Wiring system SUZUKI SWIFT 2008 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 614 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-40 Electronic Stability Program:

DTC C1041 / C1042 / C1043 / C1044 / C1045 / C1046 / C1051 / C1052 / C1053 / C1054 / C1055 / C1056:

Solenoid Circuit Failure

S7RS0B4604052

DTC C1041 / C1045 / C1051 / C1055: Right-Front / Left-Front / Right-Rear / Left-Rear Inlet Solenoid

Circuit Failure

DTC C1042 / C1046 / C1052 / C1056: Right-Front / Left-Front / Right-Rear / Left-Rear Outlet Solenoid

Circuit Failure

DTC C1043 / C1044: Master Cylinder Cut Solenoid Circuit No. 1 / No. 2 Failure

DTC C1053 / C1054: Low Pressure Solenoid Circuit No. 1 / No. 2 Failure

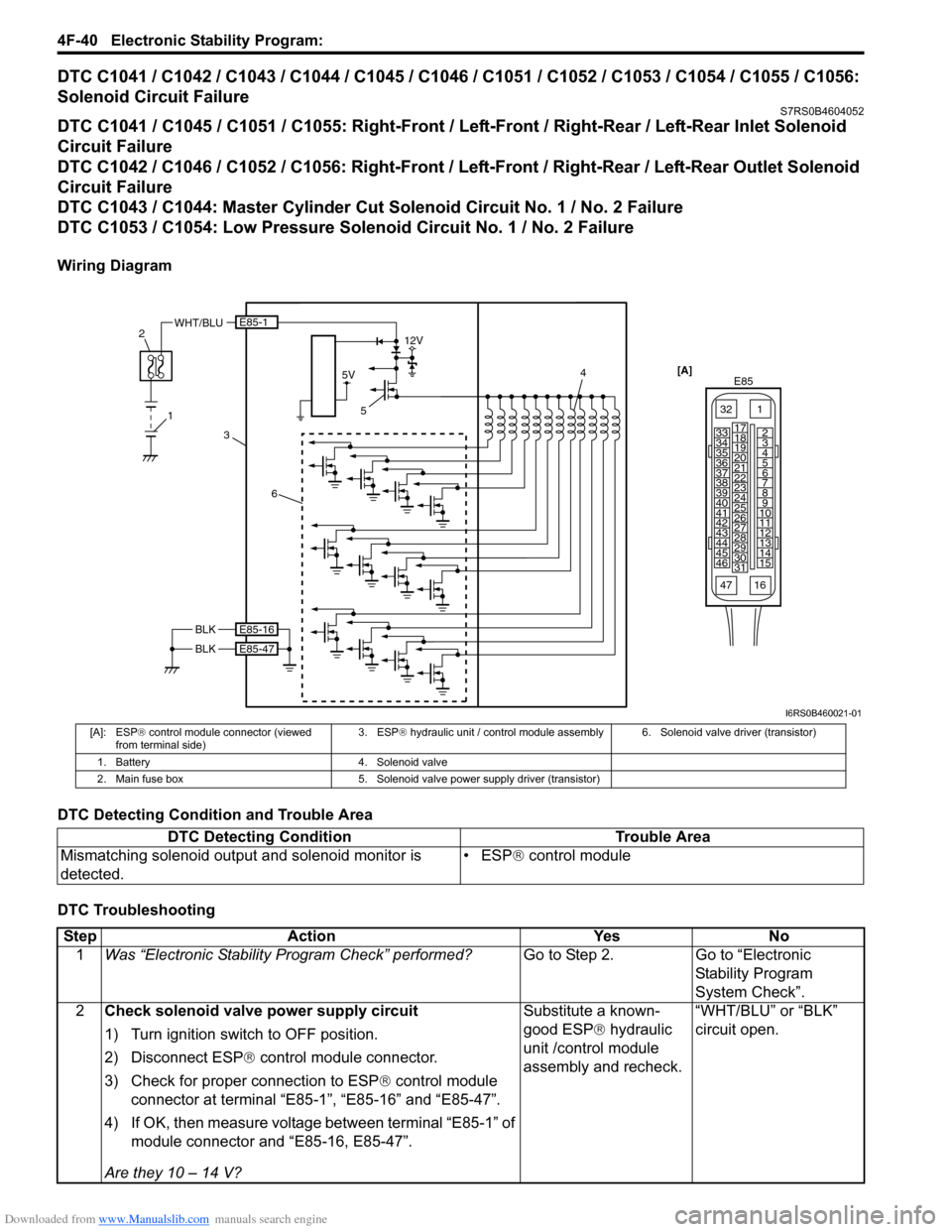

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

[A]E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

WHT/BLU

1

2

54

BLK

BLK

5V

12V

E85-1

E85-16

E85-47

6

3

I6RS0B460021-01

[A]: ESP

® control module connector (viewed

from terminal side) 3. ESP

® hydraulic unit / control module assemb ly 6. Solenoid valve driver (transistor)

1. Battery 4. Solenoid valve

2. Main fuse box 5. Solenoid valve power supply driver (transistor)

DTC Detecting Condition Trouble Area

Mismatching solenoid output and solenoid monitor is

detected. • ESP

® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 Check solenoid valve power supply circuit

1) Turn ignition switch to OFF position.

2) Disconnect ESP ® control module connector.

3) Check for proper connection to ESP ® control module

connector at terminal “E85-1”, “E85-16” and “E85-47”.

4) If OK, then measure voltage between terminal “E85-1” of module connector and “E85-16, E85-47”.

Are they 10 – 14 V? Substitute a known-

good ESP

® hydraulic

unit /control module

assembly and recheck. “WHT/BLU” or “BLK”

circuit open.

