dead battery SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 22 of 1496

Downloaded from www.Manualslib.com manuals search engine 0A-1 General Information:

General Information

General Information

General Description

AbbreviationsS7RS0B0101001

A:

ABDC: After Bottom Dead Center

ABS: Anti-lock Brake System

AC: Alternating Current

A/C: Air Conditioning

A-ELR: Automatic-Emergency Locking Retractor

A/F: Air Fuel Mixture Ratio

ALR: Automatic Locking Retractor

API: American Petroleum Institute

APP sensor: Accelerator Pedal Position Sensor

A/T: Automatic Transmission , Automatic Transaxle

AT D C : After Top Dead Center

ATF: Automatic Transmission Fluid, Automatic

Transaxle Fluid

B:

B+: Battery Positive Voltage

BBDC: Before Bottom Dead Center

BCM: Body Electrical Control Module

BDC: Bottom Dead Center

BTDC: Before Top Dead Center

C:

CAN: Controller Area Network

CKT: Circuit

CKP Sensor: Crankshaft Position Sensor

CMP Sensor: Camshaft Position Sensor

CO: Carbon Monoxide

CPP Switch: Clutch Pedal Position Switch (Clutch

Switch, Clutch Start Switch)

CPU: Central Processing Unit

CRS: Child Restraint System

D:

DC: Direct Current

DLC: Data Link Connector (Assembly Line Diag. Link,

ALDL, Serial Data Link, SDL)

DOHC: Double Over Head Camshaft

DOJ: Double Offset Joint

DRL: Daytime Running Light

DTC: Diagnostic Trouble Code (Diagnostic Code)

E:

EBCM: Electronic Brake Cont rol Module, ABS Control

Module

EBD: Electronic Brake Force Distribution

ECM: Engine Control Module

ECT Sensor: Engine Coolant Temperature Sensor (Water Temp. Sensor, WTS)

EFE Heater: Early Fuel Evaporation Heater (Positive

Temperature Coefficient, PTC Heater)

EGR: Exhaust Gas Recirculation

EGRT Sensor: EGR Temperature Sensor (Recirculated

Exhaust Gas Temp. Sensor, REGTS)

ELR: Emergency Locking Retractor

ESP ®: Electronic Stability Program

EPS: Electronic Power Steering

EVAP: Evaporative Emission EVAP Canister:

Evaporative Emission Canister

(Charcoal Canister)

F:

4WD: 4 Wheel

Drive

G:

GEN: Generator

GND: Ground

GPS: Global Positioning System

H:

HVAC: Heating, Ventilating and Air Conditioning

HC: Hydrocarbons

HO2S: Heated Oxygen Sensor

I:

IAC Valve: Idle Air Control Valve (Idle Speed Control

Solenoid Valve, ISC Solenoid Valve)

IAT Sensor: Intake Air Temperature Sensor (Air

temperature Sensor, ATS)

ICM: Immobilizer Control Module

IG: Ignition

ISC Actuator: Idle Speed Control Actuator

L:

LH: Left Hand

LHD: Left Hand Drive Vehicle

LSPV: Load Sensing Proportioning Valve

M:

MAF Sensor: Mass Air Flow Sensor (Air Flow Sensor, AFS, Air Flow Meter, AFM)

MAP Sensor: Manifold Absolute Pressure Sensor

(Pressure Sensor, PS)

Max: Maximum

MFI: Multiport Fuel Injection (Mu ltipoint Fuel Injection)

Min: Minimum

MIL: Malfunction Indicator Lamp (“SERVICE ENGINE

SOON” Light)

M/T: Manual Transmission, Manual Transaxle

N:

NOx: Nitrogen Oxides

O:

OBD: On-Board Diagnostic System (Self-Diagnosis

Function)

O/D: Overdrive

OHC: Over Head Camshaft

O2S: Oxygen Sensor

P:

PCM: Powertrain Control Module

PCV: Positive Crankcase Ventilation

PNP: Park / Neutral Position

P/S: Power Steering

PSP Switch: Power Steering Pressure Switch (P/S

Pressure Switch)

