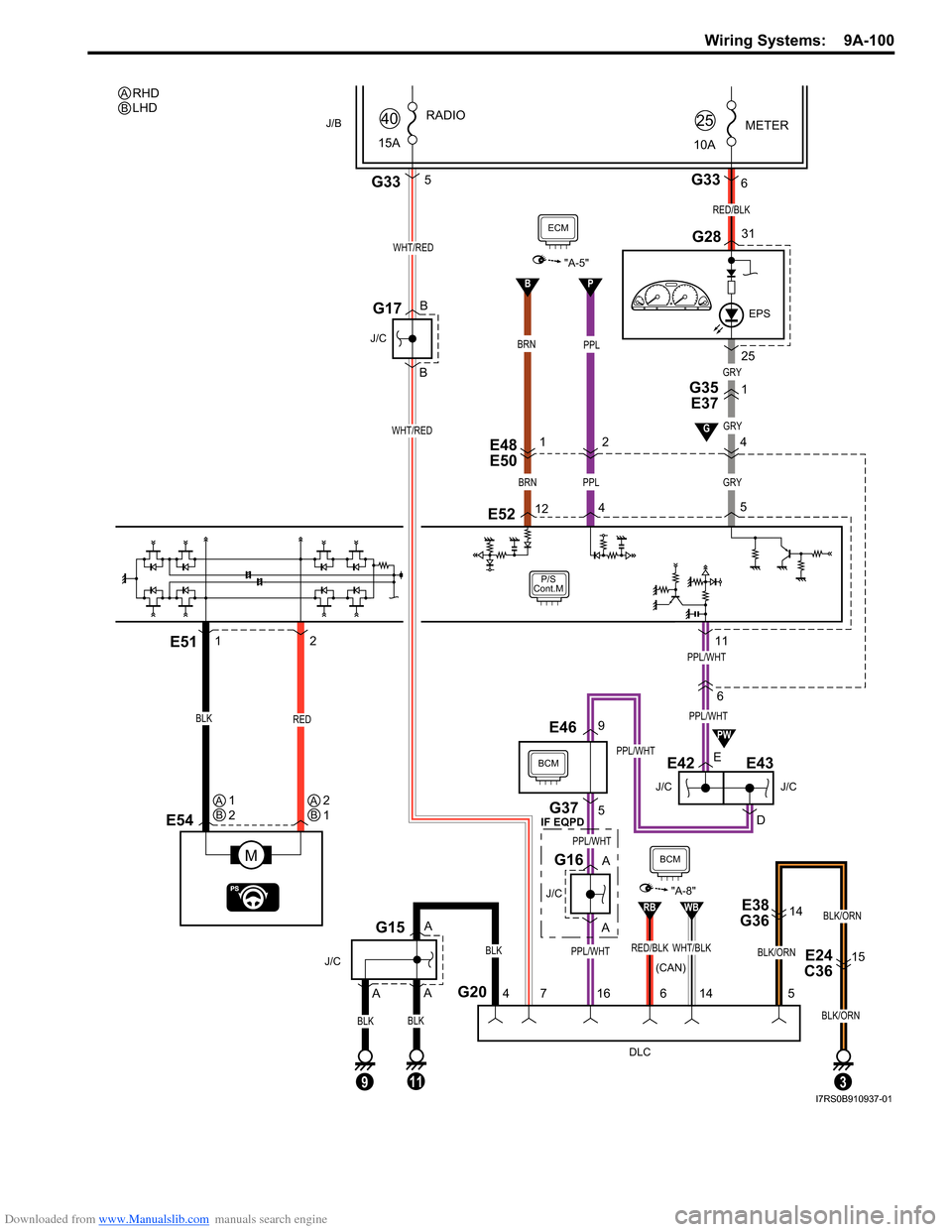

Page 1271 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-100

B

P/S

Cont.M

6

J/C

E42

E48

E50

E

D

G35 E37

J/C

E43

E54

M

REDBLK

E51

ECM

"A-5"

GRYBRN

1211

125

GRY

BRN

1 4

E52

PPL

2

P

4

PPL/WHT

PPL/WHT

EPS

METER

10A25

G2831

G336

RED/BLK

25PPL

G20

DLC

4

BLK

A

A

J/C

G15

5

PPL/WHT

PPL/WHT

A

A

J/C

G16

9E46

E38

G3614

E24

C3615

BLK/ORN

5

3

J/B

15A RADIO

40

G335

WHT/RED

BLK/ORN

16

7

B

B

J/C

G17

BLK/ORN

11

BCM

WHT/RED

G37

9

BLK

A

BLK

PW

WHT/BLKRED/BLK

RBWB

"A-8"

14

6

GRY

1

G

BCM

PPL/WHT

RHD

LHDAB

AB1

2AB2

1

(CAN)

