tightening torque SUZUKI SWIFT 2008 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 429 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 2- i

2

Section 2

CONTENTS

Suspension

Precautions ................................................. 2-1

Precautions............................................................. 2-1

Precautions on Suspension .................................. 2-1

Suspension General Dia gnosis.............. 2A-1

Diagnostic Information and Procedures ............ 2A-1

Suspension, Wheels and Tires Symptom Diagnosis .......................................................... 2A-1

Front Suspension ........... ......................... 2B-1

General Description ............................................. 2B-1

Front Suspension Construction ........................... 2B-1

Front Wheel Alignment Cons truction .................. 2B-2

Repair Instructions .............................................. 2B-2 Front Wheel Alignment Inspection and Adjustment ........................................................ 2B-2

Front Strut Assembly Comp onents ..................... 2B-4

Front Strut Assembly Removal and Installation ......................................................... 2B-4

Front Strut Assembly Disassembly and Assembly .......................................................... 2B-6

Front Strut Assembly Chec k ............................... 2B-7

Front Wheel Hub and Steering Knuckle Components...................................................... 2B-8

Front Wheel Hub, Steering Knuckle and Wheel Bearing Removal and Installation .......... 2B-8

Front Wheel Hub, Disc, Nut and Bearing Check .............................................................. 2B-12

Suspension Control Arm / Bushing Removal and Installation ................................................ 2B-12

Suspension Control Arm / Bushing Disassembly and Assembly ............................ 2B-13

Suspension Control Arm / Steering Knuckle Check .............................................................. 2B-14

Suspension Control Arm Bushing Check .......... 2B-14

Suspension Control Arm Joint Check ............... 2B-14

Front Suspension Fram e, Stabilizer Bar and/

or Bushings Components................................ 2B-15

Front Suspension Fram e, Stabilizer Bar and/

or Bushings Removal and Installation ............. 2B-15

Front Suspension Frame Ch eck ....................... 2B-19

Front Stabilizer Bar, Bushing and/or Joint Check .............................................................. 2B-19

Front Suspension Fastener s Check .................. 2B-19

Specifications ..................................................... 2B-20 Tightening Torque Specifications ...................... 2B-20

Special Tools and Equipmen t ...........................2B-21

Special Tool ...................................................... 2B-21

Rear Suspension ............ ......................... 2C-1

General Description .............................................2C-1

Rear Suspension Construction ...........................2C-1

Repair Instructions ........... ...................................2C-2

Rear Wheel Alignment Inspection .......................2C-2

Rear Shock Absorber Removal and Installation .........................................................2C-2

Rear Shock Absorber Ins pection ........................2C-3

Rear Shock Absorber Bush Removal and Installation .........................................................2C-4

Rear Shock Absorber Bush Inspection ...............2C-4

Rear Coil Spring Removal and Installation .........2C-4

Spring Upper Seat / Spring Lower Seat Inspection ..........................................................2C-5

Spring Upper Seat and Lower Seat Removal and Installation ..................................................2C-6

Rear Axle Removal and Inst allation ....................2C-6

Trailing Arm, Rear Axle and Coil Spring Inspection ..........................................................2C-9

Rear Axle Bush Inspection ..................................2C-9

Rear Wheel Hub Components ..........................2C-10

Rear Wheel Hub Removal an d Installation .......2C-10

Rear Wheel Disc, bolt and Bearing Inspection ..2C-11

Spindle Removal and Installation ......................2C-12

Spindle Inspection .............................................2C-13

Rear Suspension Fasteners Inspection ............2C-13

Specifications .................... .................................2C-13

Tightening Torque Specifications ......................2C-13

Special Tools and Equipmen t ...........................2C-13

Special Tool ......................................................2C-13

Wheels and Tires ............ ......................... 2D-1

Precautions...........................................................2D-1

Precaution for Emergency Flat Tire Repair Kit ....2D-1

General Description .............................................2D-1 Tires Description .................................................2D-1

Wheels Description .............................................2D-2

Irregular and/or Premature Wear Description .....2D-3

Wear Indicators Description ................................2D-3

Radial Tire Waddle Description...........................2D-4

Radial Tire Lead / Pull Description ......................2D-5

Page 430 of 1496

Downloaded from www.Manualslib.com manuals search engine 2-ii Table of Contents

Balancing Wheels Description ............................ 2D-5

Repair Instructions ..............................................2D-6 General Balance Procedures ..............................2D-6

Tire Rotation........................................................2D-6

Wheel Removal and Installation..........................2D-7

Tire Mounting and Dismounting ..........................2D-8 Tire Repair ..........................................................2D-8

Tire Repair for Emergency Repaired-Tire with

Sealant ..............................................................2D-8

Specifications ..................... ..................................2D-9

Wheels and Tires Specifications .........................2D-9

Tightening Torque Specifications ........................2D-9

Page 436 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-3 Front Suspension:

Adjustment1) Loosen right and left tie-rod end lock nuts (1) first.

2) Rotate right and left tie-rods (2) by the same amount to align toe to specification. In this adjustment, the

lengths “A” of both right and left tie-rod should be

equal.

NOTE

Before rotating tie-rods (2), apply grease

between tie-rods and rack boots so that

boots won’t be twisted.

3) After adjustment, tighten lock nuts (1) to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5 lb-

ft)

NOTE

Make sure that rack boots are not twisted.

