pump SUZUKI SWIFT 2008 2.G Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 386 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-11 Fuel System:

Fuel Tank Inlet Valve Removal and InstallationS7RS0B1706011

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal1) Remove fuel filler cap.

2) Insert hose of a hand oper ated pump into fuel filler

hose (1) and drain fuel in space “A” as shown in

figure.

CAUTION!

Do not force pump hose into fuel tank, or

pump hose may damage to fuel tank inlet

valve (2).

3) Hoist vehicle, and remove clamp (2) and fuel filler

hose (1) from fuel tank. 4) Remove fuel tank inlet valve (1) using flat head rod

(2) or the like.

CAUTION!

Be careful not to damage fuel tank inlet valve

(1) with flat head rod (2) or the like.

Installation

1) Install fuel tank inlet valve (1) to fuel tank.

2) Install fuel filler hose (1) to fuel tank and secure it

with clamp (2).

For proper installation, refer to “Fuel Hose

Disconnecting and Reconnecting”.

3) Lower vehicle and install fuel filler cap.

IYSQ01170010-01

1

2

I4RS0A170007-01

I6RS0C170007-01

I2RH0B170018-01

1

2

I4RS0A170007-01

Page 387 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-12

Fuel Tank Inlet Valve InspectionS7RS0B1706012

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

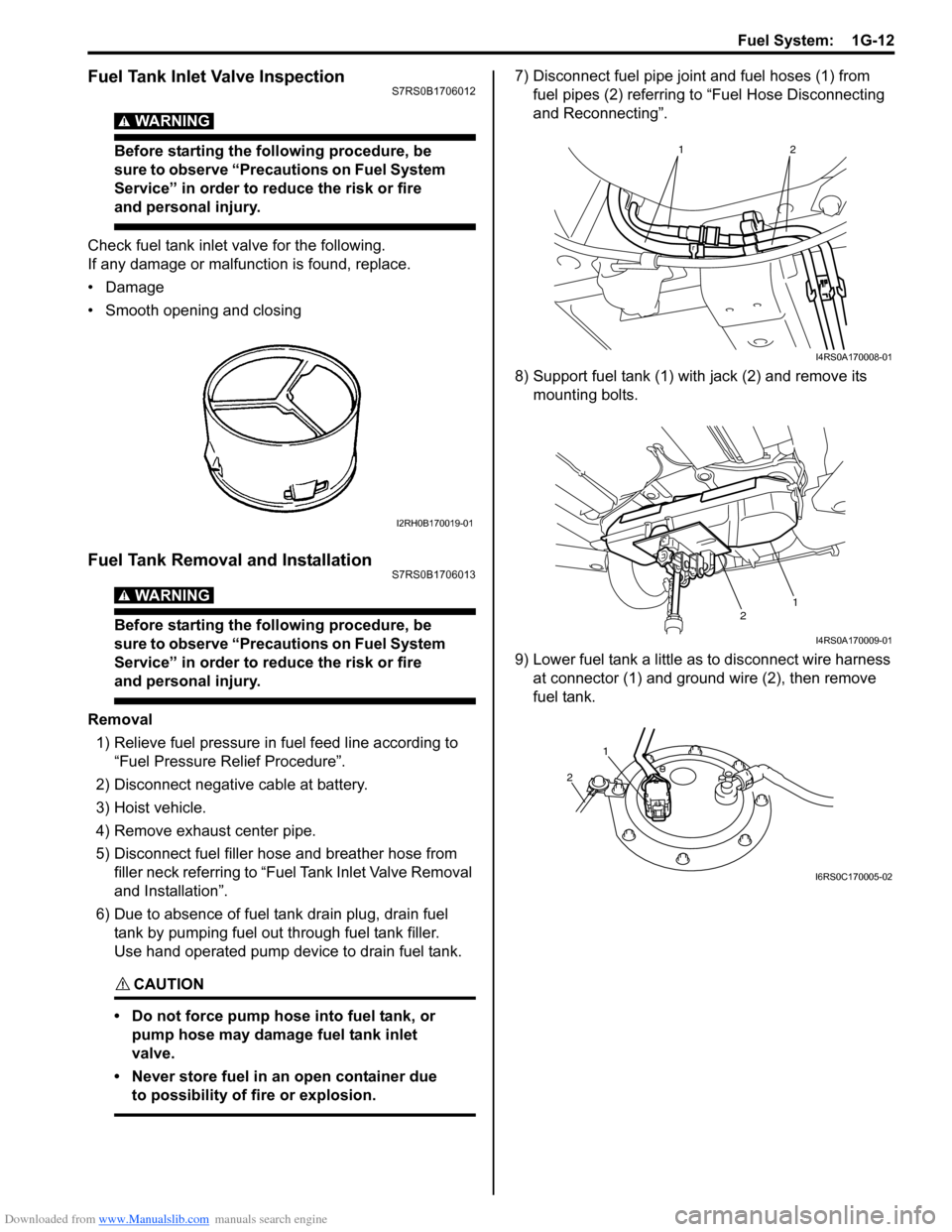

Check fuel tank inlet valve for the following.

If any damage or malfunction is found, replace.

•Damage

• Smooth opening and closing

Fuel Tank Removal and InstallationS7RS0B1706013

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal1) Relieve fuel pressure in fuel feed line according to

“Fuel Pressure Relief Procedure”.

2) Disconnect negative cable at battery.

3) Hoist vehicle.

4) Remove exhaust center pipe.

5) Disconnect fuel filler hose and breather hose from

filler neck referring to “Fue l Tank Inlet Valve Removal

and Installation”.

6) Due to absence of fuel tank drain plug, drain fuel tank by pumping fuel out through fuel tank filler.

Use hand operated pump device to drain fuel tank.

CAUTION!

• Do not force pump hose into fuel tank, or pump hose may damage fuel tank inlet

valve.

• Never store fuel in an open container due to possibility of fire or explosion.

