seats SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 4 of 1496

Downloaded from www.Manualslib.com manuals search engine 00

0

1

2

3

4

5

6

7

8

9

10

11

Vo l u m e 1

Precautions............................................................... 00-iPrecautions ............................................................ 00-1

General Information ................ ................................... 0-i

General Information ............................................... 0A-1

Maintenance and Lubricatio n ................................. 0B-1

Engine ......................................................................... 1-i Precautions .............................................................. 1-1

Engine General Information and Diagnosis ........... 1A-1

Aux. Emission Control Devices .............................. 1B-1

Engine Electrical Devices....................................... 1C-1

Engine Mechanical ................................................. 1D-1

Engine Lubrication System .................................... 1E-1

Engine Cooling System .......................................... 1F-1

Fuel System ...........................................................1G-1

Ignition System....................................................... 1H-1

Starting System ....................................................... 1I-1

Charging System.....................................................1J-1

Exhaust System ..................................................... 1K-1

Suspension ................................................................. 2-i Precautions .............................................................. 2-1

Suspension General Diagnosis .............................. 2A-1

Front Suspension ................................................... 2B-1

Rear Suspension................ .................................... 2C-1

Wheels and Tires ................................................... 2D-1

Driveline / Axle ........................................................... 3-i Precautions .............................................................. 3-1

Drive Shaft / Axle ................................................... 3A-1

Brakes ......................................................................... 4-i Precautions .............................................................. 4-1

Brake Control System and Diagnosis .................... 4A-1

Front Brakes........................................................... 4B-1

Rear Brakes ........................................................... 4C-1

Parking Brake......................................................... 4D-1

ABS ........................................................................ 4E-1

Electronic Stability Program ................................... 4F-1

Vo l u m e 2

Precautions ............................................................... 00-iPrecautions ............................................................ 00-1

Transmission / Transaxle .... ...................................... 5-i

Precautions .............................................................. 5-1

Automatic Transmission/Transaxle ........................ 5A-1

Manual Transmission/Transaxle ............................ 5B-1

Clutch .....................................................................5C-1

Steering ....................................................................... 6-i Precautions .............................................................. 6-1

Steering General Diagnosis ................................... 6A-1

Steering Wheel and Column .................................. 6B-1

Power Assisted Steering System ...........................6C-1

HVAC ........................................................................... 7-i Precautions .............................................................. 7-1

Heater and Ventilation............................................ 7A-1

Air Conditioning System ......................................... 7B-1

Restraint ...................................................................... 8-i Precautions .............................................................. 8-1

Seat Belts ............................................................... 8A-1

Air Bag System ...................................................... 8B-1

Body, Cab and Accessories .... .................................. 9-i

Precautions .............................................................. 9-1

Wiring Systems ...................................................... 9A-1

Lighting Systems .................................................... 9B-1

Instrumentation / Driver Info. / Horn .......................9C-1

Wipers / Washers ...................................................9D-1

Glass / Windows / Mirrors ...................................... 9E-1

Security and Locks ................................................. 9F-1

Seats ..................................................................... 9G-1

Interior Trim ............................................................9H-1

Hood / Fenders / Doors .......................................... 9J-1

Body Structure ....................................................... 9K-1

Paint / Coatings ...................................................... 9L-1

Exterior Trim .......................................................... 9M-1

Control Systems ....................................................... 10-i Precautions ............................................................ 10-1

Body Electrical Control Sy stem ............................ 10B-1

Immobilizer Control System .................................10C-1

Keyless Start System ........................................... 10E-1

TABLE OF CONTENTS

Page 9 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-4

General PrecautionsS7RS0B0000002

The WARNING and CAUTION describe some general

precautions that you should observe when servicing a

vehicle. These general precautions apply to many of the

service procedures, and they will not necessarily be

repeated with each procedure to which they apply.

WARNING!

• Whenever raising a vehicle for service, be sure to follow the instructions under

“Vehicle Lifting Points in Section 0A”.

• When it is necessary to do service work with the engine running, make sure that

the parking brake is set fully and the

transmission is in Neutral (for manual

transmission vehicles) or Park (for

automatic transmission vehicles), Keep

hands, hair, clothing, tools, etc. away from

the fan and belts when the engine is

running.

• When it is necessary to run the engine indoors, make sure that the exhaust gas is

forced outdoors.

• Do not perform service work in areas where combustible materials can come in

contact with a hot exhaust system. When

working with toxic or flammable materials

(such as gasoline and refrigerant), make

sure that the area you work in is well-

ventilated.

• To avoid getting burned, keep away from hot metal parts such as the radiator,

exhaust manifold, tail pipe, muffler, etc.

• New and used engine oil can be hazardous. Children and pets may be

harmed by swallowing new or used oil.

Keep new and used oil and used engine oil

filters away from children and pets.

Continuous contact with used engine oil

has been found to cause [skin] cancer in

laboratory animals. Brief contact with used

oil may irritate skin. To minimize your

exposure to used engine oil, wear a long-

sleeve shirt and moisture-proof gloves

(such as dish washing gloves) when

changing engine oil. If engine oil contacts

your skin, wash thoroughly with soap and

water. Launder any clothing or rags if wet

with oil, recycle or properly dispose of

used oil and filters. • Be sure to observe following instructions

when handling service materials such as

fuel, oil, fluid, coolant, grease, sealant,

thread lock cement, etc. Otherwise, your

health may be ruined.

– Whenever handling any of these service materials, wear safety glasses to protect

your eyes. If it gets into your eye, it may

cause inflammation.

– Whenever handling any of these service materials, wear moistu re-proof gloves to

protect your skin. If it adheres to your

skin, it may cause inflammation.

– Do not swallow any of these service materials. It would cause diarrhea or

nausea.

– Keep all these materials out of children’s reach.

• Make sure the bonnet is fully closed and latched before driving. If it is not, it can fly

up unexpectedly during driving,

obstructing your view and resulting in an

accident.

• Before starting any service work, cover fenders, seats and any other parts that are likely to get scratched or

stained during servicing. Also, be aware that what you

wear (e.g., buttons) ma y cause damage to the

vehicle’s finish.