IF EQPD

I7RS0B910937-01

Page 1296 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-1 Instrumentation / Driver Info. / Horn:

Body, Cab and Accessories

Instrumentation / Driver Info. / Horn

Precautions

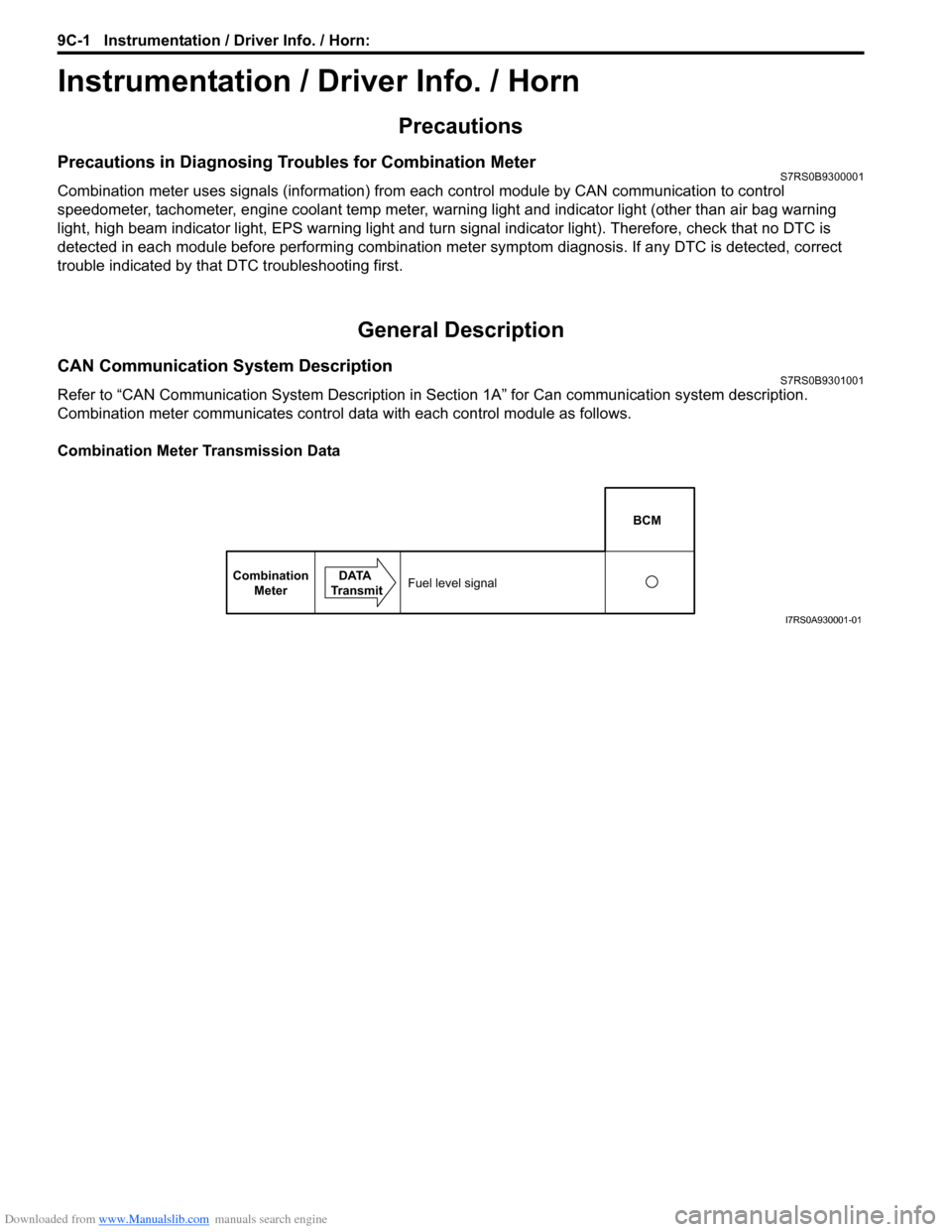

Precautions in Diagnosing Troubles for Combination MeterS7RS0B9300001

Combination meter uses signals (information) from each control module by CAN communication to control

speedometer, tachometer, engine coolant temp meter, warning light and indicator light (other than air bag warning

light, high beam indicator light, EPS warn ing light and turn signal indicator light). Therefore, check that no DTC is

detected in each module before performing combination me ter symptom diagnosis. If any DTC is detected, correct

trouble indicated by that DTC troubleshooting first.

General Description

CAN Communication System DescriptionS7RS0B9301001

Refer to “CAN Communication System Description in Section 1A” for Can communication system description.

Combination meter communicates control data with each control module as follows.

