steering wheel adjustment SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 40 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-10 Maintenance and Lubrication:

Steering System InspectionS7RS0B0206024

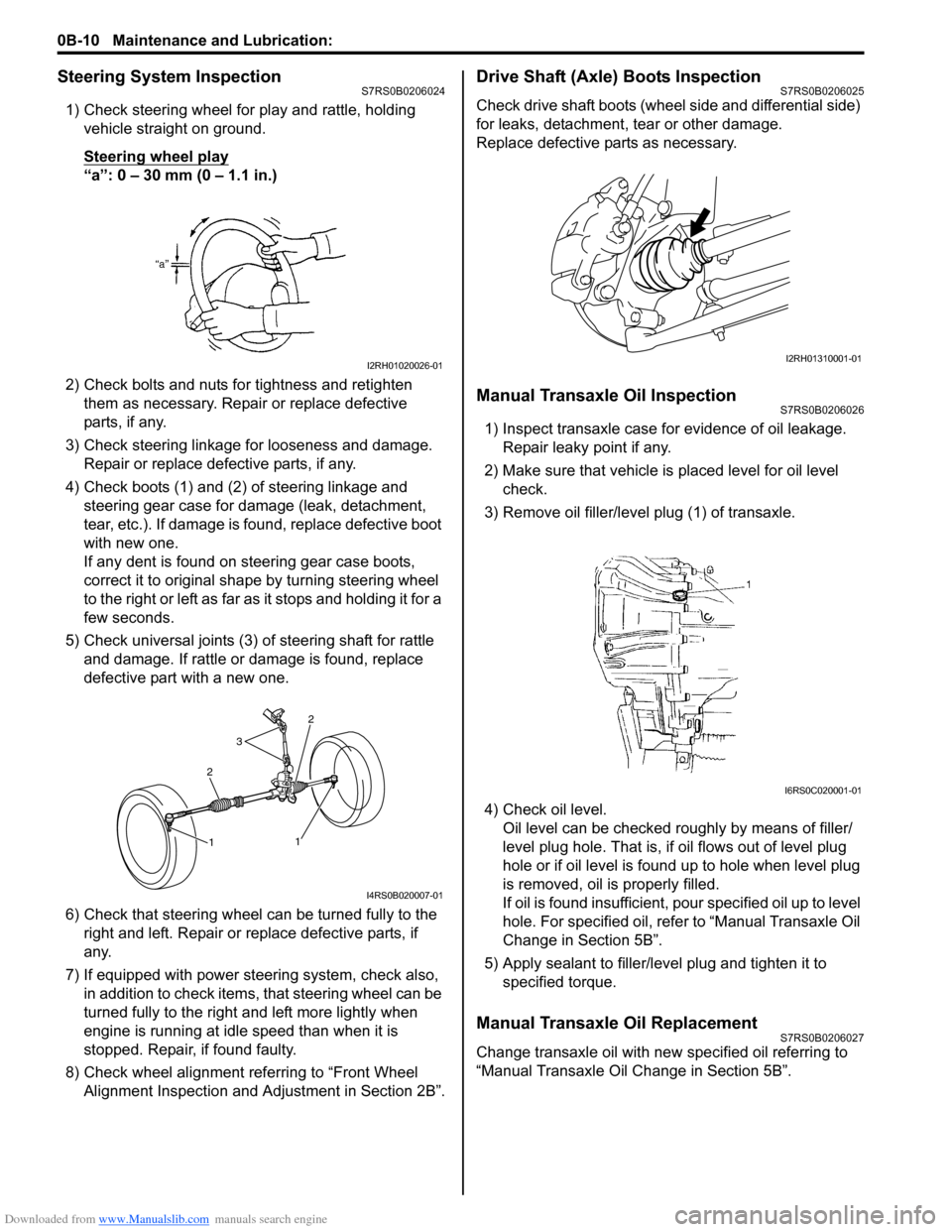

1) Check steering wheel for play and rattle, holding vehicle straight on ground.

Steering wheel play

“a”: 0 – 30 mm (0 – 1.1 in.)

2) Check bolts and nuts for tightness and retighten them as necessary. Repair or replace defective

parts, if any.

3) Check steering linkage for looseness and damage. Repair or replace defective parts, if any.

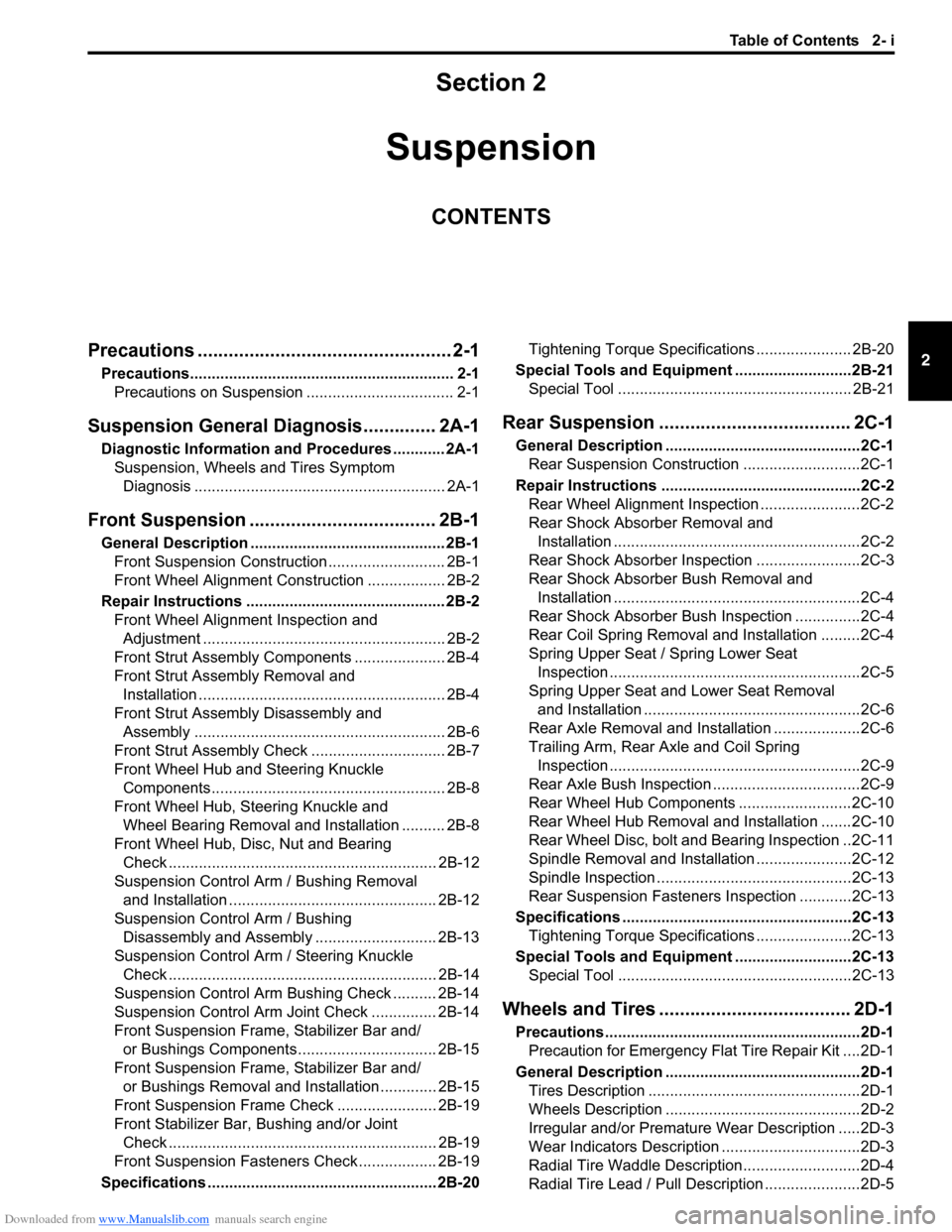

4) Check boots (1) and (2) of steering linkage and steering gear case for damage (leak, detachment,

tear, etc.). If damage is fo und, replace defective boot

with new one.