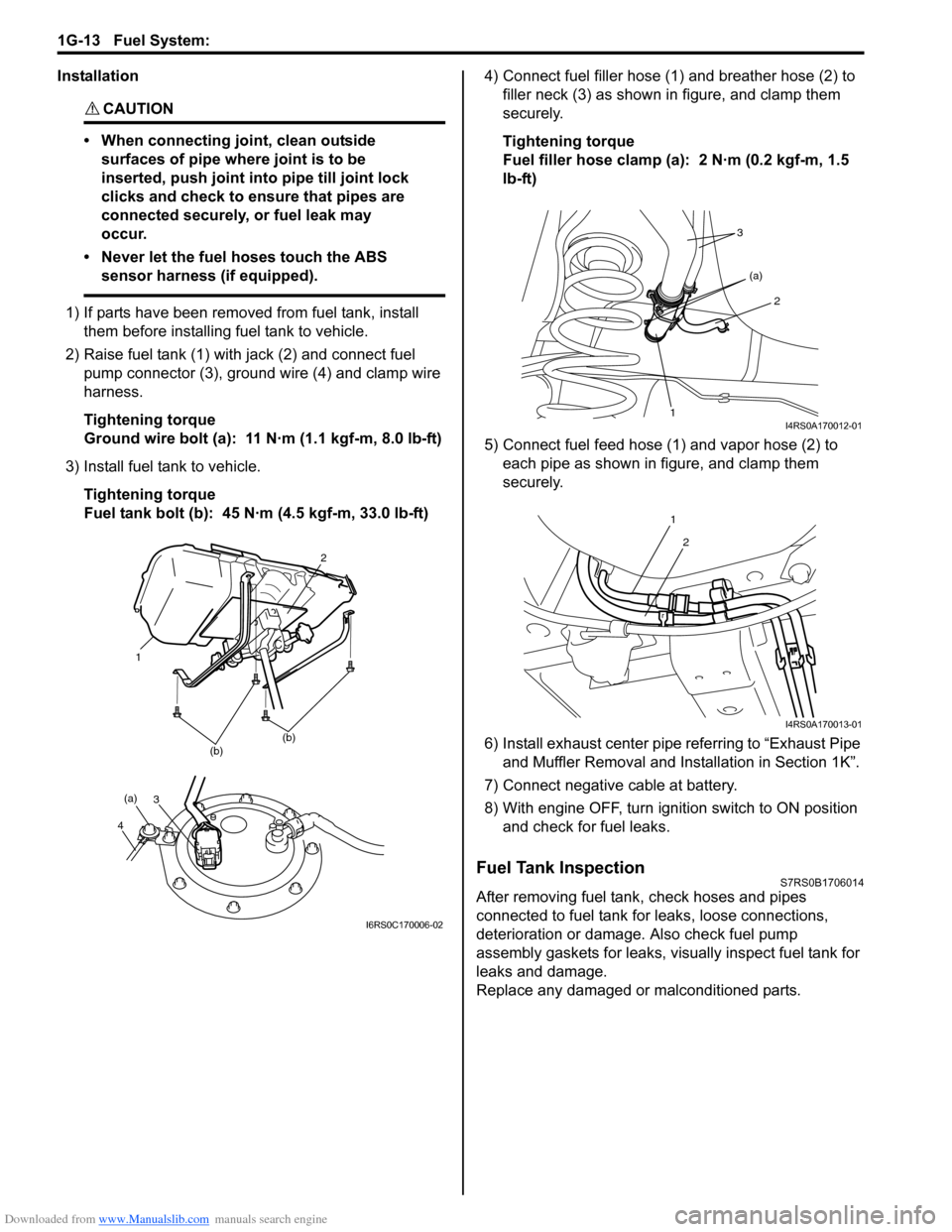

7) Disconnect fuel pipe joint and fuel hoses (1) from fuel pipes (2) referring to “Fuel Hose Disconnecting

and Reconnecting”.

8) Support fuel tank (1) with jack (2) and remove its mounting bolts.

9) Lower fuel tank a little as to disconnect wire harness at connector (1) and ground wire (2), then remove

fuel tank.

I2RH0B170019-01

12

I4RS0A170008-01

12

I4RS0A170009-01

1

2

I6RS0C170005-02

Page 388 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-13 Fuel System:

Installation

CAUTION!

• When connecting joint, clean outside surfaces of pipe where joint is to be

inserted, push joint into pipe till joint lock

clicks and check to ensure that pipes are

connected securely, or fuel leak may

occur.

• Never let the fuel hoses touch the ABS sensor harness (if equipped).

1) If parts have been removed from fuel tank, install them before installing fuel tank to vehicle.

