engine and emission control system check SUZUKI SWIFT 2008 2.G Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 216 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-166 Engine General Information and Diagnosis:

DTC P2128: Throttle / Pedal Position Sensor / Switch “E” (Sub) Circuit High InputS7RS0B1104075

Wiring Diagram

Refer to “DTC P2122: Throttle / Pedal Position Sensor / Switch “D” (Main) Circuit Low Input”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

10 APP sensor check

1) Check APP sensor (sub) re ferring to “APP Sensor

Assembly Inspection in Section 1C”.

Is output voltage within specified value? Substitute a known-

good ECM and recheck.

Replace APP sensor.

Step Action Yes No

DTC detecting condition

Trouble area

Output voltage of APP sensor (s ub) is more than specified

value for 0.2 seconds continuously.

(1 driving detection logic) • APP sensor (sub) circuit

• APP sensor

•ECM

• Incorrect mounting of

accelerator APP sensor

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 APP sensor mounting check

1) Check that APP sensor has been mounted to vehicle

body properly (no pinched floor carpet, etc.).

Is it OK? Go to Step 3.

Reinstall APP sensor

properly referring to

“APP Sensor Assembly

Removal and

Installation in Section

1C”.

3 APP sensor (sub) and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “APP Sensor 2 Volt” displayed on scan tool.

Is displayed voltage 4.75 V or more? Go to Step 4.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Page 219 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-169

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Difference between the opening angle based on TP

sensor (main) and the opening angle based on TP sensor

(sub) is more than specif ication for specified time

continuously.

(1 driving detection logic) • Throttle position sensor (main) and (sub) circuit

• Electric throttle body

•ECM

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Throttle position sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check each voltage of “TP Sensor 1 Volt” and “TP Sensor 2 Volt” displayed on scan

tool when accelerator pedal is idle position and fully

depressed.

