Warning engine light SUZUKI SWIFT 2008 2.G Service Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1413 of 1496

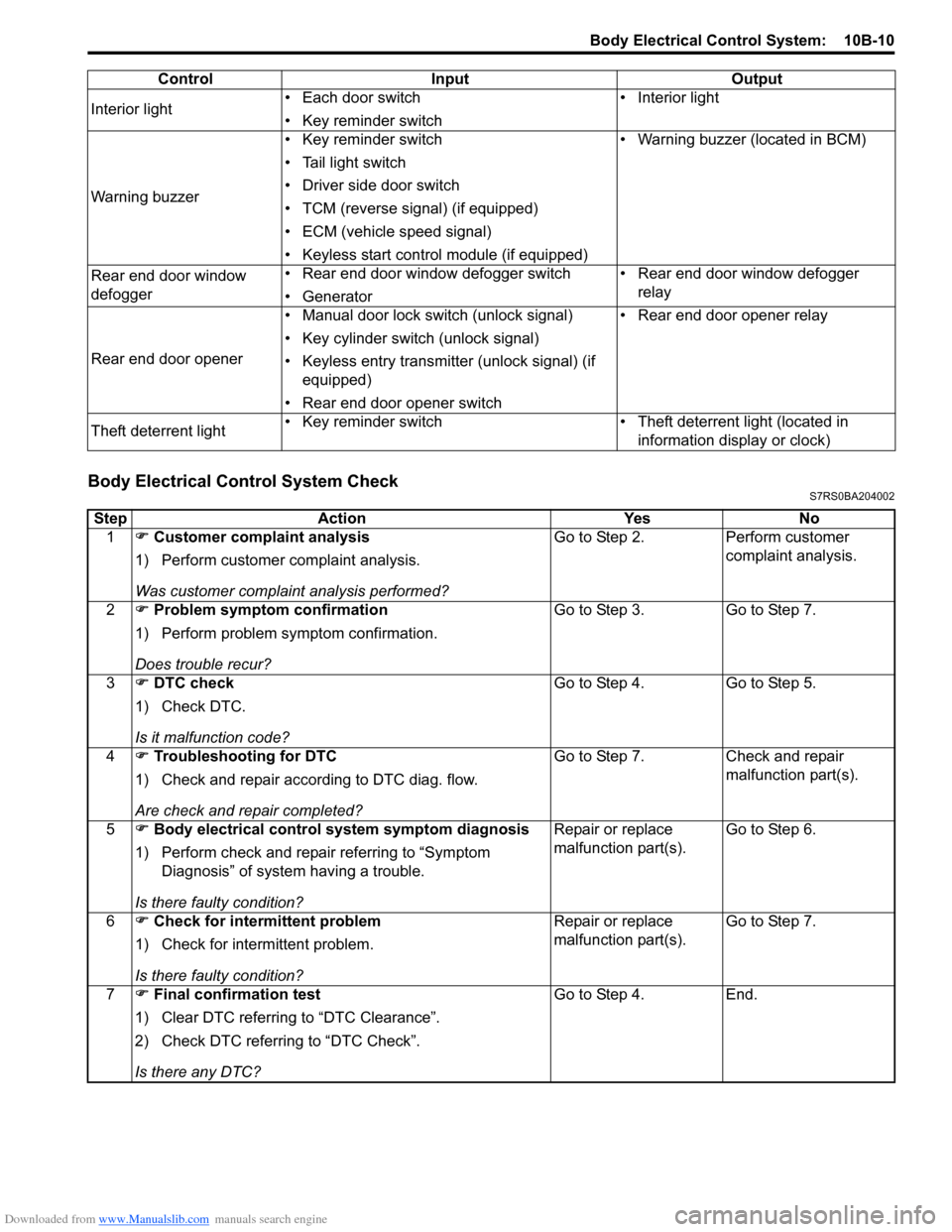

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-10

Body Electrical Control System CheckS7RS0BA204002

Interior light• Each door switch

• Key reminder switch • Interior light

Warning buzzer • Key reminder switch

• Tail light switch

• Driver side door switch

• TCM (reverse signal) (if equipped)

• ECM (vehicle speed signal)

• Keyless start control module (if equipped) • Warning buzzer (located in BCM)

Rear end door window

defogger • Rear end door window defogger switch

• Generator • Rear end door window defogger

relay

Rear end door opener • Manual door lock switch (unlock signal)

• Key cylinder switch (unlock signal)

• Keyless entry transmitter (unlock signal) (if

equipped)

• Rear end door opener switch • Rear end door opener relay

Theft deterrent light • Key reminder switch • Theft deterrent light (located in

information display or clock)

Control Input Output

Step

Action YesNo

1 �) Customer complaint analysis

1) Perform customer complaint analysis.

Was customer complaint analysis performed? Go to Step 2.

Perform customer

complaint analysis.

2 �) Problem symptom confirmation

1) Perform problem symptom confirmation.

Does trouble recur? Go to Step 3.

Go to Step 7.

3 �) DTC check

1) Check DTC.

Is it malfunction code? Go to Step 4.

Go to Step 5.

4 �) Troubleshooting for DTC

1) Check and repair according to DTC diag. flow.

Are check and repair completed? Go to Step 7.

Check and repair

malfunction part(s).

5 �) Body electrical control system symptom diagnosis

1) Perform check and repair referring to “Symptom Diagnosis” of system having a trouble.

Is there faulty condition? Repair or replace

malfunction part(s).

Go to Step 6.

6 �) Check for intermittent problem

1) Check for interm ittent problem.

Is there faulty condition? Repair or replace

malfunction part(s).

Go to Step 7.

7 �) Final confirmation test

1) Clear DTC referring to “DTC Clearance”.

2) Check DTC referring to “DTC Check”.

Is there any DTC? Go to Step 4.

End.