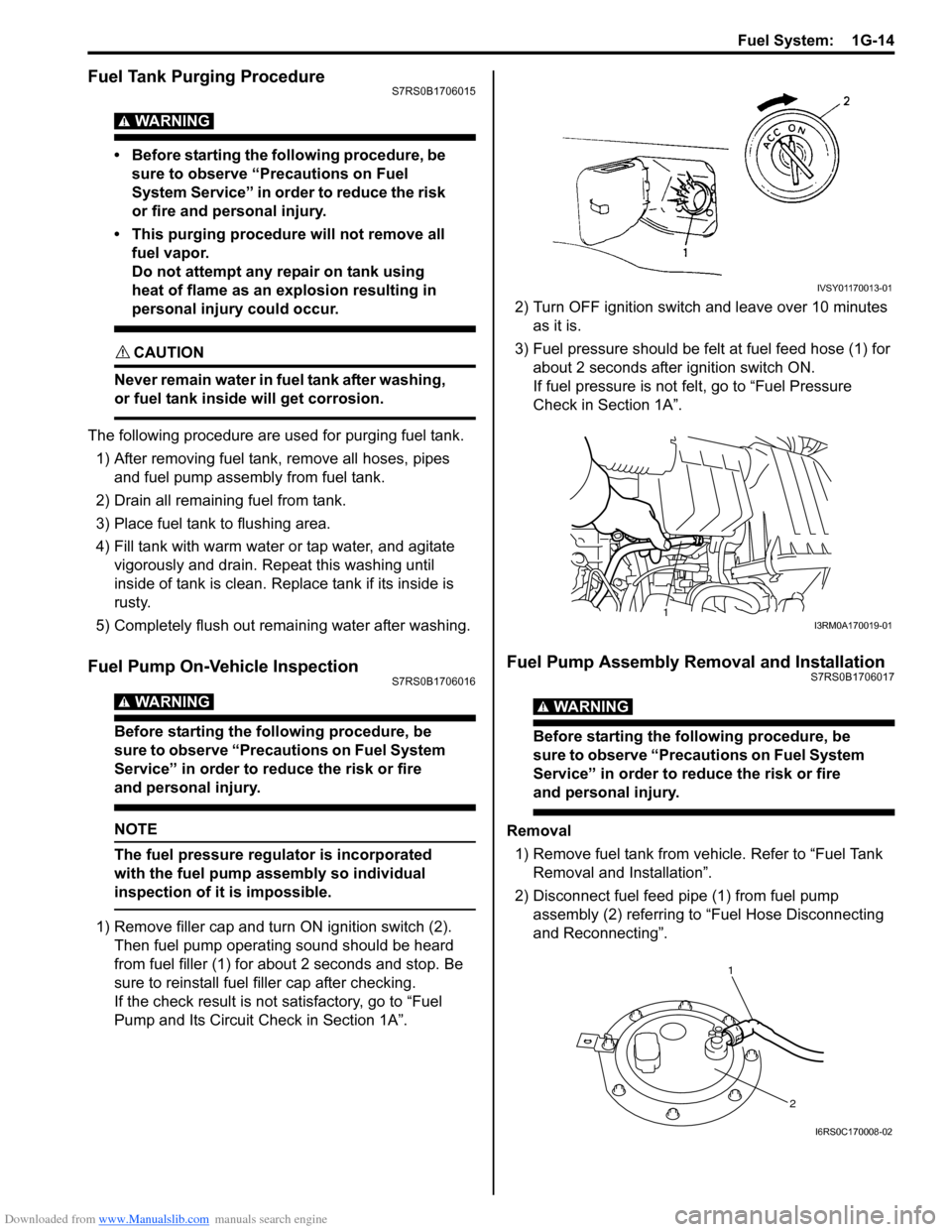

2) Raise fuel tank (1) with jack (2) and connect fuel pump connector (3), ground wire (4) and clamp wire

harness.

Tightening torque

Ground wire bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Install fuel tank to vehicle. Tightening torque

Fuel tank bolt (b): 45 N·m (4.5 kgf-m, 33.0 lb-ft) 4) Connect fuel filler hose (1

) and breather hose (2) to

filler neck (3) as shown in figure, and clamp them

securely.

Tightening torque

Fuel filler hose clamp (a): 2 N·m (0.2 kgf-m, 1.5

lb-ft)

5) Connect fuel feed hose (1) and vapor hose (2) to each pipe as shown in figure, and clamp them

securely.

6) Install exhaust center pipe referring to “Exhaust Pipe and Muffler Removal and Installation in Section 1K”.

7) Connect negative cable at battery.

8) With engine OFF, turn ignition switch to ON position and check for fuel leaks.

Fuel Tank InspectionS7RS0B1706014

After removing fuel tank, check hoses and pipes

connected to fuel tank for leaks, loose connections,

deterioration or damage. Also check fuel pump

assembly gaskets for leaks, visually inspect fuel tank for

leaks and damage.

Replace any damaged or malconditioned parts.

(b)(b)

1

2

3

4

(a)

I6RS0C170006-02

1

2

(a)

3

I4RS0A170012-01

1

2

I4RS0A170013-01

Page 389 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-14

Fuel Tank Purging ProcedureS7RS0B1706015

WARNING!

• Before starting the following procedure, be sure to observe “Precautions on Fuel

System Service” in order to reduce the risk

or fire and personal injury.

• This purging procedure will not remove all fuel vapor.

Do not attempt any repair on tank using

heat of flame as an explosion resulting in

personal injury could occur.

CAUTION!

Never remain water in fu el tank after washing,

or fuel tank inside will get corrosion.

The following procedure are used for purging fuel tank.

1) After removing fuel tank, remove all hoses, pipes and fuel pump assembly from fuel tank.

2) Drain all remaining fuel from tank.

3) Place fuel tank to flushing area.

4) Fill tank with warm water or tap water, and agitate

vigorously and drain. Repeat this washing until

inside of tank is clean. Replace tank if its inside is

rusty.

5) Completely flush out rema ining water after washing.

Fuel Pump On-Vehicle InspectionS7RS0B1706016

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

NOTE

The fuel pressure regulator is incorporated

with the fuel pump assembly so individual

inspection of it is impossible.