Combination Meter Transmission Data

BCM

Combination Meter DATA

TransmitFuel level signal

I7RS0A930001-01

Page 1418 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-15 Body Electrical Control System:

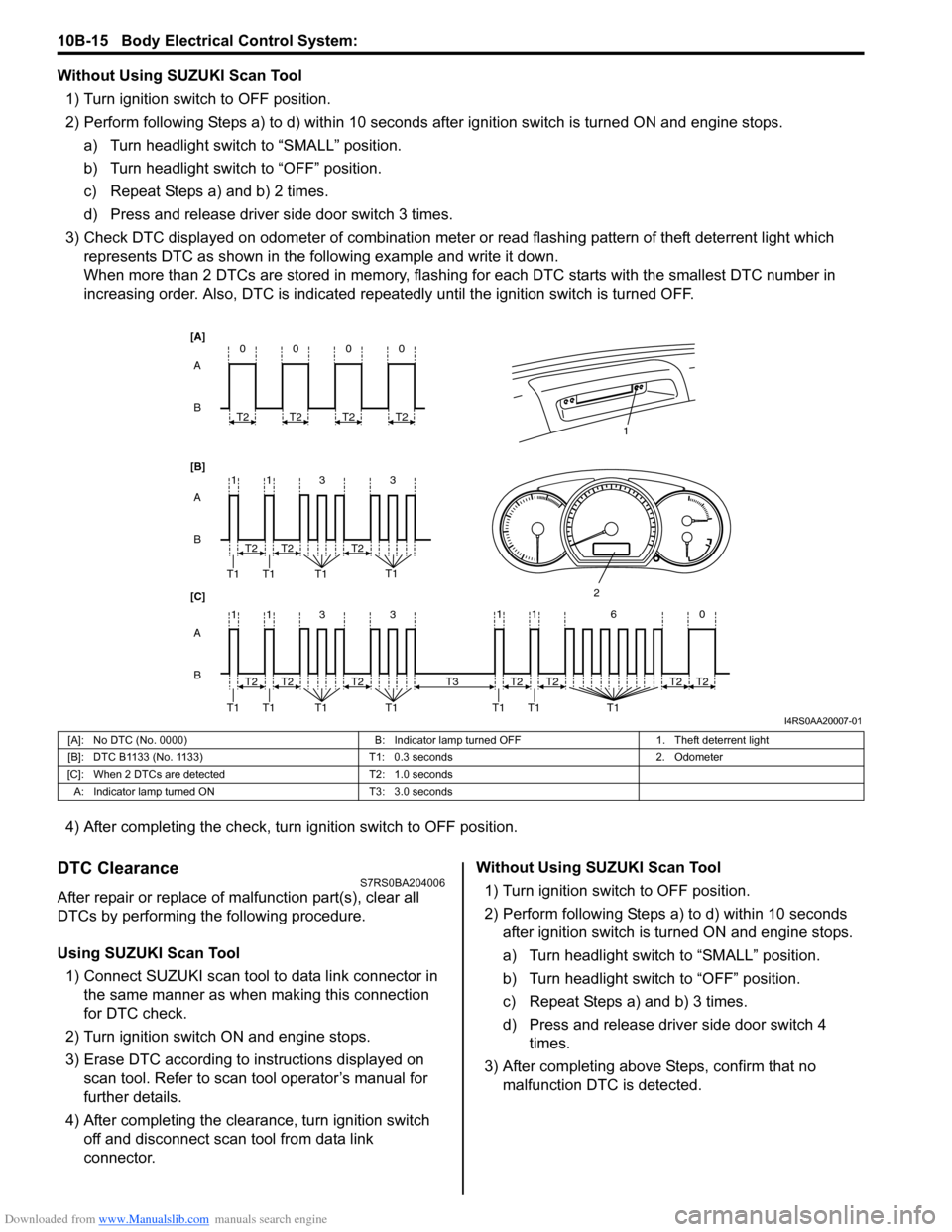

Without Using SUZUKI Scan Tool1) Turn ignition switch to OFF position.

2) Perform following Steps a) to d) within 10 seconds af ter ignition switch is turned ON and engine stops.

a) Turn headlight switch to “SMALL” position.

b) Turn headlight switch to “OFF” position.

c) Repeat Steps a) and b) 2 times.

d) Press and release driver side door switch 3 times.

3) Check DTC displayed on odometer of combination meter or read flashing pattern of theft deterrent light which

represents DTC as shown in the following example and write it down.

When more than 2 DTCs are stored in memory, flashing for each DTC starts with the smallest DTC number in

increasing order. Also, DTC is indicated repeatedly until the ignition switch is turned OFF.

4) After completing the check, turn ignition switch to OFF position.

DTC ClearanceS7RS0BA204006

After repair or replace of malfunction part(s), clear all

DTCs by performing the following procedure.

Using SUZUKI Scan Tool 1) Connect SUZUKI scan tool to data link connector in the same manner as when making this connection

for DTC check.