Page 1414 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-11 Body Electrical Control System:

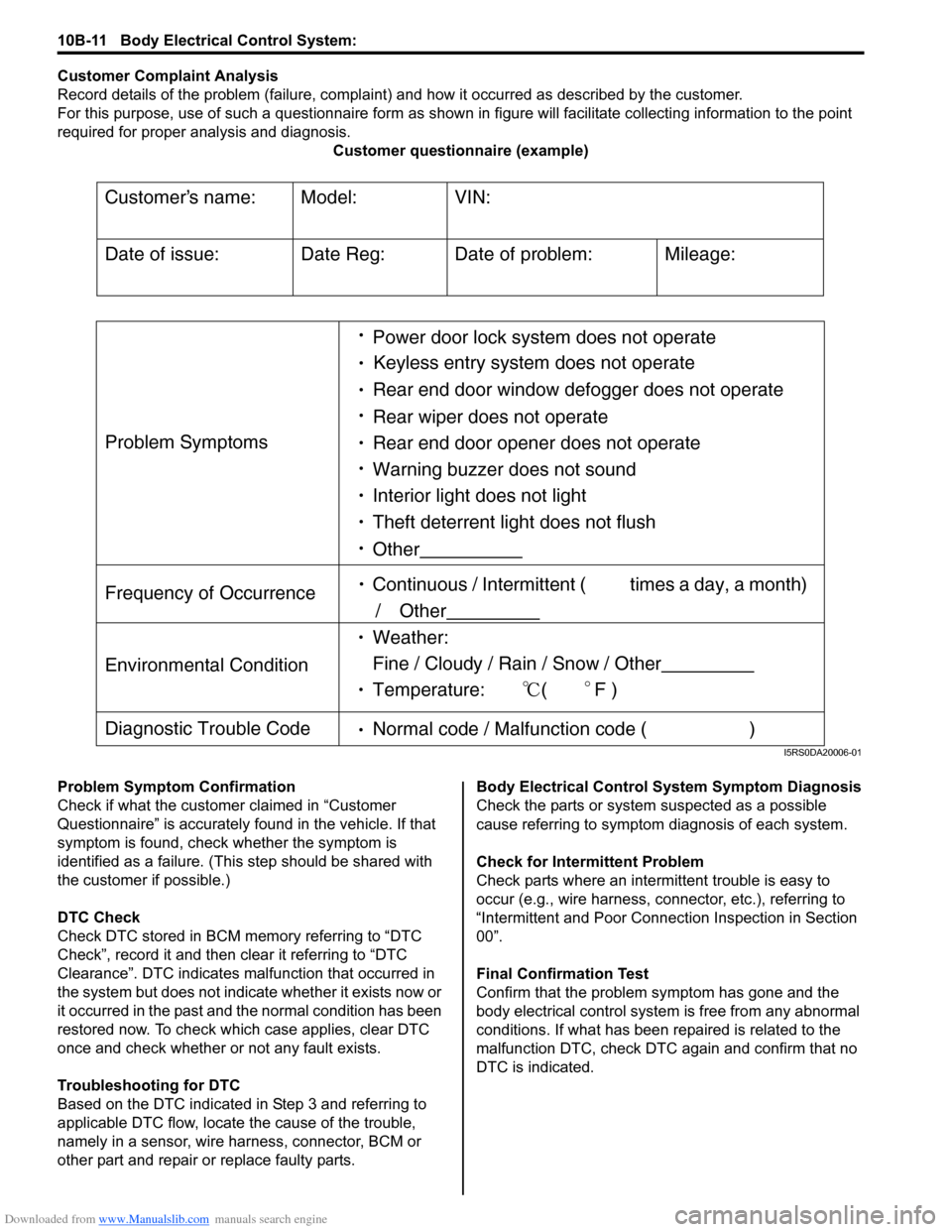

Customer Complaint Analysis

Record details of the problem (failure, complaint) and how it occurred as described by the customer.

For this purpose, use of such a questionnaire form as shown in figure will facilitate collectin g information to the point

required for proper analysis and diagnosis. Customer questionnaire (example)

Problem Symptom Confirmation

Check if what the custom er claimed in “Customer

Questionnaire” is accurately f ound in the vehicle. If that

symptom is found, check whether the symptom is

identified as a failure. (This step should be shared with

the customer if possible.)

DTC Check

Check DTC stored in BCM me mory referring to “DTC

Check”, record it and then clear it referring to “DTC

Clearance”. DTC indicates malfunction that occurred in

the system but does not indicate whether it exists now or

it occurred in the past and the normal condition has been

restored now. To check which case applies, clear DTC

once and check whether or not any fault exists.

Troubleshooting for DTC

Based on the DTC indicated in Step 3 and referring to

applicable DTC flow, locate the cause of the trouble,

namely in a sensor, wire harness, connector, BCM or

other part and repair or replace faulty parts. Body Electrical Control System Symptom Diagnosis

Check the parts or system

suspected as a possible

cause referring to symptom diagnosis of each system.

Check for Intermi ttent Problem

Check parts where an intermit tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00”.

Final Confirmation Test

Confirm that the problem symptom has gone and the

body electrical control system is free from any abnormal

conditions. If what has been repaired is related to the

malfunction DTC, check DTC again and confirm that no

DTC is indicated.

Customers name:

Model:

VIN:

Date of issue:

Date Reg:

Date of problem:

Mileage:

Problem Symptoms

Power door lock system does not operate

Keyless entry system does not operate

Rear end door window defogger does not operate

Rear wiper does not operate

Rear end door opener does not operate

Other

Frequency of Occurrence

Continuous / Intermittent ( times a day, a month)

/ Other

Environmental Condition

Weather:

Fine / Cloudy / Rain / Snow / Other

Temperature: (F )

Diagnostic Trouble Code Normal code / Malfunction code ( )

Warning buzzer does not sound

Interior light does not light

Theft deterrent light does not flush

I5RS0DA20006-01

Page 1416 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-13 Body Electrical Control System:

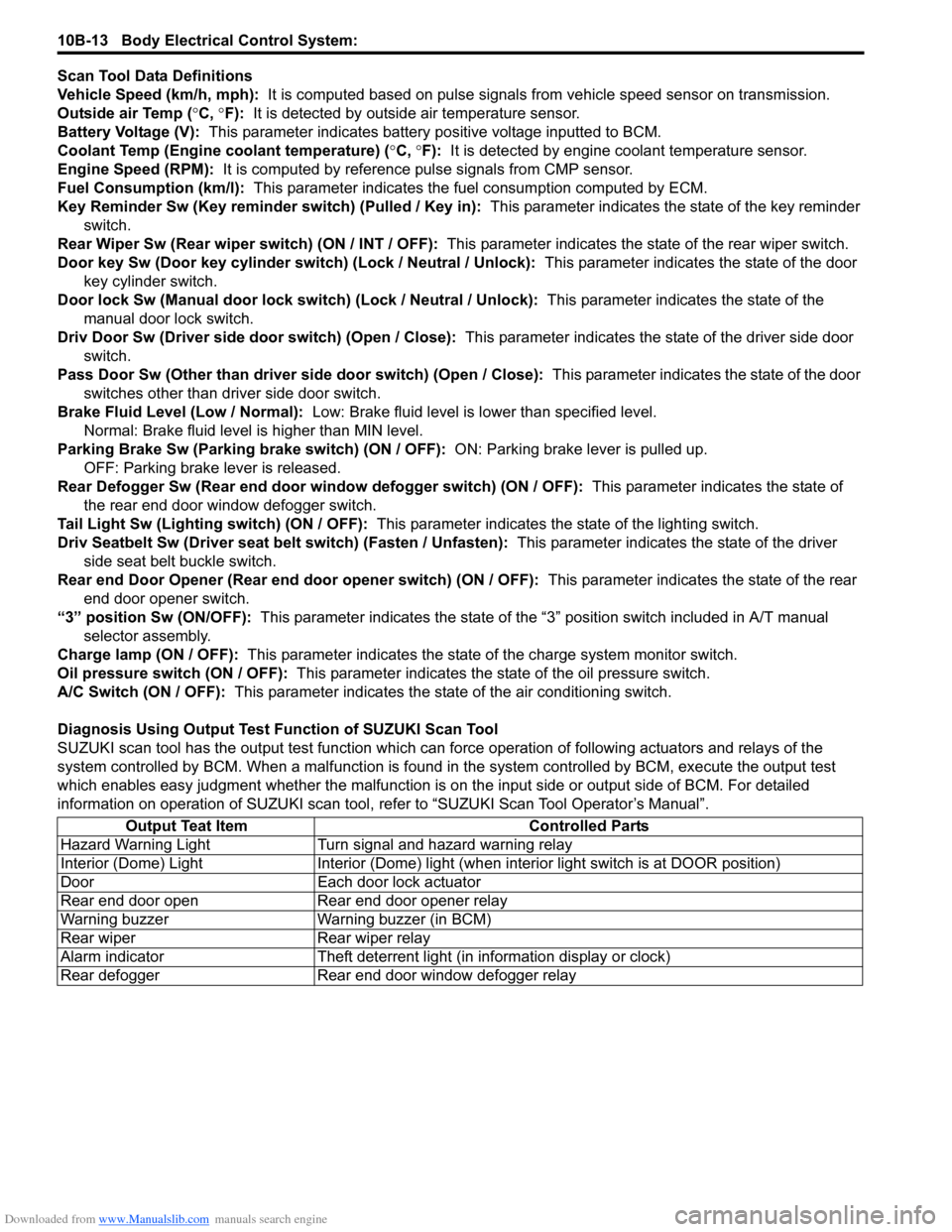

Scan Tool Data Definitions

Vehicle Speed (km/h, mph): It is computed based on pulse signals from vehicle speed sensor on transmission.

Outside air Temp ( °C, °F): It is detected by outside air temperature sensor.

Battery Voltage (V): This parameter indicates battery po sitive voltage inputted to BCM.

Coolant Temp (Engine coolant temperature) ( °C, °F): It is detected by engine coolant temperature sensor.

Engine Speed (RPM): It is computed by reference pulse signals from CMP sensor.

Fuel Consumption (km/l): This parameter indicates the fuel consumption computed by ECM.

Key Reminder Sw (Key reminder switch) (Pulled / Key in): This parameter indicates the state of the key reminder

switch.

Rear Wiper Sw (Rear wiper switch) (ON / INT / OFF): This parameter indicates the state of the rear wiper switch.

Door key Sw (Door key cylinder switch) (Lock / Neutral / Unlock): This parameter indicates the state of the door

key cylinder switch.

Door lock Sw (Manual door lock switch) (Lock / Neutral / Unlock): This parameter indicates the state of the

manual door lock switch.

Driv Door Sw (Driver side d oor switch) (Open / Close): This parameter indicates the state of the driver side door

switch.

Pass Door Sw (Other than driver side door switch) (Open / Close): This parameter indicates the state of the door

switches other than driver side door switch.

Brake Fluid Level (Low / Normal): Low: Brake fluid level is lower than specified level.

Normal: Brake fluid level is higher than MIN level.

Parking Brake Sw (Parking brake switch) (ON / OFF): ON: Parking brake lever is pulled up.

OFF: Parking brake lever is released.

Rear Defogger Sw (Rear end door window defogger switch) (ON / OFF): This parameter indicates the state of

the rear end door window defogger switch.

Tail Light Sw (Lighting switch) (ON / OFF): This parameter indicates the state of the lighting switch.

Driv Seatbelt Sw (Driver seat belt switch) (Fasten / Unfasten): This parameter indicates the state of the driver

side seat belt buckle switch.

Rear end Door Opener (Rear end door opener switch) (ON / OFF): This parameter indicates the state of the rear

end door opener switch.

“3” position Sw (ON/OFF): This parameter indicates the state of the “3 ” position switch included in A/T manual

selector assembly.

Charge lamp (ON / OFF): This parameter indicates the state of the charge system monitor switch.

Oil pressure switch (ON / OFF): This parameter indicates the state of the oil pressure switch.

A/C Switch (ON / OFF): This parameter indicates the state of the air conditioning switch.

Diagnosis Using Output Test Function of SUZUKI Scan Tool

SUZUKI scan tool has the output test function which can force operation of following actuators and relays of the

system controlled by BCM. When a malf unction is found in the system controlled by BCM, execute the output test

which enables easy judgment whether the malfunction is on the input side or output side of BCM. For detailed

information on operation of SUZUKI scan tool, refer to “SUZUKI Scan Tool Operator’s Manual”.

Output Teat Item Controlled Parts

Hazard Warning Light Turn signal and hazard warning relay

Interior (Dome) Light Interior (Dome) light (wh en interior light switch is at DOOR position)

Door Each door lock actuator

Rear end door open Rear end door opener relay

Warning buzzer Warning buzzer (in BCM)

Rear wiper Rear wiper relay

Alarm indicator Theft deterrent light (in information display or clock)

Rear defogger Rear end door window defogger relay

Page 1426 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-23 Body Electrical Control System:

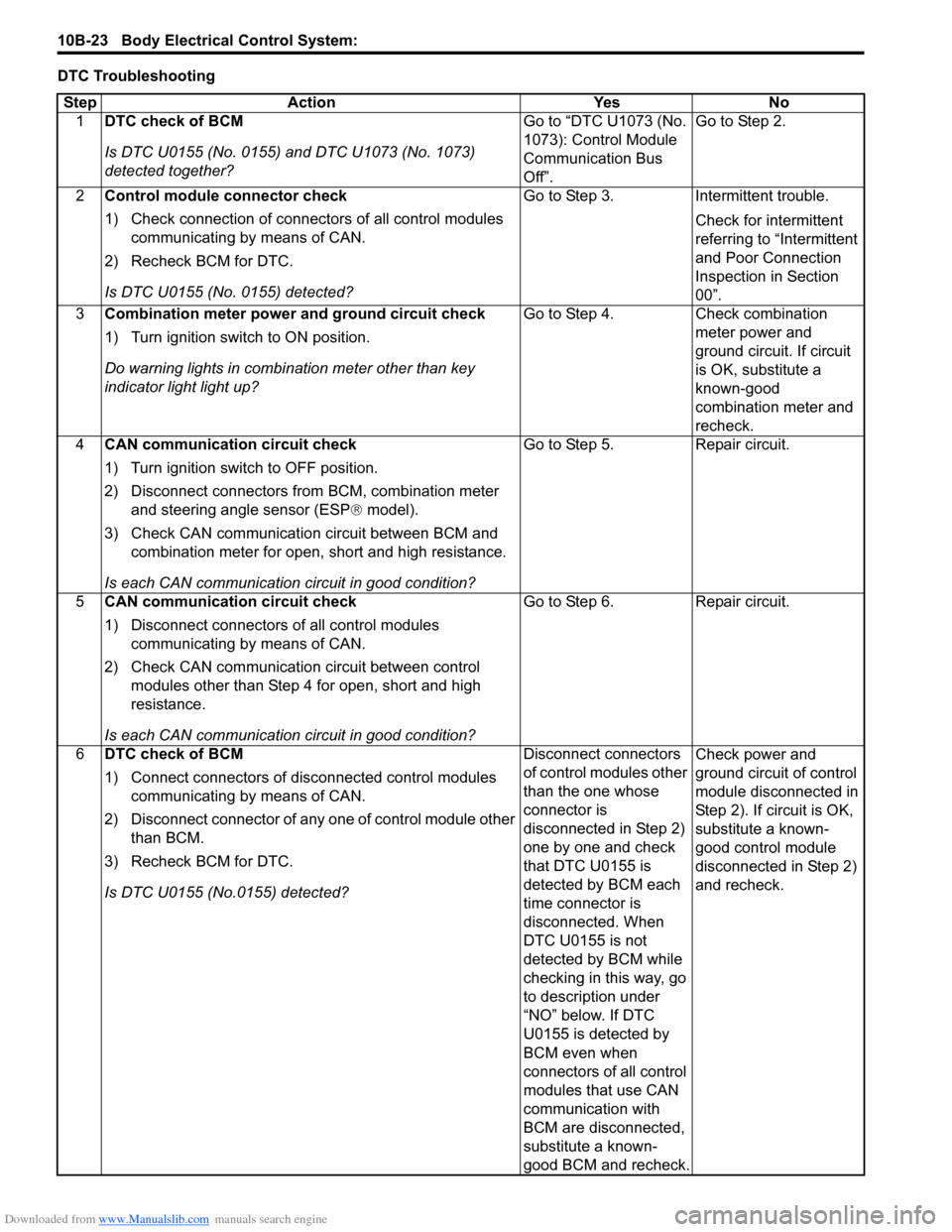

DTC TroubleshootingStep Action YesNo

1 DTC check of BCM

Is DTC U0155 (No. 0155) and DTC U1073 (No. 1073)

detected together? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus

Off”.Go to Step 2.

2 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck BCM for DTC.

Is DTC U0155 (No. 0155) detected? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 Combination meter power and ground circuit check

1) Turn ignition switch to ON position.

Do warning lights in combi nation meter other than key

indicator light light up? Go to Step 4.

Check combination

meter power and

ground circuit. If circuit

is OK, substitute a

known-good

combination meter and

recheck.

4 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors from BCM, combination meter

and steering angle sensor (ESP ® model).

3) Check CAN communication circuit between BCM and combination meter for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 5.

Repair circuit.

5 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 4 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 6.

Repair circuit.

6 DTC check of BCM

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect connector of any one of control module other than BCM.

3) Recheck BCM for DTC.

Is DTC U0155 (No.0155) detected? Disconnect connectors

of control modules other

than the one whose

connector is

disconnected in Step 2)

one by one and check

that DTC U0155 is

detected by BCM each

time connector is

disconnected. When

DTC U0155 is not

detected by BCM while

checking in this way, go

to description under

“NO” below. If DTC

U0155 is detected by

BCM even when

connectors of all control

modules that use CAN

communication with

BCM are disconnected,

substitute a known-

good BCM and recheck.Check power and

ground circuit of control

module disconnected in

Step 2). If circuit is OK,

substitute a known-

good control module

disconnected in Step 2)

and recheck.