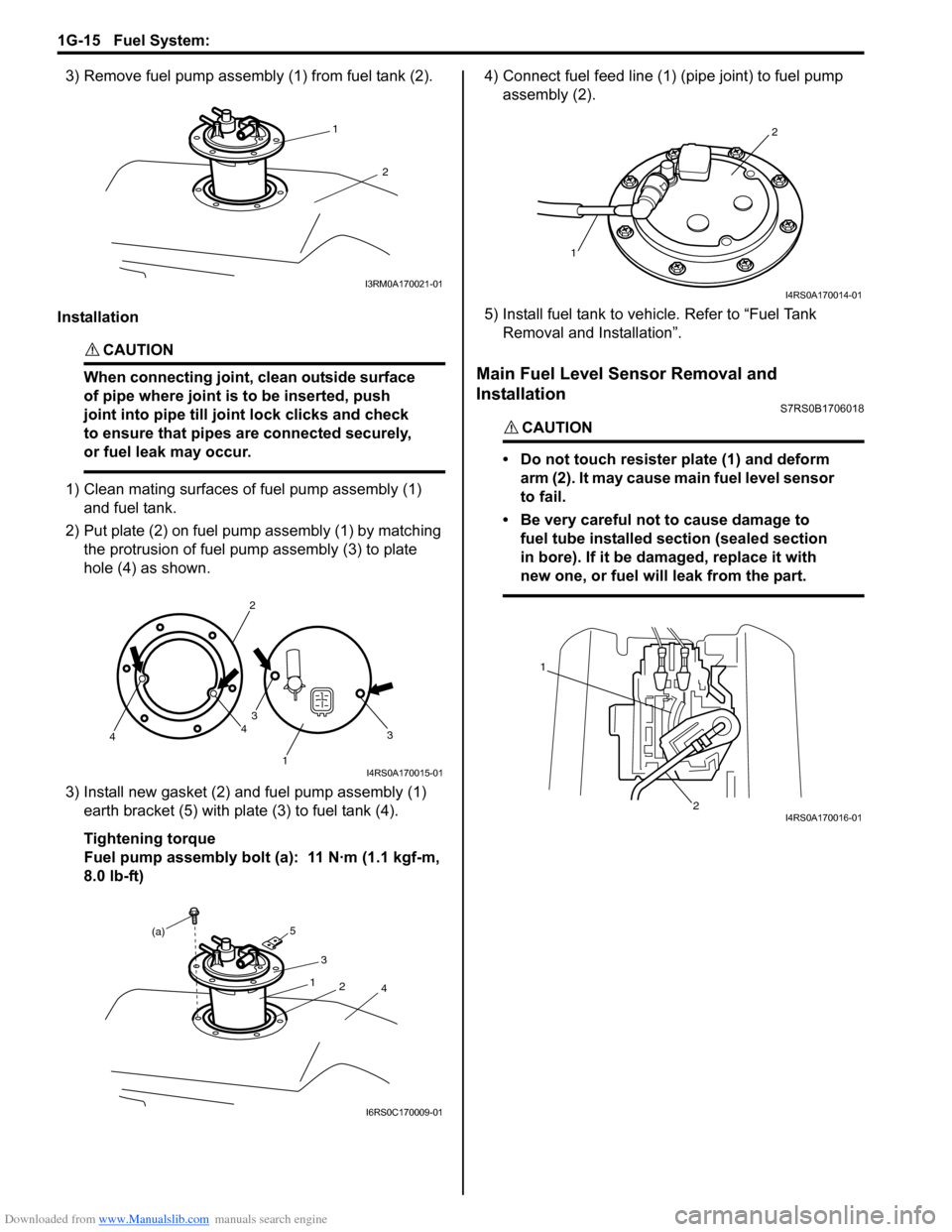

1) Remove filler cap and turn ON ignition switch (2).

Then fuel pump operating sound should be heard

from fuel filler (1) for about 2 seconds and stop. Be

sure to reinstall fuel filler cap after checking.

If the check result is not satisfactory, go to “Fuel

Pump and Its Circuit Check in Section 1A”. 2) Turn OFF ignition switch and leave over 10 minutes

as it is.

3) Fuel pressure should be felt at fuel feed hose (1) for about 2 seconds after ignition switch ON.

If fuel pressure is not felt, go to “Fuel Pressure

Check in Section 1A”.

Fuel Pump Assembly Removal and InstallationS7RS0B1706017

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal

1) Remove fuel tank from vehicle. Refer to “Fuel Tank Removal and Installation”.

2) Disconnect fuel feed pipe (1) from fuel pump assembly (2) referring to “Fuel Hose Disconnecting

and Reconnecting”.

IVSY01170013-01

1I3RM0A170019-01

1

2

I6RS0C170008-02

Page 390 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-15 Fuel System:

3) Remove fuel pump assembly (1) from fuel tank (2).

Installation

CAUTION!

When connecting joint, clean outside surface

of pipe where joint is to be inserted, push

joint into pipe till jo int lock clicks and check

to ensure that pipes are connected securely,

or fuel leak may occur.

1) Clean mating surfaces of fuel pump assembly (1) and fuel tank.

2) Put plate (2) on fuel pump assembly (1) by matching the protrusion of fuel pump assembly (3) to plate

hole (4) as shown.

3) Install new gasket (2) and fuel pump assembly (1) earth bracket (5) with plate (3) to fuel tank (4).

Tightening torque

Fuel pump assembly bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft) 4) Connect fuel feed line (1) (pipe joint) to fuel pump

assembly (2).

5) Install fuel tank to vehi cle. Refer to “Fuel Tank

Removal and Installation”.

Main Fuel Level Sensor Removal and

Installation

S7RS0B1706018

CAUTION!

• Do not touch resister plate (1) and deform arm (2). It may cause main fuel level sensor

to fail.

• Be very careful not to cause damage to fuel tube installed section (sealed section

in bore). If it be damaged, replace it with

new one, or fuel will leak from the part.

1

2

I3RM0A170021-01

3

1

3

2

44

I4RS0A170015-01

3

1 2

(a)

