belt buckle SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 42 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-12 Maintenance and Lubrication:

HVAC Air Filter (If Equipped) InspectionS7RS0B0206032

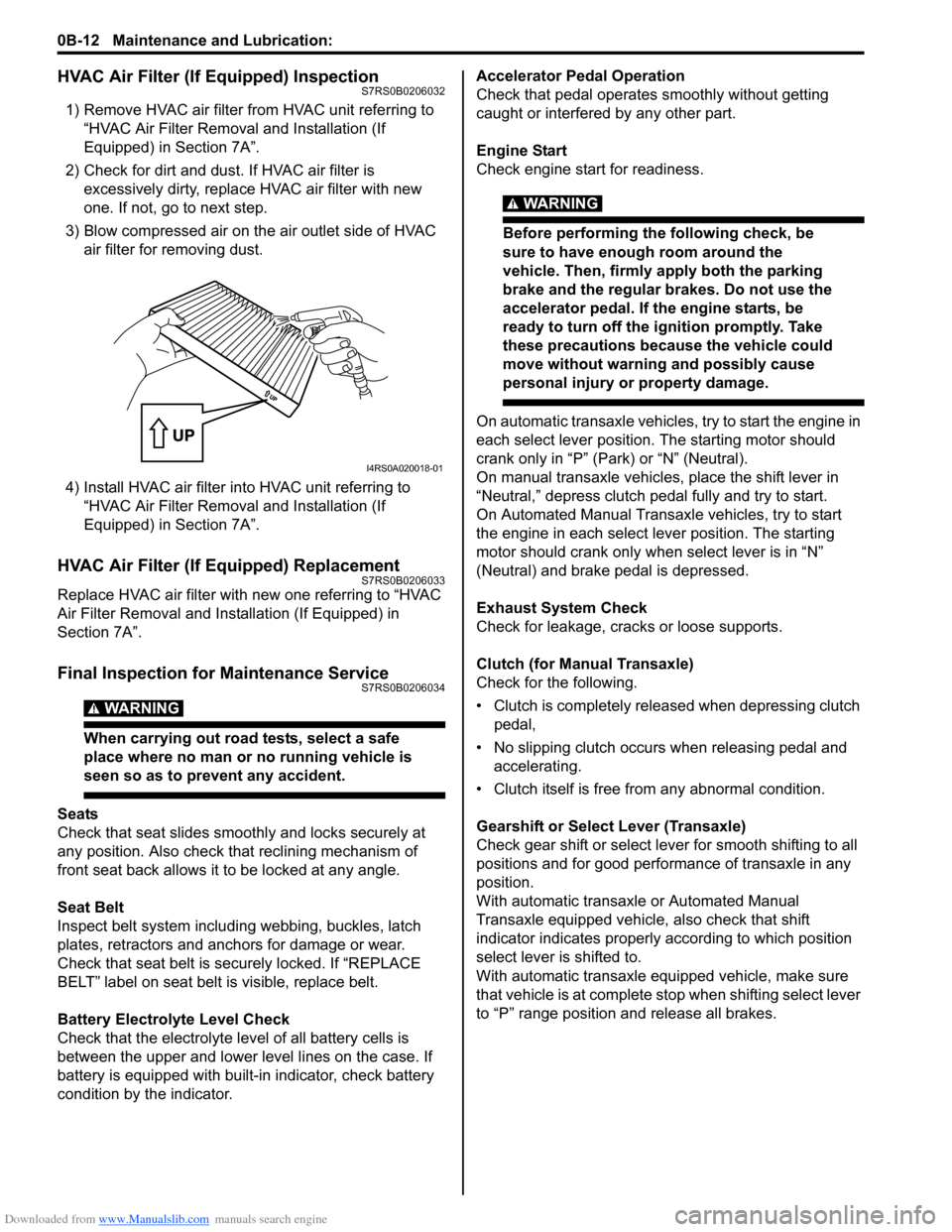

1) Remove HVAC air filter from HVAC unit referring to

“HVAC Air Filter Removal and Installation (If

Equipped) in Section 7A”.

2) Check for dirt and dust. If HVAC air filter is excessively dirty, replace HVAC air filter with new

one. If not, go to next step.

3) Blow compressed air on the air outlet side of HVAC air filter for removing dust.

4) Install HVAC air filter in to HVAC unit referring to

“HVAC Air Filter Removal and Installation (If

Equipped) in Section 7A”.

HVAC Air Filter (If Equipped) ReplacementS7RS0B0206033

Replace HVAC air filter with new one referring to “HVAC

Air Filter Removal and Installation (If Equipped) in

Section 7A”.

Final Inspection for Maintenance ServiceS7RS0B0206034

WARNING!

When carrying out road tests, select a safe

place where no man or no running vehicle is

seen so as to prevent any accident.

Seats

Check that seat slides smoot hly and locks securely at

any position. Also check that reclining mechanism of

front seat back allows it to be locked at any angle.

Seat Belt

Inspect belt system including webbing, buckles, latch

plates, retractors and anchors for damage or wear.

Check that seat belt is securely locked. If “REPLACE

BELT” label on seat belt is visible, replace belt.

Battery Electrolyte Level Check

Check that the electrolyte le vel of all battery cells is

between the upper and lower level lines on the case. If

battery is equipped with built-in indicator, check battery

condition by the indicator. Accelerator Pedal Operation

Check that pedal operates

smoothly without getting

caught or interfered by any other part.

Engine Start

Check engine start for readiness.

WARNING!

Before performing th e following check, be

sure to have enough room around the

vehicle. Then, firmly apply both the parking

brake and the regular brakes. Do not use the

accelerator pedal. If the engine starts, be

ready to turn off the ignition promptly. Take

these precautions because the vehicle could

move without warning and possibly cause

personal injury or property damage.

On automatic transaxle vehicles, try to start the engine in

each select lever position. The starting motor should

crank only in “P” (Park) or “N” (Neutral).

On manual transaxle vehicles, place the shift lever in

“Neutral,” depress clutch pedal fully and try to start.

On Automated Manual Transaxl e vehicles, try to start

the engine in each select le ver position. The starting

motor should crank only when select lever is in “N”

(Neutral) and brake pedal is depressed.

