transmission fluid SUZUKI SWIFT 2008 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 776 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-132 Automatic Transmission/Transaxle:

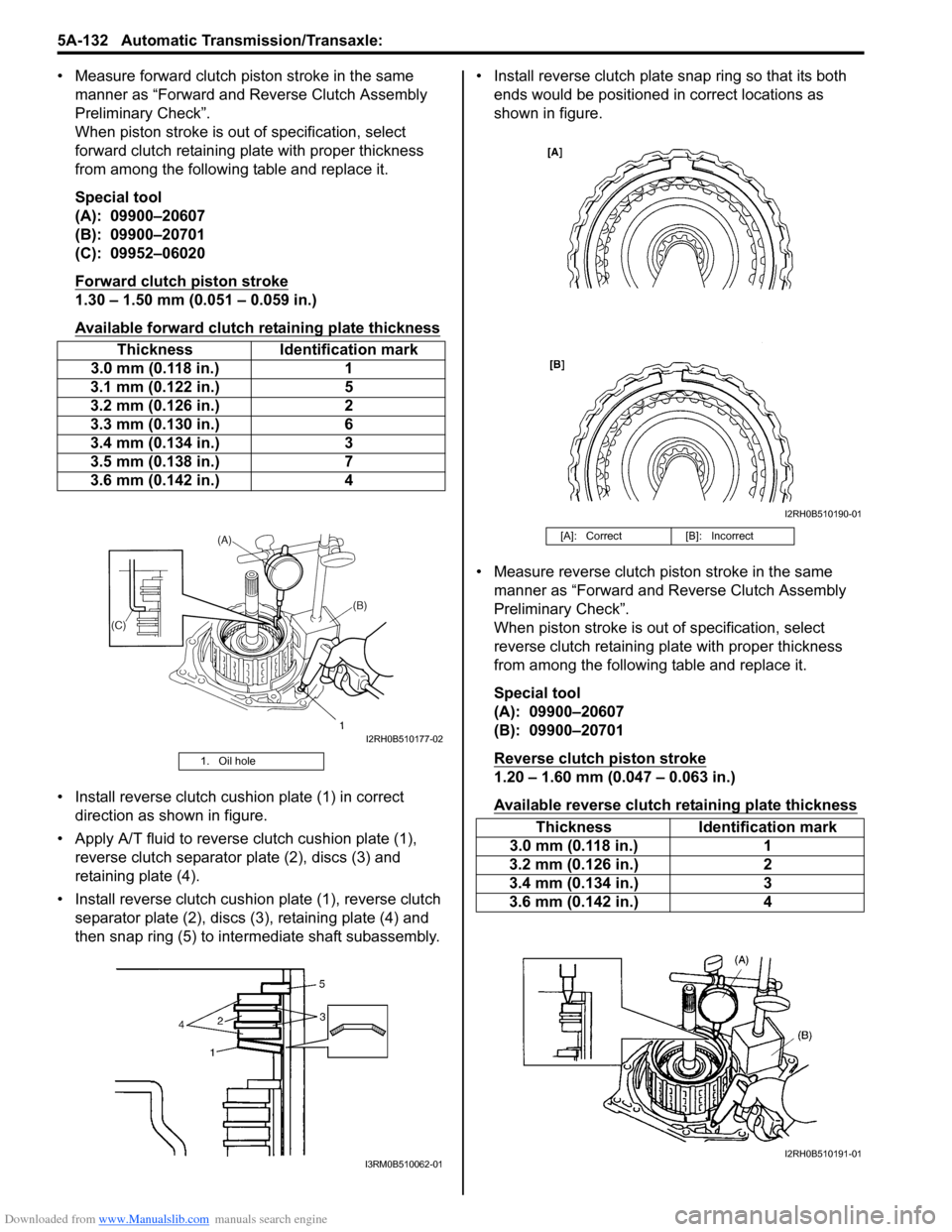

• Measure forward clutch piston stroke in the same manner as “Forward and Reverse Clutch Assembly

Preliminary Check”.

When piston stroke is out of specification, select

forward clutch retaining plate with proper thickness

from among the following table and replace it.

Special tool

(A): 09900–20607

(B): 09900–20701

(C): 09952–06020

Forward clutch piston stroke

1.30 – 1.50 mm (0.051 – 0.059 in.)

Available forward clutch retaining plate thickness

• Install reverse clutch cushion plate (1) in correct direction as shown in figure.

• Apply A/T fluid to reverse clutch cushion plate (1),

reverse clutch separator plate (2), discs (3) and

retaining plate (4).