R:

RH: Right Hand

RHD: Right Hand Drive Vehicle

S:

SAE: Society of Automotive Engineers

Page 416 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-6 Charging System:

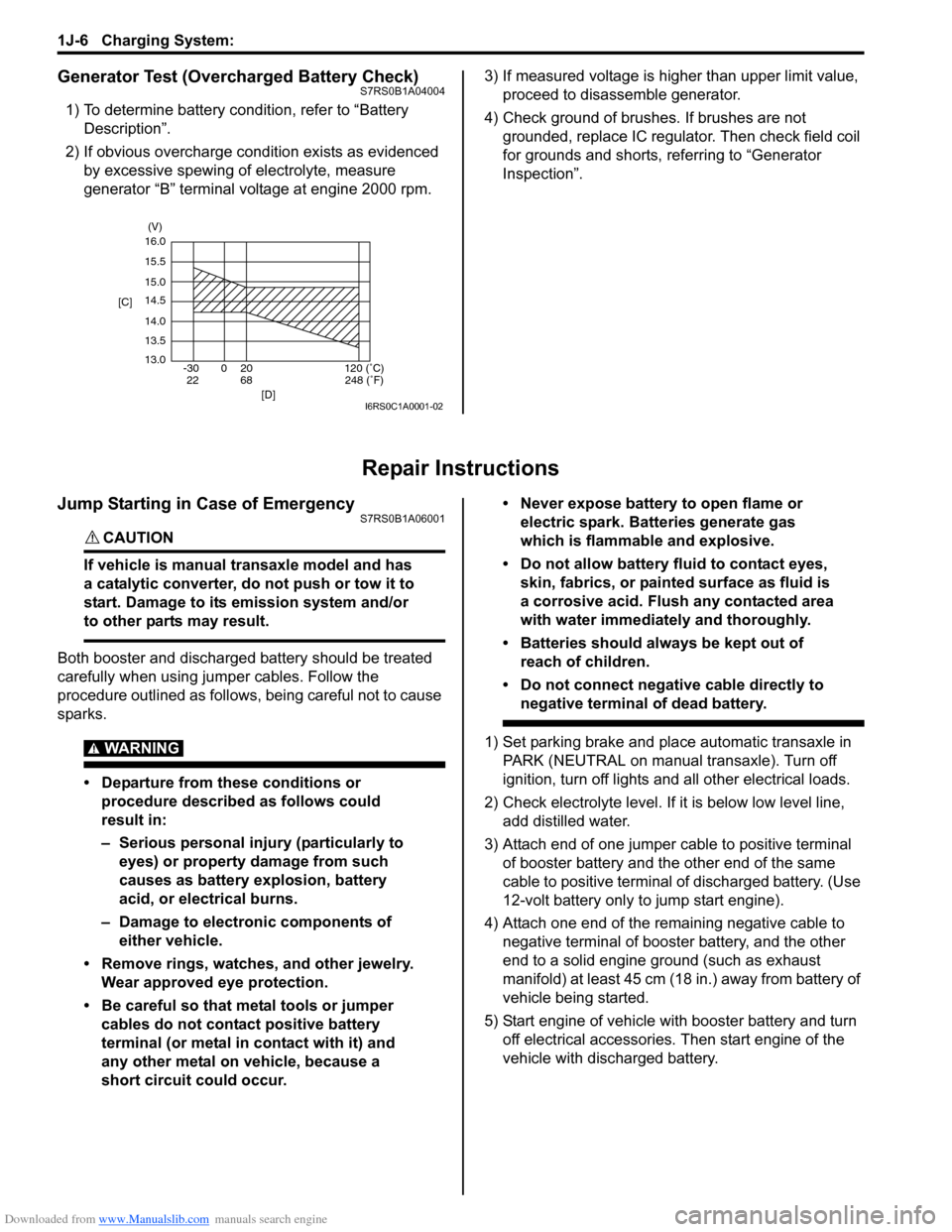

Generator Test (Overcharged Battery Check)S7RS0B1A04004

1) To determine battery condition, refer to “Battery Description”.

