fold seats SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 9 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-4

General PrecautionsS7RS0B0000002

The WARNING and CAUTION describe some general

precautions that you should observe when servicing a

vehicle. These general precautions apply to many of the

service procedures, and they will not necessarily be

repeated with each procedure to which they apply.

WARNING!

• Whenever raising a vehicle for service, be sure to follow the instructions under

“Vehicle Lifting Points in Section 0A”.

• When it is necessary to do service work with the engine running, make sure that

the parking brake is set fully and the

transmission is in Neutral (for manual

transmission vehicles) or Park (for

automatic transmission vehicles), Keep

hands, hair, clothing, tools, etc. away from

the fan and belts when the engine is

running.

• When it is necessary to run the engine indoors, make sure that the exhaust gas is

forced outdoors.

• Do not perform service work in areas where combustible materials can come in

contact with a hot exhaust system. When

working with toxic or flammable materials

(such as gasoline and refrigerant), make

sure that the area you work in is well-

ventilated.

• To avoid getting burned, keep away from hot metal parts such as the radiator,

exhaust manifold, tail pipe, muffler, etc.

• New and used engine oil can be hazardous. Children and pets may be

harmed by swallowing new or used oil.

Keep new and used oil and used engine oil

filters away from children and pets.

Continuous contact with used engine oil

has been found to cause [skin] cancer in

laboratory animals. Brief contact with used

oil may irritate skin. To minimize your

exposure to used engine oil, wear a long-

sleeve shirt and moisture-proof gloves

(such as dish washing gloves) when

changing engine oil. If engine oil contacts

your skin, wash thoroughly with soap and

water. Launder any clothing or rags if wet

with oil, recycle or properly dispose of

used oil and filters. • Be sure to observe following instructions

when handling service materials such as

fuel, oil, fluid, coolant, grease, sealant,

thread lock cement, etc. Otherwise, your

health may be ruined.

– Whenever handling any of these service materials, wear safety glasses to protect

your eyes. If it gets into your eye, it may

cause inflammation.

– Whenever handling any of these service materials, wear moistu re-proof gloves to

protect your skin. If it adheres to your

skin, it may cause inflammation.

– Do not swallow any of these service materials. It would cause diarrhea or

nausea.

– Keep all these materials out of children’s reach.

• Make sure the bonnet is fully closed and latched before driving. If it is not, it can fly

up unexpectedly during driving,

obstructing your view and resulting in an

accident.

• Before starting any service work, cover fenders, seats and any other parts that are likely to get scratched or

stained during servicing. Also, be aware that what you

wear (e.g., buttons) ma y cause damage to the

vehicle’s finish.

