throttle body system calibration SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 10 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-5 Precautions:

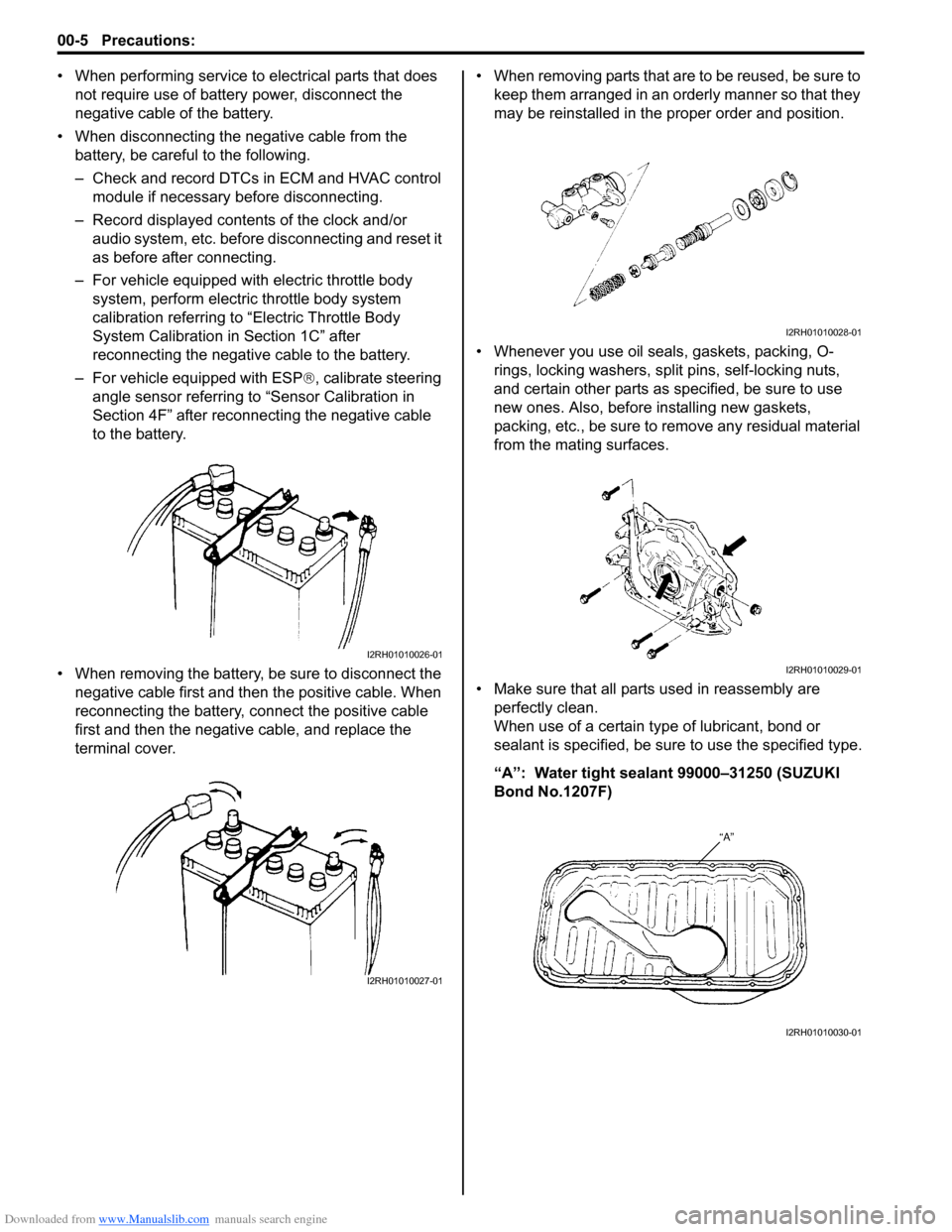

• When performing service to electrical parts that does not require use of battery power, disconnect the

negative cable of the battery.

• When disconnecting the negative cable from the battery, be careful to the following.

– Check and record DTCs in ECM and HVAC control module if necessary before disconnecting.

– Record displayed contents of the clock and/or audio system, etc. before disconnecting and reset it

as before after connecting.

– For vehicle equipped with electric throttle body system, perform electric throttle body system

calibration referring to “Electric Throttle Body

System Calibration in Section 1C” after

reconnecting the negative cable to the battery.

– For vehicle equipped with ESP ®, calibrate steering

angle sensor referring to “Sensor Calibration in

Section 4F” after reconnecting the negative cable

to the battery.

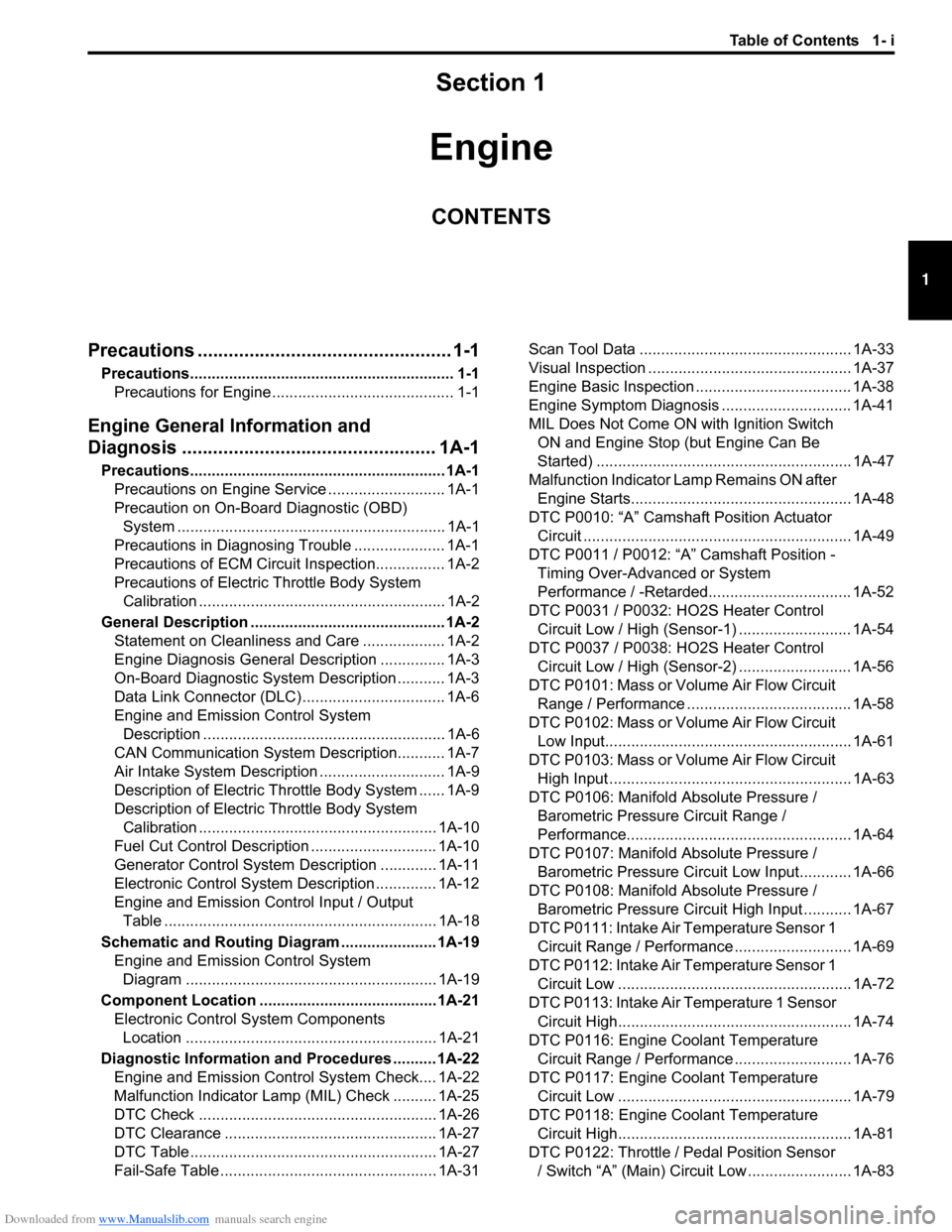

• When removing the battery, be sure to disconnect the negative cable first and then the positive cable. When