• Install reverse clutch cushio n plate (1), reverse clutch

separator plate (2), discs (3), retaining plate (4) and

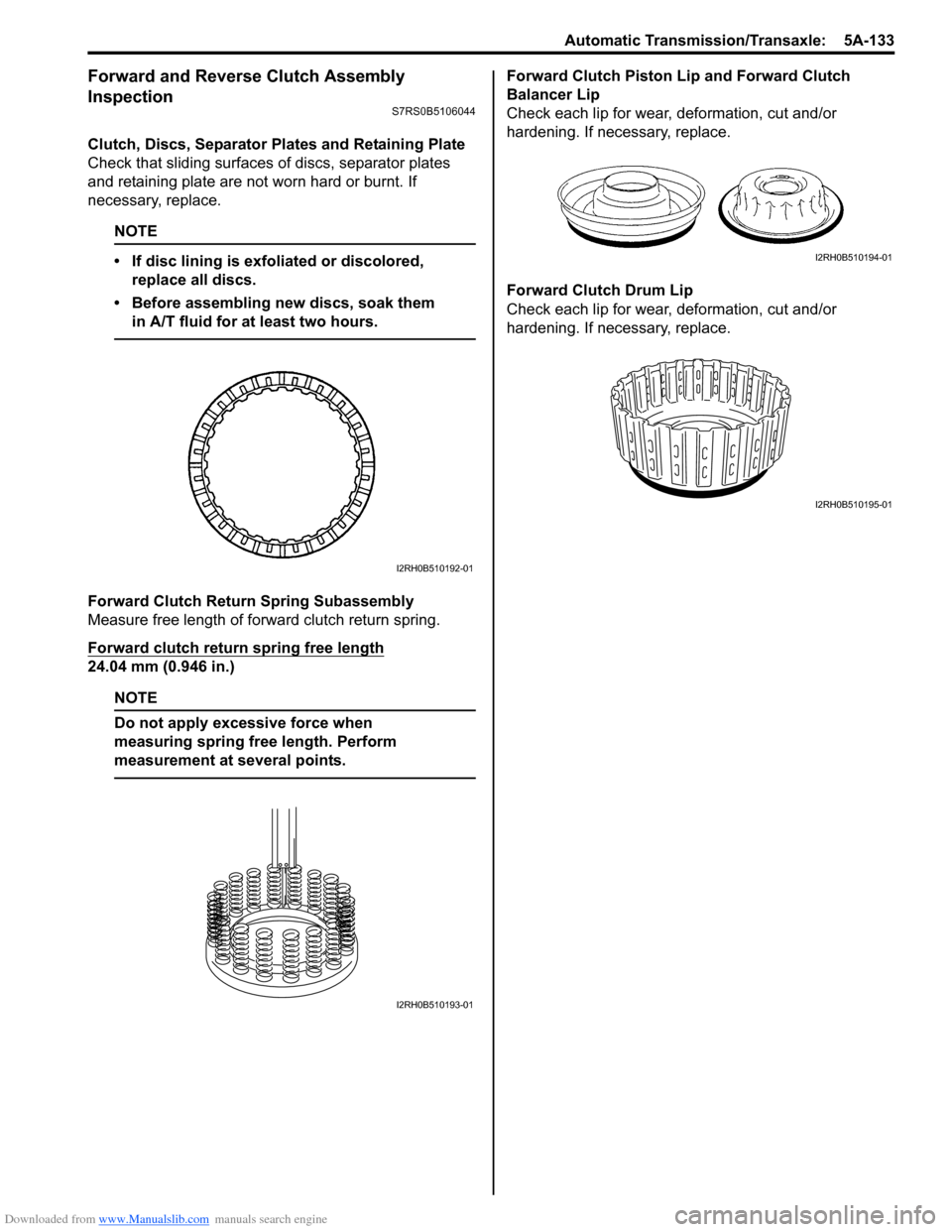

then snap ring (5) to inte rmediate shaft subassembly. • Install reverse clutch plate snap ring so that its both

ends would be positioned in correct locations as

shown in figure.

• Measure reverse clutch piston stroke in the same manner as “Forward and Reverse Clutch Assembly

Preliminary Check”.

When piston stroke is out of specification, select

reverse clutch retaining plate with proper thickness

from among the following table and replace it.

Special tool

(A): 09900–20607

(B): 09900–20701

Reverse clutch piston stroke

1.20 – 1.60 mm (0.047 – 0.063 in.)