Exhaust System Check

Check for leakage, cracks or loose supports.

Clutch (for Manual Transaxle)

Check for the following.

• Clutch is completely released when depressing clutch pedal,

• No slipping clutch occurs when releasing pedal and accelerating.

• Clutch itself is free fr om any abnormal condition.

Gearshift or Select Lever (Transaxle)

Check gear shift or select lever for smooth shifting to all

positions and for good performance of transaxle in any

position.

With automatic transaxle or Automated Manual

Transaxle equipped vehicle, also check that shift

indicator indicates properly according to which position

select lever is shifted to.

With automatic transaxle equipped vehicle, make sure

that vehicle is at complete stop when shifting select lever

to “P” range position and release all brakes.

I4RS0A020018-01

Page 1032 of 1496

Downloaded from www.Manualslib.com manuals search engine 8A-1 Seat Belts:

Restraint

Seat Belts

Precautions

Precautions on Service and Diagnosis of Seat

Belt

S7RS0B8100001

WARNING!

If replacing seat belt is necessary, replace

buckle and seat belt assembly together as a

set. This is for the reason of ensuring locking

of tongue plate with buckle. If these parts are

replaced individually, such a locking

condition may become unreliable. For this

reason, SUZUKI will supply only the spare

buckle and seat belt assembly in a set part.

Before servicing or replacing seat belts, refer to the

following precautionary items.

• Seat belts should be normal relative to strap retractor and buckle portions. • Keep sharp edges and damaging objects away from

belts.

• Avoid bending or damaging any portion of belt buckle or latch plate.

• Do not bleach or dye belt webbing. (Use only mild soap and lukewarm water to clean it.)

• When installing a seat belt anchor bolt, it should be tightened by hand at first to prevent cross-threading

and then to specified torque.

• Do not attempt any repair s on retractor mechanisms

or retractor covers. Replace defective assemblies with

new replacement parts.

• Keep belts dry and clean at all times.

• If there exist any parts in question, replace such parts.

• Replace belts whose webbing is cut or otherwise damaged.

• Do not put anything into trim panel opening which seat belt webbing passes through.

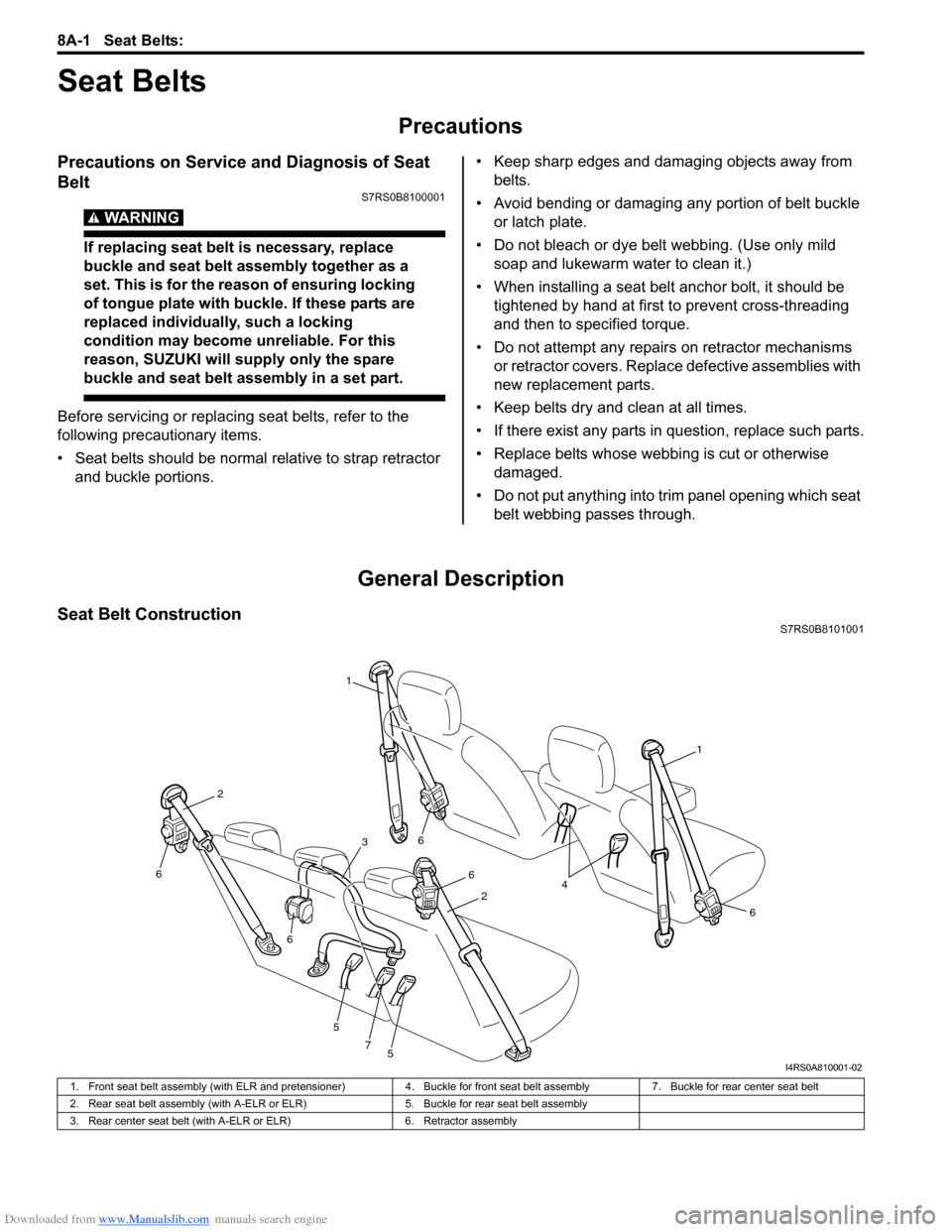

General Description

Seat Belt ConstructionS7RS0B8101001

1

1

6

6

6

5

5

7

6

6

2

2

3

4

I4RS0A810001-02

1. Front seat belt assembly (with ELR and pretensioner) 4. Buckle for front seat belt assembly7. Buckle for rear center seat belt

2. Rear seat belt assembly (with A-ELR or ELR) 5. Buckle for rear seat belt assembly

3. Rear center seat belt (with A-ELR or ELR) 6. Retractor assembly

Page 1033 of 1496

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-2

Seat Belt with ELR

The seat belt with emergency locking retractor (ELR) is

designed so that it locks immediately (to prevent the

webbing from being pulled out of the retractor any

further) when any of the following items is detected as

exceeding each set value;

• Speed at which the webbing is pulled out of the retractor.