reconnecting the battery, connect the positive cable

first and then the negative cable, and replace the

terminal cover. • When removing parts that are to be reused, be sure to

keep them arranged in an orderly manner so that they

may be reinstalled in the proper order and position.

• Whenever you use oil seals, gaskets, packing, O- rings, locking washers, split pins, self-locking nuts,

and certain other parts as specified, be sure to use

new ones. Also, before installing new gaskets,

packing, etc., be sure to remove any residual material

from the mating surfaces.

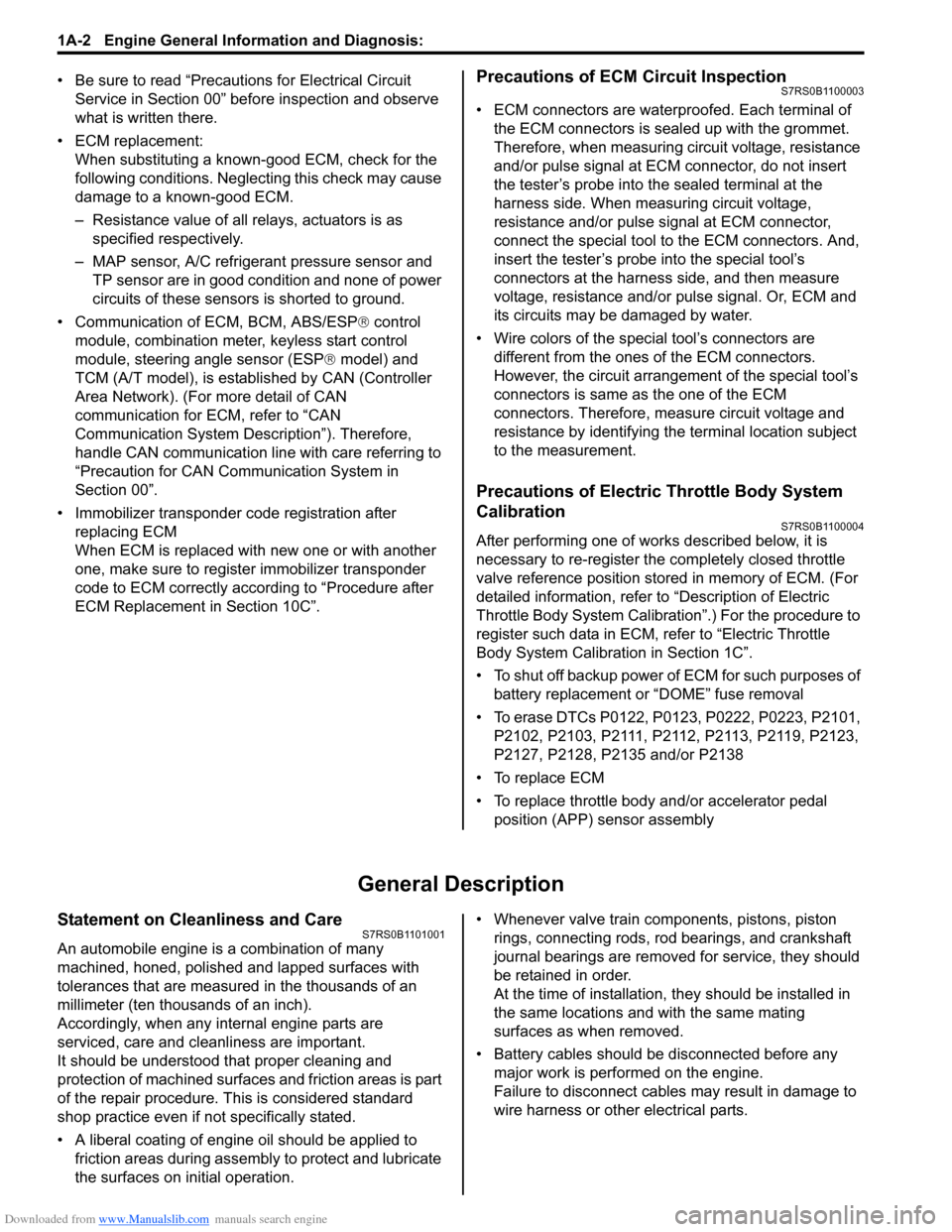

• Make sure that all parts used in reassembly are perfectly clean.

When use of a certain type of lubricant, bond or

sealant is specified, be sure to use the specified type.

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

I2RH01010026-01

I2RH01010027-01

I2RH01010028-01

I2RH01010029-01

I2RH01010030-01

Page 45 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 1- i

1

Section 1

CONTENTS

Engine

Precautions ................................................. 1-1

Precautions............................................................. 1-1

Precautions for Engine .......................................... 1-1

Engine General Information and

Diagnosis ............. .................................... 1A-1

Precautions........................................................... 1A-1

Precautions on Engine Service ........................... 1A-1

Precaution on On-Board Diagnostic (OBD) System .............................................................. 1A-1

Precautions in Diagnosing Trouble ..................... 1A-1

Precautions of ECM Circuit Inspection................ 1A-2

Precautions of Electric Throttle Body System

Calibration ......................................................... 1A-2

General Description ............................................. 1A-2 Statement on Cleanliness and Care ................... 1A-2

Engine Diagnosis General Description ............... 1A-3

On-Board Diagnostic System Description ........... 1A-3

Data Link Connector (DLC) ................................. 1A-6

Engine and Emission Control System Description ........................................................ 1A-6

CAN Communication System Description........... 1A-7

Air Intake System Description ............................. 1A-9

Description of Electric Throttle Body System ...... 1A-9

Description of Electric Throttle Body System Calibration ....................................................... 1A-10

Fuel Cut Control Description ............................. 1A-10

Generator Control System Description ............. 1A-11

Electronic Control System Description .............. 1A-12

Engine and Emission Control Input / Output Table ............................................................... 1A-18

Schematic and Routing Diagram ...................... 1A-19 Engine and Emission Control System Diagram .......................................................... 1A-19

Component Locatio n ......................................... 1A-21

Electronic Control System Components Location .......................................................... 1A-21

Diagnostic Information and Procedures .......... 1A-22 Engine and Emission Control System Check.... 1A-22