If any dent is found on steering gear case boots,

correct it to original shape by turning steering wheel

to the right or left as far as it stops and holding it for a

few seconds.

5) Check universal joints (3) of steering shaft for rattle and damage. If rattle or damage is found, replace

defective part with a new one.

6) Check that steering wheel can be turned fully to the

right and left. Repair or replace defective parts, if

any.

7) If equipped with power steering system, check also, in addition to check items, that steering wheel can be

turned fully to the right and left more lightly when

engine is running at idle speed than when it is

stopped. Repair, if found faulty.

8) Check wheel alignment referring to “Front Wheel Alignment Inspection and Adjustment in Section 2B”.

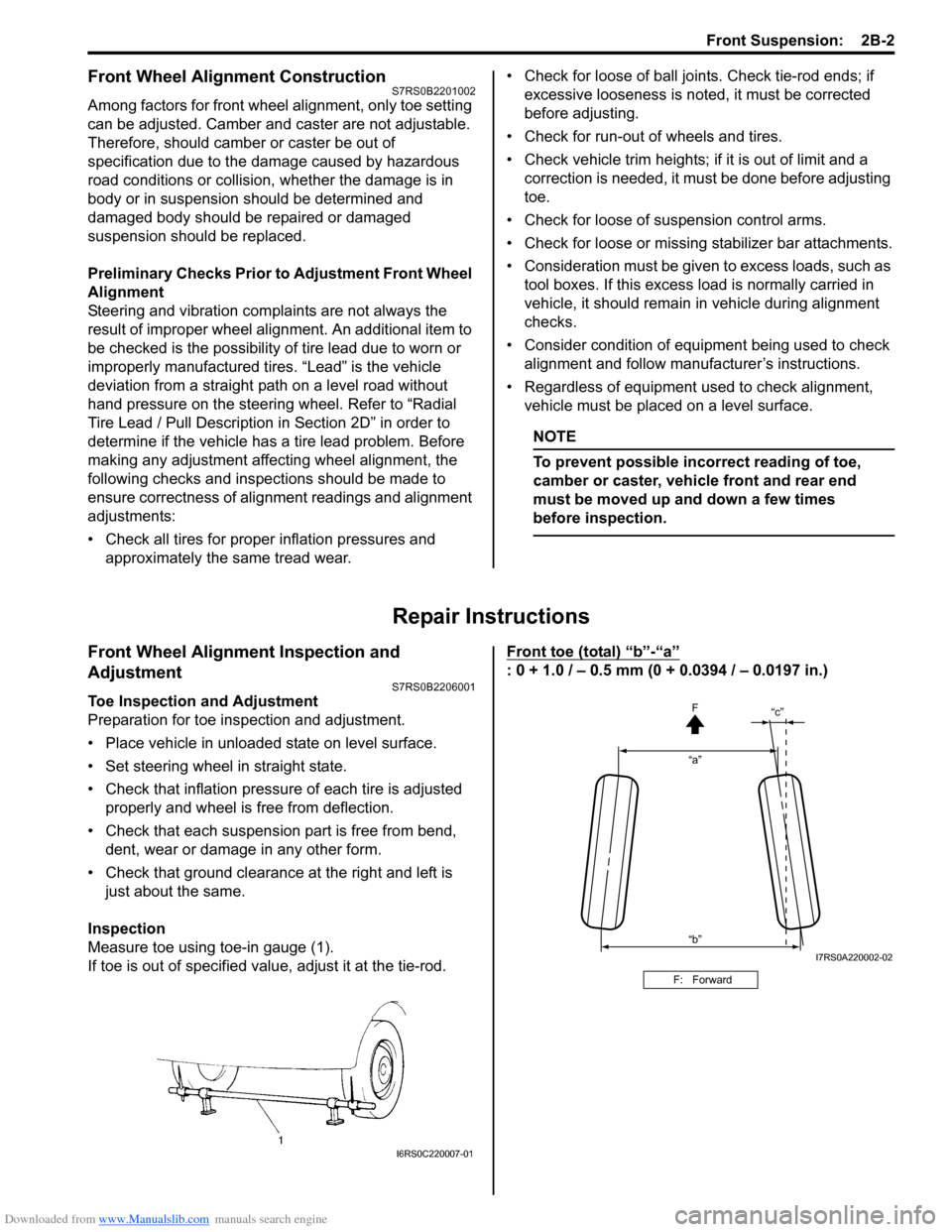

Drive Shaft (Axle) Boots InspectionS7RS0B0206025

Check drive shaft boots (wheel side and differential side)

for leaks, detachment, tear or other damage.

Replace defective parts as necessary.