Page 615 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-41

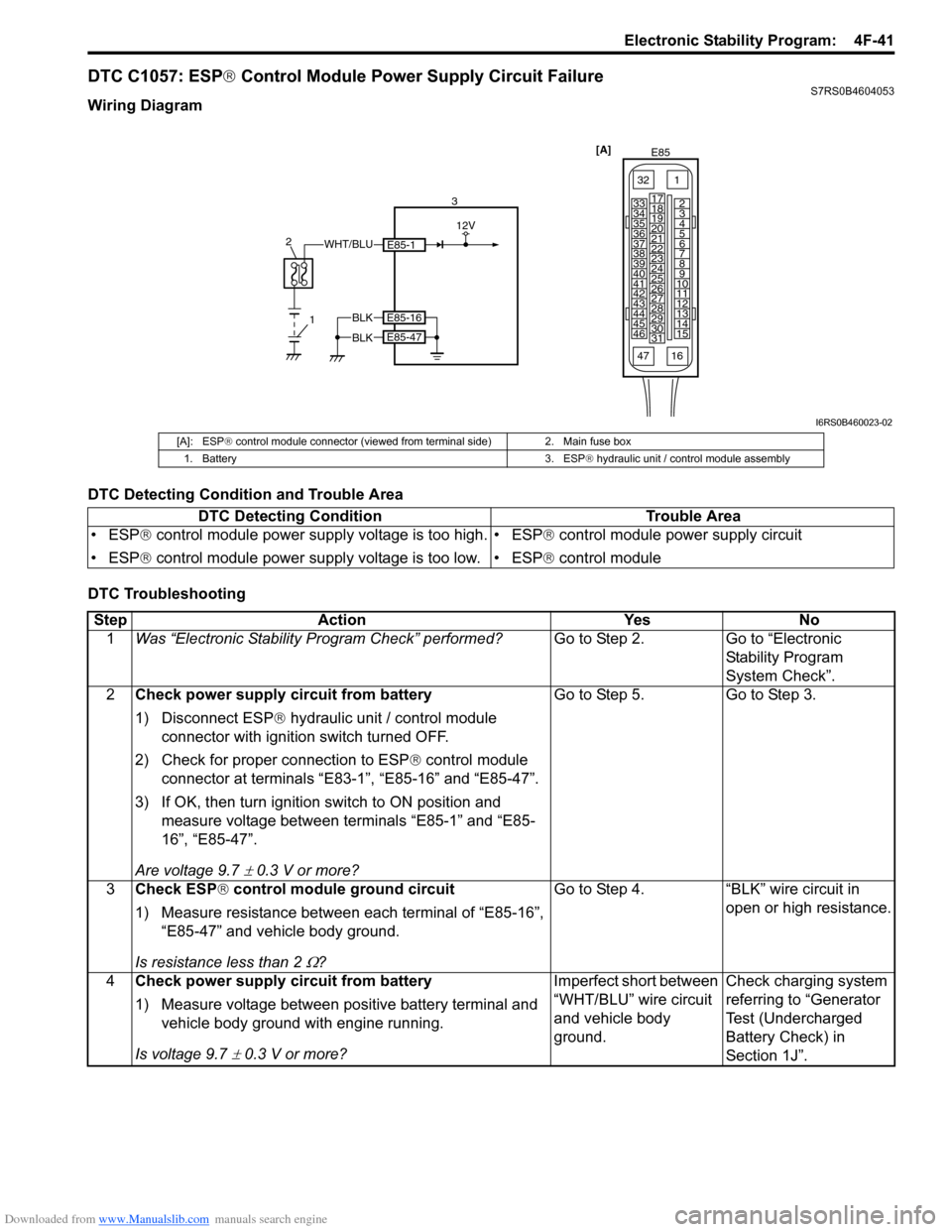

DTC C1057: ESP® Control Module Power Supply Circuit FailureS7RS0B4604053

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

[A]

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

WHT/BLU

1

2

3

12V

E85-1

BLKE85-16

E85-47BLK

I6RS0B460023-02

[A]: ESP

® control module connector (viewed from terminal side) 2. Main fuse box

1. Battery 3. ESP ® hydraulic unit / control module assembly

DTC Detecting Condition Trouble Area

• ESP ® control module power supply voltage is too high.

• ESP ® control module power supply voltage is too low. • ESP

® control module power supply circuit

• ESP ® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 Check power supply circuit from battery

1) Disconnect ESP ® hydraulic unit / control module

connector with ignition switch turned OFF.

2) Check for proper connection to ESP ® control module

connector at terminals “E83-1”, “E85-16” and “E85-47”.

3) If OK, then turn ignition switch to ON position and measure voltage between terminals “E85-1” and “E85-

16”, “E85-47”.

Are voltage 9.7

± 0.3 V or more? Go to Step 5. Go to Step 3.

3 Check ESP ® control module ground circuit

1) Measure resistance between each terminal of “E85-16”, “E85-47” and vehicle body ground.

Is resistance less than 2

Ω? Go to Step 4. “BLK” wire circuit in

open or high resistance.

4 Check power supply circuit from battery

1) Measure voltage between positive battery terminal and

vehicle body ground with engine running.

Is voltage 9.7

± 0.3 V or more? Imperfect short between

“WHT/BLU” wire circuit

and vehicle body

ground.

Check charging system

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.

Page 616 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-42 Electronic Stability Program:

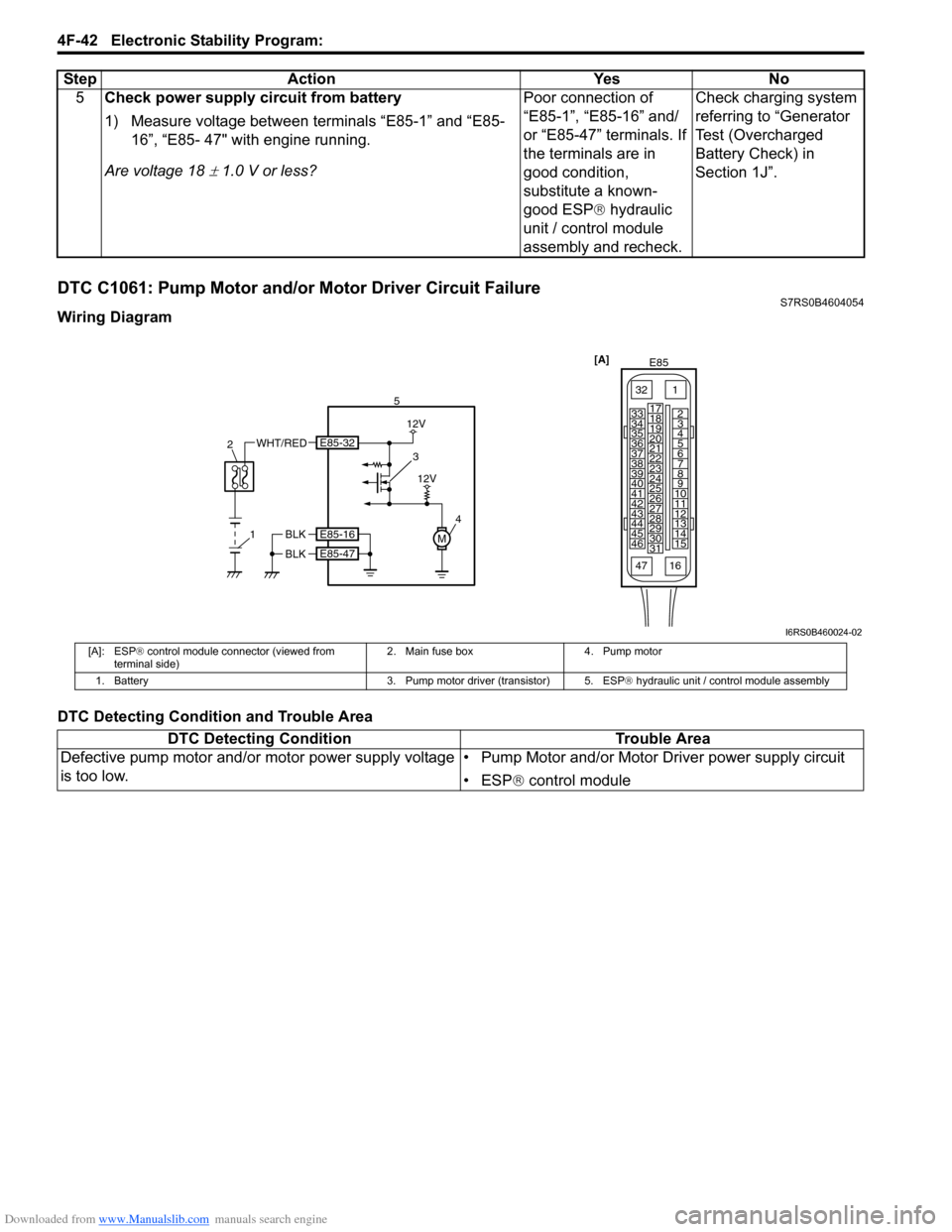

DTC C1061: Pump Motor and/or Motor Driver Circuit FailureS7RS0B4604054

Wiring Diagram

DTC Detecting Condition and Trouble Area5

Check power supply circuit from battery

1) Measure voltage between terminals “E85-1” and “E85-

16”, “E85- 47" with engine running.

Are voltage 18

± 1.0 V or less? Poor connection of

“E85-1”, “E85-16” and/

or “E85-47” terminals. If

the terminals are in

good condition,

substitute a known-

good ESP

® hydraulic

unit / control module

assembly and recheck. Check charging system

referring to “Generator

Test (Overcharged

Battery Check) in

Section 1J”.

Step Action Yes No

[A]