Available reverse clutch retaining plate thickness

Thickness Identification mark

3.0 mm (0.118 in.) 1

3.1 mm (0.122 in.) 5

3.2 mm (0.126 in.) 2

3.3 mm (0.130 in.) 6

3.4 mm (0.134 in.) 3

3.5 mm (0.138 in.) 7

3.6 mm (0.142 in.) 4

1. Oil hole

I2RH0B510177-02

I3RM0B510062-01

[A]: Correct[B]: Incorrect

ThicknessIdentification mark

3.0 mm (0.118 in.) 1

3.2 mm (0.126 in.) 2

3.4 mm (0.134 in.) 3

3.6 mm (0.142 in.) 4

I2RH0B510190-01

I2RH0B510191-01

Page 777 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-133

Forward and Reverse Clutch Assembly

Inspection

S7RS0B5106044

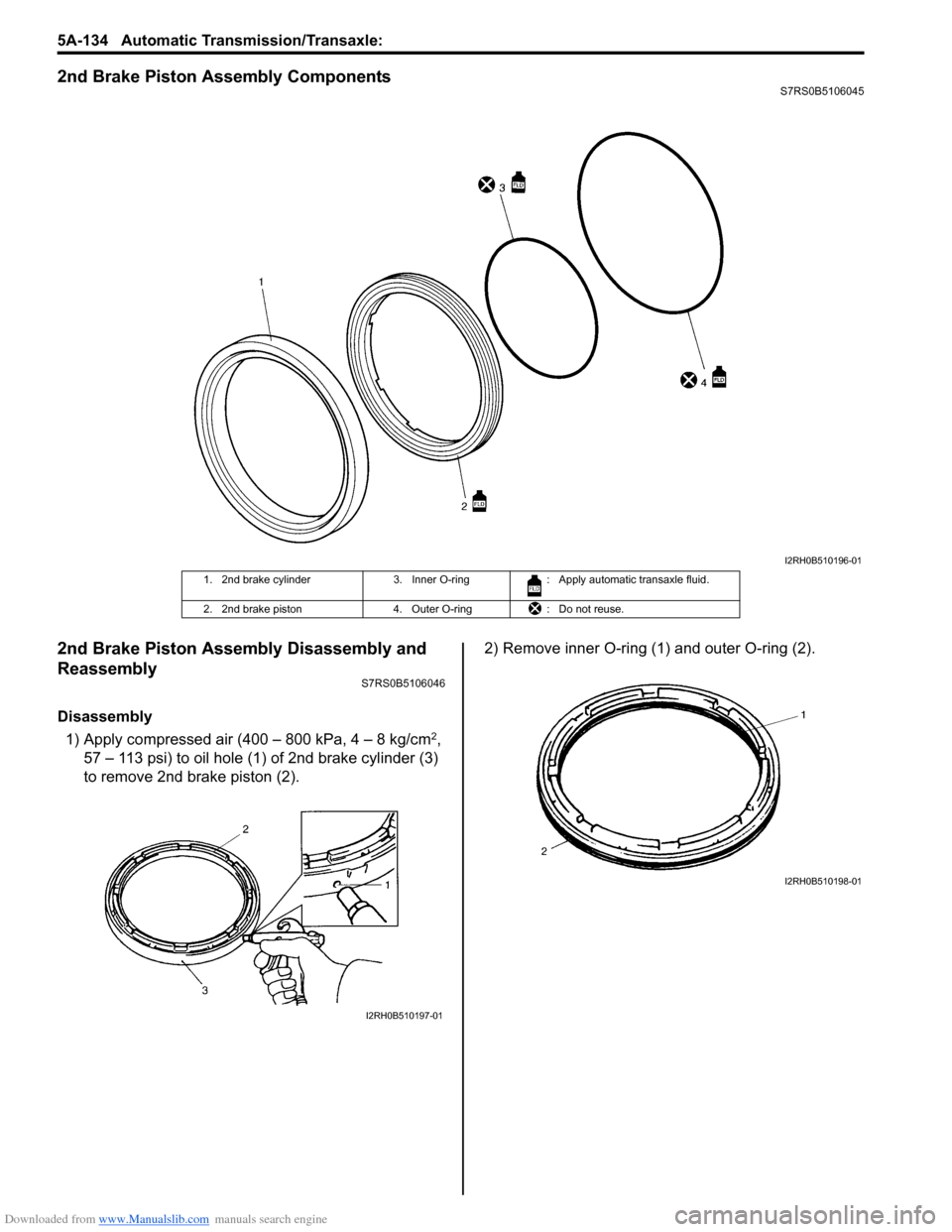

Clutch, Discs, Separator Plates and Retaining Plate

Check that sliding surfaces of discs, separator plates

and retaining plate are not worn hard or burnt. If

necessary, replace.

NOTE

• If disc lining is exfoliated or discolored, replace all discs.

• Before assembling new discs, soak them in A/T fluid for at least two hours.

Forward Clutch Return Spring Subassembly

Measure free length of fo rward clutch return spring.

Forward clutch return spring free length

24.04 mm (0.946 in.)

NOTE

Do not apply excessive force when

measuring spring free length. Perform

measurement at several points.

Forward Clutch Piston Lip and Forward Clutch

Balancer Lip

Check each lip for wear, deformation, cut and/or

hardening. If necessary, replace.

Forward Clutch Drum Lip

Check each lip for wear, deformation, cut and/or

hardening. If necessary, replace.

I2RH0B510192-01

I2RH0B510193-01

I2RH0B510194-01

I2RH0B510195-01

Page 778 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-134 Automatic Transmission/Transaxle:

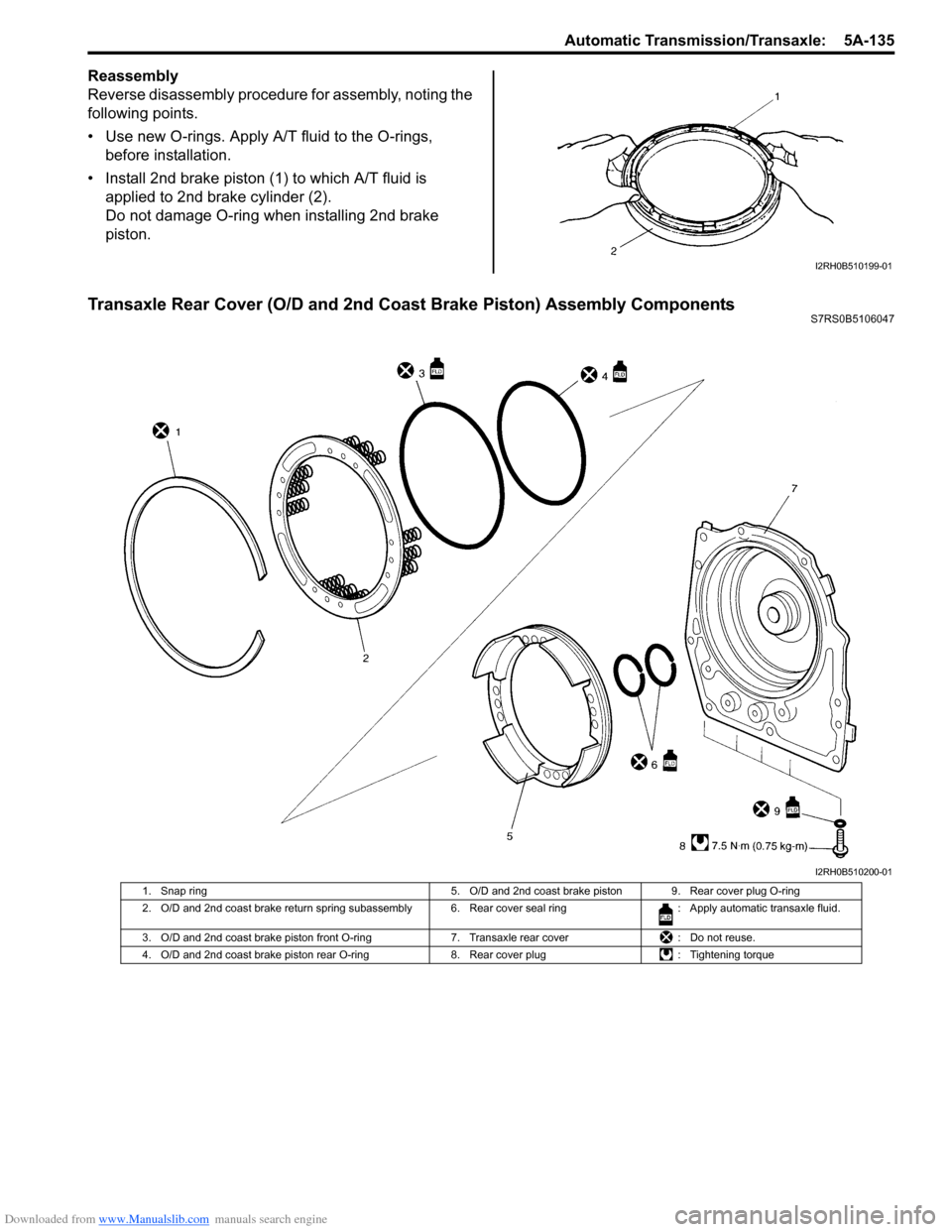

2nd Brake Piston Assembly ComponentsS7RS0B5106045

2nd Brake Piston Assembly Disassembly and

Reassembly

S7RS0B5106046

Disassembly1) Apply compressed air (400 – 800 kPa, 4 – 8 kg/cm

2,

57 – 113 psi) to oil hole (1) of 2nd brake cylinder (3)

to remove 2nd brake piston (2). 2) Remove inner O-ring (1) and outer O-ring (2).