• Acceleration or deceleration of the vehicle speed.

• Inclination.

Seat Belt with A-ELR

The automatic and emergency locking retractor (A-ELR)

works as an Emergency Locking Retractor (ELR) till its

webbing is pulled all the way out and then on as an

Automatic Locking Retractor (ALR ) till it is retracted fully.

ALR: Automatically locks when the webbing is pulled out

from the retractor and allowed to retract even a little.

Then the webbing can not be pulled out any further,

unless it is wound all the way back into the retractor,

which releases the lock and allows the webbing to be

pulled out.

Seat Belt with ELR and Pretensioner

The seat belt with ELR and a pretensioner has a

pretensioner mechanism whic h operates in linkage with

the air bag in addition to the described ELR.

The pretensioner is incorporated in retractor assembly

and controlled by SDM as one of air bag system

components. It will be activated at the same time as the

driver and passenger air bag module when an impact at

the front of vehicle exceeds the specified value.

When servicing seat belt (retractor assembly) with

pretensioner, be sure to observe all WARNINGS and

CAUTIONS and “Precautions on Service and Diagnosis

of Air Bag System in Section 8B”. CAUTION!

Do not reuse the seat belt pretensioner

(retractor assembly) that has activated.

Replace it with a new seat belt assembly and

buckle together as a set. For checking

procedure of its activation, refer to “Repair

and Inspection Required after Accident in

Section 8B”.

Seat Belt Remainder

When driver’s seat belt is unfastened (under the

following conditions), seat belt reminder light and

warning buzzer inform that driver’s seat belt is

unfastened. Seat belt reminder light located in

combination meter and warning buzzer located inside

BCM operate as follows:

• Seat belt reminder light comes on when driver’s seat belt is unfastened while igni tion key switch is at ON

position.

• If vehicle speed exceeds 15 km/h with seat belt unfastened, warning buzzer operates for

approximately 95 seconds and seat belt reminder light

flashes synchronously with buzzer. When warning

buzzer stops operating, seat belt reminder light is

turned on.

• If driver’s seat belt state is changed from “fastened” to “unfastened” while vehicle speed is above 15 km/h,

warning buzzer operates for approximately 95

seconds and seat belt reminder light flashes

synchronously with buzzer. When warning buzzer

stops operating, seat belt reminder light is turned on.

Diagnostic Information and Procedures

Repair and Inspection Required after AccidentS7RS0B8104001

After an accident, whether the seat belt pretensioner has been activated or not, be sure to perform checks and repairs

described on “Repair and Inspection Required after Accident in Section 8B”.

Page 1034 of 1496

Downloaded from www.Manualslib.com manuals search engine 8A-3 Seat Belts:

Repair Instructions

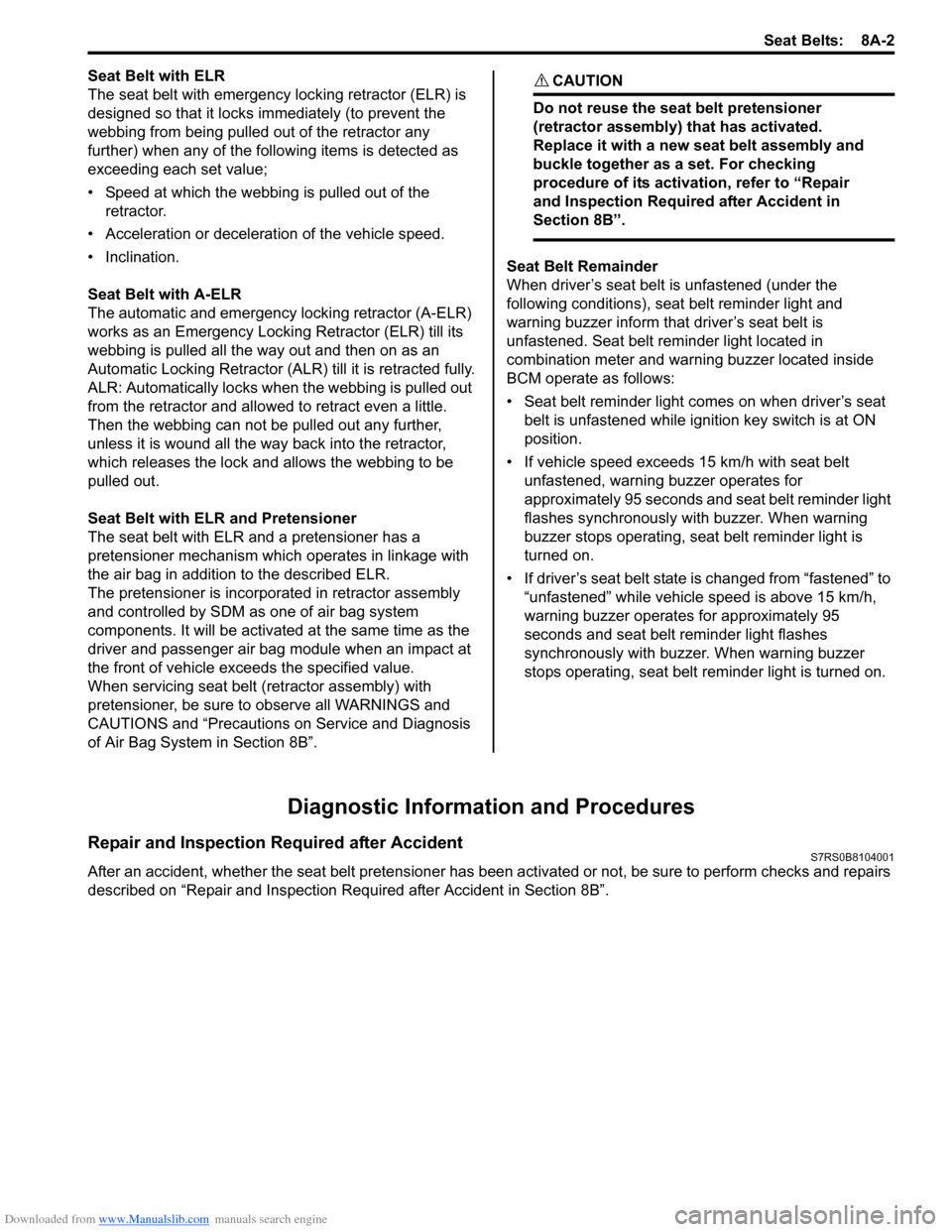

Front Seat Belt ComponentsS7RS0B8106001

WARNING!