4

5

I6RS0C170009-01

2

1

I4RS0A170014-01

1

2I4RS0A170016-01

Page 391 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-16

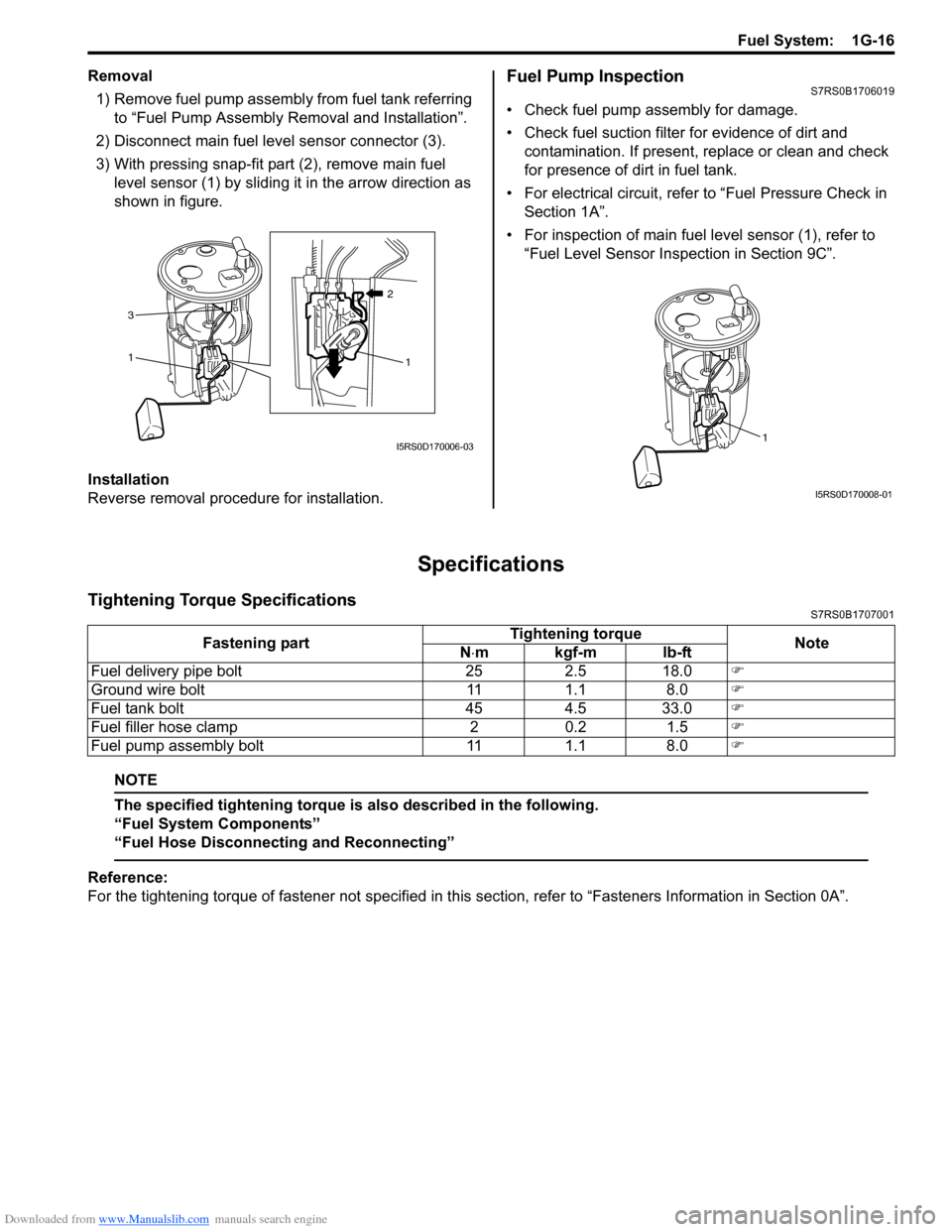

Removal1) Remove fuel pump assembly from fuel tank referring to “Fuel Pump Assembly Removal and Installation”.

2) Disconnect main fuel level sensor connector (3).

3) With pressing snap-fit part (2), remove main fuel level sensor (1) by sliding it in the arrow direction as

shown in figure.

Installation

Reverse removal procedure for installation.Fuel Pump InspectionS7RS0B1706019

• Check fuel pump assembly for damage.

• Check fuel suction filter for evidence of dirt and contamination. If present, replace or clean and check

for presence of dirt in fuel tank.

• For electrical circuit, refer to “Fuel Pressure Check in Section 1A”.

• For inspection of main fuel level sensor (1), refer to “Fuel Level Sensor Inspection in Section 9C”.

Specifications

Tightening Torque SpecificationsS7RS0B1707001

NOTE

The specified tightening torque is also described in the following.

“Fuel System Components”

“Fuel Hose Disconnecting and Reconnecting”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

1

21

3

I5RS0D170006-031

I5RS0D170008-01

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Fuel delivery pipe bolt 25 2.5 18.0 �)

Ground wire bolt 11 1.1 8.0 �)

Fuel tank bolt 45 4.5 33.0 �)

Fuel filler hose clamp 2 0.2 1.5 �)

Fuel pump assembly bolt 11 1.1 8.0 �)

Page 403 of 1496

Downloaded from www.Manualslib.com manuals search engine Starting System: 1I-2

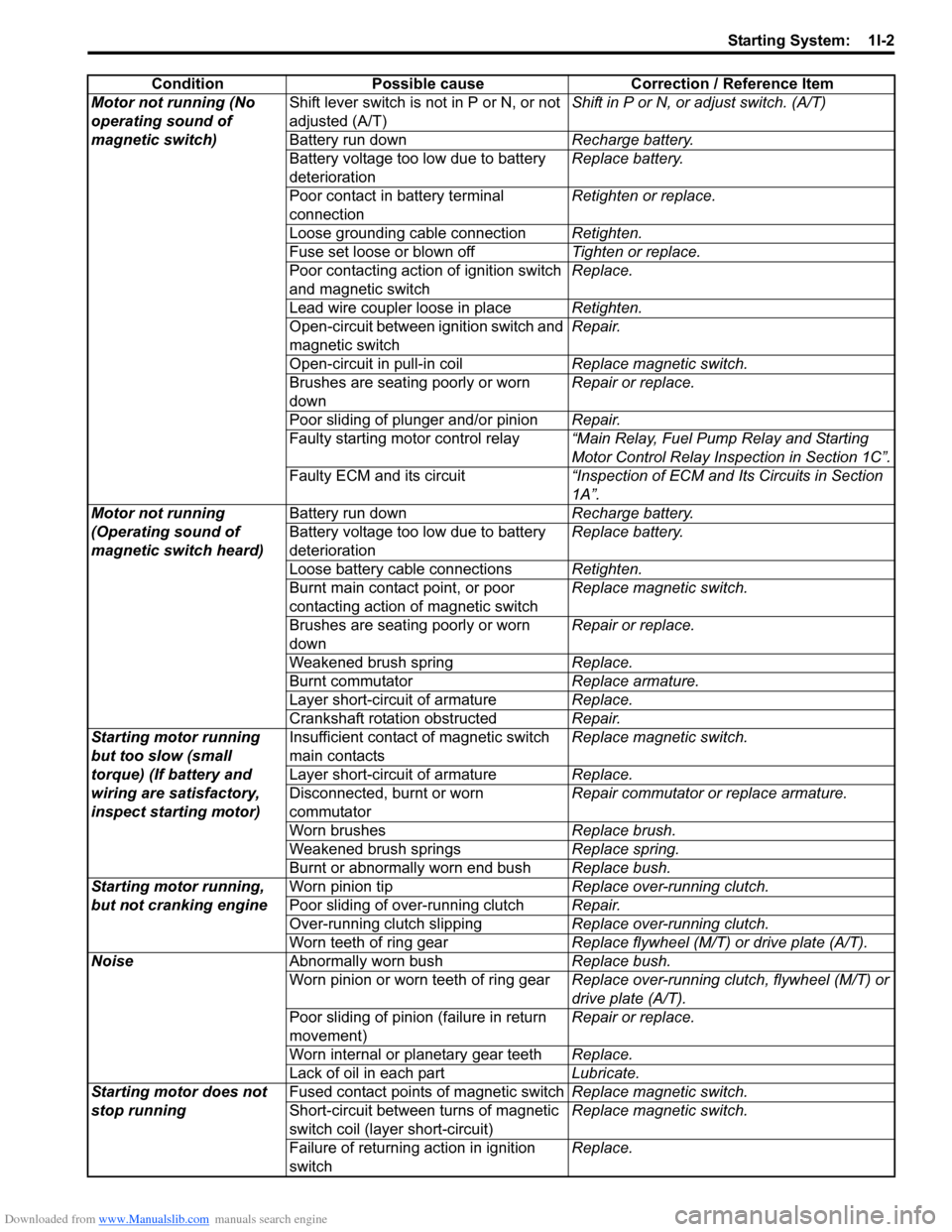

ConditionPossible cause Correction / Reference Item

Motor not running (No

operating sound of

magnetic switch) Shift lever switch is not in P or N, or not

adjusted (A/T)

Shift in P or N, or

adjust switch. (A/T)

Battery run down Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Poor contact in battery terminal

connection Retighten or replace.