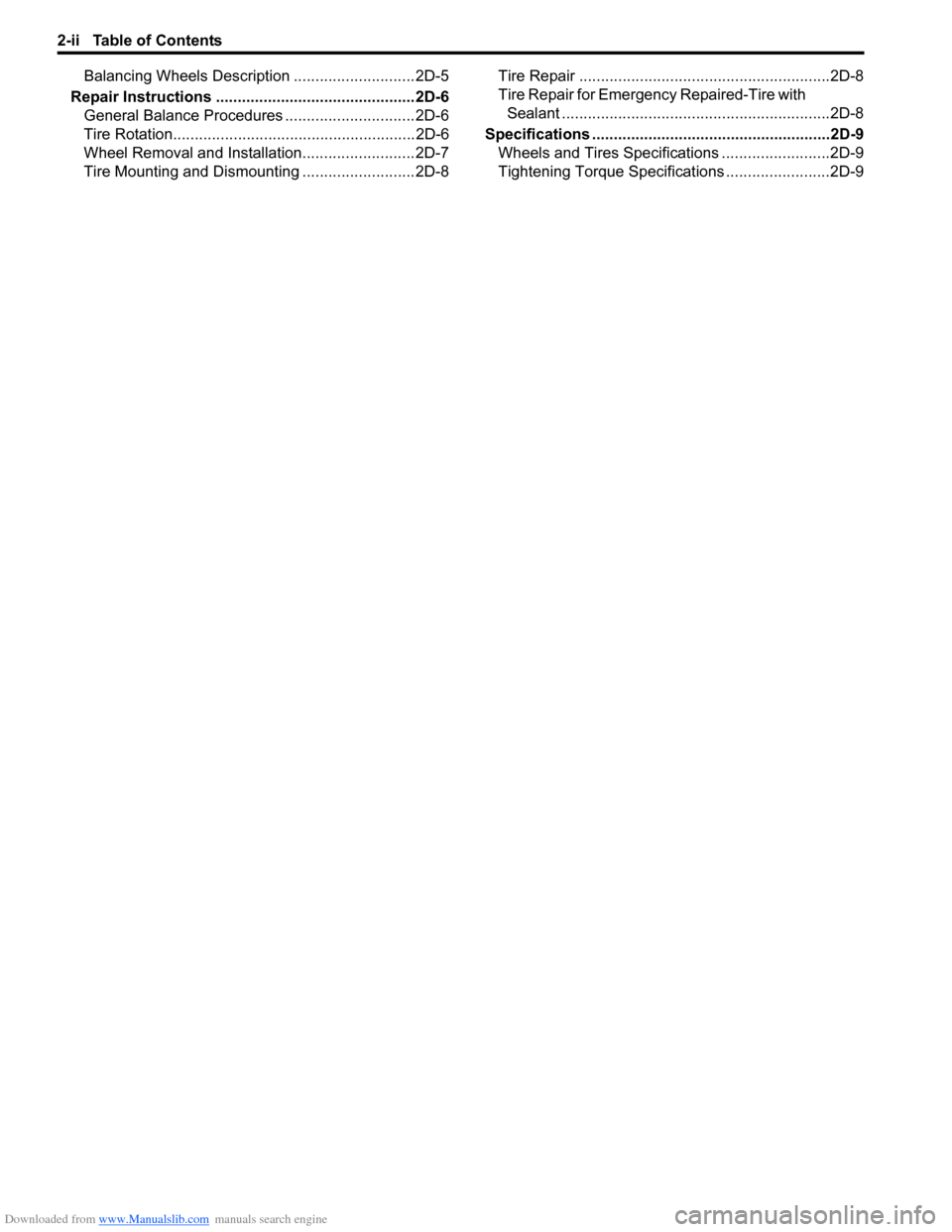

Camber and Caster Check

Check camber and caster by camber caster kingpin

gauge (1) and turning radius gauge (2).

If measured value is out of specified value, check

following items for damage, deformation and crack.

• Strut and component

• Suspension control arm and bush

• Suspension frame

• Wheel hub, steering knuckle or wheel bearing

• Vehicle body Front camber “a”

: 0

± 1°

Front caster “b”

: 5 °12’ ± 2°

NOTE

Front camber and caster are not adjustable.

Steering Angle Check and Adjustment

When tie-rod or tie-rod end was replaced, check toe and

then also steering angle with turning radius gauge.

If measured value is out of specified value, perform

inspection and adjustment of toe.

Steering angle

Inside: 33.8 ° ± 3 °

Outside: 29.8 ° (Reference)

I3RH0A220002-01

[A]: Camber (Front view) S: Body center

[B]: Caster (Side view) T: Center line of wheel

F: Forward

2

1

I7RS0B220003-01

[B]

S T

90°

“a”

[A]

F

90°

“b”

I7RS0B220004-01

Page 438 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-5 Front Suspension:

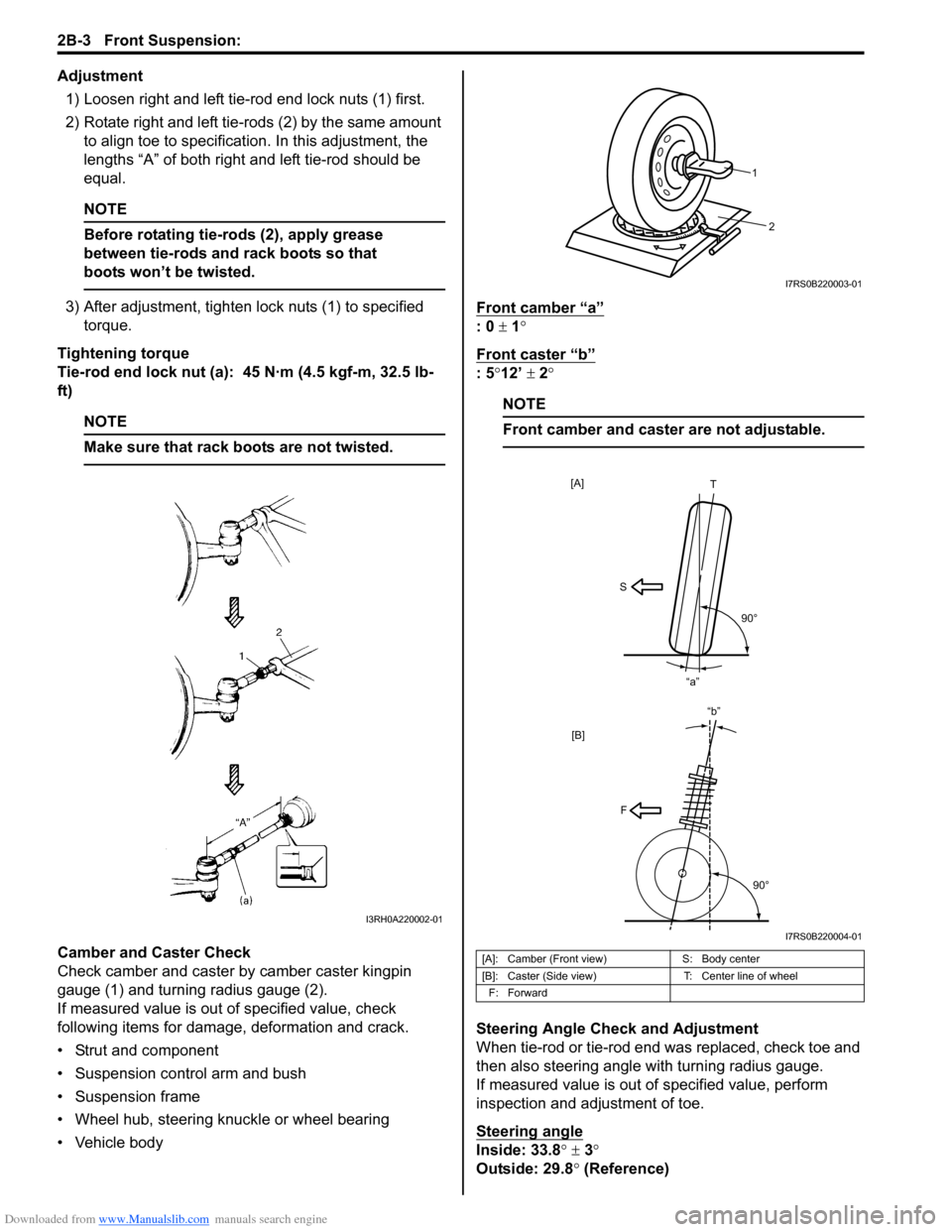

5) Remove brake hose mounting bolt (1) and remove brake hose (2) from bracket and then wheel speed

sensor harness (3) from strut bracket as shown in

figure.

6) Remove strut bracket bolts and nuts (4).

7) Remove strut rod cap.

8) Remove strut nut (1), and remove rebound stopper (2).

NOTE

Hold strut by hand so th at it will not fall off.

9) Remove strut assembly.

Installation

Install strut assembly by reversing removal procedure,

noting the following instructions.

CAUTION!

Never reuse strut bracket nuts.

Nuts are pre-coated with friction stabilizer.

Be sure to replace pre-coated nut with a new

one, or nut may loosen.

• Insert bolts in such direction as shown in figure.

• Tighten all fasteners to specified torque. Tightening torque

Strut bracket nut (a): 90 N·m (9.0 kgf-m, 65.5 lb-ft)

Brake hose mounting bolt (c): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Stabilizer joint nut (d): 50 N·m (5.0 kgf-m, 36.5 lb-

ft)

• Lower hoist and vehicle in unloaded condition, tighten strut nut (b) to specified torque.

Tightening torque

Strut nut (b): 50 N·m (5.0 kgf-m, 36.5 lb-ft)

• Install windshield wiper arms with blades referring to

“Windshield Wiper Removal and Installation in

Section 9D”.

NOTE

• Don’t twist brake hose and wheel speed sensor harness when installing them.

• Install wheel speed sensor harness (1) which marking (2) in figure is placed to

open hook side of the bracket.

1 3

2

2

1

4

4

3

I4RS0A220005-01

2

1

I4RS0A220006-01

(d) (a)

(b)

(c)

1

2

I4RS0B220012-01

Page 439 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-6

• Tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

• After installation, confirm front wheel alignment.

Front Strut Assembly Disassembly and

Assembly

S7RS0B2206004

WARNING!

Use a regular coil spring compressor and

follow the operation procedure described in

the Instruction Manual.