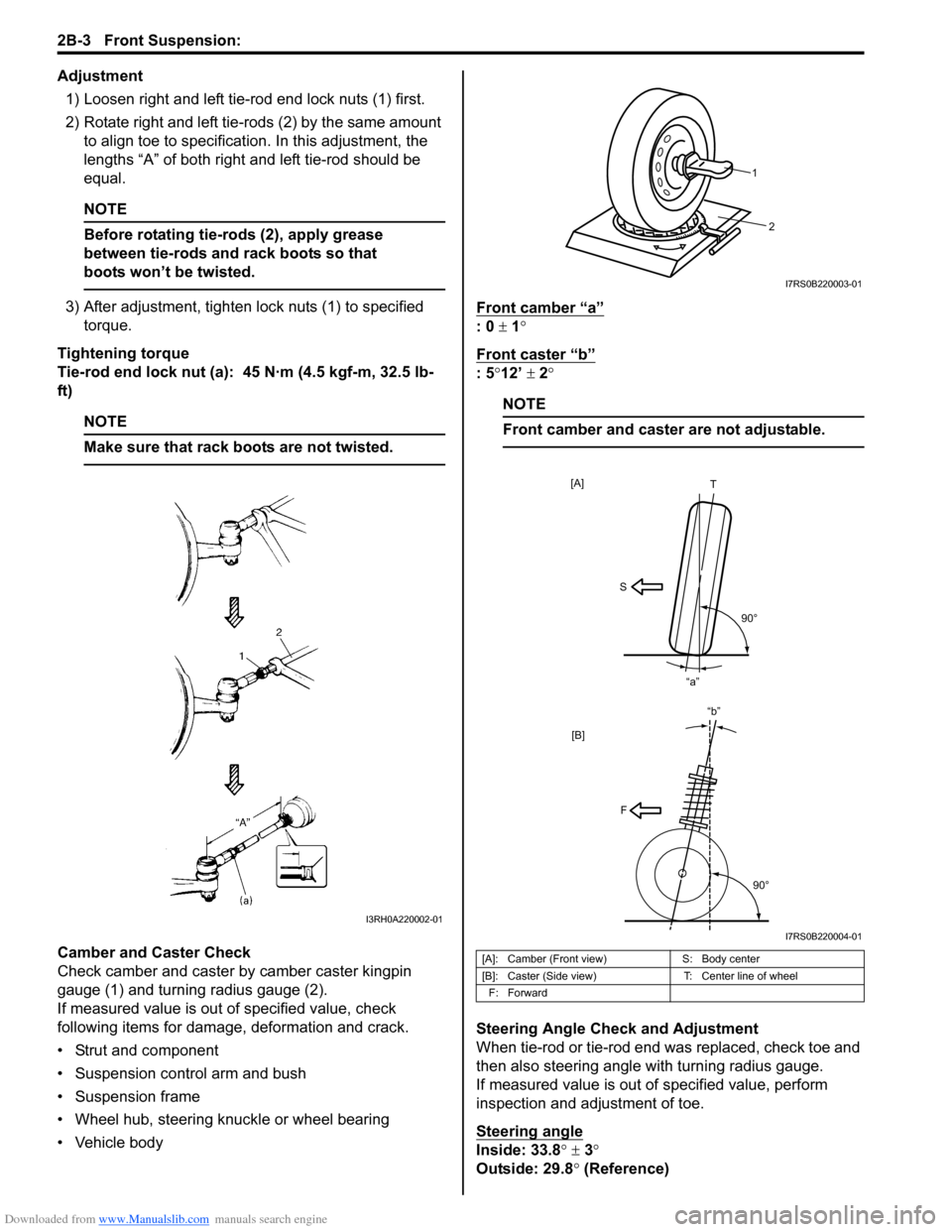

Manual Transaxle Oil InspectionS7RS0B0206026

1) Inspect transaxle case for evidence of oil leakage. Repair leaky point if any.

2) Make sure that vehicle is placed level for oil level

check.

3) Remove oil filler/leve l plug (1) of transaxle.

4) Check oil level. Oil level can be checked roughly by means of filler/

level plug hole. That is, if oil flows out of level plug

hole or if oil level is found up to hole when level plug

is removed, oil is properly filled.

If oil is found insufficient, po ur specified oil up to level

hole. For specified oil, refe r to “Manual Transaxle Oil

Change in Section 5B”.

5) Apply sealant to filler/leve l plug and tighten it to

specified torque.

Manual Transaxle Oil ReplacementS7RS0B0206027

Change transaxle oil with new specified oil referring to

“Manual Transaxle Oil Change in Section 5B”.

I2RH01020026-01

2

3

2

1

1

I4RS0B020007-01

I2RH01310001-01

I6RS0C020001-01

Page 429 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 2- i

2

Section 2

CONTENTS

Suspension

Precautions ................................................. 2-1

Precautions............................................................. 2-1

Precautions on Suspension .................................. 2-1

Suspension General Dia gnosis.............. 2A-1

Diagnostic Information and Procedures ............ 2A-1

Suspension, Wheels and Tires Symptom Diagnosis .......................................................... 2A-1

Front Suspension ........... ......................... 2B-1

General Description ............................................. 2B-1

Front Suspension Construction ........................... 2B-1

Front Wheel Alignment Cons truction .................. 2B-2

Repair Instructions .............................................. 2B-2 Front Wheel Alignment Inspection and Adjustment ........................................................ 2B-2

Front Strut Assembly Comp onents ..................... 2B-4

Front Strut Assembly Removal and Installation ......................................................... 2B-4

Front Strut Assembly Disassembly and Assembly .......................................................... 2B-6

Front Strut Assembly Chec k ............................... 2B-7

Front Wheel Hub and Steering Knuckle Components...................................................... 2B-8

Front Wheel Hub, Steering Knuckle and Wheel Bearing Removal and Installation .......... 2B-8

Front Wheel Hub, Disc, Nut and Bearing Check .............................................................. 2B-12

Suspension Control Arm / Bushing Removal and Installation ................................................ 2B-12

Suspension Control Arm / Bushing Disassembly and Assembly ............................ 2B-13

Suspension Control Arm / Steering Knuckle Check .............................................................. 2B-14

Suspension Control Arm Bushing Check .......... 2B-14

Suspension Control Arm Joint Check ............... 2B-14

Front Suspension Fram e, Stabilizer Bar and/

or Bushings Components................................ 2B-15

Front Suspension Fram e, Stabilizer Bar and/

or Bushings Removal and Installation ............. 2B-15

Front Suspension Frame Ch eck ....................... 2B-19

Front Stabilizer Bar, Bushing and/or Joint Check .............................................................. 2B-19

Front Suspension Fastener s Check .................. 2B-19

Specifications ..................................................... 2B-20 Tightening Torque Specifications ...................... 2B-20

Special Tools and Equipmen t ...........................2B-21

Special Tool ...................................................... 2B-21

Rear Suspension ............ ......................... 2C-1

General Description .............................................2C-1

Rear Suspension Construction ...........................2C-1

Repair Instructions ........... ...................................2C-2

Rear Wheel Alignment Inspection .......................2C-2

Rear Shock Absorber Removal and Installation .........................................................2C-2

Rear Shock Absorber Ins pection ........................2C-3

Rear Shock Absorber Bush Removal and Installation .........................................................2C-4

Rear Shock Absorber Bush Inspection ...............2C-4

Rear Coil Spring Removal and Installation .........2C-4

Spring Upper Seat / Spring Lower Seat Inspection ..........................................................2C-5

Spring Upper Seat and Lower Seat Removal and Installation ..................................................2C-6

Rear Axle Removal and Inst allation ....................2C-6

Trailing Arm, Rear Axle and Coil Spring Inspection ..........................................................2C-9

Rear Axle Bush Inspection ..................................2C-9

Rear Wheel Hub Components ..........................2C-10

Rear Wheel Hub Removal an d Installation .......2C-10

Rear Wheel Disc, bolt and Bearing Inspection ..2C-11

Spindle Removal and Installation ......................2C-12

Spindle Inspection .............................................2C-13

Rear Suspension Fasteners Inspection ............2C-13

Specifications .................... .................................2C-13

Tightening Torque Specifications ......................2C-13

Special Tools and Equipmen t ...........................2C-13

Special Tool ......................................................2C-13

Wheels and Tires ............ ......................... 2D-1

Precautions...........................................................2D-1

Precaution for Emergency Flat Tire Repair Kit ....2D-1

General Description .............................................2D-1 Tires Description .................................................2D-1

Wheels Description .............................................2D-2

Irregular and/or Premature Wear Description .....2D-3

Wear Indicators Description ................................2D-3

Radial Tire Waddle Description...........................2D-4

Radial Tire Lead / Pull Description ......................2D-5

Page 435 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-2

Front Wheel Alignment ConstructionS7RS0B2201002

Among factors for front wheel alignment, only toe setting

can be adjusted. Camber and caster are not adjustable.

Therefore, should camber or caster be out of

specification due to the damage caused by hazardous

road conditions or collision, whether the damage is in

body or in suspension should be determined and

damaged body should be repaired or damaged

suspension should be replaced.

Preliminary Checks Prior to Adjustment Front Wheel

Alignment

Steering and vibration complaints are not always the

result of improper wheel alignment. An additional item to

be checked is the possibility of tire lead due to worn or

improperly manufactured tires. “Lead” is the vehicle

deviation from a straight path on a level road without

hand pressure on the steering wheel. Refer to “Radial

Tire Lead / Pull Description in Section 2D” in order to

determine if the vehicle has a tire lead problem. Before

making any adjustment affecting wheel alignment, the

following checks and inspections should be made to

ensure correctness of alignment readings and alignment

adjustments:

• Check all tires for proper inflation pressures and approximately the same tread wear. • Check for loose of ball join

ts. Check tie-rod ends; if

excessive looseness is noted, it must be corrected

before adjusting.