• Never attempt to disassemble or repair the seat belt pretensioner (retractor assembly). If any abnormality is found, be sure to replace it with new one as an assembly.

• Be sure to read “Precautions on Service and Diagnosis of Seat Belt” before starting to work and observe every precaution during work. Neglecting them may result in personal injury or

unactivation of the seat belt pretensioner when necessary.

(a)

(a)

(a)

1

2

3

5

a)

b)

(a)

3

7

(b)

6

2

4

(a)

7

810

9

7 2 11

9

1012

I6RS0C810001-01

1. Upper anchor

6. Shoulder adjuster mounting bolt

: Tighten upper bolt first, then tighten lower bolt. 11. Spring washer

2. Lower anchor 7. Anchor bolt

: Tighten upper bolt first, then tighten lower bolt. 12. Wave washer

3. Retractor assembly 8. Cushion : 43 N⋅m (4.3 kgf-m, 31.5 lb-ft)

4. Buckle 9. Spacer : 5.5 N⋅m (0.55 kgf-m, 4.0 lb-ft)

5. Yellow connector (for seat belt pretensioner) 10. Washer

Page 1036 of 1496

Downloaded from www.Manualslib.com manuals search engine 8A-5 Seat Belts:

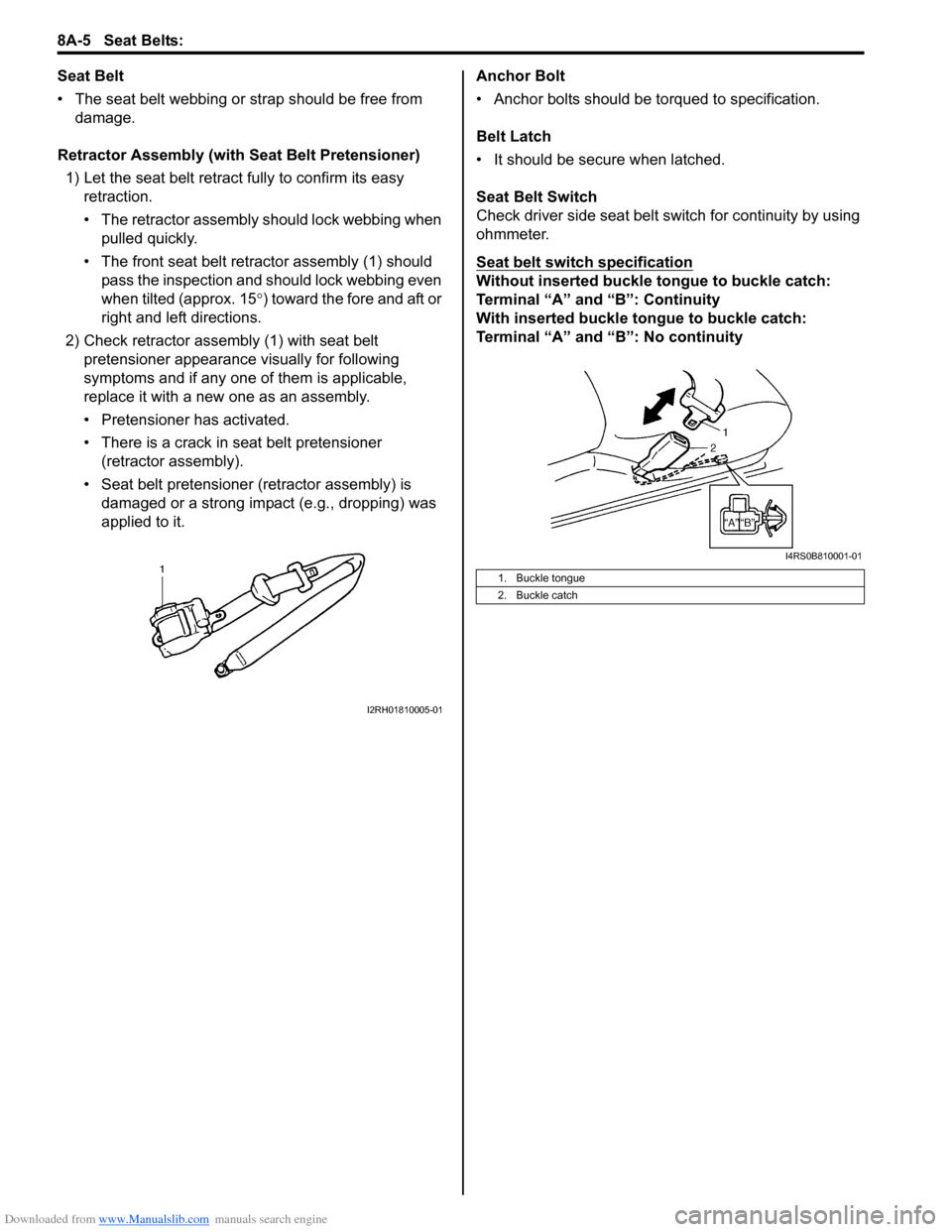

Seat Belt

• The seat belt webbing or strap should be free from damage.

Retractor Assembly (with Seat Belt Pretensioner) 1) Let the seat belt retract fully to confirm its easy retraction.

• The retractor assembly should lock webbing when

pulled quickly.

• The front seat belt retractor assembly (1) should pass the inspection and should lock webbing even

when tilted (approx. 15 °) toward the fore and aft or

right and left directions.