Malfunction Indicator Lamp (MIL) Check .......... 1A-25

DTC Check ....................................................... 1A-26

DTC Clearance ................................................. 1A-27

DTC Table ......................................................... 1A-27

Fail-Safe Table ................ .................................. 1A-31 Scan Tool Data ................................................. 1A-33

Visual Inspection ............................................... 1A-37

Engine Basic Inspection .................................... 1A-38

Engine Symptom Diagnosis .............................. 1A-41

MIL Does Not Come ON with Ignition Switch

ON and Engine Stop (but Engine Can Be

Started) ........................................................... 1A-47

Malfunction Indicator Lamp Remains ON after Engine Starts................................................... 1A-48

DTC P0010: “A” Camshaft Position Actuator Circuit .............................................................. 1A-49

DTC P0011 / P0012: “A” Camshaft Position - Timing Over-Advanced or System

Performance / -Retarded................................. 1A-52

DTC P0031 / P0032: HO2S Heater Control Circuit Low / High (Sensor-1) .......................... 1A-54

DTC P0037 / P0038: HO2S Heater Control Circuit Low / High (Sensor-2) .......................... 1A-56

DTC P0101: Mass or Volume Air Flow Circuit Range / Performance ...................................... 1A-58

DTC P0102: Mass or Volume Air Flow Circuit Low Input......................................................... 1A-61

DTC P0103: Mass or Volume Air Flow Circuit High Input ........................................................ 1A-63

DTC P0106: Manifold Absolute Pressure /

Barometric Pressure Circuit Range /

Performance.................................................... 1A-64

DTC P0107: Manifold Absolute Pressure /

Barometric Pressure Circ uit Low Input............ 1A-66

DTC P0108: Manifold Absolute Pressure /

Barometric Pressure Circ uit High Input ........... 1A-67

DTC P0111: Intake Air Temperature Sensor 1 Circuit Range / Performance ........................... 1A-69

DTC P0112: Intake Air Temperature Sensor 1 Circuit Low ...................................................... 1A-72

DTC P0113: Intake Air Temperature 1 Sensor Circuit High...................................................... 1A-74

DTC P0116: Engine Coolant Temperature Circuit Range / Performance ........................... 1A-76

DTC P0117: Engine Coolant Temperature Circuit Low ...................................................... 1A-79

DTC P0118: Engine Coolant Temperature Circuit High...................................................... 1A-81

DTC P0122: Throttle / Pedal Position Sensor / Switch “A” (Main) Circuit Low ........................ 1A-83

Page 47 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 1-iii

EVAP Canister Purge Valve and Its Circuit

Inspection.......................................................... 1B-2

Vacuum Passage Inspection .............................. 1B-3

Vacuum Hose and Purge Valve Chamber Inspection.......................................................... 1B-3

EVAP Canister Purge Valve Inspection .............. 1B-3

EVAP Canister Inspection ... ................................ 1B-4

EGR Valve Removal and Installation .................. 1B-4

EGR Valve Inspection ......................................... 1B-4

PCV Hose Inspection .......................................... 1B-4

PCV Valve Inspection ......................................... 1B-5

Special Tools and Equipmen t ............................. 1B-5

Special Tool ........................................................ 1B-5

Engine Electrical Devices .. ..................... 1C-1

Repair Instructions .............................................. 1C-1

ECM Removal and Installation ............................ 1C-1

MAP Sensor Inspection ...................................... 1C-2

Electric Throttle Body Assembly On-Vehicle

Inspection.......................................................... 1C-2

Electric Throttle Body System Calibration ........... 1C-5

APP Sensor Assembly On-V ehicle Inspection .... 1C-5

APP Sensor Assembly Removal and Installation ......................................................... 1C-5

APP Sensor Assembly Inspection ...................... 1C-6

ECT Sensor Removal and In stallation ................ 1C-6

ECT Sensor Inspection ....................................... 1C-7

HO2S-1 and HO2S-2 Heater On-Vehicle Inspection.......................................................... 1C-7

HO2S-1 and HO2S-2 Removal and Installation ......................................................... 1C-7

CMP Sensor Removal and In stallation ............... 1C-8

Camshaft Position (CMP) Se nsor Inspection ...... 1C-8

CKP Sensor Removal and Installation ................ 1C-9

CKP Sensor Inspection ....................................... 1C-9

Knock Sensor Removal and Installation ........... 1C-10

Main Relay, Fuel Pump Relay and Starting

Motor Control Relay Inspection....................... 1C-10

MAF and IAT Sensor On-Vehicle Inspection .... 1C-11

MAF and IAT Sensor Removal and Installation ....................................................... 1C-11

MAF and IAT Sensor Inspection ....................... 1C-12

Electric Load Current Sensor On-Vehicle Inspection........................................................ 1C-12

Specifications ..................................................... 1C-13

Tightening Torque Specifications ...................... 1C-13

Engine Mechanical ......... ......................... 1D-1

General Description ............................................. 1D-1

Engine Construction Description ......................... 1D-1

Camshaft Position Control (VVT Variable Valve Timing) System Description .................... 1D-2

Diagnostic Information and Procedures ............ 1D-4 Compression Check ............................................ 1D-4

Engine Vacuum Check ....................................... 1D-5

Valve Lash (Clearance) Inspection ..................... 1D-6

Repair Instructions .............................................. 1D-9 Air Cleaner Components ..................................... 1D-9

Air Cleaner Element Removal and Installation .... 1D-9 Air Cleaner Element Ins

pection and Cleaning ..1D-10

Cylinder Head Co ver Removal and

Installation .......................................................1D-10

Throttle Body and Intake Manifold

Components ....................................................1D-12

Throttle Body On-Vehicle Inspection.................1D-13

Electric Throttle Body Assembly Removal and Installation .......................................................1D-13

Throttle Body Cleaning......................................1D-14

Intake Manifold Removal and Installation .........1D-14

Engine Mountings Components ........................1D-16

Engine Assembly Removal and Installation ......1D-17

Timing Chain Cover Components .....................1D-20

Timing Chain Cover Removal and Installation ..1D-21

Timing Chain Cover Inspection .........................1D-23

Oil Control Valve Removal and Installation .......1D-23

Oil Control Valve Inspection ..............................1D-24

Timing Chain and Chain Tensioner Components ....................................................1D-24

Timing Chain and Chain Tensioner Removal and Installation ................................................1D-25

Timing Chain and Chain Tensioner Inspection ..1D-27

Camshaft, Tappet and Shim Components ........1D-28

Camshaft, Tappet and Shim Removal and Installation .......................................................1D-29

Camshaft, Tappet and Shim Inspection ............1D-31

Valves and Cylinder Head Components ...........1D-34

Valves and Cylinder Head Removal and

Installation .......................................................1D-35

Valves and Cylinder Head Disassembly and Assembly.........................................................1D-37

Valves and Valve Guides Inspection.................1D-40

Cylinder Head Inspection . .................................1D-42

Valve Spring Inspection ....................................1D-43

Pistons, Piston Rings , Connecting Rods and

Cylinders Components ....................................1D-44

Pistons, Piston Rings , Connecting Rods and

Cylinders Removal and Installation .................1D-45

Pistons, Piston Rings , Connecting Rods and

Cylinders Disassembly and Assembly ............1D-46

Cylinders, Pistons and Piston Rings Inspection ........................................................1D-47