2) If obvious overcharge condition exists as evidenced by excessive spewing of electrolyte, measure

generator “B” terminal voltage at engine 2000 rpm. 3) If measured voltage is higher than upper limit value,

proceed to disassemble generator.

4) Check ground of brushes. If brushes are not grounded, replace IC regulator. Then check field coil

for grounds and shorts, referring to “Generator

Inspection”.

Repair Instructions

Jump Starting in Case of EmergencyS7RS0B1A06001

CAUTION!

If vehicle is manual transaxle model and has

a catalytic converter, do not push or tow it to

start. Damage to its emission system and/or

to other parts may result.

Both booster and discharged battery should be treated

carefully when using ju mper cables. Follow the

procedure outlined as follows, being careful not to cause

sparks.

WARNING!

• Departure from these conditions or procedure described as follows could

result in:

– Serious personal injury (particularly to eyes) or property damage from such

causes as battery explosion, battery

acid, or electrical burns.

– Damage to electronic components of either vehicle.

• Remove rings, watches, and other jewelry. Wear approved eye protection.

• Be careful so that metal tools or jumper cables do not contact positive battery

terminal (or metal in contact with it) and

any other metal on vehicle, because a

short circuit could occur. • Never expose battery to open flame or

electric spark. Batteries generate gas

which is flammable and explosive.

• Do not allow battery fluid to contact eyes, skin, fabrics, or painted surface as fluid is

a corrosive acid. Flush any contacted area

with water immediately and thoroughly.

• Batteries should always be kept out of reach of children.

• Do not connect negative cable directly to negative terminal of dead battery.

1) Set parking brake and place automatic transaxle in PARK (NEUTRAL on manual transaxle). Turn off

ignition, turn off lights and all other electrical loads.

2) Check electrolyte level. If it is below low level line, add distilled water.

3) Attach end of one jumper cable to positive terminal of booster battery and the other end of the same

cable to positive terminal of discharged battery. (Use

12-volt battery only to jump start engine).

4) Attach one end of the remaining negative cable to negative terminal of booster battery, and the other

end to a solid engine ground (such as exhaust

manifold) at least 45 cm (18 in.) away from battery of

vehicle being started.

5) Start engine of vehicle with booster battery and turn off electrical accessories. Then start engine of the

vehicle with discharged battery.

16.0

15.5

15.0

14.5

14.0

13.5

13.0 -30 0 20

[C]

[D]

68

22120 (˚C)

248 (˚F)

(V)

I6RS0C1A0001-02

Page 1350 of 1496

Downloaded from www.Manualslib.com manuals search engine 9F-4 Security and Locks:

Keyless Entry System Symptom Diagnosis (If Equipped)S7RS0B9604003

NOTE

• Confirm that power door lock system is in good condition before referring to the following possible causes.

• Check each part in the order from the top of the following list.

Condition Possible cause Correction / Reference Item

All door can not be locked

/ unlocked by only

keyless entry transmitter Transmitter battery dead

Replace battery referring to “Replacement of

Transmitter Battery”.

Door switch faulty Check door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”

and/or “Rear End Door Switch Inspection in

Section 9C”.

Transmitter faulty Replace transmitter.

Key reminder switch in ignition switch

faulty Check ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

Keyless entry receiver faulty Check keyless entry receiver referring to

“Keyless Entry Receiver and Its Circuit

Inspection”.

BCM faulty Replace after making sure that none of above

parts is faulty.

Interior light does not

light when doors are

unlocked by keyless entry

transmitter Wiring or grounding faulty

Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Hazard warning lights do

not light when doors are

locked/unlocked by

keyless entry transmitter Turn signal and hazard warning relay

faulty

Check turn signal and hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection in Section 9B”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Transmitter code can not

be programmed to BCM Door switch faulty

Check door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”

and/or “Rear End Door Switch Inspection in

Section 9C”.