• Check for run-out of wheels and tires.

• Check vehicle trim heights; if it is out of limit and a

correction is needed, it must be done before adjusting

toe.

• Check for loose of suspension control arms.

• Check for loose or missin g stabilizer bar attachments.

• Consideration must be given to excess loads, such as

tool boxes. If this excess load is normally carried in

vehicle, it should remain in vehicle during alignment

checks.

• Consider condition of equipment being used to check alignment and follow manufa cturer’s instructions.

• Regardless of equipment used to check alignment, vehicle must be placed on a level surface.

NOTE

To prevent possible incorrect reading of toe,

camber or caster, vehicle front and rear end

must be moved up and down a few times

before inspection.

Repair Instructions

Front Wheel Alignment Inspection and

Adjustment

S7RS0B2206001

Toe Inspection and Adjustment

Preparation for toe inspection and adjustment.

• Place vehicle in unloaded state on level surface.

• Set steering wheel in straight state.

• Check that inflation pressure of each tire is adjusted properly and wheel is free from deflection.

• Check that each suspension part is free from bend, dent, wear or damage in any other form.

• Check that ground clearance at the right and left is just about the same.

Inspection

Measure toe using toe-in gauge (1).

If toe is out of specified value, adjust it at the tie-rod. Front toe (total) “b”-“a”

: 0 + 1.0 / – 0.5 mm (0 + 0.0394 / – 0.0197 in.)

I6RS0C220007-01

F: Forward

“a”

“c”

“b” F

I7RS0A220002-02

Page 436 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-3 Front Suspension:

Adjustment1) Loosen right and left tie-rod end lock nuts (1) first.

2) Rotate right and left tie-rods (2) by the same amount to align toe to specification. In this adjustment, the

lengths “A” of both right and left tie-rod should be

equal.

NOTE

Before rotating tie-rods (2), apply grease

between tie-rods and rack boots so that

boots won’t be twisted.

3) After adjustment, tighten lock nuts (1) to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5 lb-

ft)

NOTE

Make sure that rack boots are not twisted.

Camber and Caster Check

Check camber and caster by camber caster kingpin

gauge (1) and turning radius gauge (2).

If measured value is out of specified value, check

following items for damage, deformation and crack.

• Strut and component

• Suspension control arm and bush

• Suspension frame

• Wheel hub, steering knuckle or wheel bearing

• Vehicle body Front camber “a”

: 0

± 1°

Front caster “b”

: 5 °12’ ± 2°

NOTE

Front camber and caster are not adjustable.

Steering Angle Check and Adjustment

When tie-rod or tie-rod end was replaced, check toe and

then also steering angle with turning radius gauge.

If measured value is out of specified value, perform

inspection and adjustment of toe.

Steering angle

Inside: 33.8 ° ± 3 °

Outside: 29.8 ° (Reference)

I3RH0A220002-01

[A]: Camber (Front view) S: Body center

[B]: Caster (Side view) T: Center line of wheel

F: Forward

2

1

I7RS0B220003-01

[B]

S T

90°

“a”

[A]

F

90°

“b”

I7RS0B220004-01

Page 446 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-13 Front Suspension:

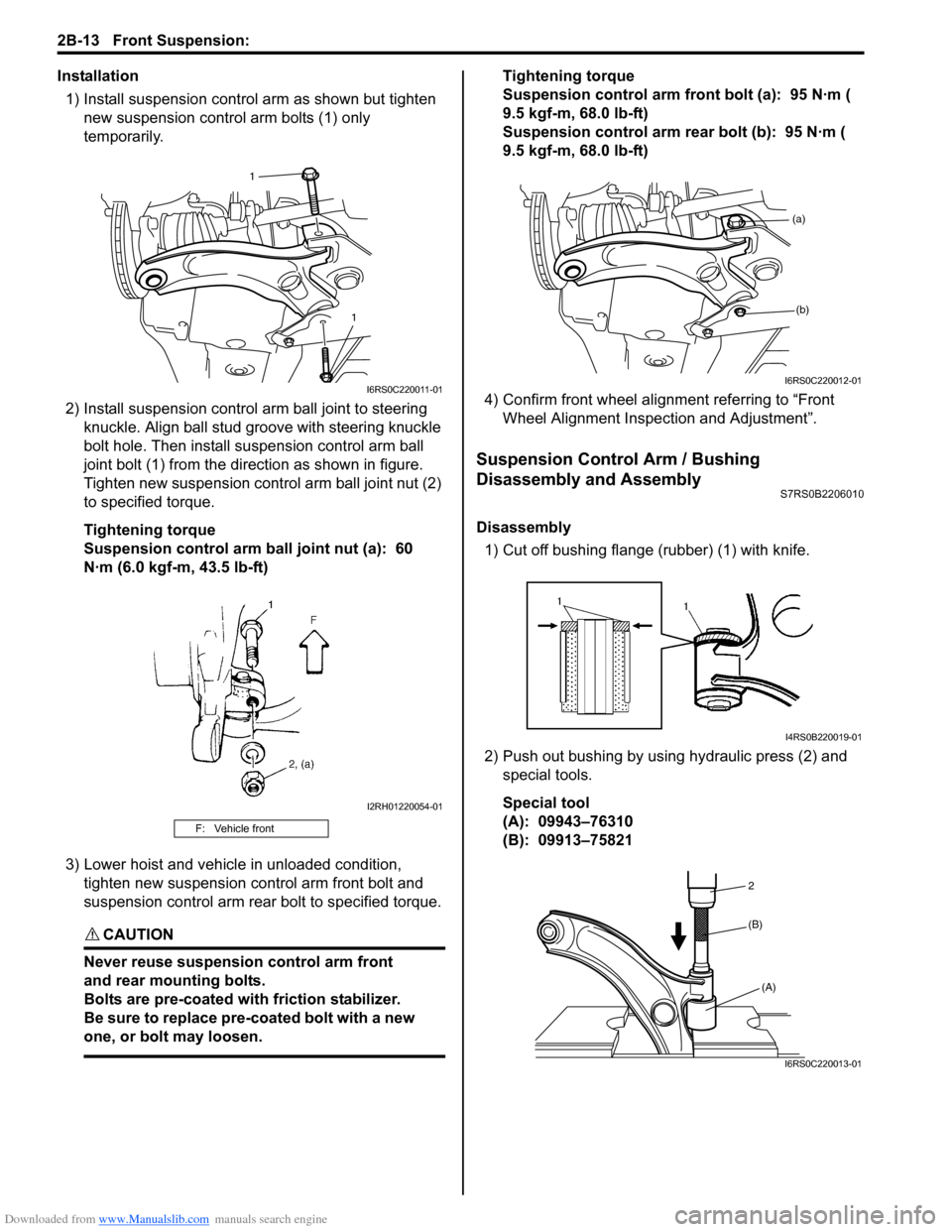

Installation1) Install suspension control arm as shown but tighten new suspension contro l arm bolts (1) only

temporarily.

2) Install suspensi on control arm ball joint to steering

knuckle. Align ball stud gr oove with steering knuckle

bolt hole. Then install su spension control arm ball

joint bolt (1) from the direction as shown in figure.

Tighten new suspension cont rol arm ball joint nut (2)

to specified torque.

Tightening torque

Suspension control arm ball joint nut (a): 60

N·m (6.0 kgf-m, 43.5 lb-ft)

3) Lower hoist and vehicle in unloaded condition, tighten new suspension control arm front bolt and

suspension control arm rear bolt to specified torque.

