temperature sensor SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 6 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-1 Precautions:

Precautions

Precautions

Precautions

Precautions for Vehicles Equipped with a

Supplemental Restraint (Air Bag) System

S7RS0B0000001

WARNING!

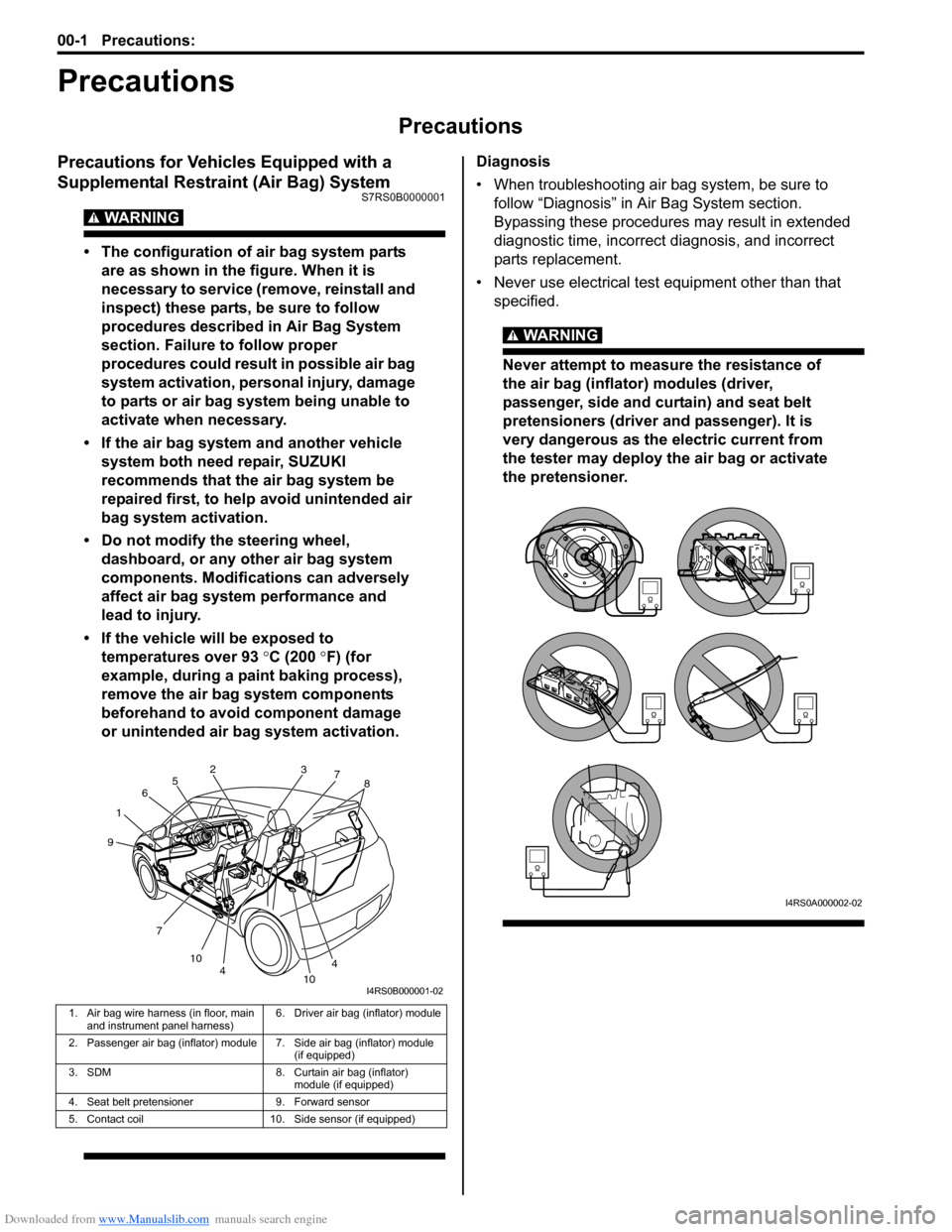

• The configuration of air bag system parts are as shown in the figure. When it is

necessary to service (remove, reinstall and

inspect) these parts, be sure to follow

procedures described in Air Bag System

section. Failure to follow proper

procedures could result in possible air bag

system activation, personal injury, damage

to parts or air bag system being unable to

activate when necessary.

• If the air bag system and another vehicle system both need repair, SUZUKI

recommends that the air bag system be

repaired first, to help avoid unintended air

bag system activation.

• Do not modify the steering wheel, dashboard, or any other air bag system

components. Modifications can adversely

affect air bag system performance and

lead to injury.

• If the vehicle will be exposed to temperatures over 93 °C (200 °F) (for

example, during a paint baking process),

remove the air bag system components

beforehand to avoid component damage

or unintended air bag system activation.

Diagnosis

• When troubleshooting air bag system, be sure to follow “Diagnosis” in Air Bag System section.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacement.

• Never use electrical test equipment other than that specified.

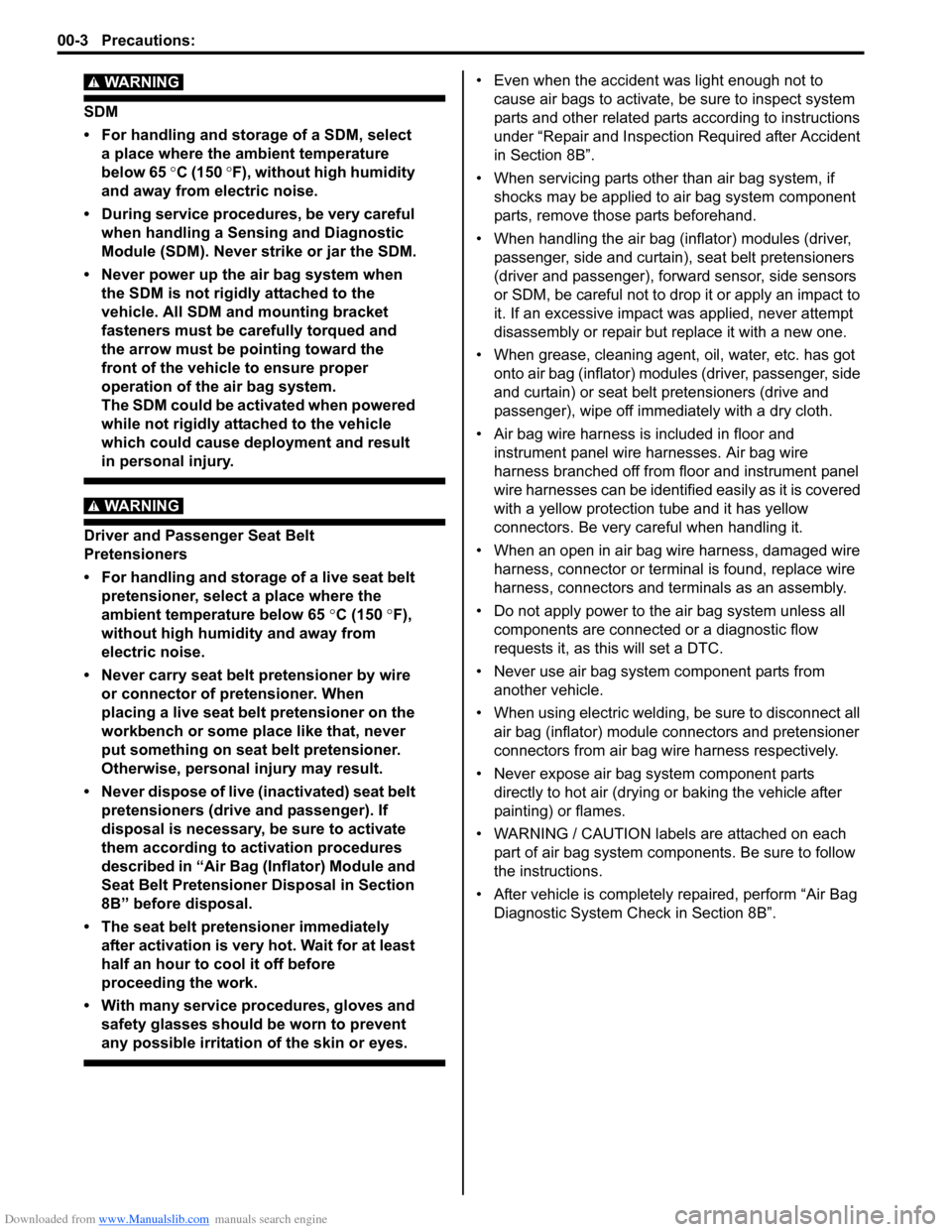

WARNING!