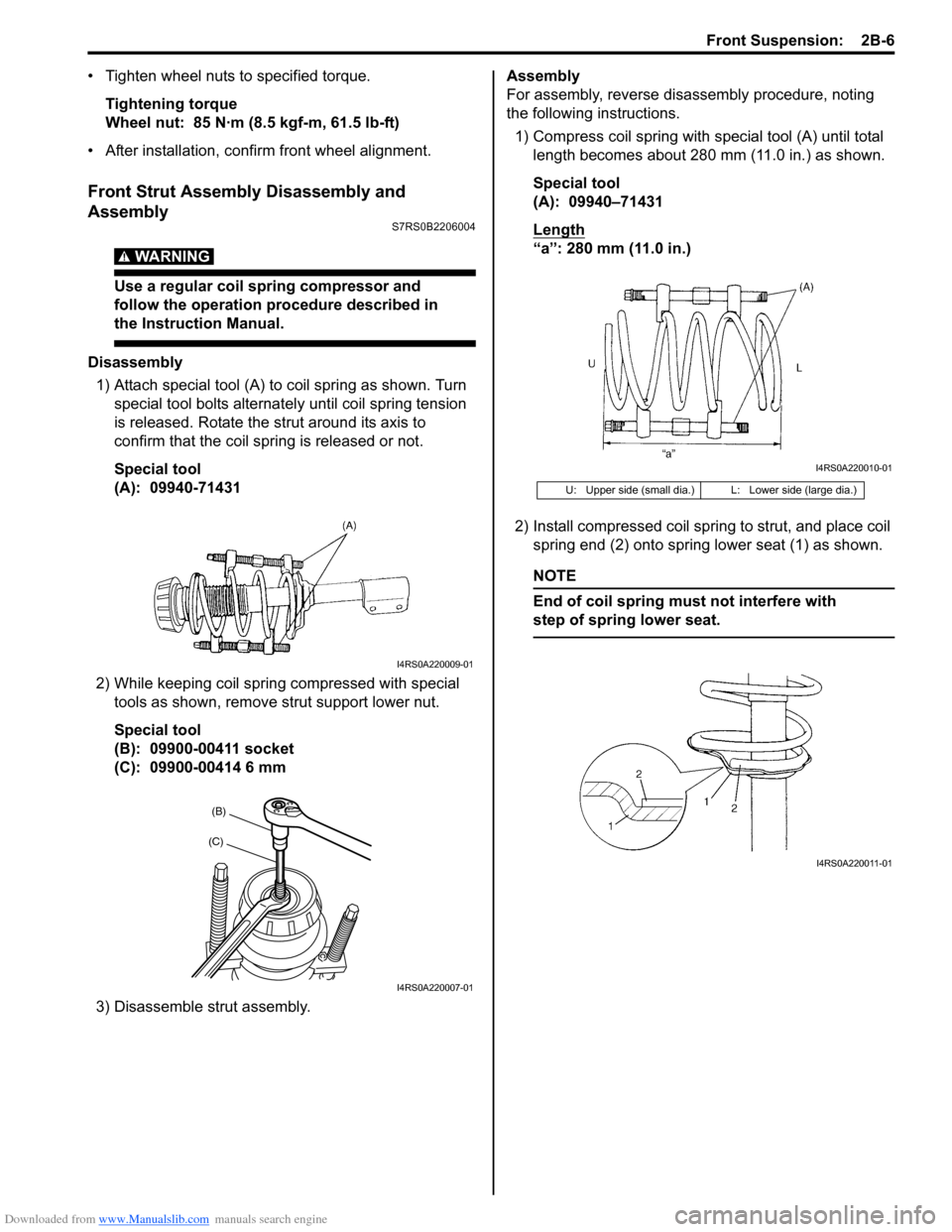

Disassembly 1) Attach special tool (A) to coil spring as shown. Turn special tool bolts alternat ely until coil spring tension

is released. Rotate the strut around its axis to

confirm that the coil spring is released or not.

Special tool

(A): 09940-71431

2) While keeping coil spring compressed with special

tools as shown, remove strut support lower nut.

Special tool

(B): 09900-00411 socket

(C): 09900-00414 6 mm

3) Disassemble strut assembly. Assembly

For assembly, reverse disassembly procedure, noting

the following instructions.

1) Compress coil spring with special tool (A) until total

length becomes about 280 mm (11.0 in.) as shown.

Special tool

(A): 09940–71431

Length

“a”: 280 mm (11.0 in.)

2) Install compressed coil spring to strut, and place coil

spring end (2) onto spring lower seat (1) as shown.

NOTE

End of coil spring must not interfere with

step of spring lower seat.

I4RS0A220009-01

(B)

(C)

I4RS0A220007-01

U: Upper side (small dia.) L: Lower side (large dia.)

I4RS0A220010-01

I4RS0A220011-01

Page 440 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-7 Front Suspension:

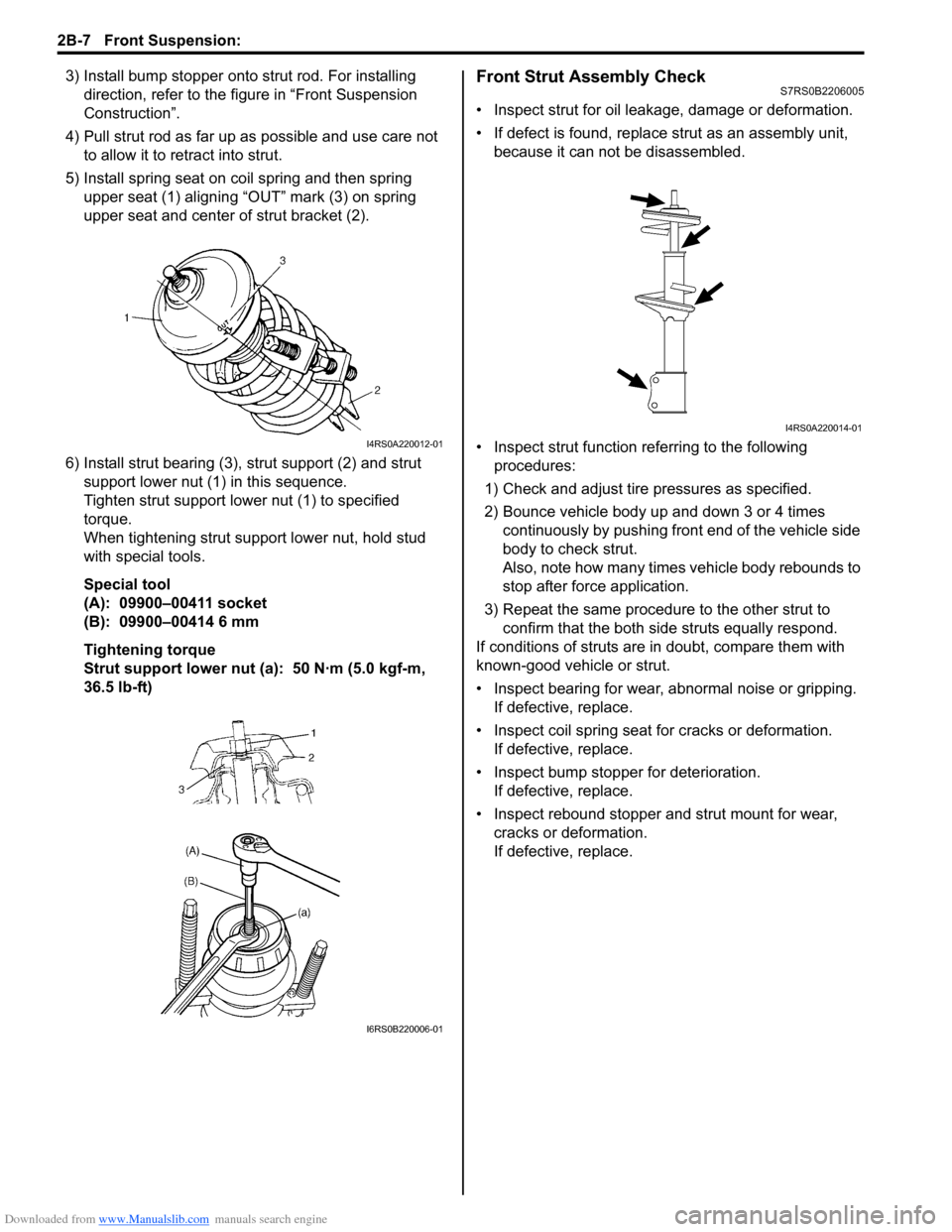

3) Install bump stopper onto strut rod. For installing

direction, refer to the figure in “Front Suspension

Construction”.