Is displayed each TP sensor value as described voltage in

“Scan Tool Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

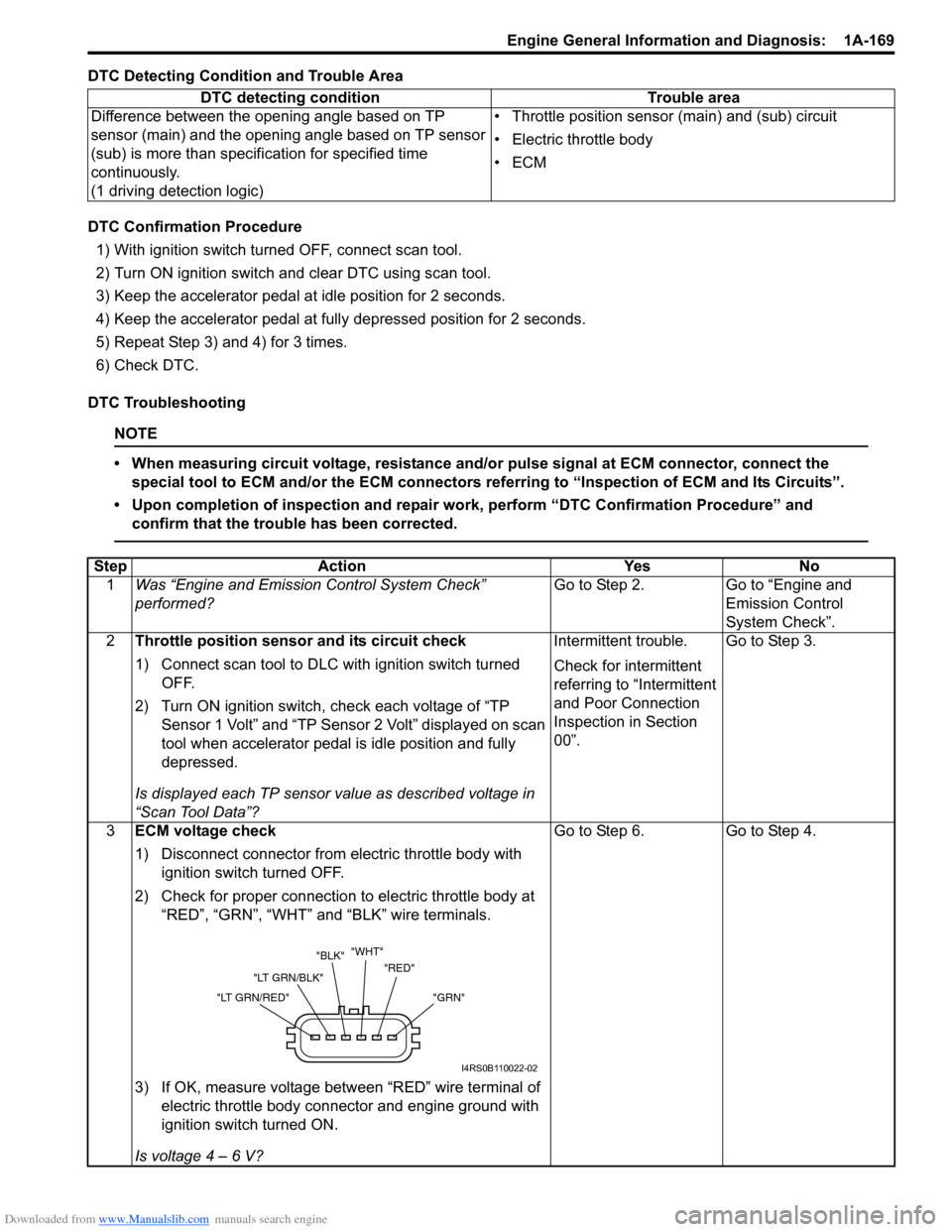

3 ECM voltage check

1) Disconnect connector from electric throttle body with

ignition switch turned OFF.

2) Check for proper connection to electric throttle body at “RED”, “GRN”, “WHT” and “BLK” wire terminals.

3) If OK, measure voltage between “RED” wire terminal of electric throttle body connector and engine ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 6.

Go to Step 4.

"GRN"

"RED"

"WHT"

"BLK"

"LT GRN/BLK"

"LT GRN/RED"

I4RS0B110022-02

Page 222 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-172 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 APP sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check each voltage of “APP Sensor 1 Volt” and “APP Sensor 2 Volt” displayed on scan tool when accelerator

pedal is idle position and fully depressed.