Page 1437 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-34

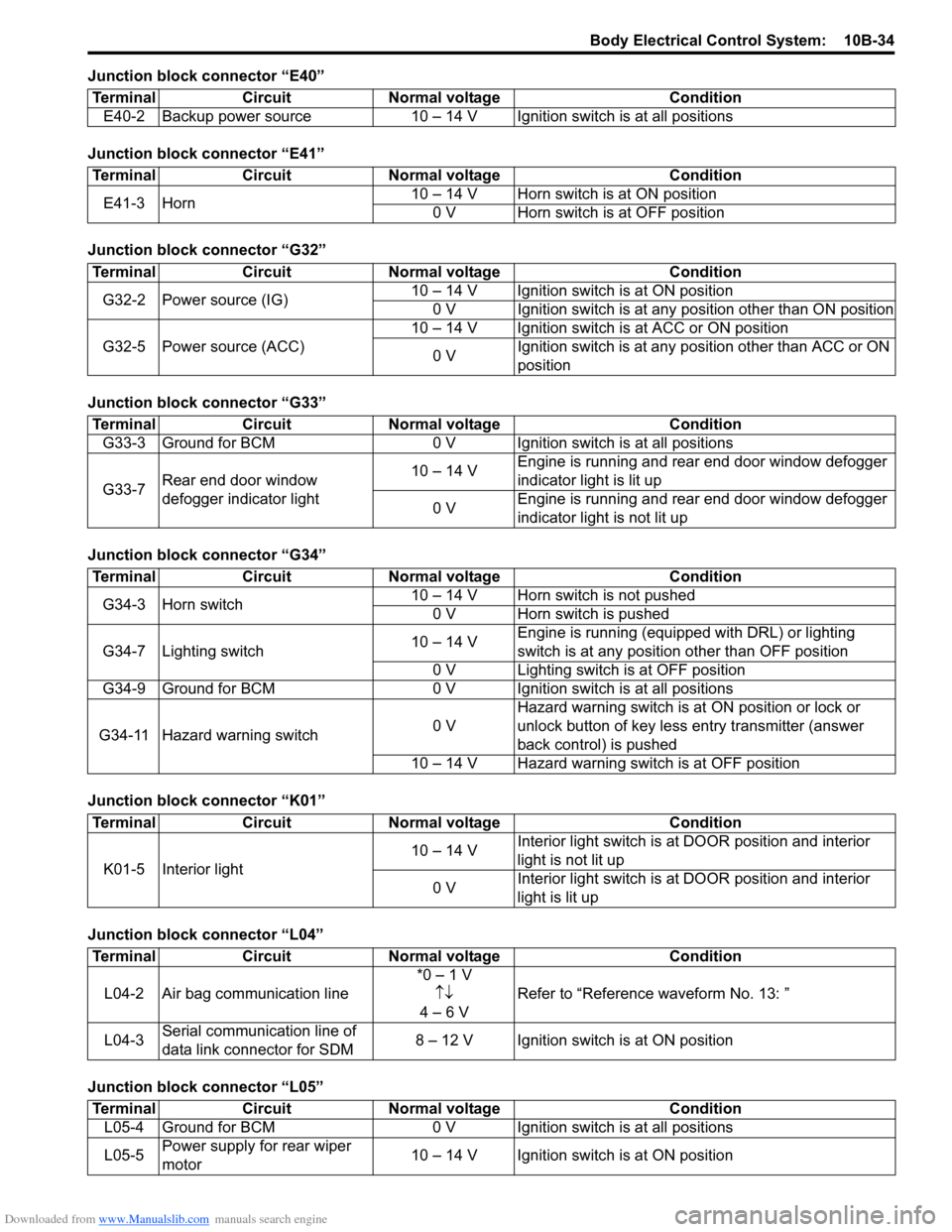

Junction block connector “E40”

Junction block connector “E41”

Junction block connector “G32”

Junction block connector “G33”

Junction block connector “G34”

Junction block connector “K01”

Junction block connector “L04”

Junction block connector “L05”Terminal Circuit Normal voltage Condition

E40-2 Backup power source 10 – 14 V Igni tion switch is at all positions

TerminalCircuitNormal voltage Condition

E41-3 Horn 10 – 14 V Horn switch is at ON position

0 V Horn switch is at OFF position

Terminal CircuitNormal voltage Condition

G32-2 Power source (IG) 10 – 14 V Ignition switch is at ON position

0 V Ignition switch is at any position other than ON position

G32-5 Power source (ACC) 10 – 14 V Ignition switch is at ACC or ON position

0 V Ignition switch is at any position other than ACC or ON

position

Terminal

CircuitNormal voltage Condition

G33-3 Ground for BCM 0 V Ignition switch is at all positions

G33-7 Rear end door window

defogger indicator light 10 – 14 V

Engine is running and rear end door window defogger

indicator light is lit up

0 V Engine is running and rear end door window defogger

indicator light is not lit up

Terminal

CircuitNormal voltage Condition

G34-3 Horn switch 10 – 14 V Horn switch is not pushed

0 V Horn switch is pushed

G34-7 Lighting switch 10 – 14 VEngine is running (equipped with DRL) or lighting

switch is at any position other than OFF position

0 V Lighting switch is at OFF position

G34-9 Ground for BCM 0 V Ignition switch is at all positions

G34-11 Hazard warning switch 0 VHazard warning switch is at

ON position or lock or

unlock button of key less entry transmitter (answer

back control) is pushed

10 – 14 V Hazard warning switch is at OFF position

Terminal CircuitNormal voltage Condition

K01-5 Interior light 10 – 14 V

Interior light switch is at

DOOR position and interior

light is not lit up

0 V Interior light switch is at

DOOR position and interior

light is lit up

Terminal CircuitNormal voltage Condition

L04-2 Air bag communication line *0 – 1 V

↑↓

4 – 6 V Refer to “Reference

waveform No. 13: ”

L04-3 Serial communication line of

data link connector for SDM 8 – 12 V Ignition switch is at ON position

Terminal

CircuitNormal voltage Condition

L05-4 Ground for BCM 0 V Ignition switch is at all positions

L05-5 Power supply for rear wiper

motor 10 – 14 V Ignition switch is at ON position

Page 1450 of 1496

Downloaded from www.Manualslib.com manuals search engine 10C-7 Immobilizer Control System:

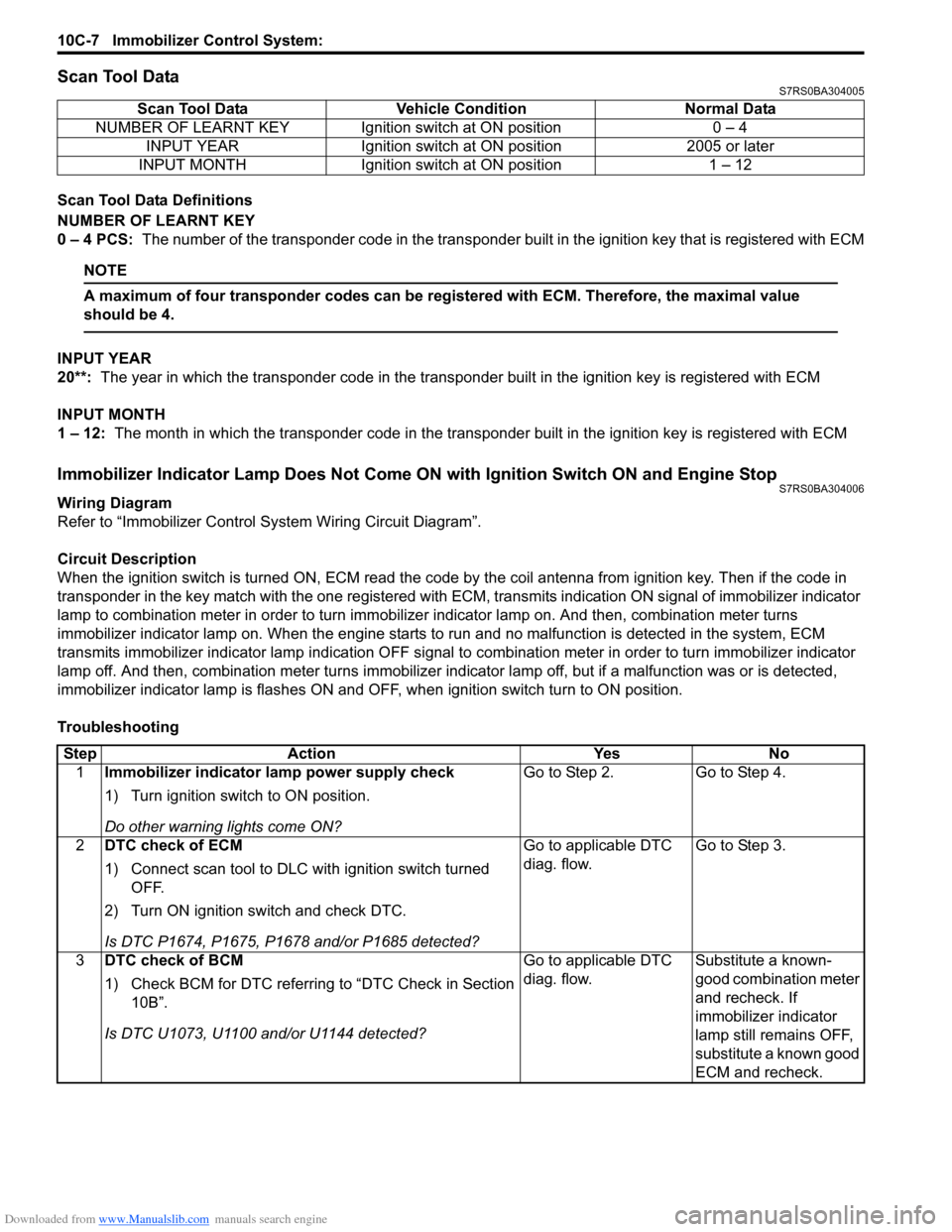

Scan Tool DataS7RS0BA304005

Scan Tool Data Definitions

NUMBER OF LEARNT KEY

0 – 4 PCS: The number of the transponder code in the transponder built in the ignition key that is registered with ECM

NOTE

A maximum of four transponder codes can be registered with ECM. Therefore, the maximal value

should be 4.

INPUT YEAR

20**: The year in which the transponder code in the transpon der built in the ignition key is registered with ECM

INPUT MONTH

1 – 12: The month in which the transponder code in the transpond er built in the ignition key is registered with ECM

Immobilizer Indicator Lamp Does Not Come ON with Ignition Switch ON and Engine StopS7RS0BA304006

Wiring Diagram

Refer to “Immobilizer Control System Wiring Circuit Diagram”.

Circuit Description

When the ignition switch is turned ON, ECM read the code by the coil antenna from ignition key. Then if the code in

transponder in the key match with the one registered with ECM, transmits indication ON signal of immobilizer indicator

lamp to combination meter in order to turn immobilizer indicator lamp on. And then, combination meter turns

immobilizer indicator lamp on. When th e engine starts to run and no malfunction is detected in the system, ECM

transmits immobilizer indi cator lamp indication OFF signal to combination meter in order to turn immobilizer indicator

lamp off. And then, comb ination meter turns immobilizer indicator lamp off, but if a malfunction was or is detected,

immobilizer indicator lamp is flashes ON and OF F, when ignition switch turn to ON position.

Troubleshooting Scan Tool Data Vehicl

e Condition Normal Data

NUMBER OF LEARNT KEY Ignition switch at ON position 0 – 4 INPUT YEAR Ignition switch at ON position 2005 or later

INPUT MONTH Ignition switch at ON position 1 – 12

Step Action YesNo

1 Immobilizer indicator lamp power supply check

1) Turn ignition switch to ON position.

Do other warning lights come ON? Go to Step 2.

Go to Step 4.

2 DTC check of ECM

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is DTC P1674, P1675, P1678 and/or P1685 detected? Go to applicable DTC

diag. flow.

Go to Step 3.

3 DTC check of BCM

1) Check BCM for DTC referring to “DTC Check in Section

10B”.

Is DTC U1073, U1100 and/or U1144 detected? Go to applicable DTC

diag. flow.

Substitute a known-

good combination meter

and recheck. If

immobilizer indicator

lamp still remains OFF,

substitute a known good

ECM and recheck.

Page 1464 of 1496

Downloaded from www.Manualslib.com manuals search engine 10E-2 Keyless Start System:

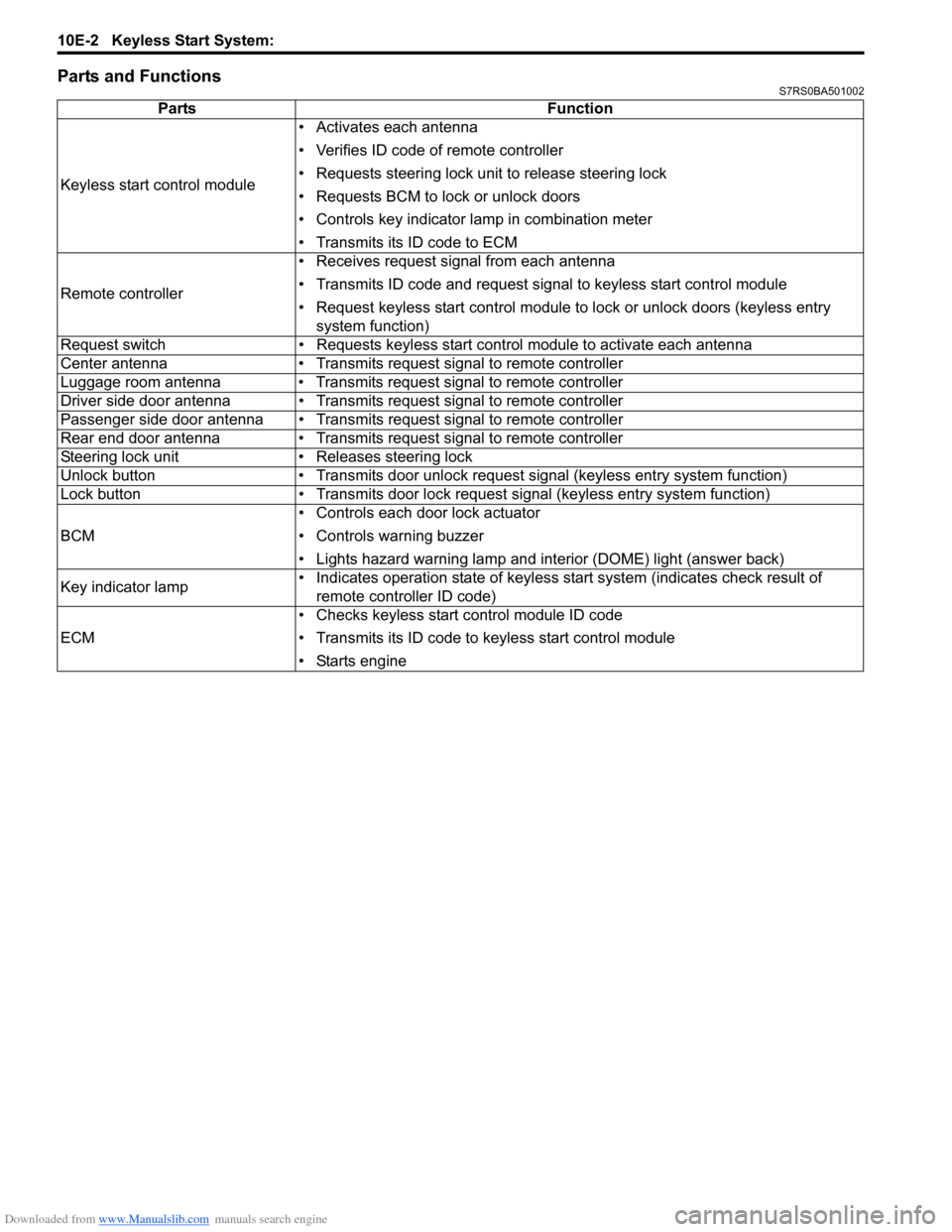

Parts and FunctionsS7RS0BA501002

PartsFunction

Keyless start control module • Activates each antenna

• Verifies ID code of remote controller

• Requests steering lock unit to release steering lock

• Requests BCM to lock or unlock doors

• Controls key indicator la

mp in combination meter

• Transmits its ID code to ECM

Remote controller • Receives request signal from each antenna

• Transmits ID code and request signal to keyless start control module

• Request keyless start control module to lock or unlock doors (keyless entry

system function)

Request switch • Requests keyless start control module to activate each antenna

Center antenna • Transmits request signal to remote controller

Luggage room antenna • Transmits request signal to remote controller

Driver side door antenna • Transmits request signal to remote controller

Passenger side door antenna • Transmits request signal to remote controller

Rear end door antenna • Transmits request signal to remote controller

Steering lock unit • Releases steering lock

Unlock button • Transmits door unlock request signal (keyless entry system function)

Lock button • Transmits door lock request signal (keyless entry system function)

BCM • Controls each door lock actuator

• Controls warning buzzer

• Lights hazard warning lamp and interior (DOME) light (answer back)

Key indicator lamp • Indicates operation state of keyless start system (indicates check result of

remote controller ID code)

ECM • Checks keyless start control module ID code

• Transmits its ID code to keyless start control module

• Starts engine

Page 1481 of 1496

Downloaded from www.Manualslib.com manuals search engine Keyless Start System: 10E-19

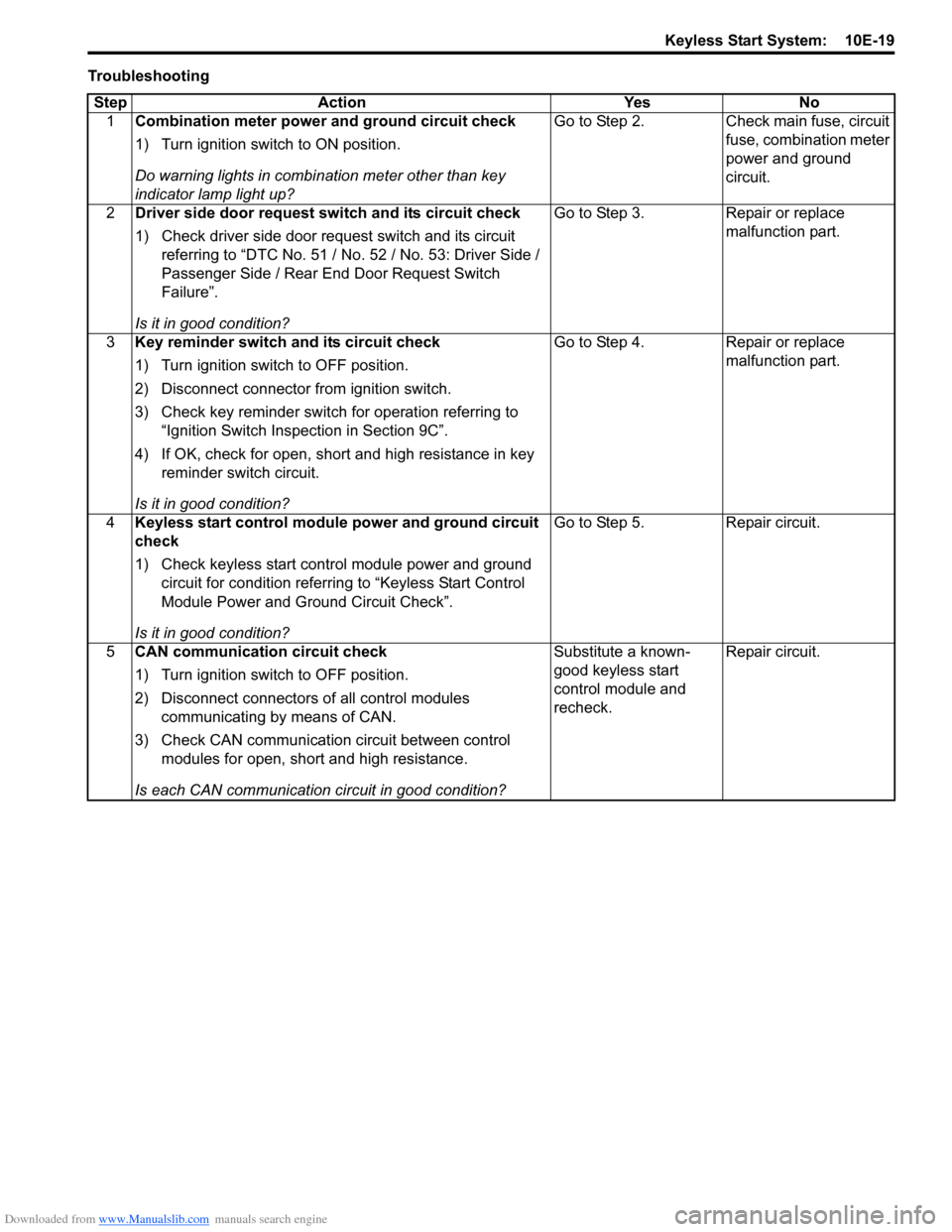

TroubleshootingStep Action Yes No 1 Combination meter power and ground circuit check

1) Turn ignition switch to ON position.