4) Pull strut rod as far up as possible and use care not to allow it to re tract into strut.

5) Install spring seat on coil spring and then spring upper seat (1) aligning “OUT” mark (3) on spring

upper seat and center of strut bracket (2).

6) Install strut bearing (3), strut support (2) and strut

support lower nut (1) in this sequence.

Tighten strut support lower nut (1) to specified

torque.

When tightening strut support lower nut, hold stud

with special tools.

Special tool

(A): 09900–00411 socket

(B): 09900–00414 6 mm

Tightening torque

Strut support lower nut (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)Front Strut Assembly CheckS7RS0B2206005

• Inspect strut for oil leakage, damage or deformation.

• If defect is found, replace strut as an assembly unit, because it can not be disassembled.

• Inspect strut function re ferring to the following

procedures:

1) Check and adjust tire pressures as specified.

2) Bounce vehicle body up and down 3 or 4 times continuously by pushing front end of the vehicle side

body to check strut.

Also, note how many times vehicle body rebounds to

stop after force application.

3) Repeat the same procedure to the other strut to confirm that the both side struts equally respond.

If conditions of struts are in doubt, compare them with

known-good vehicle or strut.

• Inspect bearing for wear, abnormal noise or gripping. If defective, replace.

• Inspect coil spring seat for cracks or deformation.

If defective, replace.

• Inspect bump stopper for deterioration. If defective, replace.

• Inspect rebound stopper and strut mount for wear, cracks or deformation.

If defective, replace.

I4RS0A220012-01

I6RS0B220006-01

I4RS0A220014-01

Page 444 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-11 Front Suspension:

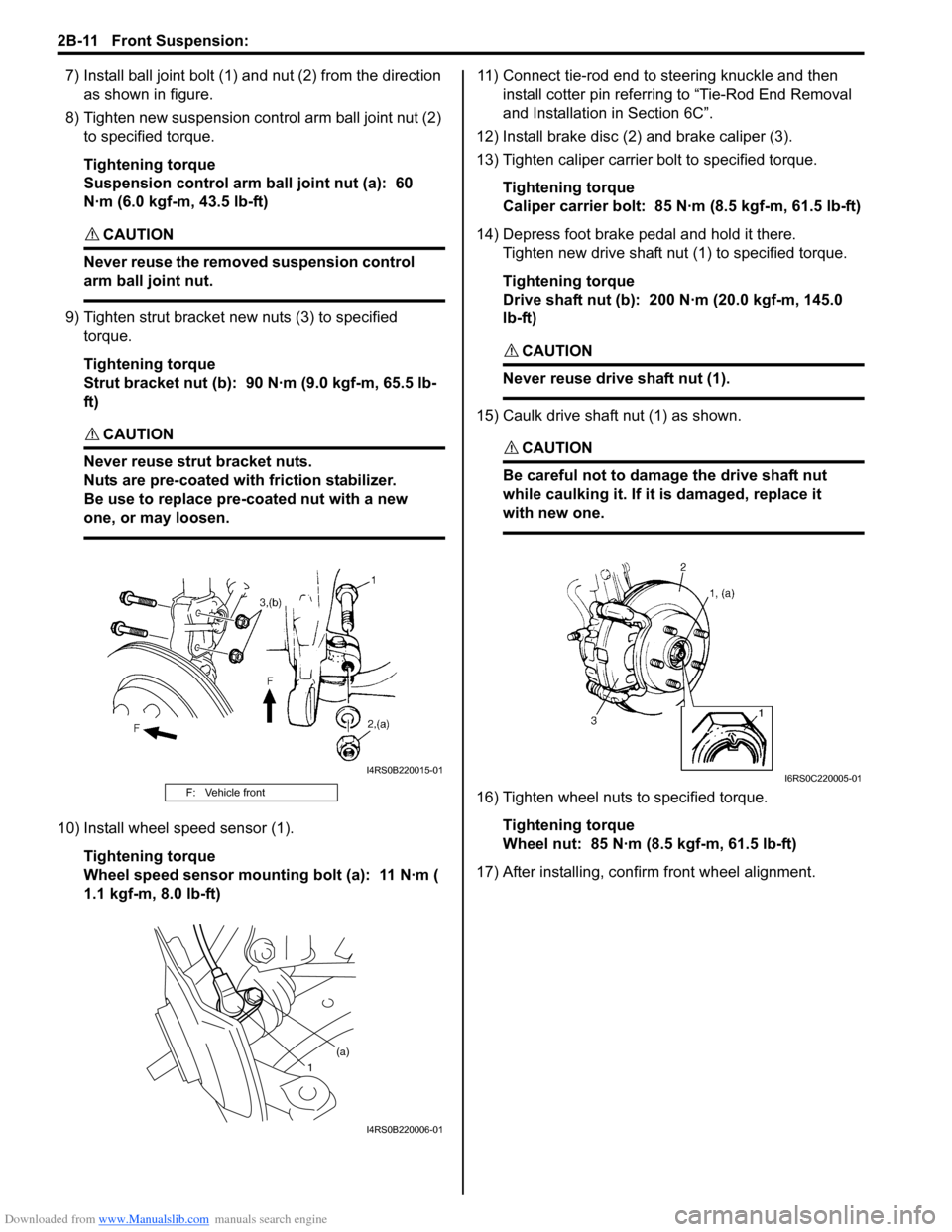

7) Install ball joint bolt (1) and nut (2) from the direction

as shown in figure.