Is displayed each APP sensor value as described voltage in

“Scan Tool Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

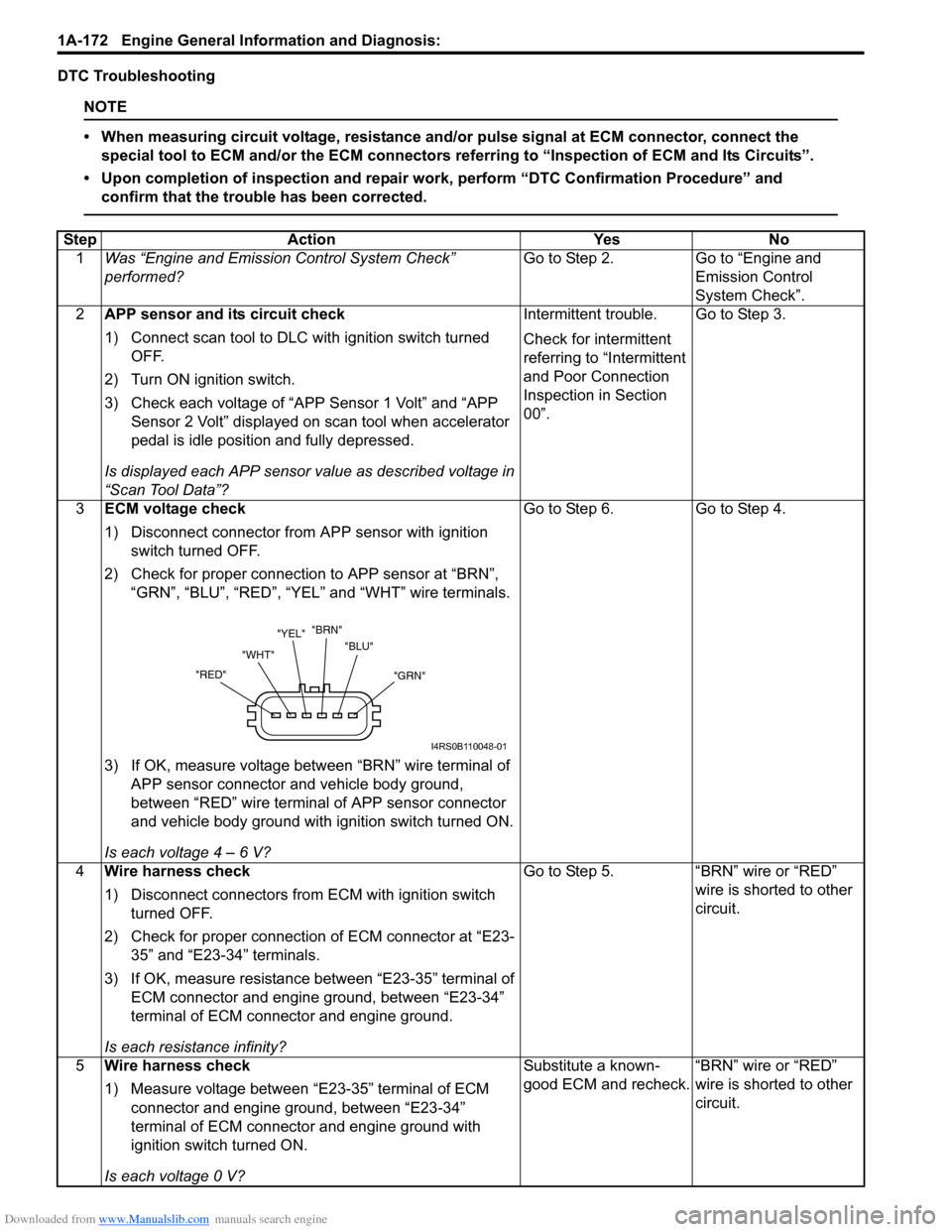

3 ECM voltage check

1) Disconnect connector from APP sensor with ignition

switch turned OFF.

2) Check for proper connection to APP sensor at “BRN”, “GRN”, “BLU”, “RED”, “YEL” and “WHT” wire terminals.

3) If OK, measure voltage between “BRN” wire terminal of APP sensor connector and vehicle body ground,

between “RED” wire terminal of APP sensor connector

and vehicle body ground with ignition switch turned ON.

Is each voltage 4 – 6 V? Go to Step 6.

Go to Step 4.

4 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E23- 35” and “E23-34” terminals.

3) If OK, measure resistance between “E23-35” terminal of ECM connector and engine ground, between “E23-34”

terminal of ECM connector and engine ground.

Is each resistance infinity? Go to Step 5.

“BRN” wire or “RED”

wire is shorted to other

circuit.

5 Wire harness check

1) Measure voltage between “E23-35” terminal of ECM

connector and engine ground, between “E23-34”

terminal of ECM connector and engine ground with

ignition switch turned ON.

Is each voltage 0 V? Substitute a known-

good ECM and recheck.

“BRN” wire or “RED”

wire is shorted to other

circuit.

"GRN"

"BLU"

"BRN"

"YEL"

"WHT"

"RED"

I4RS0B110048-01

Page 224 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-174 Engine General Information and Diagnosis:

DTC Confirmation Procedure

DTC P2227:

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool and warm up

engine to normal operating temperature.

3) Check DTC and pending DTC by using scan tool.

DTC P2228 / P2229: 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch, clear DTC by using scan tool and run engine for 1 min.

3) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Is DTC P2227 set? Go to Step 3.Substitute a known-

good ECM and recheck.

3 MAP sensor check

1) Check MAP sensor and its circuit referring to “DTC

P0107: Manifold Absolute Pressure / Barometric

Pressure Circuit Low Input” and/or “DTC P0108:

Manifold Absolute Pressure / Barometric Pressure

Circuit High Input”.

Is check result satisfactory? Substitute a known-

good ECM and recheck.

MAP sensor or its circuit

malfunction.