CAUTION!

Never reuse suspension control arm front

and rear mounting bolts.

Bolts are pre-coated with friction stabilizer.

Be sure to replace pre-coated bolt with a new

one, or bolt may loosen.

Tightening torque

Suspension control arm front bolt (a): 95 N·m (

9.5 kgf-m, 68.0 lb-ft)

Suspension control arm re ar bolt (b): 95 N·m (

9.5 kgf-m, 68.0 lb-ft)

4) Confirm front wheel alignment referring to “Front Wheel Alignment Inspection and Adjustment”.

Suspension Control Arm / Bushing

Disassembly and Assembly

S7RS0B2206010

Disassembly

1) Cut off bushing flange (rubber) (1) with knife.

2) Push out bushing by using hydraulic press (2) and special tools.

Special tool

(A): 09943–76310

(B): 09913–75821

F: Vehicle front

1

1

I6RS0C220011-01

I2RH01220054-01

(a)(b)

I6RS0C220012-01

I4RS0B220019-01

2

(A)

(B)

I6RS0C220013-01

Page 452 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-19 Front Suspension:

13) Install suspension control arm referring to

“Suspension Control Arm / Bushing Removal and

Installation”.

14) Connect couplers of torque sensor and P/S motor.

15) Connect tie-rod ends to knuckles (right & left) and then install cotter pins referring to “Tie-Rod End

Removal and Installa tion in Section 6C”.

16) Be sure that steering wheel and brake discs (right & left) are all straight-ahead position and then insert

steering lower shaft (5) into steering pinion shaft (3)

with matching marks (4).

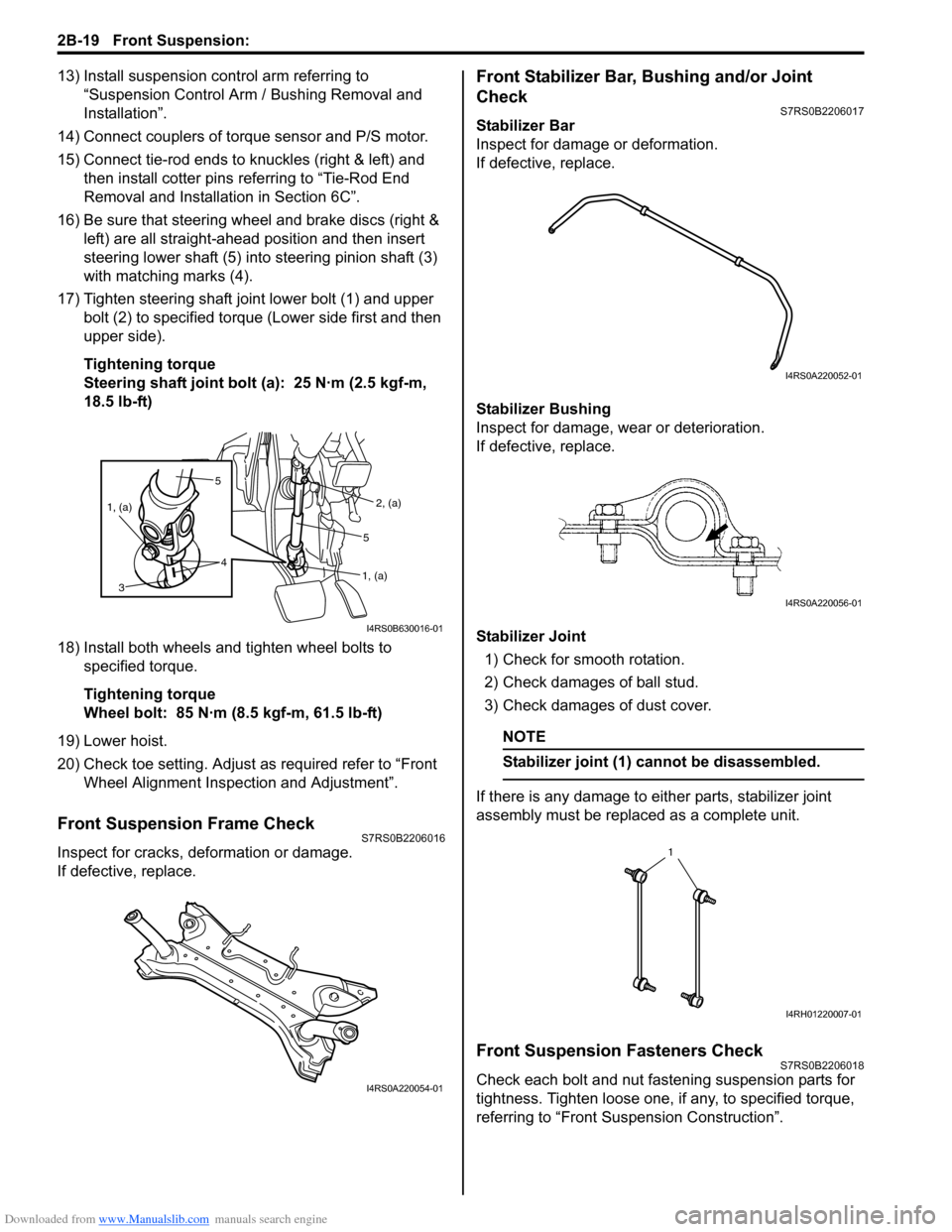

17) Tighten steering shaft joint lower bolt (1) and upper bolt (2) to specified torque (Lower side first and then

upper side).

Tightening torque

Steering shaft joint bolt (a): 25 N·m (2.5 kgf-m,

18.5 lb-ft)

18) Install both wheels and tighten wheel bolts to specified torque.

Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

19) Lower hoist.

20) Check toe setting. Adjust as required refer to “Front Wheel Alignment Inspection and Adjustment”.

Front Suspension Frame CheckS7RS0B2206016

Inspect for cracks, deformation or damage.

If defective, replace.

Front Stabilizer Bar, Bushing and/or Joint

Check

S7RS0B2206017

Stabilizer Bar

Inspect for damage or deformation.

If defective, replace.

Stabilizer Bushing

Inspect for damage, wear or deterioration.

If defective, replace.

Stabilizer Joint

1) Check for smooth rotation.

2) Check damages of ball stud.

3) Check damages of dust cover.

NOTE

Stabilizer joint (1) cannot be disassembled.

If there is any damage to either parts, stabilizer joint

assembly must be replaced as a complete unit.

Front Suspension Fasteners CheckS7RS0B2206018

Check each bolt and nut fastening suspension parts for

tightness. Tighten loose one, if any, to specified torque,

referring to “Front Suspension Construction”.

5

4

1, (a)

3

2, (a)

1, (a)

5

I4RS0B630016-01

I4RS0A220054-01

I4RS0A220052-01

I4RS0A220056-01

1

I4RH01220007-01

Page 469 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-2

Lower than recommended pressure can cause:

• Tire squeal on turns

• Hard Steering

• Rapid and uneven wear on the edges of the tread

• Tire rim bruises and rupture

• Tire cord breakage

• High tire temperature

• Reduced handling

• High fuel consumption

Replacement Tires

When replacement is necessary, the original equipment

type tire should be used. Refer to the Tire Placard.

Replacement tires should be of the same size, load

range and construction as those originally on the vehicle.

Use of any other size or type tire may affect ride,

handling, speedometer / odometer calibration, vehicle

ground clearance and tire or snow chain clearance to the

body and chassis.

It is recommended that new tires be installed in pairs on

the same axle. If necessary to replace only one tire, it

should be paired with the tire having the most tread, to

equalize braking traction.