8) Tighten new suspension co ntrol arm ball joint nut (2)

to specified torque.

Tightening torque

Suspension control arm ball joint nut (a): 60

N·m (6.0 kgf-m, 43.5 lb-ft)

CAUTION!

Never reuse the removed suspension control

arm ball joint nut.

9) Tighten strut bracket new nuts (3) to specified torque.

Tightening torque

Strut bracket nut (b): 90 N·m (9.0 kgf-m, 65.5 lb-

ft)

CAUTION!

Never reuse strut bracket nuts.

Nuts are pre-coated with friction stabilizer.

Be use to replace pre-coated nut with a new

one, or may loosen.

10) Install wheel speed sensor (1).

Tightening torque

Wheel speed sensor mounting bolt (a): 11 N·m (

1.1 kgf-m, 8.0 lb-ft) 11) Connect tie-rod end to steering knuckle and then

install cotter pin referrin g to “Tie-Rod End Removal

and Installation in Section 6C”.

12) Install brake disc (2) and brake caliper (3).

13) Tighten caliper carrier bolt to specified torque.

Tightening torque

Caliper carrier bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

14) Depress foot brake pedal and hold it there. Tighten new drive shaft nut (1) to specified torque.

Tightening torque

Drive shaft nut (b): 200 N·m (20.0 kgf-m, 145.0

lb-ft)

CAUTION!

Never reuse drive shaft nut (1).

15) Caulk drive shaft nut (1) as shown.

CAUTION!

Be careful not to damage the drive shaft nut

while caulking it. If it is damaged, replace it

with new one.

16) Tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

17) After installing, confirm front wheel alignment.F: Vehicle front

I4RS0B220015-01

1 (a)

I4RS0B220006-01

I6RS0C220005-01

Page 445 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-12

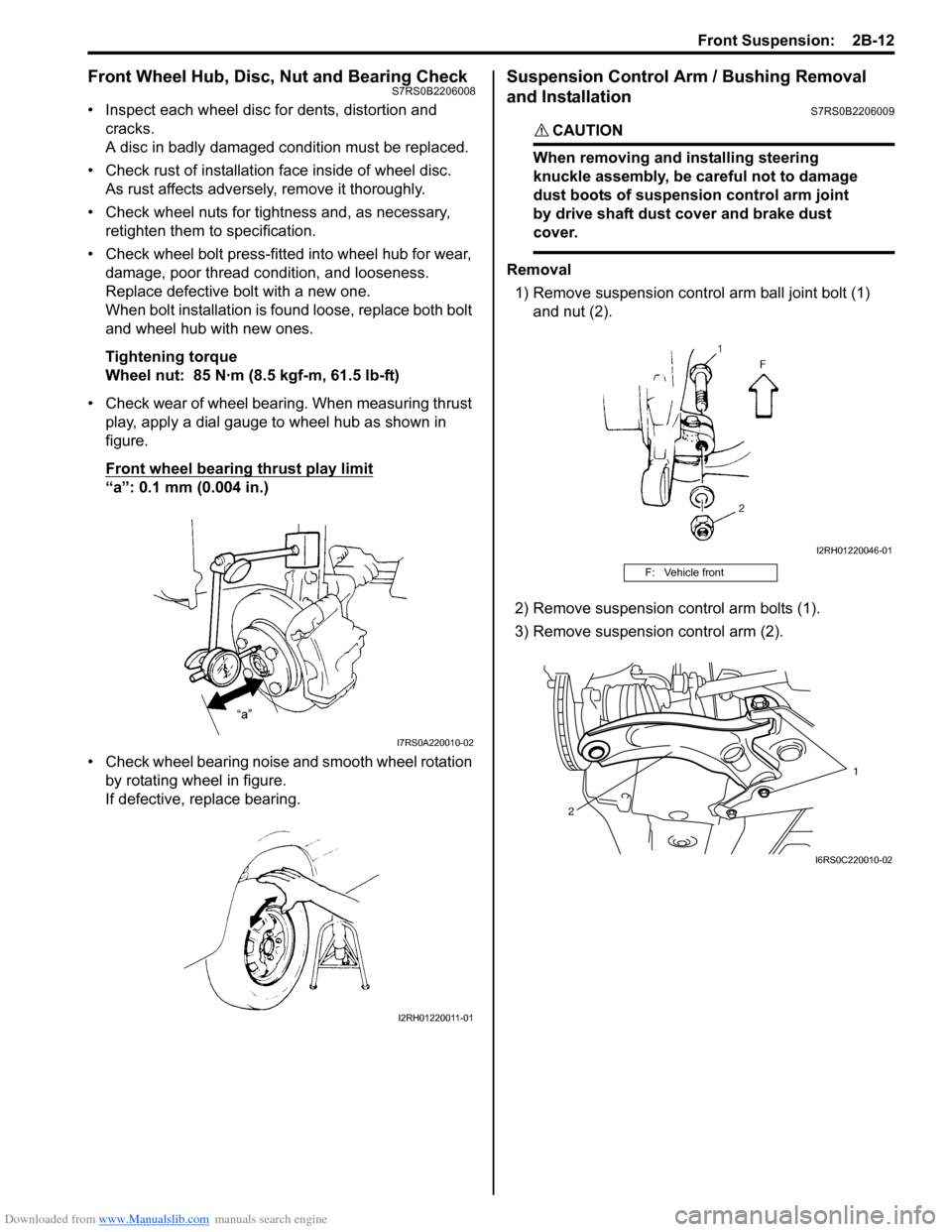

Front Wheel Hub, Disc, Nut and Bearing CheckS7RS0B2206008

• Inspect each wheel disc for dents, distortion and cracks.

A disc in badly damaged condition must be replaced.

• Check rust of installation face inside of wheel disc.

As rust affects adversely, remove it thoroughly.

• Check wheel nuts for tightness and, as necessary, retighten them to specification.