Page 266 of 1496

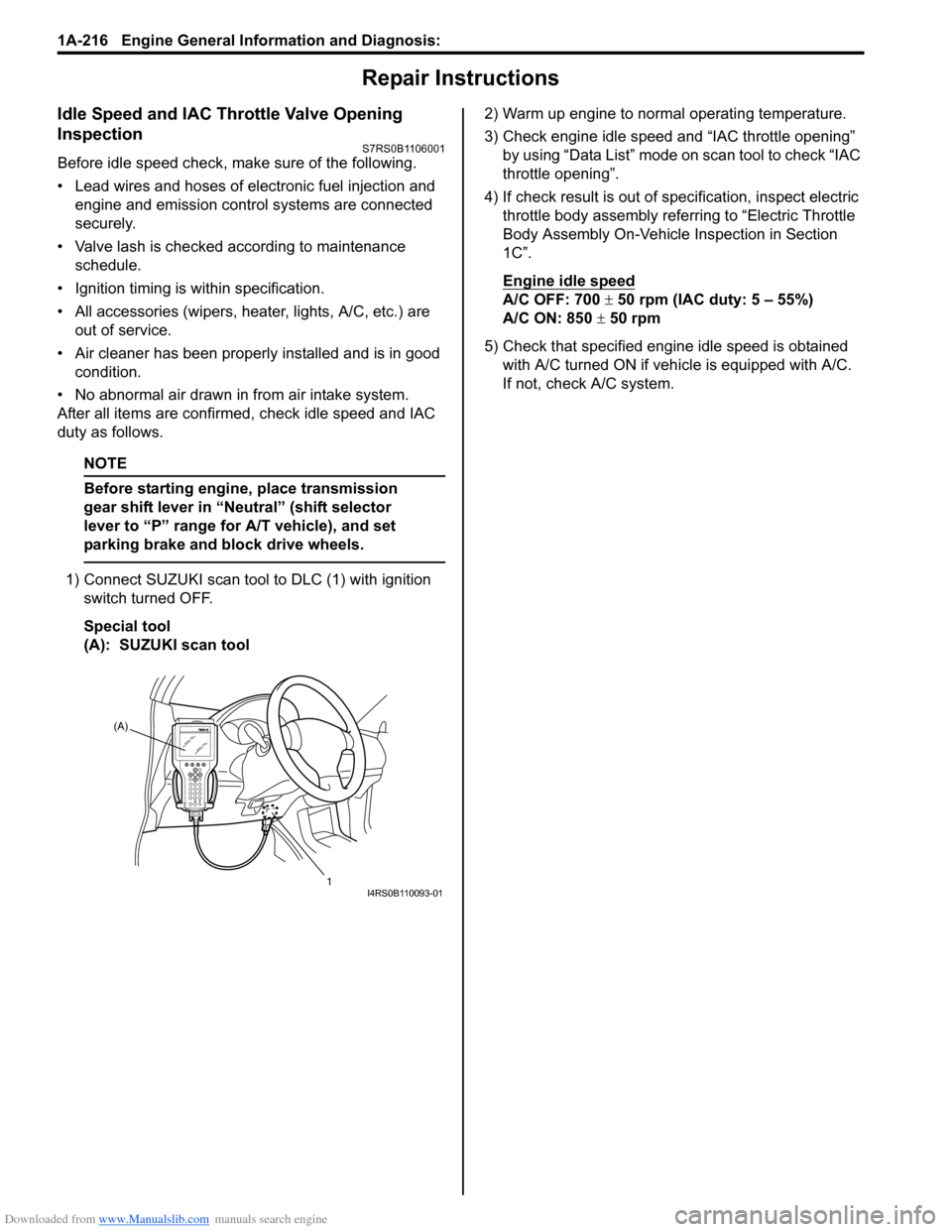

Downloaded from www.Manualslib.com manuals search engine 1A-216 Engine General Information and Diagnosis:

Repair Instructions

Idle Speed and IAC Throttle Valve Opening

Inspection

S7RS0B1106001

Before idle speed check, make sure of the following.

• Lead wires and hoses of electronic fuel injection and engine and emission control systems are connected

securely.

• Valve lash is checked according to maintenance schedule.

• Ignition timing is within specification.

• All accessories (wipers, heater, lights, A/C, etc.) are out of service.

• Air cleaner has been properly installed and is in good condition.

• No abnormal air drawn in from air intake system.

After all items are confirmed, check idle speed and IAC

duty as follows.

NOTE

Before starting engine, place transmission

gear shift lever in “Neutral” (shift selector

lever to “P” range for A/T vehicle), and set

parking brake and block drive wheels.

1) Connect SUZUKI scan tool to DLC (1) with ignition

switch turned OFF.

Special tool

(A): SUZUKI scan tool 2) Warm up engine to normal operating temperature.

3) Check engine idle speed and “IAC throttle opening”

by using “Data List” mode on scan tool to check “IAC

throttle opening”.

4) If check result is out of sp ecification, inspect electric

throttle body assembly referring to “Electric Throttle

Body Assembly On-Vehicle Inspection in Section

1C”.

Engine idle speed

A/C OFF: 700 ± 50 rpm (IAC duty: 5 – 55%)

A/C ON: 850 ± 50 rpm

5) Check that specified engine idle speed is obtained with A/C turned ON if vehi cle is equipped with A/C.

If not, check A/C system.

(A)

1

I4RS0B110093-01

Page 268 of 1496

Downloaded from www.Manualslib.com manuals search engine 1B-1 Aux. Emission Control Devices:

Engine

Aux. Emission Control Devices

Diagnostic Information and Procedures

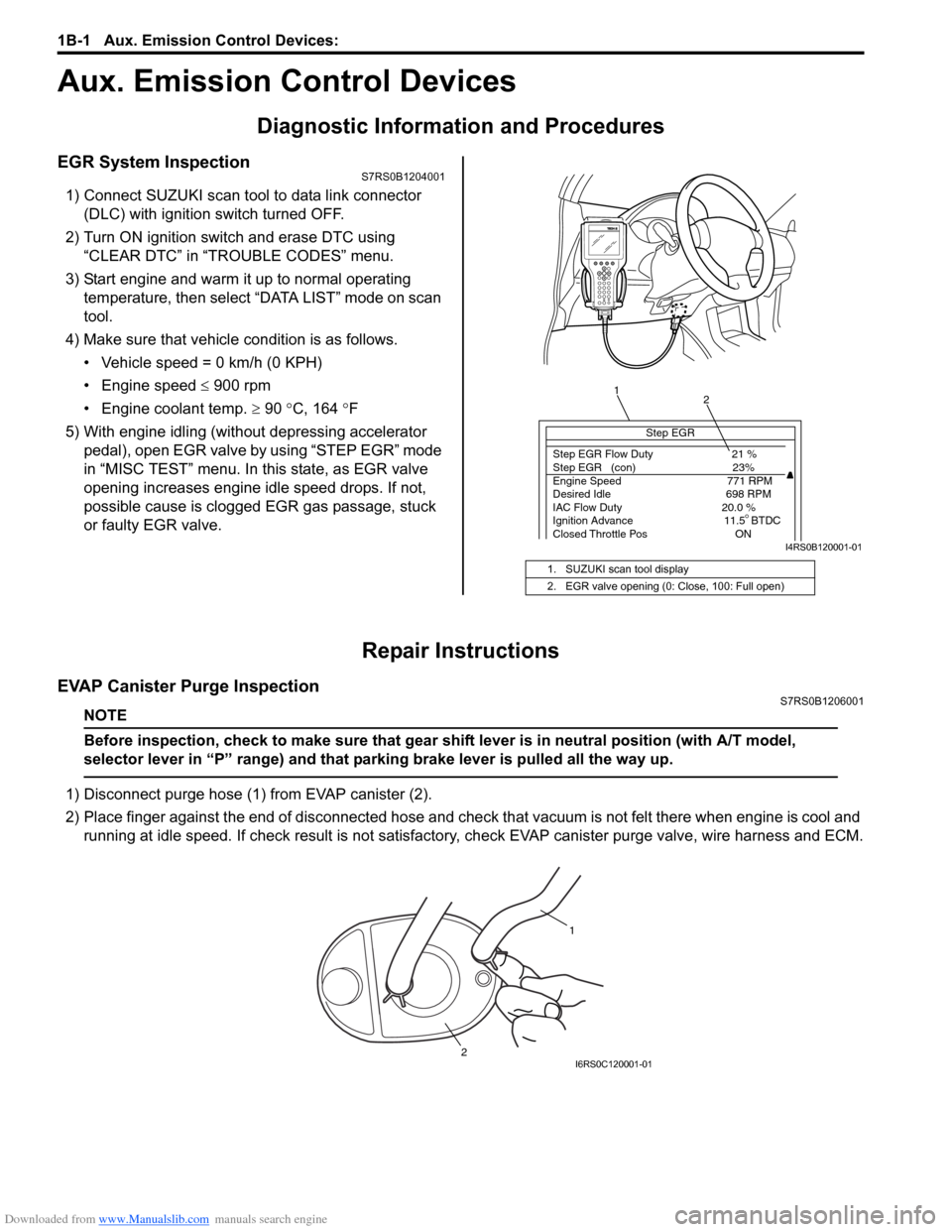

EGR System InspectionS7RS0B1204001

1) Connect SUZUKI scan tool to data link connector (DLC) with ignition switch turned OFF.

2) Turn ON ignition switch and erase DTC using “CLEAR DTC” in “TROUBLE CODES” menu.

3) Start engine and warm it up to normal operating temperature, then select “DATA LIST” mode on scan

tool.

4) Make sure that vehicle condition is as follows.

• Vehicle speed = 0 km/h (0 KPH)

• Engine speed ≤ 900 rpm

• Engine coolant temp. ≥ 90 °C, 164 °F

5) With engine idling (without depressing accelerator pedal), open EGR valve by using “STEP EGR” mode

in “MISC TEST” menu. In this state, as EGR valve

opening increases engine idle speed drops. If not,

possible cause is clogged EGR gas passage, stuck

or faulty EGR valve.

Repair Instructions

EVAP Canister Purge InspectionS7RS0B1206001

NOTE

Before inspection, check to make sure that gear shift lever is in neutral position (with A/T model,

selector lever in “P” range) and that parking brake lever is pulled all the way up.

1) Disconnect purge hose (1) from EVAP canister (2).

2) Place finger against the end of disconne cted hose and check that vacuum is not felt there when engine is cool and

running at idle speed. If check result is not satisfacto ry, check EVAP canister purge valve, wire harness and ECM.

1. SUZUKI scan tool display

2. EGR valve opening (0: Close, 100: Full open)

Step EGR

Step EGR Flow Duty 21 %

Step EGR (con) 23%

Engine Speed 771 RPM

Desired Idle 698 RPM

IAC Flow Duty 20.0 %

Ignition Advance 11.5 BTDC

Closed Throttle Pos ON

1 2

I4RS0B120001-01

1

2

I6RS0C120001-01

Page 396 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-4 Ignition System:

Diagnostic Information and Procedures

Ignition System Symptom DiagnosisS7RS0B1804001

Reference Waveform of Ignition SystemS7RS0B1804002

Refer to “Reference waveform No.5”, “Reference waveform No.6” and “Reference waveform No.7” under “Inspection

of ECM and Its Circuits in Section 1A” for waveform of Ignition trigger signal.