2) Turn ignition switch ON and engine stops.

3) Erase DTC according to instructions displayed on scan tool. Refer to scan tool operator’s manual for

further details.

4) After completing the clear ance, turn ignition switch

off and disconnect scan tool from data link

connector. Without Using SUZUKI Scan Tool

1) Turn ignition switch to OFF position.

2) Perform following Steps a) to d) within 10 seconds after ignition switch is turned ON and engine stops.

a) Turn headlight switch to “SMALL” position.

b) Turn headlight switch to “OFF” position.

c) Repeat Steps a) and b) 3 times.

d) Press and release driver side door switch 4 times.

3) After completing above Steps, confirm that no malfunction DTC is detected.

B A

[B] [A]

[C]

B A B A

3

113

3

113

T2

T1 T1 T1 T1

1

2

T2T2

T2

T1 T1 T1 T1T2T2

0

T2

0

T2

0

T2

0

T2

11 6 0

T1 T1 T1

T2

T3T2T2T2

I4RS0AA20007-01

[A]: No DTC (No. 0000) B: Indicator lamp turned OFF1. Theft deterrent light

[B]: DTC B1133 (No. 1133) T1: 0.3 seconds2. Odometer

[C]: When 2 DTCs are detected T2: 1.0 seconds

A: Indicator lamp tur ned ON T3: 3.0 seconds

Page 1424 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-21 Body Electrical Control System:

DTC B1170 (No. 1170): EEPROM Access ErrorS7RS0BA204012

DTC Detecting Condition and Possible Cause

DTC Troubleshooting

NOTE

Before performing steps below, be sure to perform “Body Electrical Control System Check”.

1) Ignition switch OFF.

2) Replace BCM.

3) Repeat BCM Check Flow Table.