I2RH01010025-01

Page 327 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-42

Cylinder Head InspectionS7RS0B1406027

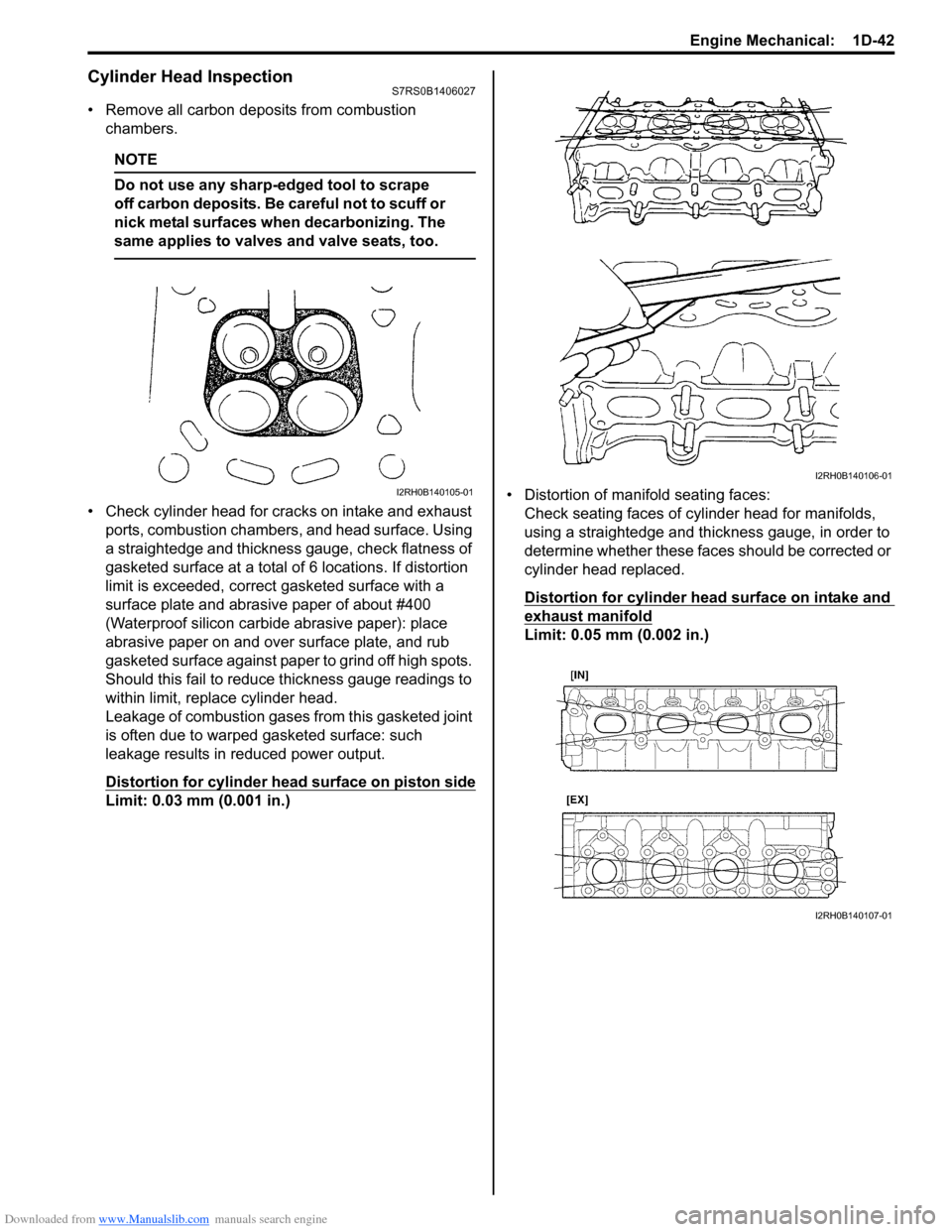

• Remove all carbon deposits from combustion chambers.

NOTE

Do not use any sharp-edged tool to scrape

off carbon deposits. Be careful not to scuff or

nick metal surfaces when decarbonizing. The

same applies to valves and valve seats, too.

• Check cylinder head for cracks on intake and exhaust ports, combustion chambers, and head surface. Using

a straightedge and thickness gauge, check flatness of

gasketed surface at a total of 6 locations. If distortion

limit is exceeded, correct gasketed surface with a

surface plate and abrasive paper of about #400

(Waterproof silicon carbide abrasive paper): place

abrasive paper on and over surface plate, and rub

gasketed surface against paper to grind off high spots.

Should this fail to reduce thickness gauge readings to

within limit, replace cylinder head.

Leakage of combustion gases from this gasketed joint

is often due to warped gasketed surface: such

leakage results in reduced power output.

Distortion for cylinder head surface on piston side

Limit: 0.03 mm (0.001 in.) • Distortion of manifold seating faces:

Check seating faces of cylinder head for manifolds,

using a straightedge and thickness gauge, in order to

determine whether these faces should be corrected or

cylinder head replaced.

Distortion for cylinder head surface on intake and

exhaust manifold

Limit: 0.05 mm (0.002 in.)

I2RH0B140105-01

I2RH0B140106-01

I2RH0B140107-01

Page 1038 of 1496

Downloaded from www.Manualslib.com manuals search engine 8A-7 Seat Belts:

Rear Seat Belt Removal and InstallationS7RS0B8106005

WARNING!

Be sure to read “Precautions on Service and

Diagnosis of Seat Belt” before starting to

work and observe every precaution during

work.