Ignition System CheckS7RS0B1804003

Condition Possible cause Correction / Reference Item

Engine cranks, but will

not start or hard to start

(No spark) Blown fuse for ignition coil

Replace.

Loose connection or disconnection of

lead wire or high-tension cord(s) Connect securely.

Faulty high-tension cord(s) Replace.

Faulty spark plug(s) Replace.

Faulty ignition coil Replace ignition coil assembly.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty ECM Replace.

Poor fuel economy or

engine performance Incorrect ignition timing

Check related sensors and CKP sensor plate.

Faulty spark plug(s) or high-tension

cord(s) Adjust, clean or replace.

Faulty ignition coil assembly Replace.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty knock sensor Replace.

Faulty ECM Replace.

StepAction YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check in

Section 1A”.

2 Ignition spark test

1) Check all spark plugs for condition and type referring to

“Spark Plug Inspection”.

2) If OK, perform ignition spark test referring to “Ignition Spar k Tes t”.

Is spark emitted from all spark plugs? Go to Step 13. Go to Step 3.

3 DTC check

1) Perform DTC check referring to “DTC Check in Section

1A”.

Is DTC stored in ECM? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Electrical connection check

1) Check ignition coil assemblies and high-tension cords

for electrical connection.

Are they connected securely? Go to Step 5.

Connect securely.

5 High-tension cords check

1) Check high-tension cord for resistance referring to

“High-Tension Cord Inspection”.

Is check result satisfactory? Go to Step 6.

Replace high-tension

cord(s).

Page 424 of 1496

Downloaded from www.Manualslib.com manuals search engine 1K-1 Exhaust System:

Engine

Exhaust System

General Description

Exhaust System DescriptionS7RS0B1B01001

The exhaust system consists of an exhaust manifold, three-way catalytic converter (TWC) in catalyst case, exhaust

pipes, a muffler and seals, gasket and etc.

The three-way catalytic converter is an emission control device added to the exhaust system to lower the levels of

Hydrocarbon (HC), Carbon Monoxide (CO), and Oxides of Nitrogen (NOx) pollutants in the exhaust gas.

Diagnostic Information and Procedures

Exhaust System CheckS7RS0B1B04001

WARNING!

To avoid the danger of being burned, do not touch the exhaust system when the system is hot. Any

service on the exhaust system should be performed when the system is cool.

At every interval of periodic maintenance service, and when vehicle is raised for other service, check exhaust system

as follows:

• Check rubber mountings for damage, deterioration, and out of position.

• Check exhaust system for leakage, loose connection, dent and damage.

• If bolts or nuts are loosened, tighten them to specified torque referring to “Exhaust System Components”.

• Check nearby body areas damaged, missing, or mispositio ned part, open seam, hole connection or any other

defect which could permit exhaust fumes to seep into vehicle.

• Make sure that exhaust system components have enough clearance from underbody to avoid overheating and

possible damage to passenger compartment carpet.

• Any defect should be fixed at once.

IYSY011B0003-01

Page 1446 of 1496

Downloaded from www.Manualslib.com manuals search engine 10C-3 Immobilizer Control System:

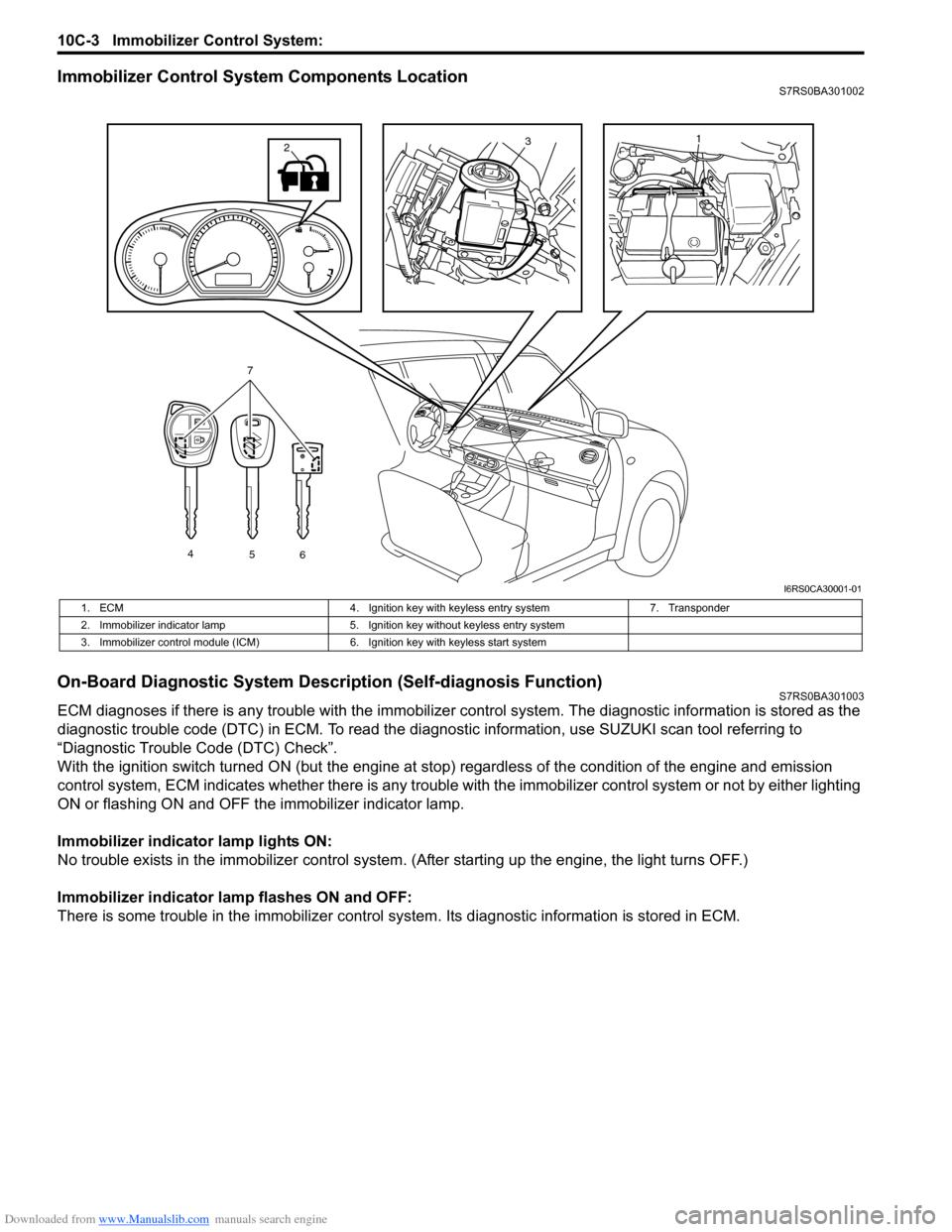

Immobilizer Control System Components LocationS7RS0BA301002

On-Board Diagnostic System Description (Self-diagnosis Function)S7RS0BA301003

ECM diagnoses if there is any trouble with the immobilizer control system. The diagnostic information is stored as the

diagnostic trouble code (DTC) in ECM. To read the di agnostic information, use SUZUKI scan tool referring to

“Diagnostic Trouble Code (DTC) Check”.

With the ignition switch turned ON (but the engine at stop) regardless of the condition of the engine and emission

control system, ECM indicates whether ther e is any trouble with the immobilizer control system or not by either lighting

ON or flashing ON and OFF t he immobilizer indicator lamp.

Immobilizer indicator lamp lights ON:

No trouble exists in the immobilizer control system. (After starting up the engine, the light turns OFF.)

Immobilizer indicator lamp flashes ON and OFF:

There is some trouble in the immo bilizer control system. Its diagnostic information is stored in ECM.

13

4

56

7

2

I6RS0CA30001-01

1. ECM 4. Ignition key with keyless entry system 7. Transponder

2. Immobilizer indicator lamp 5. Ignition key without keyless entry system

3. Immobilizer control module (ICM) 6. Ignition key with keyless start system

Page 1448 of 1496

Downloaded from www.Manualslib.com manuals search engine 10C-5 Immobilizer Control System:

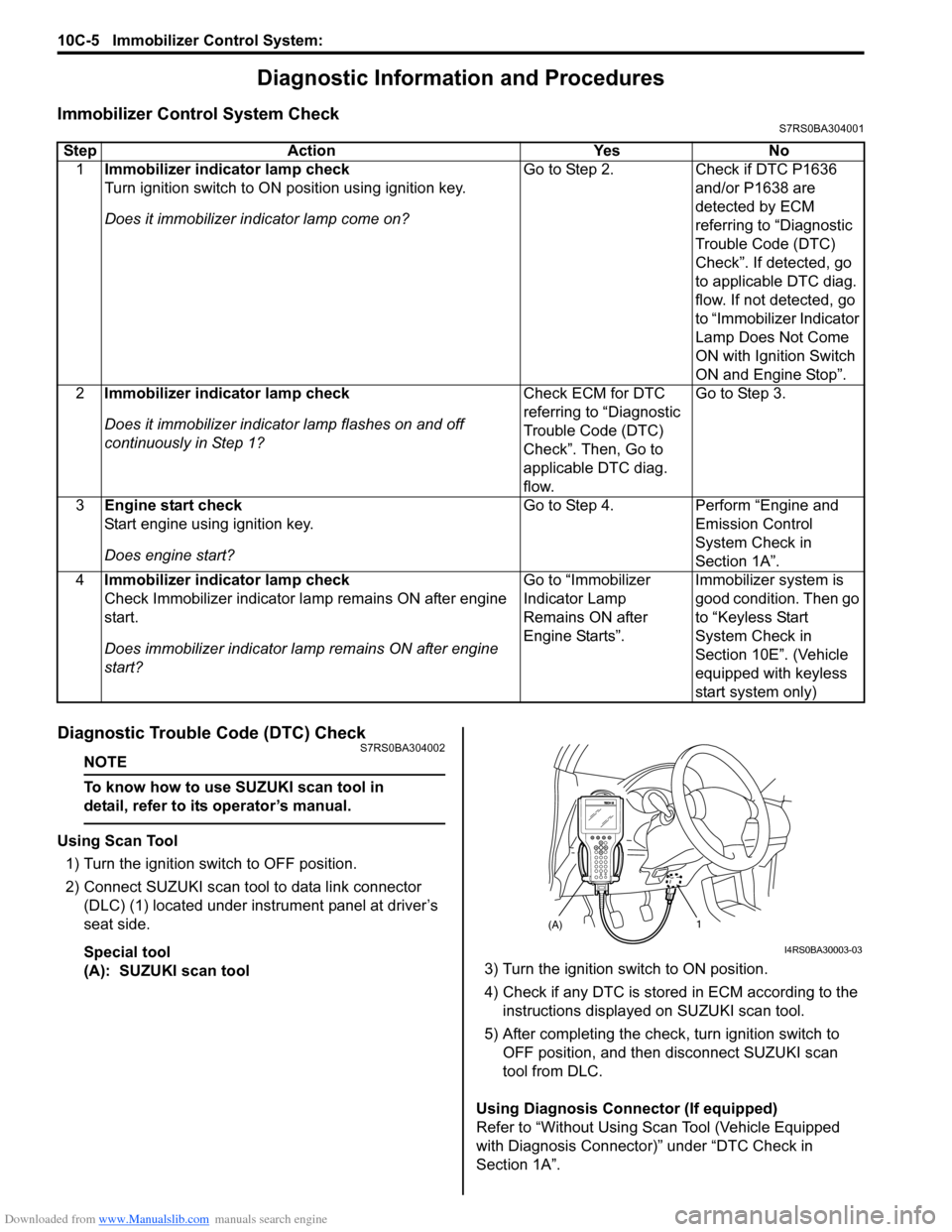

Diagnostic Information and Procedures

Immobilizer Control System CheckS7RS0BA304001

Diagnostic Trouble Code (DTC) CheckS7RS0BA304002

NOTE

To know how to use SUZUKI scan tool in

detail, refer to its operator’s manual.

Using Scan Tool

1) Turn the ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located under instrument panel at driver’s

seat side.

Special tool

(A): SUZUKI scan tool 3) Turn the ignition switch to ON position.

4) Check if any DTC is stored

in ECM according to the

instructions displayed on SUZUKI scan tool.

5) After completing the check, turn ignition switch to

OFF position, and then di sconnect SUZUKI scan

tool from DLC.

Using Diagnosis Connector (If equipped)

Refer to “Without Using Scan Tool (Vehicle Equipped

with Diagnosis Connector)” under “DTC Check in

Section 1A”.

Step Action Yes No

1 Immobilizer indicator lamp check

Turn ignition switch to ON position using ignition key.

Does it immobilizer in dicator lamp come on? Go to Step 2.

Check if DTC P1636

and/or P1638 are

detected by ECM

referring to “Diagnostic

Trouble Code (DTC)

Check”. If detected, go

to applicable DTC diag.

flow. If not detected, go

to “Immobilizer Indicator

Lamp Does Not Come

ON with Ignition Switch

ON and Engine Stop”.

2 Immobilizer indicator lamp check

Does it immobilizer indicato r lamp flashes on and off

continuously in Step 1? Check ECM for DTC

referring to “Diagnostic

Trouble Code (DTC)

Check”. Then, Go to

applicable DTC diag.

flow.Go to Step 3.

3 Engine start check

Start engine using ignition key.

Does engine start? Go to Step 4.

Perform “Engine and

Emission Control

System Check in

Section 1A”.

4 Immobilizer indicator lamp check

Check Immobilizer indicator la mp remains ON after engine

start.

Does immobilizer indicator la mp remains ON after engine

start? Go to “Immobilizer

Indicator Lamp

Remains ON after

Engine Starts”.

Immobilizer system is

good condition. Then go

to “Keyless Start

System Check in

Section 10E”. (Vehicle

equipped with keyless

start system only)

(A)1

I4RS0BA30003-03