I2RH01010025-01

Page 42 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-12 Maintenance and Lubrication:

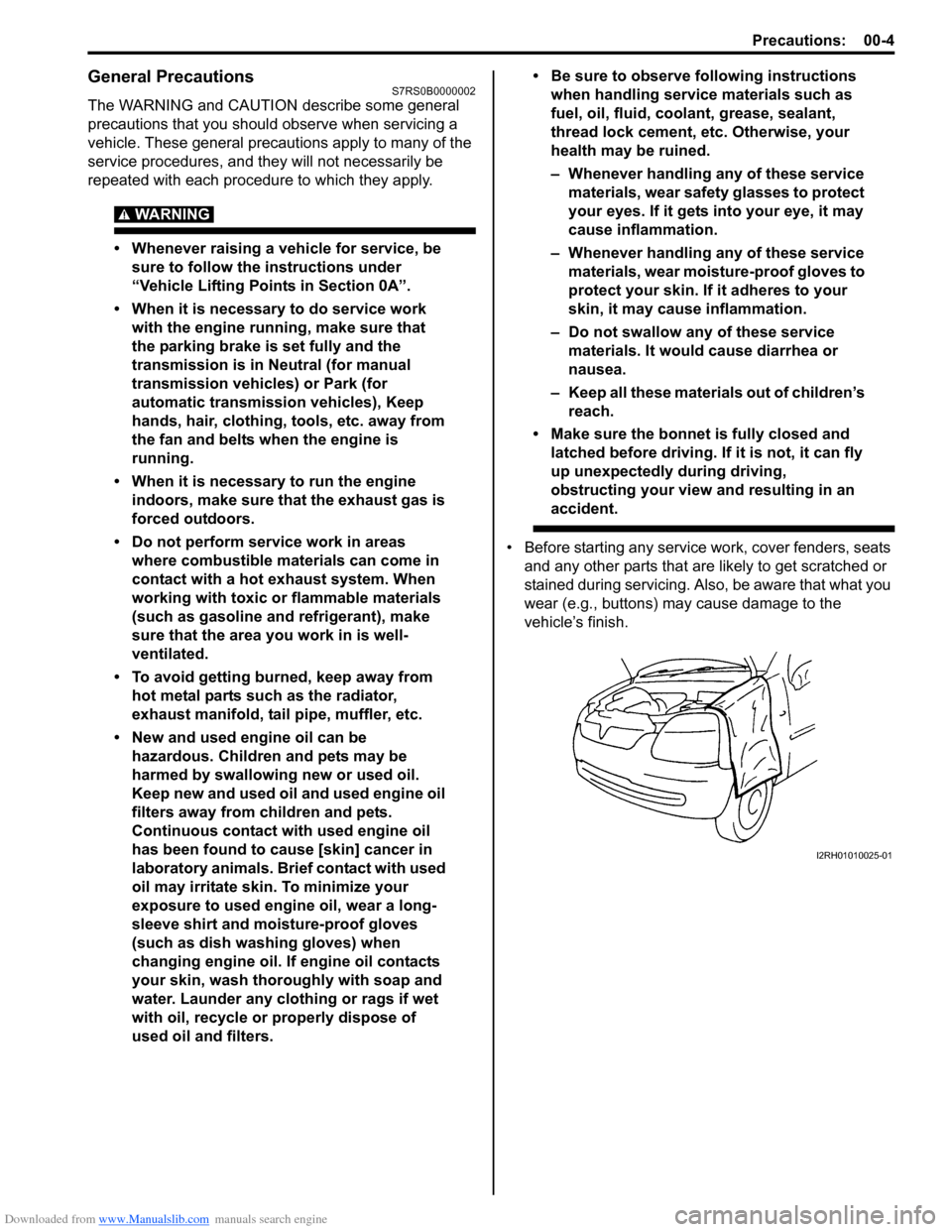

HVAC Air Filter (If Equipped) InspectionS7RS0B0206032

1) Remove HVAC air filter from HVAC unit referring to

“HVAC Air Filter Removal and Installation (If

Equipped) in Section 7A”.

2) Check for dirt and dust. If HVAC air filter is excessively dirty, replace HVAC air filter with new

one. If not, go to next step.

3) Blow compressed air on the air outlet side of HVAC air filter for removing dust.

4) Install HVAC air filter in to HVAC unit referring to

“HVAC Air Filter Removal and Installation (If

Equipped) in Section 7A”.

HVAC Air Filter (If Equipped) ReplacementS7RS0B0206033

Replace HVAC air filter with new one referring to “HVAC

Air Filter Removal and Installation (If Equipped) in

Section 7A”.

Final Inspection for Maintenance ServiceS7RS0B0206034

WARNING!

When carrying out road tests, select a safe

place where no man or no running vehicle is

seen so as to prevent any accident.

Seats

Check that seat slides smoot hly and locks securely at

any position. Also check that reclining mechanism of

front seat back allows it to be locked at any angle.

Seat Belt

Inspect belt system including webbing, buckles, latch

plates, retractors and anchors for damage or wear.

Check that seat belt is securely locked. If “REPLACE

BELT” label on seat belt is visible, replace belt.

Battery Electrolyte Level Check

Check that the electrolyte le vel of all battery cells is

between the upper and lower level lines on the case. If

battery is equipped with built-in indicator, check battery

condition by the indicator. Accelerator Pedal Operation

Check that pedal operates

smoothly without getting

caught or interfered by any other part.

Engine Start

Check engine start for readiness.

WARNING!

Before performing th e following check, be

sure to have enough room around the

vehicle. Then, firmly apply both the parking

brake and the regular brakes. Do not use the

accelerator pedal. If the engine starts, be

ready to turn off the ignition promptly. Take

these precautions because the vehicle could

move without warning and possibly cause

personal injury or property damage.

On automatic transaxle vehicles, try to start the engine in

each select lever position. The starting motor should

crank only in “P” (Park) or “N” (Neutral).

On manual transaxle vehicles, place the shift lever in

“Neutral,” depress clutch pedal fully and try to start.

On Automated Manual Transaxl e vehicles, try to start

the engine in each select le ver position. The starting

motor should crank only when select lever is in “N”

(Neutral) and brake pedal is depressed.

Exhaust System Check

Check for leakage, cracks or loose supports.

Clutch (for Manual Transaxle)

Check for the following.

• Clutch is completely released when depressing clutch pedal,

• No slipping clutch occurs when releasing pedal and accelerating.

• Clutch itself is free fr om any abnormal condition.

Gearshift or Select Lever (Transaxle)

Check gear shift or select lever for smooth shifting to all

positions and for good performance of transaxle in any

position.

With automatic transaxle or Automated Manual

Transaxle equipped vehicle, also check that shift

indicator indicates properly according to which position

select lever is shifted to.

With automatic transaxle equipped vehicle, make sure

that vehicle is at complete stop when shifting select lever

to “P” range position and release all brakes.