Never attempt to measure the resistance of

the air bag (inflator) modules (driver,

passenger, side and curtain) and seat belt

pretensioners (driver and passenger). It is

very dangerous as the electric current from

the tester may deploy the air bag or activate

the pretensioner.

1. Air bag wire harness (in floor, main and instrument panel harness) 6. Driver air bag (inflator) module

2. Passenger air bag (inflator) module 7. Side air bag (inflator) module (if equipped)

3. SDM 8. Curtain air bag (inflator) module (if equipped)

4. Seat belt pretensioner 9. Forward sensor

5. Contact coil 10. Side sensor (if equipped)

1 2

3

4

4

5

6

7 7

8

9

10 10

I4RS0B000001-02

I4RS0A000002-02

Page 8 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-3 Precautions:

WARNING!

SDM

• For handling and storage of a SDM, select a place where the ambient temperature

below 65 °C (150 °F), without high humidity

and away from electric noise.

• During service procedures, be very careful when handling a Sensing and Diagnostic

Module (SDM). Never strike or jar the SDM.

• Never power up the air bag system when the SDM is not rigidly attached to the

vehicle. All SDM and mounting bracket

fasteners must be carefully torqued and

the arrow must be pointing toward the

front of the vehicle to ensure proper

operation of the air bag system.

The SDM could be activated when powered

while not rigidly att ached to the vehicle

which could cause deployment and result

in personal injury.

WARNING!

Driver and Passenger Seat Belt

Pretensioners

• For handling and storage of a live seat belt pretensioner, select a place where the

ambient temperature below 65 °C (150 ° F),

without high humidity and away from

electric noise.

• Never carry seat belt pretensioner by wire or connector of pretensioner. When

placing a live seat belt pretensioner on the

workbench or some place like that, never

put something on seat belt pretensioner.

Otherwise, personal injury may result.

• Never dispose of live (inactivated) seat belt pretensioners (drive and passenger). If

disposal is necessary, be sure to activate

them according to activation procedures

described in “Air Bag (Inflator) Module and

Seat Belt Pretensioner Disposal in Section

8B” before disposal.

• The seat belt pretensioner immediately after activation is very hot. Wait for at least

half an hour to cool it off before

proceeding the work.

• With many service procedures, gloves and safety glasses should be worn to prevent

any possible irritation of the skin or eyes.

• Even when the accident was light enough not to cause air bags to activate, be sure to inspect system

parts and other related parts according to instructions

under “Repair and Inspection Required after Accident

in Section 8B”.

• When servicing parts other than air bag system, if shocks may be applied to air bag system component

parts, remove those parts beforehand.

• When handling the air bag (inflator) modules (driver, passenger, side and curtain), seat belt pretensioners

(driver and passenger), forward sensor, side sensors

or SDM, be careful not to drop it or apply an impact to

it. If an excessive impact was applied, never attempt

disassembly or repair but replace it with a new one.

• When grease, cleaning agent, oil, water, etc. has got onto air bag (inflator) modules (driver, passenger, side

and curtain) or seat belt pretensioners (drive and

passenger), wipe off immediately with a dry cloth.

• Air bag wire harness is included in floor and instrument panel wire harnesses. Air bag wire

harness branched off from floor and instrument panel

wire harnesses can be identifie d easily as it is covered

with a yellow protection tube and it has yellow

connectors. Be very ca reful when handling it.

• When an open in air bag wire harness, damaged wire harness, connector or terminal is found, replace wire

harness, connectors and terminals as an assembly.

• Do not apply power to the air bag system unless all components are connected or a diagnostic flow

requests it, as this will set a DTC.

• Never use air bag system component parts from another vehicle.

• When using electric welding, be sure to disconnect all air bag (inflator) module connectors and pretensioner

connectors from air bag wire harness respectively.

• Never expose air bag system component parts directly to hot air (drying or baking the vehicle after

painting) or flames.

• WARNING / CAUTION labels are attached on each

part of air bag system components. Be sure to follow

the instructions.

• After vehicle is completely repaired, perform “Air Bag Diagnostic System Check in Section 8B”.

Page 22 of 1496

Downloaded from www.Manualslib.com manuals search engine 0A-1 General Information:

General Information

General Information

General Description

AbbreviationsS7RS0B0101001

A:

ABDC: After Bottom Dead Center

ABS: Anti-lock Brake System

AC: Alternating Current

A/C: Air Conditioning

A-ELR: Automatic-Emergency Locking Retractor

A/F: Air Fuel Mixture Ratio

ALR: Automatic Locking Retractor

API: American Petroleum Institute

APP sensor: Accelerator Pedal Position Sensor

A/T: Automatic Transmission , Automatic Transaxle

AT D C : After Top Dead Center

ATF: Automatic Transmission Fluid, Automatic

Transaxle Fluid

B:

B+: Battery Positive Voltage

BBDC: Before Bottom Dead Center

BCM: Body Electrical Control Module

BDC: Bottom Dead Center

BTDC: Before Top Dead Center

C:

CAN: Controller Area Network

CKT: Circuit

CKP Sensor: Crankshaft Position Sensor

CMP Sensor: Camshaft Position Sensor

CO: Carbon Monoxide

CPP Switch: Clutch Pedal Position Switch (Clutch

Switch, Clutch Start Switch)

CPU: Central Processing Unit

CRS: Child Restraint System

D:

DC: Direct Current

DLC: Data Link Connector (Assembly Line Diag. Link,

ALDL, Serial Data Link, SDL)

DOHC: Double Over Head Camshaft

DOJ: Double Offset Joint

DRL: Daytime Running Light

DTC: Diagnostic Trouble Code (Diagnostic Code)

E:

EBCM: Electronic Brake Cont rol Module, ABS Control

Module

EBD: Electronic Brake Force Distribution

ECM: Engine Control Module

ECT Sensor: Engine Coolant Temperature Sensor (Water Temp. Sensor, WTS)

EFE Heater: Early Fuel Evaporation Heater (Positive

Temperature Coefficient, PTC Heater)

EGR: Exhaust Gas Recirculation

EGRT Sensor: EGR Temperature Sensor (Recirculated

Exhaust Gas Temp. Sensor, REGTS)

ELR: Emergency Locking Retractor

ESP ®: Electronic Stability Program

EPS: Electronic Power Steering

EVAP: Evaporative Emission EVAP Canister:

Evaporative Emission Canister

(Charcoal Canister)

F:

4WD: 4 Wheel

Drive

G:

GEN: Generator

GND: Ground

GPS: Global Positioning System

H:

HVAC: Heating, Ventilating and Air Conditioning

HC: Hydrocarbons

HO2S: Heated Oxygen Sensor

I:

IAC Valve: Idle Air Control Valve (Idle Speed Control

Solenoid Valve, ISC Solenoid Valve)

IAT Sensor: Intake Air Temperature Sensor (Air

temperature Sensor, ATS)

ICM: Immobilizer Control Module

IG: Ignition

ISC Actuator: Idle Speed Control Actuator

L:

LH: Left Hand

LHD: Left Hand Drive Vehicle

LSPV: Load Sensing Proportioning Valve

M:

MAF Sensor: Mass Air Flow Sensor (Air Flow Sensor, AFS, Air Flow Meter, AFM)

MAP Sensor: Manifold Absolute Pressure Sensor

(Pressure Sensor, PS)

Max: Maximum

MFI: Multiport Fuel Injection (Mu ltipoint Fuel Injection)

Min: Minimum

MIL: Malfunction Indicator Lamp (“SERVICE ENGINE

SOON” Light)

M/T: Manual Transmission, Manual Transaxle

N:

NOx: Nitrogen Oxides

O:

OBD: On-Board Diagnostic System (Self-Diagnosis

Function)

O/D: Overdrive

OHC: Over Head Camshaft

O2S: Oxygen Sensor

P:

PCM: Powertrain Control Module

PCV: Positive Crankcase Ventilation

PNP: Park / Neutral Position

P/S: Power Steering

PSP Switch: Power Steering Pressure Switch (P/S

Pressure Switch)

R:

RH: Right Hand

RHD: Right Hand Drive Vehicle

S:

SAE: Society of Automotive Engineers

Page 45 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 1- i

1

Section 1

CONTENTS

Engine

Precautions ................................................. 1-1

Precautions............................................................. 1-1

Precautions for Engine .......................................... 1-1

Engine General Information and

Diagnosis ............. .................................... 1A-1

Precautions........................................................... 1A-1

Precautions on Engine Service ........................... 1A-1

Precaution on On-Board Diagnostic (OBD) System .............................................................. 1A-1

Precautions in Diagnosing Trouble ..................... 1A-1

Precautions of ECM Circuit Inspection................ 1A-2

Precautions of Electric Throttle Body System

Calibration ......................................................... 1A-2

General Description ............................................. 1A-2 Statement on Cleanliness and Care ................... 1A-2

Engine Diagnosis General Description ............... 1A-3

On-Board Diagnostic System Description ........... 1A-3

Data Link Connector (DLC) ................................. 1A-6

Engine and Emission Control System Description ........................................................ 1A-6

CAN Communication System Description........... 1A-7

Air Intake System Description ............................. 1A-9

Description of Electric Throttle Body System ...... 1A-9

Description of Electric Throttle Body System Calibration ....................................................... 1A-10

Fuel Cut Control Description ............................. 1A-10

Generator Control System Description ............. 1A-11

Electronic Control System Description .............. 1A-12

Engine and Emission Control Input / Output Table ............................................................... 1A-18

Schematic and Routing Diagram ...................... 1A-19 Engine and Emission Control System Diagram .......................................................... 1A-19

Component Locatio n ......................................... 1A-21

Electronic Control System Components Location .......................................................... 1A-21

Diagnostic Information and Procedures .......... 1A-22 Engine and Emission Control System Check.... 1A-22

Malfunction Indicator Lamp (MIL) Check .......... 1A-25

DTC Check ....................................................... 1A-26

DTC Clearance ................................................. 1A-27

DTC Table ......................................................... 1A-27

Fail-Safe Table ................ .................................. 1A-31 Scan Tool Data ................................................. 1A-33

Visual Inspection ............................................... 1A-37

Engine Basic Inspection .................................... 1A-38

Engine Symptom Diagnosis .............................. 1A-41

MIL Does Not Come ON with Ignition Switch

ON and Engine Stop (but Engine Can Be

Started) ........................................................... 1A-47

Malfunction Indicator Lamp Remains ON after Engine Starts................................................... 1A-48

DTC P0010: “A” Camshaft Position Actuator Circuit .............................................................. 1A-49

DTC P0011 / P0012: “A” Camshaft Position - Timing Over-Advanced or System

Performance / -Retarded................................. 1A-52

DTC P0031 / P0032: HO2S Heater Control Circuit Low / High (Sensor-1) .......................... 1A-54

DTC P0037 / P0038: HO2S Heater Control Circuit Low / High (Sensor-2) .......................... 1A-56

DTC P0101: Mass or Volume Air Flow Circuit Range / Performance ...................................... 1A-58

DTC P0102: Mass or Volume Air Flow Circuit Low Input......................................................... 1A-61

DTC P0103: Mass or Volume Air Flow Circuit High Input ........................................................ 1A-63

DTC P0106: Manifold Absolute Pressure /

Barometric Pressure Circuit Range /

Performance.................................................... 1A-64

DTC P0107: Manifold Absolute Pressure /

Barometric Pressure Circ uit Low Input............ 1A-66

DTC P0108: Manifold Absolute Pressure /

Barometric Pressure Circ uit High Input ........... 1A-67

DTC P0111: Intake Air Temperature Sensor 1 Circuit Range / Performance ........................... 1A-69

DTC P0112: Intake Air Temperature Sensor 1 Circuit Low ...................................................... 1A-72

DTC P0113: Intake Air Temperature 1 Sensor Circuit High...................................................... 1A-74

DTC P0116: Engine Coolant Temperature Circuit Range / Performance ........................... 1A-76

DTC P0117: Engine Coolant Temperature Circuit Low ...................................................... 1A-79

DTC P0118: Engine Coolant Temperature Circuit High...................................................... 1A-81

DTC P0122: Throttle / Pedal Position Sensor / Switch “A” (Main) Circuit Low ........................ 1A-83