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

4

51

2

WHT/RED3

12V

M

12V

BLK

BLK

E85-16

E85-47

E85-32

I6RS0B460024-02

[A]: ESP

® control module connector (viewed from

terminal side) 2. Main fuse box 4. Pump motor

1. Battery 3. Pump motor driver (transistor) 5. ESP® hydraulic unit / control module assembly

DTC Detecting ConditionTrouble Area

Defective pump motor and/or motor power supply voltage

is too low. • Pump Motor and/or Motor Driver power supply circuit

• ESP

® control module

Page 617 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-43

DTC Troubleshooting

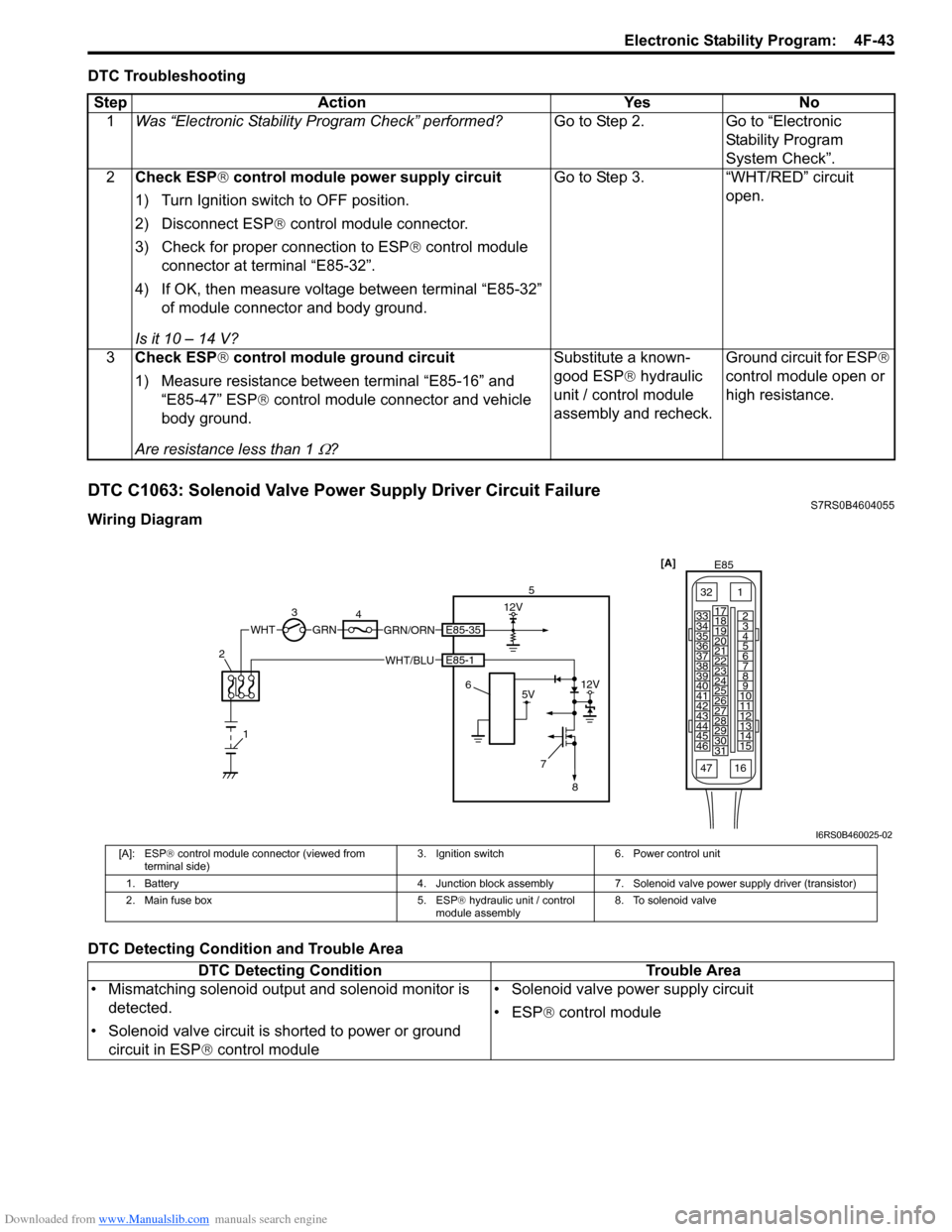

DTC C1063: Solenoid Valve Power Supply Driver Circuit FailureS7RS0B4604055

Wiring Diagram

DTC Detecting Condition and Trouble AreaStep Action Yes No

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2. Go to “Electronic

Stability Program

System Check”.

2 Check ESP ® control module power supply circuit

1) Turn Ignition switch to OFF position.

2) Disconnect ESP ® control module connector.

3) Check for proper connection to ESP ® control module

connector at terminal “E85-32”.

4) If OK, then measure voltage between terminal “E85-32” of module connector and body ground.

Is it 10 – 14 V? Go to Step 3. “WHT/RED” circuit

open.

3 Check ESP ® control module ground circuit

1) Measure resistance between terminal “E85-16” and “E85-47” ESP ® control module connector and vehicle

body ground.

Are resistance less than 1

Ω? Substitute a known-

good ESP

® hydraulic

unit / control module

assembly and recheck. Ground circuit for ESP

®

control module open or

high resistance.

3 4 12V

GRN/ORNGRN

7

5V12V

WHTE85-35

E85-1WHT/BLU5

6

8

1

2

[A]

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

I6RS0B460025-02

[A]: ESP ® control module connector (viewed from

terminal side) 3. Ignition switch 6. Power control unit

1. Battery 4. Junction block assembly 7. Solenoid valve power supply driver (transistor)

2. Main fuse box 5. ESP® hydraulic unit / control

module assembly 8. To solenoid valve

DTC Detecting Condition

Trouble Area

• Mismatching solenoid output and solenoid monitor is detected.

• Solenoid valve circuit is shorted to power or ground circuit in ESP ® control module • Solenoid valve power supply circuit