• Check wheel bolt press-fitted into wheel hub for wear, damage, poor thread condition, and looseness.

Replace defective bolt with a new one.

When bolt installation is found loose, replace both bolt

and wheel hub with new ones.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

• Check wear of wheel bearing. When measuring thrust play, apply a dial gauge to wheel hub as shown in

figure.

Front wheel bearing thrust play limit

“a”: 0.1 mm (0.004 in.)

• Check wheel bearing noise and smooth wheel rotation by rotating wheel in figure.

If defective, replace bearing.

Suspension Control Arm / Bushing Removal

and Installation

S7RS0B2206009

CAUTION!

When removing and installing steering

knuckle assembly, be ca reful not to damage

dust boots of suspension control arm joint

by drive shaft dust cover and brake dust

cover.

Removal

1) Remove suspension contro l arm ball joint bolt (1)

and nut (2).

2) Remove suspension control arm bolts (1).

3) Remove suspension control arm (2).

I7RS0A220010-02

I2RH01220011-01

F: Vehicle front

I2RH01220046-01

1

2

I6RS0C220010-02

Page 446 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-13 Front Suspension:

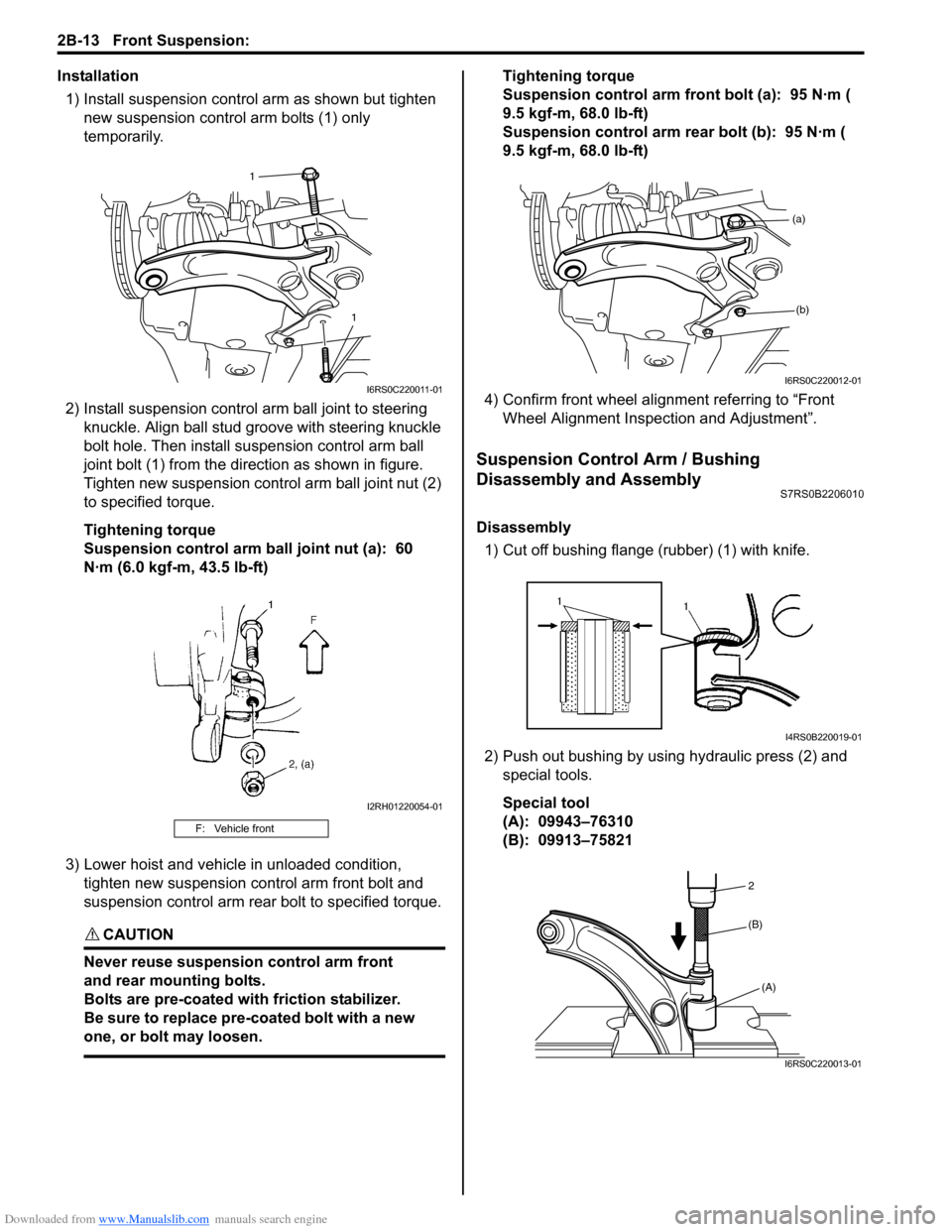

Installation1) Install suspension control arm as shown but tighten new suspension contro l arm bolts (1) only

temporarily.

2) Install suspensi on control arm ball joint to steering

knuckle. Align ball stud gr oove with steering knuckle

bolt hole. Then install su spension control arm ball

joint bolt (1) from the direction as shown in figure.

Tighten new suspension cont rol arm ball joint nut (2)

to specified torque.

Tightening torque

Suspension control arm ball joint nut (a): 60

N·m (6.0 kgf-m, 43.5 lb-ft)

3) Lower hoist and vehicle in unloaded condition, tighten new suspension control arm front bolt and

suspension control arm rear bolt to specified torque.

CAUTION!

Never reuse suspension control arm front

and rear mounting bolts.

Bolts are pre-coated with friction stabilizer.

Be sure to replace pre-coated bolt with a new

one, or bolt may loosen.

Tightening torque

Suspension control arm front bolt (a): 95 N·m (

9.5 kgf-m, 68.0 lb-ft)

Suspension control arm re ar bolt (b): 95 N·m (

9.5 kgf-m, 68.0 lb-ft)

4) Confirm front wheel alignment referring to “Front Wheel Alignment Inspection and Adjustment”.