Loose grounding cable connection Retighten.

Fuse set loose or blown off Tighten or replace.

Poor contacting action of ignition switch

and magnetic switch Replace.

Lead wire coupler loose in place Retighten.

Open-circuit between ignition switch and

magnetic switch Repair.

Open-circuit in pull-in coil Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Poor sliding of plunger and/or pinion Repair.

Faulty starting motor control relay “Main Relay, Fuel Pump Relay and Starting

Motor Control Relay Inspection in Section 1C”.

Faulty ECM and its circuit “Inspection of ECM and Its Circuits in Section

1A”.

Motor not running

(Operating sound of

magnetic switch heard) Battery run down

Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Loose battery cable connections Retighten.

Burnt main contact point, or poor

contacting action of magnetic switch Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Weakened brush spring Replace.

Burnt commutator Replace armature.

Layer short-circuit of armature Replace.

Crankshaft rotation obstructed Repair.

Starting motor running

but too slow (small

torque) (If battery and

wiring are satisfactory,

inspect starting motor) Insufficient contact

of magnetic switch

main contacts Replace magnetic switch.

Layer short-circuit of armature Replace.

Disconnected, burnt or worn

commutator Repair commutator or replace armature.

Worn brushes Replace brush.

Weakened brush springs Replace spring.

Burnt or abnormally worn end bush Replace bush.

Starting motor running,

but not cranking engine Worn pinion tip

Replace over-running clutch.

Poor sliding of over-running clutch Repair.

Over-running clutch slipping Replace over-running clutch.

Worn teeth of ring gear Replace flywheel (M/T) or drive plate (A/T).

Noise Abnormally worn bush Replace bush.

Worn pinion or worn teeth of ring gear Replace over-running clutch, flywheel (M/T) or

drive plate (A/T).

Poor sliding of pinion (failure in return

movement) Repair or replace.

Worn internal or planetary gear teeth Replace.

Lack of oil in each part Lubricate.

Starting motor does not

stop running Fused contact points of magnetic switch

Replace magnetic switch.

Short-circuit between turns of magnetic

switch coil (layer short-circuit) Replace magnetic switch.

Failure of returning action in ignition

switch Replace.

Page 417 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-7

With Charging Equipment

CAUTION!

When jump starting engine with charging

equipment, be sure equipment used is 12-

volt and negative ground. Do not use 24-volt

charging equipment. Using such equipment

can cause serious damage to electrical

system or electronic parts.

Battery Dismounting and RemountingS7RS0B1A06002

WARNING!

When handling battery, following safety

precautions should be followed:

• Hydrogen gas is produced by battery. A flame or spark near battery may cause the

gas to ignite.

• Battery fluid is highly acidic. Avoid spilling on clothing or other fabric. Any spilled

electrolyte should be flushed with large

quantity of water and cleaned immediately.

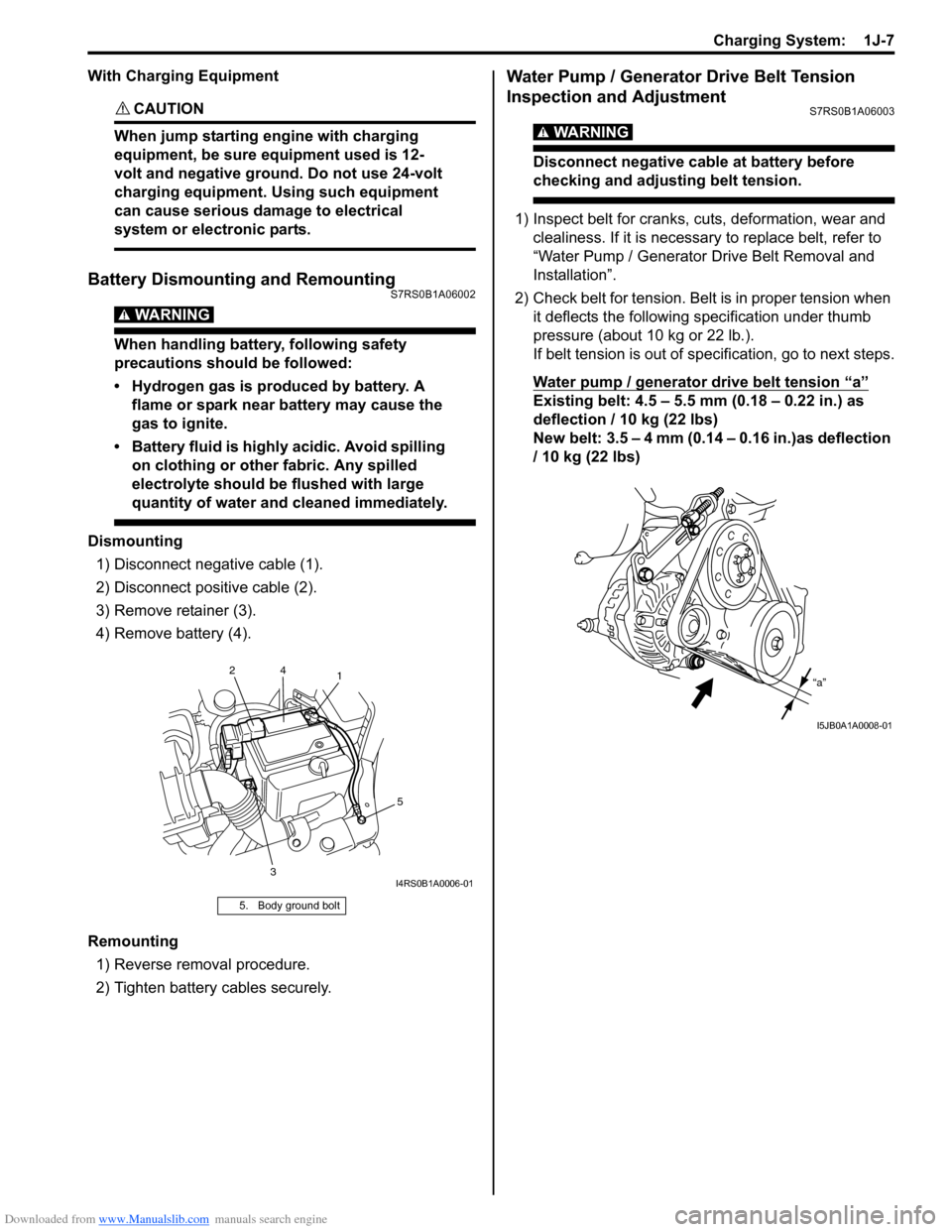

Dismounting

1) Disconnect negative cable (1).