Piston Pins and Connecting Rods Inspection ...1D-49

Crank Pin and Connecting Rod Bearings Inspection ........................................................1D-50

Main Bearings, Cran kshaft and Cylinder

Block Components ..........................................1D-53

Main Bearings, Cran kshaft and Cylinder

Block Removal and Installa tion .......................1D-54

Crankshaft Inspection .......................................1D-57

Main Bearings Inspection . .................................1D-59

Sensor Plate Inspection ....................................1D-63

Rear Oil Seal Inspection ...................................1D-63

Flywheel Inspection...........................................1D-63

Cylinder Block Inspection ..................................1D-63

Specifications .................... .................................1D-64

Tightening Torque Specifications ......................1D-64

Special Tools and Equipmen t ...........................1D-66

Recommended Service Material .......................1D-66

Special Tool ......................................................1D-66

Page 50 of 1496

Downloaded from www.Manualslib.com manuals search engine 1-1 Precautions:

Engine

Precautions

Precautions

Precautions for EngineS7RS0B1000001

Air Bag Warning

Refer to “Air Bag Warning in Section 00”.

Precautions on Engine Service

Refer to “Precautions on Engine Service in Section 1A”.

Precautions in Diagnosing Trouble

Refer to “Precautions in Diagnosing Trouble in Section 1A”.

Precautions of ECM Circuit Inspection

Refer to “Precautions of ECM Circuit Inspection in Section 1A”.

Precautions on Fuel System Service

Refer to “Precautions on Fuel System Service in Section 1G”.

Precaution for CAN Communication System

Refer to “Precaution for CAN Communication System in Section 00”.

Precautions for Catalytic Converter

Refer to “Precautions for Catalytic Converter in Section 00”.

Precautions for Electrical Circuit Service

Refer to “Precautions for Electric al Circuit Service in Section 00”.

Precautions of Electric Throttle Body System Calibration

Refer to “Precautions of El ectric Throttle Body System Calibration in Section 1A”.

Page 52 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-2 Engine General Information and Diagnosis:

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• ECM replacement: When substituting a known-good ECM, check for the

following conditions. Neglec ting this check may cause

damage to a known-good ECM.

– Resistance value of all relays, actuators is as specified respectively.

– MAP sensor, A/C refrigerant pressure sensor and TP sensor are in good condition and none of power

circuits of these sensors is shorted to ground.

• Communication of ECM, BCM, ABS/ESP ® control

module, combination meter, keyless start control

module, steering angle sensor (ESP ® model) and

TCM (A/T model), is esta blished by CAN (Controller

Area Network). (For more detail of CAN

communication for ECM, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”.

• Immobilizer transponder code registration after

replacing ECM

When ECM is replaced with new one or with another

one, make sure to register immobilizer transponder

code to ECM correctly according to “Procedure after

ECM Replacement in Section 10C”.Precautions of ECM Circuit InspectionS7RS0B1100003

• ECM connectors are waterproofed. Each terminal of the ECM connectors is sealed up with the grommet.

Therefore, when measuring ci rcuit voltage, resistance

and/or pulse signal at ECM connector, do not insert

the tester’s probe into th e sealed terminal at the

harness side. When measuring circuit voltage,

resistance and/or pulse signal at ECM connector,

connect the special tool to the ECM connectors. And,

insert the tester’s probe into the special tool’s

connectors at the harness side, and then measure

voltage, resistance and/or pulse signal. Or, ECM and

its circuits may be damaged by water.

• Wire colors of the special tool’s connectors are different from the ones of the ECM connectors.

However, the circuit arrangement of the special tool’s

connectors is same as the one of the ECM

connectors. Therefore, measure circuit voltage and

resistance by identifying the terminal location subject

to the measurement.

Precautions of Electric Throttle Body System

Calibration

S7RS0B1100004

After performing one of works described below, it is

necessary to re-register the completely closed throttle

valve reference position stored in memory of ECM. (For

detailed information, refer to “Description of Electric

Throttle Body System Calibration”.) For the procedure to

register such data in ECM, refer to “Electric Throttle

Body System Calibration in Section 1C”.

• To shut off backup power of ECM for such purposes of battery replacement or “DOME” fuse removal

• To erase DTCs P0122, P01 23, P0222, P0223, P2101,

P2102, P2103, P2111, P2112, P2113, P2119, P2123,

P2127, P2128, P2135 and/or P2138

• To replace ECM

• To replace throttle body and/or accelerator pedal position (APP) sensor assembly

General Description

Statement on Cleanliness and CareS7RS0B1101001

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousands of an

millimeter (ten thous ands of an inch).

Accordingly, when any internal engine parts are

serviced, care and cleanliness are important.

It should be understood that proper cleaning and

protection of machined surfaces and friction areas is part

of the repair procedure. This is considered standard

shop practice even if not specifically stated.

• A liberal coating of engine oil should be applied to friction areas during assembly to protect and lubricate

the surfaces on initial operation. • Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

• Battery cables should be disconnected before any major work is performed on the engine.

Failure to disconnect cables may result in damage to

wire harness or other electrical parts.

Page 60 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-10 Engine General Information and Diagnosis:

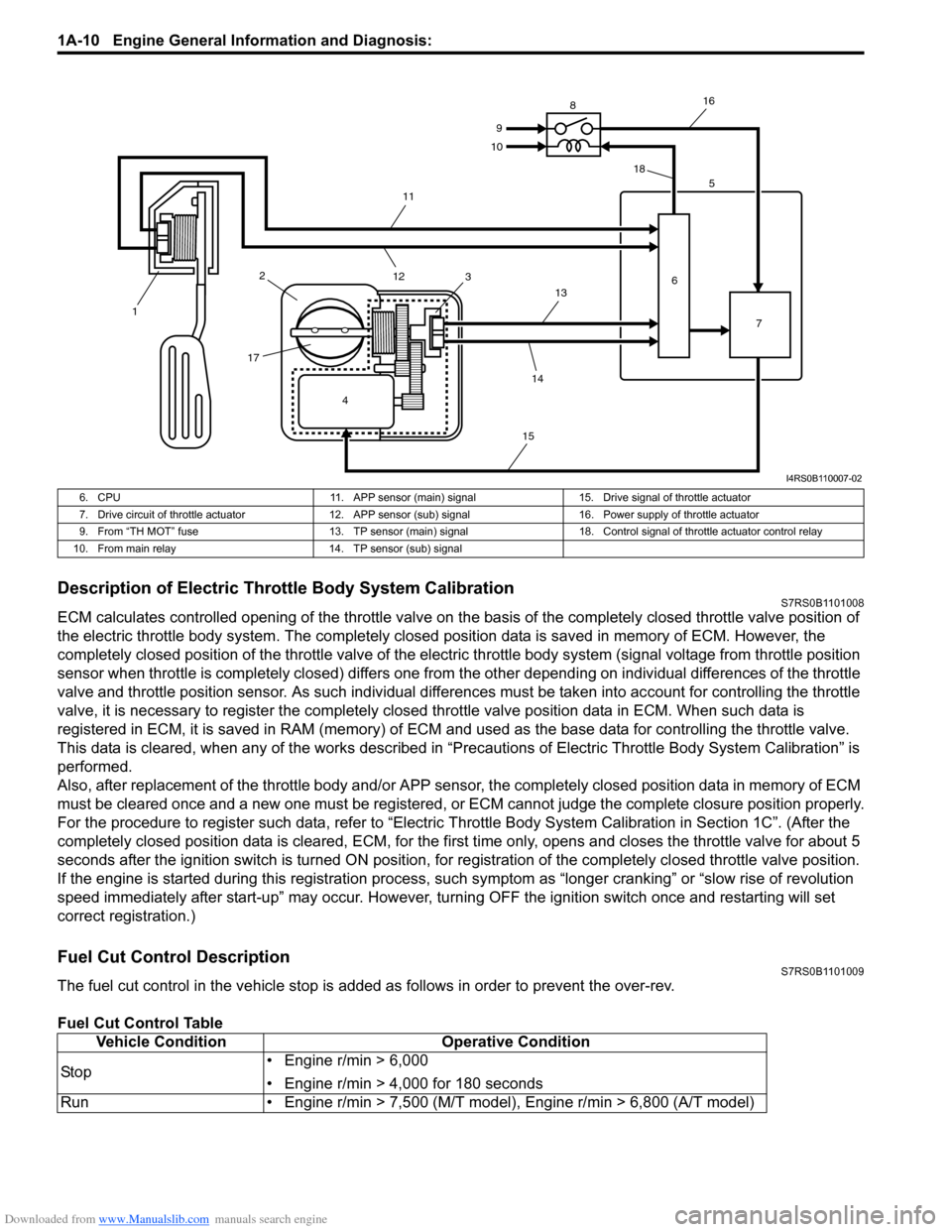

Description of Electric Throttle Body System CalibrationS7RS0B1101008

ECM calculates controlled opening of the throttle valve on the basis of the completely closed throttle valve position of

the electric throttle body system. The completely closed position data is saved in memory of ECM. However, the

completely closed position of the throttle valve of the electric throttle body system (signal voltage from throttle position

sensor when throttle is completely closed) differs one from the other depending on individual differences of the throttle

valve and throttle position sensor. As such individual diff erences must be taken into account for controlling the throttle

valve, it is necessary to register the completely closed throttle valve position data in ECM. When such data is

registered in ECM, it is sa ved in RAM (memory) of ECM and used as the base data for controlling the throttle valve.

This data is cleared, when any of the works described in “Preca utions of Electric Throttle Body System Calibration” is

performed.

Also, after replacement of the throttle body and/or APP sensor , the completely closed position data in memory of ECM

must be cleared once and a new one must be registered, or ECM cannot judge the complete closure position properly.

For the procedure to register such data, refer to “Electric Throttle Body System Calibration in Section 1C”. (After the

completely closed position data is cleared , ECM, for the first time only, opens and closes the throttle valve for about 5

seconds after the ignition switch is turned ON position, for re gistration of the completely closed throttle valve position.

If the engine is started during this registration process, such symptom as “longe r cranking” or “slow rise of revolution

speed immediately after start-up” may occur. However, turning OFF the ignition switch once and restarting will set

correct registration.)

Fuel Cut Control DescriptionS7RS0B1101009

The fuel cut control in the vehicle stop is add ed as follows in order to prevent the over-rev.

Fuel Cut Control Table

4

1

2

17 3 5

6 7

8

9

10

11

12 13

14

15 16

18

I4RS0B110007-02

6. CPU 11. APP sensor (main) signal15. Drive signal of throttle actuator

7. Drive circuit of throttle actuator 12. APP sensor (sub) signal 16. Power supply of throttle actuator

9. From “TH MOT” fuse 13. TP sensor (main) signal 18. Control signal of throttle actuator control relay

10. From main relay 14. TP sensor (sub) signal

Vehicle ConditionOperative Condition

Sto p • Engine r/min > 6,000

• Engine r/min > 4,000 for 180 seconds

Run • Engine r/min > 7,500 (M/T model), Engine r/min > 6,800 (A/T model)

Page 274 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-2 Engine Electrical Devices:

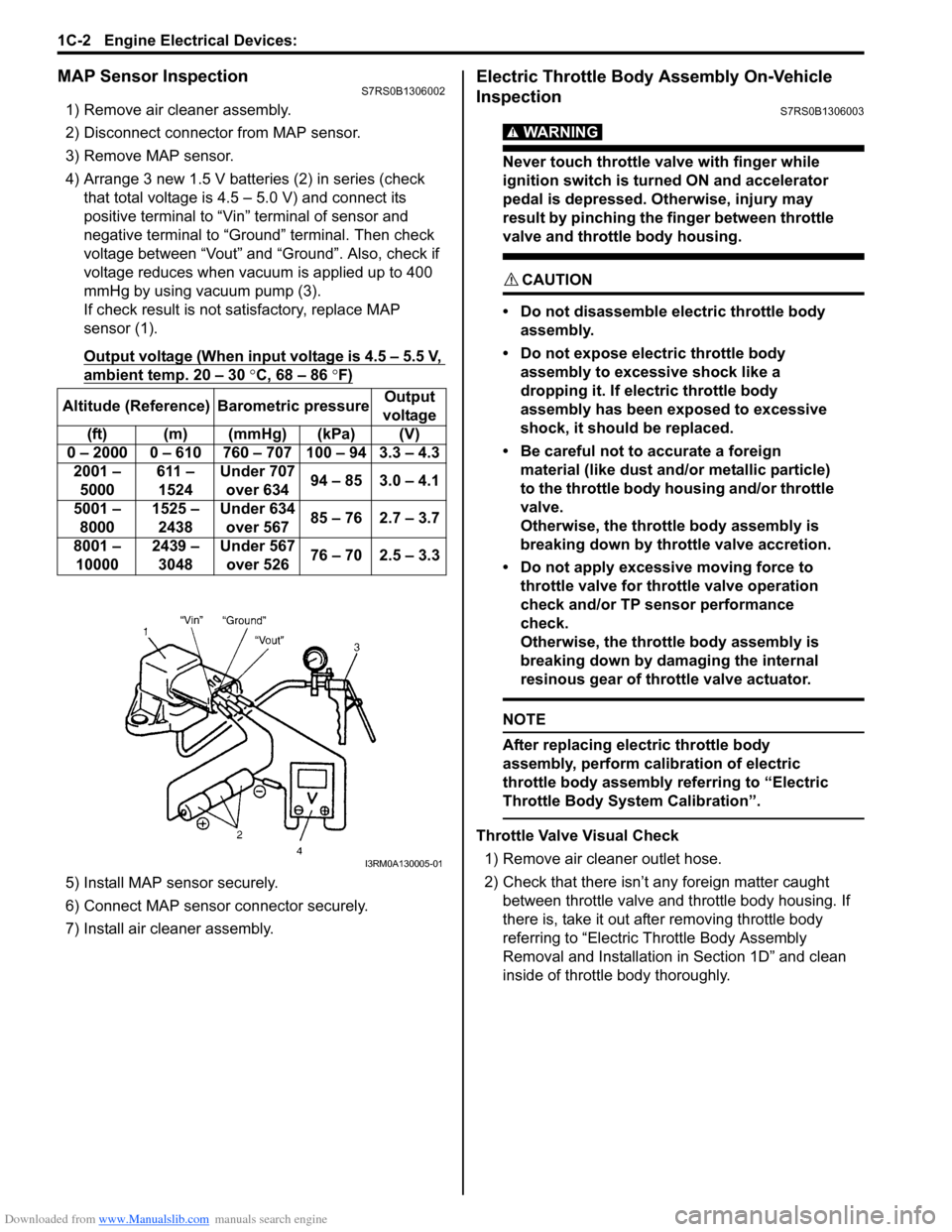

MAP Sensor InspectionS7RS0B1306002

1) Remove air cleaner assembly.