Page 58 of 1496

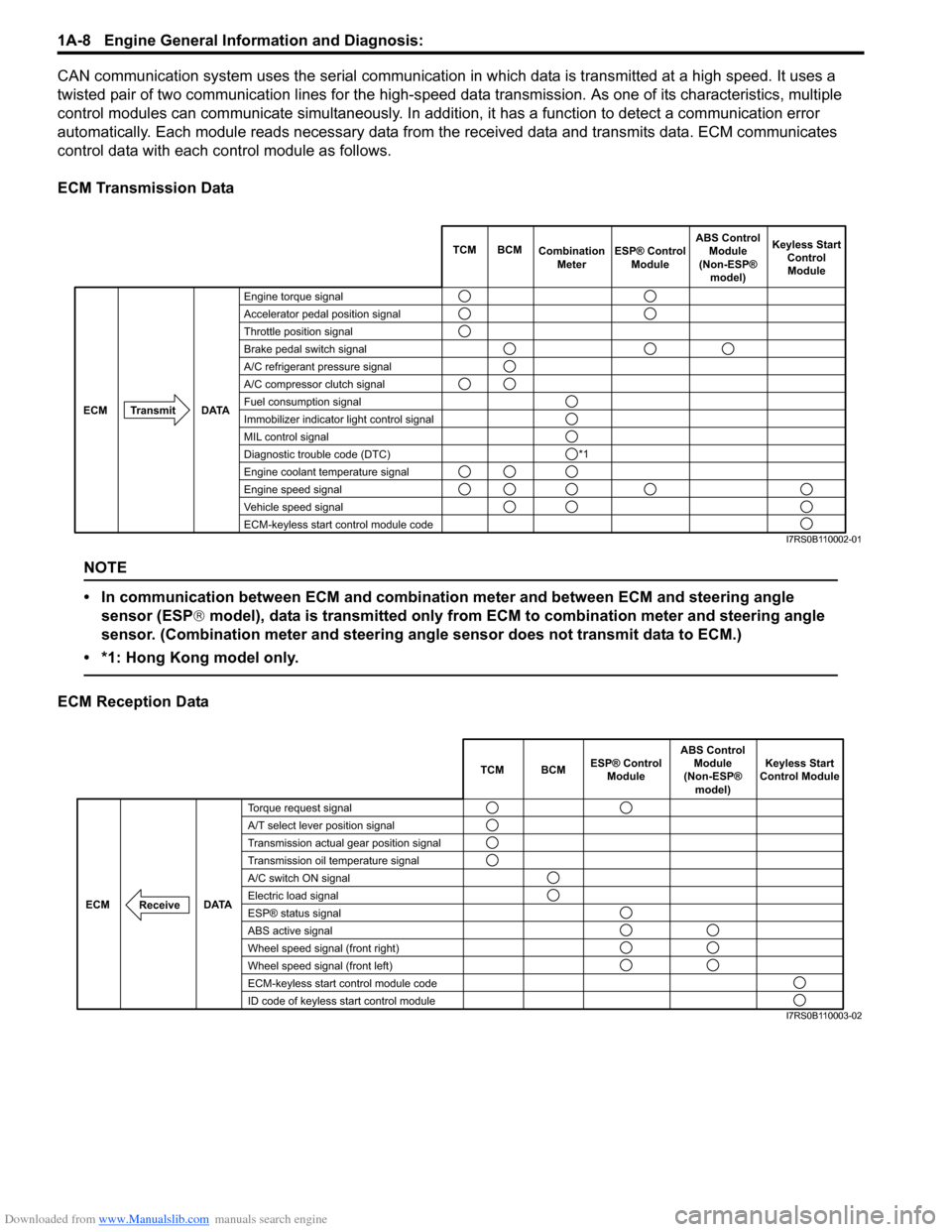

Downloaded from www.Manualslib.com manuals search engine 1A-8 Engine General Information and Diagnosis:

CAN communication system uses the serial communication in which data is transmitted at a high speed. It uses a

twisted pair of two communication lines for the high-speed da ta transmission. As one of its characteristics, multiple

control modules can communicate simultaneously. In addition, it has a function to detect a communication error

automatically. Each module reads necessary data from the received data and transmits data. ECM communicates

control data with each control module as follows.

ECM Transmission Data

NOTE

• In communication between ECM and combination meter and between ECM and steering angle sensor (ESP ® model), data is transmitted only from ECM to combination meter and steering angle

sensor. (Combination meter and steering angle sensor does not transmit data to ECM.)

• *1: Hong Kong model only.

ECM Reception Data

Engine torque signal

Accelerator pedal position signal

Throttle position signal

Brake pedal switch signal

A/C refrigerant pressure signal

A/C compressor clutch signal

Fuel consumption signal

Immobilizer indicator light control signal

MIL control signal

Diagnostic trouble code (DTC)

Engine coolant temperature signal

Engine speed signal

Vehicle speed signal

ECM-keyless start control module code TCM BCM

Combination

Meter Keyless Start

ControlModule

Transmit DATA

ECM

ESP® Control

Module ABS Control

Module

(Non-ESP® model)

*1

I7RS0B110002-01

TCM BCM Keyless Start

Control Module

DATA

ECM

Torque request signal

A/T select lever position signal

Transmission actual gear position signal

Transmission oil temperature signal

A/C switch ON signal

Electric load signal

ESP® status signal

ABS active signal

Wheel speed signal (front right)

Wheel speed signal (front left)

ECM-keyless start control module code

ID code of keyless start control module

Receive

ABS Control

Module

(Non-ESP® model)

ESP® Control

Module

I7RS0B110003-02

Page 78 of 1496

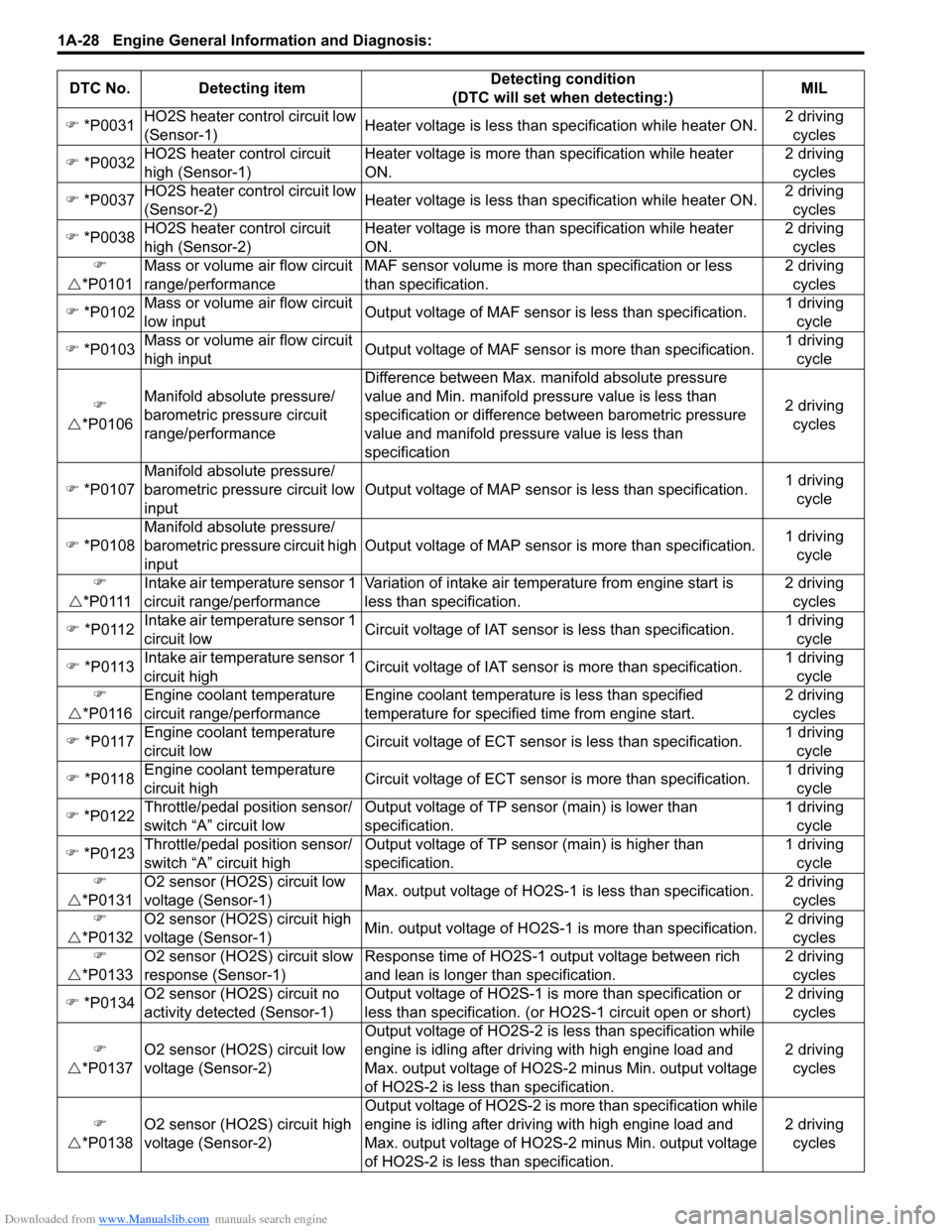

Downloaded from www.Manualslib.com manuals search engine 1A-28 Engine General Information and Diagnosis:

�) *P0031 HO2S heater control circuit low

(Sensor-1) Heater voltage is less than specification while heater ON. 2 driving

cycles

�) *P0032 HO2S heater control circuit

high (Sensor-1) Heater voltage is more than

specification while heater

ON. 2 driving

cycles

�) *P0037 HO2S heater control circuit low

(Sensor-2) Heater voltage is less than specification while heater ON. 2 driving

cycles

�) *P0038 HO2S heater control circuit

high (Sensor-2) Heater voltage is more than

specification while heater

ON. 2 driving

cycles

�)

�U *P0101 Mass or volume air flow circuit

range/performance MAF sensor volume is more

than specification or less

than specification. 2 driving

cycles

�) *P0102 Mass or volume air flow circuit

low input Output voltage of MAF sensor is less than specification. 1 driving

cycle

�) *P0103 Mass or volume air flow circuit

high input Output voltage of MAF sensor is more than specification. 1 driving

cycle

�)

�U *P0106 Manifold absolute pressure/

barometric pressure circuit

range/performance Difference between Max. manifold absolute pressure

value and Min. manifold pressure value is less than

specification or difference between barometric pressure

value and manifold pressure value is less than

specification

2 driving

cycles

�) *P0107 Manifold absolute pressure/

barometric pressure circuit low

input Output voltage of MAP sensor

is less than specification.1 driving

cycle

�) *P0108 Manifold absolute pressure/

barometric pressure circuit high

input Output voltage of MAP sensor is more than specification.