2) Disconnect positive cable (2).

3) Remove retainer (3).

4) Remove battery (4).

Remounting 1) Reverse removal procedure.

2) Tighten battery cables securely.

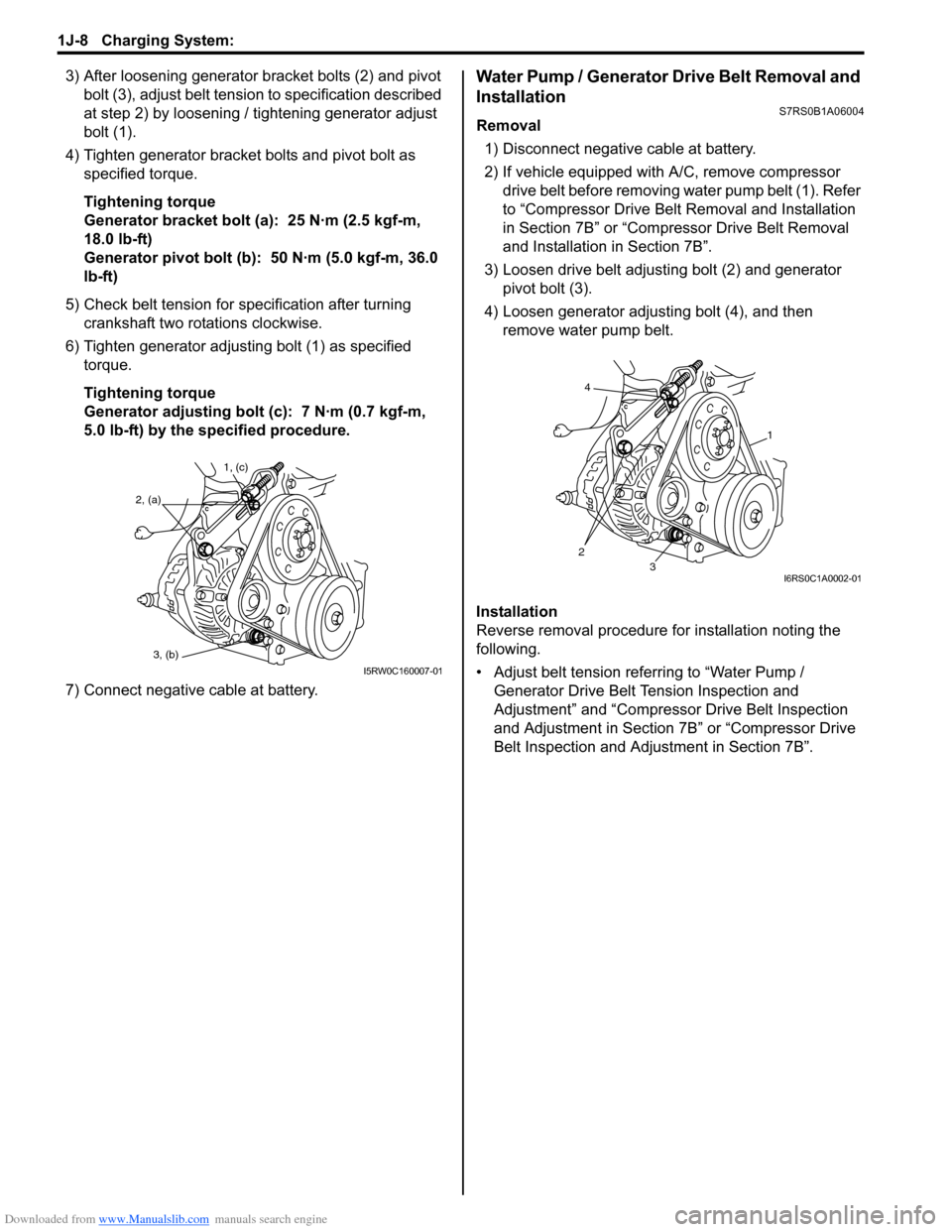

Water Pump / Generator Drive Belt Tension

Inspection and Adjustment

S7RS0B1A06003

WARNING!

Disconnect negative cable at battery before

checking and adjusting belt tension.

1) Inspect belt for cranks, cuts, deformation, wear and clealiness. If it is necessary to replace belt, refer to

“Water Pump / Generator Drive Belt Removal and

Installation”.

2) Check belt for tension. Belt is in proper tension when it deflects the following specification under thumb

pressure (about 10 kg or 22 lb.).

If belt tension is out of spec ification, go to next steps.

Water pump / generator drive belt tension

“a”

Existing belt: 4.5 – 5.5 mm (0.18 – 0.22 in.) as

deflection / 10 kg (22 lbs)

New belt: 3.5 – 4 mm (0.14 – 0.16 in.)as deflection

/ 10 kg (22 lbs)

5. Body ground bolt

1

3 5

2

4

I4RS0B1A0006-01

“a”

I5JB0A1A0008-01

Page 418 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-8 Charging System:

3) After loosening generator bracket bolts (2) and pivot bolt (3), adjust belt tensio n to specification described

at step 2) by loosening / tightening generator adjust

bolt (1).

4) Tighten generator bracket bolts and pivot bolt as specified torque.

Tightening torque

Generator bracket bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Generator pivot bolt (b): 50 N·m (5.0 kgf-m, 36.0

lb-ft)

5) Check belt tension for specification after turning crankshaft two rotations clockwise.

6) Tighten generator adjusting bolt (1) as specified torque.

