bolt SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 12 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-7 Precautions:

Warning for Wheel (with tire) RemovalS7RS0B0000003

WARNING!

When removing any of these wheels installed

with wheel bolts, never remove all wheel

bolts at the same time. Leave at least 1 bolt

for each wheel as it is to prevent wheel from

dropping. When removing this remaining 1

bolt, hold wheel and tire so as not to allow

them to come off.

Warning for Handling Emergency Flat Tire

Repair Kit

S7RS0B0000004

WARNING!

If vehicle is equipped with Emergency Flat

Tire Repair Kit instead of spare tire, be sure

to observe “Precaution for Emergency Flat

Tire Repair Kit in Section 2D” when handling

Emergency Flat Tire Repair Kit and repairing

flat tire.

Otherwise, your health may be ruined or it

will be impossible to repair flat tire.

Precautions for Catalytic ConverterS7RS0B0000005

For vehicles equipped with a catalytic converter, use

only unleaded gasoline and be careful not to let a large

amount of unburned gasoline enter the converter or it

can be damaged.

• Conduct a spark jump test only when necessary, make it as short as possible, and do not open the

throttle.

• Conduct engine compression checks within the shortest possible time.

• Avoid situations which can result in engine misfire (e.g. starting the engine when the fuel tank is nearly

empty.)

Precautions for Installing Mobile

Communication Equipment

S7RS0B0000006

When installing mobile communication equipment such

as CB (Citizens-Band)-radi o or cellular-telephone, be

sure to observe the following precautions.

Failure to follow cautions may adversely affect electronic

control system.

• Keep the antenna as far away as possible from the vehicle’s electronic control unit.

• Keep the antenna feeder more than 20 cm (7.9 in.) away from electronic control unit and its wire

harnesses.

• Do not run the antenna feeder parallel with other wire harnesses.

• Confirm that the antenna and feeder are correctly adjusted.

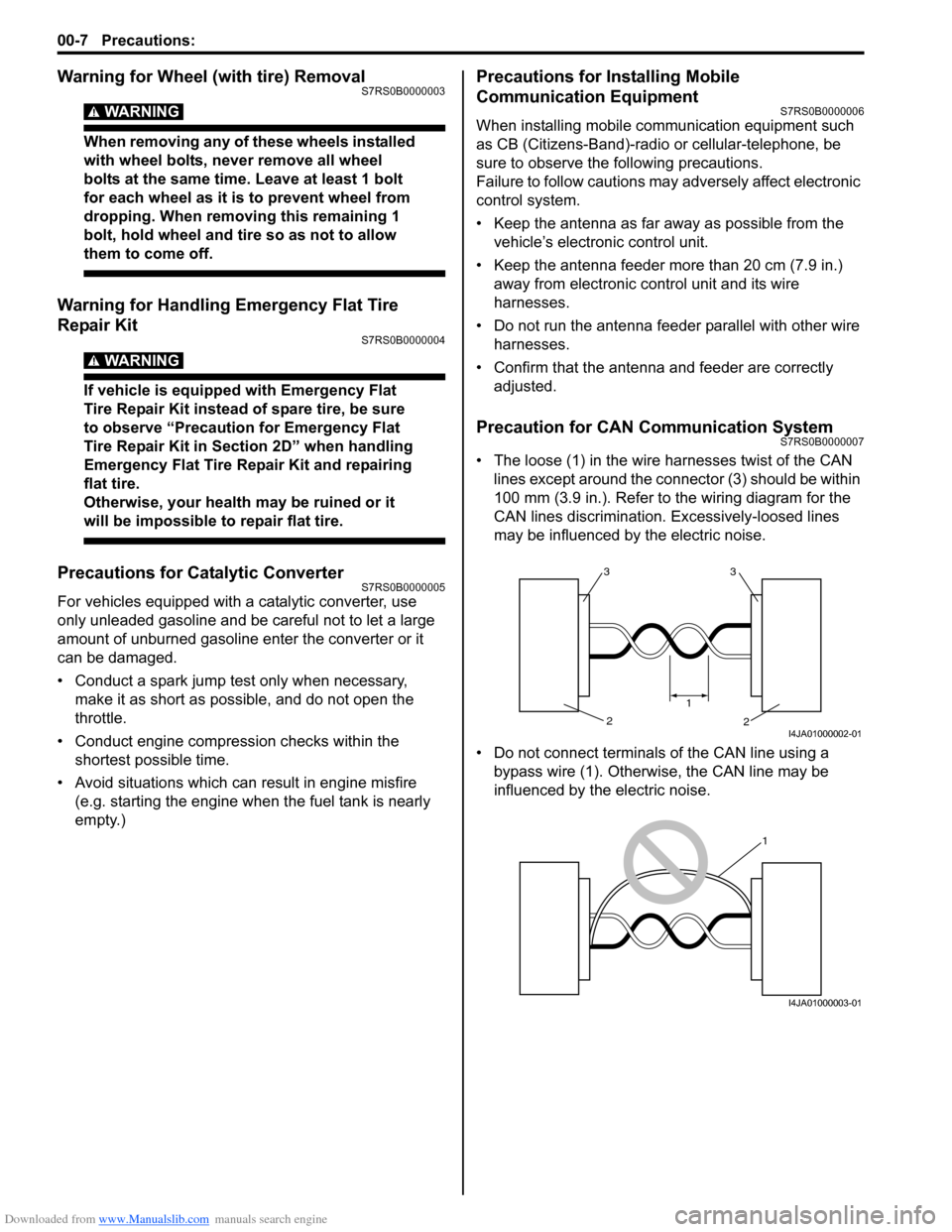

Precaution for CAN Communication SystemS7RS0B0000007

• The loose (1) in the wire harnesses twist of the CAN lines except around the connector (3) should be within

100 mm (3.9 in.). Refer to the wiring diagram for the

CAN lines discrimination. Excessively-loosed lines

may be influenced by the electric noise.

• Do not connect terminals of the CAN line using a bypass wire (1). Otherwise, the CAN line may be

influenced by the electric noise.

33

2

2

1

I4JA01000002-01

1

I4JA01000003-01

Page 24 of 1496

Downloaded from www.Manualslib.com manuals search engine 0A-3 General Information:

There are two kinds of colored wire used in this vehicle. One is single-colored wire and the other is dual-colored

(striped) wire.

The single-colored wire uses only one color symbol (i.e. “GRN”).

The dual-colored wire uses two color sy mbols (i.e. “GRN/YEL”). The first symbo l represents the base color of the wire

(“GRN” in the figure) and the second symbol represents the color of the stripe (“YEL” in the figure).