I4RS0A020018-01

Page 327 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-42

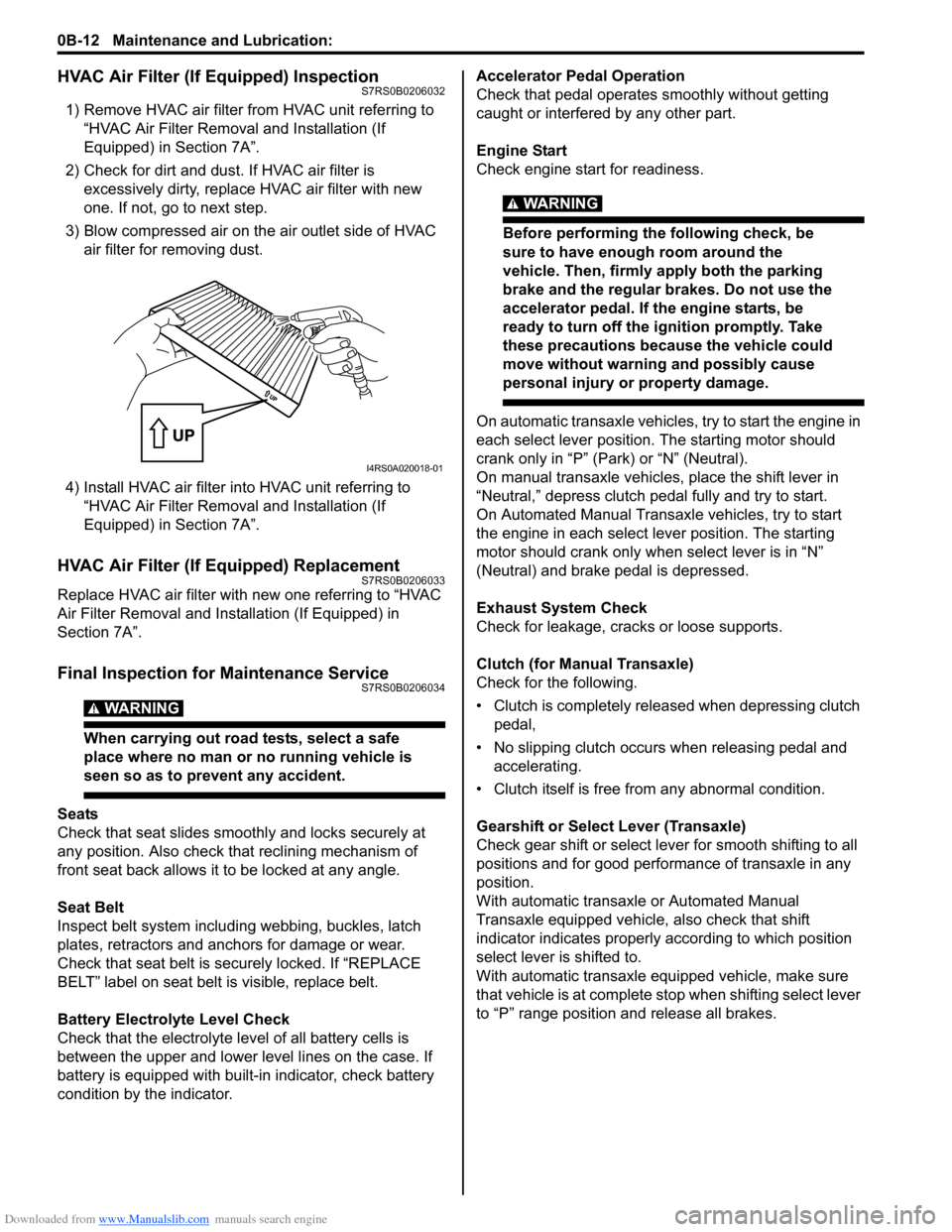

Cylinder Head InspectionS7RS0B1406027

• Remove all carbon deposits from combustion chambers.

NOTE

Do not use any sharp-edged tool to scrape

off carbon deposits. Be careful not to scuff or

nick metal surfaces when decarbonizing. The

same applies to valves and valve seats, too.

• Check cylinder head for cracks on intake and exhaust ports, combustion chambers, and head surface. Using

a straightedge and thickness gauge, check flatness of

gasketed surface at a total of 6 locations. If distortion

limit is exceeded, correct gasketed surface with a

surface plate and abrasive paper of about #400

(Waterproof silicon carbide abrasive paper): place

abrasive paper on and over surface plate, and rub

gasketed surface against paper to grind off high spots.

Should this fail to reduce thickness gauge readings to

within limit, replace cylinder head.

Leakage of combustion gases from this gasketed joint

is often due to warped gasketed surface: such

leakage results in reduced power output.

Distortion for cylinder head surface on piston side

Limit: 0.03 mm (0.001 in.) • Distortion of manifold seating faces:

Check seating faces of cylinder head for manifolds,

using a straightedge and thickness gauge, in order to

determine whether these faces should be corrected or

cylinder head replaced.

Distortion for cylinder head surface on intake and

exhaust manifold

Limit: 0.05 mm (0.002 in.)

I2RH0B140105-01

I2RH0B140106-01

I2RH0B140107-01

Page 462 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-8 Rear Suspension:

3) Install coil springs (right & left) on spring seats of rear

axle referring to “Spring Upper Seat and Lower Seat

Removal and Installation” and “Rear Coil Spring

Removal and Installation”.

4) Install shock absorbers lower side (right & left) and washers referring to “Rear Shock Absorber Removal

and Installation”.

5) Install brake dust covers, spindles and wheel speed sensors (right and left) referring to “Spindle Removal

and Installation”.

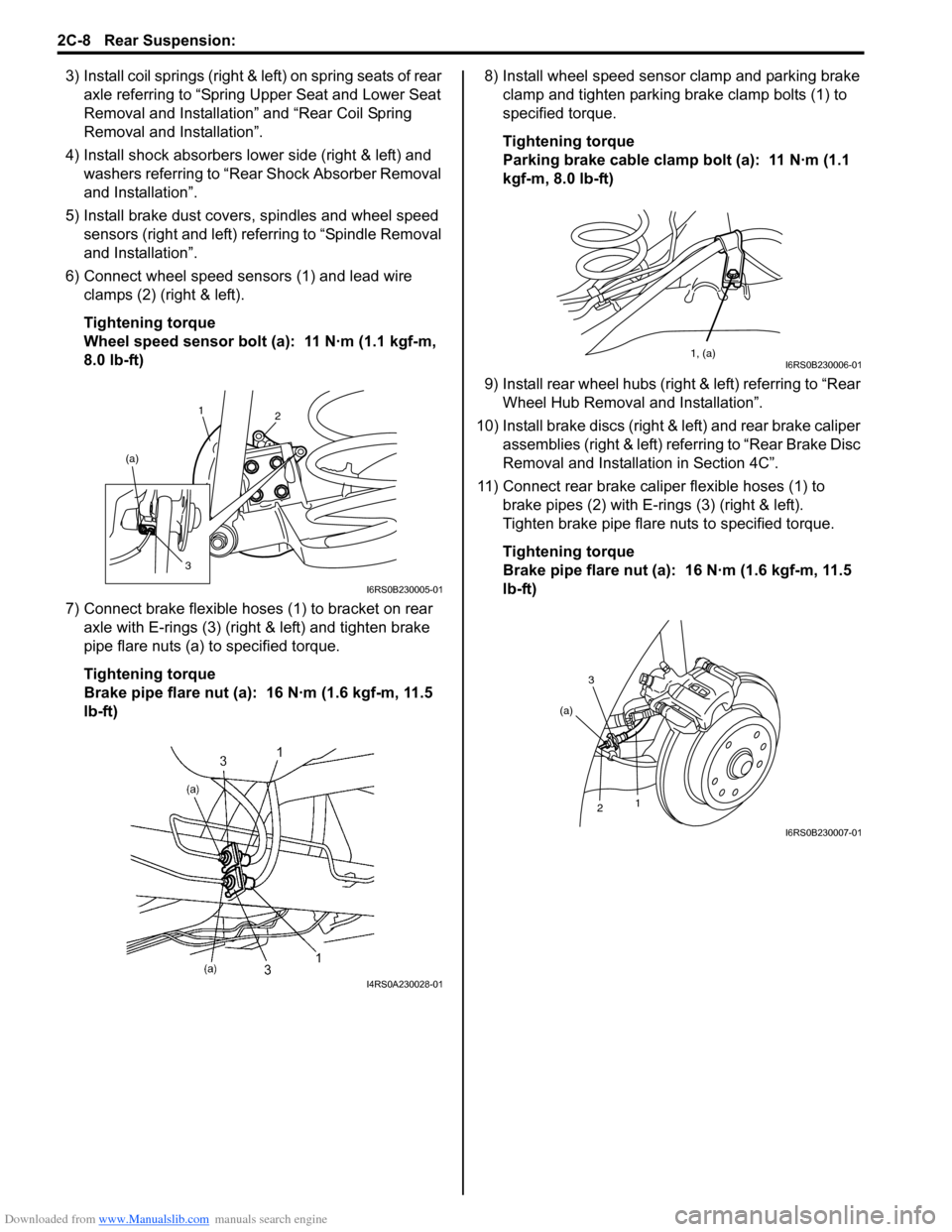

6) Connect wheel speed sensors (1) and lead wire clamps (2) (right & left).

Tightening torque

Wheel speed sensor bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

7) Connect brake flexible hoses (1) to bracket on rear axle with E-rings (3) (right & left) and tighten brake

pipe flare nuts (a) to specified torque.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 11.5

lb-ft) 8) Install wheel speed sensor clamp and parking brake

clamp and tighten parking brake clamp bolts (1) to

specified torque.

Tightening torque

Parking brake cable clamp bolt (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

9) Install rear wheel hubs (right & left) referring to “Rear Wheel Hub Removal and Installation”.

10) Install brake discs (right & left) and rear brake caliper assemblies (right & left) referring to “Rear Brake Disc

Removal and Installati on in Section 4C”.

11) Connect rear brake caliper flexible hoses (1) to brake pipes (2) with E-rings (3) (right & left).

Tighten brake pipe flare nuts to specified torque.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 11.5

lb-ft)

1 2

(a)

3

I6RS0B230005-01

I4RS0A230028-01

1, (a)I6RS0B230006-01

3

2 1

(a)

I6RS0B230007-01

Page 475 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-8

Tire Mounting and DismountingS7RS0B2406004

CAUTION!

When installing tire which has arrow

indicating tire rotation direction to wheel,

make sure that this tire rotation direction is

same as actual tire rotation direction when

vehicle is moving forward. Otherwise, it is

not possible to install wheel with tire to

vehicle in specified direction.

Use a tire changing machine to mount or dismount tires.

Follow equipment manufacturer’s instructions. Do not

use hand tools or tire irons al one to change tires as they

may damage tire beads or wheel rim.

Rim bead seats should be cleaned with a wire brush or

coarse steel wool to remove lubricants, old rubber and

light rust. Before mounting or dismounting a tire, bead

area should be well lubricated with approved tire

lubricant.

After mounting, inflate to specified pressure shown on

tire placard so that beads are completely seated.

WARNING!

Do not stand over tire when inflating. Bead

may break when bead snaps over rim’s safety

hump and cause serious personal injury.

Do not exceed 330 kpa (47.9 psi) pressure

when inflating. If 330 kpa (47.9 psi) pressure

will not seat beads, deflate, re-lubricate and

reinflate.

Over inflation may cause bead to break and

cause serious personal injury.

Install valve core and inflate to proper pressure.

Tire RepairS7RS0B2406005

There are many different materials and techniques on

the market to repair tires. As not all of these work on all

types of tires, tire manufacturers have published detailed

instructions on how and when to repair tires. These

instructions can be obtained from each tire

manufacturer.

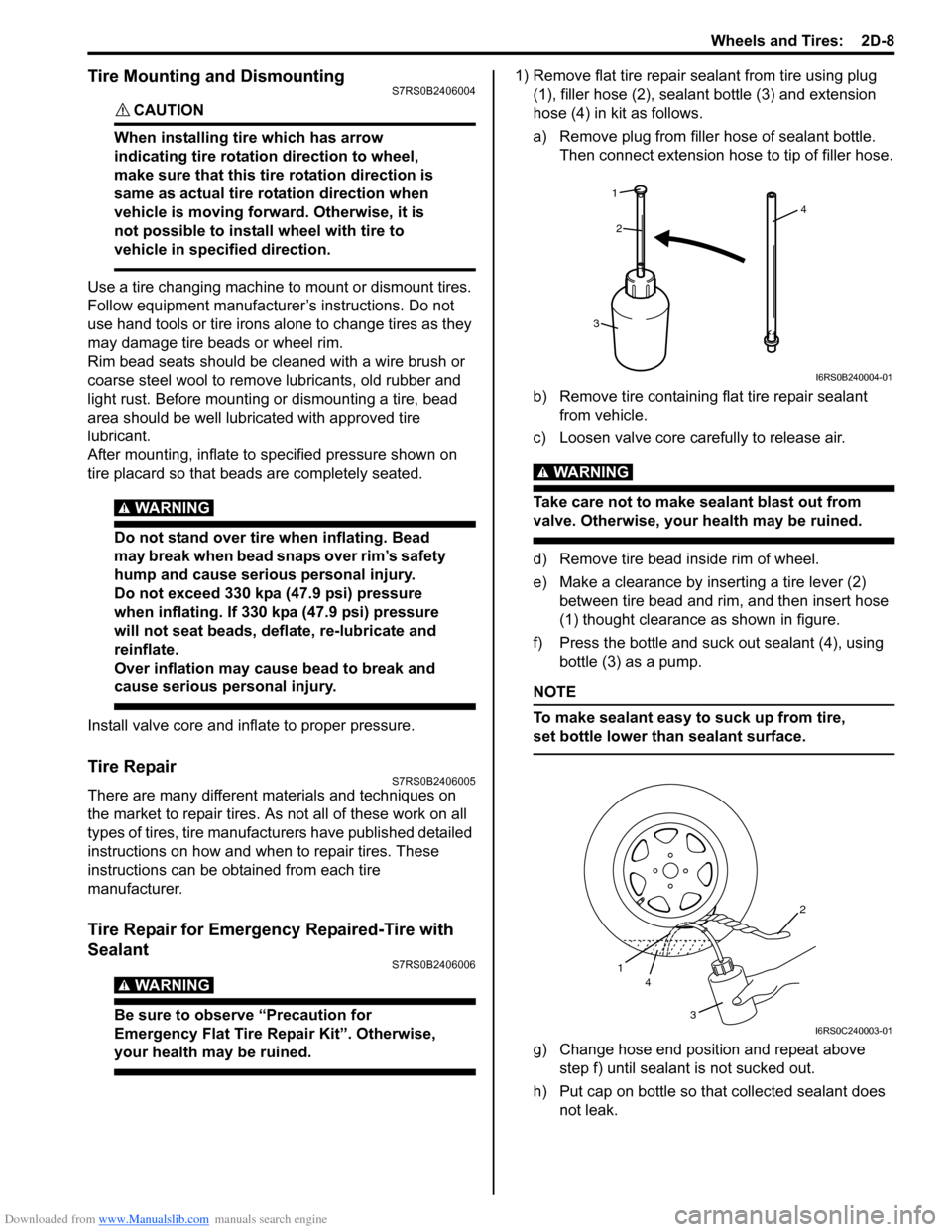

Tire Repair for Emergency Repaired-Tire with

Sealant

S7RS0B2406006

WARNING!

Be sure to observe “Precaution for

Emergency Flat Tire Repair Kit”. Otherwise,

your health may be ruined.

1) Remove flat tire repair sealant from tire using plug (1), filler hose (2), sealant bottle (3) and extension

hose (4) in kit as follows.

a) Remove plug from fille r hose of sealant bottle.

Then connect ext ension hose to tip of filler hose.

b) Remove tire containing flat tire repair sealant from vehicle.

c) Loosen valve core carefully to release air.

WARNING!

Take care not to make sealant blast out from

valve. Otherwise, your health may be ruined.

d) Remove tire bead inside rim of wheel.

e) Make a clearance by inserting a tire lever (2) between tire bead and rim, and then insert hose

(1) thought clearance as shown in figure.

f) Press the bottle and suck out sealant (4), using bottle (3) as a pump.

NOTE

To make sealant easy to suck up from tire,

set bottle lower than sealant surface.

g) Change hose end position and repeat above step f) until sealant is not sucked out.

h) Put cap on bottle so that collected sealant does not leak.

4

1

2

3

I6RS0B240004-01

1 4

3 2

I6RS0C240003-01

Page 1038 of 1496

Downloaded from www.Manualslib.com manuals search engine 8A-7 Seat Belts:

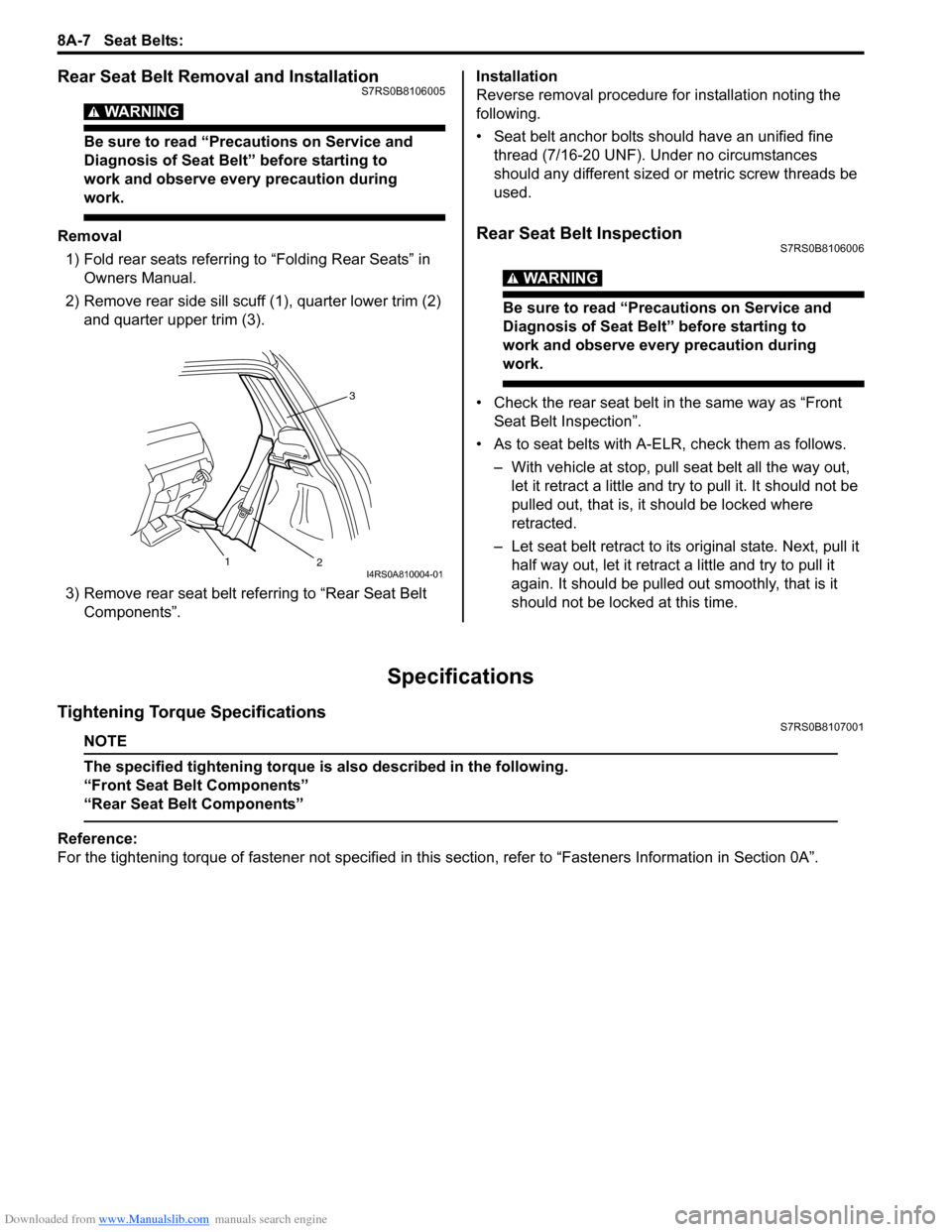

Rear Seat Belt Removal and InstallationS7RS0B8106005

WARNING!