1 driving

cycle

�)

�U *P0111 Intake air temperature sensor 1

circuit range/performance Variation of intake air temperature from engine start is

less than specification. 2 driving

cycles

�) *P0112 Intake air temperature sensor 1

circuit low Circuit voltage of IAT sensor is less than specification. 1 driving

cycle

�) *P0113 Intake air temperature sensor 1

circuit hig

h Circuit voltage of IAT sensor

is more than specification. 1 driving

cycle

�)

�U *P0116 Engine coolant temperature

circuit range/performance Engine coolant temperature is less than specified

temperature for specified time from engine start. 2 driving

cycles

�) *P0117 Engine coolant temperature

circuit low Circuit voltage of ECT sensor

is less than specification. 1 driving

cycle

�) *P0118 Engine coolant temperature

circuit high Circuit voltage of ECT sensor

is more than specification. 1 driving

cycle

�) *P0122 Throttle/pedal position sensor/

switch “A” circuit low Output voltage of TP sensor (main) is lower than

specification. 1 driving

cycle

�) *P0123 Throttle/pedal position sensor/

switch “A” circuit high Output voltage of TP sensor (main) is higher than

specification. 1 driving

cycle

�)

�U *P0131 O2 sensor (HO2S) circuit low

voltage (Sensor-1)

Max. output voltage of HO2S-1

is less than specification.2 driving

cycles

�)

�U *P0132 O2 sensor (HO2S) circuit high

voltage (Sensor-1)

Min. output voltage of HO2S-1

is more than specification. 2 driving

cycles

�)

�U *P0133 O2 sensor (HO2S) circuit slow

response (Sensor-1) Response time of HO2S-1 output voltage between rich

and lean is longer than specification. 2 driving

cycles

�) *P0134 O2 sensor (HO2S) circuit no

activity detected (Sensor-1) Output voltage of HO2S-1 is

more than specification or

less than specification. (or HO2S-1 circuit open or short) 2 driving

cycles

�)

�U *P0137 O2 sensor (HO2S) circuit low

voltage (Sensor-2) Output voltage of HO2S-2 is

less than specification while

engine is idling after driving with high engine load and

Max. output voltage of HO2S-2 minus Min. output voltage

of HO2S-2 is less than specification. 2 driving

cycles

�)

�U *P013

8 O2 sensor (HO2S) circuit high

voltage (Sensor-2) Output voltage of HO2S-2 is

more than specification while

engine is idling after driving with high engine load and

Max. output voltage of HO2S-2 minus Min. output voltage

of HO2S-2 is less than specification. 2 driving

cycles

DTC No. Detecting item

Detecting condition

(DTC will set when detecting:) MIL

Page 81 of 1496

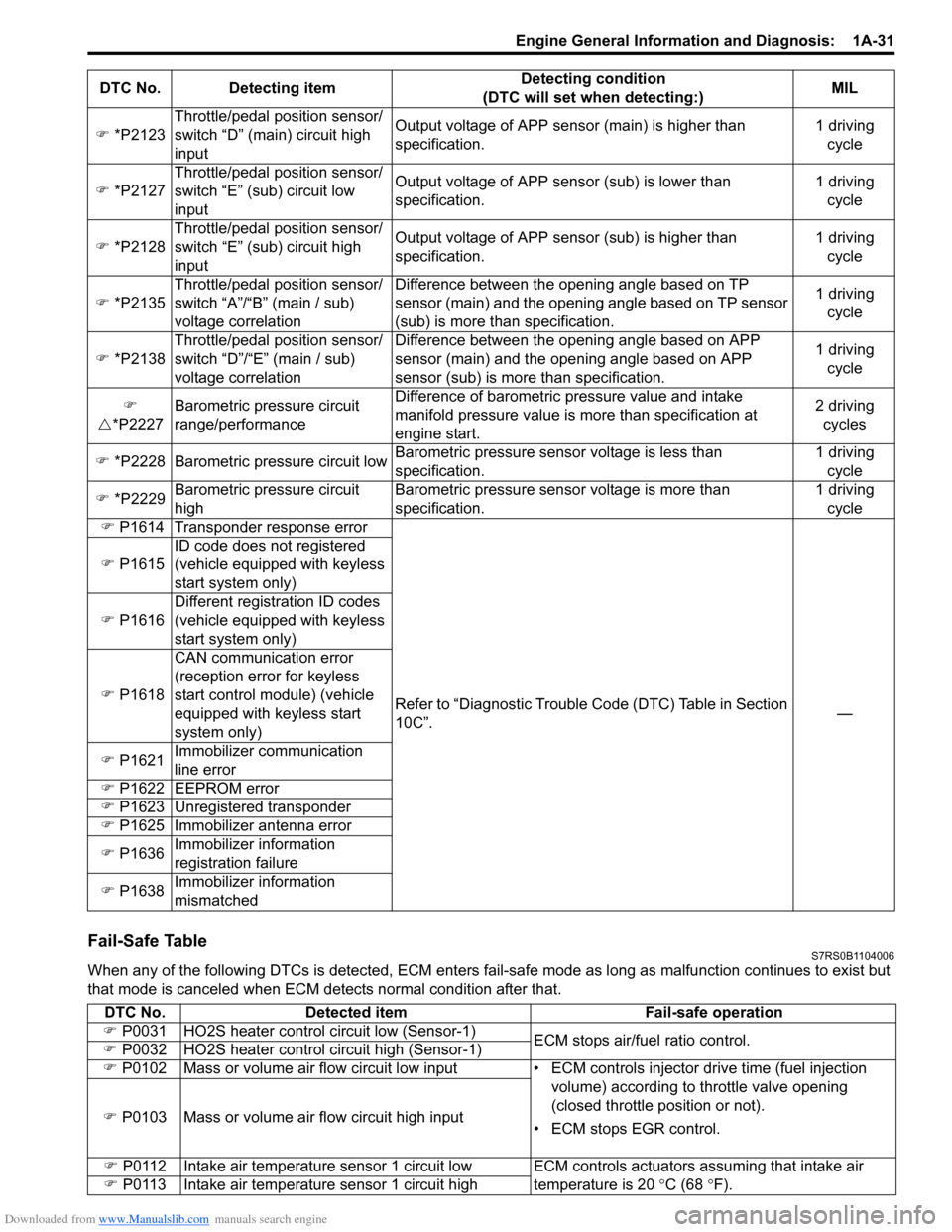

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-31

Fail-Safe TableS7RS0B1104006

When any of the following DTCs is detected, ECM enters fail-safe mode as long as malfunction continues to exist but

that mode is canceled when ECM de tects normal condition after that.

�)

*P2123 Throttle/pedal position sensor/

switch “D” (main) circuit high

input Output voltage of APP sensor (main) is higher than

specification.

1 driving

cycle

�) *P2127 Throttle/pedal position sensor/

switch “E” (sub) circuit low

input Output voltage of APP sens

or (sub) is lower than

specification. 1 driving

cycle

�) *P2128 Throttle/pedal position sensor/

switch “E” (sub) circuit high

input Output voltage of APP sensor (sub) is higher than

specification.