Keyless entry receiver faulty Check keyless entry receiver referring to

“Keyless Entry Receiver and Its Circuit

Inspection”.

Key reminder switch in ignition switch

faulty Check ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Page 1474 of 1496

Downloaded from www.Manualslib.com manuals search engine 10E-12 Keyless Start System:

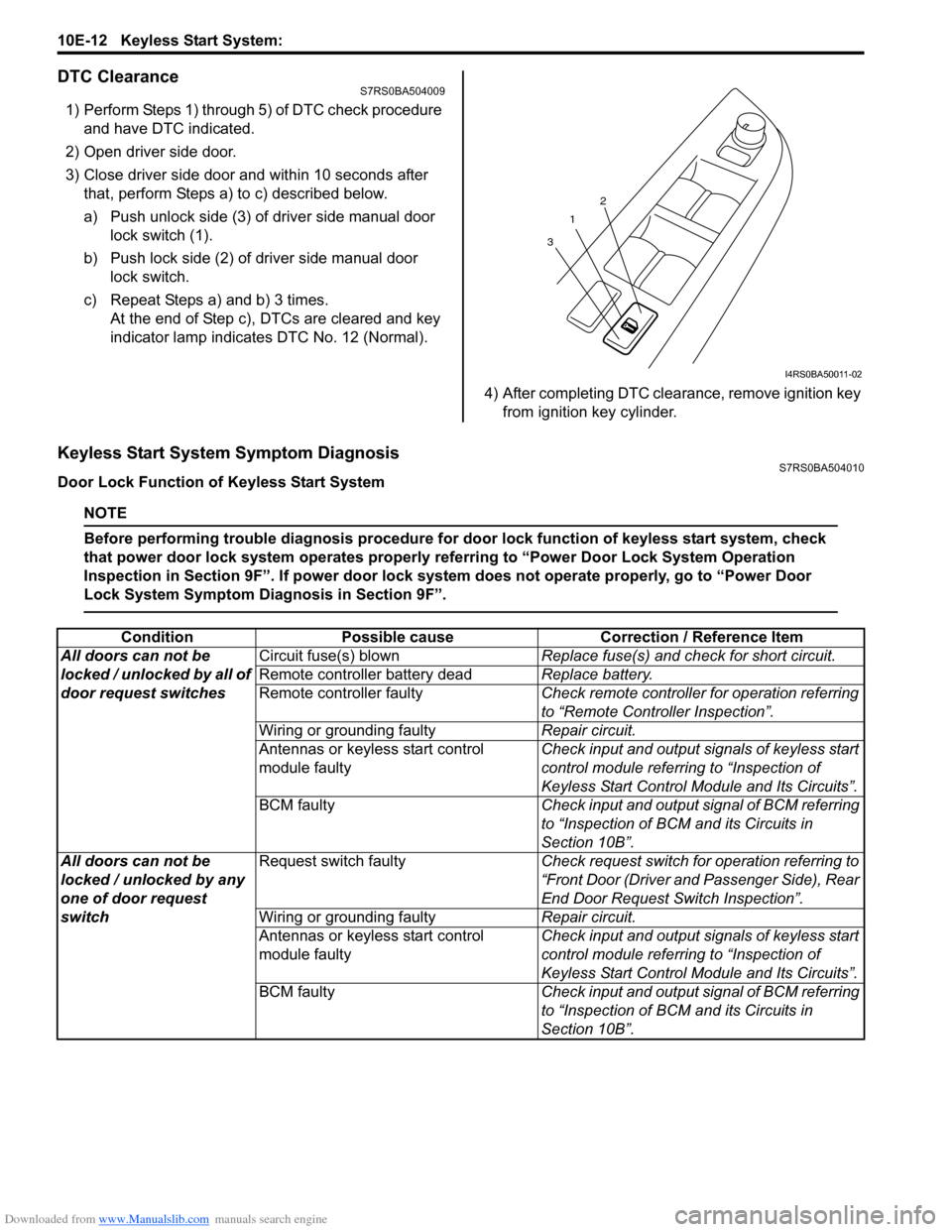

DTC ClearanceS7RS0BA504009

1) Perform Steps 1) through 5) of DTC check procedure and have DTC indicated.