• ESP

® control module

Page 619 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-45

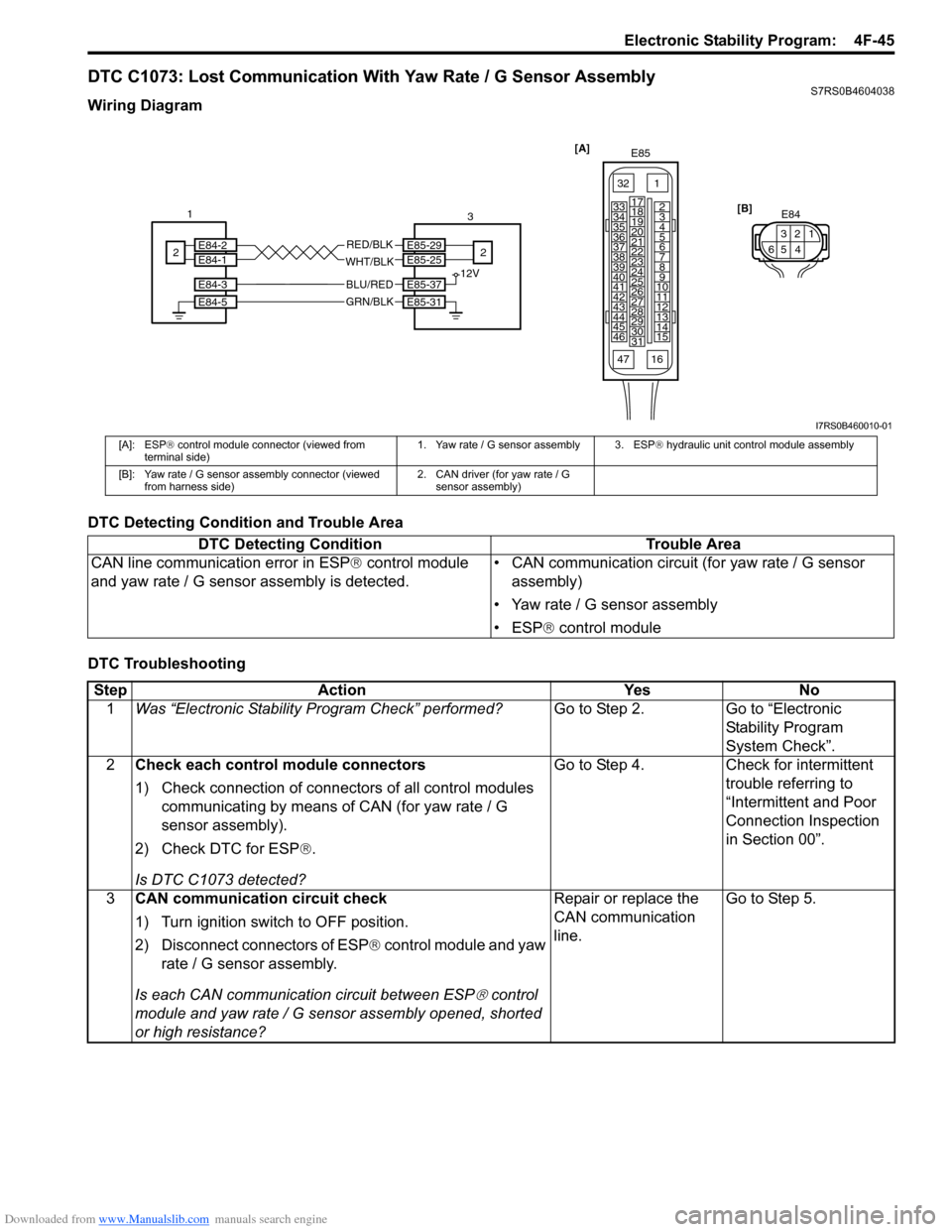

DTC C1073: Lost Communication With Yaw Rate / G Sensor AssemblyS7RS0B4604038

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

[A]E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

E85-29E85-25

E85-37

E85-31

E84-3

E84-5

E84-2E84-1 12V

GRN/BLK

BLU/RED

WHT/BLK

RED/BLK [B]

E843

521

46

1

2 3

2

I7RS0B460010-01

[A]: ESP ® control module connector (viewed from

terminal side) 1. Yaw rate / G sensor assembly 3. ESP

® hydraulic unit control module assembly

[B]: Yaw rate / G sensor assembly connector (viewed from harness side) 2. CAN driver (for yaw rate / G

sensor assembly)

DTC Detecting Condition Trouble Area

CAN line communication error in ESP ® control module

and yaw rate / G sensor assembly is detected. • CAN communication circuit (for yaw rate / G sensor

assembly)

• Yaw rate / G sensor assembly

• ESP ® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 Check each control module connectors

1) Check connection of connectors of all control modules

communicating by means of CAN (for yaw rate / G

sensor assembly).

2) Check DTC for ESP ®.

Is DTC C1073 detected? Go to Step 4.

Check for intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

3 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of ESP ® control module and yaw

rate / G sensor assembly.

Is each CAN communicati on circuit between ESP

® control

module and yaw rate / G sensor assembly opened, shorted

or high resistance? Repair or replace the

CAN communication

line.

Go to Step 5.

Page 624 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-50 Electronic Stability Program:

DTC Troubleshooting

DTC U1100: Lost Communication with ECM (Reception Error)S7RS0B4604058

Wiring Diagram

Refer to “Wiring Diagram” under “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition and Trouble Area

DTC TroubleshootingStep Action Yes No

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2. Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC for ESP ®.

Is DTC U1073 indicated? Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 4. Repair or replace the

CAN communication

line.

4 DTC check for ESP®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector. •ECM

• Keyless start control module (if equipped)

• Combination meter

• Steering angle sensor

•BCM

3) Recheck DTC for ESP ®.

Is DTC U1073 detected? Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

DTC Detecting Condition

Trouble Area

ECM message data is missing from CAN communication. • CAN communication circuit

•ECM

• ESP® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check DTC for ESP ®.

Is DTC U1100 and DTC U1073 detected together? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

3 DTC check for ECM

1) Check DTC for ECM.

Is DTC P1674 detected? Go to “DTC P1674:

CAN Communication

(Bus Off Error) in

Section 1A”.Go to Step 4.

Page 625 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-51

DTC U1126: Lost Communication with Steering Angle Sensor (Reception Error)S7RS0B4604043

Wiring Diagram

Refer to “Wiring Diagram” under “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition and Trouble Area

DTC Troubleshooting4

Check each control module connectors

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Check DTC for ESP ®.

Is DTC U1100 detected? Go to Step 5. Check for intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

5 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of ESP ® control module and

ECM communicating by means of CAN.

3) Check CAN communication circuit between ESP®

control module and ECM for open, short and high

resistance.

Is each CAN communication circuit in good condition? Repair or replace the

CAN communication

line.

Go to Step 6.

6 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 5 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 7. Repair or replace the

CAN communication

line.

7 DTC check for ESP®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector. •ECM

• Keyless start control module (if equipped)

• Combination meter

• Steering angle sensor

•BCM

3) Recheck DTC for ESP ®.

Is DTC U1100 detected? Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

Step Action Yes No

DTC Detecting Condition

Trouble Area

Steering angle sensor message data is missing from CAN

communication. • CAN communication circuit

• Steering angle sensor

• ESP

® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check DTC for ESP ®.

Is DTC U1126 and DTC U1073 detected together? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

