lighting switch SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 236 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-186 Engine General Information and Diagnosis:

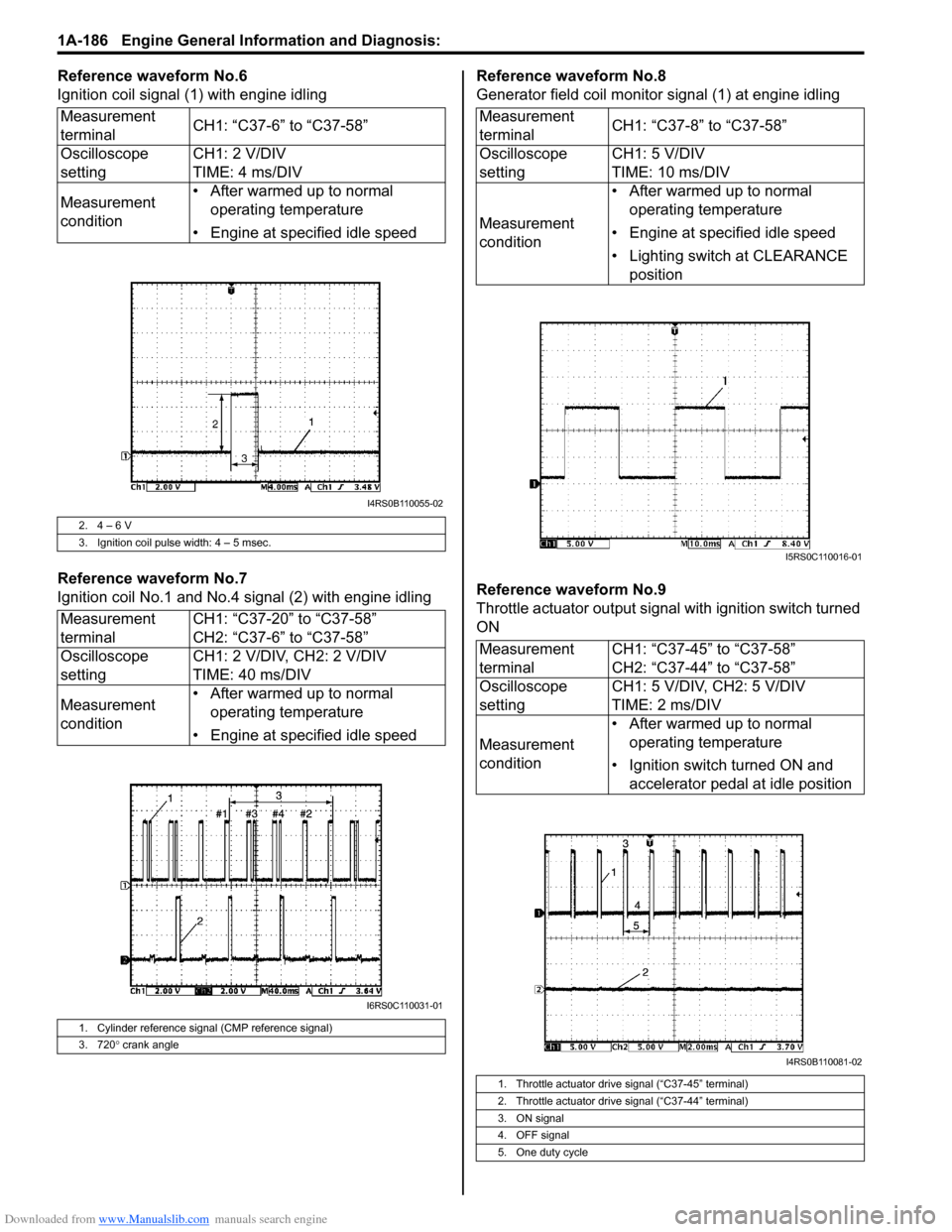

Reference waveform No.6

Ignition coil signal (1) with engine idling

Reference waveform No.7

Ignition coil No.1 and No.4 signal (2) with engine idlingReference waveform No.8

Generator field coil monitor signal (1) at engine idling

Reference waveform No.9

Throttle actuator output signal with ignition switch turned

ON

Measurement

terminal

CH1: “C37-6” to “C37-58”

Oscilloscope

setting CH1: 2 V/DIV

TIME: 4 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

2. 4 – 6 V

3. Ignition coil pulse width: 4 – 5 msec.

Measurement

terminal CH1: “C37-20” to “C37-58”

CH2: “C37-6” to “C37-58”

Oscilloscope

setting CH1: 2 V/DIV, CH2: 2 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 720 ° crank angle

I4RS0B110055-02

I6RS0C110031-01

Measurement

terminal CH1: “C37-8” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV

TIME: 10 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

• Lighting switch at CLEARANCE position

Measurement

terminal CH1: “C37-45” to “C37-58”

CH2: “C37-44” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 2 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Ignition switch turned ON and accelerator pedal at idle position

1. Throttle actuator drive signal (“C37-45” terminal)

2. Throttle actuator drive signal (“C37-44” terminal)

3. ON signal

4. OFF signal

5. One duty cycle

I5RS0C110016-01

I4RS0B110081-02

Page 549 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-10

Problem symptom confirmation

Check if what the customer claimed in “Customer

Questionnaire” is actually found in the vehicle and if that

symptom is found, whether it is identified as a failure.

(This step should be shared with the customer if

possible.) Check warning lights related to brake system

referring to “EBD Warning Light (Brake Warning Light)

Check” and “ABS Warning Light Check”.

DTC check, record and clearance

Perform “DTC Check” proced ure, record it and then

clear it referring to “DTC Clearance”.

Recheck DTC referring to “DTC Check”.

When DTC which is recorded at DTC check procedure is

detected again after performi ng DTC clearance, go to

“Step 4: ABS Check: ” to proceed the diagnosis.

When DTC which is recorded at DTC check procedure is

not indicated anymore after performing DTC clearance,

ABS control module does not perform the system

diagnosis, or temporary abnormality may occur,

therefore go to “Step 2: Driving Test: ” to proceed the

diagnosis.

Step 2: Driving Test

Test drive the vehicle at 40 km/h for more than a minute

and check if any trouble symptom (such as abnormal

lighting of ABS warn ing light) exists.

If the malfunction DTC is co nfirmed again at ignition

switch ON, driving test as described is not necessary.

Proceed to Step 3.

Step 3: DTC Check

Recheck DTC referring to “DTC Check”.

Step 4: ABS Check

According to ABS Check for the DTC confirmation in

Step 3, locate the cause of the trouble, namely in a

sensor, switch, wire harness, connector, actuator

assembly or other part and repair or replace faulty parts.

Step 5: Brakes Diagnosis

Check the parts or system suspected as a possible

cause referring to “Brakes Symptom Diagnosis in

Section 4A” and based on symptoms appearing on the

vehicle (symptom obtained through Steps 1 and 2 and

repair or replace faulty parts, if any).

Step 6: Check for Intermittent Problem

Check parts where an intermittent trouble is easy to

occur (e.g., wire harness, con nector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of trouble code recorded in Step 1

to 3.