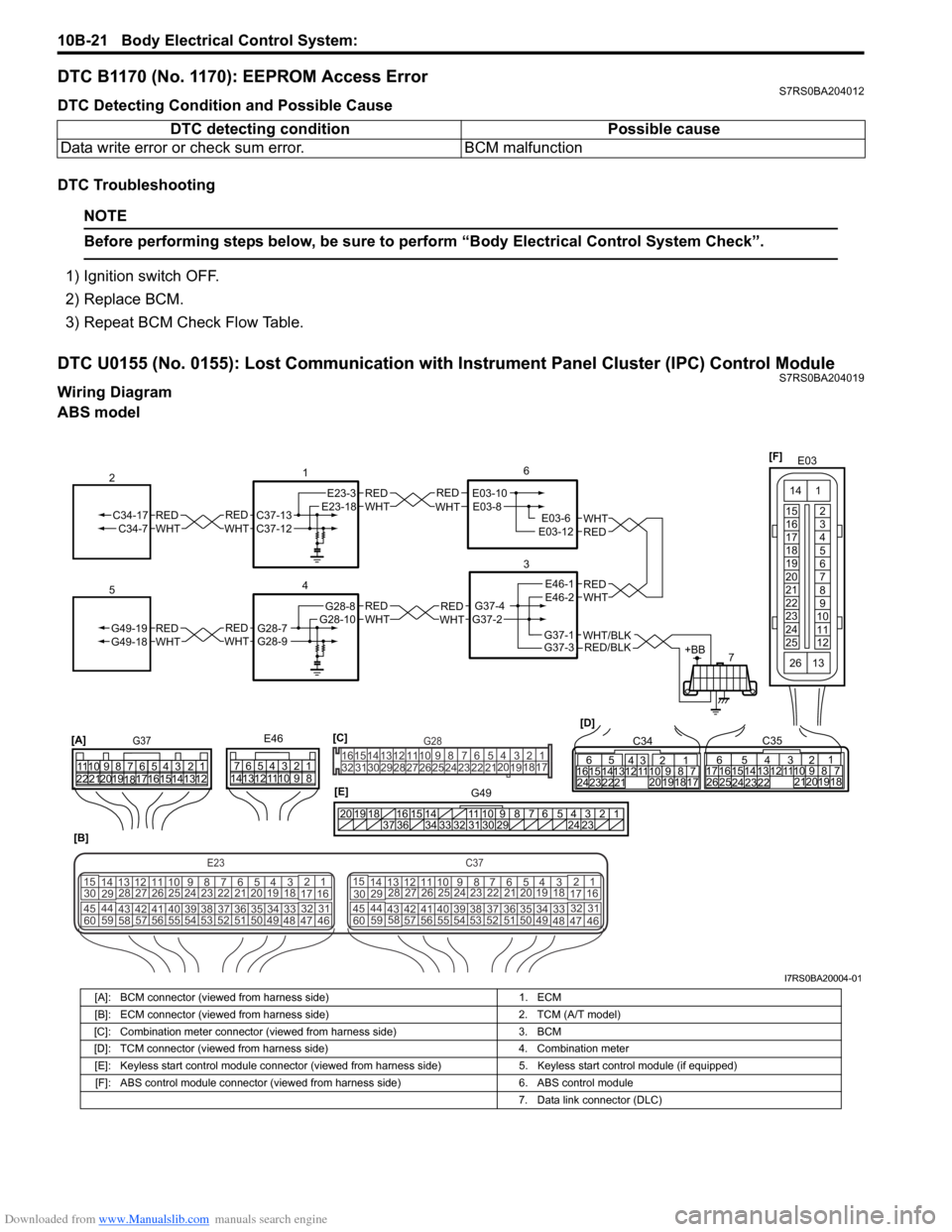

DTC U0155 (No. 0155): Lost Communication with Instrument Panel Cluster (IPC) Control ModuleS7RS0BA204019

Wiring Diagram

ABS model DTC detecting condition Possible cause

Data write error or check sum error. BCM malfunction

REDWHTE03-6E03-12

6

3

7

REDWHT

1

[B]

[A]

G37E46

1234567

1234567

8910

11

8910

11

121314 121314

151617

18

19202122 [D]65

1615 141312 11 43

2423 2122 10 9 8 7

21

1920 1817

C3417 16

26 2515 14

65 3

42

13 12

23 2224 1110 9

212019 87

18

1

C35

[E]

REDWHTC37-13C37-12REDWHTC34-17C34-7

2

12345678910

11

141516

36 34 33 32 31 30 29 24 23

37

181920

[C] [F]

G49

E23-3E23-18

4

REDWHTG28-7G28-9REDWHTG49-19G49-18

5

REDWHTE03-10E03-8

G37-4G37-2

REDWHTE46-1E46-2REDWHTREDWHTG28-8G28-10

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

E23C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 33 1

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

1213

238

G281234567

8

910111213141516

1718

19

20

212223242526272829303132

RED/BLKWHT/BLKG37-3G37-1+BB

I7RS0BA20004-01

[A]: BCM connector (viewed from harness side) 1. ECM

[B]: ECM connector (viewed from harness side) 2. TCM (A/T model)

[C]: Combination meter connector (viewed from harness side) 3. BCM

[D]: TCM connector (viewed from harness side) 4. Combination meter

[E]: Keyless start control module connector (viewed from harness side) 5. Keyless start control module (if equipped)

[F]: ABS control module connector (viewed from harness side) 6. ABS control module

7. Data link connector (DLC)

Page 1472 of 1496

Downloaded from www.Manualslib.com manuals search engine 10E-10 Keyless Start System:

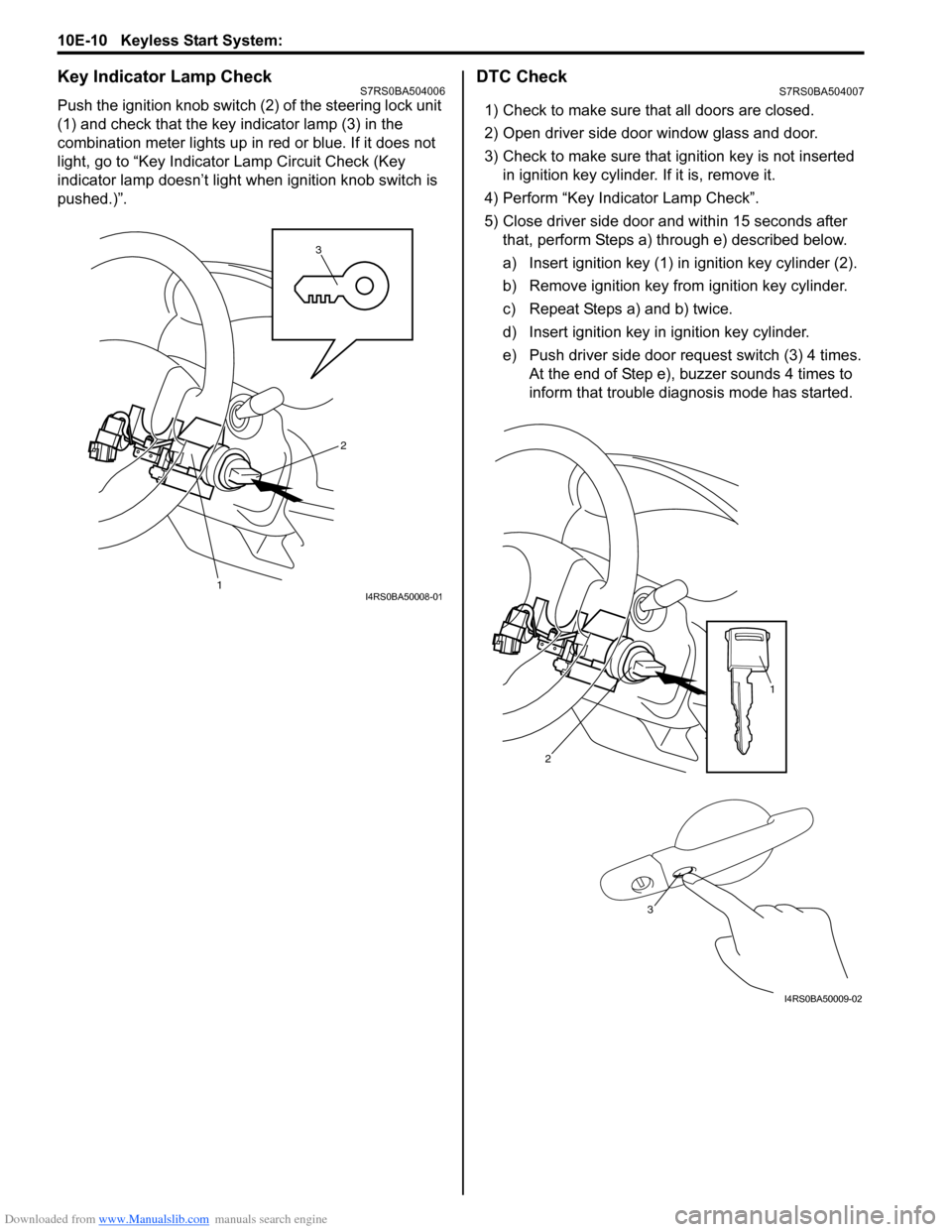

Key Indicator Lamp CheckS7RS0BA504006

Push the ignition knob switch (2) of the steering lock unit

(1) and check that the key indicator lamp (3) in the

combination meter lights up in red or blue. If it does not

light, go to “Key Indicator Lamp Circuit Check (Key

indicator lamp doesn’t light when ignition knob switch is

pushed.)”.

DTC CheckS7RS0BA504007

1) Check to make sure that all doors are closed.

2) Open driver side door window glass and door.

3) Check to make sure that ignition key is not inserted in ignition key cylinder. If it is, remove it.

4) Perform “Key Indicator Lamp Check”.

5) Close driver side door and within 15 seconds after that, perform Steps a) through e) described below.

a) Insert ignition key (1) in ignition key cylinder (2).

b) Remove ignition key from ignition key cylinder.

c) Repeat Steps a) and b) twice.

d) Insert ignition key in ignition key cylinder.

e) Push driver side door request switch (3) 4 times. At the end of Step e), buzzer sounds 4 times to

inform that trouble diagnosis mode has started.

3

1

2

I4RS0BA50008-01

2

1

3

I4RS0BA50009-02

Page 1474 of 1496

Downloaded from www.Manualslib.com manuals search engine 10E-12 Keyless Start System:

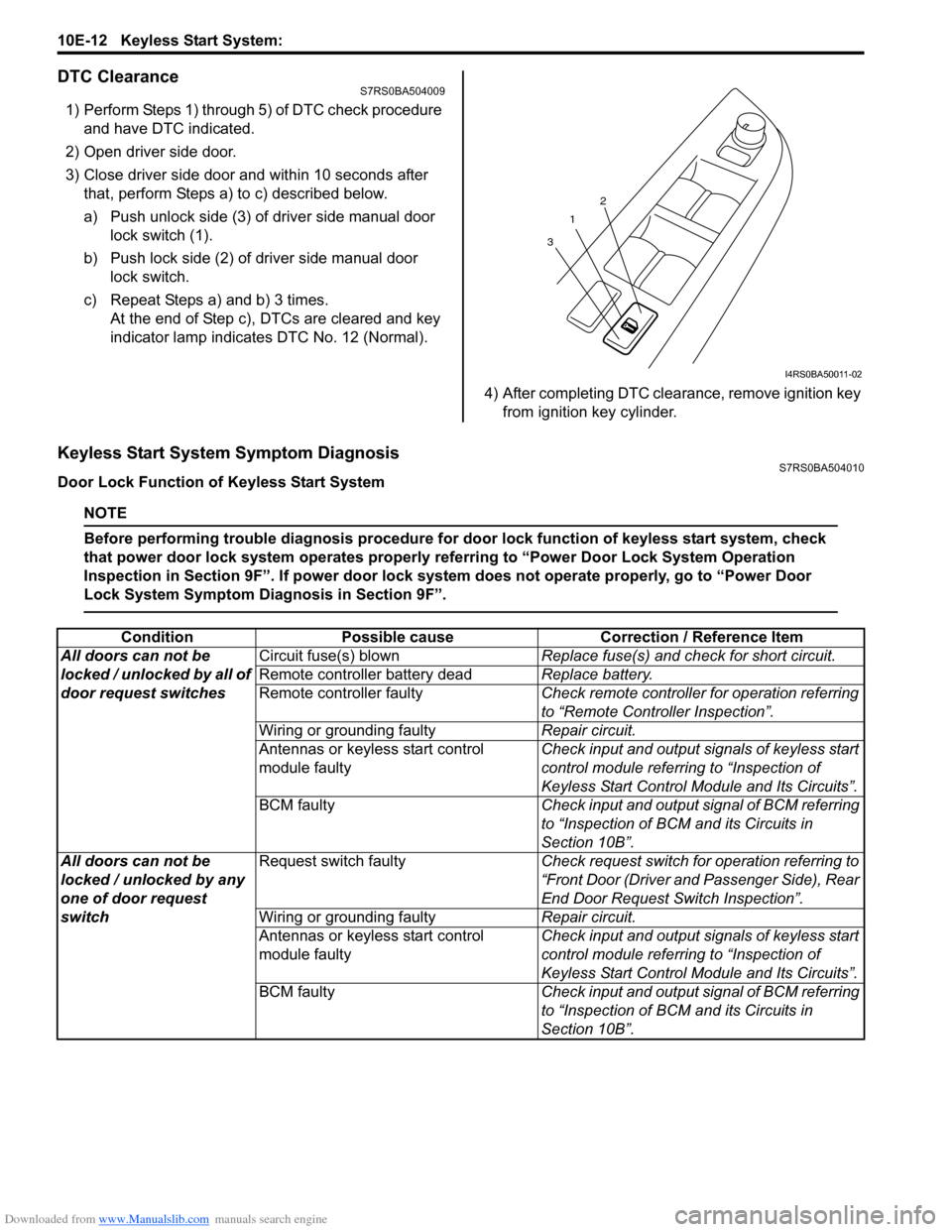

DTC ClearanceS7RS0BA504009

1) Perform Steps 1) through 5) of DTC check procedure and have DTC indicated.

2) Open driver side door.

3) Close driver side door and within 10 seconds after that, perform Steps a) to c) described below.

a) Push unlock side (3) of driver side manual door lock switch (1).

b) Push lock side (2) of driver side manual door lock switch.

c) Repeat Steps a) and b) 3 times. At the end of Step c), DTCs are cleared and key

indicator lamp indicates DTC No. 12 (Normal).

4) After completing DTC clearance, remove ignition key from ignition key cylinder.

Keyless Start System Symptom DiagnosisS7RS0BA504010

Door Lock Function of Keyless Start System

NOTE

Before performing trouble diagnosis procedure for door lock function of keyless start system, check

that power door lock system operates properly referring to “Power Door Lock System Operation

Inspection in Section 9F”. If power door lock system does not operate properly, go to “Power Door

Lock System Symptom Diagnosis in Section 9F”.

1

3 2

I4RS0BA50011-02

Condition

Possible cause Correction / Reference Item

All doors can not be

locked / unlocked by all of

door request switches Circuit fuse(s) blown

Replace fuse(s) and check for short circuit.

Remote controller battery dead Replace battery.

Remote controller faulty Check remote controller for operation referring

to “Remote Controller Inspection”.

Wiring or grounding faulty Repair circuit.

Antennas or keyless start control

module faulty Check input and output signals of keyless start

control module referring to “Inspection of

Keyless Start Control Mo

dule and Its Circuits”.

BCM faulty Check input and output signal of BCM referring

to “Inspection of BCM and its Circuits in

Section 10B”.

All doors can not be

locked / unlocked by any

one of door request

switch Request switch faulty

Check request switch for operation referring to

“Front Door (Driver and Passenger Side), Rear

End Door Request Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Antennas or keyless start control

module faulty Check input and output signals of keyless start

control module referring to “Inspection of

Keyless Start Control Mo

dule and Its Circuits”.

BCM faulty Check input and output signal of BCM referring

to “Inspection of BCM and its Circuits in

Section 10B”.

Page 1496 of 1496

Downloaded from www.Manualslib.com manuals search engine 10E-34 Keyless Start System:

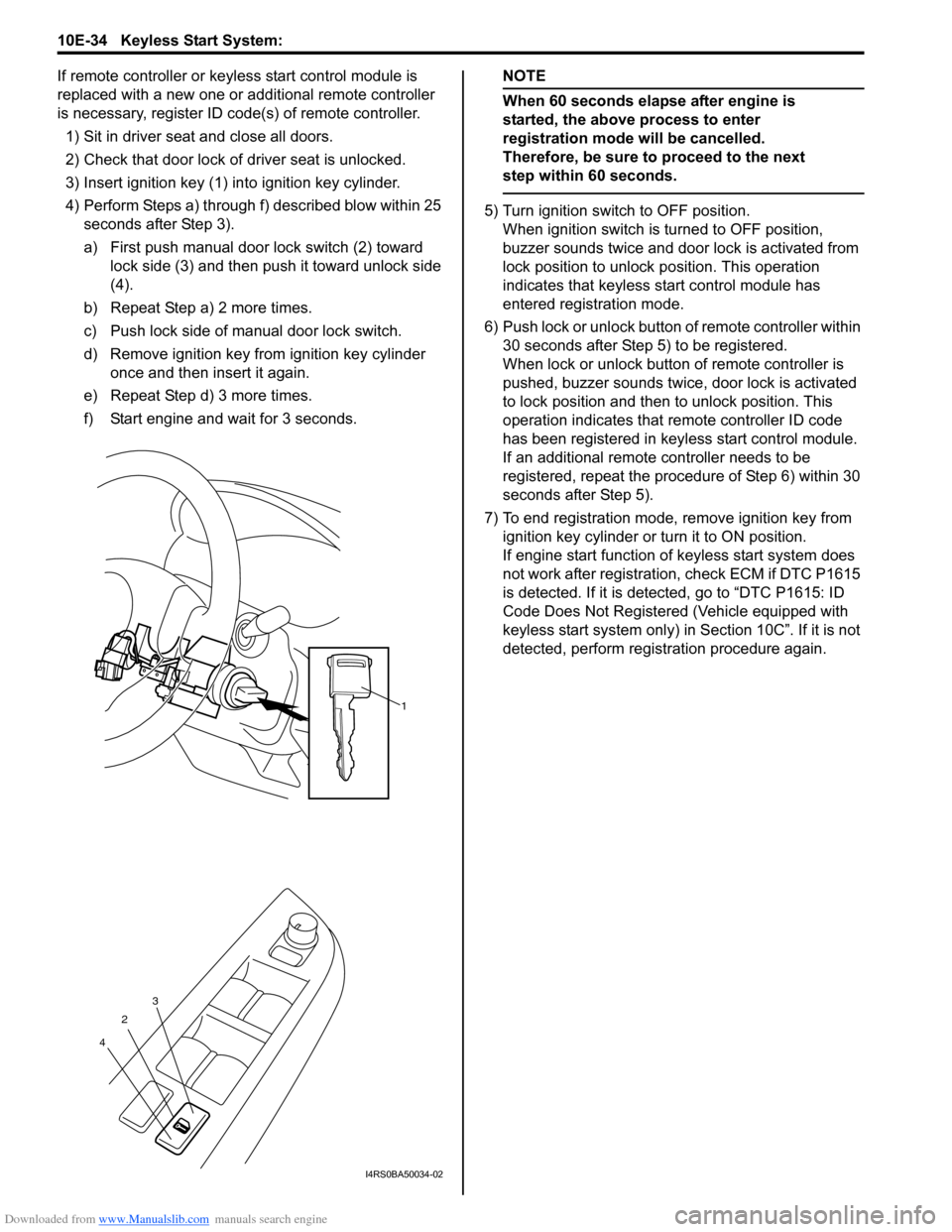

If remote controller or keyless start control module is

replaced with a new one or additional remote controller

is necessary, register ID code(s) of remote controller.1) Sit in driver seat and close all doors.

2) Check that door lock of driver seat is unlocked.

3) Insert ignition key (1) in to ignition key cylinder.

4) Perform Steps a) through f) described blow within 25 seconds after Step 3).

a) First push manual door lock switch (2) toward

lock side (3) and then push it toward unlock side

(4).

b) Repeat Step a) 2 more times.

c) Push lock side of manual door lock switch.

d) Remove ignition key from ignition key cylinder once and then insert it again.

e) Repeat Step d) 3 more times.

f) Start engine and wait for 3 seconds.NOTE

When 60 seconds elapse after engine is

started, the above process to enter

registration mode will be cancelled.

Therefore, be sure to proceed to the next

step within 60 seconds.

5) Turn ignition switch to OFF position. When ignition switch is turned to OFF position,

buzzer sounds twice and door lock is activated from

lock position to unlock po sition. This operation

indicates that keyless st art control module has

entered registration mode.

6) Push lock or unlock button of remote controller within 30 seconds after Step 5) to be registered.

When lock or unlock button of remote controller is

pushed, buzzer sounds twice, door lock is activated

to lock position and then to unlock position. This

operation indicates that remote controller ID code

has been registered in keyless start control module.

If an additional remote controller needs to be

registered, repeat the procedure of Step 6) within 30

seconds after Step 5).

7) To end registration mode, remove ignition key from ignition key cylinder or turn it to ON position.

If engine start function of keyless start system does

not work after registration , check ECM if DTC P1615

is detected. If it is detected, go to “DTC P1615: ID

Code Does Not Registered (Vehicle equipped with

keyless start system only) in Section 10C”. If it is not

detected, perform registration procedure again.

1

2

4 3

I4RS0BA50034-02