500 SUZUKI SWIFT 2008 2.G Service Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 908 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-26 Power Assisted Steering System:

DTC C1121 / C1123 / C1124: VSS Circuit FailureS7RS0B6304017

DTC C1121: No Vehicle Speed Signal (60 Seconds or More)

DTC C1123: No Vehicle Speed Signal (30 Seconds or More)

DTC C1124: Vehicle Speed Performance (Impossible Deceleration)

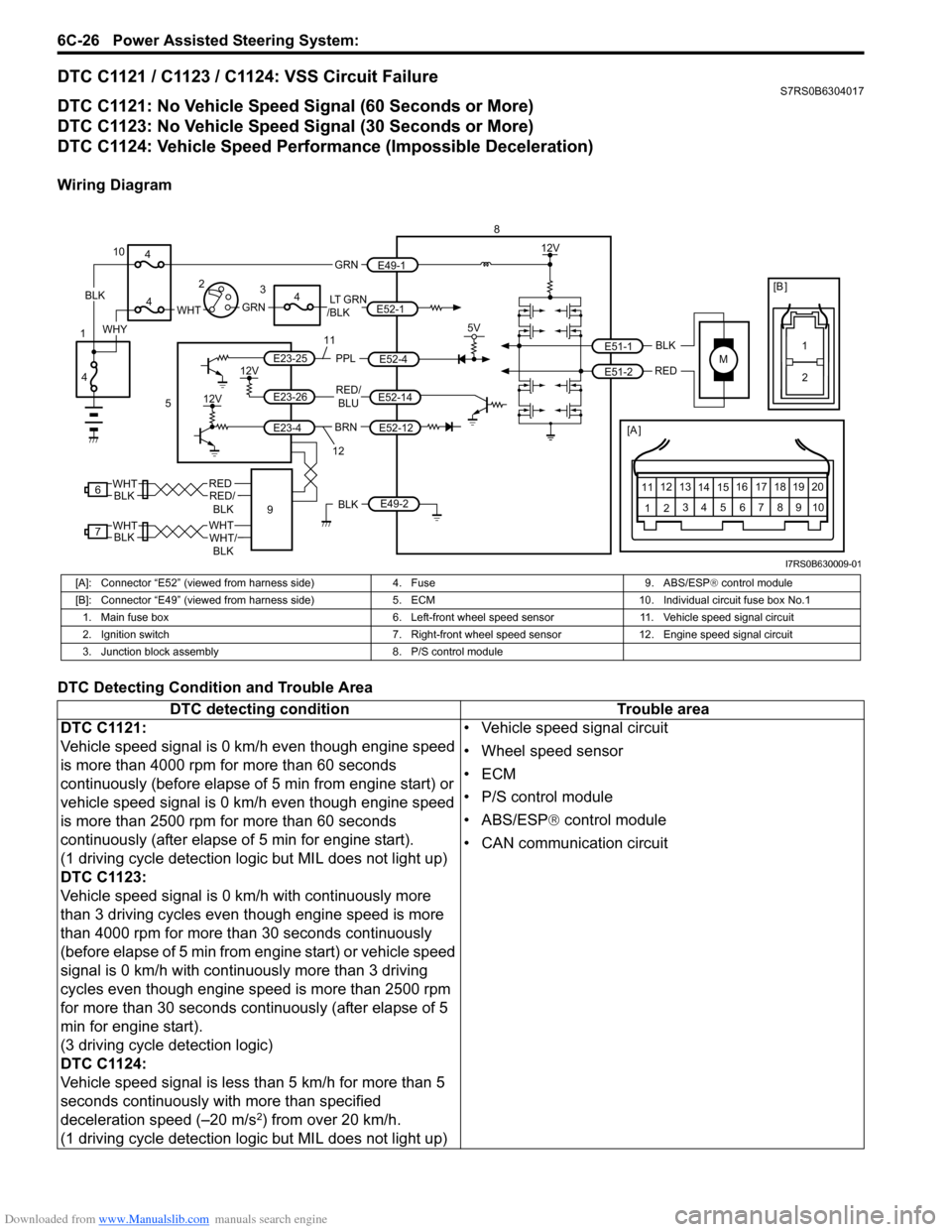

Wiring Diagram

DTC Detecting Condition and Trouble Area

M

BRNRED/

BLU

BLK

RED

E52-14

E52-12

E23-4

E23-26

E23-25 E51-1

E51-2

[A ]

12

3

4 5 67

89

11

10

12 13

141516

17 18 19 20

5V

PPL

E52-4

8

5

12V

E49-2BLK

12V

12V

6REDRED/ BLKWHT

7WHTWHT/BLKWHTBLK BLK

111

2

[B ]

9

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

10

3

4

4

4

4

1 2

12

I7RS0B630009-01

[A]: Connector “E52” (viewed from harness side)

4. Fuse9. ABS/ESP® control module

[B]: Connector “E49” (viewed from harness si de)5. ECM 10. Individual circuit fuse box No.1

1. Main fuse box 6. Left-front wheel speed sensor11. Vehicle speed signal circuit

2. Ignition switch 7. Right-front wheel speed sensor 12. Engine speed signal circuit

3. Junction block assembly 8. P/S control module

DTC detecting condition Trouble area

DTC C1121:

Vehicle speed signal is 0 km/h even though engine speed

is more than 4000 rpm for more than 60 seconds

continuously (before elapse of 5 min from engine start) or

vehicle speed signal is 0 km/h even though engine speed

is more than 2500 rpm for more than 60 seconds

continuously (after elapse of 5 min for engine start).

(1 driving cycle detection logic but MIL does not light up)

DTC C1123:

Vehicle speed signal is 0 km/h with continuously more

than 3 driving cycles even though engine speed is more

than 4000 rpm for more than 30 seconds continuously

(before elapse of 5 min from engine start) or vehicle speed

signal is 0 km/h with continuously more than 3 driving

cycles even though engine speed is more than 2500 rpm

for more than 30 seconds continuously (after elapse of 5

min for engine start).

(3 driving cycle detection logic)

DTC C1124:

Vehicle speed signal is less than 5 km/h for more than 5

seconds continuously with more than specified

deceleration speed (–20 m/s

2) from over 20 km/h.

(1 driving cycle detection logic but MIL does not light up) • Vehicle speed signal circuit

• Wheel speed sensor

•ECM

• P/S control module

• ABS/ESP®

control module

• CAN communication circuit

Page 959 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-11

5) Warm up engine to the normal operating temperature and keep it at the specified idle speed.

6) Turn A/C switch ON, set blower speed selector at maximum speed position, temperature selector at

maximum cold position, airflow selector at face

position, and air intake switch at recirculation

position. (Confirm that A/C compressor and

condenser fans are working.)

7) Wait for ten minutes to stabilize the A/C operation.

8) Open front windows, front doors and engine hood.