Step 7: Final Confirmation Test

Confirm that the problem symptom has gone and the

ABS is free from any abnormal conditions. If what has

been repaired is related to the malfunction DTC, clear

the DTC once referring to “DTC Clearance” and perform

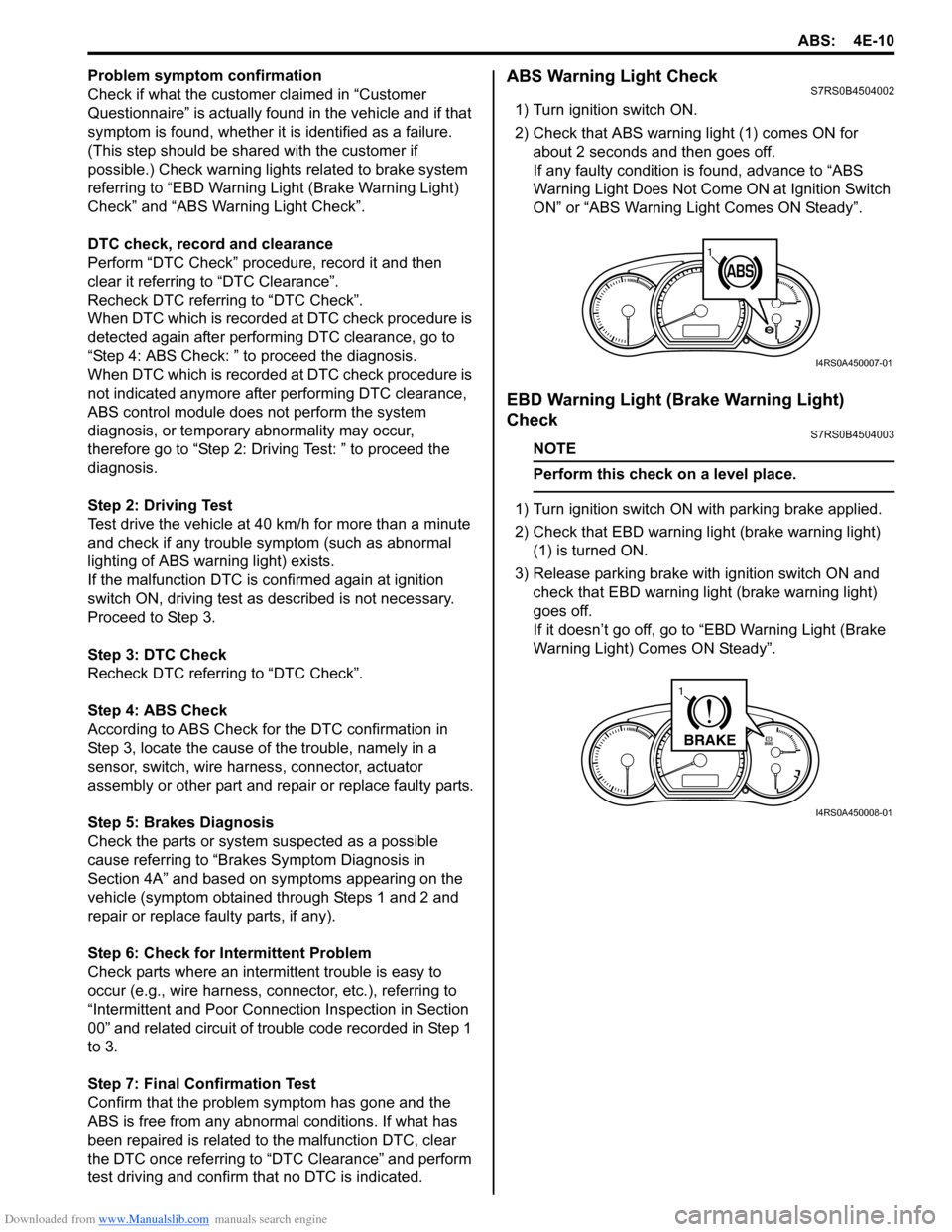

test driving and confirm that no DTC is indicated.ABS Warning Light CheckS7RS0B4504002

1) Turn ignition switch ON.

2) Check that ABS warning light (1) comes ON for

about 2 seconds and then goes off.

If any faulty condition is found, advance to “ABS

Warning Light Does Not Come ON at Ignition Switch

ON” or “ABS Warning Light Comes ON Steady”.

EBD Warning Light (Brake Warning Light)

Check

S7RS0B4504003

NOTE

Perform this check on a level place.

1) Turn ignition switch ON with parking brake applied.

2) Check that EBD warning lig ht (brake warning light)

(1) is turned ON.

3) Release parking brake with ignition switch ON and check that EBD warning lig ht (brake warning light)

goes off.

If it doesn’t go off, go to “EBD Warning Light (Brake

Warning Light) Comes ON Steady”.

11

I4RS0A450007-01

BRAKE

1

I4RS0A450008-01

Page 663 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-19

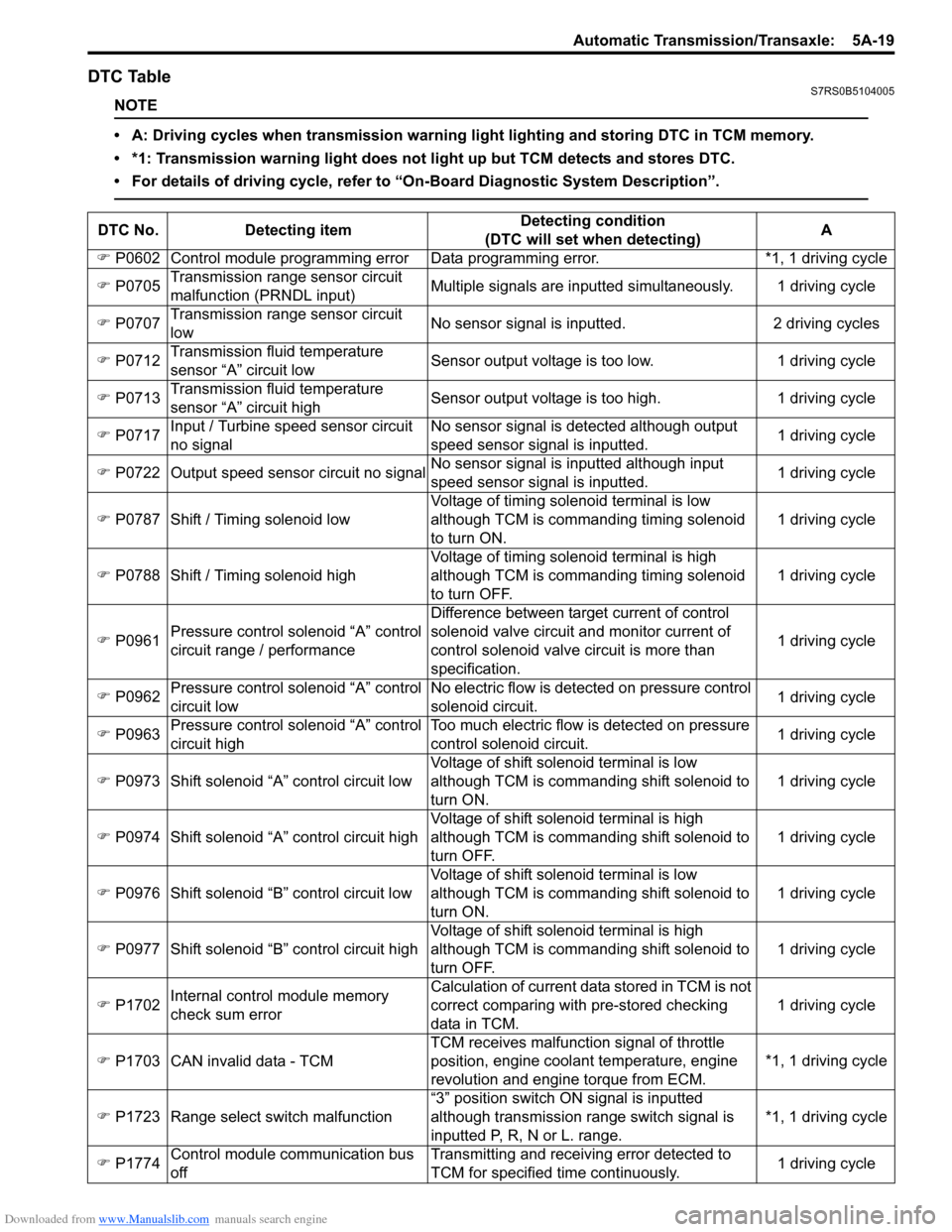

DTC TableS7RS0B5104005

NOTE

• A: Driving cycles when transmission warning light lighting and storing DTC in TCM memory.