Suspension Control Arm / Bushing

Disassembly and Assembly

S7RS0B2206010

Disassembly

1) Cut off bushing flange (rubber) (1) with knife.

2) Push out bushing by using hydraulic press (2) and special tools.

Special tool

(A): 09943–76310

(B): 09913–75821

F: Vehicle front

1

1

I6RS0C220011-01

I2RH01220054-01

(a)(b)

I6RS0C220012-01

I4RS0B220019-01

2

(A)

(B)

I6RS0C220013-01

Page 450 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-17 Front Suspension:

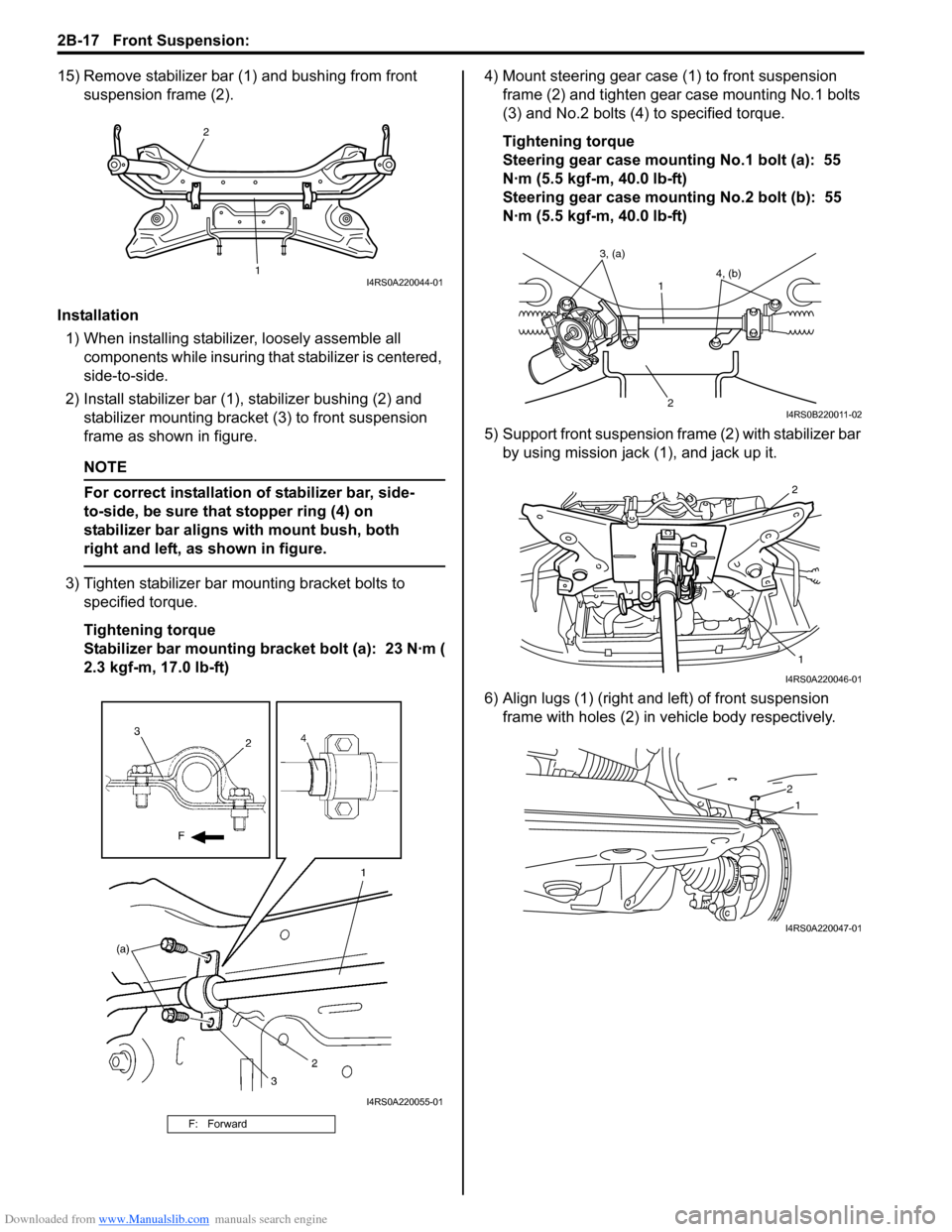

15) Remove stabilizer bar (1) and bushing from front

suspension frame (2).

Installation 1) When installing stabilizer, loosely assemble all components while insuring that stabilizer is centered,

side-to-side.

2) Install stabilizer bar (1), stabilizer bushing (2) and

stabilizer mounting bracket (3) to front suspension

frame as shown in figure.

NOTE

For correct installation of stabilizer bar, side-

to-side, be sure that stopper ring (4) on

stabilizer bar aligns with mount bush, both

right and left, as shown in figure.

3) Tighten stabilizer bar mounting bracket bolts to specified torque.

Tightening torque

Stabilizer bar mounting bracket bolt (a): 23 N·m (

2.3 kgf-m, 17.0 lb-ft) 4) Mount steering gear case

(1) to front suspension

frame (2) and tighten gear case mounting No.1 bolts

(3) and No.2 bolts (4) to specified torque.

Tightening torque

Steering gear case mounting No.1 bolt (a): 55

N·m (5.5 kgf-m, 40.0 lb-ft)

Steering gear case mounting No.2 bolt (b): 55

N·m (5.5 kgf-m, 40.0 lb-ft)

5) Support front suspension frame (2) with stabilizer bar by using mission jack (1), and jack up it.

6) Align lugs (1) (right and left) of front suspension frame with holes (2) in vehicle body respectively.

F: Forward

1

2I4RS0A220044-01

I4RS0A220055-01

3, (a)

1

2 4, (b)

I4RS0B220011-02

2

1

I4RS0A220046-01

1

2

I4RS0A220047-01