check engine codes SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 268 of 1496

Downloaded from www.Manualslib.com manuals search engine 1B-1 Aux. Emission Control Devices:

Engine

Aux. Emission Control Devices

Diagnostic Information and Procedures

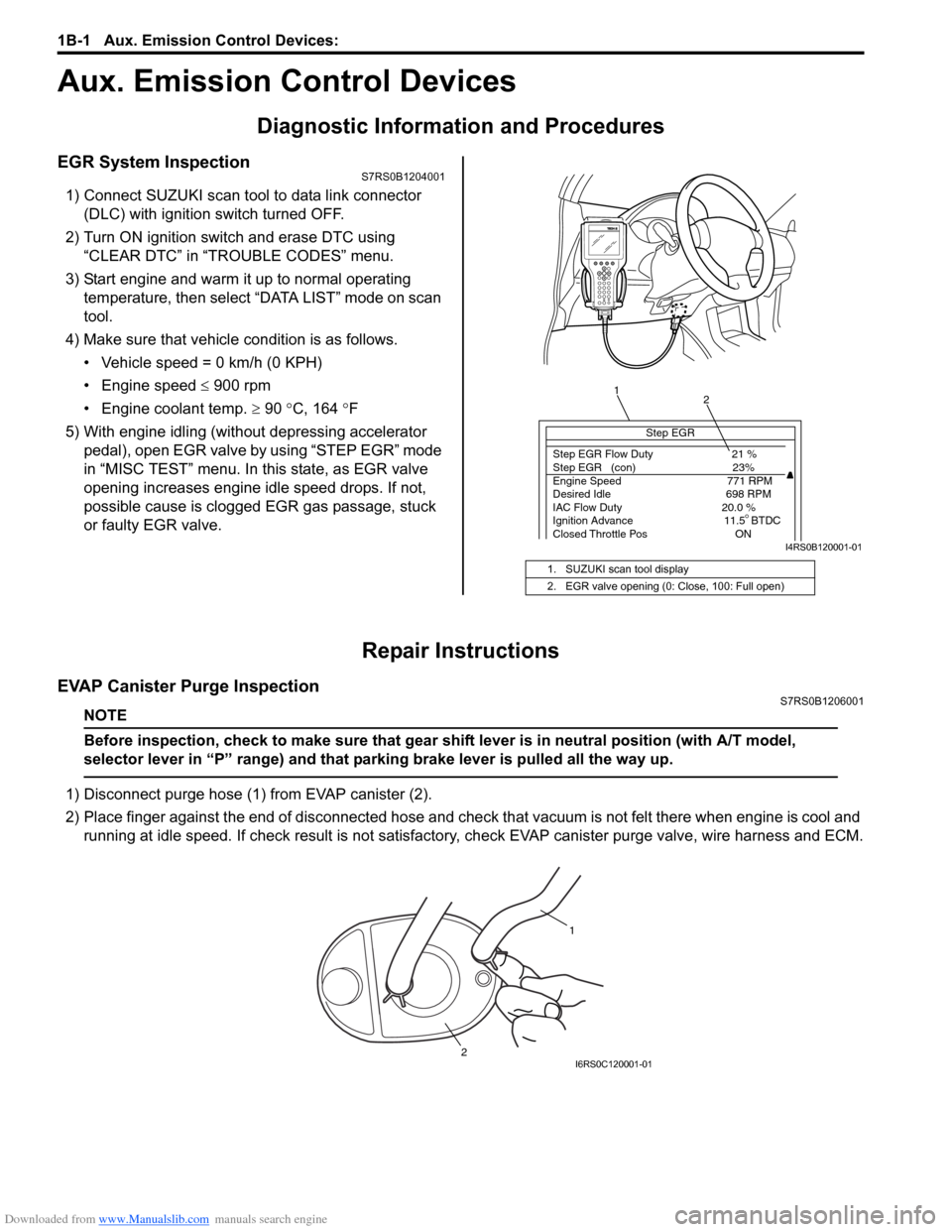

EGR System InspectionS7RS0B1204001

1) Connect SUZUKI scan tool to data link connector (DLC) with ignition switch turned OFF.

2) Turn ON ignition switch and erase DTC using “CLEAR DTC” in “TROUBLE CODES” menu.

3) Start engine and warm it up to normal operating temperature, then select “DATA LIST” mode on scan

tool.

4) Make sure that vehicle condition is as follows.

• Vehicle speed = 0 km/h (0 KPH)

• Engine speed ≤ 900 rpm

• Engine coolant temp. ≥ 90 °C, 164 °F

5) With engine idling (without depressing accelerator pedal), open EGR valve by using “STEP EGR” mode

in “MISC TEST” menu. In this state, as EGR valve

opening increases engine idle speed drops. If not,

possible cause is clogged EGR gas passage, stuck

or faulty EGR valve.

Repair Instructions

EVAP Canister Purge InspectionS7RS0B1206001

NOTE

Before inspection, check to make sure that gear shift lever is in neutral position (with A/T model,

selector lever in “P” range) and that parking brake lever is pulled all the way up.

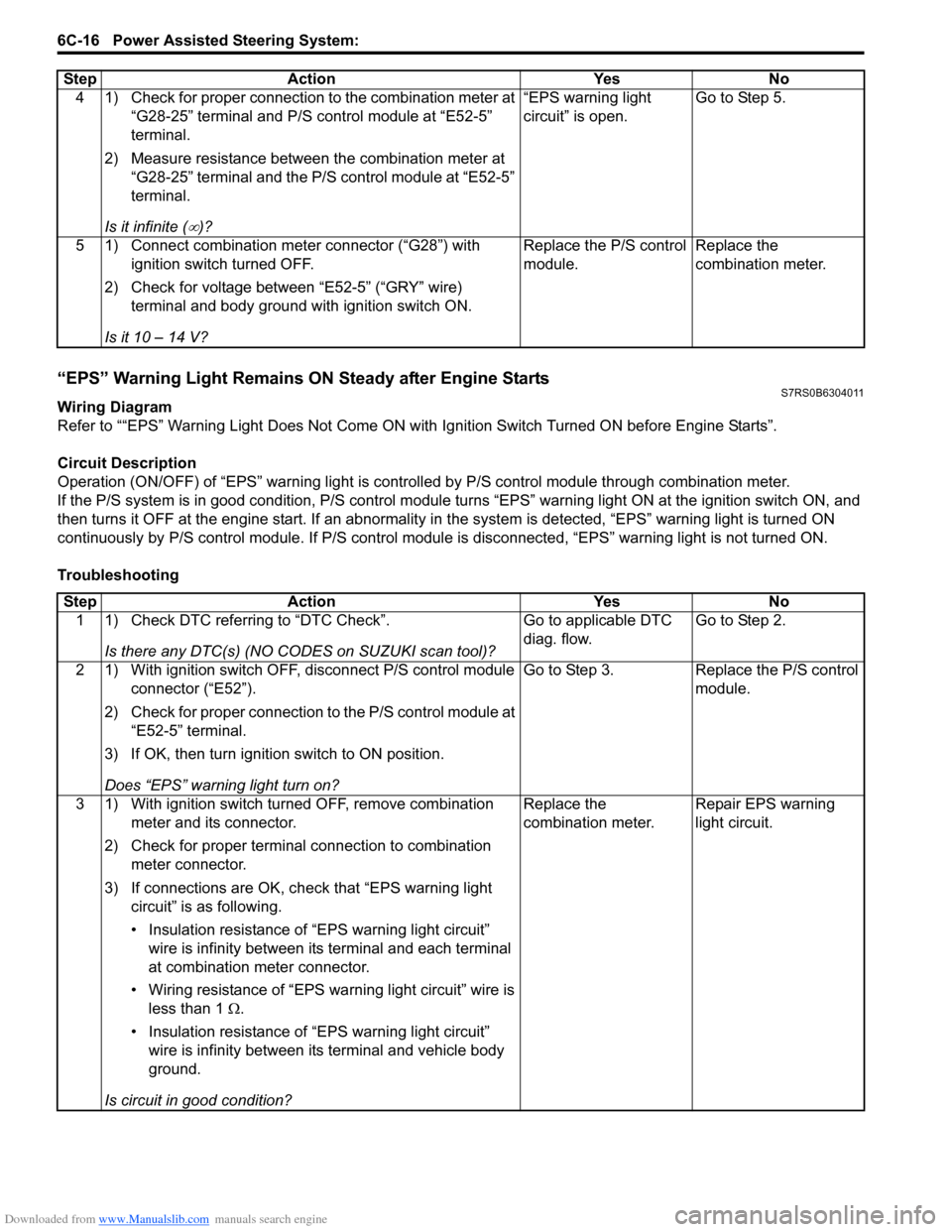

1) Disconnect purge hose (1) from EVAP canister (2).

2) Place finger against the end of disconne cted hose and check that vacuum is not felt there when engine is cool and

running at idle speed. If check result is not satisfacto ry, check EVAP canister purge valve, wire harness and ECM.

1. SUZUKI scan tool display

2. EGR valve opening (0: Close, 100: Full open)

Step EGR

Step EGR Flow Duty 21 %

Step EGR (con) 23%

Engine Speed 771 RPM

Desired Idle 698 RPM

IAC Flow Duty 20.0 %

Ignition Advance 11.5 BTDC

Closed Throttle Pos ON

1 2

I4RS0B120001-01

1

2

I6RS0C120001-01

Page 891 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-9

3) Start engine.

4) Read DTC according to the instructions displayed on

SUZUKI scan tool. For further details, refer to

operator’s manual for SUZUKI scan tool.

NOTE

• If communication between SUZUKI scan tool and the vehicle can not be

established, perform “Serial Data Link

Circuit Check”.

• DTC C1122 (engine speed signal failure) is indicated when ignition switch is at ON

position and engine is not running, but it

means there is nothing abnormal if

indication changes to a normal one when

engine is started.

5) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

DLC.

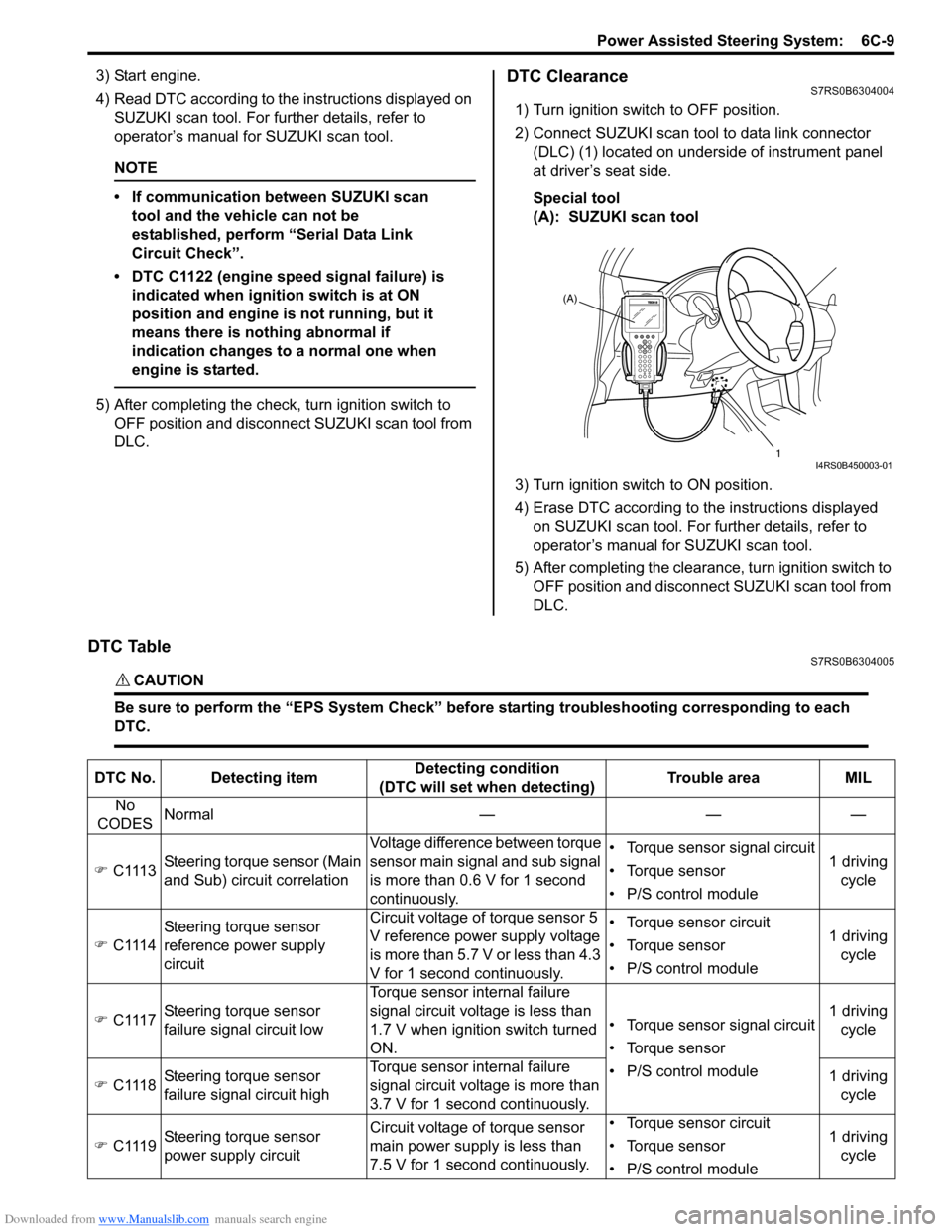

DTC ClearanceS7RS0B6304004

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Erase DTC according to the instructions displayed on SUZUKI scan tool. For further details, refer to

operator’s manual for SUZUKI scan tool.

5) After completing the clearance, turn ignition switch to OFF position and disconnect SUZUKI scan tool from

DLC.

DTC TableS7RS0B6304005

CAUTION!

Be sure to perform the “EPS Syst em Check” before starting troubleshooting corresponding to each

DTC.

(A)

1

I4RS0B450003-01

DTC No. Detecting item Detecting condition

(DTC will set when detecting) Trouble area MIL

No

CODES Normal — — —

�) C1113 Steering torque sensor (Main

and Sub) circuit correlation Voltage difference between torque

sensor main signal and sub signal

is more than 0.6 V for 1 second

continuously. • Torque sensor signal circuit

• Torque sensor

• P/S control module

1 driving

cycle

�) C1114 Steering torque sensor

reference power supply

circuit Circuit voltage of torque sensor 5

V reference power supply voltage

is more than 5.7 V or less than 4.3

V for 1 second continuously. • Torque sensor circuit

• Torque sensor

• P/S control module

1 driving

cycle

�) C1117 Steering torque sensor

failure signal circuit low Torque sensor internal failure

signal circuit voltage is less than

1.7 V when ignition switch turned

ON.

• Torque sensor signal circuit

• Torque sensor

• P/S control module1 driving

cycle

�) C1118 Steering torque sensor

failure signal circuit high Torque sensor internal failure

signal circuit voltage is more than

3.7 V for 1 second continuously. 1 driving

cycle

�) C1119 Steering torque sensor

power supply circuit Circuit voltage of torque sensor

main power supply

is less than

7.5 V for 1 second continuously. • Torque sensor circuit

• Torque sensor

• P/S control module

1 driving

cycle

Page 898 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-16 Power Assisted Steering System:

“EPS” Warning Light Remains ON Steady after Engine StartsS7RS0B6304011

Wiring Diagram

Refer to ““EPS” Warning Light Does Not Come ON with Ignition Switch Turned ON before Engine Starts”.

Circuit Description

Operation (ON/OFF) of “EPS” warning light is controlled by P/S c ontrol module through combination meter.

If the P/S system is in good condition, P/S control module tu rns “EPS” warning light ON at the ignition switch ON, and

then turns it OFF at the engine start. If an abnormality in the system is detected, “EPS” warning light is turned ON

continuously by P/S control module. If P/S control module is disconnected, “EPS” warning light is not turned ON.

Troubleshooting 4 1) Check for proper connection to the combination meter at

“G28-25” terminal and P/S control module at “E52-5”

terminal.

2) Measure resistance between the combination meter at “G28-25” terminal and the P/S control module at “E52-5”

terminal.

Is it infinite (

∞)? “EPS warning light

circuit” is open.

Go to Step 5.

5 1) Connect combination meter connector (“G28”) with ignition switch turned OFF.

2) Check for voltage between “E52-5” (“GRY” wire) terminal and body ground with ignition switch ON.

Is it 10 – 14 V? Replace the P/S control

module.

Replace the

combination meter.

Step

Action YesNo

Step Action YesNo

1 1) Check DTC referring to “DTC Check”.

Is there any DTC(s) (NO CODES on SUZUKI scan tool)? Go to applicable DTC

diag. flow.

Go to Step 2.

2 1) With ignition switch OFF, disconnect P/S control module connector (“E52”).

2) Check for proper connection to the P/S control module at “E52-5” terminal.

3) If OK, then turn ignition switch to ON position.

Does “EPS” warning light turn on? Go to Step 3.

Replace the P/S control

module.

3 1) With ignition switch turned OFF, remove combination meter and its connector.

2) Check for proper terminal connection to combination meter connector.

3) If connections are OK, ch eck that “EPS warning light

circuit” is as following.

• Insulation resistance of “EPS warning light circuit” wire is infinity between its terminal and each terminal

at combination meter connector.

• Wiring resistance of “EPS wa rning light circuit” wire is

less than 1 Ω.

• Insulation resistance of “EPS warning light circuit” wire is infinity between its terminal and vehicle body

ground.

Is circuit in good condition? Replace the

combination meter.

Repair EPS warning

light circuit.

Page 1048 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-10 Air Bag System:

Diagnostic Information and Procedures

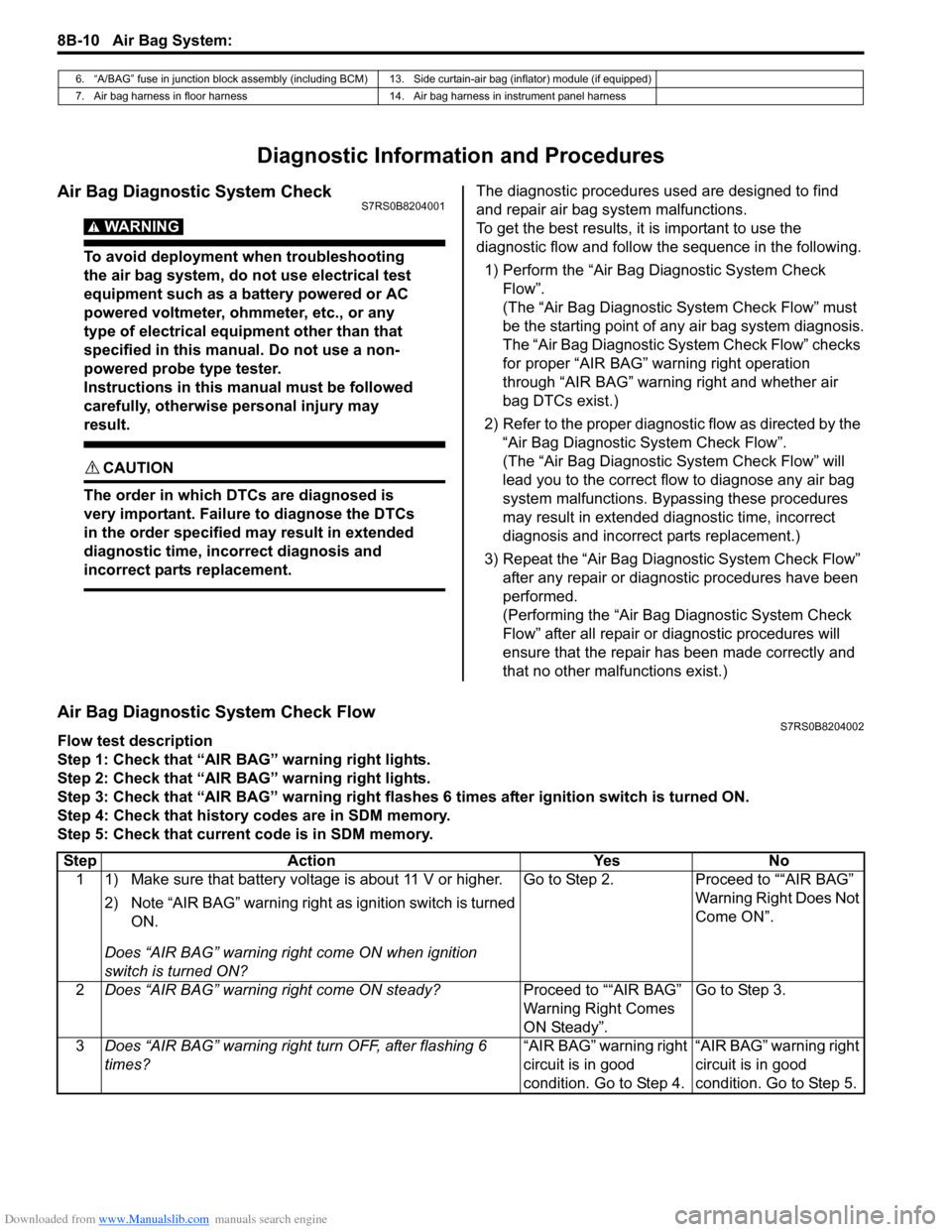

Air Bag Diagnostic System CheckS7RS0B8204001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified in this manual. Do not use a non-

powered probe type tester.

Instructions in this manual must be followed

carefully, otherwise personal injury may

result.

CAUTION!

The order in which DTCs are diagnosed is

very important. Failure to diagnose the DTCs

in the order specified may result in extended

diagnostic time, incorrect diagnosis and

incorrect parts replacement.

The diagnostic procedures used are designed to find

and repair air bag system malfunctions.

To get the best results, it is important to use the

diagnostic flow and follow the sequence in the following.1) Perform the “Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” must

be the starting point of any air bag system diagnosis.

The “Air Bag Diagnostic System Check Flow” checks

for proper “AIR BAG” warning right operation

through “AIR BAG” warning right and whether air

bag DTCs exist.)

2) Refer to the proper diagnost ic flow as directed by the

“Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” will

lead you to the correct flow to diagnose any air bag

system malfunctions. Bypassing these procedures

may result in extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.)

3) Repeat the “Air Bag Diagnostic System Check Flow” after any repair or diagnostic procedures have been

performed.

(Performing the “Air Bag Diagnostic System Check

Flow” after all repair or diagnostic procedures will

ensure that the repair has been made correctly and

that no other malfunctions exist.)

Air Bag Diagnostic System Check FlowS7RS0B8204002

Flow test description

Step 1: Check that “AIR BAG” warning right lights.

Step 2: Check that “AIR BAG” warning right lights.

Step 3: Check that “AIR BAG” warning right flas hes 6 times after ignition switch is turned ON.

Step 4: Check that history codes are in SDM memory.

Step 5: Check that current code is in SDM memory.

6. “A/BAG” fuse in junction block assembly (including BCM) 13. Side curtain-air bag (inflator) module (if equipped)

7. Air bag harness in floor harness 14. Air bag harness in instrument panel harness

Step Action YesNo

1 1) Make sure that battery voltage is about 11 V or higher.

2) Note “AIR BAG” warning right as ignition switch is turned

ON.

Does “AIR BAG” warning ri ght come ON when ignition

switch is turned ON? Go to Step 2.

Proceed to ““AIR BAG”

Warning Right Does Not

Come ON”.

2 Does “AIR BAG” warning right come ON steady? Proceed to ““AIR BAG”

Warning Right Comes

ON Steady”.Go to Step 3.

3 Does “AIR BAG” warning right turn OFF, after flashing 6

times? “AIR BAG” warning right

circuit is in good

condition. Go to Step 4.“AIR BAG” warning right

circuit is in good

condition. Go to Step 5.

Page 1049 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-11

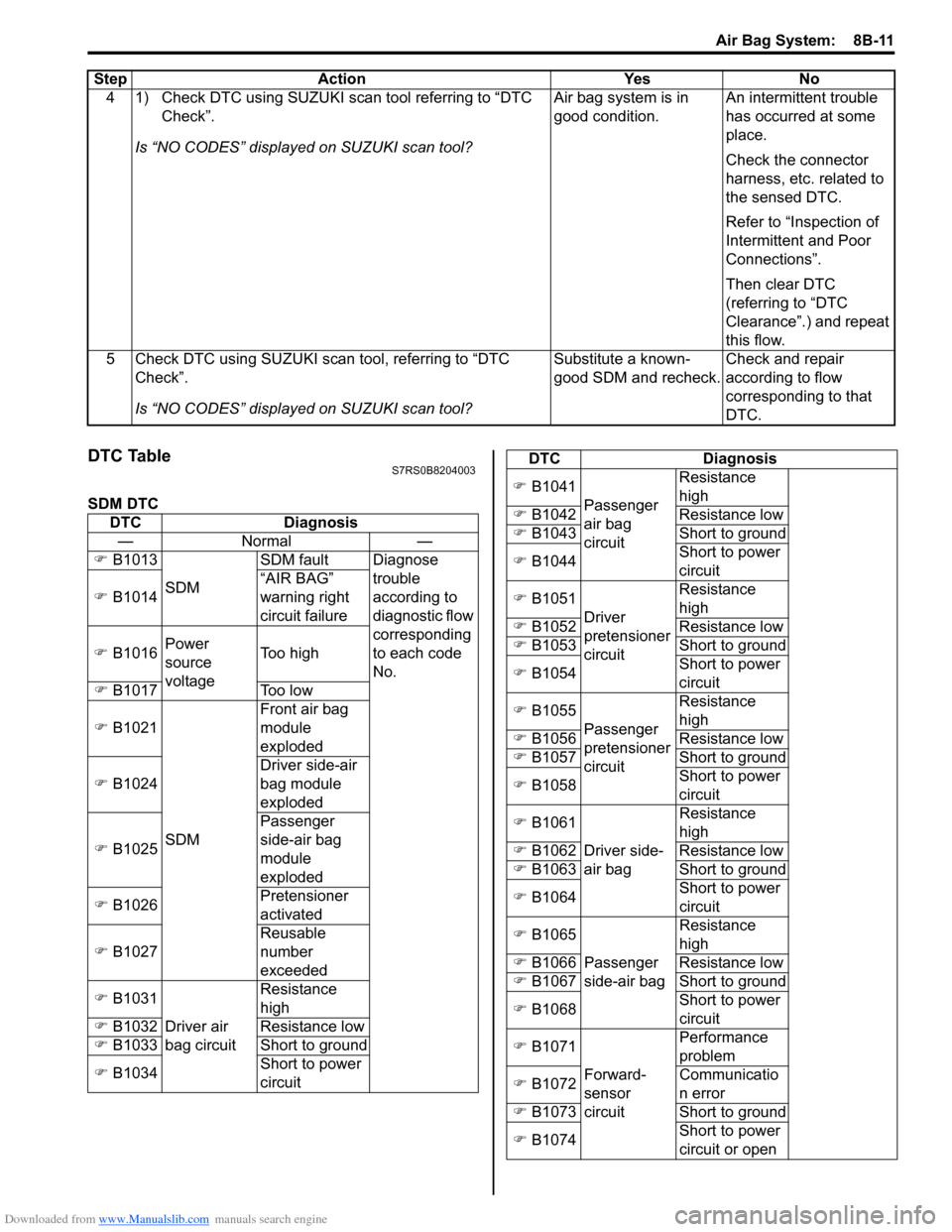

DTC TableS7RS0B8204003

SDM DTC4 1) Check DTC using SUZUKI scan tool referring to “DTC

Check”.

Is “NO CODES” displayed on SUZUKI scan tool? Air bag system is in

good condition.

An intermittent trouble

has occurred at some

place.

Check the connector

harness, etc. related to

the sensed DTC.

Refer to “Inspection of

Intermittent and Poor

Connections”.

Then clear DTC

(referring to “DTC

Clearance”.) and repeat

this flow.

5 Check DTC using SUZUKI scan tool, referring to “DTC Check”.

Is “NO CODES” displayed on SUZUKI scan tool? Substitute a known-

good SDM and recheck.

Check and repair

according to flow

corresponding to that

DTC.

Step Action Yes No

DTC

Diagnosis

—N orm al —

�) B1013

SDM SDM fault Diagnose

trouble

according to

diagnostic flow

corresponding

to each code

No.

�)

B1014 “AIR BAG”

warning right

circuit failure

�) B1016 Power

source

voltage Too high

�) B1017 Too low

�) B1021

SDM Front air bag

module

exploded

�) B1024 Driver side-air

bag module

exploded

�) B1025 Passenger

side-air bag

module

exploded

�) B1026 Pretensioner

activated

�) B1027 Reusable

number

exceeded

�) B1031

Driver air

bag circuit Resistance

high

�) B1032 Resistance low

�) B1033 Short to ground

�) B1034 Short to power

circuit

�)

B1041

Passenger

air bag

circuit Resistance

high

�) B1042 Resistance low

�) B1043 Short to ground

�) B1044 Short to power

circuit

�) B1051

Driver

pretensioner

circuit Resistance

high

�) B1052 Resistance low

�) B1053 Short to ground

�) B1054 Short to power

circuit

�) B1055

Passenger

pretensioner

circuit Resistance

high

�) B1056 Resistance low

�) B1057 Short to ground

�) B1058 Short to power

circuit

�) B1061

Driver side-

air bag Resistance

high

�) B1062 Resistance low

�) B1063 Short to ground

�) B1064 Short to power

circuit

�) B1065

Passenger

side-air bag Resistance

high

�) B1066 Resistance low

�) B1067 Short to ground

�) B1068 Short to power

circuit

�) B1071

Forward-

sensor

circuit Performance

problem

�) B1072 Communicatio

n error

�) B1073 Short to ground

�) B1074 Short to power

circuit or open

DTC Diagnosis

Page 1050 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-12 Air Bag System:

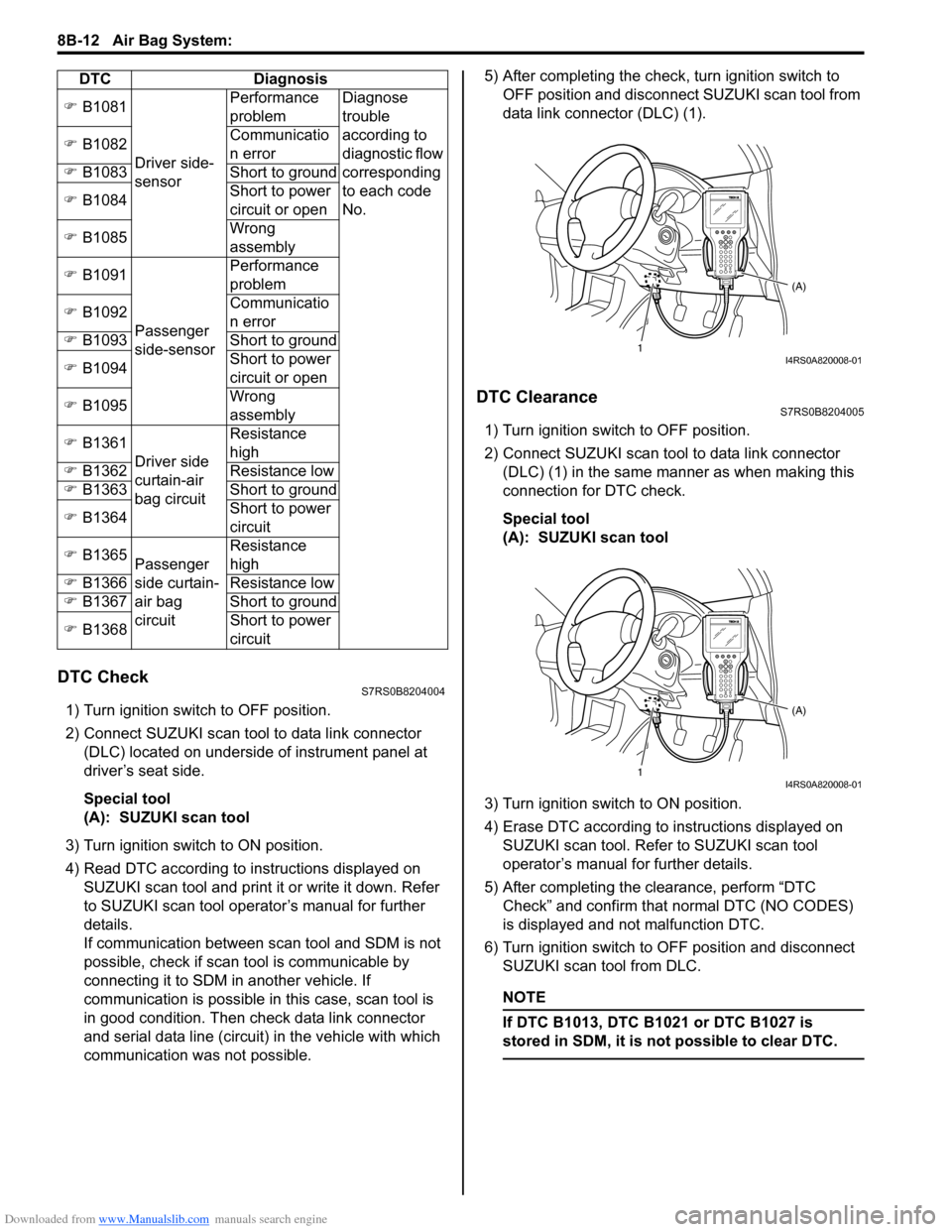

DTC CheckS7RS0B8204004

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) located on underside of instrument panel at

driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Read DTC according to instructions displayed on SUZUKI scan tool and print it or write it down. Refer

to SUZUKI scan tool operator’s manual for further

details.

If communication between scan tool and SDM is not

possible, check if scan tool is communicable by

connecting it to SDM in another vehicle. If

communication is possible in this case, scan tool is

in good condition. Then check data link connector

and serial data line (circuit) in the vehicle with which

communication was not possible. 5) After completing the check,

turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

data link connector (DLC) (1).

DTC ClearanceS7RS0B8204005

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) in the same manner as when making this

connection for DTC check.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Erase DTC according to instructions displayed on

SUZUKI scan tool. Refer to SUZUKI scan tool

operator’s manual for further details.

5) After completing the clearance, perform “DTC Check” and confirm that normal DTC (NO CODES)

is displayed and not malfunction DTC.

6) Turn ignition switch to OFF position and disconnect SUZUKI scan tool from DLC.

NOTE

If DTC B1013, DTC B1 021 or DTC B1027 is

stored in SDM, it is not possible to clear DTC.

�) B1081

Driver side-

sensor Performance

problem

Diagnose

trouble

according to

diagnostic flow

corresponding

to each code

No.

�)

B1082 Communicatio

n error

�) B1083 Short to ground

�) B1084 Short to power

circuit or open

�) B1085 Wrong

assembly

�) B1091

Passenger

side-sensor Performance

problem

�) B1092 Communicatio

n error

�) B1093 Short to ground

�) B1094 Short to power

circuit or open

�) B1095 Wrong

assembly

�) B1361

Driver side

curtain-air

bag circuit Resistance

high

�) B1362 Resistance low

�) B1363 Short to ground

�) B1364 Short to power

circuit

�) B1365

Passenger

side curtain-

air bag

circuit Resistance

high

�) B1366 Resistance low

�) B1367 Short to ground

�) B1368 Short to power

circuit

DTC Diagnosis

1

(A)I4RS0A820008-01

1(A)I4RS0A820008-01

Page 1402 of 1496

Downloaded from www.Manualslib.com manuals search engine 10-ii Table of Contents

DTC P1615: ID Code Does Not Registered (Vehicle equipped with keyless start system

only) ................................................................10C-9

DTC P1616: Different Registration ID Codes (Vehicle equipped with keyless start system

only) ..............................................................10C-10

DTC P1618: CAN Communication Error (Reception Error for Keyless Start Control

Module) (Vehicle equipped with keyless

start system only) ..........................................10C-11

DTC P1621: Immobilizer Communication Line Error ......................................................10C-12

DTC P1622: EEPROM Reading / Writing Error ..............................................................10C-13

DTC P1623: Unregistered Transponder .........10C-13

DTC P1625: Immobilizer An tenna Error..........10C-14

DTC P1636: Immobilizer Information Registration Failure .......................................10C-14

DTC P1638: Immobilizer Information Mismatched ...................................................10C-15

Inspection of Immobilizer Control Module (ICM) and Its Circuit ....... ...............................10C-16

Repair Instructions ........... ...............................10C-18

Immobilizer Control Mo dule (ICM) Removal

and Installation ..............................................10C-18

Registration of the Ignition Key .......................10C-18

Procedure after ECM Replacement ................10C-18

Special Tools and Equipmen t .........................10C-19

Special Tool ....................................................10C-19

Keyless Start System ....... ......................10E-1

General Description ........................................... 10E-1

Keyless Start System Description ..................... 10E-1

Parts and Functions .......................................... 10E-2

Keyless Engine Start Function .......................... 10E-3

Door Lock Function of Keyless Start System .... 10E-4

Operation Area of Remote Controller................ 10E-5

Alarm Function .................................................. 10E-6

CAN Communication System Description......... 10E-6

Schematic and Routing Diagram ...................... 10E-7 Keyless Start System El ectric Wiring Circuit

Diagram .......................................................... 10E-7

Diagnostic Information and Procedures .......... 10E-8 Precautions in Diagnosing Troubles ................. 10E-8

Self-Diagnosis Function .................................... 10E-8

Keyless Start System Diagn osis Introduction ... 10E-8 Keyless Start System Chec

k ............................. 10E-8

Customer Questionnaire (E xample) .................. 10E-9

Key Indicator Lamp Check .............................. 10E-10

DTC Check...................................................... 10E-10

DTC Table ....................................................... 10E-11

DTC Clearance ............................................... 10E-12

Keyless Start System Symp tom Diagnosis ..... 10E-12

Keyless Start System Operation Inspection .... 10E-13

Door Lock Operation (Keyless Start System) . 10E-14

Inspection of Keyless Start Control Module and Its Circuits .............................................. 10E-14

No DTC Detection After Performing DTC Check ............................................................ 10E-18

Key Indicator Lamp Circuit Check (Key indicator lamp doesn’t light when ignition

knob switch is pushed.) ................................. 10E-20

Keyless Start Control Module Power and Ground Circuit Check .................................... 10E-22

DTC No. 11: Communi cation Error with

Steering Lock Unit ......................................... 10E-23

DTC No. 13 / No. 14: Release Signal Error from Steering Lock Unit / Steering Lock Unit

Malfunction .................................................... 10E-24

DTC No. 21 / No. 22: Internal Error of Keyless Start Control Module (EEPROM reading

error) / (EEPROM writing error) ............ ........ 10E-24

DTC No. 31: Lost Commun ication with BCM .. 10E-25

DTC No. 33: Control Module Communication

Bus Off .......................................................... 10E-27

DTC No. 51 / No. 52 / No. 53: Driver Side / Passenger Side / Rear End Door Request

Switch Failure................................................ 10E-28

Repair Instructions ............ .............................. 10E-30

Antennas and Request Switches Removal and Installation .............................................. 10E-30

Front Door (Driver and Passenger Side), Rear End Door Request Switch Inspection............ 10E-31

Steering Lock Unit Removal and Installation .. 10E-31

Steering Lock Unit Inspection ......................... 10E-31

Front Door Lock Switch In spection ................. 10E-31

Keyless Start Control Module Removal and Installation ..................................................... 10E-32

Remote Controller Inspection.......................... 10E-32

Replacement of Remote Controller Battery .... 10E-32

Registration Procedure for Remote Controller

ID Code ......................................................... 10E-33

Page 1450 of 1496

Downloaded from www.Manualslib.com manuals search engine 10C-7 Immobilizer Control System:

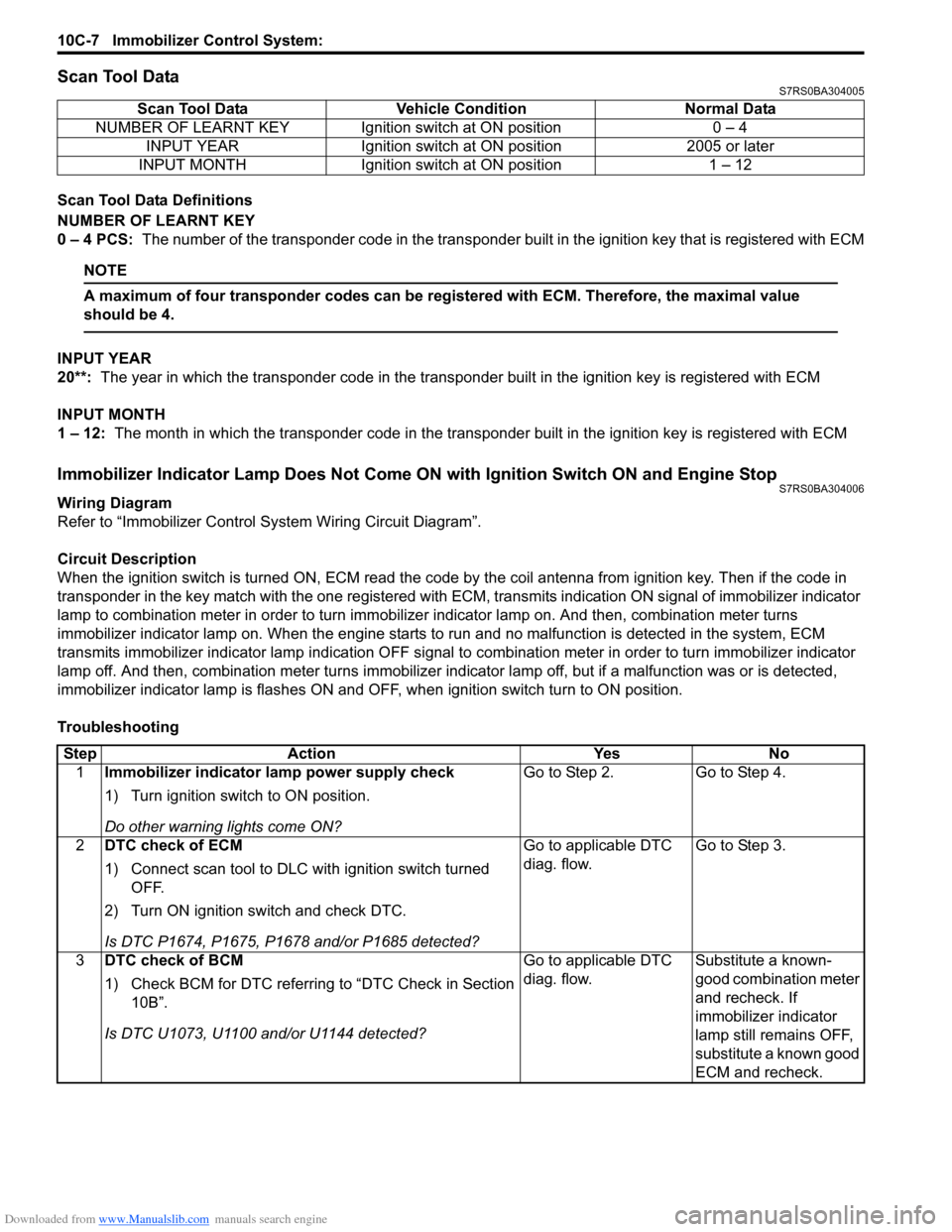

Scan Tool DataS7RS0BA304005

Scan Tool Data Definitions

NUMBER OF LEARNT KEY

0 – 4 PCS: The number of the transponder code in the transponder built in the ignition key that is registered with ECM

NOTE

A maximum of four transponder codes can be registered with ECM. Therefore, the maximal value

should be 4.

INPUT YEAR

20**: The year in which the transponder code in the transpon der built in the ignition key is registered with ECM

INPUT MONTH

1 – 12: The month in which the transponder code in the transpond er built in the ignition key is registered with ECM

Immobilizer Indicator Lamp Does Not Come ON with Ignition Switch ON and Engine StopS7RS0BA304006

Wiring Diagram

Refer to “Immobilizer Control System Wiring Circuit Diagram”.

Circuit Description

When the ignition switch is turned ON, ECM read the code by the coil antenna from ignition key. Then if the code in

transponder in the key match with the one registered with ECM, transmits indication ON signal of immobilizer indicator

lamp to combination meter in order to turn immobilizer indicator lamp on. And then, combination meter turns

immobilizer indicator lamp on. When th e engine starts to run and no malfunction is detected in the system, ECM

transmits immobilizer indi cator lamp indication OFF signal to combination meter in order to turn immobilizer indicator

lamp off. And then, comb ination meter turns immobilizer indicator lamp off, but if a malfunction was or is detected,

immobilizer indicator lamp is flashes ON and OF F, when ignition switch turn to ON position.

Troubleshooting Scan Tool Data Vehicl

e Condition Normal Data

NUMBER OF LEARNT KEY Ignition switch at ON position 0 – 4 INPUT YEAR Ignition switch at ON position 2005 or later

INPUT MONTH Ignition switch at ON position 1 – 12

Step Action YesNo

1 Immobilizer indicator lamp power supply check

1) Turn ignition switch to ON position.

Do other warning lights come ON? Go to Step 2.

Go to Step 4.

2 DTC check of ECM

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is DTC P1674, P1675, P1678 and/or P1685 detected? Go to applicable DTC

diag. flow.

Go to Step 3.

3 DTC check of BCM

1) Check BCM for DTC referring to “DTC Check in Section

10B”.

Is DTC U1073, U1100 and/or U1144 detected? Go to applicable DTC

diag. flow.

Substitute a known-

good combination meter

and recheck. If

immobilizer indicator

lamp still remains OFF,

substitute a known good

ECM and recheck.

Page 1453 of 1496

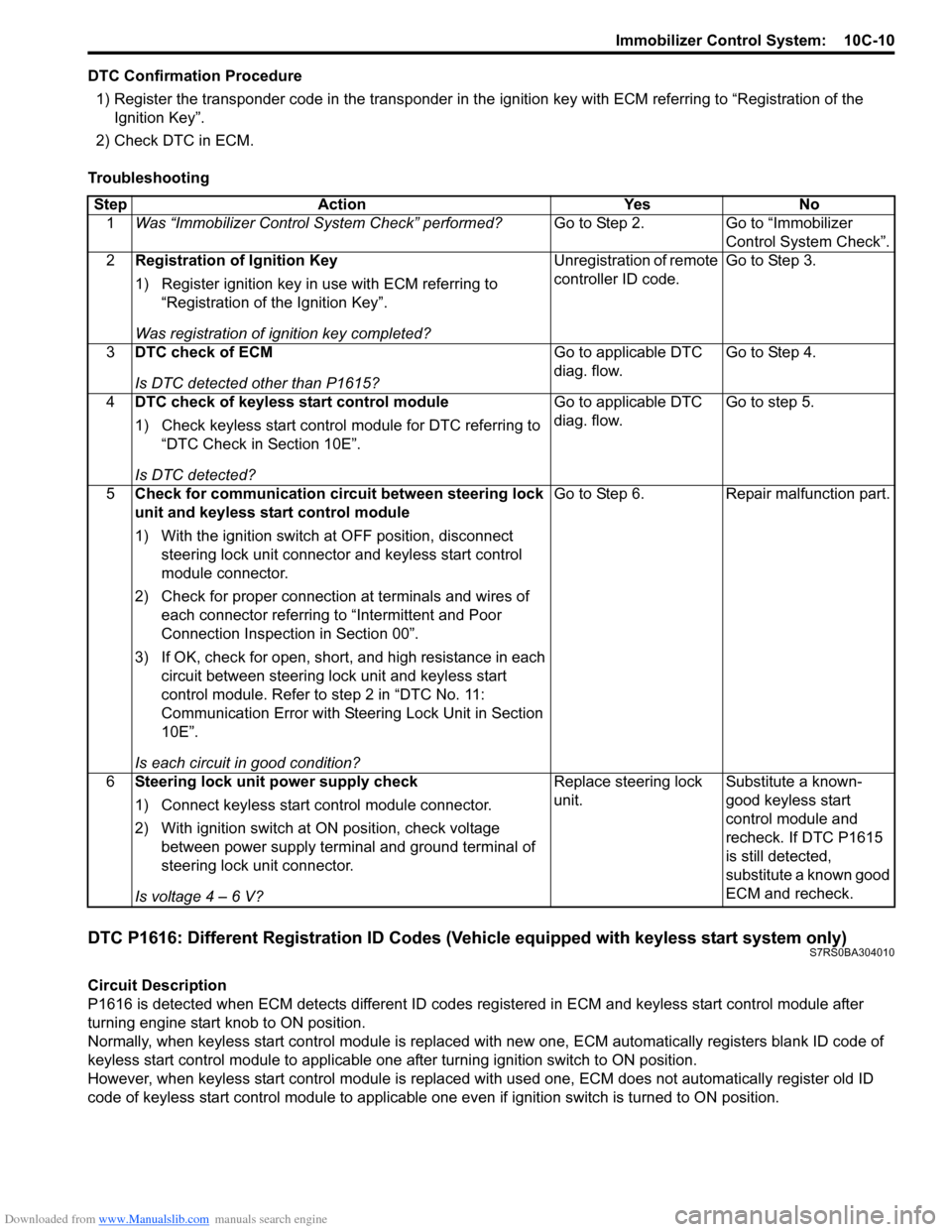

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-10

DTC Confirmation Procedure1) Register the transponder code in the transponder in the ignition key with ECM referring to “Registration of the

Ignition Key”.

2) Check DTC in ECM.

Troubleshooting

DTC P1616: Different Registration ID Codes (Vehicle equipped with keyless start system only)S7RS0BA304010

Circuit Description

P1616 is detected when ECM detects different ID codes registered in ECM and keyless start control module after

turning engine start knob to ON position.

Normally, when keyless start control module is replaced with new one, ECM automatically registers blank ID code of

keyless start control module to applicable one after turning ignition switch to ON position.

However, when keyless start control module is replaced wit h used one, ECM does not automatically register old ID

code of keyless start control module to applicable one ev en if ignition switch is turned to ON position.

Step Action Yes No

1 Was “Immobilizer Control S ystem Check” performed? Go to Step 2. Go to “Immobilizer

Control System Check”.

2 Registration of Ignition Key

1) Register ignition key in use with ECM referring to

“Registration of the Ignition Key”.

Was registration of ignition key completed? Unregistration of remote

controller ID code.

Go to Step 3.

3 DTC check of ECM

Is DTC detected other than P1615? Go to applicable DTC

diag. flow.

Go to Step 4.

4 DTC check of keyless start control module

1) Check keyless start control module for DTC referring to

“DTC Check in Section 10E”.

Is DTC detected? Go to applicable DTC

diag. flow.

Go to step 5.

5 Check for communication circuit between steering lock

unit and keyless start control module

1) With the ignition switch at OFF position, disconnect

steering lock unit connector and keyless start control

module connector.

2) Check for proper connection at terminals and wires of

each connector referring to “Intermittent and Poor

Connection Inspection in Section 00”.

3) If OK, check for open, short, and high resistance in each circuit between steering lock unit and keyless start

control module. Refer to step 2 in “DTC No. 11:

Communication Error with Steeri ng Lock Unit in Section

10E”.

Is each circuit in good condition? Go to Step 6. Repair malfunction part.

6 Steering lock unit power supply check

1) Connect keyless start control module connector.

2) With ignition switch at ON position, check voltage

between power supply terminal and ground terminal of

steering lock unit connector.

Is voltage 4 – 6 V? Replace steering lock

unit.

Substitute a known-

good keyless start

control module and

recheck. If DTC P1615

is still detected,

substitute a known good

ECM and recheck.

Page 1454 of 1496

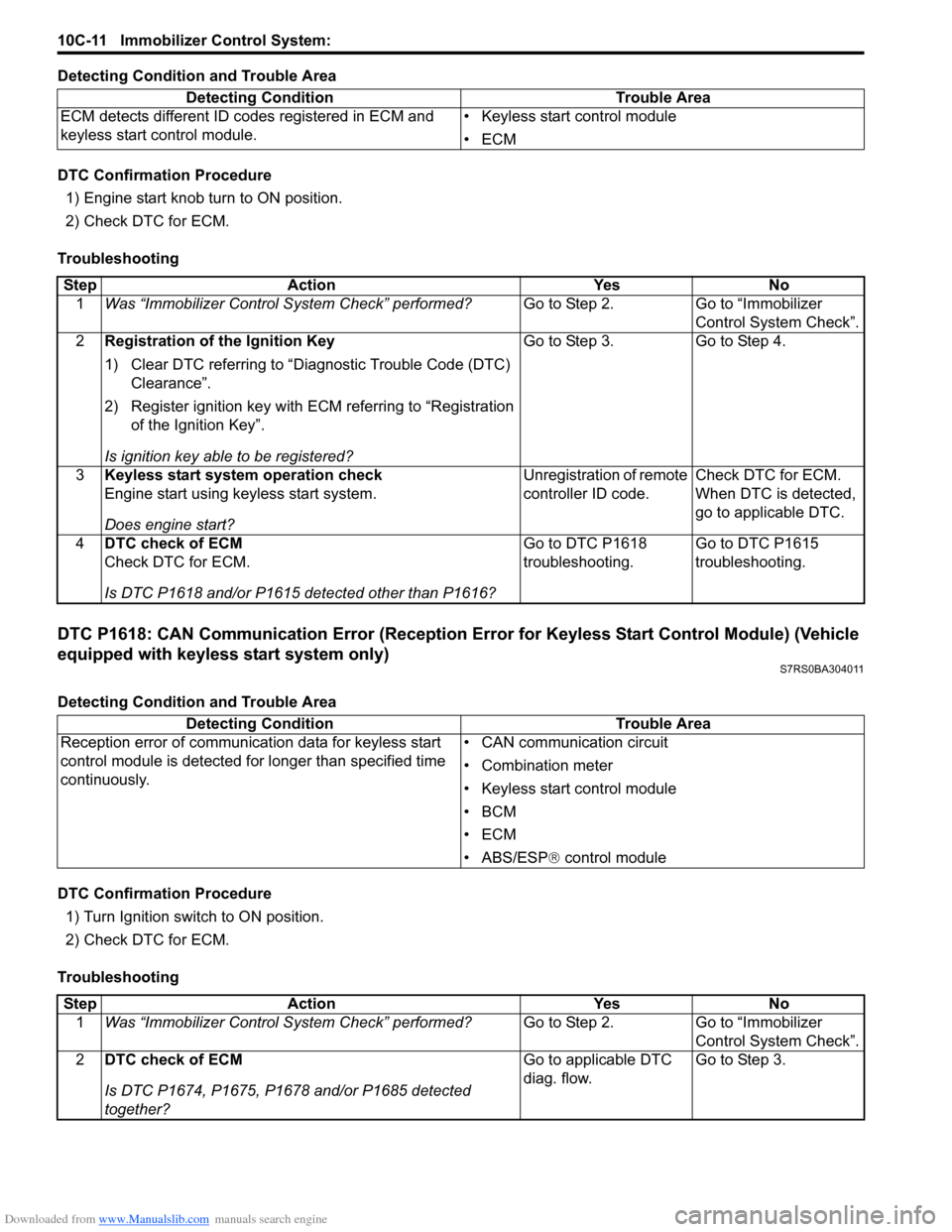

Downloaded from www.Manualslib.com manuals search engine 10C-11 Immobilizer Control System:

Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Engine start knob turn to ON position.

2) Check DTC for ECM.

Troubleshooting

DTC P1618: CAN Communication Error (Reception Error for Keyless Start Control Module) (Vehicle

equipped with keyless start system only)

S7RS0BA304011

Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Turn Ignition switch to ON position.

2) Check DTC for ECM.

Troubleshooting Detecting Condition Trouble Area

ECM detects different ID codes registered in ECM and

keyless start control module. • Keyless start control module

•ECM

Step

Action YesNo

1 Was “Immobilizer Control S ystem Check” performed? Go to Step 2.Go to “Immobilizer

Control System Check”.

2 Registration of the Ignition Key

1) Clear DTC referring to “Diagnostic Trouble Code (DTC)

Clearance”.

2) Register ignition key with ECM referring to “Registration of the Ignition Key”.

Is ignition key able to be registered? Go to Step 3.

Go to Step 4.

3 Keyless start system operation check

Engine start using keyless start system.

Does engine start? Unregistration of remote

controller ID code.

Check DTC for ECM.

When DTC is detected,

go to applicable DTC.

4 DTC check of ECM

Check DTC for ECM.

Is DTC P1618 and/or P1615 detected other than P1616? Go to DTC P1618

troubleshooting.

Go to DTC P1615

troubleshooting.

Detecting Condition

Trouble Area

Reception error of communication data for keyless start

control module is detected for longer than specified time

continuously. • CAN communication circuit

• Combination meter

• Keyless start control module

•BCM

•ECM

• ABS/ESP®

control module

Step Action YesNo

1 Was “Immobilizer Control S ystem Check” performed? Go to Step 2.Go to “Immobilizer

Control System Check”.

2 DTC check of ECM

Is DTC P1674, P1675, P1678 and/or P1685 detected

together? Go to applicable DTC

diag. flow.

Go to Step 3.