1 driving

cycle

�) *P2135 Throttle/pedal position sensor/

switch “A”/“B” (main / sub)

voltage correlation Difference between the opening angle based on TP

sensor (main) and the opening angle based on TP sensor

(sub) is more than specification.

1 driving

cycle

�) *P2138 Throttle/pedal position sensor/

switch “D”/“E” (main / sub)

voltage correlation Difference between the opening angle based on APP

sensor (main) and the opening angle based on APP

sensor (sub) is more

than specification. 1 driving

cycle

�)

�U *P2227 Barometric pressure circuit

range/performance Difference of barometric pressure value and intake

manifold pressure value is

more than specification at

engine start. 2 driving

cycles

�) *P2228 Barometric pressure circuit low Barometric pressure sens

or voltage is less than

specification. 1 driving

cycle

�) *P2229 Barometric pressure circuit

high Barometric pressure sensor voltage is more than

specification. 1 driving

cycle

�) P1614 Transponder response error

Refer to “Diagnostic Trouble Code (DTC) Table in Section

10C”. —

�) P1615 ID code does not registered

(vehicle equipped with keyless

start system only)

�) P1616 Different registration ID codes

(vehicle equipped with keyless

start system only)

�) P1618 CAN communication error

(reception error for keyless

start control module) (vehicle

equipped with keyless start

system only)

�) P1621 Immobilizer communication

line error

�) P1622

EEPROM error

�) P1623 Unregistered transponder

�) P1625 Immobilizer antenna error

�) P1636 Immobilizer information

registration failure

�) P1638 Immobilizer information

mismatched

DTC No. Detecting item

Detecting condition

(DTC will set when detecting:) MIL

DTC No.

Detected item Fail-safe operation

�) P0031 HO2S heater control circuit low (Sensor-1)

ECM stops air/fuel ratio control.

�) P0032 HO2S heater control circuit high (Sensor-1)

�) P0102 Mass or volume air flow circuit low input • ECM controls injector drive time (fuel injection

volume) according to throttle valve opening

(closed throttle position or not).

• ECM stops EGR control.

�)

P0103 Mass or volume air flow circuit high input

�) P0112 Intake air temperature sensor 1 circuit low ECM controls actuators assuming that intake air

temperature is 20 °C (68 ° F).

�) P0113 Intake air temperature sensor 1 circuit high

Page 82 of 1496

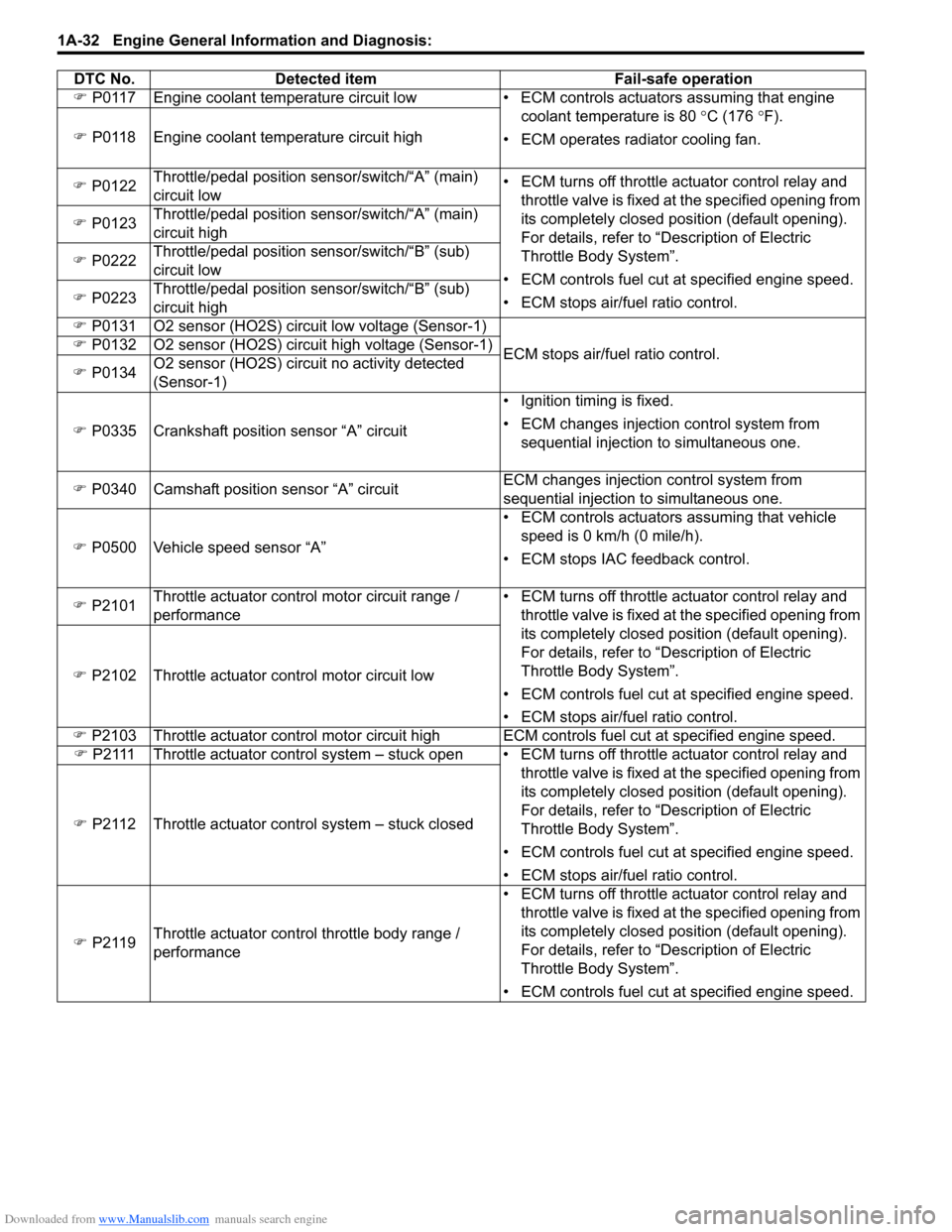

Downloaded from www.Manualslib.com manuals search engine 1A-32 Engine General Information and Diagnosis:

�) P0117 Engine coolant temperature circuit low • EC M controls actuators assuming that engine

coolant temperature is 80 °C (176 °F).

• ECM operates radiator cooling fan.

�)

P0118 Engine coolant temperature circuit high

�) P0122 Throttle/pedal position sensor/switch/“A” (main)

circuit low • ECM turns off throttle actuator control relay and

throttle valve is fixed at the specified opening from

its completely closed position (default opening).

For details, refer to “Description of Electric

Throttle Body System”.

• ECM controls fuel cut at specified engine speed.

• ECM stops air/fuel ratio control.

�)

P0123 Throttle/pedal position sensor/switch/“A” (main)

circuit high

�) P0222 Throttle/pedal position sensor/switch/“B” (sub)

circuit low

�) P0223 Throttle/pedal position sensor/switch/“B” (sub)

circuit high

�) P0131 O2 sensor (HO2S) circuit low voltage (Sensor-1)

ECM stops air/fuel ratio control.

�)

P0132 O2 sensor (HO2S) circuit high voltage (Sensor-1)

�) P0134 O2 sensor (HO2S) circuit no activity detected

(Sensor-1)

�) P0335 Crankshaft position sensor “A” circuit • Ignition timing is fixed.

• ECM changes injection control system from

sequential injection to simultaneous one.

�) P0340 Camshaft position sensor “A” circuit ECM changes injection

control system from

sequential injection to simultaneous one.

�) P0500 Vehicle speed sensor “A” • ECM controls actuators assuming that vehicle

speed is 0 km/h (0 mile/h).

• ECM stops IAC feedback control.

�) P2101 Throttle actuator control motor circuit range /

performance • ECM turns off throttle actuator control relay and

throttle valve is fixed at the specified opening from

its completely closed position (default opening).

