camshaft nm SUZUKI SWIFT 2008 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 397 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-5

6Ignition coil assembly power supply and ground circuit

check

1) Check ignition coil assembly power supply and ground

circuits for open and short.

Are circuits in good condition? Go to Step 7.

Repair or replace.

7 Ignition coil assembly check

1) Check ignition coil for resistance referring to “Ignition

Coil Assembly (Including ignitor) Inspection”.

Is check result satisfactory? Go to Step 8.

Replace ignition coil

assembly.

8 CKP sensor check

1) Check CKP sensor referring to “CKP Sensor Inspection

in Section 1C”.

Is check result satisfactory? Go to Step 9.

Tighten CKP sensor

bolt, replace CKP

sensor or CKP sensor

plate.

9 CMP sensor check

1) Check CMP sensor referring to “Camshaft Position

(CMP) Sensor Inspection in Section 1C”.

Is check result satisfactory? Go to Step 10. Tighten CMP sensor

bolt, replace CMP

sensor or intake

camshaft.

10 Ignition trigger signal circuit check

1) Check ignition trigger signal wire for open, short and

poor connection.

Is circuit in good condition? Go to Step 11. Repair or replace.

11 A known-good ignition coil assembly substitution

1) Substitute a known-good ignition coil assembly and then

repeat Step 2.

Is check result of Step 2 satisfactory? Go to Step 12. Substitute a known-

good ECM and then

repeat Step 2.

12 Knock sensor check

1) Confirm that knock sensor circuit is in good condition

referring to “DTC P0327 / P0328: Knock Sensor 1 Circuit

Low / High in Section 1A”.

2) Check oscilloscope waveform of knock sensor signal

referring to “Reference waveform No.25” and

“Reference waveform No.26” under “Inspection of ECM

and Its Circuits in Section 1A”.

Is check result satisfactory? Go to Step 13. Substitute a known-

good knock sensor and

recheck.

13 Ignition timing check

1) Check initial ignition timing and ignition timing advance

referring to “Ignition Timing Inspection”.

Is check result satisfactory? System is in good

condition.

Check CMP sensor,

CMP sensor rotor tooth

of camshaft, CKP

sensor, CKP sensor

plate and/or input

signals related to this

system.

Step

Action YesNo

Page 401 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-9

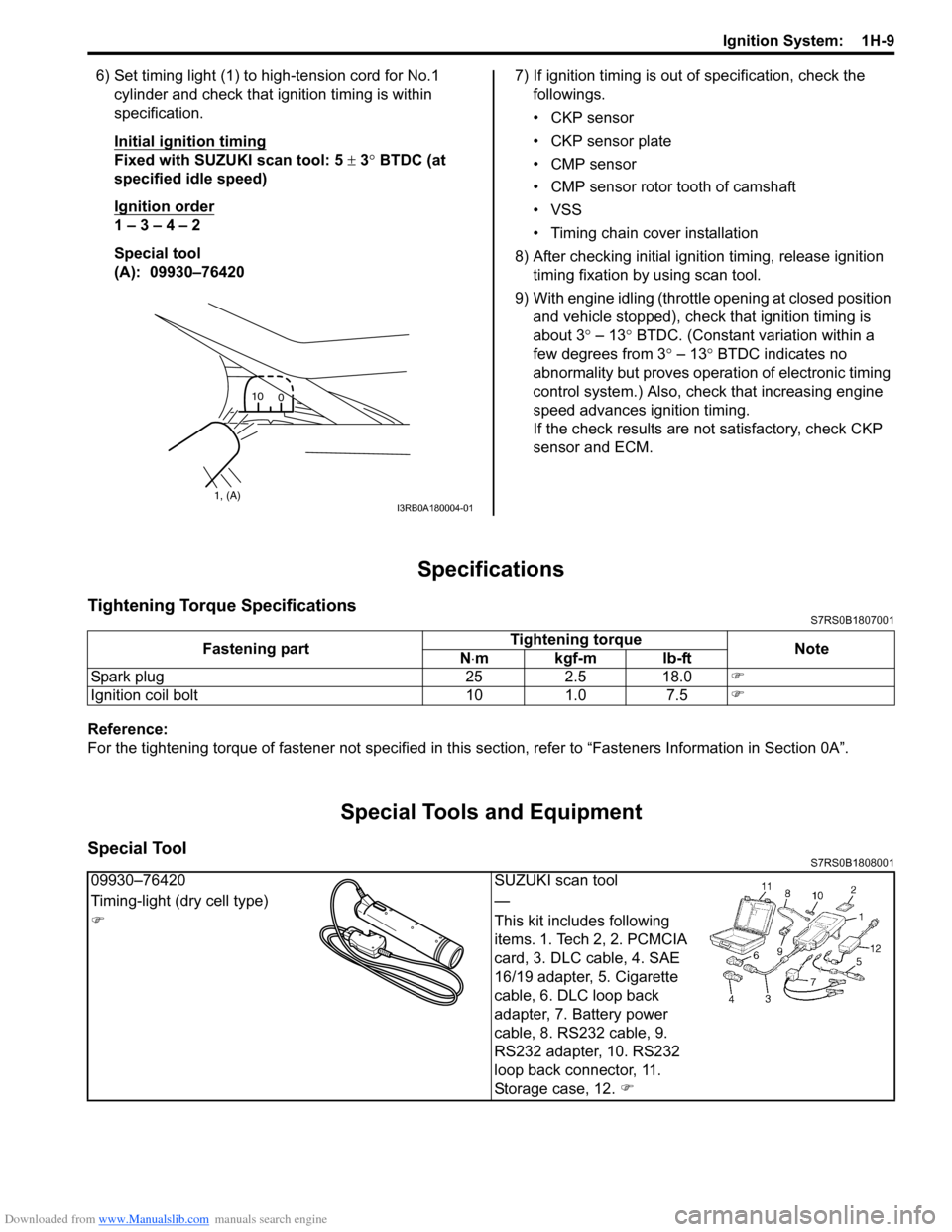

6) Set timing light (1) to high-tension cord for No.1 cylinder and check that ignition timing is within

specification.

Initial ignition timing

Fixed with SUZUKI scan tool: 5 ± 3° BTDC (at

specified idle speed)

Ignition order

1 – 3 – 4 – 2

Special tool

(A): 09930–76420 7) If ignition timing is out

of specification, check the

followings.

• CKP sensor

• CKP sensor plate

• CMP sensor

• CMP sensor rotor tooth of camshaft

• VSS

• Timing chain cover installation

8) After checking initial igniti on timing, release ignition

timing fixation by using scan tool.

9) With engine idling (throttl e opening at closed position

and vehicle stopped), check that ignition timing is

about 3 ° – 13° BTDC. (Constant variation within a

few degrees from 3 ° – 13° BTDC indicates no

abnormality but proves operation of electronic timing

control system.) Also, check that increasing engine

speed advances ignition timing.

If the check results are not satisfactory, check CKP

sensor and ECM.

Specifications

Tightening Torque SpecificationsS7RS0B1807001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B1808001

1, (A)10

0I3RB0A180004-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Spark plug 25 2.5 18.0 �)

Ignition coil bolt 10 1.0 7.5 �)

09930–76420SUZUKI scan tool

Timing-light (dry cell type) —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �)