cord break SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 326 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-41 Engine Mechanical:

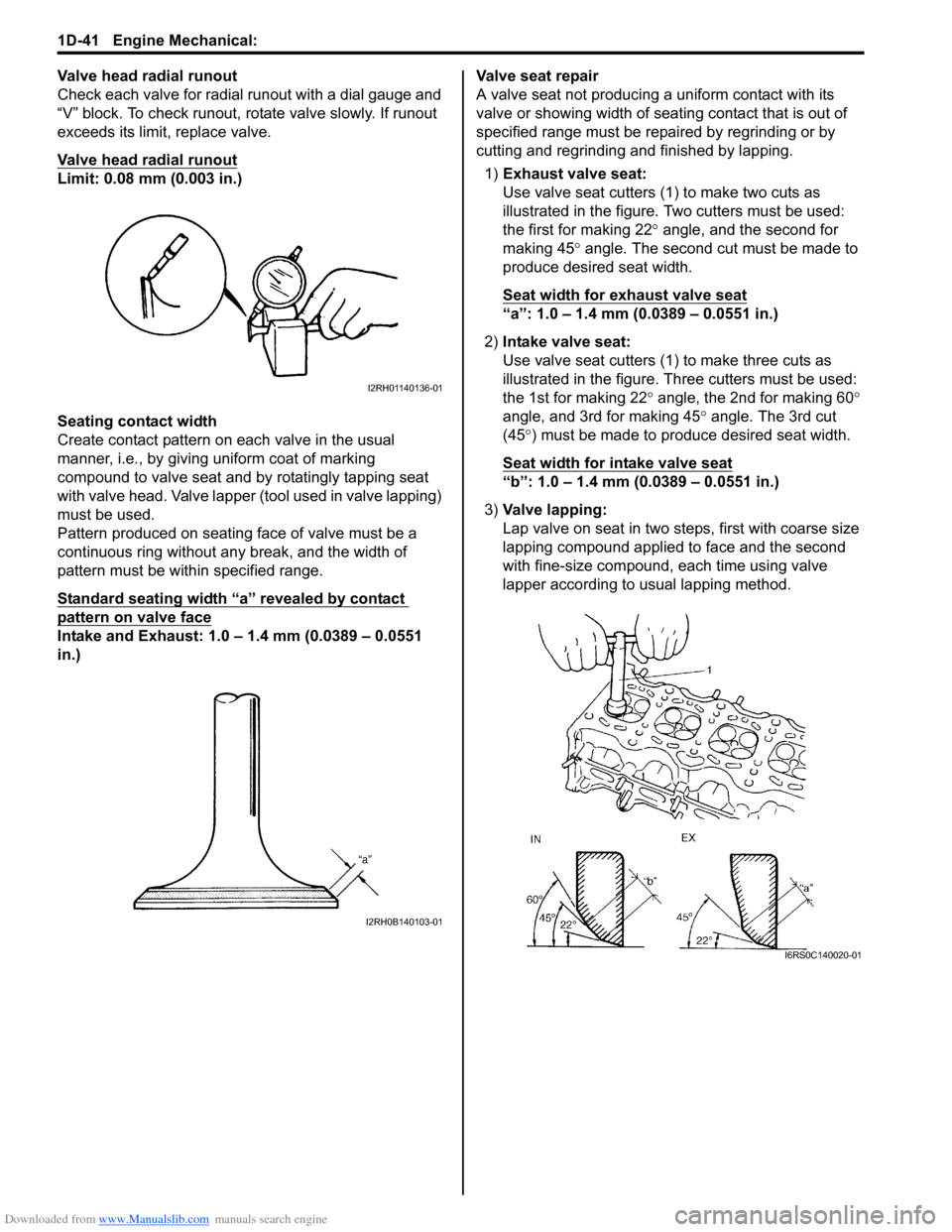

Valve head radial runout

Check each valve for radial runout with a dial gauge and

“V” block. To check runout, rotate valve slowly. If runout

exceeds its limit, replace valve.

Valve head radial runout

Limit: 0.08 mm (0.003 in.)

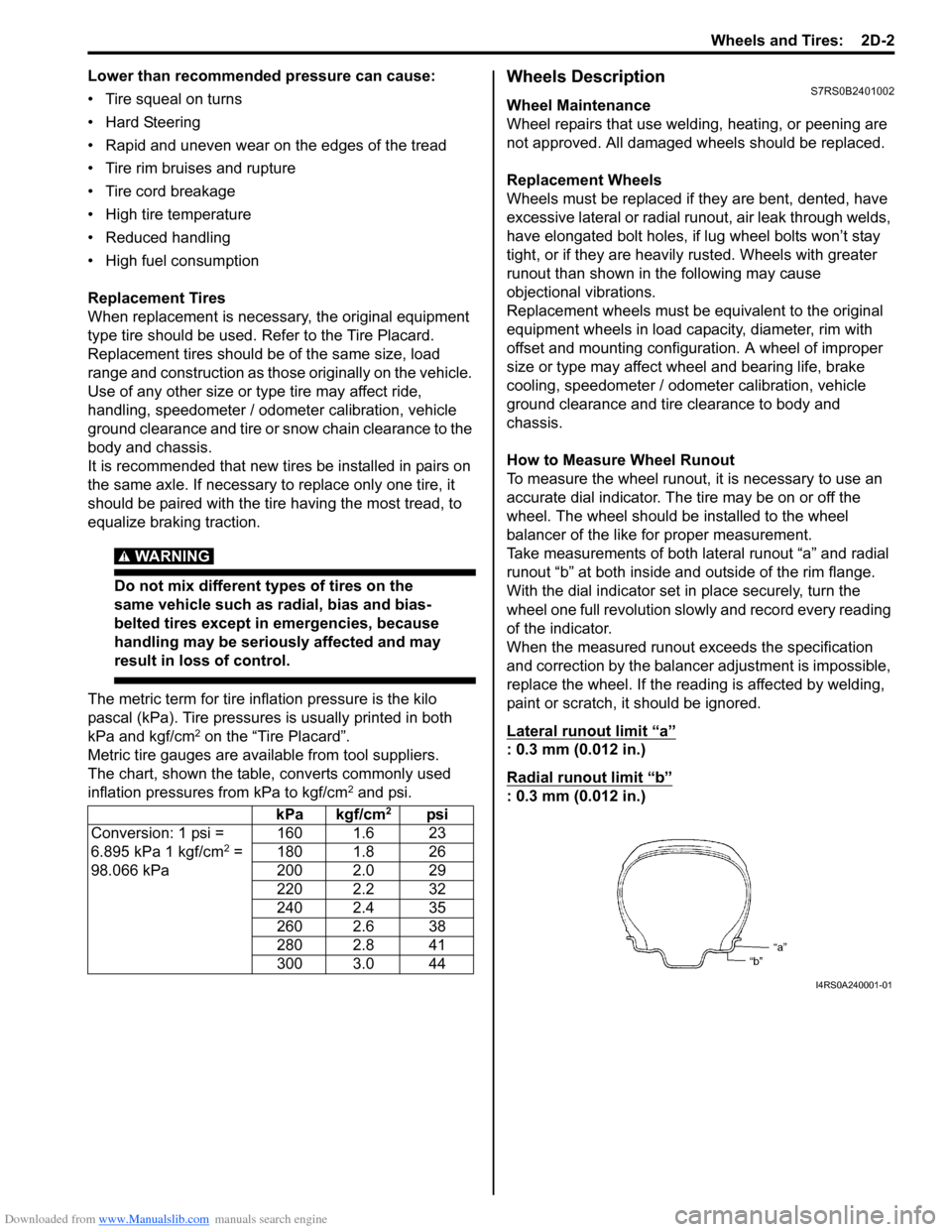

Seating contact width

Create contact pattern on each valve in the usual

manner, i.e., by giving uniform coat of marking

compound to valve seat and by rotatingly tapping seat

with valve head. Valve lapper (tool used in valve lapping)

must be used.

Pattern produced on seating face of valve must be a

continuous ring without any break, and the width of

pattern must be within specified range.

Standard seating width “a” revealed by contact

pattern on valve face

Intake and Exhaust: 1.0 – 1.4 mm (0.0389 – 0.0551

in.)Valve seat repair

A valve seat not producing

a uniform contact with its

valve or showing width of seating contact that is out of

specified range must be repaired by regrinding or by

cutting and regrinding and finished by lapping.

1) Exhaust valve seat:

Use valve seat cutters (1 ) to make two cuts as

illustrated in the figure. Two cutters must be used:

the first for making 22 ° angle, and the second for

making 45 ° angle. The second cut must be made to

produce desired seat width.

Seat width for exhaust valve seat

“a”: 1.0 – 1.4 mm (0.0389 – 0.0551 in.)

2) Intake valve seat:

Use valve seat cutters (1) to make three cuts as

illustrated in the figure. Th ree cutters must be used:

the 1st for making 22 ° angle, the 2nd for making 60 °

angle, and 3rd for making 45 ° angle. The 3rd cut

(45 °) must be made to produce desired seat width.

Seat width for intake valve seat

“b”: 1.0 – 1.4 mm (0.0389 – 0.0551 in.)

3) Valve lapping:

Lap valve on seat in two steps, first with coarse size

lapping compound applied to face and the second

with fine-size compound, each time using valve

lapper according to usual lapping method.

I2RH01140136-01

I2RH0B140103-01

I6RS0C140020-01

Page 469 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-2

Lower than recommended pressure can cause:

• Tire squeal on turns

• Hard Steering

• Rapid and uneven wear on the edges of the tread

• Tire rim bruises and rupture

• Tire cord breakage

• High tire temperature

• Reduced handling

• High fuel consumption

Replacement Tires

When replacement is necessary, the original equipment

type tire should be used. Refer to the Tire Placard.

Replacement tires should be of the same size, load

range and construction as those originally on the vehicle.

Use of any other size or type tire may affect ride,

handling, speedometer / odometer calibration, vehicle

ground clearance and tire or snow chain clearance to the

body and chassis.

It is recommended that new tires be installed in pairs on

the same axle. If necessary to replace only one tire, it

should be paired with the tire having the most tread, to

equalize braking traction.

WARNING!

Do not mix different types of tires on the

same vehicle such as radial, bias and bias-

belted tires except in emergencies, because

handling may be seriously affected and may

result in loss of control.

The metric term for tire infl ation pressure is the kilo

pascal (kPa). Tire pressures is usually printed in both

kPa and kgf/cm

2 on the “Tire Placard”.

Metric tire gauges are available from tool suppliers.

The chart, shown the table, converts commonly used

inflation pressures from kPa to kgf/cm

2 and psi.

Wheels DescriptionS7RS0B2401002

Wheel Maintenance

Wheel repairs that use welding, heating, or peening are

not approved. All damaged wheels should be replaced.

Replacement Wheels

Wheels must be replaced if they are bent, dented, have

excessive lateral or radial runout, air leak through welds,

have elongated bolt holes, if lug wheel bolts won’t stay

tight, or if they are heavily rusted. Wheels with greater

runout than shown in the following may cause

objectional vibrations.

Replacement wheels must be equivalent to the original

equipment wheels in load capacity, diameter, rim with

offset and mounting configuration. A wheel of improper

size or type may affect wheel and bearing life, brake

cooling, speedometer / odometer calibration, vehicle

ground clearance and tire clearance to body and

chassis.

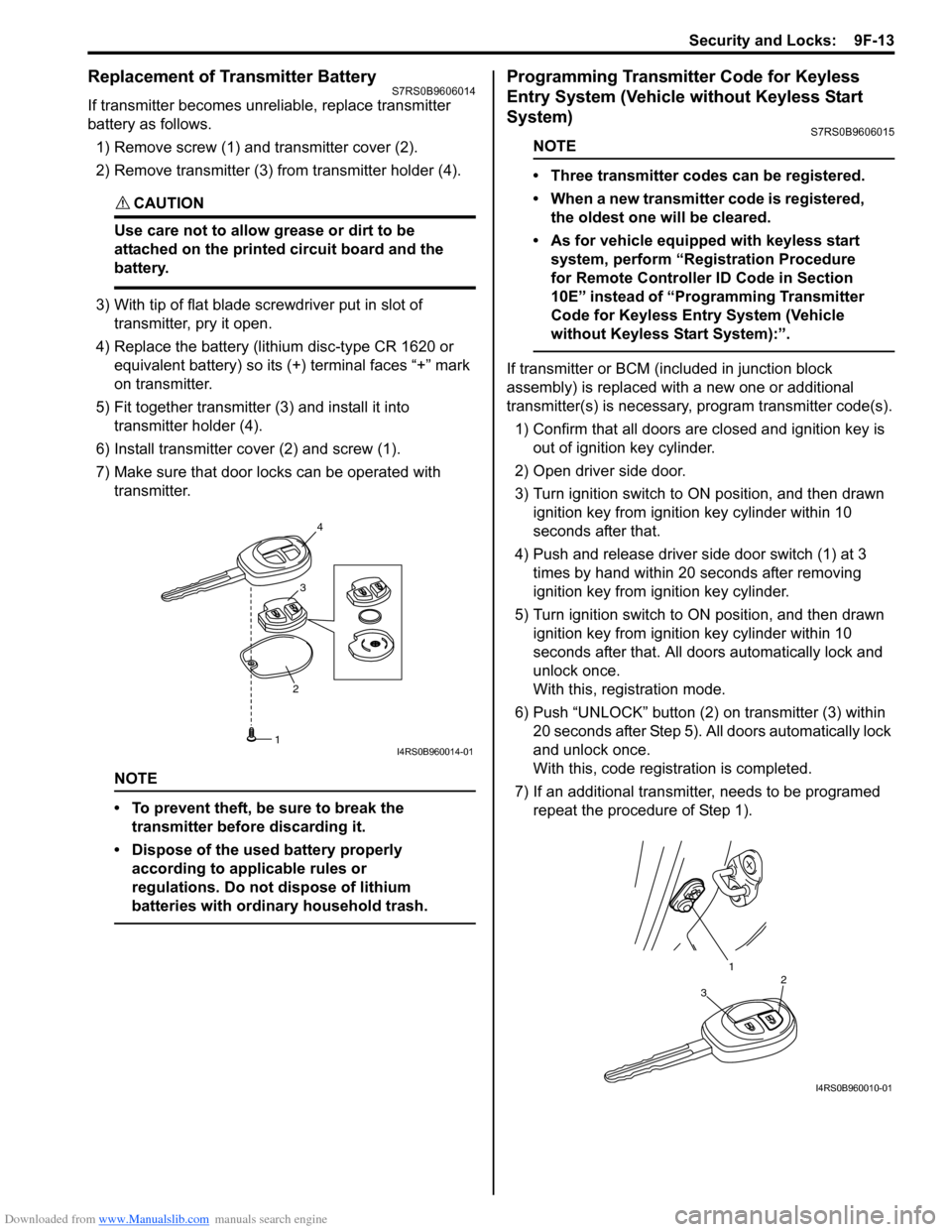

How to Measure Wheel Runout

To measure the wheel runout, it is necessary to use an

accurate dial indicator. The tire may be on or off the

wheel. The wheel should be installed to the wheel

balancer of the like for proper measurement.

Take measurements of both lateral runout “a” and radial

runout “b” at both inside an d outside of the rim flange.

With the dial indicator set in place securely, turn the

wheel one full revolution slowly and record every reading

of the indicator.

When the measured runout exceeds the specification

and correction by the balancer adjustment is impossible,

replace the wheel. If the reading is affected by welding,

paint or scratch, it should be ignored.

Lateral runout limit “a”

: 0.3 mm (0.012 in.)

Radial runout limit “b”

: 0.3 mm (0.012 in.)

kPa kgf/cm2psi

Conversion: 1 psi =

6.895 kPa 1 kgf/cm

2 =

98.066 kPa 160 1.6 23

180 1.8 26

200 2.0 29

220 2.2 32

240 2.4 35

260 2.6 38

280 2.8 41

300 3.0 44

I4RS0A240001-01

Page 1359 of 1496

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-13

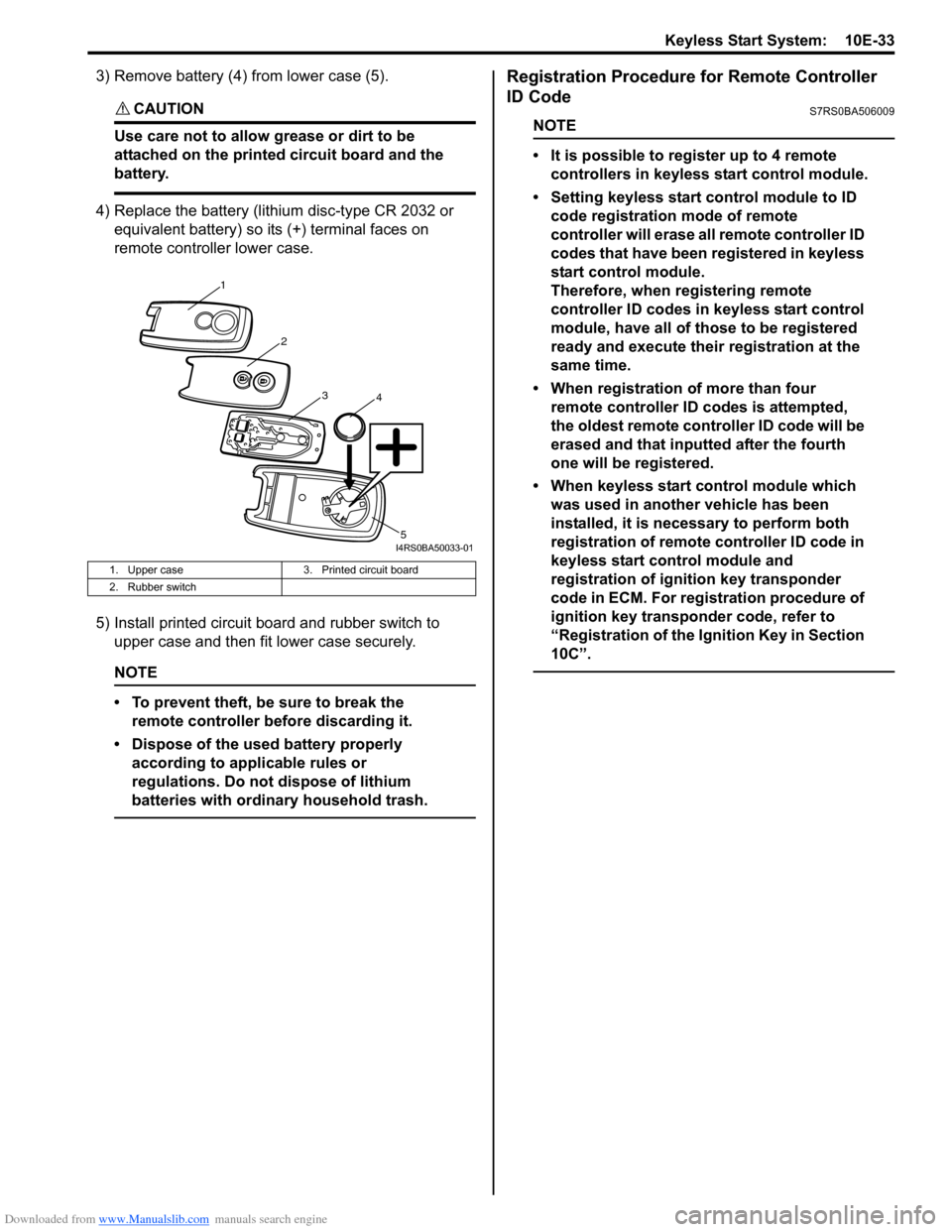

Replacement of Transmitter Battery S7RS0B9606014

If transmitter becomes unreliable, replace transmitter

battery as follows.

1) Remove screw (1) and transmitter cover (2).

2) Remove transmitter (3) from transmitter holder (4).

CAUTION!

Use care not to allow grease or dirt to be

attached on the printed circuit board and the

battery.

3) With tip of flat blade screwdriver put in slot of transmitter, pry it open.

4) Replace the battery (lithium disc-type CR 1620 or equivalent battery) so its (+) terminal faces “+” mark

on transmitter.

5) Fit together transmitter (3) and install it into

transmitter holder (4).

6) Install transmitter co ver (2) and screw (1).

7) Make sure that door locks can be operated with transmitter.

NOTE

• To prevent theft, be sure to break the transmitter before discarding it.

• Dispose of the used battery properly according to applicable rules or

regulations. Do not dispose of lithium

batteries with ordinary household trash.

Programming Transmitter Code for Keyless

Entry System (Vehicle without Keyless Start

System)

S7RS0B9606015

NOTE

• Three transmitter codes can be registered.

• When a new transmitter code is registered, the oldest one will be cleared.

• As for vehicle equipped with keyless start system, perform “Registration Procedure

for Remote Controller ID Code in Section

10E” instead of “Programming Transmitter

Code for Keyless Entry System (Vehicle

without Keyless Start System):”.

If transmitter or BCM (included in junction block

assembly) is replaced with a new one or additional

transmitter(s) is necessary, program transmitter code(s).

1) Confirm that all doors are closed and ignition key is

out of ignition key cylinder.

2) Open driver side door.

3) Turn ignition switch to ON position, and then drawn ignition key from igniti on key cylinder within 10

seconds after that.

4) Push and release driver side door switch (1) at 3 times by hand within 20 seconds after removing

ignition key from ig nition key cylinder.

5) Turn ignition switch to ON position, and then drawn ignition key from igniti on key cylinder within 10

seconds after that. All d oors automatically lock and

unlock once.

With this, registration mode.

6) Push “UNLOCK” button (2) on transmitter (3) within

20 seconds after Step 5). All doors automatically lock

and unlock once.

With this, code registration is completed.

7) If an additional transmitter, needs to be programed repeat the procedure of Step 1).

23

4

1I4RS0B960014-01

1

32

I4RS0B960010-01

Page 1495 of 1496

Downloaded from www.Manualslib.com manuals search engine Keyless Start System: 10E-33

3) Remove battery (4) from lower case (5).

CAUTION!

Use care not to allow grease or dirt to be

attached on the printed circuit board and the

battery.

4) Replace the battery (lithium disc-type CR 2032 or equivalent battery) so its (+) terminal faces on

remote controller lower case.

5) Install printed circuit board and rubber switch to upper case and then fit lower case securely.

NOTE

• To prevent theft, be sure to break the remote controller be fore discarding it.

• Dispose of the used battery properly according to applicable rules or

regulations. Do not dispose of lithium

batteries with ordinary household trash.

Registration Procedure for Remote Controller

ID Code

S7RS0BA506009

NOTE

• It is possible to register up to 4 remote controllers in keyless start control module.

• Setting keyless start control module to ID code registration mode of remote

controller will erase all remote controller ID

codes that have been registered in keyless

start control module.

Therefore, when re gistering remote

controller ID codes in keyless start control

module, have all of those to be registered

ready and execute their registration at the

same time.

• When registration of more than four remote controller ID codes is attempted,

the oldest remote cont roller ID code will be

erased and that inputted after the fourth

one will be registered.

• When keyless start control module which was used in another vehicle has been

installed, it is nece ssary to perform both

registration of remote controller ID code in

keyless start control module and

registration of ignition key transponder

code in ECM. For registration procedure of

ignition key transponder code, refer to

“Registration of the Ignition Key in Section

10C”.

1. Upper case 3. Printed circuit board

2. Rubber switch

1

2

34

5I4RS0BA50033-01