Do warning lights in combi nation meter other than key

indicator lamp light up? Go to Step 2. Check main fuse, circuit

fuse, combination meter

power and ground

circuit.

2 Driver side door request switch and its circuit check

1) Check driver side door request switch and its circuit

referring to “DTC No. 51 / No . 52 / No. 53: Driver Side /

Passenger Side / Rear End Door Request Switch

Failure”.

Is it in good condition? Go to Step 3. Repair or replace

malfunction part.

3 Key reminder switch and its circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connector from ignition switch.

3) Check key reminder switch for operation referring to

“Ignition Switch Inspection in Section 9C”.

4) If OK, check for open, short and high resistance in key reminder switch circuit.

Is it in good condition? Go to Step 4. Repair or replace

malfunction part.

4 Keyless start control module power and ground circuit

check

1) Check keyless start control module power and ground

circuit for condition referrin g to “Keyless Start Control

Module Power and Ground Circuit Check”.

Is it in good condition? Go to Step 5. Repair circuit.

5 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Substitute a known-

good keyless start

control module and

recheck.

Repair circuit.

Page 1483 of 1496

Downloaded from www.Manualslib.com manuals search engine Keyless Start System: 10E-21

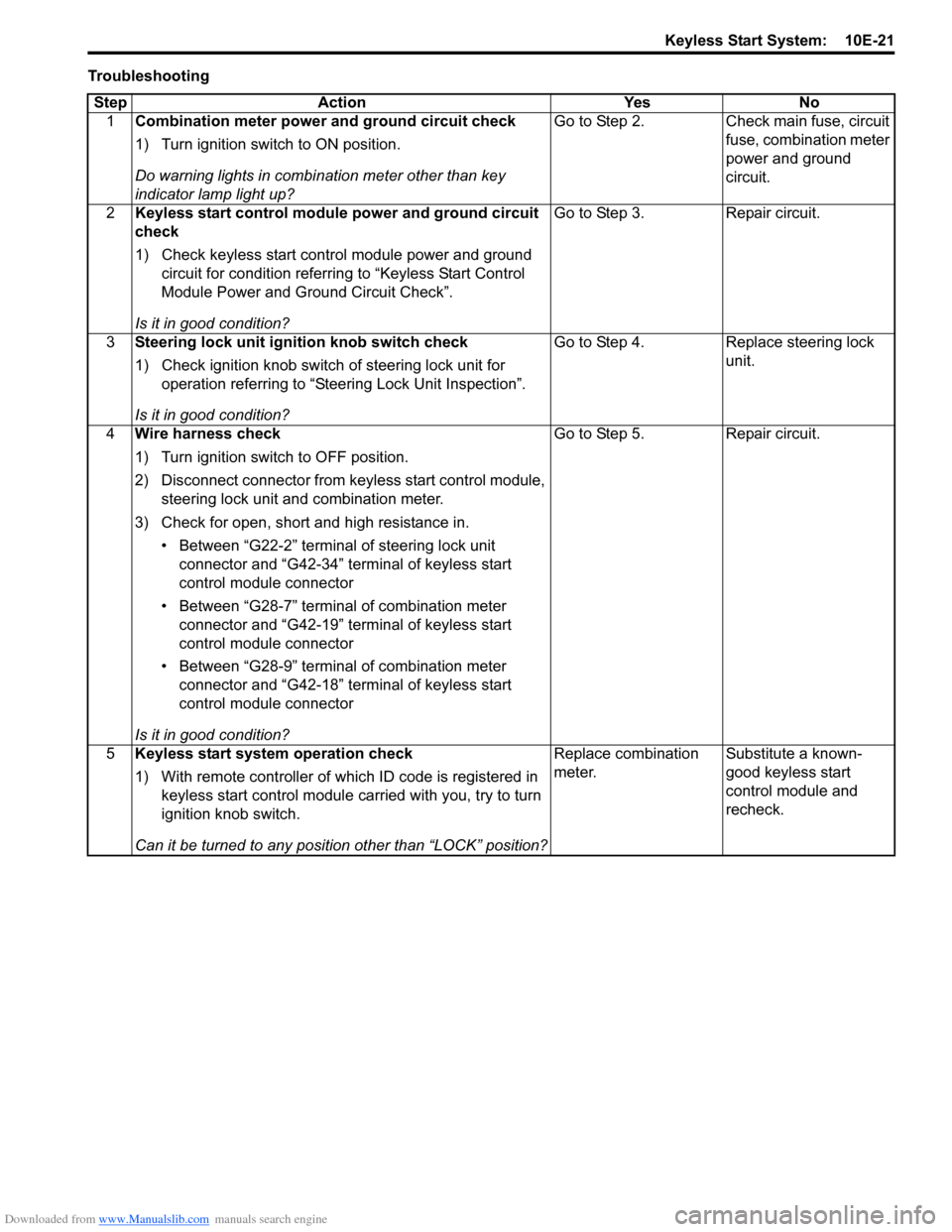

TroubleshootingStep Action Yes No 1 Combination meter power and ground circuit check

1) Turn ignition switch to ON position.

Do warning lights in combi nation meter other than key

indicator lamp light up? Go to Step 2. Check main fuse, circuit

fuse, combination meter

power and ground

circuit.

2 Keyless start control module power and ground circuit

check

1) Check keyless start control module power and ground

circuit for condition referrin g to “Keyless Start Control

Module Power and Ground Circuit Check”.

Is it in good condition? Go to Step 3. Repair circuit.

3 Steering lock unit ignition knob switch check

1) Check ignition knob switch of steering lock unit for

operation referring to “Steering Lock Unit Inspection”.

Is it in good condition? Go to Step 4. Replace steering lock

unit.

4 Wire harness check

1) Turn ignition switch to OFF position.

2) Disconnect connector from ke yless start control module,

steering lock unit and combination meter.

3) Check for open, short and high resistance in. • Between “G22-2” terminal of steering lock unit connector and “G42-34” terminal of keyless start

control module connector

• Between “G28-7” terminal of combination meter connector and “G42-19” terminal of keyless start

control module connector

• Between “G28-9” terminal of combination meter connector and “G42-18” terminal of keyless start

control module connector

Is it in good condition? Go to Step 5. Repair circuit.

5 Keyless start system operation check

1) With remote controller of which ID code is registered in

keyless start control module carried with you, try to turn

ignition knob switch.

Can it be turned to any position other than “LOCK” position? Replace combination

meter.

Substitute a known-

good keyless start

control module and

recheck.