I2RH0B510196-01

1. 2nd brake cylinder

3. Inner O-ring: Apply automatic transaxle fluid.

2. 2nd brake piston 4. Outer O-ring: Do not reuse.

I2RH0B510197-01

I2RH0B510198-01

Page 779 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-135

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Use new O-rings. Apply A/T fluid to the O-rings, before installation.

• Install 2nd brake piston (1) to which A/T fluid is applied to 2nd brake cylinder (2).

Do not damage O-ring wh en installing 2nd brake

piston.

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly ComponentsS7RS0B5106047

I2RH0B510199-01

I2RH0B510200-01

1. Snap ring 5. O/D and 2nd coast brake piston 9. Rear cover plug O-ring

2. O/D and 2nd coast brake return spring subassembly 6. R ear cover seal ring: Apply automatic transaxle fluid.

3. O/D and 2nd coast brake piston front O- ring7. Transaxle rear cover : Do not reuse.

4. O/D and 2nd coast brake piston rear O- ring8. Rear cover plug : Tightening torque

Page 781 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-137

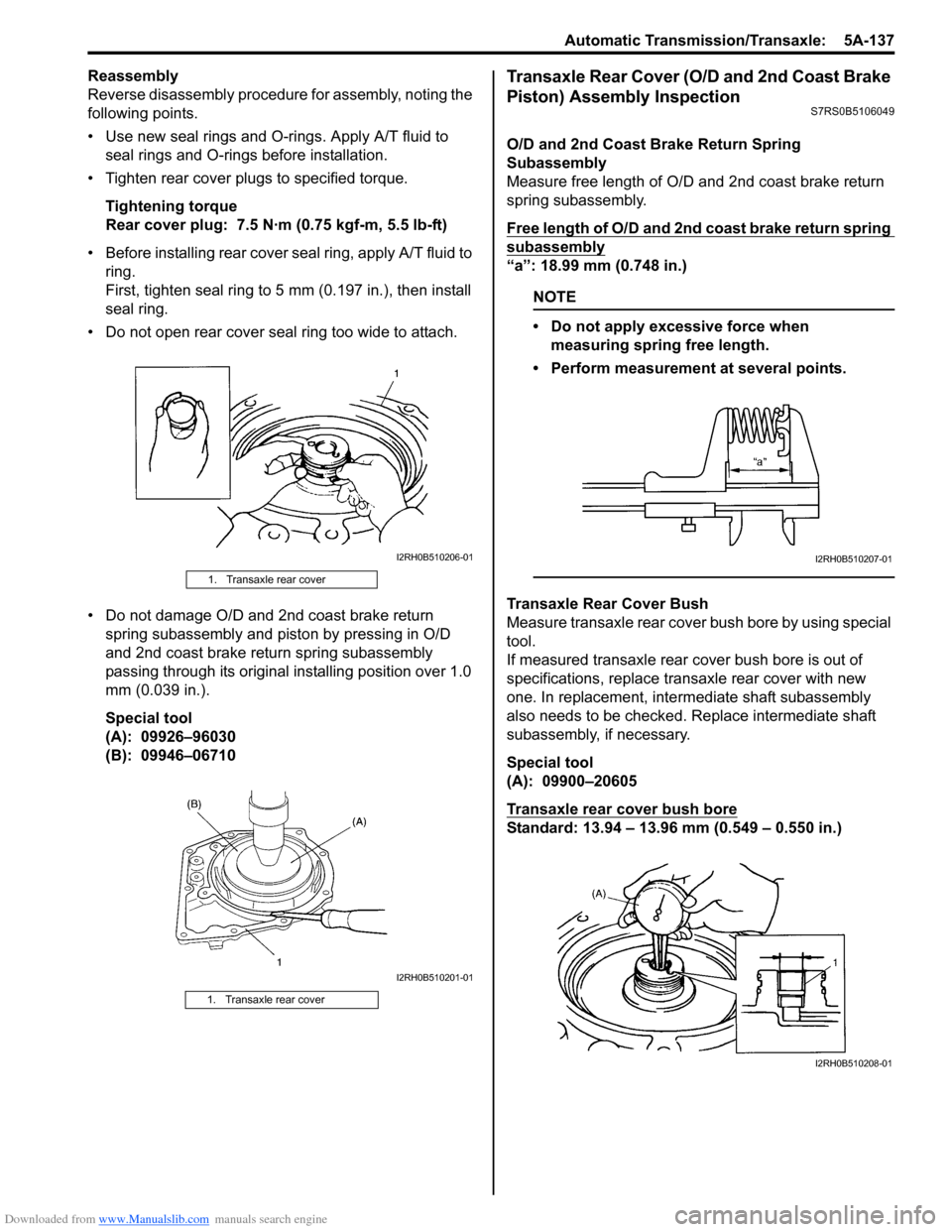

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Use new seal rings and O-rings. Apply A/T fluid to seal rings and O-rings before installation.

• Tighten rear cover plugs to specified torque.

Tightening torque

Rear cover plug: 7.5 N·m (0.75 kgf-m, 5.5 lb-ft)

• Before installing rear cover seal ring, apply A/T fluid to ring.

First, tighten seal ring to 5 mm (0.197 in.), then install

seal ring.

• Do not open rear cover seal ring too wide to attach.

• Do not damage O/D and 2nd coast brake return spring subassembly and piston by pressing in O/D

and 2nd coast brake return spring subassembly

passing through its original installing position over 1.0

mm (0.039 in.).

Special tool

(A): 09926–96030

(B): 09946–06710Transaxle Rear Cover (O/D and 2nd Coast Brake

Piston) Assembly Inspection

S7RS0B5106049

O/D and 2nd Coast Brake Return Spring

Subassembly

Measure free length of O/D and 2nd coast brake return

spring subassembly.

Free length of O/D and 2nd coast brake return spring

subassembly

“a”: 18.99 mm (0.748 in.)