Page 641 of 1496

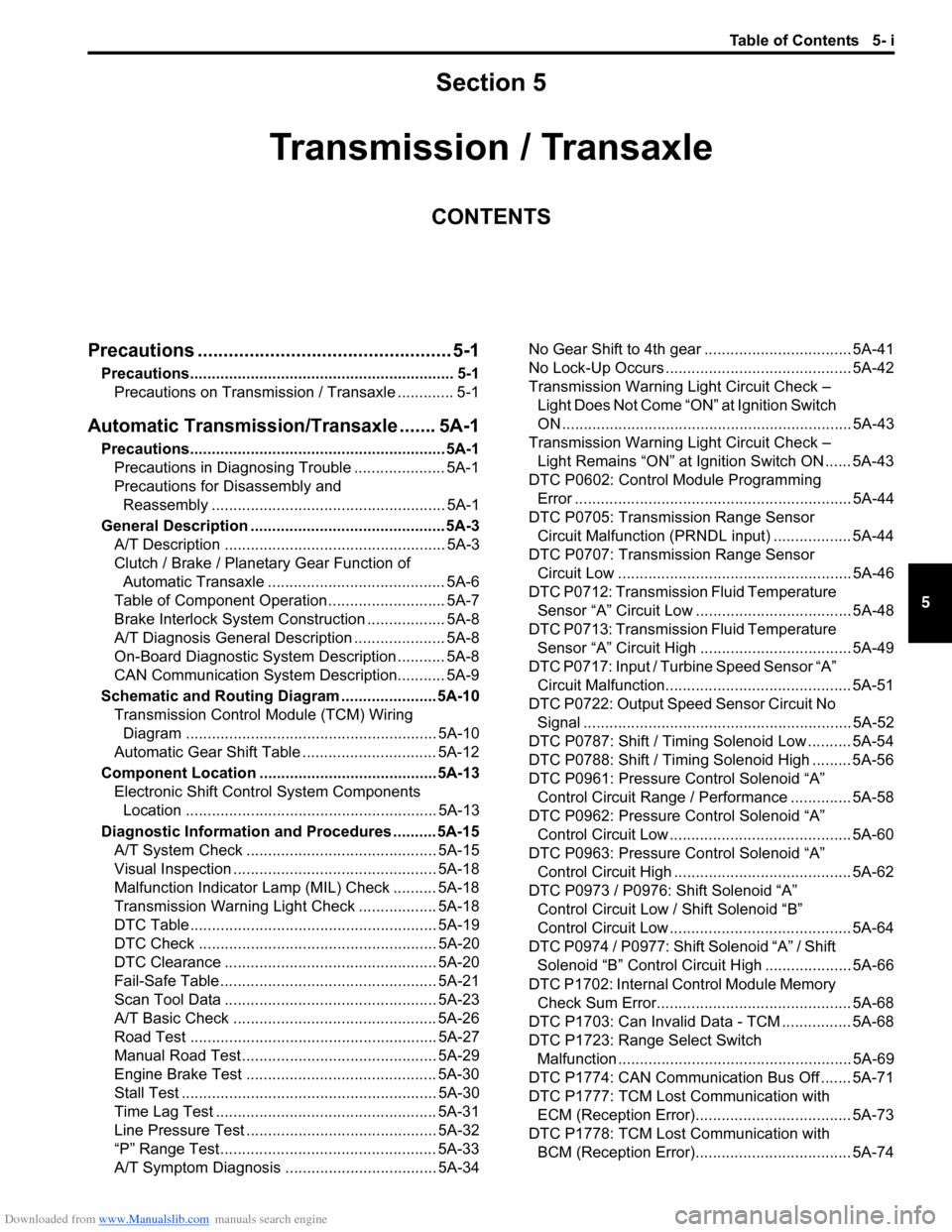

Downloaded from www.Manualslib.com manuals search engine Table of Contents 5- i

5

Section 5

CONTENTS

Transmission / Transaxle

Precautions ................................................. 5-1

Precautions............................................................. 5-1

Precautions on Transmission / Transaxle ............. 5-1

Automatic Transmission/Transaxle ....... 5A-1

Precautions........................................................... 5A-1Precautions in Diagnosing Trouble ..................... 5A-1

Precautions for Disassembly and Reassembly ...................................................... 5A-1

General Description ............................................. 5A-3 A/T Description ................................................... 5A-3

Clutch / Brake / Planetary Gear Function of Automatic Transaxle ......................................... 5A-6

Table of Component Operation ........................... 5A-7

Brake Interlock System Construction .................. 5A-8

A/T Diagnosis General Description ..................... 5A-8

On-Board Diagnostic System Description ........... 5A-8

CAN Communication System Description........... 5A-9

Schematic and Routing Diagram ...................... 5A-10 Transmission Control Module (TCM) Wiring

Diagram .......................................................... 5A-10

Automatic Gear Shift Table ............................... 5A-12

Component Locatio n ......................................... 5A-13

Electronic Shift Cont rol System Components

Location .......................................................... 5A-13

Diagnostic Information and Procedures .......... 5A-15 A/T System Check ............................................ 5A-15

Visual Inspection ............................................... 5A-18

Malfunction Indicator Lamp (MIL) Check .......... 5A-18

Transmission Warning Ligh t Check .................. 5A-18

DTC Table ......................................................... 5A-19

DTC Check ....................................................... 5A-20

DTC Clearance ................................................. 5A-20

Fail-Safe Table ................ .................................. 5A-21

Scan Tool Data ................................................. 5A-23

A/T Basic Check ............................................... 5A-26

Road Test ......................................................... 5A-27

Manual Road Test ........... .................................. 5A-29

Engine Brake Test ............................................ 5A-30

Stall Test ........................................................... 5A-30

Time Lag Test ................................................... 5A-31

Line Pressure Test .......... .................................. 5A-32

“P” Range Test.................................................. 5A-33

A/T Symptom Diagnosis ..... .............................. 5A-34 No Gear Shift to 4th gear .................................. 5A-41

No Lock-Up Occurs ........................................... 5A-42

Transmission Warning Light Circuit Check –

Light Does Not Come “ON” at Ignition Switch

ON ................................................................... 5A-43

Transmission Warning Light Circuit Check – Light Remains “ON” at Ignition Switch ON ...... 5A-43

DTC P0602: Control Module Programming Error ................................................................ 5A-44

DTC P0705: Transmission Range Sensor Circuit Malfunction (PRNDL input) .................. 5A-44

DTC P0707: Transmission Range Sensor Circuit Low ...................................................... 5A-46

DTC P0712: Transmission Fluid Temperature Sensor “A” Circuit Low ... ................................. 5A-48

DTC P0713: Transmission Fluid Temperature Sensor “A” Circuit High .. ................................. 5A-49

DTC P0717: Input / Turbine Speed Sensor “A” Circuit Malfunction........................................... 5A-51