2) Check retractor assembly (1) with seat belt pretensioner appearance visually for following

symptoms and if any one of them is applicable,

replace it with a new one as an assembly.

• Pretensioner has activated.

• There is a crack in seat belt pretensioner (retractor assembly).

• Seat belt pretensioner (retractor assembly) is damaged or a strong impact (e.g., dropping) was

applied to it. Anchor Bolt

• Anchor bolts should be torqued to specification.

Belt Latch

• It should be secure when latched.

Seat Belt Switch

Check driver side seat belt s

witch for continuity by using

ohmmeter.

Seat belt switch specification

Without inserted buckle tongue to buckle catch:

Terminal “A” and “B”: Continuity

With inserted buckle tongue to buckle catch:

Terminal “A” and “B”: No continuity

I2RH01810005-01

1. Buckle tongue

2. Buckle catch

I4RS0B810001-01

Page 1037 of 1496

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-6

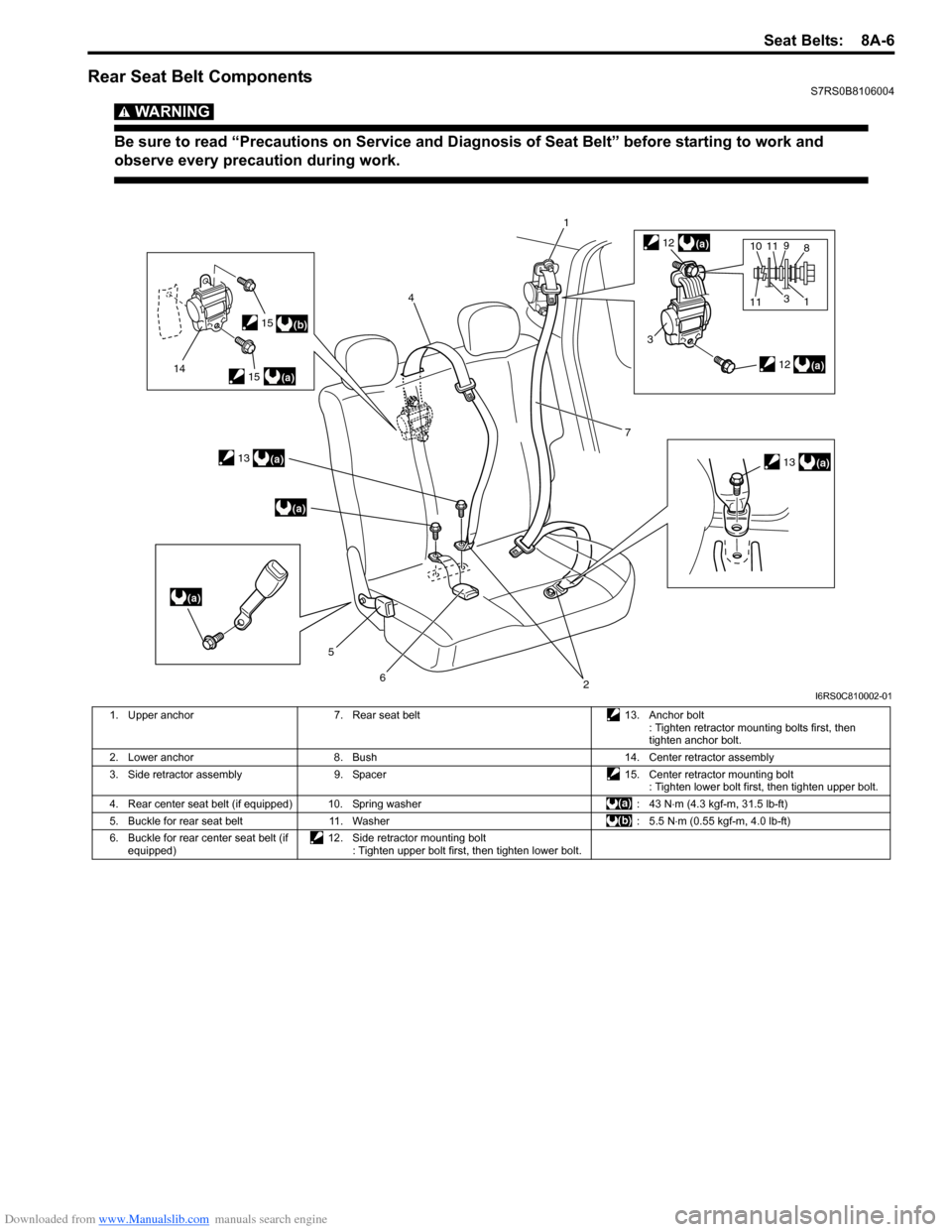

Rear Seat Belt ComponentsS7RS0B8106004

WARNING!

Be sure to read “Precautions on Service and Diagnosis of Seat Belt” before starting to work and

observe every precaution during work.

(b)

(a)

(a)

(a)

(a)

14

4

5

62

1

7

(a)

(a)

3

8

1

10

3

11911(a)

12

13

12

13

15

15

I6RS0C810002-01

1. Upper anchor 7. Rear seat belt 13. Anchor bolt

: Tighten retractor mounting bolts first, then

tighten anchor bolt.

2. Lower anchor 8. Bush 14. Center retractor assembly

3. Side retractor assembly 9. Spacer 15. Center retractor mounting bolt

: Tighten lower bolt first, then tighten upper bolt.

4. Rear center seat belt (if equipped) 10. Spring washer : 43 N⋅m (4.3 kgf-m, 31.5 lb-ft)

5. Buckle for rear seat belt 11. Washer : 5.5 N⋅m (0.55 kgf-m, 4.0 lb-ft)

6. Buckle for rear center seat belt (if equipped) 12. Side retractor mounting bolt

: Tighten upper bolt first, then tighten lower bolt.