NOTE

• Do not apply excessive force when measuring spring free length.

• Perform measurement at several points.

Transaxle Rear Cover Bush

Measure transaxle rear cover bush bore by using special

tool.

If measured transaxle rear cover bush bore is out of

specifications, replace transaxle rear cover with new

one. In replacement, inte rmediate shaft subassembly

also needs to be checked. Replace intermediate shaft

subassembly, if necessary.

Special tool

(A): 09900–20605

Transaxle rear cover bush bore

Standard: 13.94 – 13.96 mm (0.549 – 0.550 in.)

1. Transaxle rear cover

1. Transaxle rear cover

I2RH0B510206-01

I2RH0B510201-01

I2RH0B510207-01

I2RH0B510208-01

Page 782 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-138 Automatic Transmission/Transaxle:

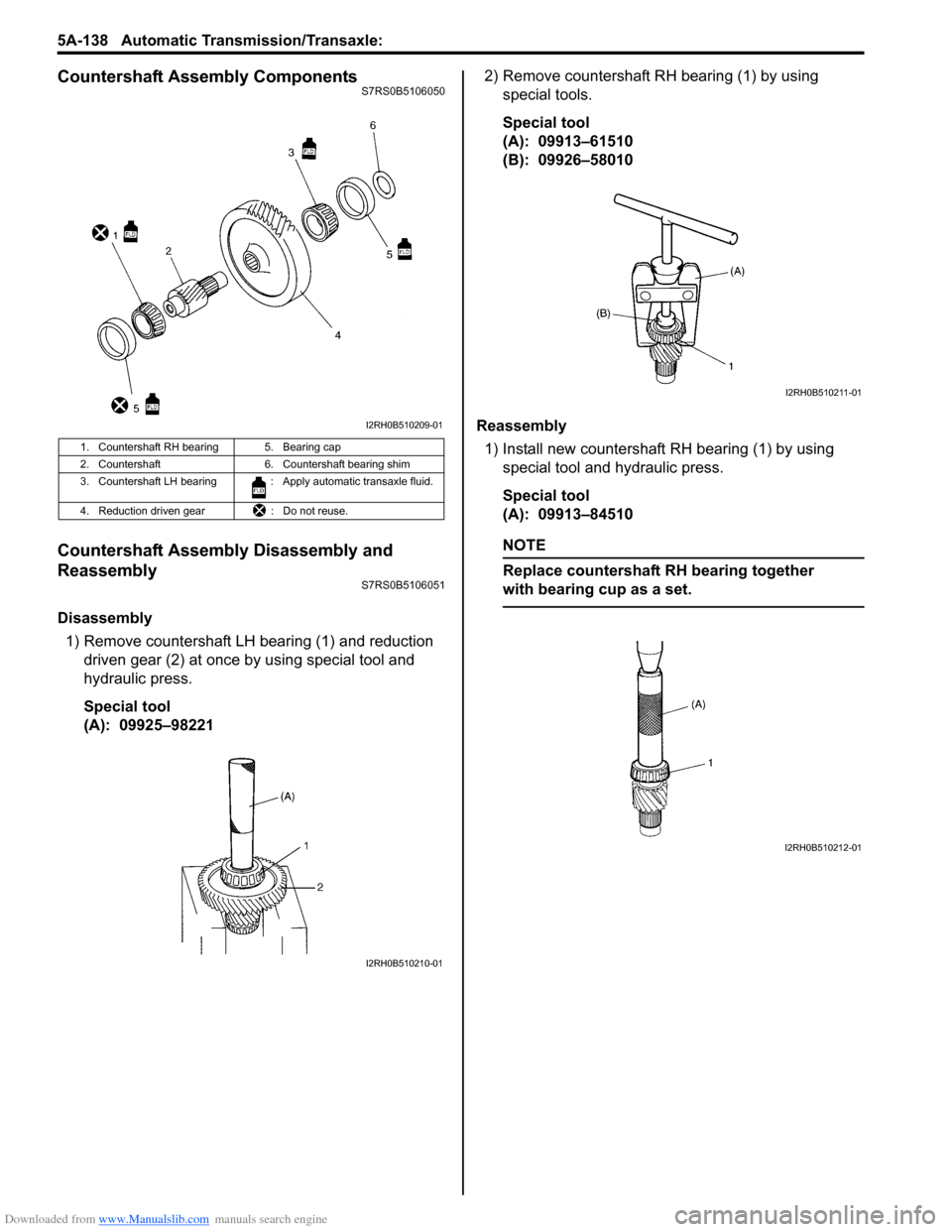

Countershaft Assembly ComponentsS7RS0B5106050

Countershaft Assembly Disassembly and

Reassembly

S7RS0B5106051

Disassembly1) Remove countershaft LH bearing (1) and reduction driven gear (2) at once by using special tool and

hydraulic press.

Special tool

(A): 09925–98221 2) Remove countershaft RH bearing (1) by using

special tools.

Special tool

(A): 09913–61510

(B): 09926–58010

Reassembly 1) Install new countershaft RH bearing (1) by using special tool and hydraulic press.

Special tool

(A): 09913–84510

NOTE

Replace countershaft RH bearing together

with bearing cup as a set.

1. Countershaft RH bearing 5. Bearing cap

2. Countershaft 6. Countershaft bearing shim

3. Countershaft LH bearing : Apply automatic transaxle fluid.

4. Reduction driven gear : Do not reuse.

I2RH0B510209-01

I2RH0B510210-01

I2RH0B510211-01

I2RH0B510212-01

Page 783 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-139

2) Install reduction driven gear (1) with special tools and hydraulic press.

Special tool

(A): 09913–84510

(B): 09925–88210 3) Install countershaft LH bearing (1) with special tools

and hydraulic press.