Tightening torque

Generator adjusting bolt (c): 7 N·m (0.7 kgf-m,

5.0 lb-ft) by the specified procedure.

7) Connect negative cable at battery.Water Pump / Generator Drive Belt Removal and

Installation

S7RS0B1A06004

Removal 1) Disconnect negative cable at battery.

2) If vehicle equipped with A/C, remove compressor drive belt before removing water pump belt (1). Refer

to “Compressor Drive Belt Removal and Installation

in Section 7B” or “Compr essor Drive Belt Removal

and Installation in Section 7B”.

3) Loosen drive belt adjusting bolt (2) and generator pivot bolt (3).

4) Loosen generator adjusting bolt (4), and then remove water pump belt.

Installation

Reverse removal procedure for installation noting the

following.

• Adjust belt tension referring to “Water Pump / Generator Drive Belt Tension Inspection and

Adjustment” and “Compressor Drive Belt Inspection

and Adjustment in Section 7B” or “Compressor Drive

Belt Inspection and Adjustment in Section 7B”.

1, (c)

2, (a)

3, (b)

I5RW0C160007-01

4

23

1

I6RS0C1A0002-01

Page 419 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-9

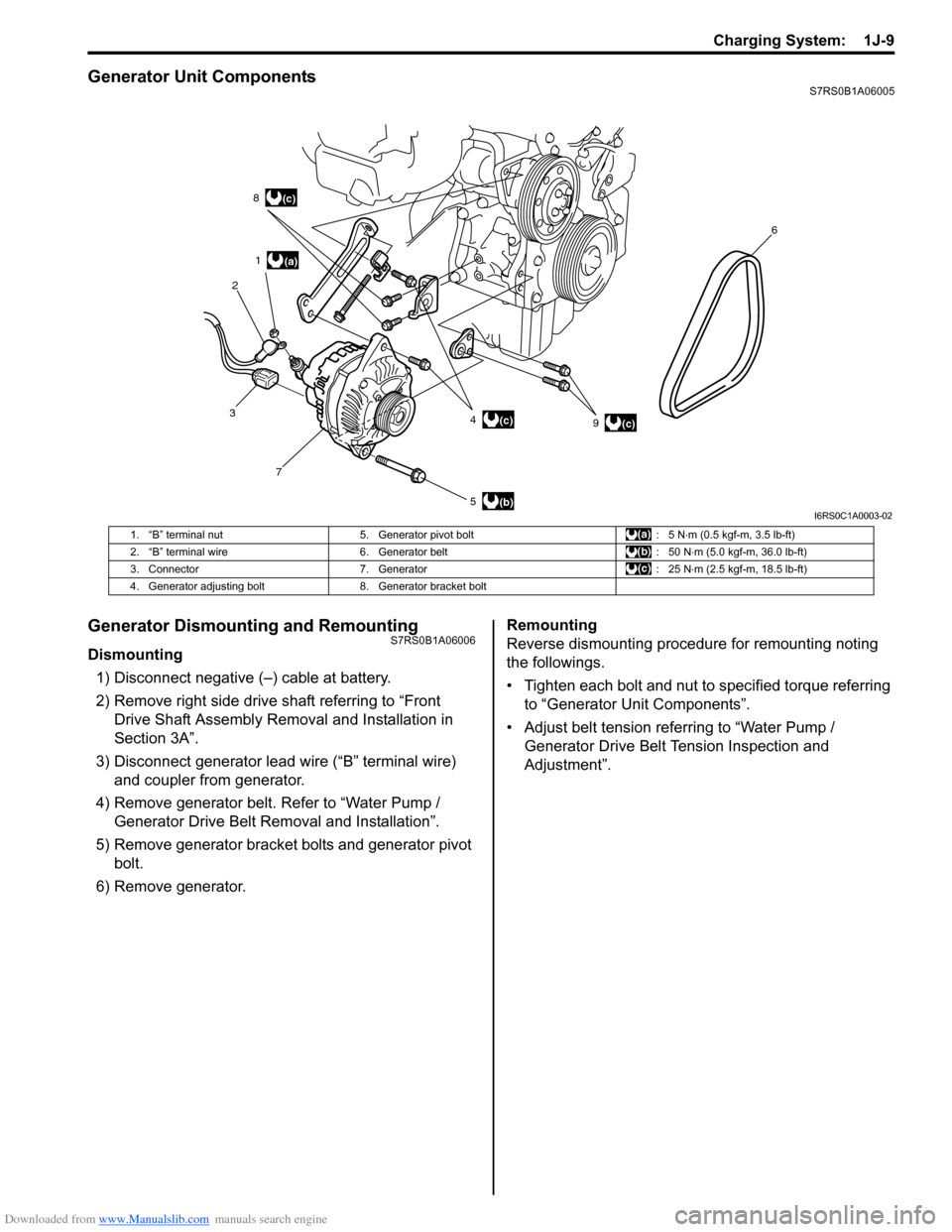

Generator Unit ComponentsS7RS0B1A06005

Generator Dismounting and RemountingS7RS0B1A06006

Dismounting1) Disconnect negative (–) cable at battery.

2) Remove right side drive shaft referring to “Front Drive Shaft Assembly Removal and Installation in

Section 3A”.

3) Disconnect generator lead wire (“B” terminal wire) and coupler from generator.

4) Remove generator belt. Refer to “Water Pump / Generator Drive Belt Re moval and Installation”.

5) Remove generator bracket bolts and generator pivot bolt.

6) Remove generator. Remounting

Reverse dismounting procedure for remounting noting

the followings.

• Tighten each bolt and nut to specified torque referring

to “Generator Unit Components”.

• Adjust belt tension referring to “Water Pump / Generator Drive Belt Tension Inspection and

Adjustment”.

(a)

(b)

(c)

1

2 8

3 7 5 49 6(c)

(c)

I6RS0C1A0003-02

1. “B” terminal nut

5. Generator pivot bolt : 5 N⋅m (0.5 kgf-m, 3.5 lb-ft)

2. “B” terminal wire 6. Generator belt : 50 N⋅m (5.0 kgf-m, 36.0 lb-ft)

3. Connector 7. Generator : 25 N⋅m (2.5 kgf-m, 18.5 lb-ft)

4. Generator adjusting bolt 8. Generator bracket bolt