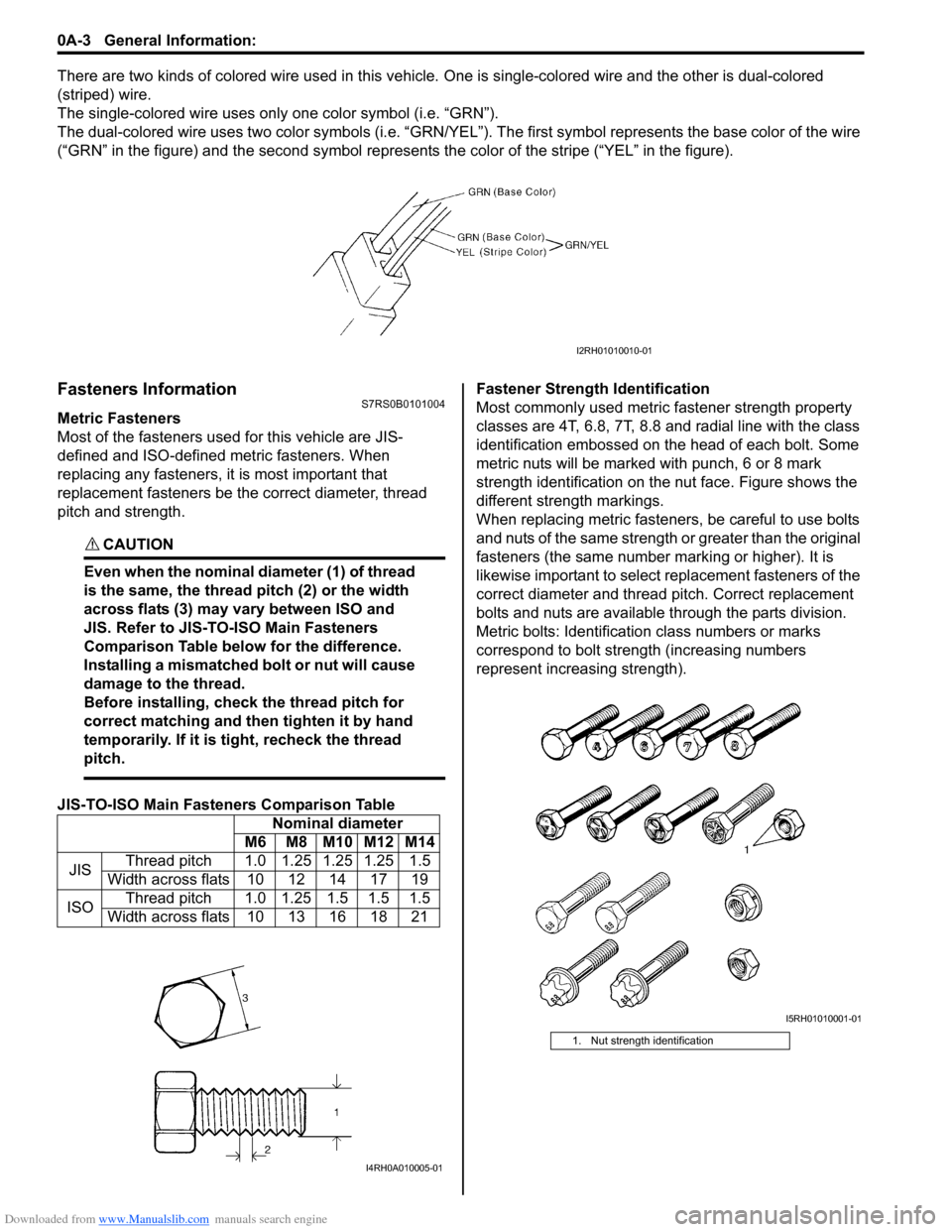

Fasteners InformationS7RS0B0101004

Metric Fasteners

Most of the fasteners used for this vehicle are JIS-

defined and ISO-defined metric fasteners. When

replacing any fasteners, it is most important that

replacement fasteners be the correct diameter, thread

pitch and strength.

CAUTION!

Even when the nominal diameter (1) of thread

is the same, the thread pitch (2) or the width

across flats (3) may vary between ISO and

JIS. Refer to JIS-TO-ISO Main Fasteners

Comparison Table below for the difference.

Installing a mismatched bolt or nut will cause

damage to the thread.

Before installing, check the thread pitch for

correct matching and then tighten it by hand

temporarily. If it is tight, recheck the thread

pitch.

JIS-TO-ISO Main Fasteners Comparison Table Fastener Strength Identification

Most commonly used metric fastener strength property

classes are 4T, 6.8, 7T, 8.8 and radial line with the class

identification embossed on the head of each bolt. Some

metric nuts will be marked with punch, 6 or 8 mark

strength identification on the nut face. Figure shows the

different strength markings.

When replacing metric fasteners, be careful to use bolts

and nuts of the same strength or greater than the original

fasteners (the same number marking or higher). It is

likewise important to select replacement fasteners of the

correct diameter and thread

pitch. Correct replacement

bolts and nuts are available through the parts division.

Metric bolts: Identification class numbers or marks

correspond to bolt strength (increasing numbers

represent increasing strength).

I2RH01010010-01

Nominal diameter

M6 M8 M10 M12 M14

JIS Thread pitch 1.0 1.25 1.25 1.25 1.5

Width across flats 10 12 14 17 19

ISO Thread pitch 1.0 1.25 1.5 1.5 1.5

Width across flats 10 13 16 18 21

I4RH0A010005-01

1. Nut strength identification

I5RH01010001-01

Page 25 of 1496

Downloaded from www.Manualslib.com manuals search engine General Information: 0A-4

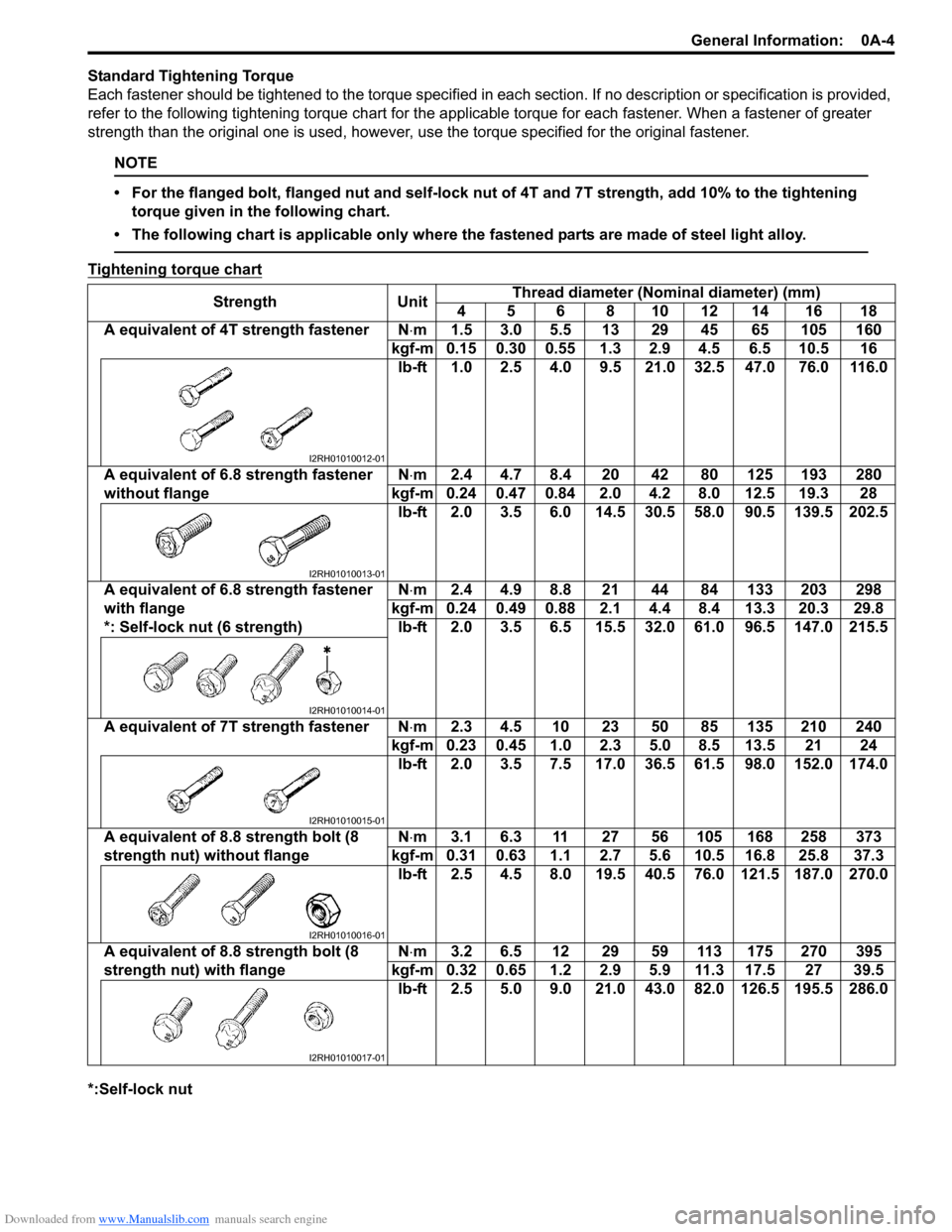

Standard Tightening Torque

Each fastener should be tightened to the torque specified in each section. If no description or specification is provided,

refer to the following tightening torque chart for the applicable torque for each fastener. When a fastener of greater

strength than the original one is used, however, use the torque specified for the original fastener.

NOTE

• For the flanged bolt, flanged nut and self-lock nut of 4T and 7T strength, add 10% to the tightening torque given in the following chart.

• The following chart is applicable only where the fastened parts are made of steel light alloy.

Tightening torque chart

*:Self-lock nut Strength Unit

Thread diameter (Nominal diameter) (mm)

4 5 6 8 10 12 14 16 18

A equivalent of 4T strength fastener N⋅ m 1.5 3.0 5.5 13 29 45 65 105 160

kgf-m 0.15 0.30 0.55 1.3 2.9 4.5 6.5 10.5 16 lb-ft 1.0 2.5 4.0 9.5 21.0 32.5 47.0 76.0 116.0

A equivalent of 6.8 strength fastener

without flange N

⋅m 2.4 4.7 8.4 20 42 80 125 193 280

kgf-m 0.24 0.47 0.84 2.0 4.2 8.0 12.5 19.3 28 lb-ft 2.0 3.5 6.0 14.5 30.5 58.0 90.5 139.5 202.5

A equivalent of 6.8 strength fastener

with flange

*: Self-lock nut (6 strength) N

⋅m 2.4 4.9 8.8 21 44 84 133 203 298

kgf-m 0.24 0.49 0.88 2.1 4.4 8.4 13.3 20.3 29.8 lb-ft 2.0 3.5 6.5 15.5 32.0 61.0 96.5 147.0 215.5

A equivalent of 7T strength fastener N⋅ m 2.3 4.5 10 23 50 85 135 210 240

kgf-m 0.23 0.45 1.0 2.3 5.0 8.5 13.5 21 24 lb-ft 2.0 3.5 7.5 17.0 36.5 61.5 98.0 152.0 174.0

A equivalent of 8.8 strength bolt (8

strength nut) without flange N

⋅m 3.1 6.3 11 27 56 105 168 258 373

kgf-m 0.31 0.63 1.1 2.7 5.6 10.5 16.8 25.8 37.3 lb-ft 2.5 4.5 8.0 19.5 40.5 76.0 121.5 187.0 270.0

A equivalent of 8.8 strength bolt (8

strength nut) with flange N

⋅m 3.2 6.5 12 29 59 113 175 270 395

kgf-m 0.32 0.65 1.2 2.9 5.9 11.3 17.5 27 39.5 lb-ft 2.5 5.0 9.0 21.0 43.0 82.0 126.5 195.5 286.0

I2RH01010012-01

I2RH01010013-01

I2RH01010014-01

I2RH01010015-01

I2RH01010016-01

I2RH01010017-01

Page 33 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-3

NOTE

• “I”: Inspect and correct or replace if necessary

• “R”: Replace or change

• *1: Inspect or replace more frequently if the vehicle is used under dusty conditions.

• *2: Clean or replace more frequently if the air from the air conditioning decreases.

Repair Instructions

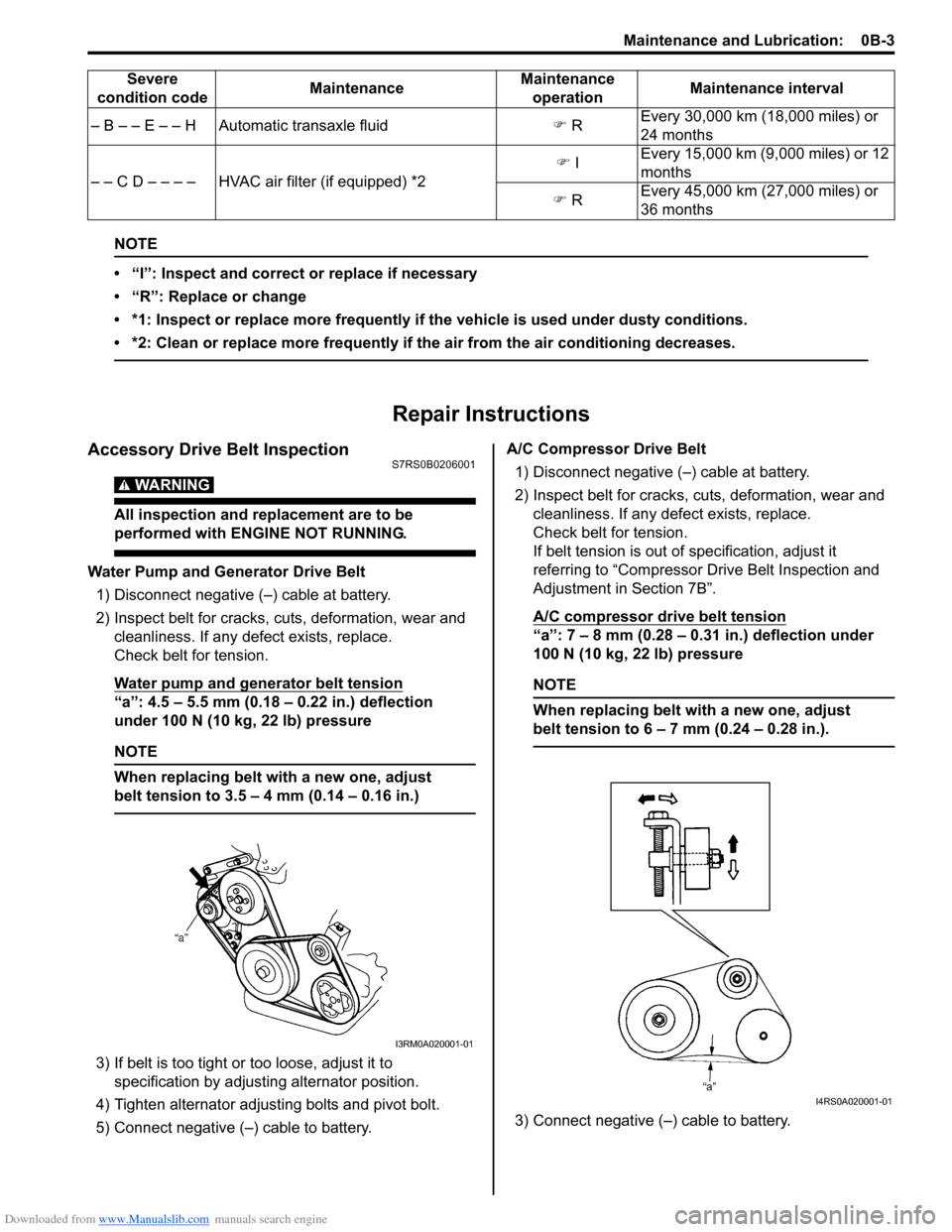

Accessory Drive Belt InspectionS7RS0B0206001

WARNING!

All inspection and replacement are to be

performed with ENGINE NOT RUNNING.

Water Pump and Generator Drive Belt1) Disconnect negative (–) cable at battery.

2) Inspect belt for cracks, cu ts, deformation, wear and

cleanliness. If any defect exists, replace.

Check belt for tension.

Water pump and generator belt tension

“a”: 4.5 – 5.5 mm (0.18 – 0.22 in.) deflection

under 100 N (10 kg, 22 lb) pressure

NOTE

When replacing belt with a new one, adjust

belt tension to 3.5 – 4 mm (0.14 – 0.16 in.)

3) If belt is too tight or too loose, adjust it to

specification by adjusting alternator position.

4) Tighten alternator adjusting bolts and pivot bolt.

5) Connect negative (–) cable to battery. A/C Compressor Drive Belt

1) Disconnect negative (–) cable at battery.

2) Inspect belt for cracks, cuts, deformation, wear and cleanliness. If any defect exists, replace.

Check belt for tension.

If belt tension is out of specification, adjust it

referring to “Compressor Dr ive Belt Inspection and

Adjustment in Section 7B”.

A/C compressor drive belt tension

“a”: 7 – 8 mm (0.28 – 0.31 in.) deflection under

100 N (10 kg, 22 lb) pressure

NOTE

When replacing belt with a new one, adjust

belt tension to 6 – 7 mm (0.24 – 0.28 in.).

3) Connect negative (–) cable to battery.

– B – – E – – H Automatic transaxle fluid

�) R Every 30,000 km (18,000 miles) or

24 months

– – C D – – – – HVAC air filter (if equipped) *2 �)

I Every 15,000 km (9,000 miles) or 12

months

�) R Every 45,000 km (27,000 miles) or

36 months

Severe

condition code MaintenanceMaintenance

operation Maintenance interval

I3RM0A020001-01

I4RS0A020001-01

Page 36 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-6 Maintenance and Lubrication:

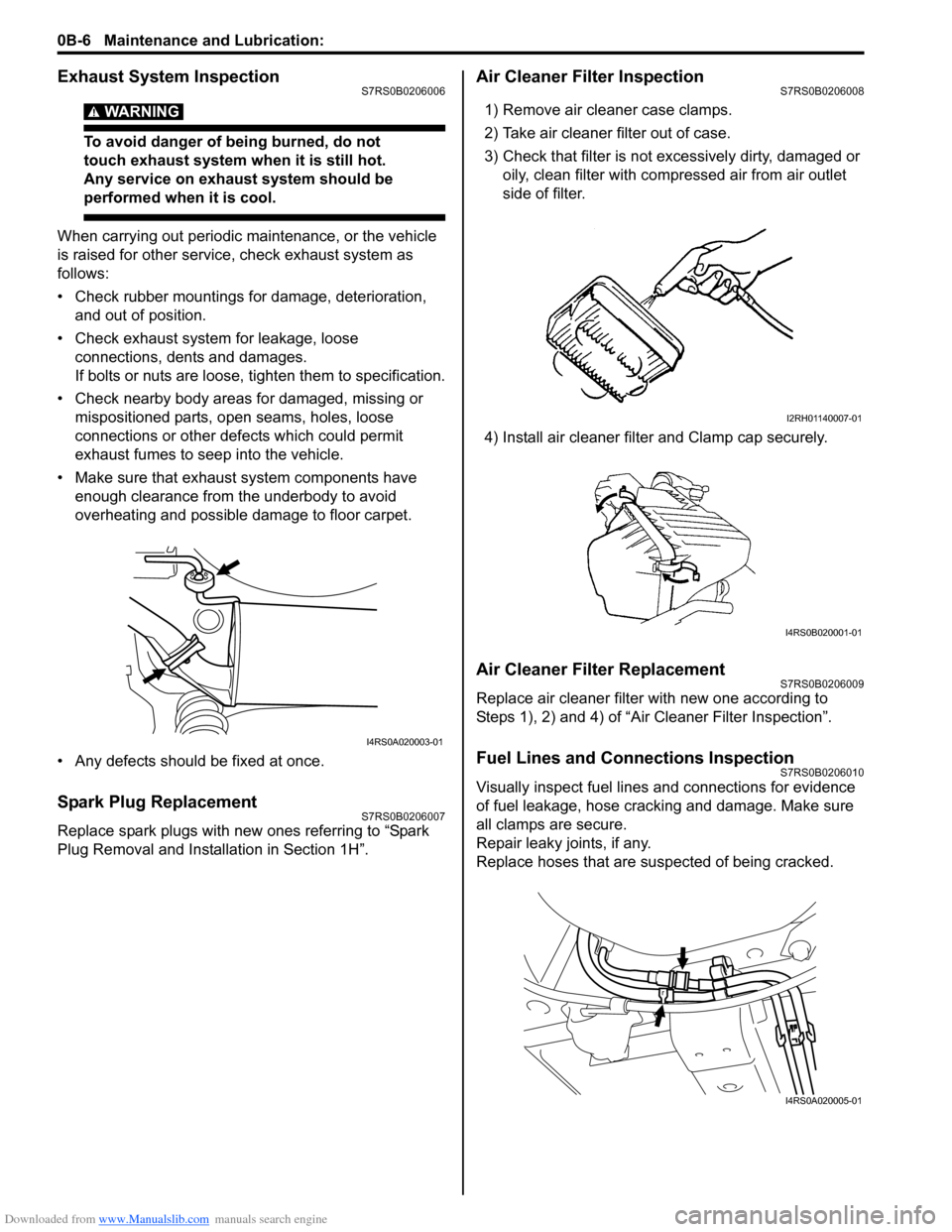

Exhaust System InspectionS7RS0B0206006

WARNING!

To avoid danger of being burned, do not

touch exhaust system when it is still hot.

Any service on exhaust system should be

performed when it is cool.

When carrying out periodic maintenance, or the vehicle

is raised for other service, check exhaust system as

follows:

• Check rubber mountings for damage, deterioration, and out of position.

• Check exhaust system for leakage, loose connections, dents and damages.

If bolts or nuts are loose, tighten them to specification.

• Check nearby body areas for damaged, missing or mispositioned parts, ope n seams, holes, loose

connections or other defects which could permit

exhaust fumes to seep into the vehicle.

• Make sure that exhaust system components have enough clearance from the underbody to avoid

overheating and possible damage to floor carpet.

• Any defects should be fixed at once.

Spark Plug ReplacementS7RS0B0206007

Replace spark plugs with new ones referring to “Spark

Plug Removal and Installation in Section 1H”.

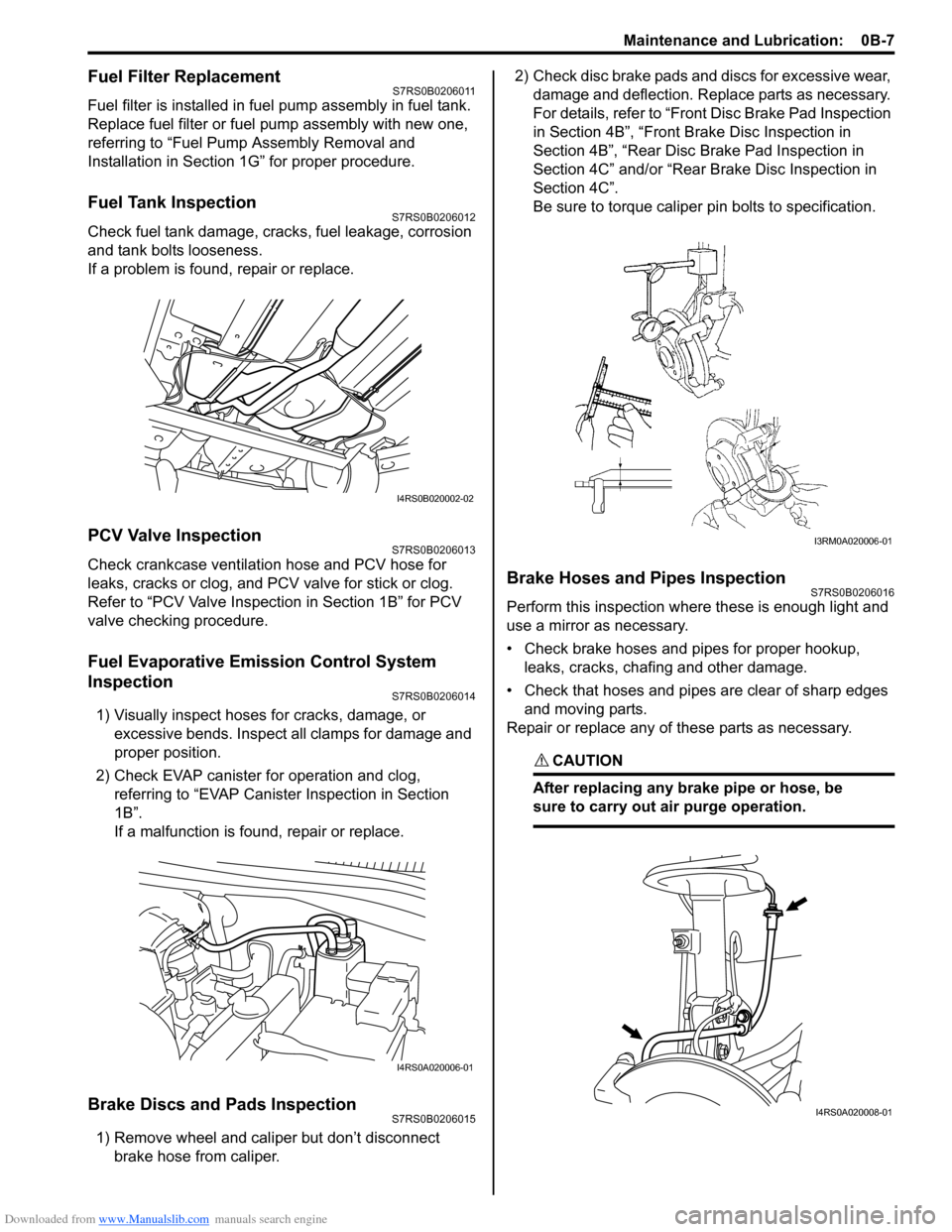

Air Cleaner Filter InspectionS7RS0B0206008

1) Remove air cleaner case clamps.

2) Take air cleaner filter out of case.

3) Check that filter is not excessively dirty, damaged or oily, clean filter with compressed air from air outlet

side of filter.

4) Install air cleaner filter and Clamp cap securely.

Air Cleaner Filter ReplacementS7RS0B0206009

Replace air cleaner filter with new one according to

Steps 1), 2) and 4) of “Air Cleaner Filter Inspection”.

Fuel Lines and Connections InspectionS7RS0B0206010

Visually inspect fuel lines and connections for evidence

of fuel leakage, hose cracking and damage. Make sure

all clamps are secure.

Repair leaky joints, if any.

Replace hoses that are suspected of being cracked.

I4RS0A020003-01

I2RH01140007-01

I4RS0B020001-01

I4RS0A020005-01

Page 37 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-7

Fuel Filter ReplacementS7RS0B0206011

Fuel filter is installed in fuel pump assembly in fuel tank.

Replace fuel filter or fuel pump assembly with new one,

referring to “Fuel Pump Assembly Removal and

Installation in Section 1G” for proper procedure.

Fuel Tank InspectionS7RS0B0206012

Check fuel tank damage, cracks, fuel leakage, corrosion

and tank bolts looseness.

If a problem is found, repair or replace.

PCV Valve InspectionS7RS0B0206013

Check crankcase ventilation hose and PCV hose for

leaks, cracks or clog, and PCV valve for stick or clog.

Refer to “PCV Valve Inspection in Section 1B” for PCV

valve checking procedure.

Fuel Evaporative Emission Control System

Inspection

S7RS0B0206014

1) Visually inspect hoses for cracks, damage, or excessive bends. Inspect a ll clamps for damage and

proper position.

2) Check EVAP canister for operation and clog, referring to “EVAP Canister Inspection in Section

1B”.

If a malfunction is found, repair or replace.

Brake Discs and Pads InspectionS7RS0B0206015

1) Remove wheel and caliper but don’t disconnect brake hose from caliper. 2) Check disc brake pads and discs for excessive wear,

damage and deflection. Replace parts as necessary.

For details, refer to “Front Disc Brake Pad Inspection

in Section 4B”, “Front Brake Disc Inspection in

Section 4B”, “Rear Disc Brake Pad Inspection in

Section 4C” and/or “Rear Brake Disc Inspection in

Section 4C”.

Be sure to torque caliper pin bolts to specification.

Brake Hoses and Pipes InspectionS7RS0B0206016

Perform this inspection where these is enough light and

use a mirror as necessary.

• Check brake hoses and pipes for proper hookup, leaks, cracks, chafing and other damage.

• Check that hoses and pipes are clear of sharp edges and moving parts.

Repair or replace any of these parts as necessary.

CAUTION!

After replacing any brake pipe or hose, be

sure to carry out air purge operation.

I4RS0B020002-02

I4RS0A020006-01

I3RM0A020006-01

I4RS0A020008-01

Page 39 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-9

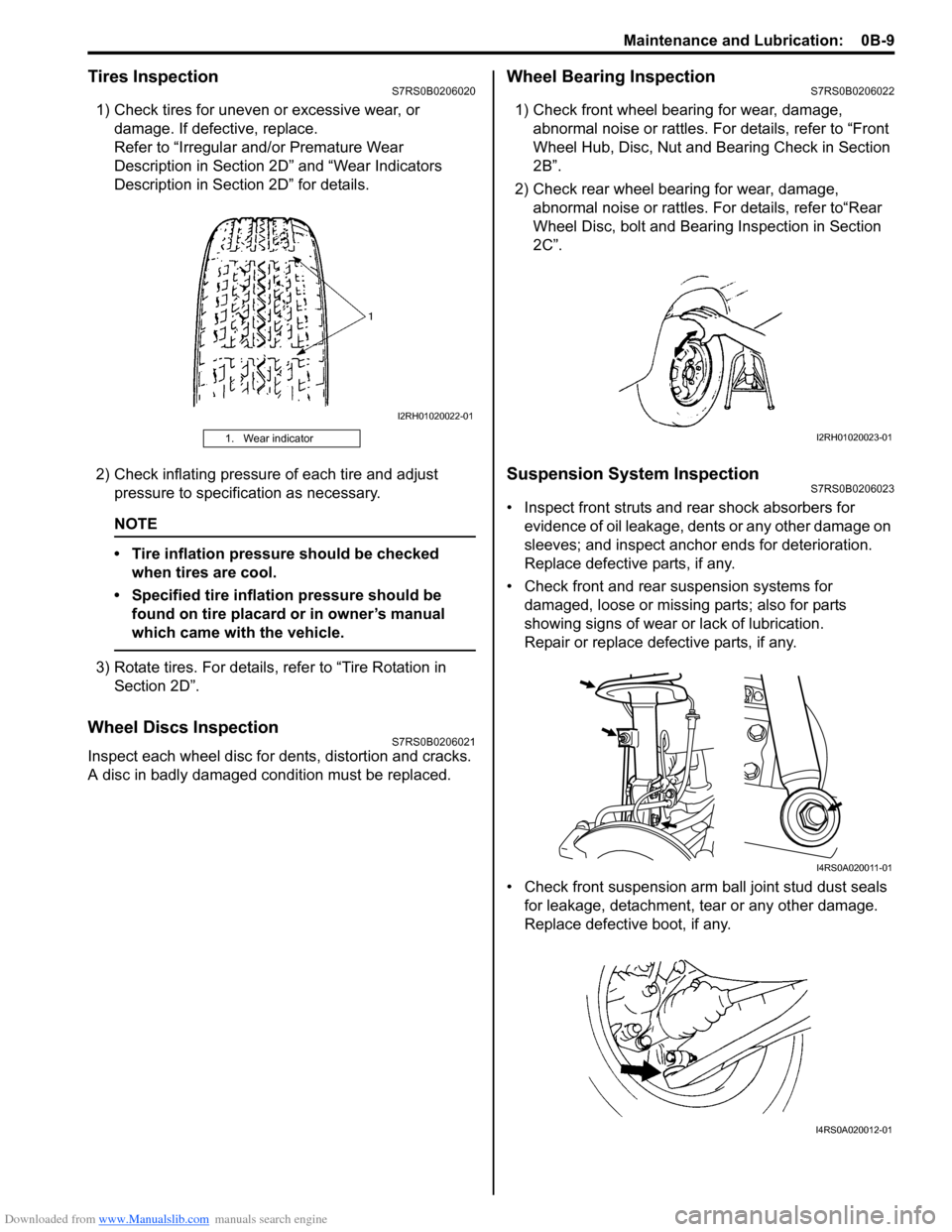

Tires InspectionS7RS0B0206020

1) Check tires for uneven or excessive wear, or damage. If defective, replace.

Refer to “Irregular and/or Premature Wear

Description in Section 2D” and “Wear Indicators

Description in Section 2D” for details.

2) Check inflating pressure of each tire and adjust pressure to specification as necessary.

NOTE

• Tire inflation pressure should be checked when tires are cool.

• Specified tire inflation pressure should be found on tire placard or in owner’s manual

which came with the vehicle.

3) Rotate tires. For details, refer to “Tire Rotation in Section 2D”.

Wheel Discs InspectionS7RS0B0206021

Inspect each wheel disc for de nts, distortion and cracks.

A disc in badly damaged condition must be replaced.

Wheel Bearing InspectionS7RS0B0206022

1) Check front wheel bearing for wear, damage, abnormal noise or rattles. For details, refer to “Front

Wheel Hub, Disc, Nut and Bearing Check in Section

2B”.

2) Check rear wheel bearing for wear, damage, abnormal noise or rattles. For details, refer to“Rear

Wheel Disc, bolt and Bearing Inspection in Section

2C”.

Suspension System InspectionS7RS0B0206023

• Inspect front struts and rear shock absorbers for evidence of oil leakage, dents or any other damage on

sleeves; and inspect anchor ends for deterioration.

Replace defective parts, if any.

• Check front and rear suspension systems for damaged, loose or missing parts; also for parts

showing signs of wear or lack of lubrication.

Repair or replace defective parts, if any.

• Check front suspension arm ball joint stud dust seals for leakage, detachment, tear or any other damage.

Replace defective boot, if any.

1. Wear indicator

I2RH01020022-01

I2RH01020023-01

I4RS0A020011-01

I4RS0A020012-01

Page 40 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-10 Maintenance and Lubrication:

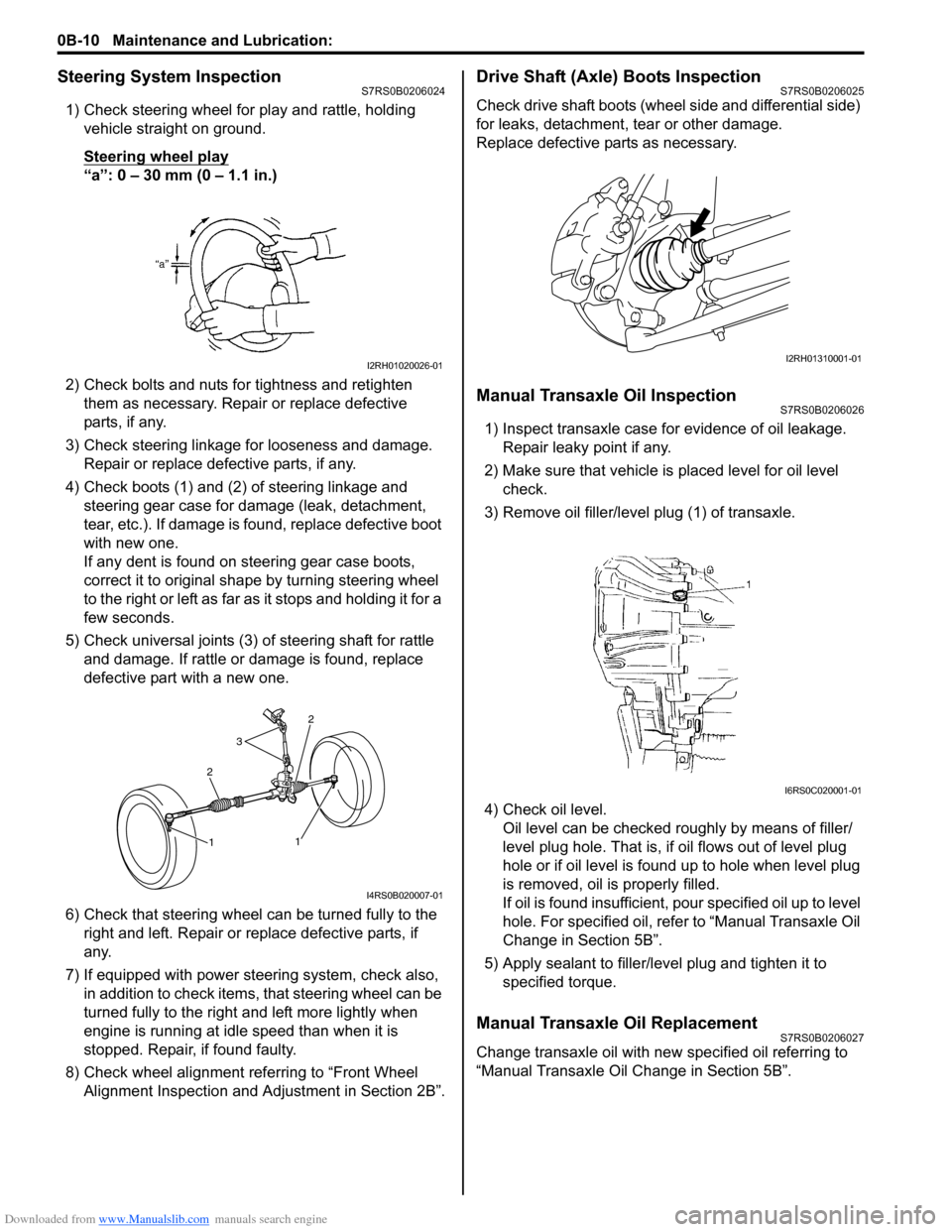

Steering System InspectionS7RS0B0206024

1) Check steering wheel for play and rattle, holding vehicle straight on ground.