Special tool

(A): 09913–84510

(B): 09925–88210

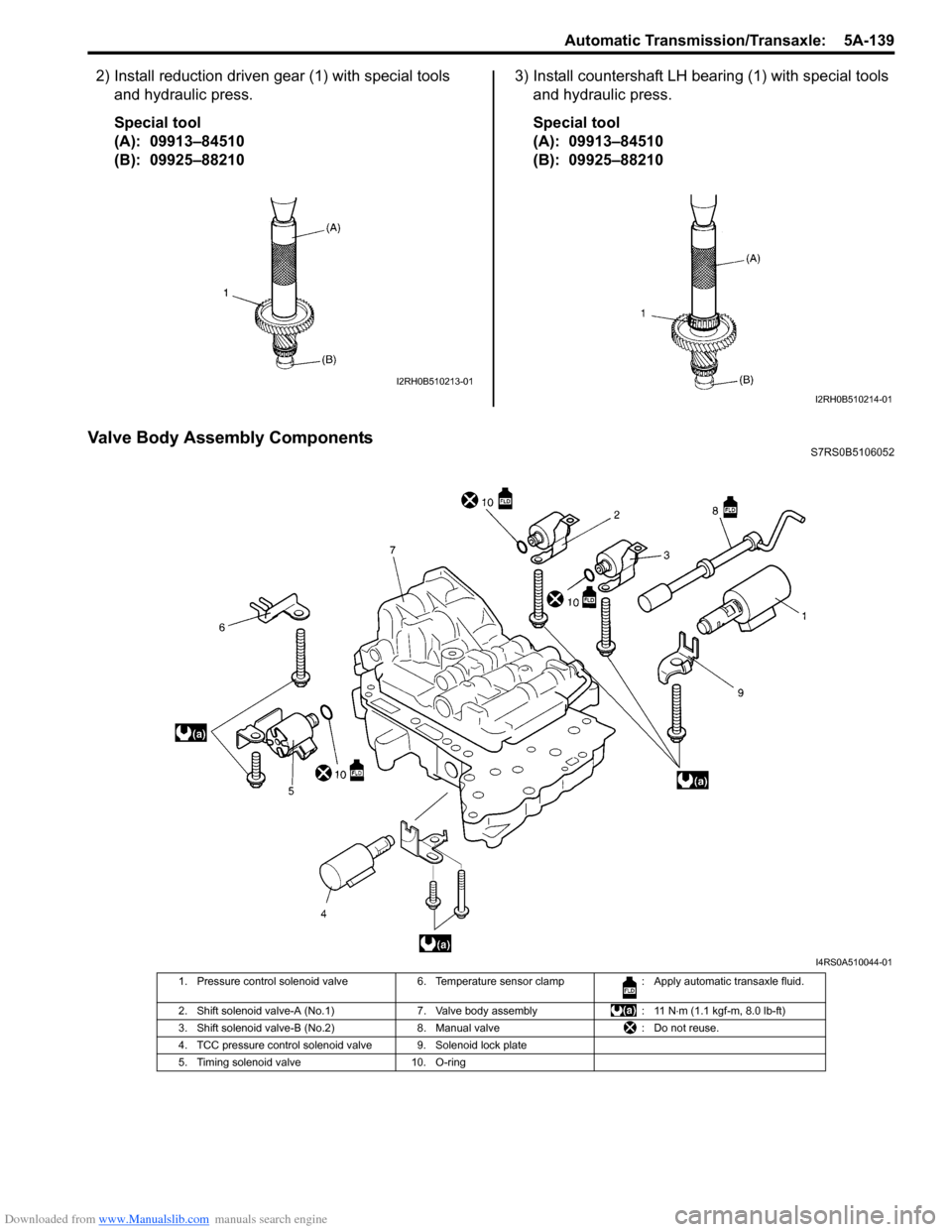

Valve Body Assembly ComponentsS7RS0B5106052

I2RH0B510213-01

I2RH0B510214-01

I4RS0A510044-01

1. Pressure control solenoid valve 6. Temperature sensor clamp : Apply automatic transaxle fluid.

2. Shift solenoid valve-A (No.1) 7. Valve body assembly: 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

3. Shift solenoid valve-B (No.2) 8. Manual valve: Do not reuse.

4. TCC pressure control solenoid valve 9. Solenoid lock plate

5. Timing solenoid valve 10. O-ring

Page 785 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-141

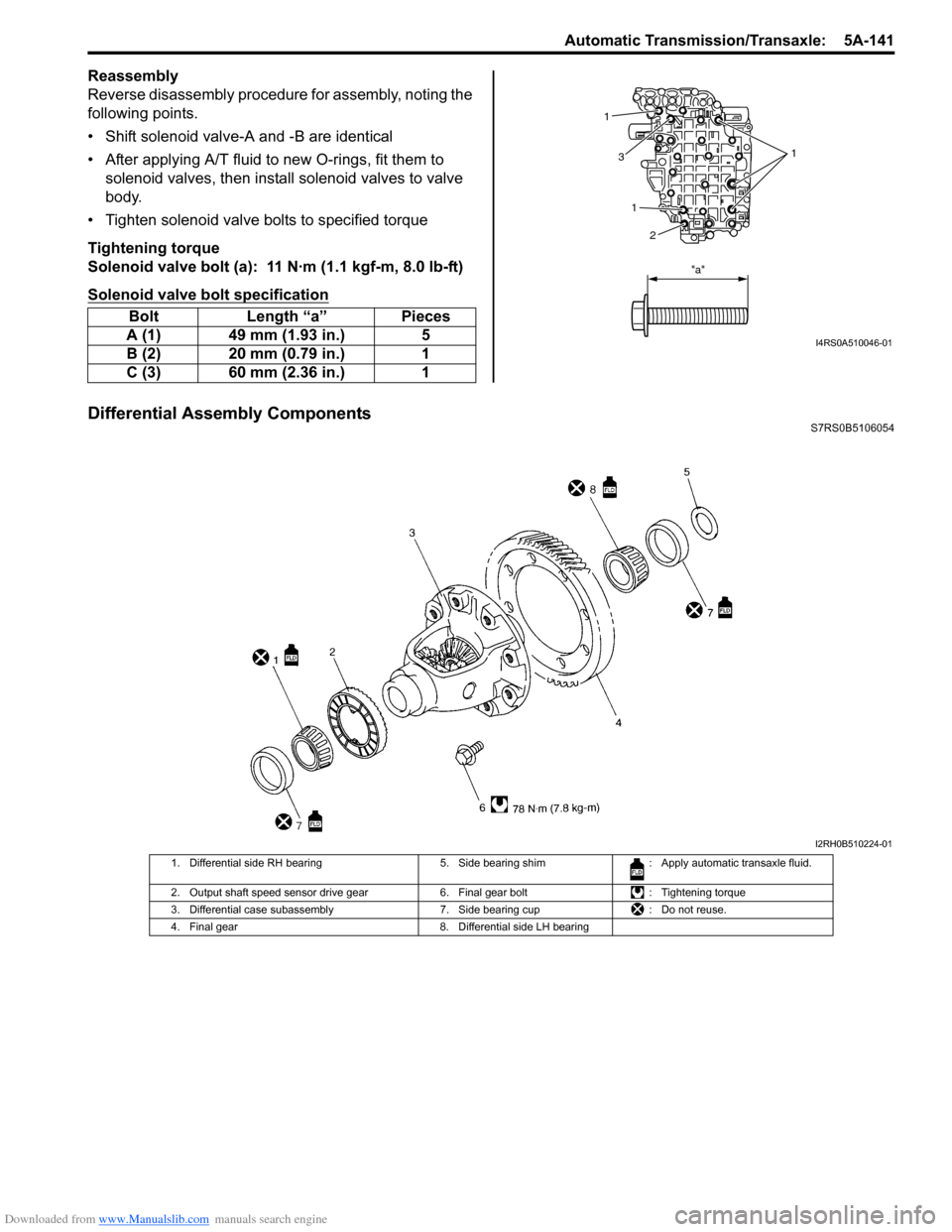

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Shift solenoid valve-A and -B are identical

• After applying A/T fluid to new O-rings, fit them to solenoid valves, then insta ll solenoid valves to valve