Page 1297 of 1496

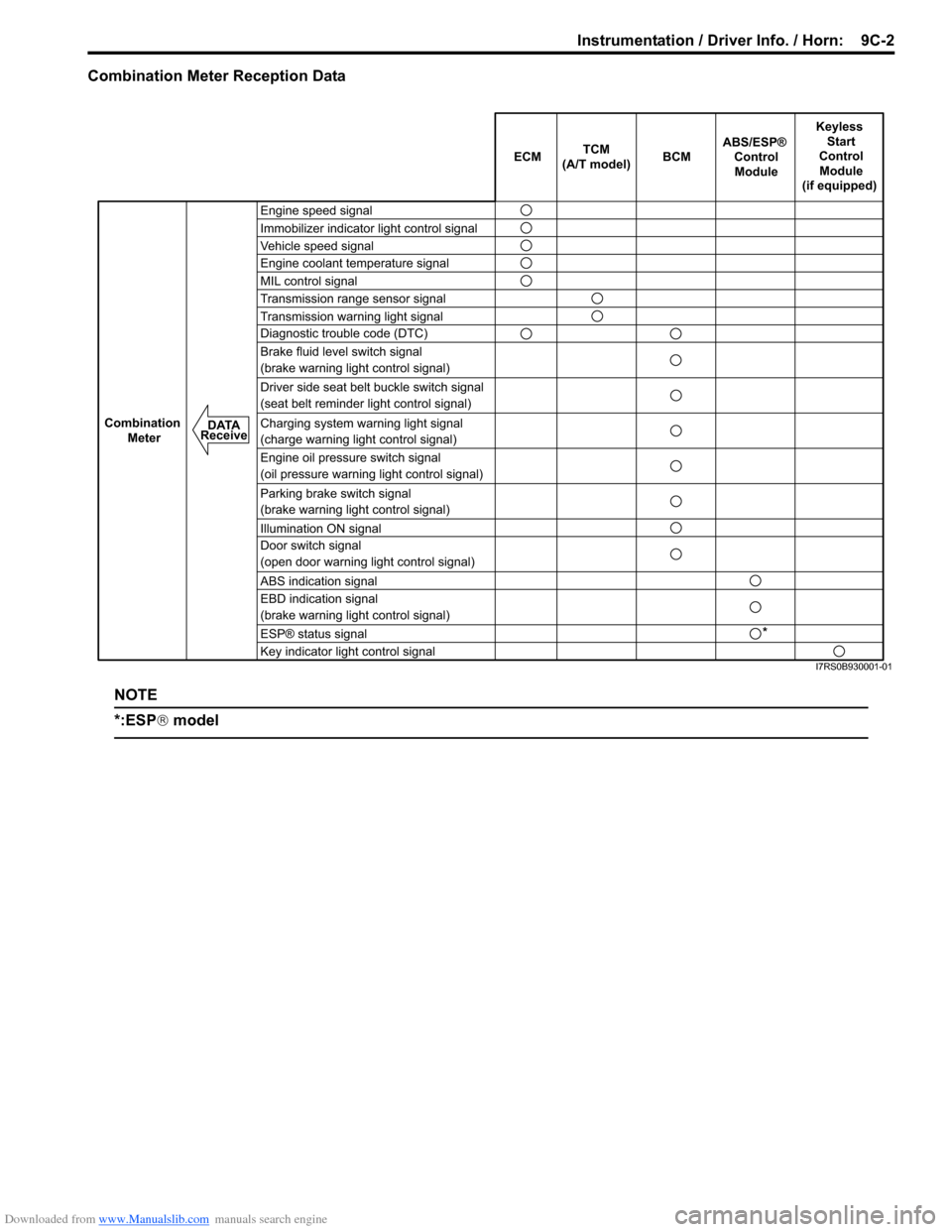

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-2

Combination Meter Reception Data

NOTE

*:ESP® model

ECM BCM

Keyless

Start

Control Module

(if equipped)

Combination Meter

TCM

(A/T model)

Engine speed signal

Immobilizer indicator light control signal

Vehicle speed signal

Engine coolant temperature signal

MIL control signal

Transmission range sensor signal

Transmission warning light signal

Diagnostic trouble code (DTC)

Brake fluid level switch signal

(brake warning light control signal)

Driver side seat belt buckle switch signal

(seat belt reminder light control signal)

Charging system warning light signal

(charge warning light control signal)

Engine oil pressure switch signal

(oil pressure warning light control signal)

Parking brake switch signal

(brake warning light control signal)

Illumination ON signal

Door switch signal

(open door warning light control signal)

ABS indication signal

EBD indication signal

(brake warning light control signal)