WARNING!

Do not mix different types of tires on the

same vehicle such as radial, bias and bias-

belted tires except in emergencies, because

handling may be seriously affected and may

result in loss of control.

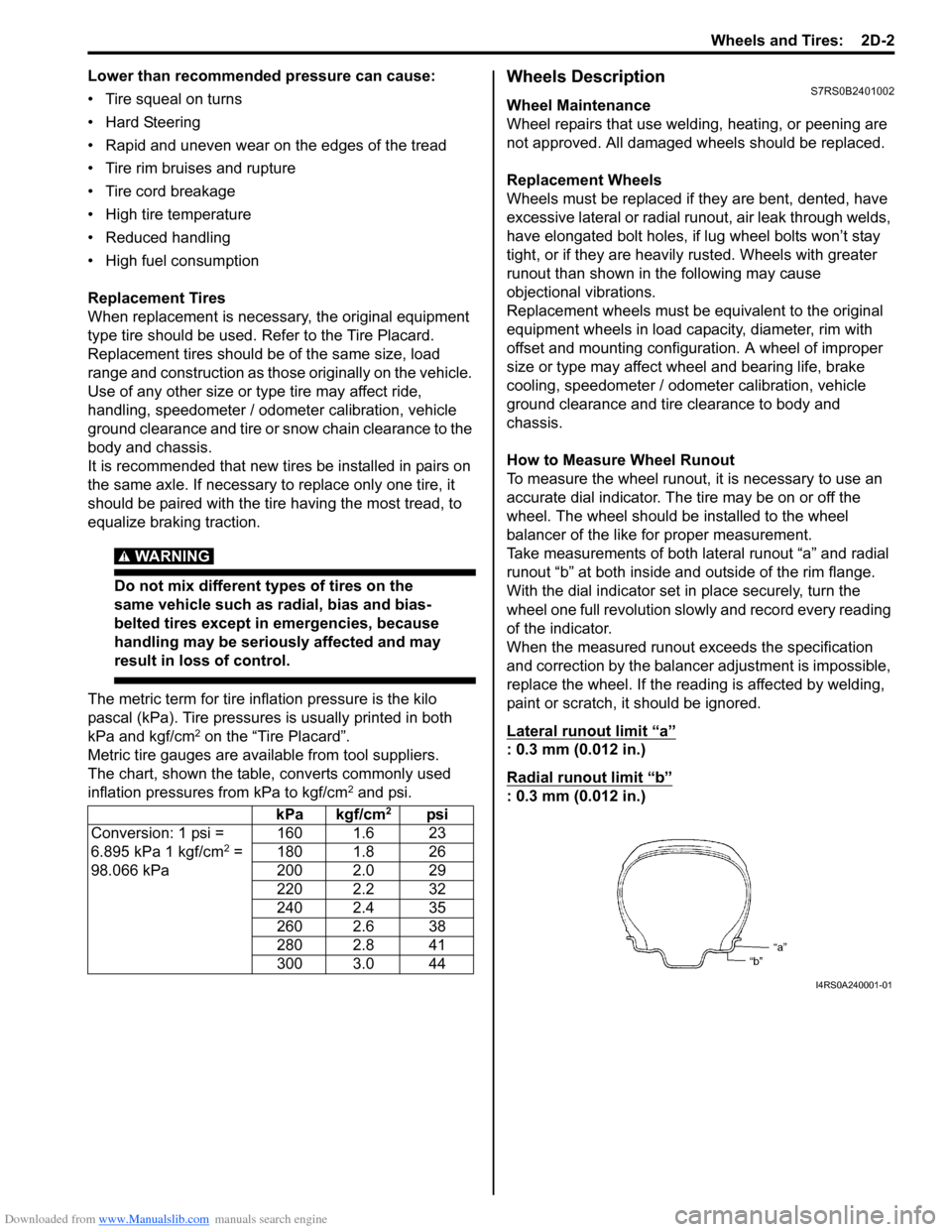

The metric term for tire infl ation pressure is the kilo

pascal (kPa). Tire pressures is usually printed in both

kPa and kgf/cm

2 on the “Tire Placard”.

Metric tire gauges are available from tool suppliers.

The chart, shown the table, converts commonly used

inflation pressures from kPa to kgf/cm

2 and psi.

Wheels DescriptionS7RS0B2401002

Wheel Maintenance

Wheel repairs that use welding, heating, or peening are

not approved. All damaged wheels should be replaced.

Replacement Wheels

Wheels must be replaced if they are bent, dented, have

excessive lateral or radial runout, air leak through welds,

have elongated bolt holes, if lug wheel bolts won’t stay

tight, or if they are heavily rusted. Wheels with greater

runout than shown in the following may cause

objectional vibrations.

Replacement wheels must be equivalent to the original

equipment wheels in load capacity, diameter, rim with

offset and mounting configuration. A wheel of improper

size or type may affect wheel and bearing life, brake

cooling, speedometer / odometer calibration, vehicle

ground clearance and tire clearance to body and

chassis.

How to Measure Wheel Runout

To measure the wheel runout, it is necessary to use an

accurate dial indicator. The tire may be on or off the

wheel. The wheel should be installed to the wheel

balancer of the like for proper measurement.

Take measurements of both lateral runout “a” and radial

runout “b” at both inside an d outside of the rim flange.

With the dial indicator set in place securely, turn the

wheel one full revolution slowly and record every reading

of the indicator.

When the measured runout exceeds the specification

and correction by the balancer adjustment is impossible,

replace the wheel. If the reading is affected by welding,

paint or scratch, it should be ignored.

Lateral runout limit “a”

: 0.3 mm (0.012 in.)

Radial runout limit “b”

: 0.3 mm (0.012 in.)