• *1: Transmission warning light does not light up but TCM detects and stores DTC.

• For details of driving cycle, refer to “On-Board Diagnostic System Description”.

DTC No.Detecting item Detecting condition

(DTC will set when detecting) A

�) P0602 Control module programming error D ata programming error. *1, 1 driving cycle

�) P0705 Transmission range sensor circuit

malfunction (PRNDL input) Multiple signals are inputted

simultaneously. 1 driving cycle

�) P0707 Transmission range sensor circuit

low No sensor signal is inputted.

2 driving cycles

�) P0712 Transmission fluid temperature

sensor “A” circuit low Sensor output voltage is too low.

1 driving cycle

�) P0713 Transmission fluid temperature

sensor “A” circuit high Sensor output voltage is too high.

1 driving cycle

�) P0717 Input / Turbine speed sensor circuit

no signal No sensor signal is detected although output

speed sensor signal is inputted.

1 driving cycle

�) P0722 Output speed sensor circuit no signal No sensor signal is inputted although input

speed sensor signal is inputted. 1 driving cycle

�) P0787 Shift / Timing solenoid low Voltage of timing solenoid terminal is low

although TCM is commanding timing solenoid

to turn ON. 1 driving cycle

�) P0788 Shift / Timing solenoid high Voltage of timing solenoid terminal is high

although TCM is commanding timing solenoid

to turn OFF. 1 driving cycle

�) P0961 Pressure control solenoid “A” control

circuit range / performance Difference between target current of control

solenoid valve circuit and monitor current of

control solenoid valve circuit is more than

specification.

1 driving cycle

�) P0962 Pressure control solenoid “A” control

circuit low No electric flow is detected on pressure control

solenoid circuit.

1 driving cycle

�) P0963 Pressure control solenoid “A” control

circuit high Too much electric flow is detected on pressure

control solenoid circuit.

1 driving cycle

�) P0973 Shift solenoid “A” control circuit low Voltage of shift solenoid terminal is low

although TCM is commanding shift solenoid to

turn ON. 1 driving cycle

�) P0974 Shift solenoid “A” control circuit high Voltage of shift solenoid terminal is high

although TCM is commanding shift solenoid to

turn OFF. 1 driving cycle

�) P0976 Shift solenoid “B” control circuit low Voltage of shift solenoid terminal is low

although TCM is commanding shift solenoid to

turn ON. 1 driving cycle

�) P0977 Shift solenoid “B” control circuit high Voltage of shift solenoid terminal is high

although TCM is commanding shift solenoid to

turn OFF. 1 driving cycle

�) P1702 Internal control module memory

check sum error Calculation of current data stored in TCM is not

correct comparing with pre-stored checking

data in TCM.

1 driving cycle

�) P1703 CAN invalid data - TCM TCM receives malfunction signal of throttle

position

, engine coolan t temperature, engine

revolution and engine torque from ECM. *1, 1 driving cycle

�) P1723 Range select switch malfunction “3” position switch ON signal is inputted

although transmission range switch signal is

inputted P, R, N or L. range. *1, 1 driving cycle

�) P1774 Control module communication bus

off Transmitting and receiving error detected to

TCM for specified time continuously.

1 driving cycle

Page 874 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-3 Steering Wheel and Column:

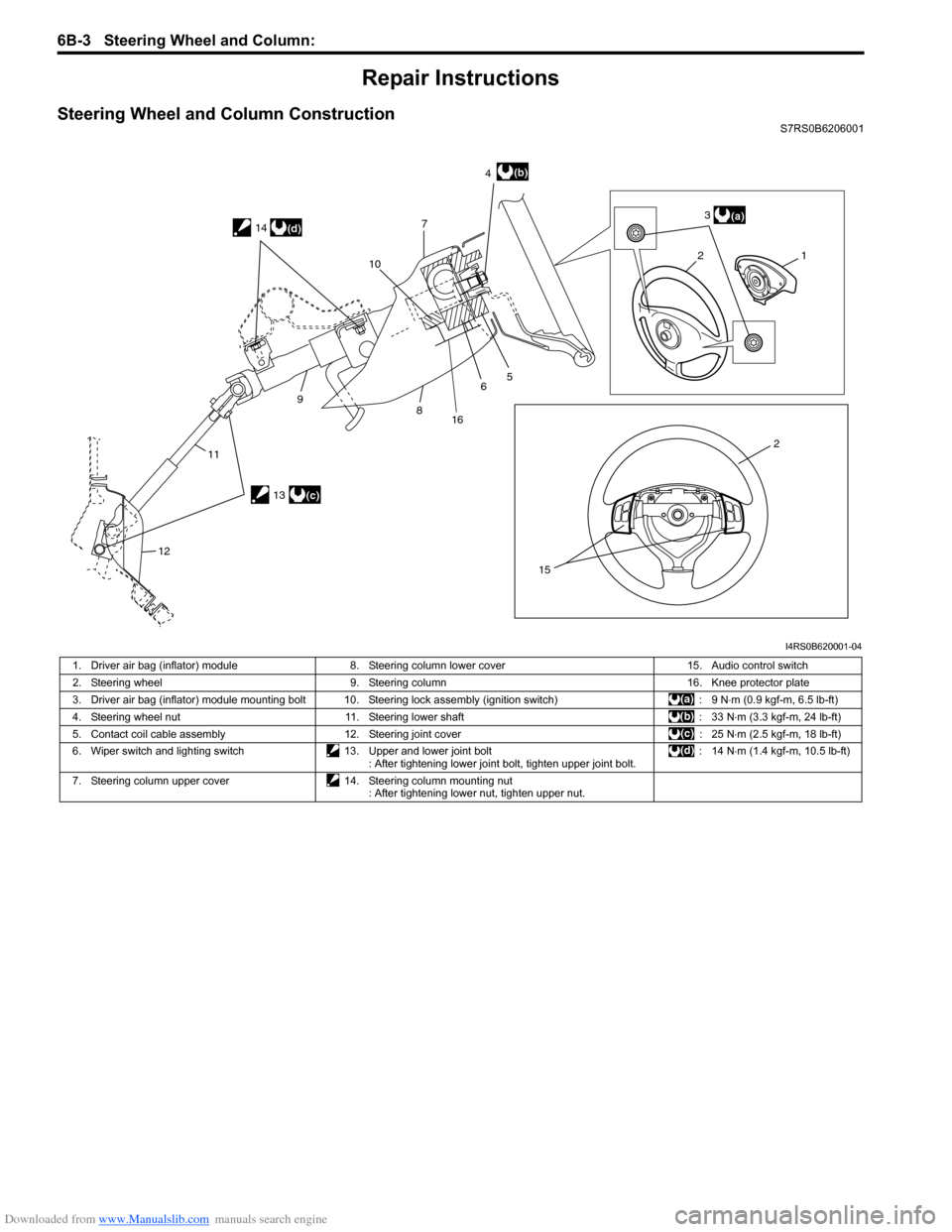

Repair Instructions

Steering Wheel and Column ConstructionS7RS0B6206001

21

2 3

4

7

5

6

8

9

11

12 10

15

(a)

(b)

13(c)

14

(d)

16

I4RS0B620001-04

1. Driver air bag (inflator) module

8. Steering column lower cover 15. Audio control switch

2. Steering wheel 9. Steering column 16. Knee protector plate

3. Driver air bag (inflator) module mounting bolt 10. Steering lock assembly (ignition switch) : 9 N⋅m (0.9 kgf-m, 6.5 lb-ft)

4. Steering wheel nut 11. Steering lower shaft : 33 N⋅m (3.3 kgf-m, 24 lb-ft)

5. Contact coil cable assembly 12. Steering joint cover : 25 N⋅m (2.5 kgf-m, 18 lb-ft)

6. Wiper switch and lighting switch 13. Upper and lower joint bolt

: After tightening lower joint bolt, tighten upper joint bolt. : 14 N

⋅m (1.4 kgf-m, 10.5 lb-ft)

7. Steering column upper cover 14. Steering column mounting nut

: After tightening lower nut, tighten upper nut.

Page 878 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-7 Steering Wheel and Column:

Steering Column Removal and InstallationS7RS0B6206006

CAUTION!

Once the steering column is removed from

the vehicle, the column is extremely

susceptible to damage.

• Dropping the column assembly on its end could collapse the steering shaft or loosen

the plastic shear pins which maintain

column length.

• Leaning on the column assembly could cause it to bend or deform.

Any of the damage could impair the column’s

collapsible design.

Steering column mounting nuts should not

be loosened with steering shaft joint upper

side bolt tightened as this could cause

damage to shaft joint bearing.

NOTE

When servicing steering column or any

column-mounted component, remove

steering wheel. But when removing steering

column simply to gain access to instrument

panel components, leave steering wheel

installed on steering column.

Removal

WARNING!

Never rest a steering column assembly on

the steering wheel with the air bag (inflator)

module face down and column vertical.

Otherwise, personal injury may result.

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Re fer to “Disabling Air Bag

System in Section 8B”.

3) Remove steering wheel and contact coil cable assembly referring to “S teering Wheel Removal and

Installation” and “Contact Coil Cable Assembly

Removal and Installation”.

4) Detach lighting switch and wiper switch from steering column.

5) Remove immobilizer cont rol module from steering

column, referring to “Immo bilizer Control Module

(ICM) Removal and Installation in Section 10C”.

6) Remove steering column hole cover.

7) Remove steering joint cover.

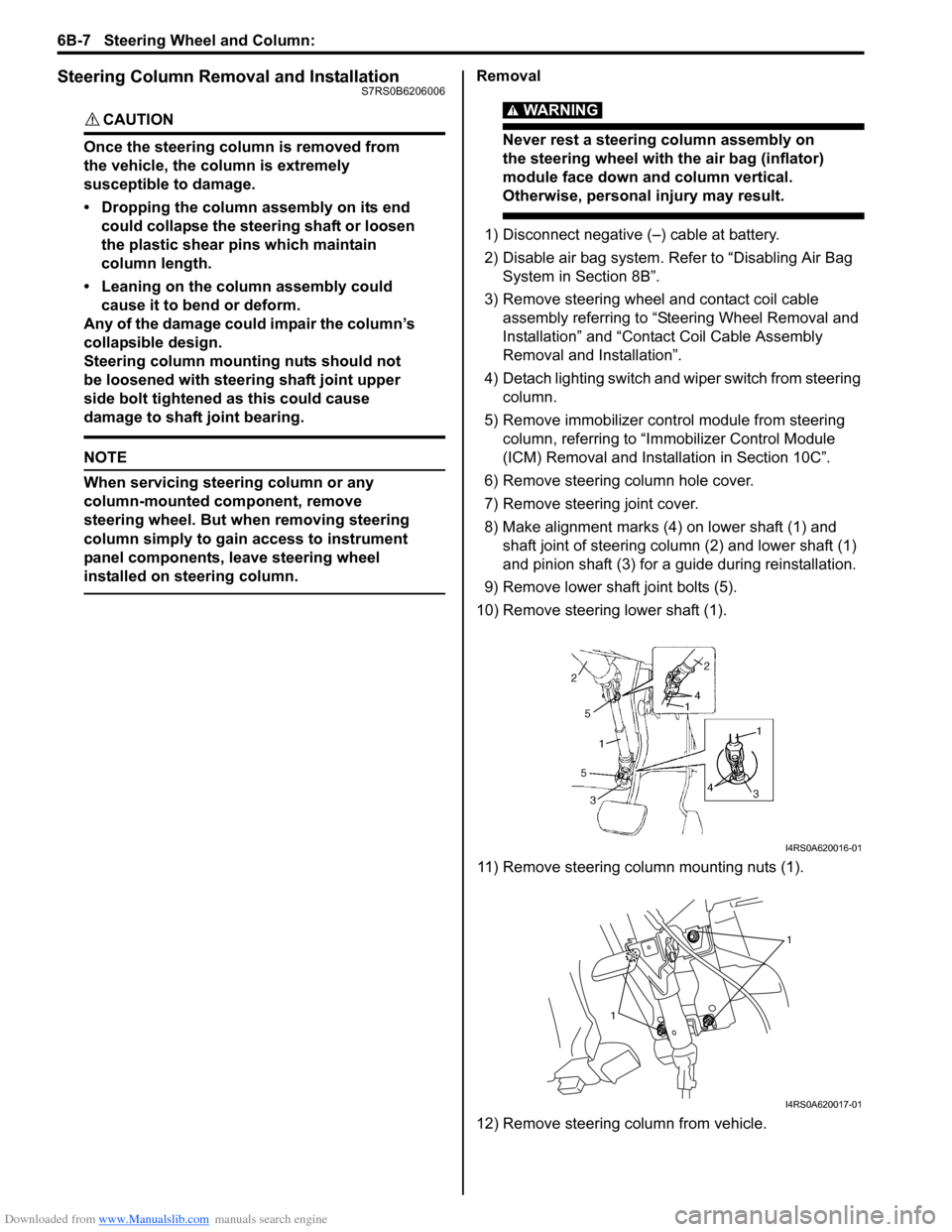

8) Make alignment marks (4) on lower shaft (1) and shaft joint of steering column (2) and lower shaft (1)

and pinion shaft (3) for a guide during reinstallation.

9) Remove lower shaf t joint bolts (5).

10) Remove steering lower shaft (1).

11) Remove steering column mounting nuts (1).

12) Remove steering column from vehicle.

I4RS0A620016-01

1

1

I4RS0A620017-01

Page 879 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-8

Installation

CAUTION!