2) Disconnect connector from MAP sensor.

3) Remove MAP sensor.

4) Arrange 3 new 1.5 V batteries (2) in series (check that total voltage is 4.5 – 5.0 V) and connect its

positive terminal to “Vin ” terminal of sensor and

negative terminal to “Ground” terminal. Then check

voltage between “Vout” and “Ground”. Also, check if

voltage reduces when vacuum is applied up to 400

mmHg by using vacuum pump (3).

If check result is not satisfactory, replace MAP

sensor (1).

Output voltage (When input voltage is 4.5 – 5.5 V,

ambient temp. 20 – 30 °C, 68 – 86 °F)

5) Install MAP sensor securely.

6) Connect MAP sensor connector securely.

7) Install air cleaner assembly.

Electric Throttle Body Assembly On-Vehicle

Inspection

S7RS0B1306003

WARNING!

Never touch throttle valve with finger while

ignition switch is turned ON and accelerator

pedal is depressed. Otherwise, injury may

result by pinching the finger between throttle

valve and throttle body housing.

CAUTION!

• Do not disassemble electric throttle body assembly.

• Do not expose electric throttle body assembly to excessive shock like a

dropping it. If electric throttle body

assembly has been exposed to excessive

shock, it should be replaced.

• Be careful not to accurate a foreign material (like dust and/ or metallic particle)

to the throttle body housing and/or throttle

valve.

Otherwise, the throttle body assembly is

breaking down by throttle valve accretion.

• Do not apply excessive moving force to throttle valve for thro ttle valve operation

check and/or TP sensor performance

check.

Otherwise, the throttle body assembly is

breaking down by damaging the internal

resinous gear of throttle valve actuator.

NOTE

After replacing electric throttle body

assembly, perform calibration of electric

throttle body assembly referring to “Electric

Throttle Body System Calibration”.

Throttle Valve Visual Check

1) Remove air cleaner outlet hose.

2) Check that there isn’t any foreign matter caught between throttle valve and throttle body housing. If

there is, take it out after removing throttle body

referring to “Electric Th rottle Body Assembly

Removal and Installation in Section 1D” and clean

inside of throttle body thoroughly.

Altitude (Reference) Barometric pressure

Output

voltage

(ft) (m) (mmHg) (kPa) (V)

0 – 2000 0 – 610 760 – 707 100 – 94 3.3 – 4.3 2001 – 5000 611 –

1524 Under 707

over 634 94 – 85 3.0 – 4.1

5001 – 8000 1525 –

2438 Under 634

over 567 85 – 76 2.7 – 3.7

8001 – 10000 2439 –

3048 Under 567

over 526 76 – 70 2.5 – 3.3

I3RM0A130005-01

Page 277 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-5

Electric Throttle Body System CalibrationS7RS0B1306004

NOTE

If working the service described under the

“Precautions of Electric Throttle Body

System Calibration in Section 1A” perform

following steps for electric throttle body

system calibration.

1) If electric throttle body assembly and/or APP sensor

assembly are replaced, perform following steps.

a) Disconnect negative cable at battery for 20 seconds or more for the purpose of clearing

calibration data of closed throttle position from

memory in ECM.

b) Connect negative cable to battery.

2) Keep ignition switch at ON position for 5 seconds or more without running engine.

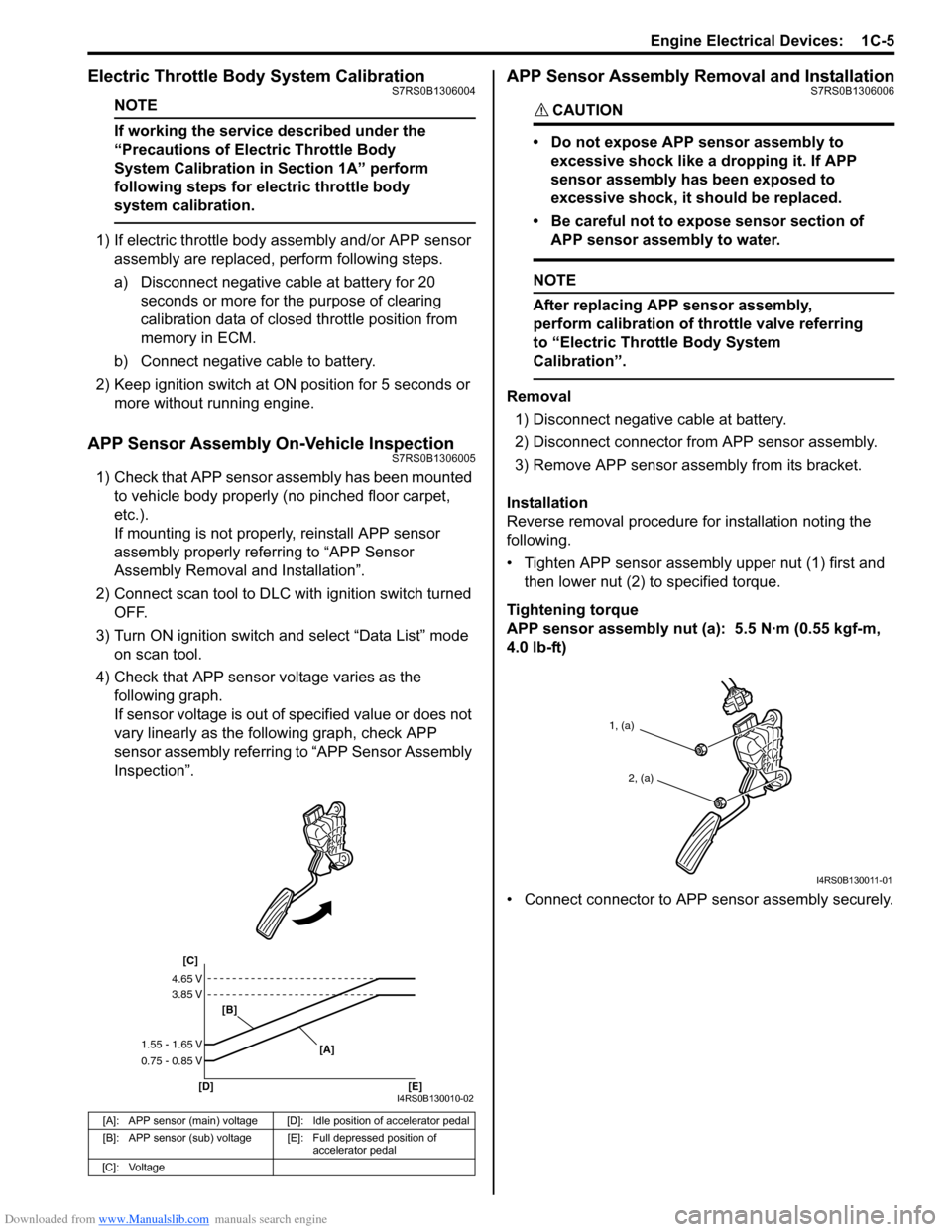

APP Sensor Assembly On-Vehicle InspectionS7RS0B1306005

1) Check that APP sensor a ssembly has been mounted

to vehicle body properly (no pinched floor carpet,

etc.).