Steering wheel play

“a”: 0 – 30 mm (0 – 1.1 in.)

2) Check bolts and nuts for tightness and retighten them as necessary. Repair or replace defective

parts, if any.

3) Check steering linkage for looseness and damage. Repair or replace defective parts, if any.

4) Check boots (1) and (2) of steering linkage and steering gear case for damage (leak, detachment,

tear, etc.). If damage is fo und, replace defective boot

with new one.

If any dent is found on steering gear case boots,

correct it to original shape by turning steering wheel

to the right or left as far as it stops and holding it for a

few seconds.

5) Check universal joints (3) of steering shaft for rattle and damage. If rattle or damage is found, replace

defective part with a new one.

6) Check that steering wheel can be turned fully to the

right and left. Repair or replace defective parts, if

any.

7) If equipped with power steering system, check also, in addition to check items, that steering wheel can be

turned fully to the right and left more lightly when

engine is running at idle speed than when it is

stopped. Repair, if found faulty.

8) Check wheel alignment referring to “Front Wheel Alignment Inspection and Adjustment in Section 2B”.

Drive Shaft (Axle) Boots InspectionS7RS0B0206025

Check drive shaft boots (wheel side and differential side)

for leaks, detachment, tear or other damage.

Replace defective parts as necessary.

Manual Transaxle Oil InspectionS7RS0B0206026

1) Inspect transaxle case for evidence of oil leakage. Repair leaky point if any.

2) Make sure that vehicle is placed level for oil level

check.

3) Remove oil filler/leve l plug (1) of transaxle.

4) Check oil level. Oil level can be checked roughly by means of filler/

level plug hole. That is, if oil flows out of level plug

hole or if oil level is found up to hole when level plug

is removed, oil is properly filled.

If oil is found insufficient, po ur specified oil up to level

hole. For specified oil, refe r to “Manual Transaxle Oil

Change in Section 5B”.

5) Apply sealant to filler/leve l plug and tighten it to

specified torque.

Manual Transaxle Oil ReplacementS7RS0B0206027

Change transaxle oil with new specified oil referring to

“Manual Transaxle Oil Change in Section 5B”.

I2RH01020026-01

2

3

2

1

1

I4RS0B020007-01

I2RH01310001-01

I6RS0C020001-01

Page 87 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-37

TP SENSOR 2 VOLT (THROTTLE POSITION SENSOR

(SUB) OUTPUT VOLTAGE, V)

The TP sensor (sub) reading provides throttle valve

opening information in the form of voltage.

APP SENSOR 1 VOLT (ACCELERATOR PEDAL

POSITION (APP) SENSOR (MAIN) OUTPUT

VOLTAGE, V)

The APP sensor (main) read ing provides accelerator

pedal opening information in the form of voltage.

APP SENSOR 2 VOLT (ACCELERATOR PEDAL

POSITION (APP) SENSOR (S UB) OUTPUT VOLTAGE,

V)

The APP sensor (sub) reading provides accelerator

pedal opening information in the form of voltage.

ACCEL POSITION (ABSOLUTE ACCELERATOR

PEDAL POSITION, %)

When accelerator pedal is at fully released position,

accelerator pedal is indicated as 0 – 5% and 90 – 100%

fully depressed position. THROTTLE TARGET POSI (TARGET THROTTLE

VALVE POSITION, %)

Target throttle valve position is ECM internal parameter

which indicates the ECM requested throttle valve

position.

BATTERY CURRENT (A)

This parameter indicates elec

tric load value (current

consumption) that detected by electric load current

sensor.

GENERATOR CONT DUTY (GENERATOR CONTROL

DUTY, %)

This parameter indicates generator control duty ratio that

controls production electricity of generator by ECM.

100%: No limitation for the generating

0%: Maximum limitation for the generating

GENERATOR FIELD DUTY (GENERATOR FIELD

COIL DUTY, %)

This parameter indicates ope rating rate (status of

production electricity) for gen erator by field coil duty

ratio.

100%: maximum operation.

0%: minimum operation.

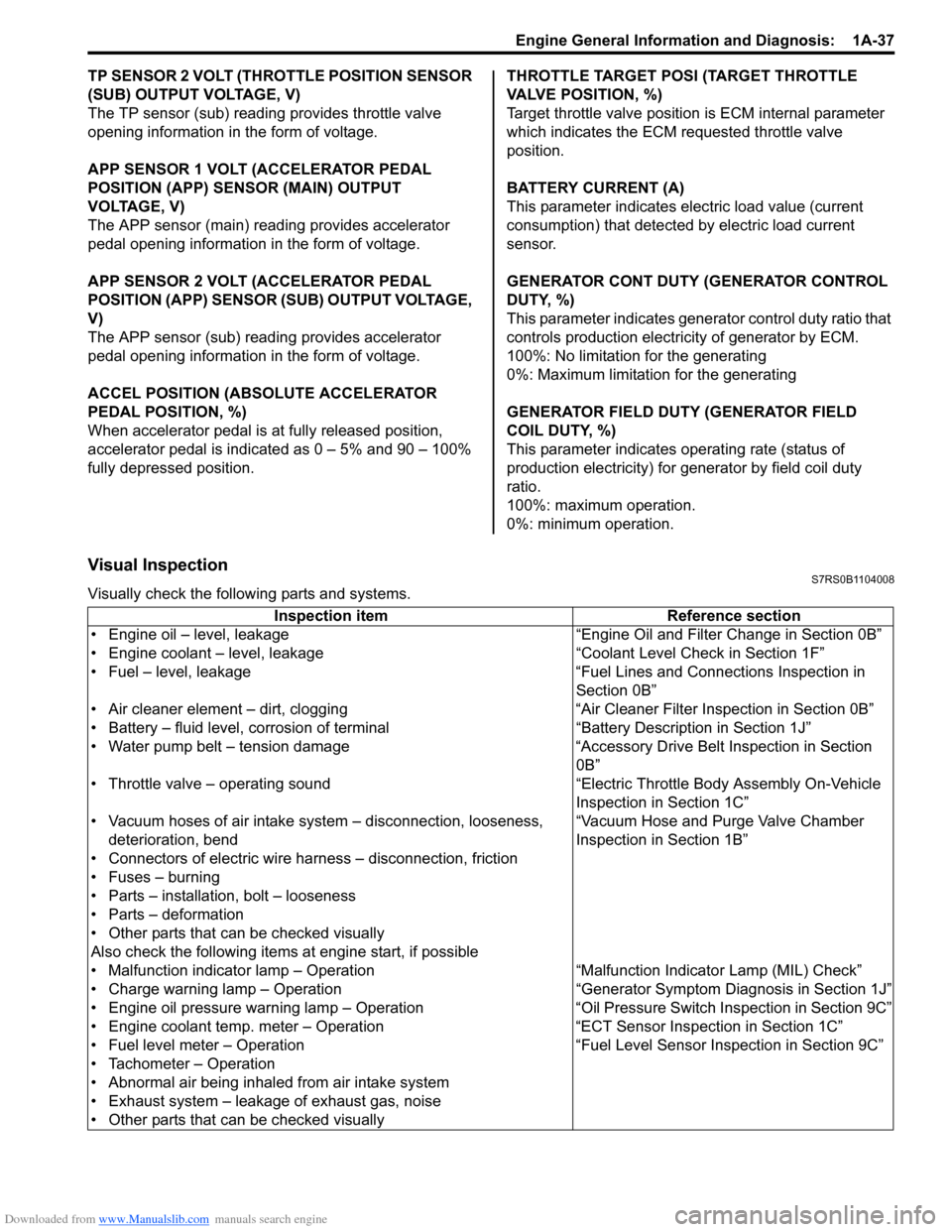

Visual InspectionS7RS0B1104008

Visually check the following parts and systems.