After tightening steering column mounting

nuts, shaft joint bolts should be tightened.

Wrong tightening order could cause a

damage to shaft joint.

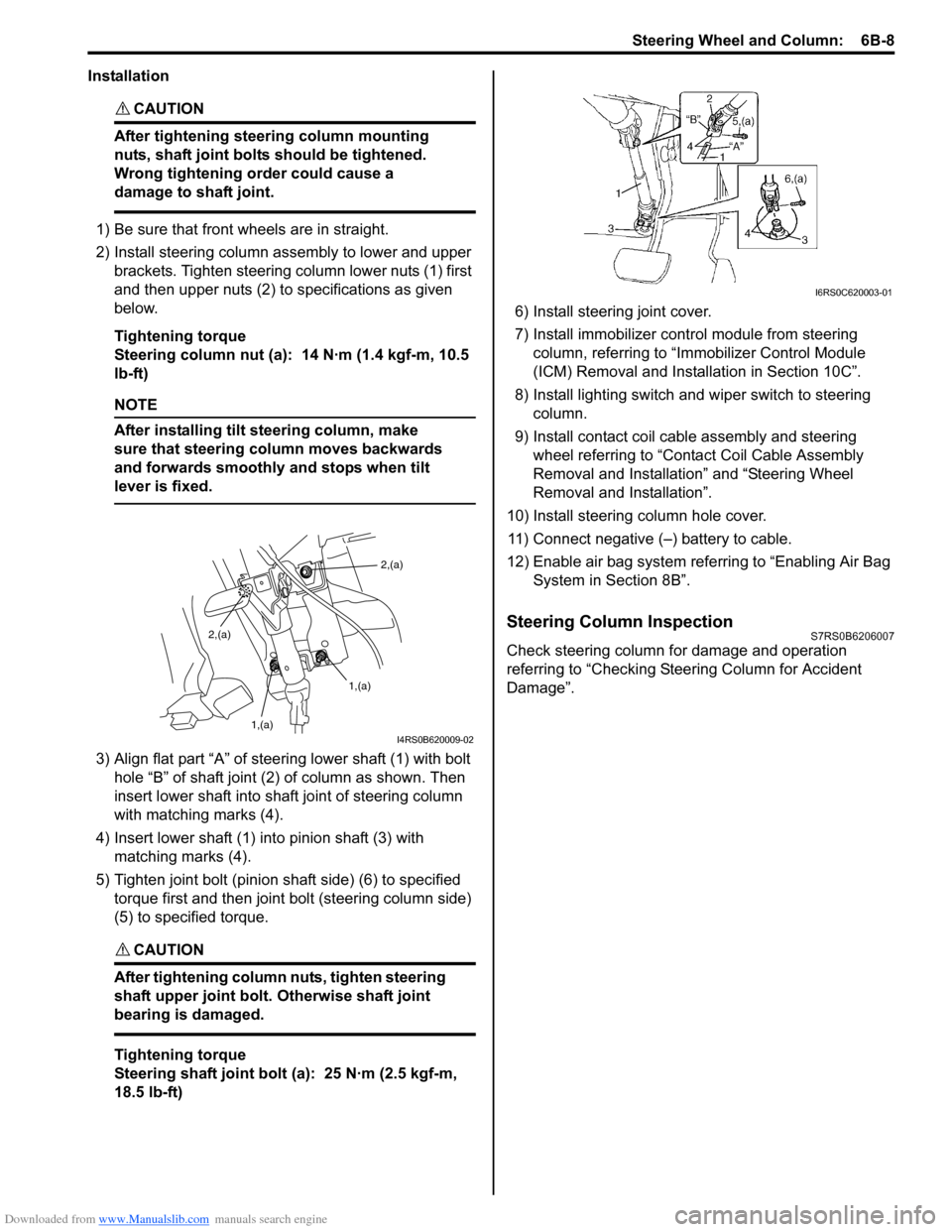

1) Be sure that front wheels are in straight.

2) Install steering column assembly to lower and upper brackets. Tighten steering column lower nuts (1) first

and then upper nuts (2) to specifications as given

below.

Tightening torque

Steering column nut (a): 14 N·m (1.4 kgf-m, 10.5

lb-ft)

NOTE

After installing tilt steering column, make

sure that steering column moves backwards

and forwards smoothly and stops when tilt

lever is fixed.

3) Align flat part “A” of stee ring lower shaft (1) with bolt

hole “B” of shaft joint (2) of column as shown. Then

insert lower shaft into shaf t joint of steering column

with matching marks (4).

4) Insert lower shaft (1) into pinion shaft (3) with matching marks (4).

5) Tighten joint bolt (pinion shaft side) (6) to specified torque first and then joint bolt (steering column side)

(5) to specified torque.

CAUTION!

After tightening column nuts, tighten steering

shaft upper joint bolt. Otherwise shaft joint

bearing is damaged.

Tightening torque

Steering shaft joint bolt (a): 25 N·m (2.5 kgf-m,

18.5 lb-ft) 6) Install steering joint cover.

7) Install immobilizer cont

rol module from steering

column, referring to “Immo bilizer Control Module

(ICM) Removal and Installation in Section 10C”.

8) Install lighting switch and wiper switch to steering column.

9) Install contact coil cable assembly and steering wheel referring to “Conta ct Coil Cable Assembly

Removal and Installation” and “Steering Wheel

Removal and Installation”.

10) Install steering column hole cover. 11) Connect negative (–) battery to cable.

12) Enable air bag system refe rring to “Enabling Air Bag

System in Section 8B”.

Steering Column InspectionS7RS0B6206007

Check steering column for damage and operation

referring to “Checking Steering Column for Accident

Damage”.

2,(a)

1,(a)

1,(a)

2,(a)

I4RS0B620009-02

I6RS0C620003-01

Page 938 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-2 Heater and Ventilation:

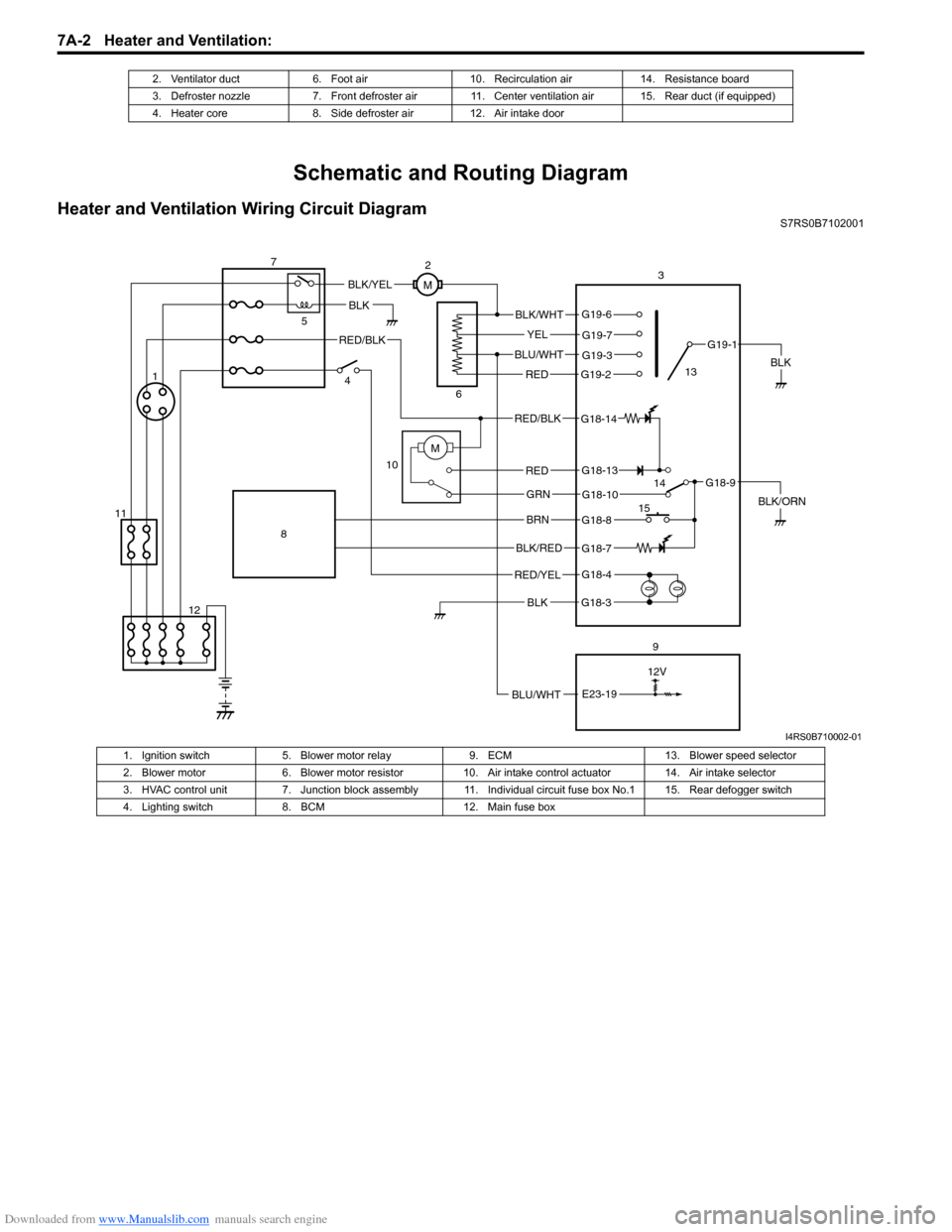

Schematic and Routing Diagram

Heater and Ventilation Wiring Circuit DiagramS7RS0B7102001

2. Ventilator duct 6. Foot air 10. Recirculation air 14. Resistance board

3. Defroster nozzle 7. Front defroster air 11. Center ventilation air 15. Rear duct (if equipped)

4. Heater core 8. Side defroster air 12. Air intake door

BLK

RED/BLK

3

5

7

BLK

2

M

12V

BLU/WHTE23-19

G18-3

G18-4

G18-7

G18-8

G18-10

G18-13

G19-2

G19-3

G19-7

G19-6

G19-1

G18-9

G18-14

BLK/WHT

YEL

BLU/WHT

RED

RED/BLK

RED

GRN

BRN

BLK/RED

RED/YEL

BLK

BLK/YEL

BLK/ORN

4

6

10

8

9

M1

12

11 13

14

15

I4RS0B710002-01

1. Ignition switch 5. Blower motor relay 9. ECM 13. Blower speed selector

2. Blower motor 6. Blower motor resistor 10. Air intake control actuator 14. Air intake selector

3. HVAC control unit 7. Junction block assembly 11. Ind ividual circuit fuse box No.1 15. Rear defogger switch

4. Lighting switch 8. BCM 12. Main fuse box

Page 954 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-6 Air Conditioning System: Manual Type