2) Open driver side door.

3) Close driver side door and within 10 seconds after that, perform Steps a) to c) described below.

a) Push unlock side (3) of driver side manual door lock switch (1).

b) Push lock side (2) of driver side manual door lock switch.

c) Repeat Steps a) and b) 3 times. At the end of Step c), DTCs are cleared and key

indicator lamp indicates DTC No. 12 (Normal).

4) After completing DTC clearance, remove ignition key from ignition key cylinder.

Keyless Start System Symptom DiagnosisS7RS0BA504010

Door Lock Function of Keyless Start System

NOTE

Before performing trouble diagnosis procedure for door lock function of keyless start system, check

that power door lock system operates properly referring to “Power Door Lock System Operation

Inspection in Section 9F”. If power door lock system does not operate properly, go to “Power Door

Lock System Symptom Diagnosis in Section 9F”.

1

3 2

I4RS0BA50011-02

Condition

Possible cause Correction / Reference Item

All doors can not be

locked / unlocked by all of

door request switches Circuit fuse(s) blown

Replace fuse(s) and check for short circuit.

Remote controller battery dead Replace battery.

Remote controller faulty Check remote controller for operation referring

to “Remote Controller Inspection”.

Wiring or grounding faulty Repair circuit.

Antennas or keyless start control

module faulty Check input and output signals of keyless start

control module referring to “Inspection of

Keyless Start Control Mo

dule and Its Circuits”.

BCM faulty Check input and output signal of BCM referring

to “Inspection of BCM and its Circuits in

Section 10B”.

All doors can not be

locked / unlocked by any

one of door request

switch Request switch faulty

Check request switch for operation referring to

“Front Door (Driver and Passenger Side), Rear

End Door Request Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Antennas or keyless start control

module faulty Check input and output signals of keyless start

control module referring to “Inspection of

Keyless Start Control Mo

dule and Its Circuits”.

BCM faulty Check input and output signal of BCM referring

to “Inspection of BCM and its Circuits in

Section 10B”.

Page 1475 of 1496

Downloaded from www.Manualslib.com manuals search engine Keyless Start System: 10E-13

Keyless Engine Start Function

NOTE

Before performing symptom diagnosis procedure for keyless engine start system, check that engine

starts by using ignition key. If it cannot be started by using ignition key, go to “Engine Symptom

Diagnosis in Section 1A”.