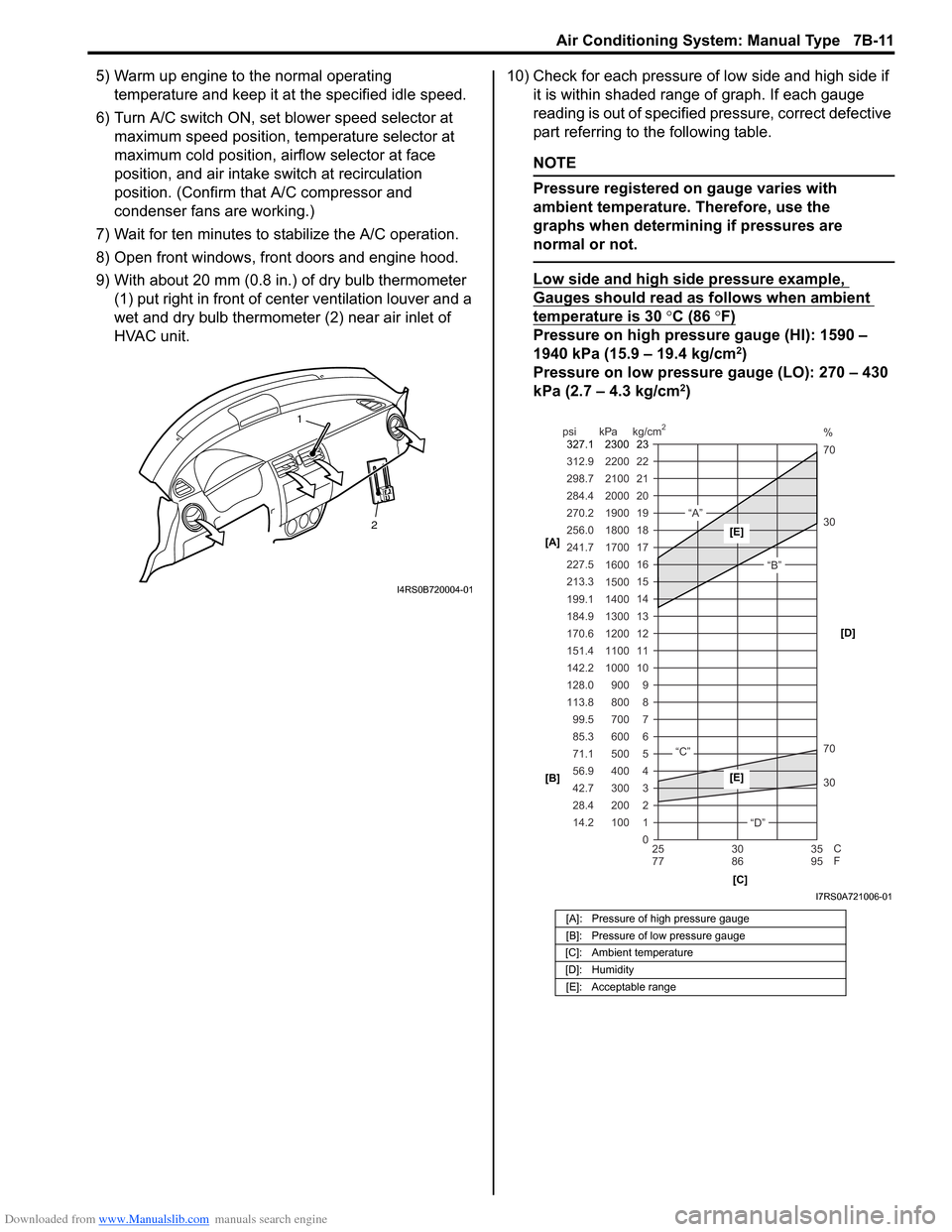

9) With about 20 mm (0.8 in.) of dry bulb thermometer

(1) put right in front of center ventilation louver and a

wet and dry bulb thermometer (2) near air inlet of

HVAC unit. 10) Check for each pressure of low side and high side if

it is within shaded range of graph. If each gauge

reading is out of specified pressure, correct defective

part referring to the following table.

NOTE

Pressure registered on gauge varies with

ambient temperature. Therefore, use the

graphs when determining if pressures are

normal or not.

Low side and high side pressure example,

Gauges should read as follows when ambient

temperature is 30 °C (86 °F)

Pressure on high pressure gauge (HI): 1590 –

1940 kPa (15.9 – 19.4 kg/cm2)

Pressure on low pressure gauge (LO): 270 – 430

kPa (2.7 – 4.3 kg/cm

2)

2

1

I4RS0B720004-01

[A]: Pressure of high pressure gauge

[B]: Pressure of low pressure gauge

[C]: Ambient temperature

[D]: Humidity [E]: Acceptable range

22

312.9 2200

0 1

2 3 30 70 30 70 %

4 5 6 7 8 9

10

11 12 13 14 15

16 17

18

19 21

298.7 2100

20

14.2 28.4 42.7 56.9 71.1 85.3 99.5

113.8 128.0 142.2

151.4

170.6

184.9 199.1

213.3 227.5

241.7

256.0

270.2

284.4

100 200 300 400 500 600 700 800 900

1000 1100 1200

1300

1400 1500 1600

1700 1800

1900

2000

25 30 35

77 86 95

psi kPa kg/cm

2

C

F

“A”

“B”

“C”

“D”

23

2300

327.1

[A]

[B]

[C][D][E]

[E]

I7RS0A721006-01

Page 967 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-19

Charge

CAUTION!

• Because the sight glass is not used for this A/C system, do not perform an additional

charge to the A/C system. To charge the

proper amount of refrigerant, recover and

evacuate the A/C system first. And then,

charge the proper amount of refrigerant

into the A/C system.

• Always charge refrigerant through low pressure side of A/C system after the initial

charge is performed from the high

pressure side with the engine stopped.

• Never charge refrigerant through high pressure side of A/C system with engine

running.

• Do not charge refrigerant while compressor is hot.

• When installing tap valve to refrigerant container to make a hole there through,

carefully follow dire ctions given by

manufacturer.

• A pressure gauge should always be used before and during refrigerant charge.

• The refrigerant container should be emptied of refrigerant when discarding it.

• The refrigerant container should not be heated up to 40 °C (104 °F) or over.

• Refrigerant container should not be reversed in direction during refrigerant

charge. Reversing in direction causes

liquid refrigerant to enter compressor,

causing troubles, such as compression of

liquid refrigerant and the like.

NOTE

The air conditioning system contains HFC-

134a (R-134a).

Described here is a method to charge the air

conditioning system with refrigerant from the

refrigerant service container.

When charging refrigerant recovered by

using the refrigerant and recycling

equipment (when recycling refrigerant),

follow the procedure described in the

equipment manufacturer’s instruction

manual.