Be sure to read “Precautions on Service and

Diagnosis of Seat Belt” before starting to

work and observe every precaution during

work.

Removal1) Fold rear seats referring to “Folding Rear Seats” in Owners Manual.

2) Remove rear side sill scuff (1), quarter lower trim (2)

and quarter upper trim (3).

3) Remove rear seat belt referring to “Rear Seat Belt Components”. Installation

Reverse removal procedure for installation noting the

following.

• Seat belt anchor bolts should have an unified fine

thread (7/16-20 UNF). Under no circumstances

should any different sized or metric screw threads be

used.Rear Seat Belt InspectionS7RS0B8106006

WARNING!

Be sure to read “Precautions on Service and

Diagnosis of Seat Belt” before starting to

work and observe every precaution during

work.

• Check the rear seat belt in the same way as “Front Seat Belt Inspection”.

• As to seat belts with A-ELR, check them as follows. – With vehicle at stop, pull seat belt all the way out, let it retract a little and try to pull it. It should not be

pulled out, that is, it should be locked where

retracted.

– Let seat belt retract to its original state. Next, pull it

half way out, let it retrac t a little and try to pull it

again. It should be pulled out smoothly, that is it

should not be locked at this time.

Specifications

Tightening Torque SpecificationsS7RS0B8107001

NOTE

The specified tightening torque is also described in the following.

“Front Seat Belt Components”

“Rear Seat Belt Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

3

2

1

I4RS0A810004-01

Page 1159 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-121

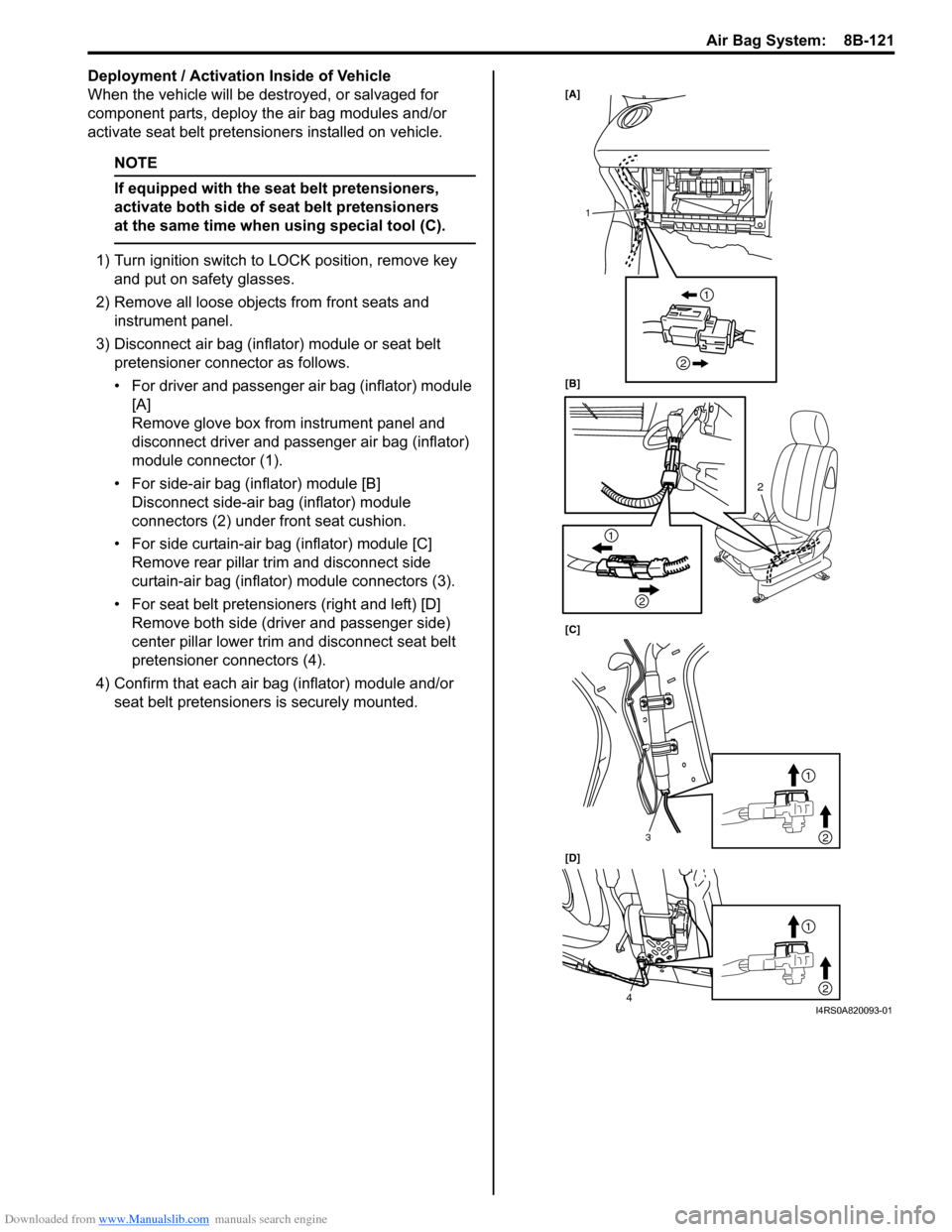

Deployment / Activation Inside of Vehicle

When the vehicle will be destroyed, or salvaged for

component parts, deploy the air bag modules and/or

activate seat belt pretensioners installed on vehicle.

NOTE

If equipped with the seat belt pretensioners,

activate both side of seat belt pretensioners

at the same time when using special tool (C).

1) Turn ignition switch to LOCK position, remove key

and put on safety glasses.

2) Remove all loose objects from front seats and instrument panel.

3) Disconnect air bag (inflator) module or seat belt pretensioner connector as follows.

• For driver and passenger air bag (inflator) module [A]

Remove glove box from instrument panel and

disconnect driver and passenger air bag (inflator)

module connector (1).

• For side-air bag (inflator) module [B] Disconnect side-air bag (inflator) module

connectors (2) under front seat cushion.

• For side curtain-air bag (inflator) module [C] Remove rear pillar trim and disconnect side

curtain-air bag (inflator) module connectors (3).