If mounting is not pro perly, reinstall APP sensor

assembly properly refe rring to “APP Sensor

Assembly Removal and Installation”.

2) Connect scan tool to DLC with ignition switch turned OFF.

3) Turn ON ignition switch and select “Data List” mode on scan tool.

4) Check that APP sensor voltage varies as the following graph.

If sensor voltage is out of specified value or does not

vary linearly as the fo llowing graph, check APP

sensor assembly referring to “APP Sensor Assembly

Inspection”.

APP Sensor Assembly Removal and InstallationS7RS0B1306006

CAUTION!

• Do not expose APP sensor assembly to

excessive shock like a dropping it. If APP

sensor assembly has been exposed to

excessive shock, it should be replaced.

• Be careful not to expose sensor section of APP sensor assembly to water.

NOTE

After replacing APP sensor assembly,

perform calibration of th rottle valve referring

to “Electric Throttle Body System

Calibration”.

Removal

1) Disconnect negative cable at battery.

2) Disconnect connector from APP sensor assembly.

3) Remove APP sensor asse mbly from its bracket.

Installation

Reverse removal procedure for installation noting the

following.

• Tighten APP sensor assembly upper nut (1) first and then lower nut (2) to specified torque.

Tightening torque

APP sensor assembly nut (a): 5.5 N·m (0.55 kgf-m,

4.0 lb-ft)

• Connect connector to APP sensor assembly securely.

[A]: APP sensor (main) voltage [D]: Idle position of accelerator pedal

[B]: APP sensor (sub) voltage [E]: Full depressed position of

accelerator pedal

[C]: Voltage

[C]

[B]

[D] [E] [A]

4.65 V

3.85 V

1.55 - 1.65 V

0.75 - 0.85 V

I4RS0B130010-02

1, (a)

2, (a)

I4RS0B130011-01

Page 298 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-13 Engine Mechanical:

Throttle Body On-Vehicle InspectionS7RS0B1406006

Check electric throttle body assembly referring to

“Throttle Valve Operation Check” and “Electric Throttle

Body Assembly Operation Check” under “Electric

Throttle Body Assembly On-Vehicle Inspection in

Section 1C”.

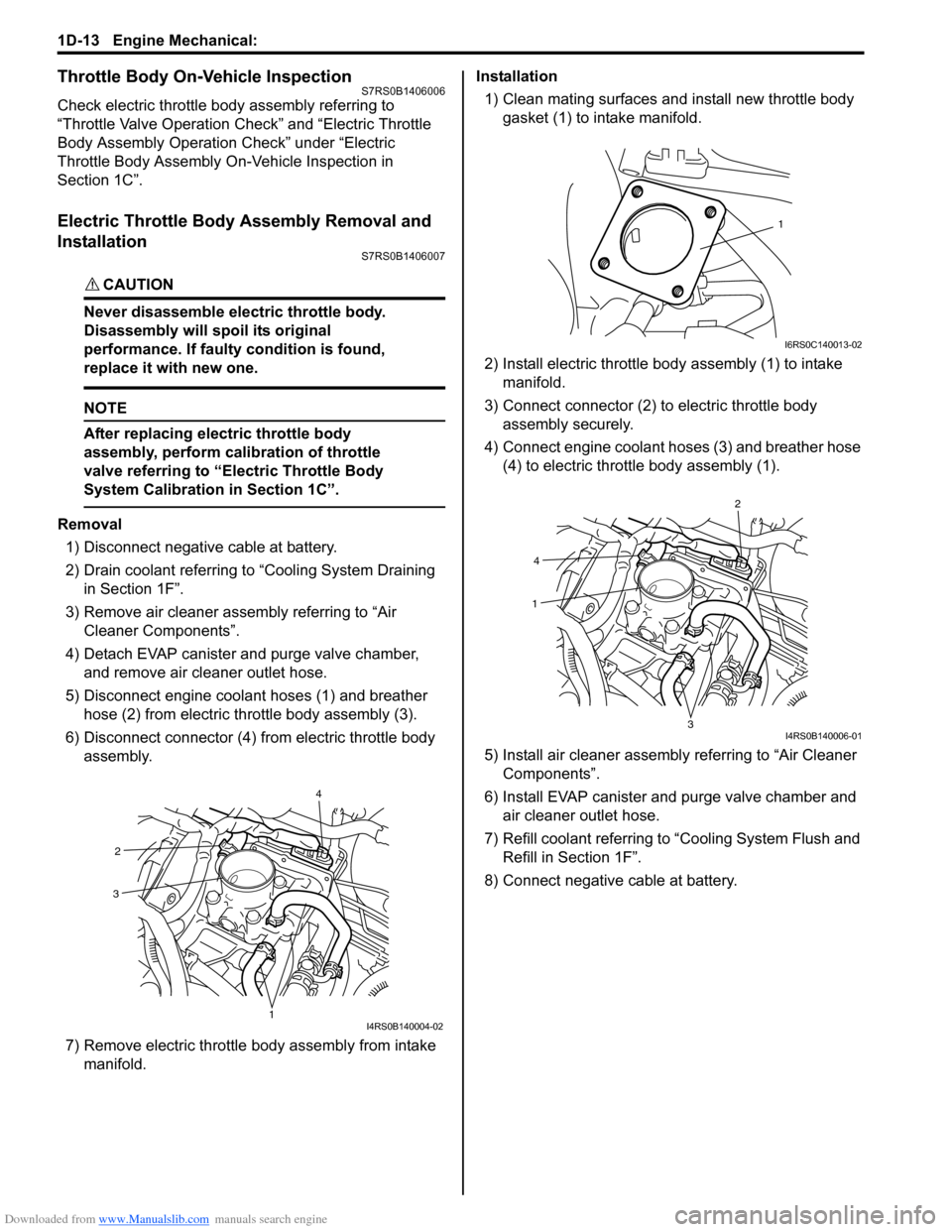

Electric Throttle Body Assembly Removal and

Installation

S7RS0B1406007

CAUTION!

Never disassemble electric throttle body.

Disassembly will spoil its original

performance. If faulty condition is found,

replace it with new one.

NOTE

After replacing electric throttle body

assembly, perform calibration of throttle

valve referring to “Electric Throttle Body

System Calibration in Section 1C”.

Removal

1) Disconnect negative cable at battery.

2) Drain coolant referring to “Cooling System Draining in Section 1F”.

3) Remove air cleaner assembly referring to “Air Cleaner Components”.

4) Detach EVAP canister and purge valve chamber, and remove air cleaner outlet hose.

5) Disconnect engine coolant hoses (1) and breather hose (2) from electric throttle body assembly (3).

6) Disconnect connector (4) from electric throttle body assembly.

7) Remove electric throttle body assembly from intake

manifold. Installation

1) Clean mating surfaces and install new throttle body gasket (1) to intake manifold.

2) Install electric throttle bo dy assembly (1) to intake

manifold.