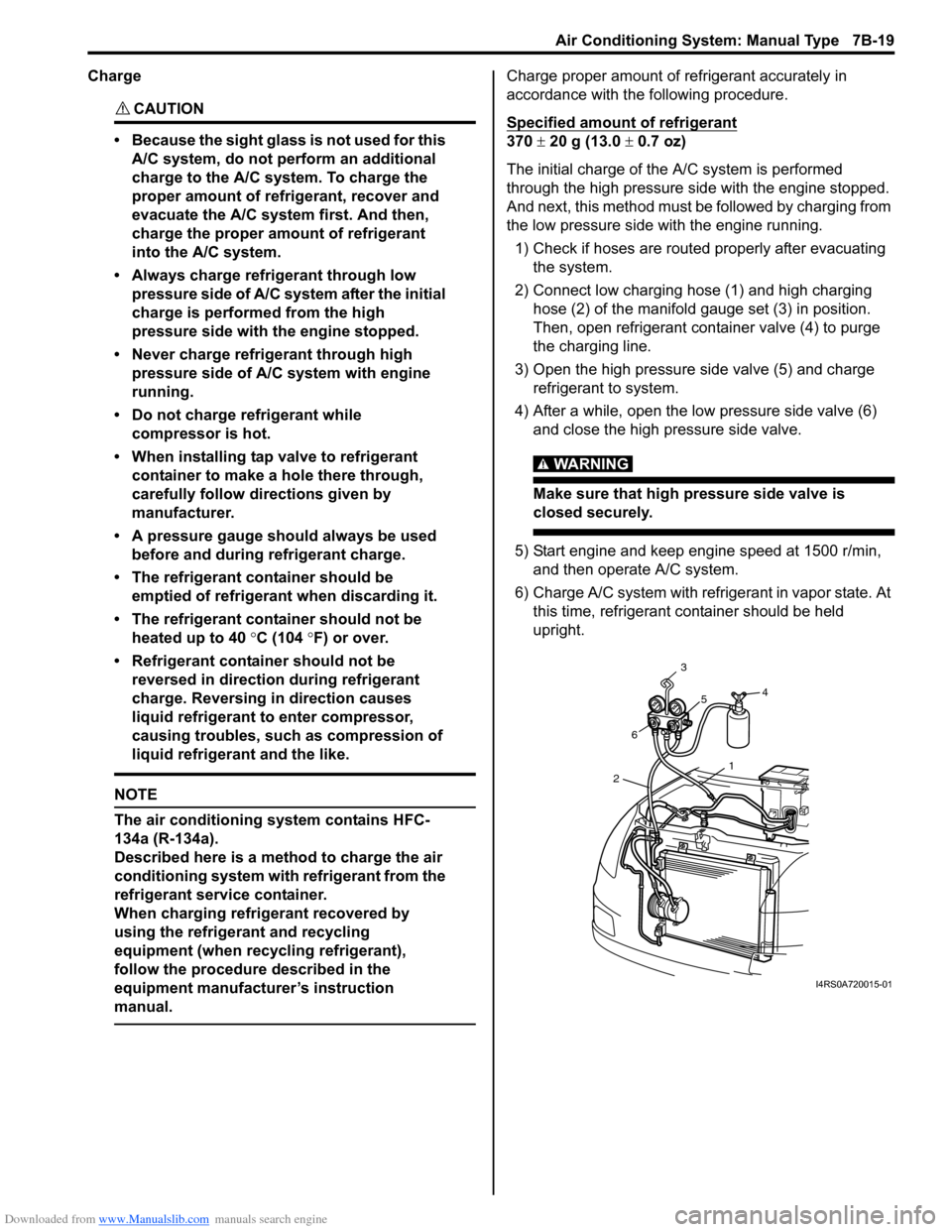

Charge proper amount of refrigerant accurately in

accordance with the following procedure.

Specified amount of refrigerant

370 ± 20 g (13.0 ± 0.7 oz)

The initial charge of the A/C system is performed

through the high pressure side with the engine stopped.

And next, this method must be followed by charging from

the low pressure side with the engine running.

1) Check if hoses are routed properly after evacuating the system.

2) Connect low charging hose (1) and high charging hose (2) of the manifold gauge set (3) in position.

Then, open refrigerant container valve (4) to purge

the charging line.

3) Open the high pressure side valve (5) and charge refrigerant to system.

4) After a while, open the low pressure side valve (6) and close the high pressure side valve.

WARNING!

Make sure that high pressure side valve is

closed securely.

5) Start engine and keep engine speed at 1500 r/min, and then operate A/C system.

6) Charge A/C system with refrigerant in vapor state. At this time, refrigerant container should be held

upright.

1

2 6 3

5 4

I4RS0A720015-01

Page 1013 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-65

DTC Troubleshooting

DTC B1553: CAN Communication Signal MalfunctionS7RS0B7224021

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1557: Vehicle Speed Sensor Signal MalfunctionS7RS0B7224022

DTC Detecting Condition and Trouble Area

DTC TroubleshootingStep Action Yes No

1 Serial communication signal data check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure”, “Vehicle Speed”, “Coolant Temp” and “Outside Air Temp” varies displayed on scan

tool.

Is displayed each va ries described varies in “Scan Tool

Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 2.

2 Serial communication signal check

1) Connect connectors to BCM and HVAC control module.

2) Using oscilloscope, check that serial communication

signal is outputted referring to “Reference waveform

No.8” of “Inspection of BCM and its Circuits in Section

10B”.

Is serial communication signal outputted at “G37-11”

terminal of BCM connector? HVAC control module

faulty.

BCM (included in

junction block

assembly) faulty.

DTC detecting condition

Trouble area

HVAC control module receives error code fr om BCM continuously.• CAN communication circuit

• BCM (included in junction block assembly)

•ECM

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM and BCM for DTC.

Is there DTC(s)? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives error code from BCM continuously. • VSS circuit

• VSS

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Is there DTC P0500? Go to “DTC P0480: Fan

1 (Radiator Cooling

Fan) Control Circuit in

Section 1A”.

Substitute a known-

good HVAC control

module and recheck.