For details, refer to “Description of Electric

Throttle Body System”.

• ECM controls fuel cut at specified engine speed.

• ECM stops air/fuel ratio control.

�)

P2102 Throttle actuator control motor circuit low

�) P2103 Throttle actuator control motor circuit high ECM controls fuel cut at specified engine speed.

�) P2111 Throttle actuator control system – stuck open • EC M turns off throttle actuator control relay and

throttle valve is fixed at the specified opening from

its completely closed position (default opening).

For details, refer to “Description of Electric

Throttle Body System”.

• ECM controls fuel cut at specified engine speed.

• ECM stops air/fuel ratio control.

�)

P2112 Throttle actuator control system – stuck closed

�) P2119 Throttle actuator control throttle body range /

performance • ECM turns off throttle actuator control relay and

throttle valve is fixed at the specified opening from

its completely closed position (default opening).

For details, refer to “Description of Electric

Throttle Body System”.

• ECM controls fuel cut at specified engine speed.

DTC No.

Detected item Fail-safe operation

Page 84 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-34 Engine General Information and Diagnosis:

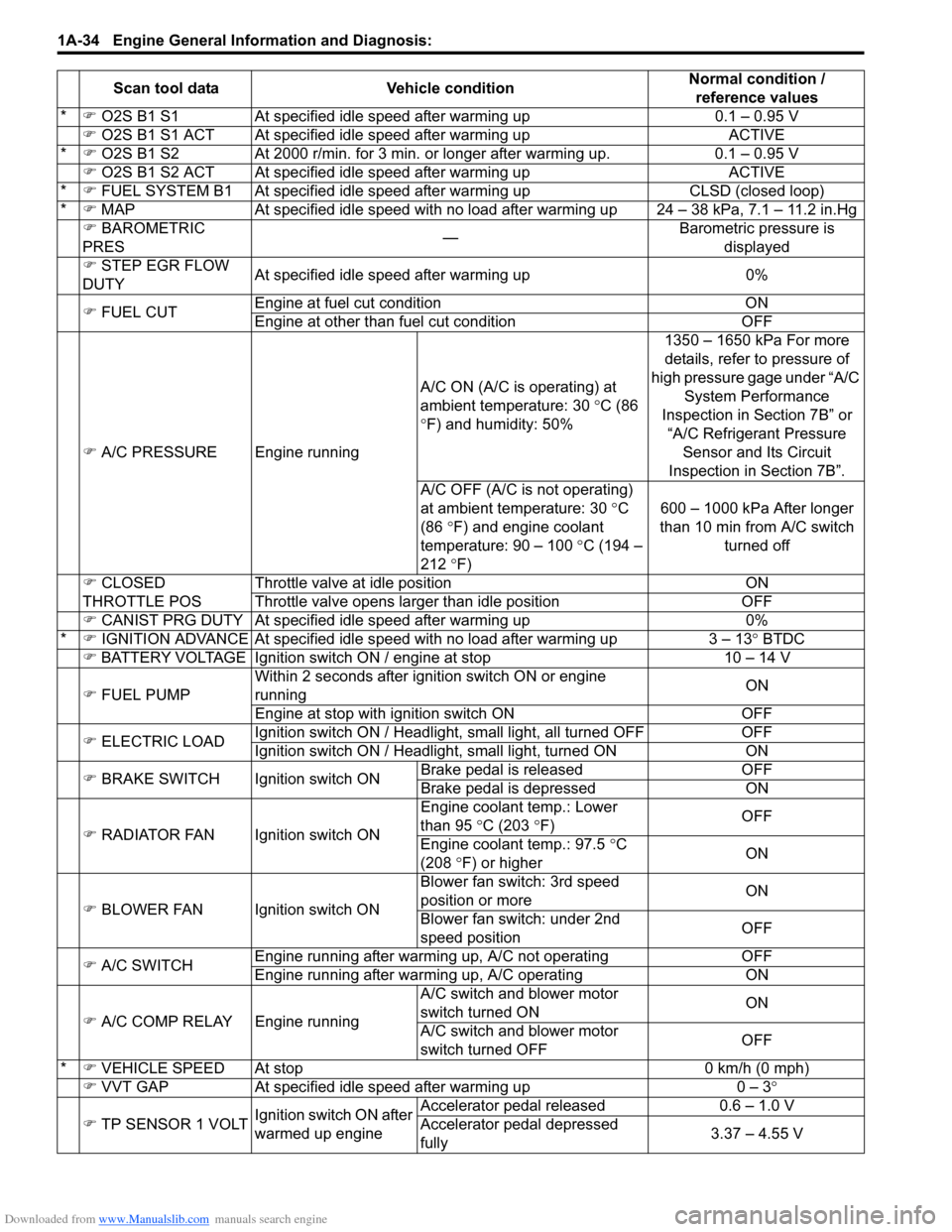

*�) O2S B1 S1 At specified idle speed after warming up 0.1 – 0.95 V

�) O2S B1 S1 ACT At specified id le speed after warming up ACTIVE

* �) O2S B1 S2 At 2000 r/min. for 3 min. or longer after warming up. 0.1 – 0.95 V

�) O2S B1 S2 ACT At specified id le speed after warming up ACTIVE

* �) FUEL SYSTEM B1 At specif ied idle speed after warming up CLSD (closed loop)

* �) MAP At specified idle speed with no load after warming up 24 – 38 kPa, 7.1 – 11.2 in.Hg

�) BAROMETRIC

PRES —Barometric pressure is

displayed

�) STEP EGR FLOW

DUTY At specified idle speed after warming up 0%

�) FUEL CUT Engine at fuel cut condition ON

Engine at other than fuel cut condition OFF

�) A/C PRESSURE Engine running A/C ON (A/C is operating) at

ambient temperature: 30

°C (86

° F) and humidity: 50% 1350 – 1650 kPa For more

details, refer to pressure of

high pressure gage under “A/C System Performance

Inspection in Section 7B” or “A/C Refrigerant Pressure Sensor and Its Circuit

Inspection in Section 7B”.

A/C OFF (A/C is not operating)

at ambient temperature: 30 ° C

(86 °F) and engine coolant

temperature: 90 – 100 °C (194 –

212 °F) 600 – 1000 kPa After longer

than 10 min from A/C switch turned off

�) CLOSED

THROTTLE POS Throttle valve at idle position ON

Throttle valve opens larger than idle position OFF

�) CANIST PRG DUTY At specified idle speed after warming up 0%

* �) IGNITION ADVANCE At specified idle s peed with no load after warming up 3 – 13 ° BTDC

�) BATTERY VOLTAGE Ignition switch ON / engine at stop 10 – 14 V

�) FUEL PUMP Within 2 seconds after ignition switch ON or engine

running

ON

Engine at stop with ignition switch ON OFF

�) ELECTRIC LOAD Ignition switch ON / Headligh

t, small light, all turned OFF OFF

Ignition switch ON / Headli ght, small light, turned ON ON

�) BRAKE SWITCH Igni tion switch ONBrake pedal is released OFF

Brake pedal is depressed ON

�) RADIATOR FAN Ignition switch ON Engin

e coolant temp.: Lower

than 95 °C (203 °F) OFF

Engine coolant temp.: 97.5 °C

(208 °F) or higher ON

�) BLOWER FAN Ignition switch ON Blower fan switch: 3rd speed

position or more

ON

Blower fan switch: under 2nd

speed position OFF

�) A/C SWITCH Engine running after warming up, A/C not operating

OFF

Engine running after warming up, A/C operating ON

�) A/C COMP RELAY Engine running A/C switch and blower motor

switch turned ON

ON

A/C switch and blower motor

switch turned OFF OFF

* �) VEHICLE SPEED At stop 0 km/h (0 mph)