kPa kgf/cm2psi

Conversion: 1 psi =

6.895 kPa 1 kgf/cm

2 =

98.066 kPa 160 1.6 23

180 1.8 26

200 2.0 29

220 2.2 32

240 2.4 35

260 2.6 38

280 2.8 41

300 3.0 44

I4RS0A240001-01

Page 483 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-5

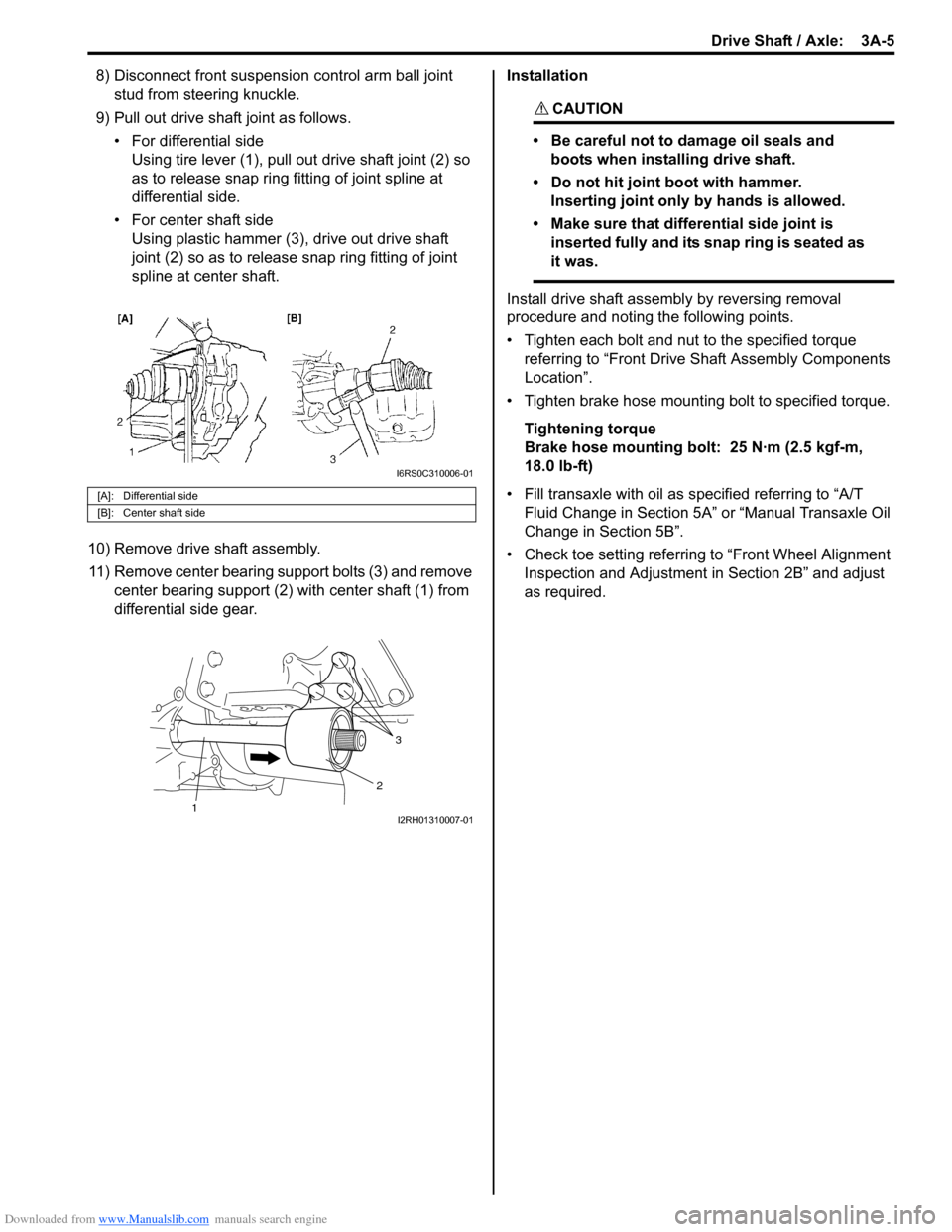

8) Disconnect front suspension control arm ball joint

stud from steering knuckle.

9) Pull out drive shaft joint as follows. • For differential sideUsing tire lever (1), pull out drive shaft joint (2) so

as to release snap ring fitting of joint spline at

differential side.

• For center shaft side Using plastic hammer (3), drive out drive shaft

joint (2) so as to release snap ring fitting of joint

spline at center shaft.

10) Remove drive shaft assembly. 11) Remove center bearing support bolts (3) and remove center bearing support (2) with center shaft (1) from

differential side gear. Installation

CAUTION!

• Be careful not to damage oil seals and

boots when installing drive shaft.

• Do not hit joint boot with hammer. Inserting joint only by hands is allowed.

• Make sure that differential side joint is inserted fully and its snap ring is seated as

it was.

Install drive shaft assemb ly by reversing removal

procedure and noting the following points.

• Tighten each bolt and nut to the specified torque referring to “Front Drive Shaft Assembly Components

Location”.

• Tighten brake hose mounting bolt to specified torque.

Tightening torque

Brake hose mounting bolt: 25 N·m (2.5 kgf-m,

18.0 lb-ft)

• Fill transaxle with oil as sp ecified referring to “A/T

Fluid Change in Section 5A” or “Manual Transaxle Oil

Change in Section 5B”.

• Check toe setting referring to “Front Wheel Alignment Inspection and Adjustment in Section 2B” and adjust

as required.

[A]: Differential side

[B]: Center shaft side

I6RS0C310006-01

3

2

1I2RH01310007-01

Page 871 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering General Diagnosis: 6A-2

Diagnostic Information and Procedures

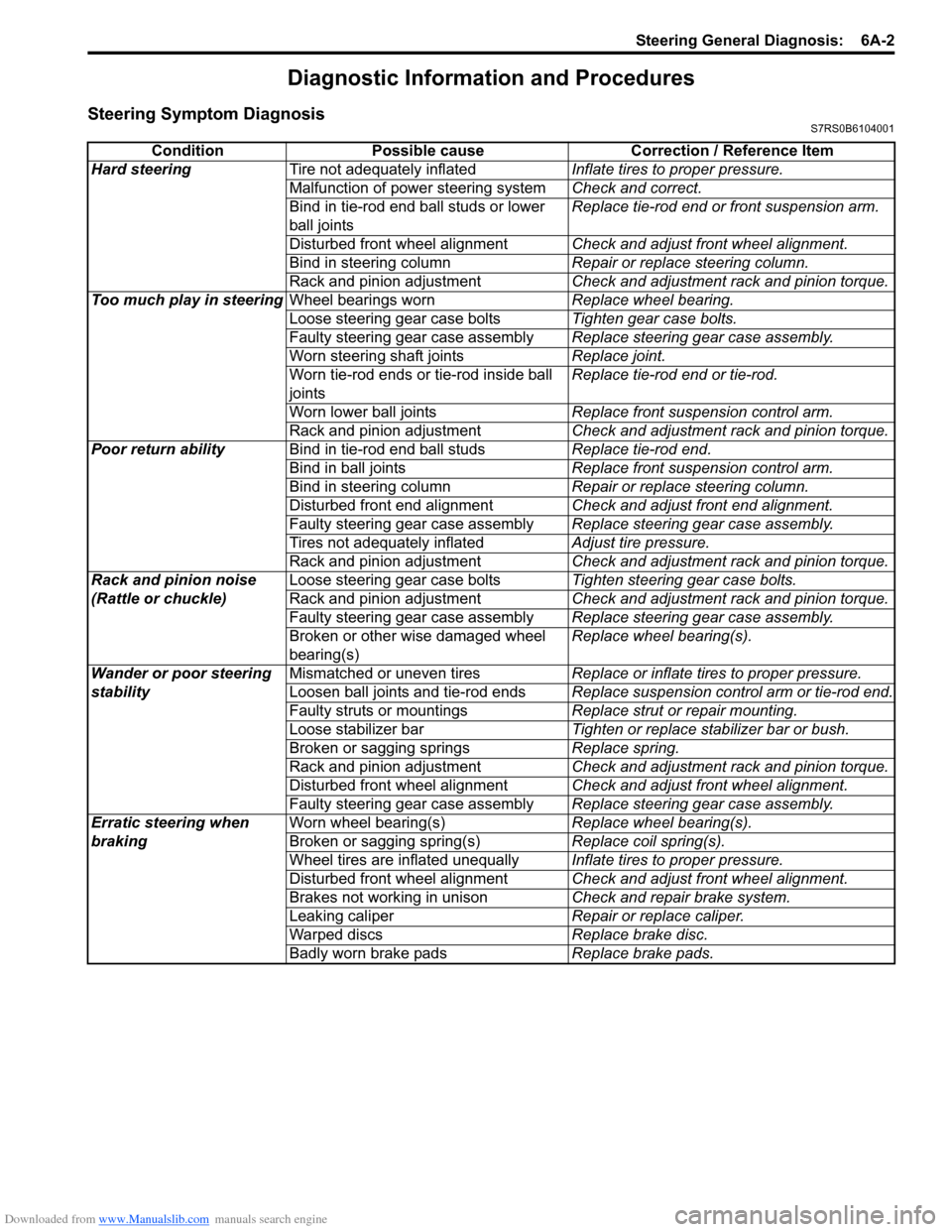

Steering Symptom DiagnosisS7RS0B6104001

ConditionPossible cause Correction / Reference Item

Hard steering Tire not adequately inflated Inflate tires to proper pressure.