Page 1019 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-71

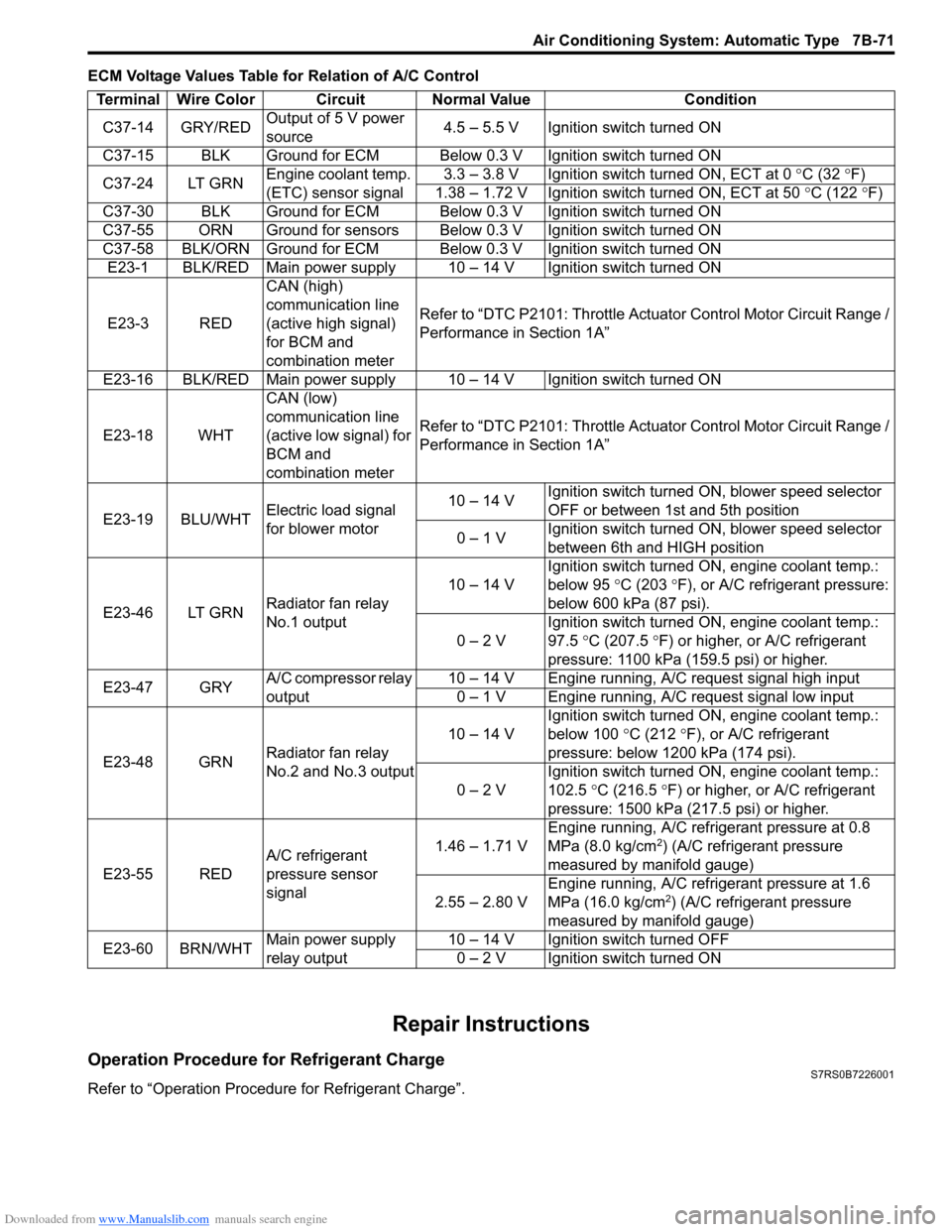

ECM Voltage Values Table for Relation of A/C Control

Repair Instructions

Operation Procedure for Refrigerant ChargeS7RS0B7226001

Refer to “Operation Procedure for Refrigerant Charge”.Terminal Wire Color Circuit Normal Value Condition

C37-14 GRY/RED Output of 5 V power

source 4.5 – 5.5 V Ignition switch turned ON

C37-15 BLK Ground for ECM Below 0.3 V Ignition switch turned ON

C37-24 LT GRN Engine coolant temp.

(ETC) sensor signal 3.3 – 3.8 V Ignition switch turned ON, ECT at 0

°C (32 ° F)

1.38 – 1.72 V Ignition switch turned ON, ECT at 50 °C (122 °F)

C37-30 BLK Ground for ECM Below 0.3 V Ignition switch turned ON

C37-55 ORN Ground for sensors Below 0.3 V Ignition switch turned ON

C37-58 BLK/ORN Ground for ECM Below 0.3 V Ignition switch turned ON E23-1 BLK/RED Main power supply 10 – 14 V Ignition switch turned ON

E23-3 RED CAN (high)

communication line

(active high signal)

for BCM and

combination meterRefer to “DTC P2101: Throttle Actu

ator Control Motor Circuit Range /

Performance in Section 1A”

E23-16 BLK/RED Main power supply 10 – 14 V Ignition switch turned ON

E23-18 WHT CAN (low)

communication line

(active low signal) for

BCM and

combination meterRefer to “DTC P2101: Throttle Actu

ator Control Motor Circuit Range /

Performance in Section 1A”

E23-19 BLU/WHT Electric load signal

for blower motor 10 – 14 V

Ignition switch turned ON, blower speed selector

OFF or between 1st and 5th position

0 – 1 V Ignition switch turned ON, blower speed selector

between 6th and HIGH position

E23-46 LT GRN Radiator fan relay

No.1 output 10 – 14 V

Ignition switch turned ON, engine coolant temp.:

below 95

°C (203 ° F), or A/C refrigerant pressure:

below 600 kPa (87 psi).

0 – 2 V Ignition switch turned ON, engine coolant temp.:

97.5

°C (207.5 °F) or higher, or A/C refrigerant

pressure: 1100 kPa (159.5 psi) or higher.

E23-47 GRY A/C compressor relay

output 10 – 14 V Engine running, A/C request signal high input

0 – 1 V Engine running, A/C request signal low input

E23-48 GRN Radiator fan relay

No.2 and No.3 output 10 – 14 V

Ignition switch turned ON, engine coolant temp.:

below 100

°C (212 °F), or A/C refrigerant

pressure: below 1200 kPa (174 psi).

0 – 2 V Ignition switch turned ON, engine coolant temp.:

102.5

°C (216.5 ° F) or higher, or A/C refrigerant

pressure: 1500 kPa (217.5 psi) or higher.

E23-55 RED A/C refrigerant

pressure sensor

signal 1.46 – 1.71 V

Engine running, A/C refrigerant pressure at 0.8

MPa (8.0 kg/cm

2) (A/C refrigerant pressure

measured by manifold gauge)

2.55 – 2.80 V Engine running, A/C refrigerant pressure at 1.6

MPa (16.0 kg/cm

2) (A/C refrigerant pressure

measured by manifold gauge)

E23-60 BRN/WHT Main power supply

relay output 10 – 14 V Ignition switch turned OFF

0 – 2 V Ignition switch turned ON

Page 1274 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-103 Wiring Systems:

List of Connector

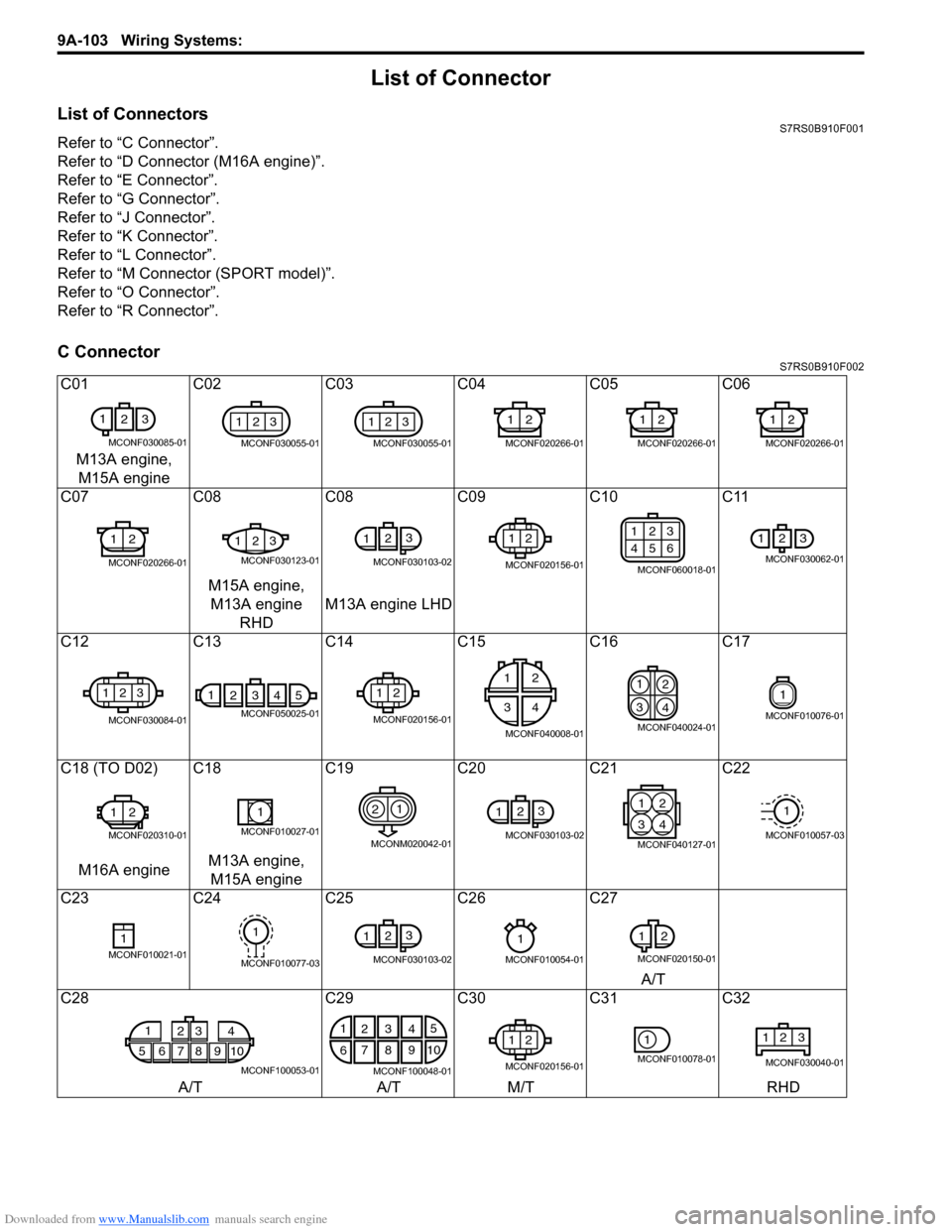

List of ConnectorsS7RS0B910F001

Refer to “C Connector”.

Refer to “D Connector (M16A engine)”.

Refer to “E Connector”.

Refer to “G Connector”.

Refer to “J Connector”.

Refer to “K Connector”.

Refer to “L Connector”.

Refer to “M Connector (SPORT model)”.

Refer to “O Connector”.

Refer to “R Connector”.