Inspection item Reference section

• Engine oil – level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant – level, leakage “Co olant Level Check in Section 1F”

• Fuel – level, leakage “Fuel Lines and Connections Inspection in Section 0B”

• Air cleaner element – dirt, clogging “Air Cleaner Filter Inspection in Section 0B”

• Battery – fluid level, corrosion of terminal “Battery Description in Section 1J”

• Water pump belt – tension damage “Accessory Drive Belt Inspection in Section 0B”

• Throttle valve – operating sound “Electric Throttle Body Assembly On-Vehicle Inspection in Section 1C”

• Vacuum hoses of air intake system – disconnection, looseness,

deterioration, bend “Vacuum Hose and Purge Valve Chamber

Inspection in Section 1B”

• Connectors of electric wire harness – disconnection, friction

• Fuses – burning

• Parts – installation, bolt – looseness

• Parts – deformation

• Other parts that can be checked visually

Also check the following items at engine start, if possible

• Malfunction indicator lamp – Operation “Malfunction Indicator Lamp (MIL) Check”

• Charge warning lamp – Operation “Genera tor Symptom Diagnosis in Section 1J”

• Engine oil pressure warning lamp – Operation “O il Pressure Switch Inspection in Section 9C”

• Engine coolant temp. meter – Operation “ECT Sensor Inspection in Section 1C”

• Fuel level meter – Operation “Fuel Level Sensor Inspection in Section 9C”

• Tachometer – Operation

• Abnormal air being inhaled from air intake system

• Exhaust system – leakage of exhaust gas, noise

• Other parts that can be checked visually

Page 92 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-42 Engine General Information and Diagnosis:

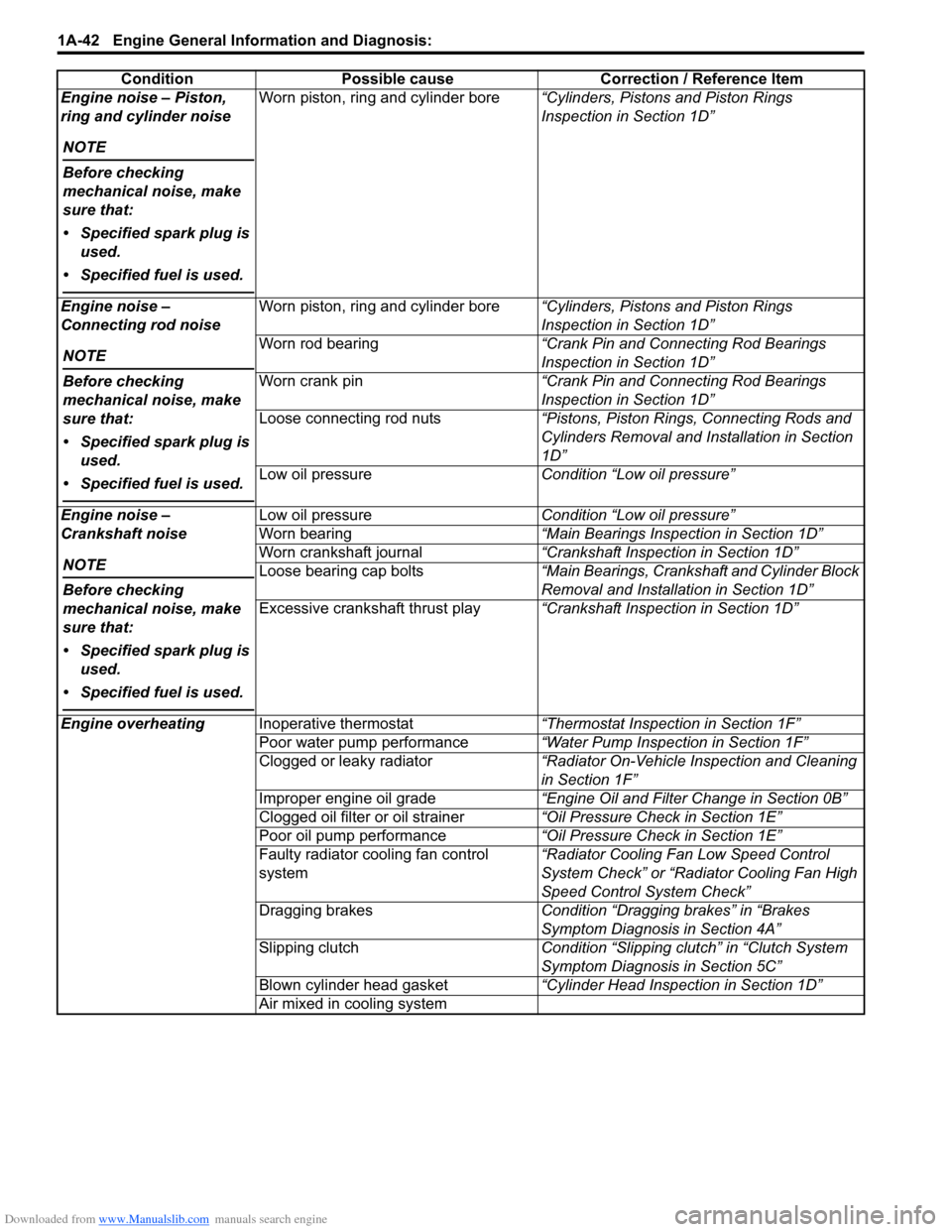

Engine noise – Piston,

ring and cylinder noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Worn piston, ring and cylinder bore “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Engine noise –

Connecting rod noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Worn piston, ring and cylinder bore “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn rod bearing “Crank Pin and Connecting Rod Bearings

Inspection in Section 1D”

Worn crank pin “Crank Pin and Connecting Rod Bearings

Inspection in Section 1D”

Loose connecting rod nuts “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation in Section

1D”

Low oil pressure Condition “Low oil pressure”

Engine noise –

Crankshaft noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Low oil pressure Condition “Low oil pressure”

Worn bearing “Main Bearings Inspection in Section 1D”

Worn crankshaft journal “Crankshaft Inspection in Section 1D”

Loose bearing cap bolts “Main Bearings, Crankshaft and Cylinder Block

Removal and Installation in Section 1D”

Excessive crankshaft thrust play “Crankshaft Inspection in Section 1D”

Engine overheating Inoperative thermostat “Thermostat Inspection in Section 1F”

Poor water pump performance “Water Pump Inspection in Section 1F”

Clogged or leaky radiator “Radiator On-Vehicle Inspection and Cleaning

in Section 1F”

Improper engine oil grade “Engine Oil and Filter Change in Section 0B”

Clogged oil filter or oil strainer “Oil Pressure Check in Section 1E”

Poor oil pump performance “Oil Pressure Check in Section 1E”

Faulty radiator cooling fan control

system “Radiator Cooling Fan Low Speed Control

System Check” or “Rad

iator Cooling Fan High

Speed Control System Check”

Dragging brakes Condition “Dragging brakes” in “Brakes

Symptom Diagnosis in Section 4A”

Slipping clutch Condition “Slipping clutch” in “Clutch System

Symptom Diagnosis in Section 5C”

Blown cylinder head gasket “Cylinder Head Inspection in Section 1D”

Air mixed in cooling system

Condition Possible cause Correction / Reference Item