Malfunction of power steering system Check and correct.

Bind in tie-rod end ball studs or lower

ball joints Replace tie-rod end or front suspension arm.

Disturbed front wheel alignment Check and adjust front wheel alignment.

Bind in steering column Repair or replace steering column.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Too much play in steering Wheel bearings worn Replace wheel bearing.

Loose steering gear case bolts Tighten gear case bolts.

Faulty steering gear case assembly Replace steering gear case assembly.

Worn steering shaft joints Replace joint.

Worn tie-rod ends or tie-rod inside ball

joints Replace tie-rod end or tie-rod.

Worn lower ball joints Replace front suspension control arm.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Poor return ability Bind in tie-rod end ball studs Replace tie-rod end.

Bind in ball joints Replace front suspension control arm.

Bind in steering column Repair or replace steering column.

Disturbed front end alignment Check and adjust front end alignment.

Faulty steering gear case assembly Replace steering gear case assembly.

Tires not adequately inflated Adjust tire pressure.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Rack and pinion noise

(Rattle or chuckle) Loose steering gear case bolts

Tighten steering gear case bolts.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Faulty steering gear case assembly Replace steering gear case assembly.

Broken or other wise damaged wheel

bearing(s) Replace wheel bearing(s).

Wander or poor steering

stability Mismatched or uneven tires

Replace or inflate tires to proper pressure.

Loosen ball joints and tie-rod ends Replace suspension control arm or tie-rod end.

Faulty struts or mountings Replace strut or repair mounting.

Loose stabilizer bar Tighten or replace stabilizer bar or bush.

Broken or sagging springs Replace spring.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Disturbed front wheel alignment Check and adjust front wheel alignment.

Faulty steering gear case assembly Replace steering gear case assembly.

Erratic steering when

braking Worn wheel bearing(s)

Replace wheel bearing(s).

Broken or sagging spring(s) Replace coil spring(s).

Wheel tires are inflated unequally Inflate tires to proper pressure.

Disturbed front wheel alignment Check and adjust front wheel alignment.

Brakes not working in unison Check and repair brake system.

Leaking caliper Repair or replace caliper.

Warped discs Replace brake disc.

Badly worn brake pads Replace brake pads.

Page 923 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-41

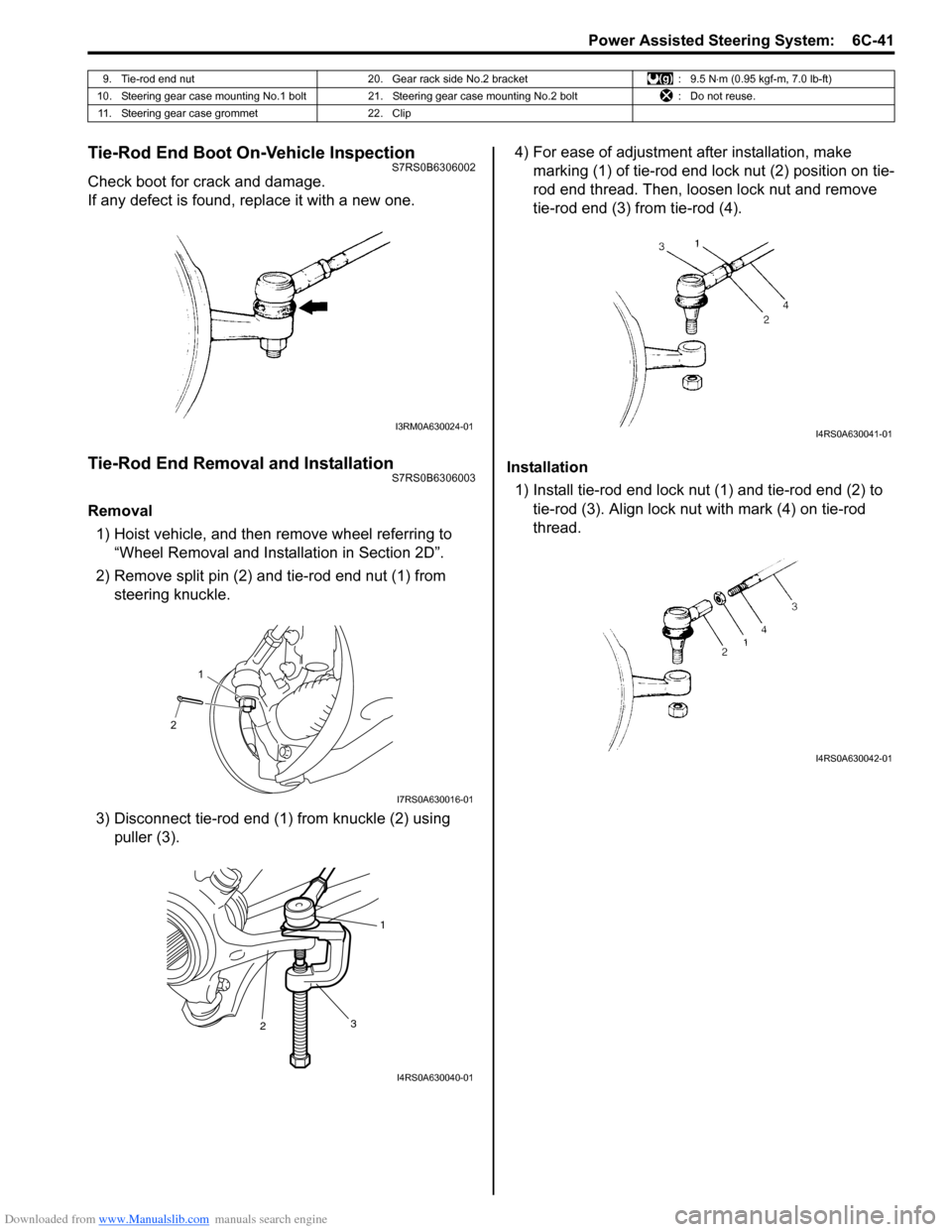

Tie-Rod End Boot On-Vehicle InspectionS7RS0B6306002

Check boot for crack and damage.

If any defect is found, replace it with a new one.

Tie-Rod End Removal and InstallationS7RS0B6306003

Removal1) Hoist vehicle, and then remove wheel referring to “Wheel Removal and Installation in Section 2D”.

2) Remove split pin (2) and tie-rod end nut (1) from steering knuckle.

3) Disconnect tie-rod end (1) from knuckle (2) using puller (3). 4) For ease of adjustment after installation, make

marking (1) of tie-rod end lock nut (2) position on tie-

rod end thread. Then, loosen lock nut and remove

tie-rod end (3) from tie-rod (4).

Installation 1) Install tie-rod end lock nut (1) and tie-rod end (2) to tie-rod (3). Align lock nut with mark (4) on tie-rod

thread.

9. Tie-rod end nut 20. Gear rack side No.2 bracket : 9.5 N⋅m (0.95 kgf-m, 7.0 lb-ft)

10. Steering gear case mounting No.1 bolt 21. Steering gear case mounting No.2 bolt : Do not reuse.

11. Steering gear case grommet 22. Clip

I3RM0A630024-01

21

I7RS0A630016-01

2 1

3

I4RS0A630040-01

I4RS0A630041-01

I4RS0A630042-01