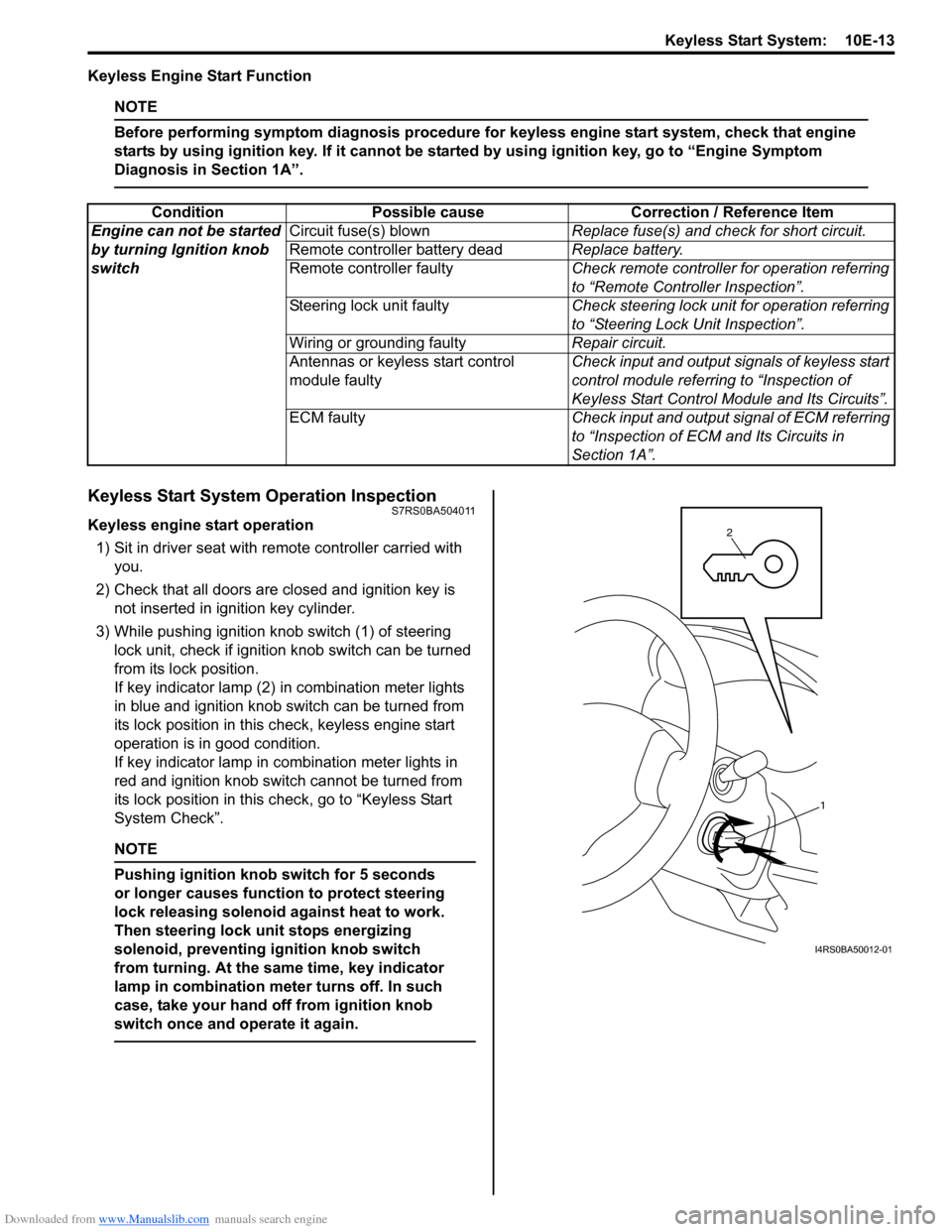

Keyless Start System Operation InspectionS7RS0BA504011

Keyless engine start operation

1) Sit in driver seat with re mote controller carried with

you.

2) Check that all doors are closed and ignition key is not inserted in ignition key cylinder.

3) While pushing ignition knob switch (1) of steering lock unit, check if ignition knob switch can be turned

from its lock position.

If key indicator lamp (2) in combination meter lights

in blue and ignition knob switch can be turned from

its lock position in this check, keyless engine start

operation is in good condition.

If key indicator lamp in combination meter lights in

red and ignition knob switch cannot be turned from

its lock position in this check, go to “Keyless Start

System Check”.

NOTE

Pushing ignition knob switch for 5 seconds

or longer causes function to protect steering

lock releasing solenoid against heat to work.

Then steering lock unit stops energizing

solenoid, preventing ignition knob switch

from turning. At the same time, key indicator

lamp in combination mete r turns off. In such

case, take your hand off from ignition knob

switch once and operate it again.

Condition Possible cause Correction / Reference Item

Engine can not be started

by turning Ignition knob

switch Circuit fuse(s) blown

Replace fuse(s) and check for short circuit.

Remote controller battery dead Replace battery.

Remote controller faulty Check remote controller for operation referring

to “Remote Controller Inspection”.

Steering lock unit faulty Check steering lock unit for operation referring

to “Steering Lock Unit Inspection”.

Wiring or grounding faulty Repair circuit.

Antennas or keyless start control

module faulty Check input and output signals of keyless start

control module referring to “Inspection of

Keyless Start Control Mo

dule and Its Circuits”.

ECM faulty Check input and output signal of ECM referring

to “Inspection of ECM and Its Circuits in

Section 1A”.

1

2

I4RS0BA50012-01