DTC P0722: Output Speed Sensor Circuit No Signal .............................................................. 5A-52

DTC P0787: Shift / Timing Solenoid Low .......... 5A-54

DTC P0788: Shift / Timing Solenoid High ......... 5A-56

DTC P0961: Pressure Control Solenoid “A”

Control Circuit Range / Performance .............. 5A-58

DTC P0962: Pressure Control Solenoid “A”

Control Circuit Low .......................................... 5A-60

DTC P0963: Pressure Control Solenoid “A”

Control Circuit High ......................................... 5A-62

DTC P0973 / P0976: Shift Solenoid “A” Control Circuit Low / Shift Solenoid “B”

Control Circuit Low .......................................... 5A-64

DTC P0974 / P0977: Shift Solenoid “A” / Shift Solenoid “B” Control Circuit High .................... 5A-66

DTC P1702: Internal Co ntrol Module Memory

Check Sum Error............................................. 5A-68

DTC P1703: Can Invalid Data - TCM ................ 5A-68

DTC P1723: Range Select Switch Malfunction ...................................................... 5A-69

DTC P1774: CAN Communication Bus Off ....... 5A-71

DTC P1777: TCM Lost Communication with ECM (Reception Error).................................... 5A-73

DTC P1778: TCM Lost Communication with BCM (Reception Error).................................... 5A-74

Page 688 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-44 Automatic Transmission/Transaxle:

DTC P0602: Control Module Programming ErrorS7RS0B5104048

System Description

Internal control module is installed in ECM.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Clear DTC, pending DTC and freeze frame data by using scan tool.

3) Start engine and run it at idle if possible.

4) Check DTC.

DTC Troubleshooting

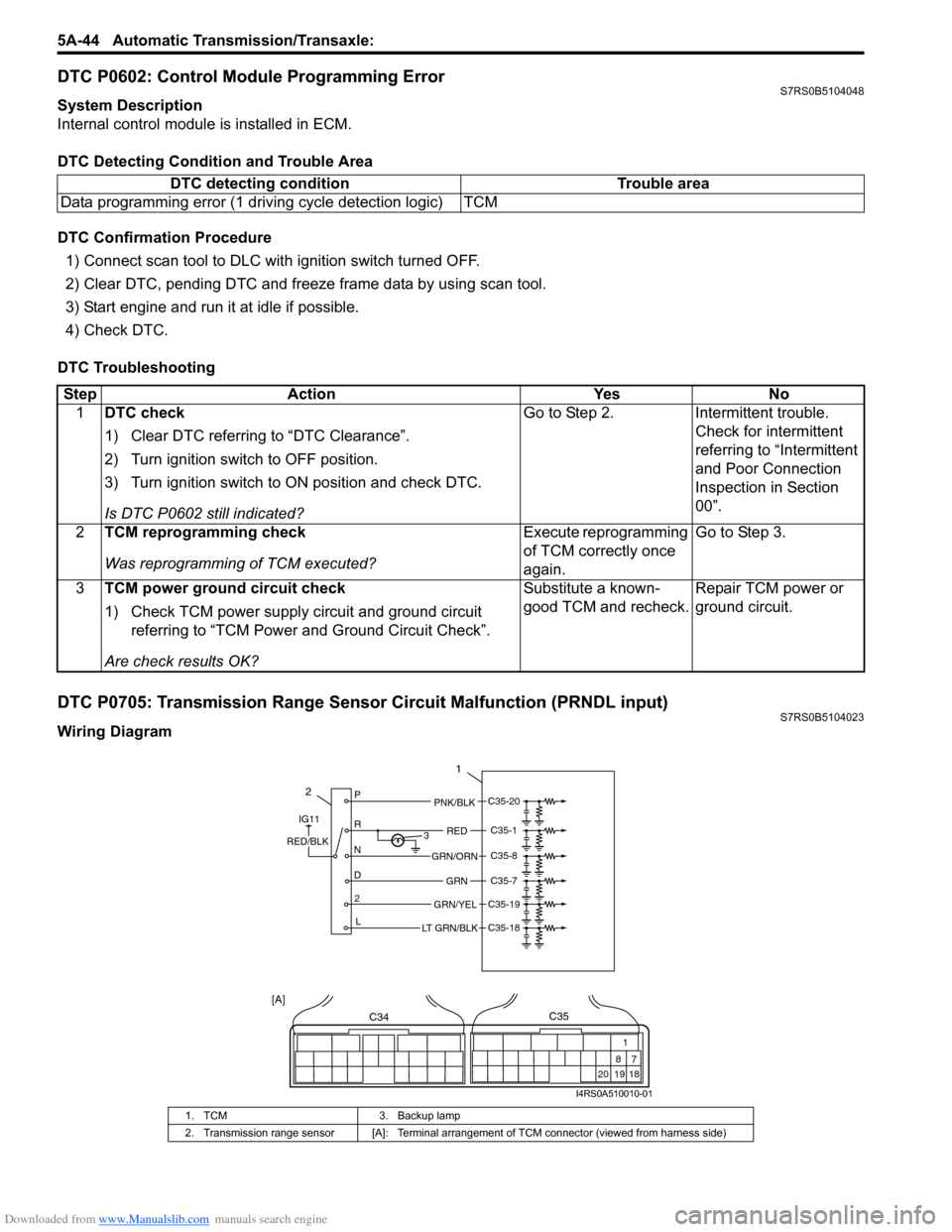

DTC P0705: Transmission Range Sensor Circuit Malfunction (PRNDL input)S7RS0B5104023

Wiring DiagramDTC detecting condition Trouble area

Data programming error (1 driving cycle detection logic) TCM

Step Action YesNo

1 DTC check

1) Clear DTC referring to “DTC Clearance”.

2) Turn ignition switch to OFF position.

3) Turn ignition switch to ON position and check DTC.

Is DTC P0602 still indicated? Go to Step 2.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2 TCM reprogramming check

Was reprogramming of TCM executed? Execute reprogramming

of TCM correctly once

again.Go to Step 3.