Key indicator light control signal ABS/ESP®

ControlModule

DATA

Receive

*

ESP® status signal

I7RS0B930001-01

Page 1365 of 1496

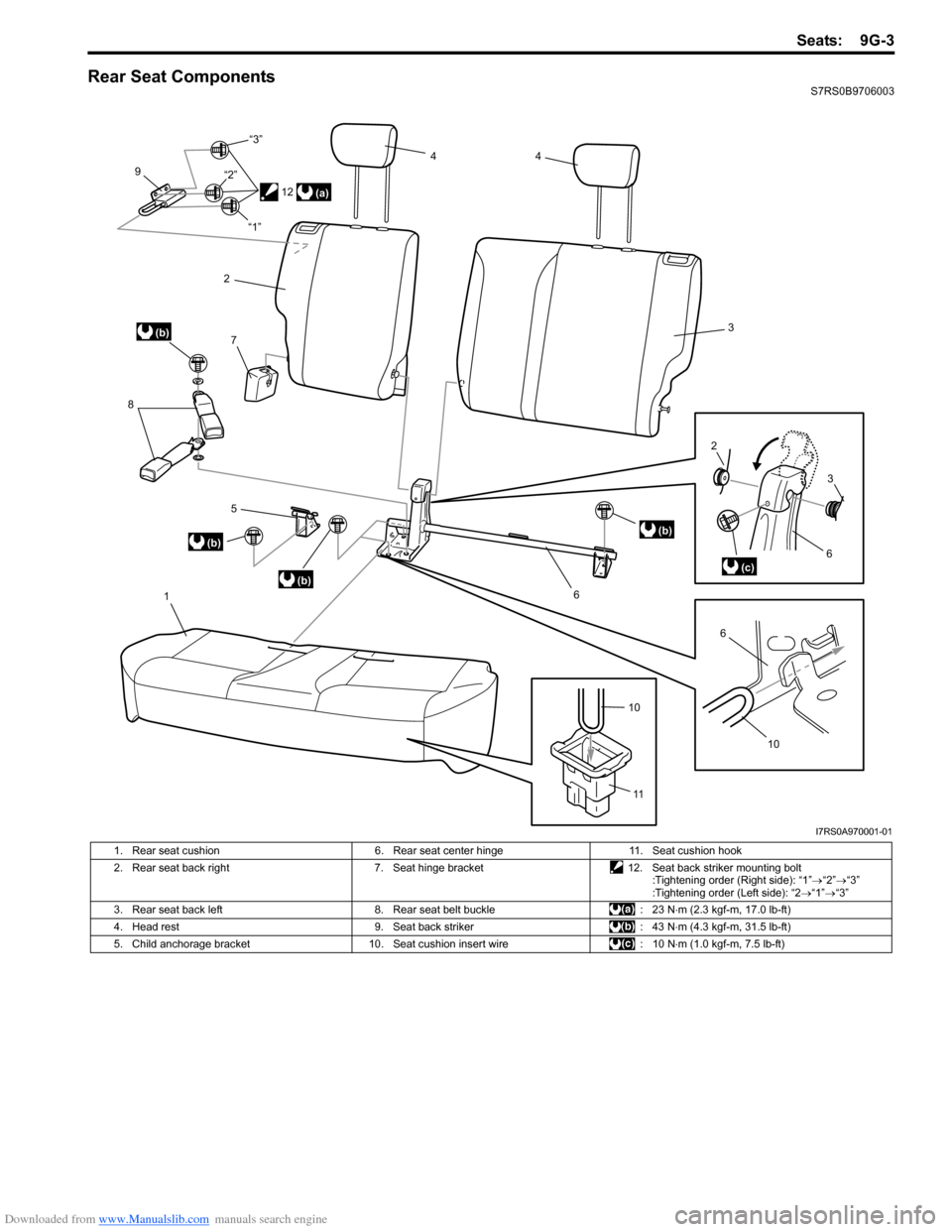

Downloaded from www.Manualslib.com manuals search engine Seats: 9G-3

Rear Seat ComponentsS7RS0B9706003

1

5

(b)

(b)

(b)

8

7

9

2

4

4

3

(b)

6

6(c)

2

3

10

6

(a)

10

11

12

“1”

“2”

“3”

I7RS0A970001-01

1. Rear seat cushion

6. Rear seat center hinge11. Seat cushion hook

2. Rear seat back right 7. Seat hinge bracket12. Seat back striker mounting bolt

:Tightening order (Right side): “1” →“2” →“3”

:Tightening order (Left side): “2 →“1” →“3”

3. Rear seat back left 8. Rear seat belt buckle : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

4. Head rest 9. Seat back striker : 43 N⋅m (4.3 kgf-m, 31.5 lb-ft)

5. Child anchorage bracket 10. Seat cushion insert wire : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

Page 1405 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-2

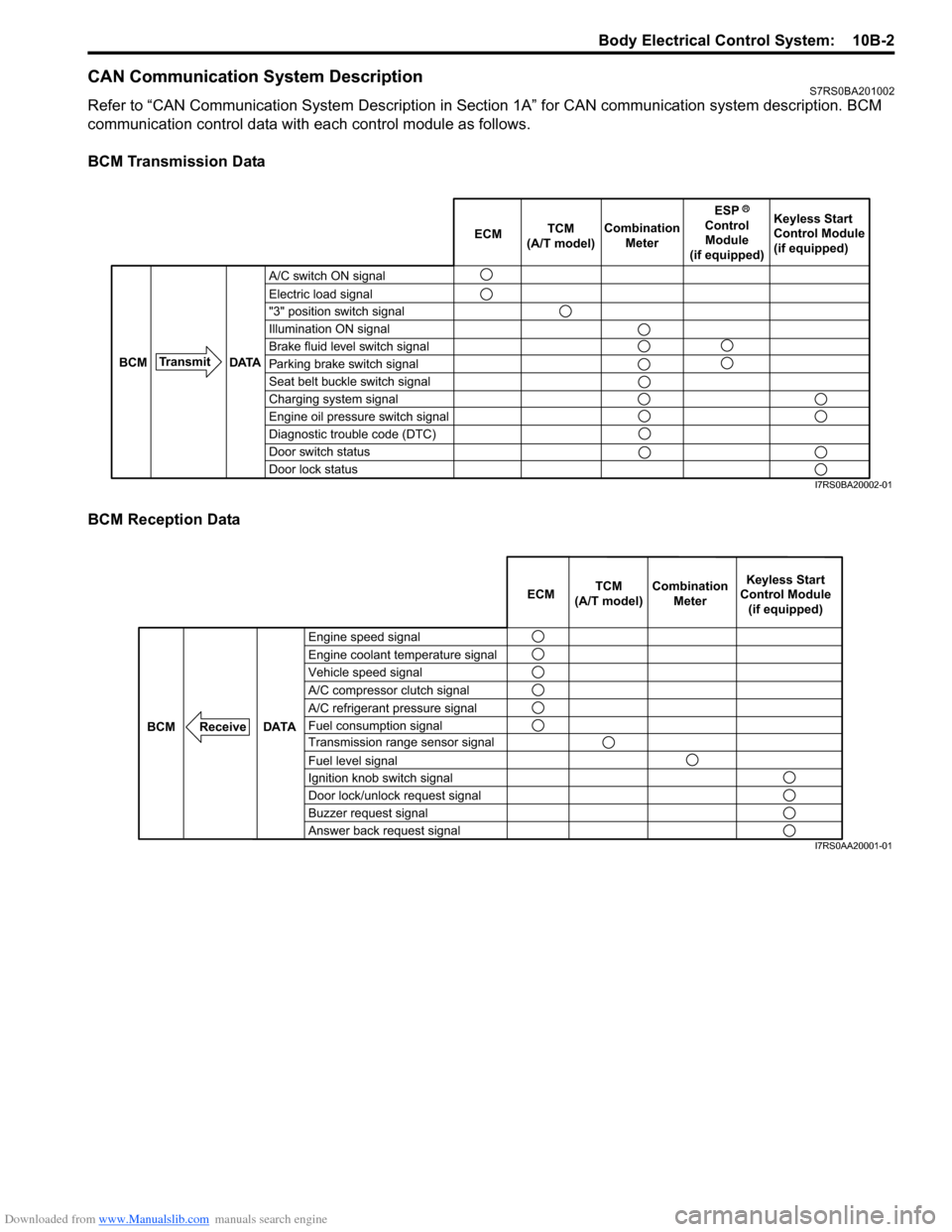

CAN Communication System DescriptionS7RS0BA201002

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description. BCM

communication control data with ea ch control module as follows.