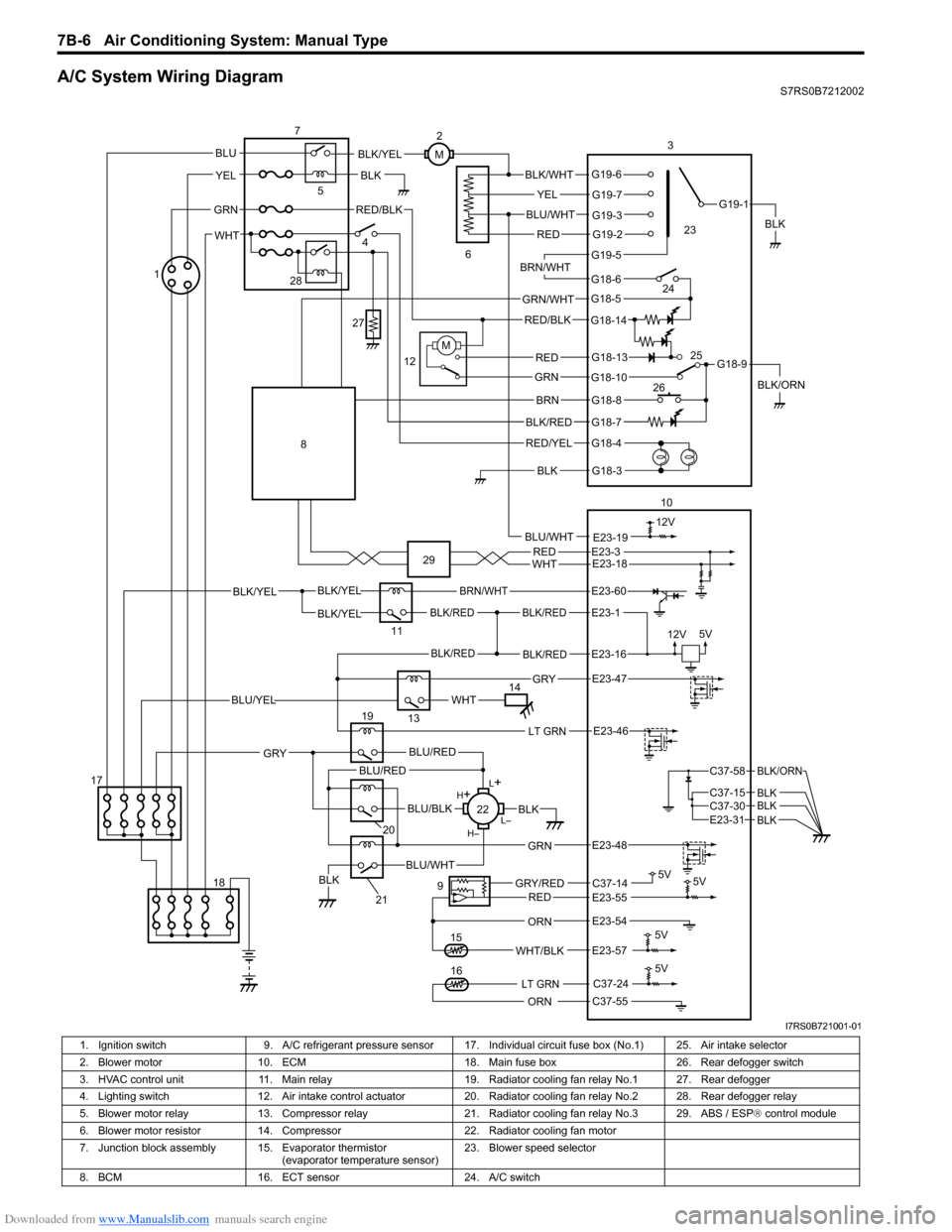

A/C System Wiring DiagramS7RS0B7212002

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

12V5V

5V 5V

5V11

E23-1

E23-60

BLK/REDBLK/REDE23-16

E23-57WHT/BLK

9

13

E23-55C37-14GRY/REDRED

BLK

ORN

E23-47 GRY

WHTBLU/YEL

RED/BLK

14 3

1

15

5

7

BLK

2

M

12VBLU/WHTE23-19

C37-24

C37-55ORN

5V

LT GRN16

G18-3

G18-4

G18-7

G18-8

G18-10

G18-13

G18-5

G18-6

G19-5

G19-2

G19-3

G19-7

G19-6

G19-1

G18-9

G18-14

BLK/WHT

YEL

BLU/WHT

RED

BRN/WHT

GRN/WHT

RED/BLK

RED

GRN

BRN

BLK/RED

RED/YEL

BLK

BLK/YEL

BLK/ORN

4

6

12

10

M

E23-54

REDWHTE23-3E23-18

17 18

LT GRNE23-46

L+

L–

H–

H

+

BLU/RED

BLK

BLU/WHTBLK

BLU/BLK

20

GRN

GRY

E23-48

19

21

22

BLU/REDC37-58

C37-15 C37-30

BLK/ORN

BLKBLKE23-31 BLK

BLU

YEL

GRN

WHT

23

24

26 25

28

27

8

29

I7RS0B721001-01

1. Ignition switch

9. A/C refrigerant pressure sensor 17. I ndividual circuit fuse box (No.1) 25. Air intake selector

2. Blower motor 10. ECM 18. Main fuse box 26. Rear defogger switch

3. HVAC control unit 11. Main relay 19. Radiator cooling fan relay No.1 27. Rear defogger

4. Lighting switch 12. Air intake control actuator 20. Radiator cooling fan relay No.2 28. Rear defogger relay

5. Blower motor relay 13. Compressor relay 21. Radiator cooling fan relay No.3 29. ABS / ESP ® control module

6. Blower motor resistor 14. Compressor 22. Radiator cooling fan motor

7. Junction block assembly 15. Evaporator thermistor (evaporator temperature sensor)23. Blower speed selector

8. BCM 16. ECT sensor 24. A/C switch

Page 987 of 1496

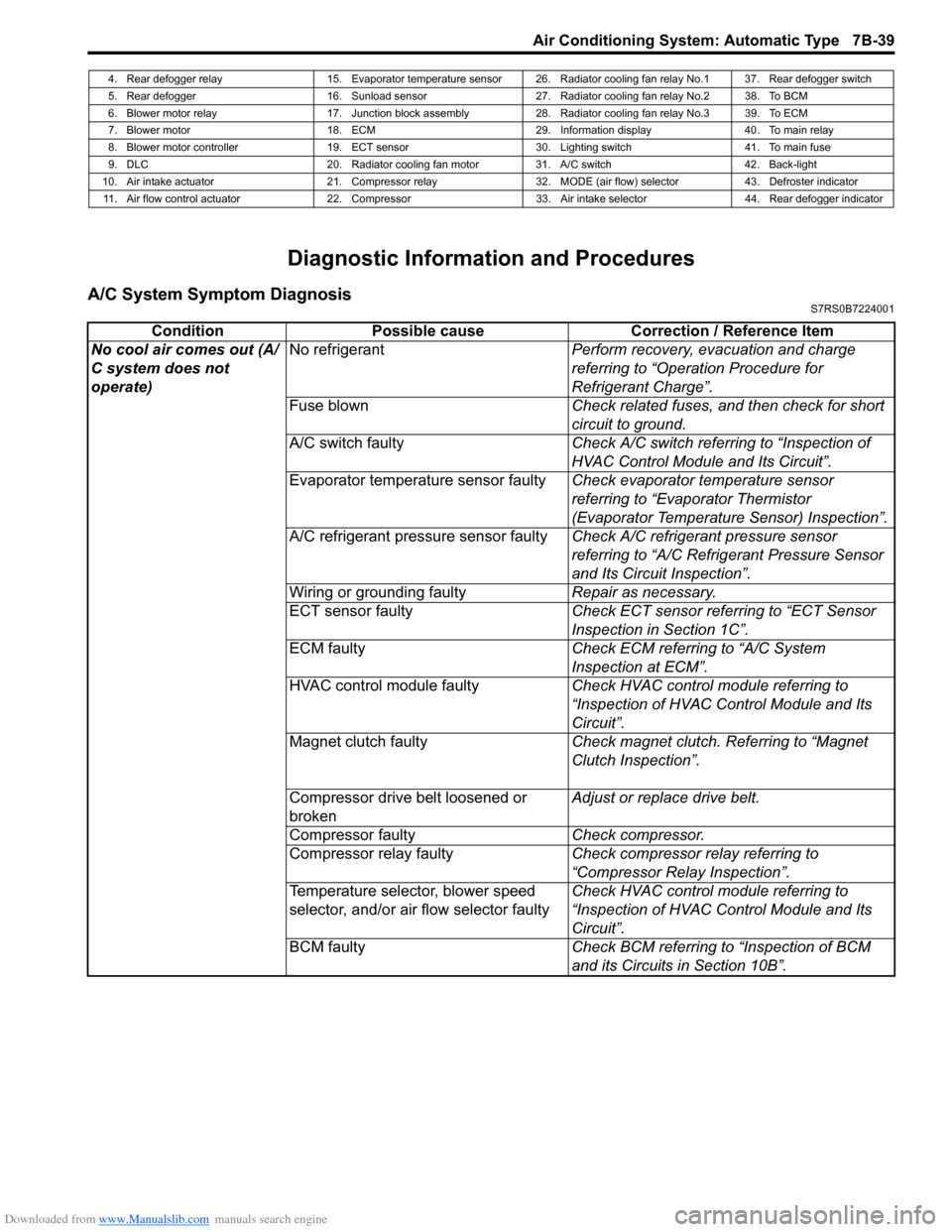

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-39

Diagnostic Information and Procedures

A/C System Symptom DiagnosisS7RS0B7224001

4. Rear defogger relay 15. Evaporator temperature sensor 26. Radiator cooling fan relay No.1 37. Rear defogger switch

5. Rear defogger 16. Sunload sensor 27. Radiator cooling fan relay No.2 38. To BCM

6. Blower motor relay 17. Junction block assembly 28. Radiator cooling fan relay No.3 39. To ECM

7. Blower motor 18. ECM 29. Information display 40. To main relay

8. Blower motor controller 19. ECT sensor 30. Lighting switch 41. To main fuse

9. DLC 20. Radiator cooling fan motor 31. A/C switch 42. Back-light

10. Air intake actuator 21. Compressor relay 32. MODE (air flow) selector 43. Defroster indicator 11. Air flow control actuator 22. Compressor 33. Air intake selector 44. Rear defogger indicator

Condition Possible cause Correction / Reference Item

No cool air comes out (A/

C system does not

operate) No refrigerant

Perform recovery, evacuation and charge

referring to “Operation Procedure for

Refrigerant Charge”.

Fuse blown Check related fuses, and then check for short

circuit to ground.

A/C switch faulty Check A/C switch referring to “Inspection of

HVAC Control Module and Its Circuit”.

Evaporator temperature sensor faulty Check evaporator temperature sensor

referring to “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

A/C refrigerant pressure sensor faulty Check A/C refrigerant pressure sensor

referring to “A/C Refrigerant Pressure Sensor

and Its Circuit Inspection”.

Wiring or grounding faulty Repair as necessary.