3 TCM power ground circuit check

1) Check TCM power supply circuit and ground circuit

referring to “TCM Power and Ground Circuit Check”.

Are check results OK? Substitute a known-

good TCM and recheck.

Repair TCM power or

ground circuit.

1. TCM

3. Backup lamp

2. Transmission range sensor [A]: Terminal arrangem ent of TCM connector (viewed from harness side)

2P

R

N

D 2 L 3

1

PNK/BLK

RED

GRN

GRN/ORN

GRN/YEL

IG11

RED/BLK

LT GRN/BLK

C35-20

C35-1

C35-8

C35-7

C35-19

C35-18

C34

20 19

87

18

1

C35

[A]

I4RS0A510010-01

Page 693 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-49

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory and start engine.

3) Keep engine running at idle speed for 10 minutes or more.

4) Stop vehicle and check DTC.

DTC Troubleshooting

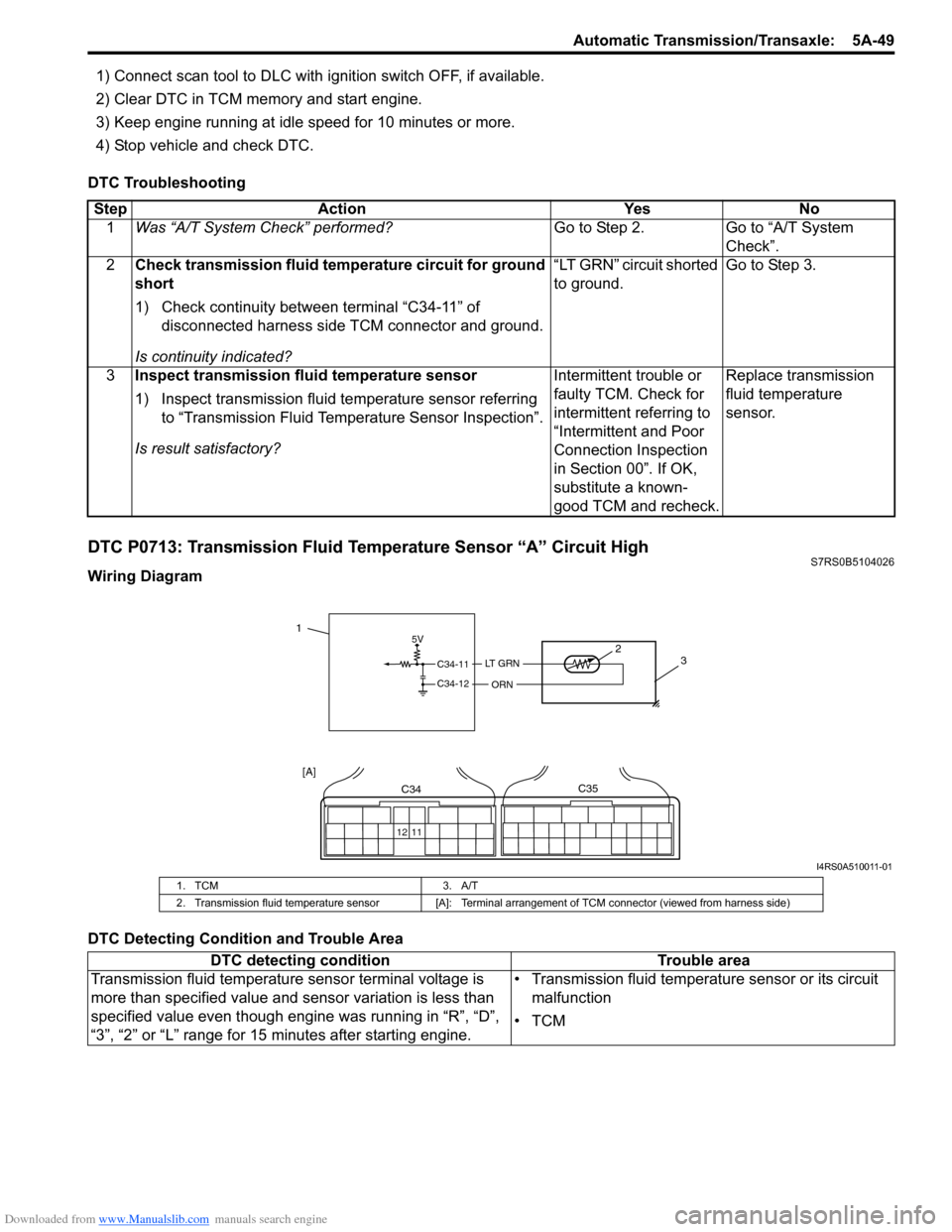

DTC P0713: Transmission Fluid Temperature Sensor “A” Circuit HighS7RS0B5104026

Wiring Diagram

DTC Detecting Condition and Trouble Area Step Action Yes No

1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

2 Check transmission fluid temperature circuit for ground

short

1) Check continuity between terminal “C34-11” of

disconnected harness side TCM connector and ground.

Is continuity indicated? “LT GRN” circuit shorted

to ground.

Go to Step 3.

3 Inspect transmission fluid temperature sensor

1) Inspect transmission fluid temperature sensor referring

to “Transmission Fluid Temperature Sensor Inspection”.

Is result satisfactory? Intermittent trouble or

faulty TCM. Check for

intermittent referring to

“Intermittent and Poor

Connection Inspection

in Section 00”. If OK,

substitute a known-

good TCM and recheck.Replace transmission

fluid temperature

sensor.

5V

C34-11

C34-12

LT G R N

ORN

2

3

12 11

C34C35

[A]

1

I4RS0A510011-01

1. TCM 3. A/T

2. Transmission fluid temperature sensor [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Transmission fluid temperature sensor terminal voltage is

more than specified value and sensor variation is less than

specified value even though engine was running in “R”, “D”,

“3”, “2” or “L” range for 15 minutes after starting engine. • Transmission fluid temperature sensor or its circuit

malfunction

•TCM