body.

• Tighten solenoid valve bolts to specified torque

Tightening torque

Solenoid valve bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

Solenoid valve bolt specification

Differential Assembly ComponentsS7RS0B5106054

Bolt Length “a” Pieces

A (1) 49 mm (1.93 in.) 5

B (2) 20 mm (0.79 in.) 1

C (3) 60 mm (2.36 in.) 1

1

1

1

3

2

"a"

I4RS0A510046-01

I2RH0B510224-01

1. Differential side RH bearing 5. Side bearing shim: Apply automatic transaxle fluid.

2. Output shaft speed sensor drive gear 6. Final gear bolt: Tightening torque

3. Differential case subassembly 7. Side bearing cup: Do not reuse.

4. Final gear 8. Differential side LH bearing

Page 787 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-143

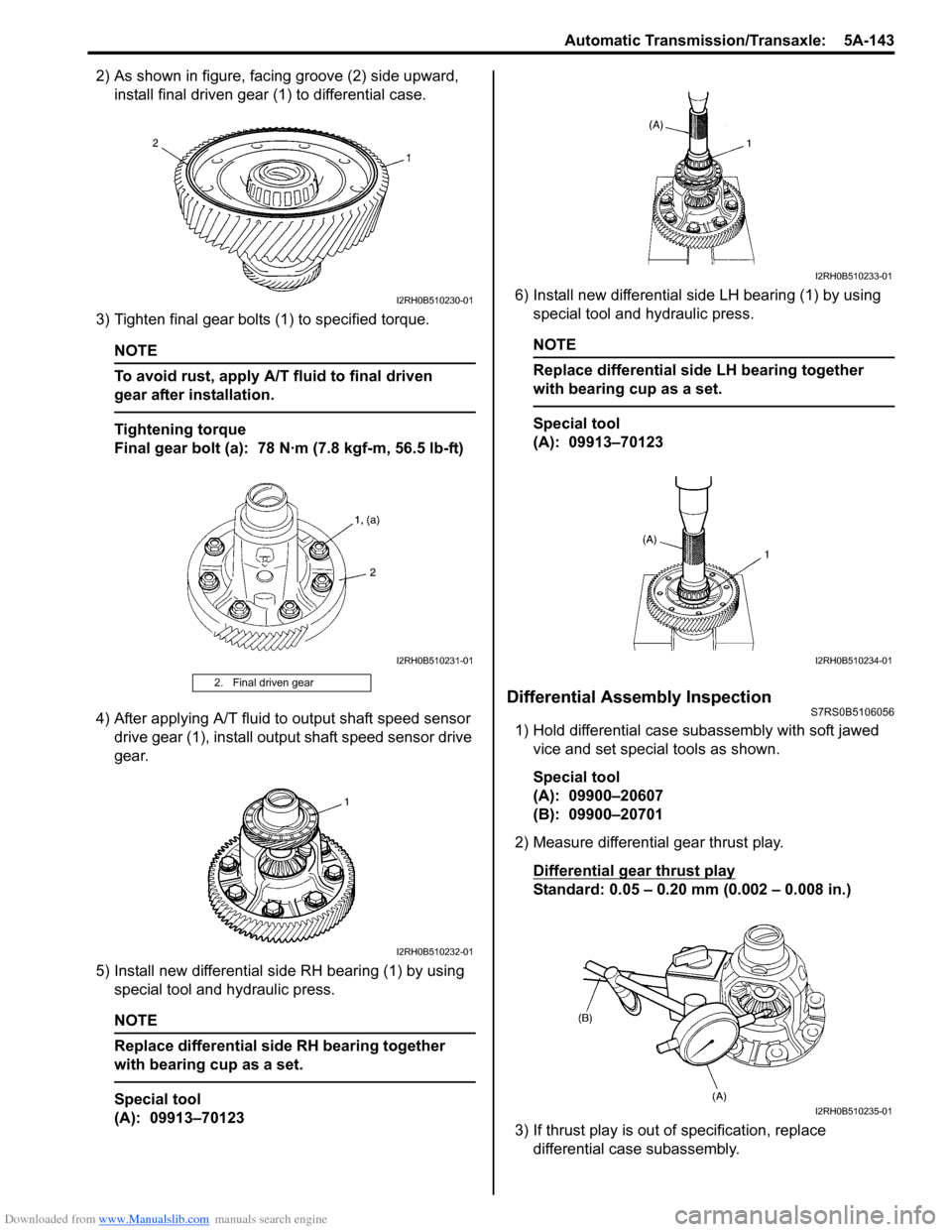

2) As shown in figure, facing groove (2) side upward, install final driven gear (1) to differential case.