ECT sensor faulty Check ECT sensor referring to “ECT Sensor

Inspection in Section 1C”.

ECM faulty Check ECM referring to “A/C System

Inspection at ECM”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Compressor relay faulty Check compressor relay referring to

“Compressor Relay Inspection”.

Temperature selector, blower speed

selector, and/or air flow selector faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

BCM faulty Check BCM referring to “Inspection of BCM

and its Circuits in Section 10B”.

Page 1016 of 1496

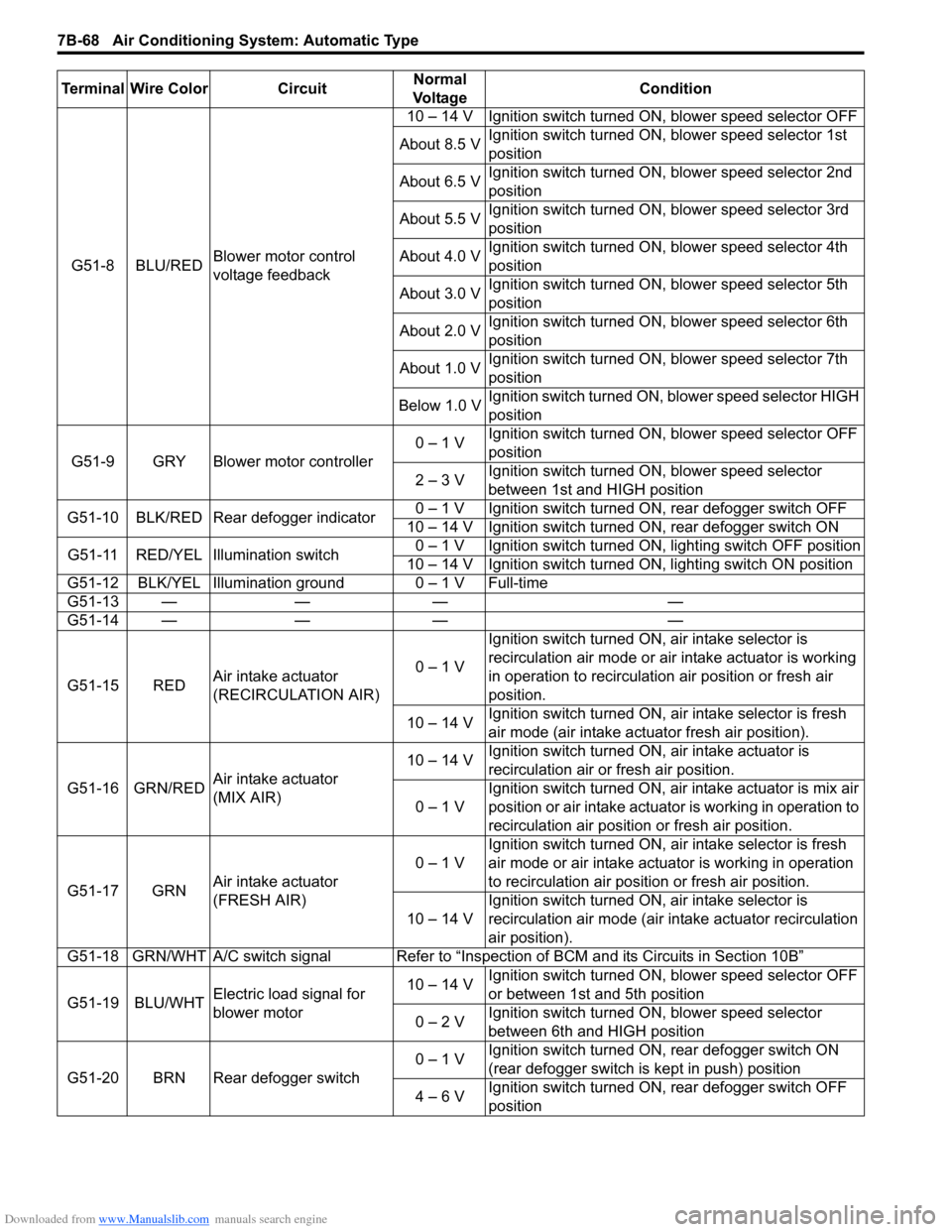

Downloaded from www.Manualslib.com manuals search engine 7B-68 Air Conditioning System: Automatic Type

G51-8 BLU/REDBlower motor control

voltage feedback 10 – 14 V Ignition switch turned ON, blower speed selector OFF

About 8.5 V Ignition switch turned ON, blower speed selector 1st

position

About 6.5 V Ignition switch turned ON, blower speed selector 2nd

position

About 5.5 V Ignition switch turned ON, blower speed selector 3rd

position

About 4.0 V Ignition switch turned ON, blower speed selector 4th

position

About 3.0 V Ignition switch turned ON, blower speed selector 5th

position

About 2.0 V Ignition switch turned ON, blower speed selector 6th

position

About 1.0 V Ignition switch turned ON, blower speed selector 7th

position

Below 1.0 V Ignition switch turned ON, blower speed selector HIGH

position

G51-9 GRY Blower motor controller 0 – 1 V

Ignition switch turned ON, blower speed selector OFF

position

2 – 3 V Ignition switch turned ON, blower speed selector

between 1st and HIGH position

G51-10 BLK/RED Rear defogger indicator 0 – 1 V Ignition switch turned ON, rear defogger switch OFF

10 – 14 V Ignition switch turned ON, rear defogger switch ON

G51-11 RED/YEL Illumination switch 0 – 1 V Ignition switch turned ON, lighting switch OFF position

10 – 14 V Ignition switch turned ON, lighting switch ON position

G51-12 BLK/YEL Illumination ground 0 – 1 V Full-time

G51-13 — — — —

G51-14 — — — —

G51-15 RED Air intake actuator

(RECIRCULATION AIR) 0 – 1 VIgnition switch turned ON, air intake selector is

recirculation air mode or air intake actuator is working

in operation to recirculation air position or fresh air

position.

10 – 14 V Ignition switch turned ON, ai

r intake selector is fresh

air mode (air intake actuator fresh air position).

G51-16 GRN/RED Air intake actuator

(MIX AIR) 10 – 14 V

Ignition switch turned ON, air intake actuator is

recirculation air or fresh air position.

0 – 1 V Ignition switch turned ON, air intake actuator is mix air

position or air intake actuator is working in operation to

recirculation air position or fresh air position.

G51-17 GRN Air intake actuator

(FRESH AIR) 0 – 1 V

Ignition switch turned ON, ai

r intake selector is fresh

air mode or air intake actuator is working in operation

to recirculation air position or fresh air position.

10 – 14 V Ignition switch turned ON, air intake selector is

recirculation air mode (air intake actuator recirculation

air position).

G51-18 GRN/WHT A/C switch signal Refer to “Inspe ction of BCM and its Circuits in Section 10B”

G51-19 BLU/WHT Electric load signal for

blower motor 10 – 14 V

Ignition switch turned ON, blower speed selector OFF

or between 1st and 5th position

0 – 2 V Ignition switch turned ON, blower speed selector

between 6th and HIGH position

G51-20 BRN Rear defogger switch 0 – 1 V

Ignition switch turned ON, rear defogger switch ON

(rear defogger switch is kept in push) position

4 – 6 V Ignition switch turned ON, rear defogger switch OFF

position

Terminal Wire Color Circuit

Normal

Vo l ta g e Condition