C ConnectorS7RS0B910F002

C01C02C03 C04 C05 C06

M13A engine, M15A engine

C07 C08C08 C09 C10 C11

M15A engine, M13A engine RHD M13A engine LHD

C12 C13C14 C15 C16 C17

C18 (TO D02) C18 C19C20C21C22

M16A engine M13A engine,

M15A engine

C23 C24C25 C26 C27

A/T

C28 C29C30C31C32

A/T A/TM/T RHD

1

23

MCONF030085-01

123

MCONF030055-01

123

MCONF030055-01

12

MCONF020266-01

12

MCONF020266-01

12

MCONF020266-01

12

MCONF020266-01

123

MCONF030123-01

123

MCONF030103-02

12

MCONF020156-01

123

456

MCONF060018-01

123

MCONF030062-01

123

MCONF030084-01

14325

MCONF050025-01

12

MCONF020156-01

12

34

MCONF040008-01

1

2

3 4

MCONF040024-01

1

MCONF010076-01

12

MCONF020310-01

1

MCONF010027-01

21

MCONM020042-01

12

3

MCONF030103-02

21

43

MCONF040127-01

1

MCONF010057-03

1MCONF010021-01

1

MCONF010077-03

123

MCONF030103-02

1

MCONF010054-01

1

2

MCONF020150-01

1

5678910 23 4

MCONF100053-01

1

2 5

6 7

103

84

9

MCONF100048-01

12

MCONF020156-01

1

MCONF010078-01

123

MCONF030040-01

Page 1276 of 1496

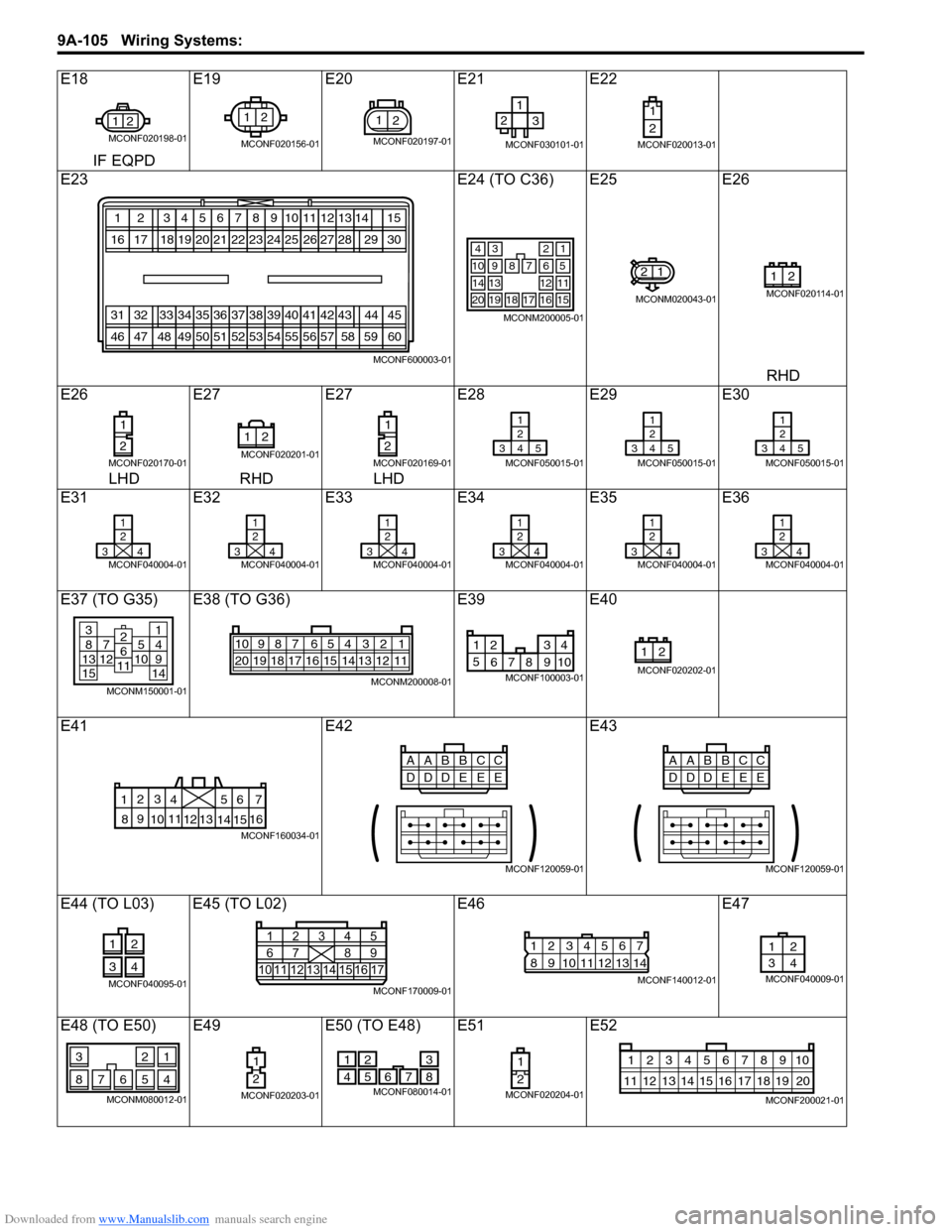

Downloaded from www.Manualslib.com manuals search engine 9A-105 Wiring Systems:

E18E19E20E21 E22

IF EQPD

E23 E24 (TO C36) E25E26

RHD

E26 E27E27E28 E29E30

LHD RHD LHD

E31 E32E33E34 E35E36

E37 (TO G35) E38 (TO G36) E39E40

E41 E42E43

E44 (TO L03) E45 (TO L02) E46E47

E48 (TO E50) E49 E50 (TO E48) E51E52

21

MCONF020198-01

12

MCONF020156-01

21

MCONF020197-01

12

3

MCONF030101-01

1

2

MCONF020013-01

123456

202116171819

78910

22232425

12

2726

13

28

313233343536

505146474849

37383940

52535455

11

41

56

42

57

43

58

1415

2930

44

60

45

59

MCONF600003-01

34

7

2

68910

121314

1716

1

5

11

15181920

MCONM200005-01

21

MCONM020043-01

21

MCONF020114-01

1

2

MCONF020170-01

21

MCONF020201-01

1

2

MCONF020169-01

1

2

345

MCONF050015-01

1

2

345

MCONF050015-01

1

2

345

MCONF050015-01

1

2

34

MCONF040004-01

1

2

34

MCONF040004-01

1

2

34

MCONF040004-01

1

2

34

MCONF040004-01

1

2

34

MCONF040004-01

1

2

34

MCONF040004-01

381371251015

14914

2611

MCONM150001-01

54 32 167910

20 19 18 17 16 15 14 13 12 118

MCONM200008-01

1 234

5 678 910

MCONF100003-01

21

MCONF020202-01

6

5

4

3

2

17

11

10

9

8 15

14

13

12 16

MCONF160034-01

CC

AABB

DE

DD

EE

MCONF120059-01

CC

AABB

DE

DD

EE

MCONF120059-01

12

34

MCONF040095-0110 1

6111415 16 171213

2

734

85

9

MCONF170009-01

12567

8

9 1011121314

34

MCONF140012-01

12

34

MCONF040009-01

21

7654

3

8

MCONM080012-01

1

2

MCONF020203-01

2

51

47 6

8

3

MCONF080014-01

1

2

MCONF020204-01

10

11 12 13 14 15 16 17 18 19 123456789

20

MCONF200021-01

Page 1278 of 1496

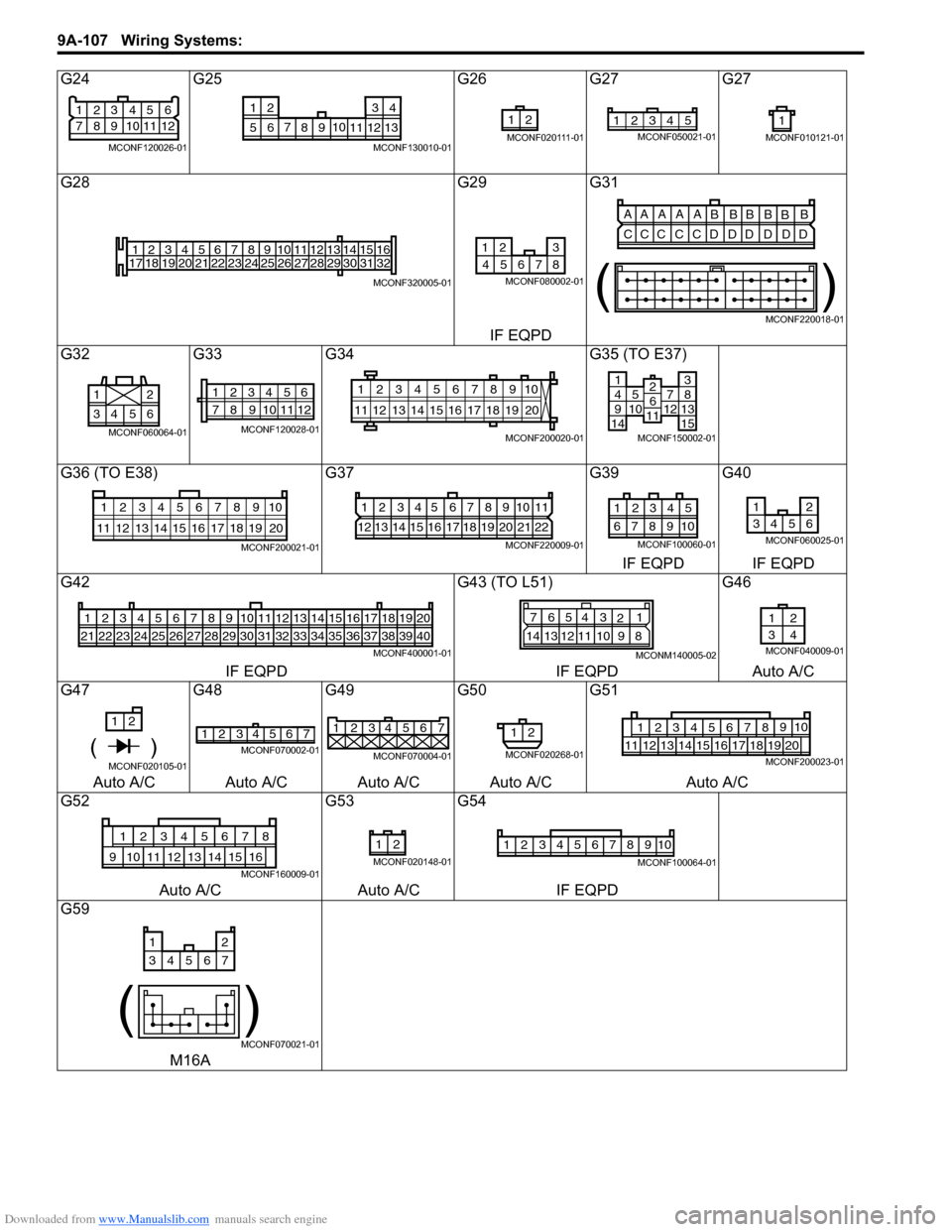

Downloaded from www.Manualslib.com manuals search engine 9A-107 Wiring Systems:

G24G25 G26G27 G27

G28 G29G31

IF EQPD

G32 G33G34 G35 (TO E37)

G36 (TO E38) G37G39G40

IF EQPD IF EQPD

G42 G43 (TO L51)G46

IF EQPD IF EQPDAuto A/C

G47 G48G49G50G51

Auto A/C Auto A/C Auto A/C Auto A/C Auto A/C

G52 G53G54

Auto A/C Auto A/CIF EQPD

G59

M16A

21

83

9 4

10 5

11 6

12

7

MCONF120026-01

710

56 12 34

8 9 11 12 13

MCONF130010-01

21

MCONF020111-01

12345MCONF050021-011

MCONF010121-01

1

17 2

18 3

19 4

20 5

21 6

22 7

23 8

24 9

25 10

26 11

27 12

28 13

29 14

30 15

31 16

32

MCONF320005-01

12 3

8

467 5

MCONF080002-01

AA A A A

BBBB

BB

CCC C CD DD D DD

()

MCONF220018-01

6543 21

MCONF060064-01

12345

78 11 6

12

910

MCONF120028-01

10

11 12 13 14 15 16 17 18 19 123456789

20

MCONF200020-01

14951071214

381315

2611

MCONF150002-01

10

11 12 13 14 15 16 17 18 19 123456789

20

MCONF200021-01

1234567891011

12 13 14 15 16 17 18 19 20 21 22

MCONF220009-01

54321

109876

MCONF100060-01

12

3456

MCONF060025-01

123456

212223242526

7

27

8

28

9

29

10

30

11

31

12

32

13

33

14

34

15

35

16

36

17

37

18

38

19

39

20

40

MCONF400001-01

7 654 3

21

14 13 12 11 10 9 8

MCONM140005-02

12

34

MCONF040009-01

1 2

( )MCONF020105-01

2

14 3657MCONF070002-01

1234567

MCONF070004-01

12

MCONF020268-01

12349105678

11121718192013141516MCONF200023-01

12345678

910151611121314

MCONF160009-01

21

MCONF020148-01

12345678910

MCONF100064-01

12

34567

()

MCONF070021-01

Page 1279 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-108

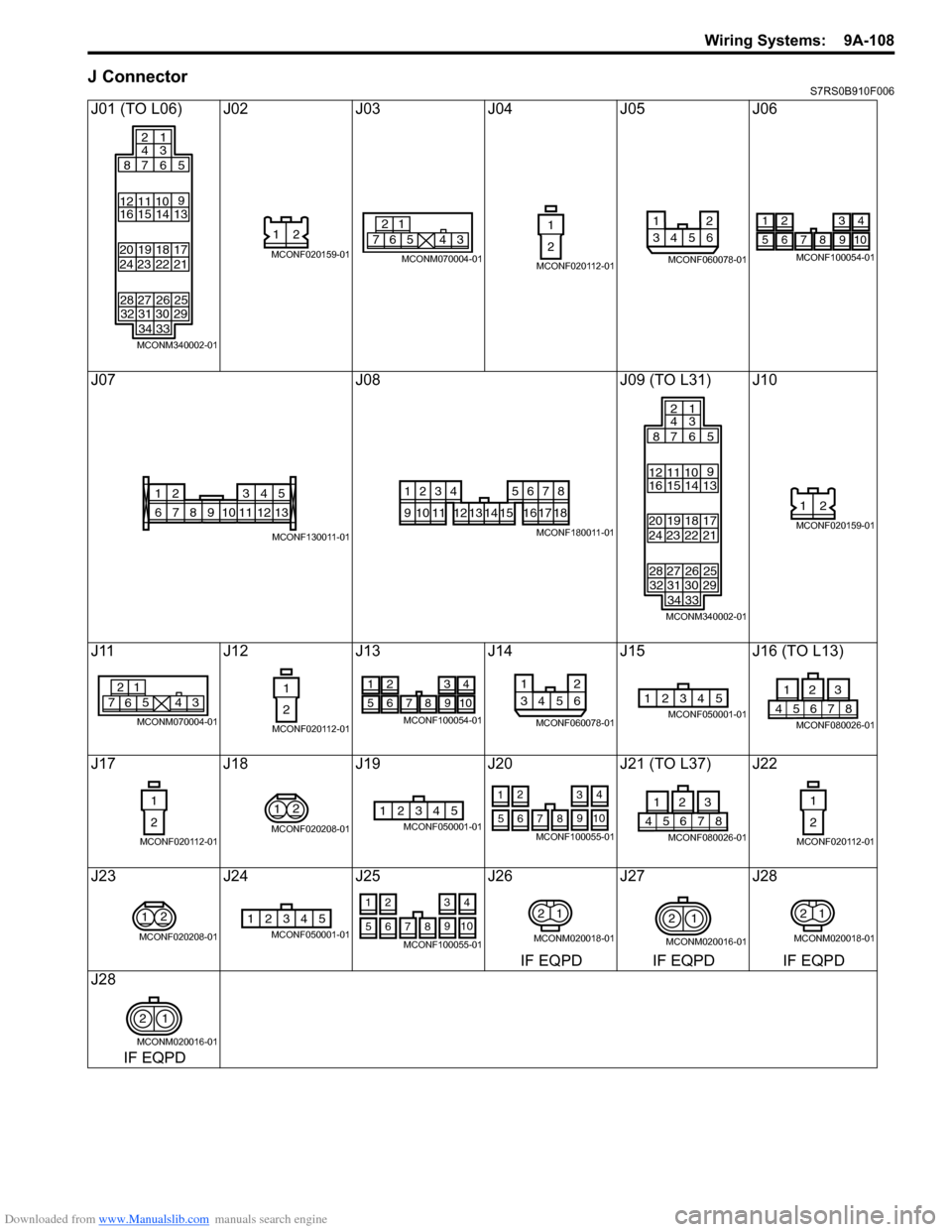

J ConnectorS7RS0B910F006

J01 (TO L06) J02J03J04J05J06

J07 J08J09 (TO L31) J10

J11 J12J13J14 J15 J16 (TO L13)