3) Connect connector (2) to electric throttle body assembly securely.

4) Connect engine coolant hoses (3) and breather hose (4) to electric thrott le body assembly (1).

5) Install air cleaner assembly referring to “Air Cleaner

Components”.

6) Install EVAP canister and purge valve chamber and air cleaner outlet hose.

7) Refill coolant referring to “Cooling System Flush and

Refill in Section 1F”.

8) Connect negative cable at battery.

2

4

3

1I4RS0B140004-02

1

I6RS0C140013-02

4

2

1

3I4RS0B140006-01

Page 302 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-17 Engine Mechanical:

Engine Assembly Removal and InstallationS7RS0B1406011

NOTE

After replacing electric throttle body

assembly, perform calibration of throttle

valve referring to “Electric Throttle Body

System Calibration in Section 1C”.

Removal1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure in Section 1G”.

2) Disconnect negative and pos itive cable at battery.

3) Remove battery and tray.

4) Remove engine hood after disconnecting windshield washer hose.

5) Remove right and left side engine under covers.

6) Remove A/C compressor belt by referring to “Compressor Drive Belt Remo val and Installation in

Section 7B” or “Compressor Drive Belt Removal and

Installation in Section 7B”.

7) Drain engine oil, transaxle oil and coolant.

8) Remove cowl top plate referring to “Cowl Top Components in Section 9K”.

9) Remove air cleaner assembly referring to “Air Cleaner Components”.

10) With hose connected, detach A/C compressor from its bracket (A/C model) referring to “Compressor

Assembly Removal and Installation in Section 7B” or

“Compressor Assembly Removal and Installation in

Section 7B”.

CAUTION!

Suspend removed A/C compressor at a place

where no damage will be caused during

removal and installation of engine assembly.

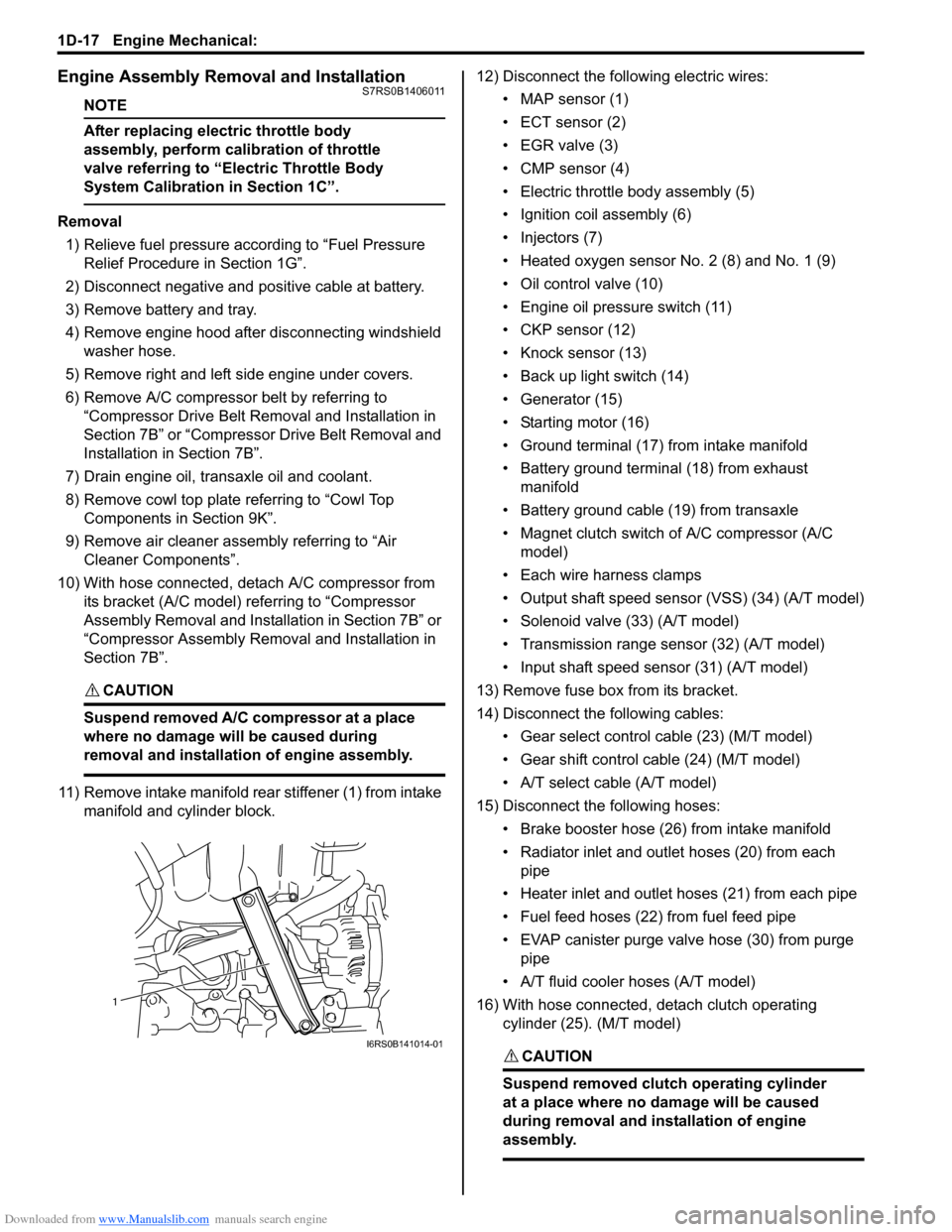

11) Remove intake manifold rear stiffener (1) from intake manifold and cylinder block. 12) Disconnect the following electric wires:

• MAP sensor (1)

• ECT sensor (2)

•EGR valve (3)

• CMP sensor (4)

• Electric throttle body assembly (5)

• Ignition coil assembly (6)

• Injectors (7)

• Heated oxygen sensor No. 2 (8) and No. 1 (9)

• Oil control valve (10)

• Engine oil pressure switch (11)

• CKP sensor (12)

• Knock sensor (13)

• Back up light switch (14)

• Generator (15)

• Starting motor (16)

• Ground terminal (17) from intake manifold

• Battery ground terminal (18) from exhaust manifold

• Battery ground cable (19) from transaxle

• Magnet clutch switch of A/C compressor (A/C model)

• Each wire harness clamps

• Output shaft speed sensor (VSS) (34) (A/T model)

• Solenoid valve (33) (A/T model)

• Transmission range sensor (32) (A/T model)

• Input shaft speed sensor (31) (A/T model)

13) Remove fuse box from its bracket.

14) Disconnect the following cables: • Gear select control cable (23) (M/T model)

• Gear shift control cable (24) (M/T model)

• A/T select cable (A/T model)

15) Disconnect the following hoses: • Brake booster hose (26) from intake manifold

• Radiator inlet and outlet hoses (20) from each pipe

• Heater inlet and outlet hoses (21) from each pipe

• Fuel feed hoses (22) from fuel feed pipe

• EVAP canister purge valve hose (30) from purge pipe

• A/T fluid cooler hoses (A/T model)

16) With hose connected, detach clutch operating cylinder (25). (M/T model)

CAUTION!

Suspend removed clutch operating cylinder

at a place where no damage will be caused

during removal and installation of engine

assembly.

1

I6RS0B141014-01