3) Tighten final gear bolts (1) to specified torque.

NOTE

To avoid rust, apply A/T fluid to final driven

gear after installation.

Tightening torque

Final gear bolt (a): 78 N·m (7.8 kgf-m, 56.5 lb-ft)

4) After applying A/T fluid to output shaft speed sensor drive gear (1), install output shaft speed sensor drive

gear.

5) Install new differential side RH bearing (1) by using special tool and hydraulic press.

NOTE

Replace differential side RH bearing together

with bearing cup as a set.

Special tool

(A): 09913–70123 6) Install new differential side LH bearing (1) by using

special tool and hydraulic press.

NOTE

Replace differential side LH bearing together

with bearing cup as a set.

Special tool

(A): 09913–70123

Differential Assembly InspectionS7RS0B5106056

1) Hold differential case subassembly with soft jawed

vice and set special tools as shown.

Special tool

(A): 09900–20607

(B): 09900–20701

2) Measure differential gear thrust play.

Differential gear thrust play

Standard: 0.05 – 0.20 mm (0.002 – 0.008 in.)

3) If thrust play is out of specification, replace differential case subassembly.

2. Final driven gear

I2RH0B510230-01

I2RH0B510231-01

I2RH0B510232-01

I2RH0B510233-01

I2RH0B510234-01

I2RH0B510235-01

Page 788 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-144 Automatic Transmission/Transaxle:

Torque Converter Housing Disassembly and

Reassembly

S7RS0B5106057

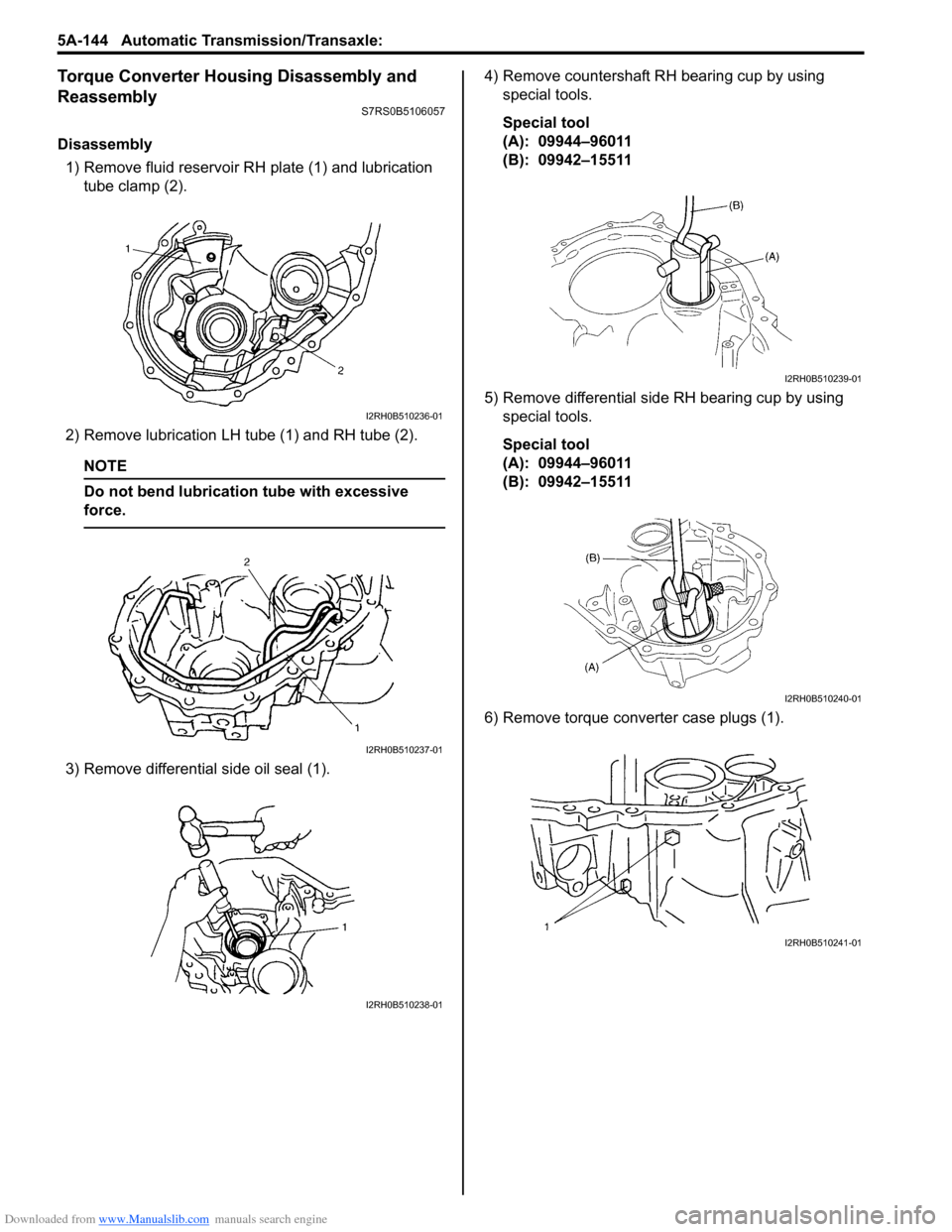

Disassembly1) Remove fluid reservoir RH plate (1) and lubrication tube clamp (2).

2) Remove lubrication LH tube (1) and RH tube (2).

NOTE

Do not bend lubrication tube with excessive

force.

3) Remove differential side oil seal (1). 4) Remove countershaft RH bearing cup by using

special tools.

Special tool

(A): 09944–96011

(B): 09942–15511

5) Remove differential side RH bearing cup by using special tools.

Special tool

(A): 09944–96011

(B): 09942–15511

6) Remove torque converter case plugs (1).

I2RH0B510236-01

I2RH0B510237-01

I2RH0B510238-01

I2RH0B510239-01

I2RH0B510240-01

I2RH0B510241-01