J17 J18J19 J20 J21 (TO L37) J22

J23 J24J25 J26 J27 J28

IF EQPD IF EQPD IF EQPD

J28

IF EQPD

313234 33 30 29

24

28 23

27 22

26 21

25

16

20 19 15

12 11 10

14

1813

17

87 6

2

4

1

3

5

9

MCONM340002-01

21

MCONF020159-016

21

7543

MCONM070004-01

1

2

MCONF020112-01

12

3456

MCONF060078-01

1234

5678910

MCONF100054-01

135

68910111324

712

MCONF130011-01

1234

91011

5678

12131415161718

MCONF180011-01

3132 34 33 30 29

24

28 23

27 22

26 21

25

16

20 19 15

12 11 10

14

1813

17

87 6

2

4

1

3

5

9

MCONM340002-01

21

MCONF020159-01

6

21

7543

MCONM070004-01

1

2

MCONF020112-01

1234

5678910

MCONF100054-01

12

3456

MCONF060078-01

12345MCONF050001-0187654

231

MCONF080026-01

1

2

MCONF020112-01

2

1

MCONF020208-01

12345MCONF050001-01

2

1 4

3

7 9

65 108

MCONF100055-0187654

231

MCONF080026-01

1

2

MCONF020112-01

2

1

MCONF020208-01

12345MCONF050001-01

2

1 4

3

7 9

65 108

MCONF100055-01

12

MCONM020018-01

2

1

MCONM020016-01

12

MCONM020018-01

21

MCONM020016-01

Page 1328 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-1 Glass / Windows / Mirrors:

Body, Cab and Accessories

Glass / Windows / Mirrors

General Description

Rear End Door Window Defogger System DescriptionS7RS0B9501001

The rear end door window defogger is controlled by BCM. For the BCM description refer to “BCM General Description

in Section 10B”.

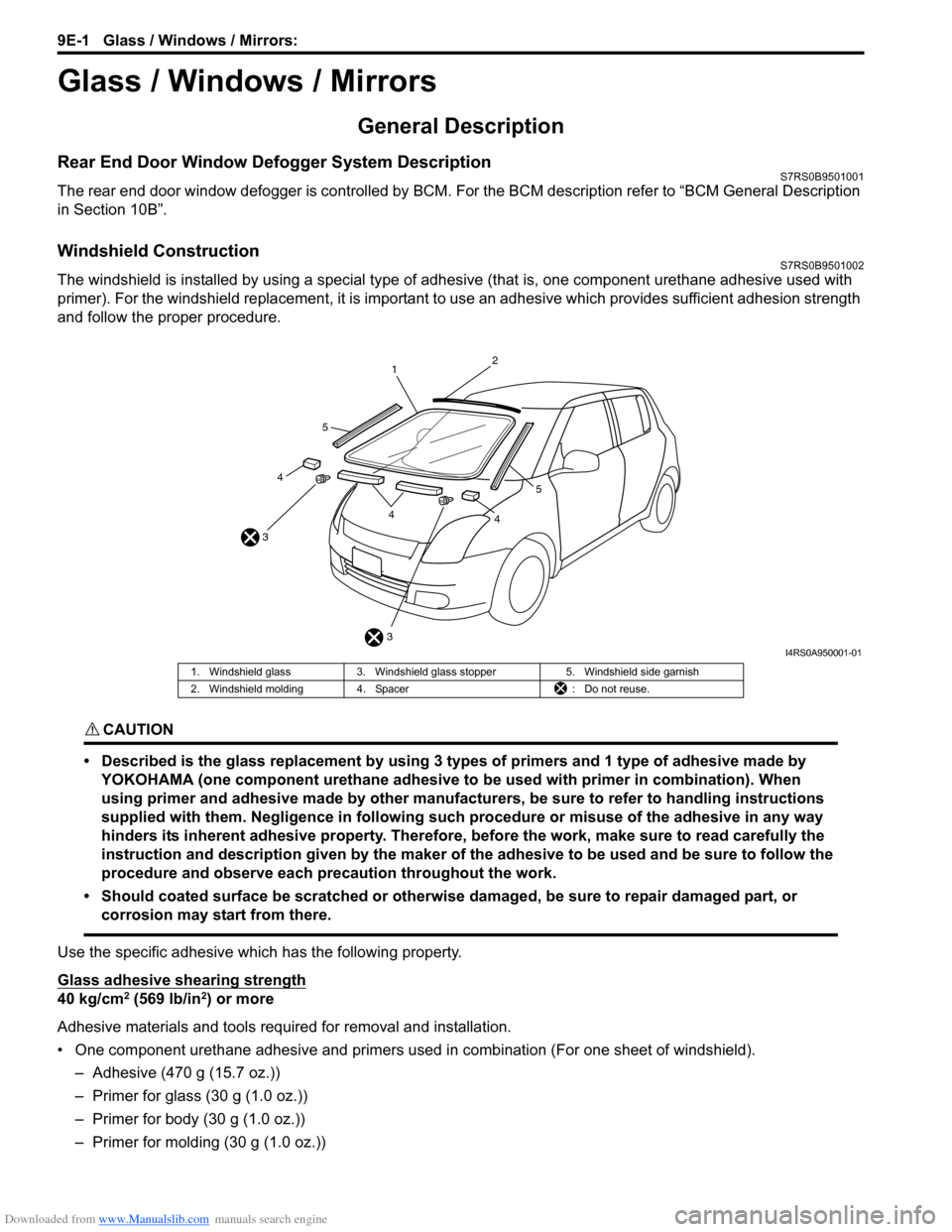

Windshield ConstructionS7RS0B9501002

The windshield is installed by using a special type of adhesive (that is, one component urethane adhesive used with

primer). For the windshield replacement, it is important to use an adhesive which provides sufficient adhesion strength

and follow the proper procedure.

CAUTION!

• Described is the glass replacement by using 3 types of primers and 1 type of adhesive made by YOKOHAMA (one component urethane adhesive to be used with primer in combination). When

using primer and adhesive made by other manufacturers, be sure to refer to handling instructions

supplied with them. Negligence in following such procedure or misuse of the adhesive in any way

hinders its inherent adhesive property. Therefore, before the work, make sure to read carefully the

instruction and description given by the maker of the adhesive to be used and be sure to follow the

procedure and observe each precaution throughout the work.

• Should coated surface be scratched or otherwise damaged, be sure to repair damaged part, or corrosion may start from there.

Use the specific adhesive which has the following property.

Glass adhesive shearing strength

40 kg/cm2 (569 lb/in2) or more

Adhesive materials and tools required for removal and installation.

• One component urethane adhesive and primers used in combination (For one sheet of windshield). – Adhesive (470 g (15.7 oz.))

– Primer for glass (30 g (1.0 oz.))

– Primer for body (30 g (1.0 oz.))

– Primer for molding (30 g (1.0 oz.))

3

3 1

2

44

4

5

5

I4RS0A950001-01

1. Windshield glass

3. Windshield glass stopper 5. Windshield side garnish

2. Windshield molding 4. Spacer : Do not reuse.