�) VVT GAP At specified idle speed after warming up 0 – 3°

�) TP SENSOR 1 VOLT Ignition switch ON after

warmed up engine Accelerator pedal released

0.6 – 1.0 V

Accelerator pedal depressed

fully 3.37 – 4.55 V

Scan tool data

Vehicle condition Normal condition /

reference values

Page 85 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-35

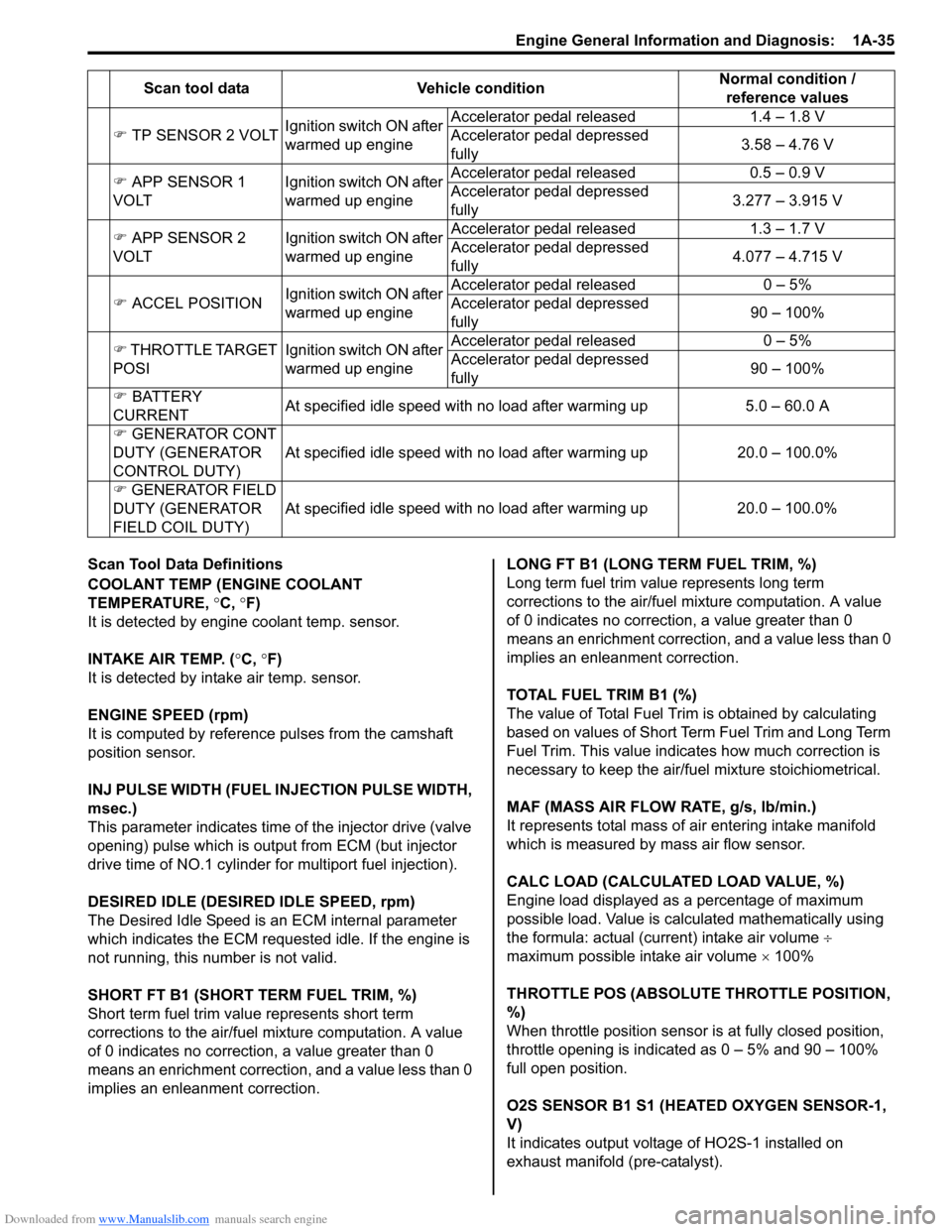

Scan Tool Data Definitions

COOLANT TEMP (ENGINE COOLANT

TEMPERATURE, °C, °F)

It is detected by engine coolant temp. sensor.

INTAKE AIR TEMP. ( °C, °F)

It is detected by intake air temp. sensor.

ENGINE SPEED (rpm)

It is computed by reference pulses from the camshaft

position sensor.

INJ PULSE WIDTH (FUEL INJECTION PULSE WIDTH,

msec.)

This parameter indicates time of the injector drive (valve

opening) pulse which is output from ECM (but injector

drive time of NO.1 cylinder fo r multiport fuel injection).

DESIRED IDLE (DESIRED IDLE SPEED, rpm)

The Desired Idle Speed is an ECM internal parameter

which indicates the ECM requested idle. If the engine is

not running, this number is not valid.

SHORT FT B1 (SHORT TERM FUEL TRIM, %)

Short term fuel trim valu e represents short term

corrections to the air/fuel mixture computation. A value

of 0 indicates no correction, a value greater than 0

means an enrichment correction, and a value less than 0

implies an enleanment correction. LONG FT B1 (LONG TERM FUEL TRIM, %)

Long term fuel trim value represents long term

corrections to the air/fuel mixture computation. A value

of 0 indicates no correction, a value greater than 0

means an enrichment correction, and a value less than 0

implies an enleanment correction.

TOTAL FUEL TRIM B1 (%)

The value of Total Fuel Trim is obtained by calculating

based on values of Short Term Fuel Trim and Long Term

Fuel Trim. This value indica

tes how much correction is

necessary to keep the air/fuel mixture stoichiometrical.

MAF (MASS AIR FLOW RATE, g/s, lb/min.)

It represents total mass of air entering intake manifold

which is measured by mass air flow sensor.

CALC LOAD (CALCULATED LOAD VALUE, %)

Engine load displayed as a percentage of maximum

possible load. Value is calculated mathematically using

the formula: actual (current) intake air volume ÷

maximum possible intake air volume × 100%

THROTTLE POS (ABSOLUTE THROTTLE POSITION,

%)

When throttle position sensor is at fully closed position,

throttle opening is indicated as 0 – 5% and 90 – 100%

full open position.

O2S SENSOR B1 S1 (HEA TED OXYGEN SENSOR-1,

V)

It indicates output voltage of HO2S-1 installed on

exhaust manifold (pre-catalyst).

�)

TP SENSOR 2 VOLT Ignition switch ON after

warmed up engine Accelerator pedal released

1.4 – 1.8 V

Accelerator pedal depressed

fully 3.58 – 4.76 V

�) APP SENSOR 1

VOLT Ignition switch ON after

warmed up engineAccelerator pedal released

0.5 – 0.9 V

Accelerator pedal depressed

fully 3.277 – 3.915 V

�) APP SENSOR 2

VOLT Ignition switch ON after

warmed up engineAccelerator pedal released

1.3 – 1.7 V

Accelerator pedal depressed

fully 4.077 – 4.715 V

�) ACCEL POSITION Ignition switch ON after

warmed up engine Accelerator pedal released

0 – 5%

Accelerator pedal depressed

fully 90 – 100%

�) THROTTLE TARGET

POSI Ignition switch ON after

warmed up engineAccelerator pedal released

0 – 5%

Accelerator pedal depressed

fully 90 – 100%

�) BATTERY

CURRENT At specified idle speed with no load after warming up

5.0 – 60.0 A

�) GENERATOR CONT

DUTY (GENERATOR

CONTROL DUTY) At specified idle speed with no load after warming up

20.0 – 100.0%

�) GENERATOR FIELD

DUTY (GENERATOR

FIELD COIL DUTY) At spe

cified idle speed with no load after warming up

20.0 – 100.0%

Scan tool data

Vehicle condition Normal condition /

reference values