• For seat belt pretensioners (right and left) [D] Remove both side (driver and passenger side)

center pillar lower trim an d disconnect seat belt

pretensioner connectors (4).

4) Confirm that each air bag (inflator) module and/or seat belt pretensioners is securely mounted.

[A]

[B]

[C]

[D]

2

1

3

4

1

2

1

2

1

2

1

2

I4RS0A820093-01

Page 1170 of 1496

Downloaded from www.Manualslib.com manuals search engine 9-iv Table of Contents

Rear End Door Opener System Symptom Diagnosis .......................................................... 9F-5

Rear End Door Opener System Operation Inspection .......................................................... 9F-5

Repair Instructions ........... ................................... 9F-6

Front Door Lock Assembly Components ............ 9F-6

Front Door Lock Assembly Removal and Installation ......................................................... 9F-6

Front Door Lock Assembly Inspection ................ 9F-8

Power Door Lock Switch In spection.................... 9F-8

Door Key Cylinder Switch Inspection .................. 9F-8

Power Door Lock Actuator Inspection ................. 9F-9

Rear Door Lock Assembly Components ........... 9F-10

Rear Door Lock Assembly Removal and Installation ....................................................... 9F-10

Rear Door Lock Assembly Inspection ............... 9F-10

Rear End Door Lock Assembly Components.... 9F-11

Rear End Door Lock Assembly Removal and Installation ....................................................... 9F-11

Rear End Door Lock Assembly Inspection........ 9F-12

Rear End Door Opener Switch Inspection ........ 9F-12

Replacement of Transmitte r Battery ................. 9F-13

Programming Transmitter Code for Keyless Entry System (Vehicle without Keyless Start

System) ........................................................... 9F-13

Keyless Entry Answer Back Function

Change-over Procedure (If Equipped) ............ 9F-14

Keyless Entry Receiver Removal and

Installation ....................................................... 9F-14

Keyless Entry Receiver and Its Circuit Inspection ........................................................ 9F-15

Specifications .... ................................................. 9F-16

Tightening Torque Specifications ...................... 9F-16

Special Tools and Equipmen t ........................... 9F-16

Recommended Service Material ....................... 9F-16

Seats ............. ............................................ 9G-1

Repair Instructions ............................................. 9G-1

Front Seat Components ..................................... 9G-1

Front Seat Removal and In stallation .................. 9G-2

Rear Seat Components...................................... 9G-3

Rear Seat Removal and Installation................... 9G-4

Specifications .... .................................................. 9G-4

Tightening Torque Specifications ....................... 9G-4

Special Tools and Equipmen t ............................ 9G-4

Recommended Service Material ........................ 9G-4

Interior Trim ................. ............................ 9H-1

Repair Instructions ............ ..................................9H-1

Floor Carpet Removal and Installation ................9H-1

Head Lining Removal and Installation.................9H-1

Console Box Components ..................................9H-2

Specifications ..................... ..................................9H-3

Tightening Torque Specifications ........................9H-3

Hood / Fenders / Doors ...... ...................... 9J-1

Repair Instructions ............ .................................. 9J-1

Hood Removal and Installation ........................... 9J-1

Hood Inspection and Adjustment ........................ 9J-1

Front Fender Components .................................. 9J-2

Front Fender Removal and Installation ............... 9J-2

Front Door Assembly Comp onents ..................... 9J-3

Front Door Assembly Removal and Installation ......................................................... 9J-3

Rear Door Assembly Components...................... 9J-5

Rear Door Assembly Removal and Installation ......................................................... 9J-5

Rear End Door Assembly Components .............. 9J-6

Rear End Door Assembly Removal and Installation ......................................................... 9J-6