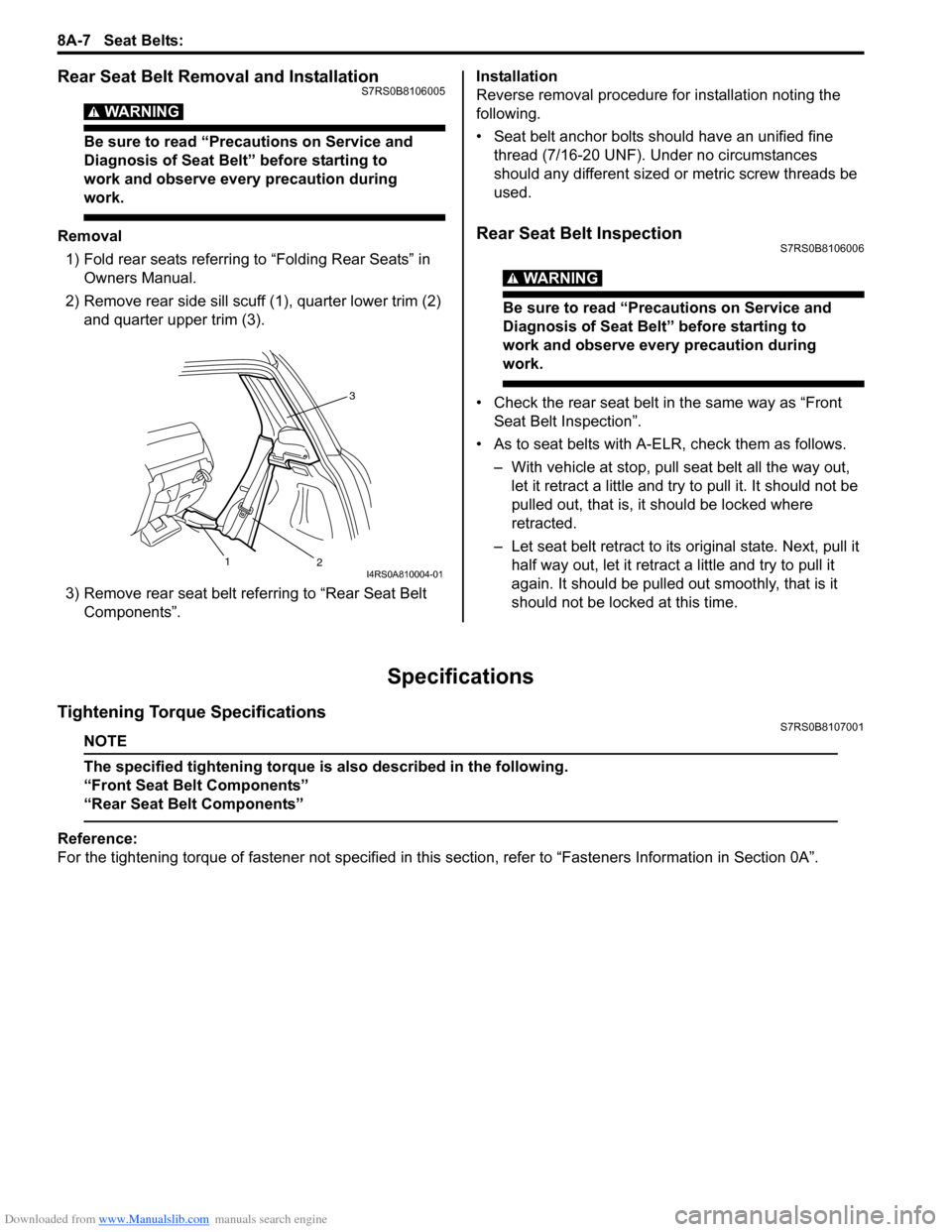

Removal1) Fold rear seats referring to “Folding Rear Seats” in Owners Manual.

2) Remove rear side sill scuff (1), quarter lower trim (2)

and quarter upper trim (3).

3) Remove rear seat belt referring to “Rear Seat Belt Components”. Installation

Reverse removal procedure for installation noting the

following.

• Seat belt anchor bolts should have an unified fine

thread (7/16-20 UNF). Under no circumstances

should any different sized or metric screw threads be

used.Rear Seat Belt InspectionS7RS0B8106006

WARNING!

Be sure to read “Precautions on Service and

Diagnosis of Seat Belt” before starting to

work and observe every precaution during

work.

• Check the rear seat belt in the same way as “Front Seat Belt Inspection”.

• As to seat belts with A-ELR, check them as follows. – With vehicle at stop, pull seat belt all the way out, let it retract a little and try to pull it. It should not be

pulled out, that is, it should be locked where

retracted.

– Let seat belt retract to its original state. Next, pull it

half way out, let it retrac t a little and try to pull it

again. It should be pulled out smoothly, that is it

should not be locked at this time.

Specifications

Tightening Torque SpecificationsS7RS0B8107001

NOTE

The specified tightening torque is also described in the following.

“Front Seat Belt Components”

“Rear Seat Belt Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

3

2

1

I4RS0A810004-01

Page 1366 of 1496

Downloaded from www.Manualslib.com manuals search engine 9G-4 Seats:

Rear Seat Removal and InstallationS7RS0B9706004

Removal1) Fold rear seat back forward.

2) Remove seat mounting bolts and nuts to remove seat assembly.

3) Disassemble and repair seat as necessary.

Installation

Reverse removal procedure to install rear seat.

• Tighten seat back striker mounting bolts according to “Rear Seat Components”.

• Torque to specifications in “Rear Seat Components”.

• When installing seat cushion, align seat cushion hook with center hinge bracket.

Specifications

Tightening Torque SpecificationsS7RS0B9707001

NOTE

The specified tightening torque is also described in the following.

“Front Seat Components”

“Rear Seat Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B9708001

NOTE

Required service material is also described in the following.

“Front Seat Components”

Material SUZUKI recommended product or Specification Note

Thread lock cement Thread Lock Cement Super 1303B P/No.: 99000–32030 �)

Thread Lock Cement 1305 P/No.: 99000–32100 �)