BCM Transmission Data

BCM Reception Data

A/C switch ON signal

Electric load signal

"3" position switch signal

Illumination ON signal

Brake fluid level switch signal

Parking brake switch signal

Seat belt buckle switch signal

Charging system signal

Engine oil pressure switch signal

Diagnostic trouble code (DTC)

Door switch status

Door lock status ECM

TCM

(A/T model) Combination

Meter Keyless Start

Control Module

(if equipped)

Transmit DATA

BCM

ESP

Control Module

(if equipped)

I7RS0BA20002-01

Engine speed signal

Vehicle speed signal Engine coolant temperature signal

A/C refrigerant pressure signal

Fuel consumption signal A/C compressor clutch signal

Transmission range sensor signal

Fuel level signal

Ignition knob switch signal

Door lock/unlock request signal

Buzzer request signal

Answer back request signal

DATA

BCM

Receive

Combination

Meter

TCM

(A/T model) Keyless Start

Control Module (if equipped)

ECM

I7RS0AA20001-01

Page 1411 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-8

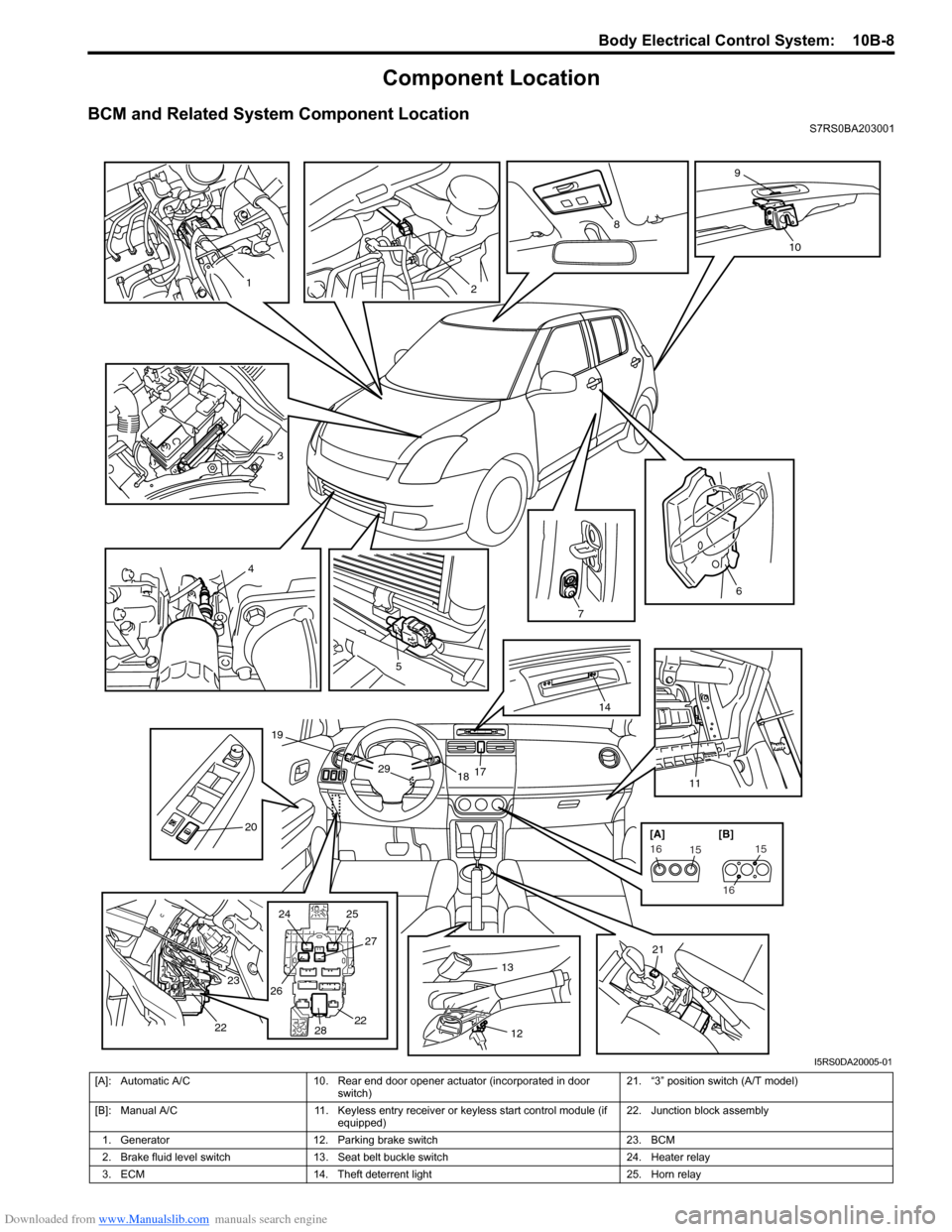

Component Location

BCM and Related System Component LocationS7RS0BA203001

3

4

5

7

6

1117

1829

19

14

20

21

24

25

26 27

28 22

23

22

1

2

8

9

10

1312

151615

16

[A] [B]

I5RS0DA20005-01

[A]: Automatic A/C

10. Rear end door opener actuator (incorporated in door

switch) 21. “3” position switch (A/T model)

[B]: Manual A/C 11. Keyless entry receiver or keyless start control module (if

equipped) 22. Junction block assembly

1. Generator 12. Parking brake switch 23. BCM

2. Brake fluid level switch 13. Seat belt buckle switch 24. Heater relay

3. ECM 14. Theft deterrent light 25. Horn relay