Specifications ..................... .................................. 9J-8

Tightening Torque Specifications ........................ 9J-8

Special Tools and Equipmen t ............................. 9J-8

Recommended Service Material ......................... 9J-8

Body Structure............... .......................... 9K-1

Repair Instructions ............ ..................................9K-1

Front Bumper and Rear Bumper Components .... 9K-1

Cowl Top Components........................................ 9K-2

Specifications ..................... ..................................9K-3

Body Dimensions ................................................ 9K-3

Panel Clearance................................................ 9K-10

Paint / Coatings ............. ...........................9L-1

General Description ............................................. 9L-1

Anti-Corrosion Treatment Construction............... 9L-1

Plastic Parts Finishing ......................................... 9L-2

Component Location ............ ............................... 9L-3

Sealant Application Areas ................................... 9L-3

Under Coating Application Areas ........................ 9L-8

Anti-Corrosion Compound Application Area ..... 9L-10

Exterior Trim ...... ...................................... 9M-1

Repair Instructions ......... .................................... 9M-1

Roof Molding Components................................. 9M-1

Splash Guard (If Equipped) Components .......... 9M-2

Page 1363 of 1496

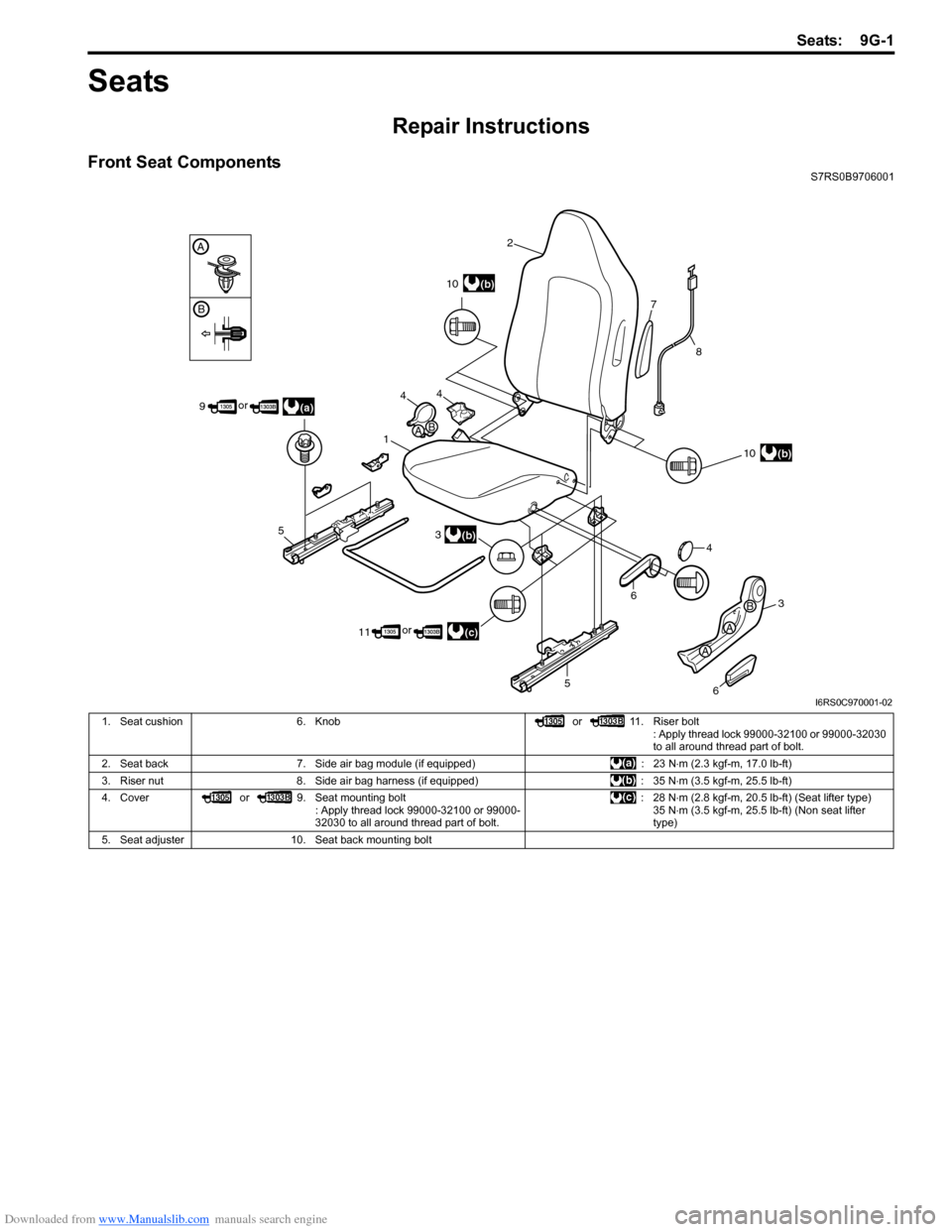

Downloaded from www.Manualslib.com manuals search engine Seats: 9G-1

Body, Cab and Accessories

Seats

Repair Instructions

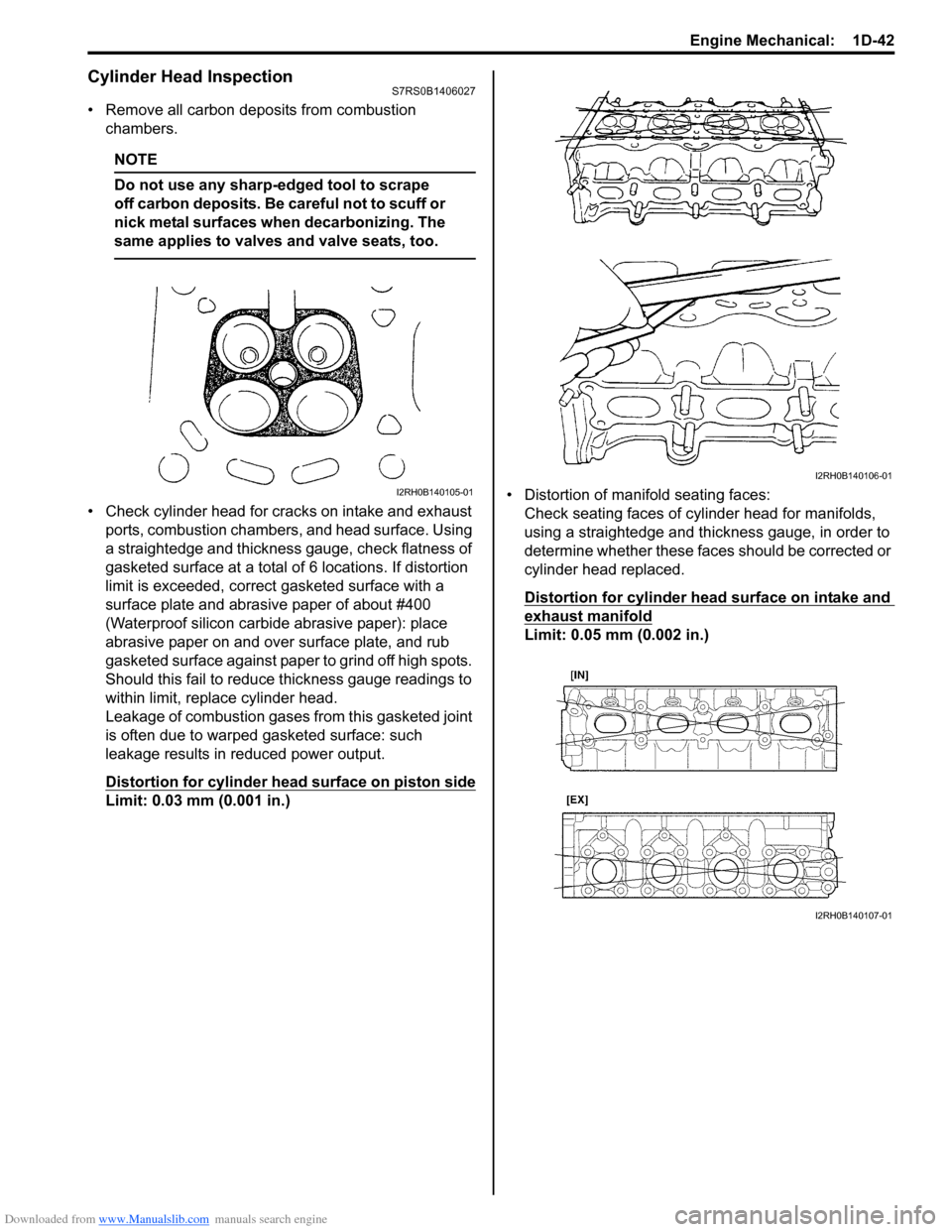

Front Seat ComponentsS7RS0B9706001

2

4

1 3

11

6

3

4

6

7

8

(b)

(b)

10

5

(a)

or

94

5

(c)

(b)

10

or

A

A

B

AB

B

A

I6RS0C970001-02

1. Seat cushion 6. Knob or 11. Riser bolt

: Apply thread lock 99000-32100 or 99000-32030

to all around thread part of bolt.

2. Seat back 7. Side air bag module (if equipped) : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

3. Riser nut 8. Side air bag harness (if equipped) : 35 N⋅m (3.5 kgf-m, 25.5 lb-ft)

4. Cover or 9. Seat mounting bolt

: Apply thread lock 99000-32100 or 99000-

32030 to all around thread part of bolt. :28 N

⋅m (2.8 kgf-m, 20.5 lb-ft) (Seat lifter type)

35 N ⋅m (3.5 kgf-m, 25.5 lb-ft) (Non seat lifter

type)

5. Seat adjuster 10. Seat back mounting bolt