trailer SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 32 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-2 Maintenance and Lubrication:

NOTE

• “R”: Replace or change

• “I”: Inspect and correct, replace or lubricate if necessary

• For spark plugs, replace every 50,000 km if the local law requires.

• Periodic replacement of fuel filter is not necessary if it is not instructed in “Periodic Maintenance Schedule” section of the Owner’s manual. The scheduled maintenance varies depending on the

vehicle specification.

Maintenance Recommended under Severe Driving ConditionsS7RS0B0205002

If the vehicle is usually used under the conditions corres ponding to any severe condition code given below, IT IS

RECOMMENDED that applicable maintenance operation be per formed at the particular interval as shown in the

following table.

Severe condition code:

A: Repeated short trips

B: Driving on rough and/or muddy roads

C: Driving on dusty roads

D: Driving in extremely cold weather and/or salted roads

E: Repeated short trips in extremely cold weather

F: Leaded fuel use

G: – – – – –

H: Towing a trailer (if admitted) Automatic transaxle fluid

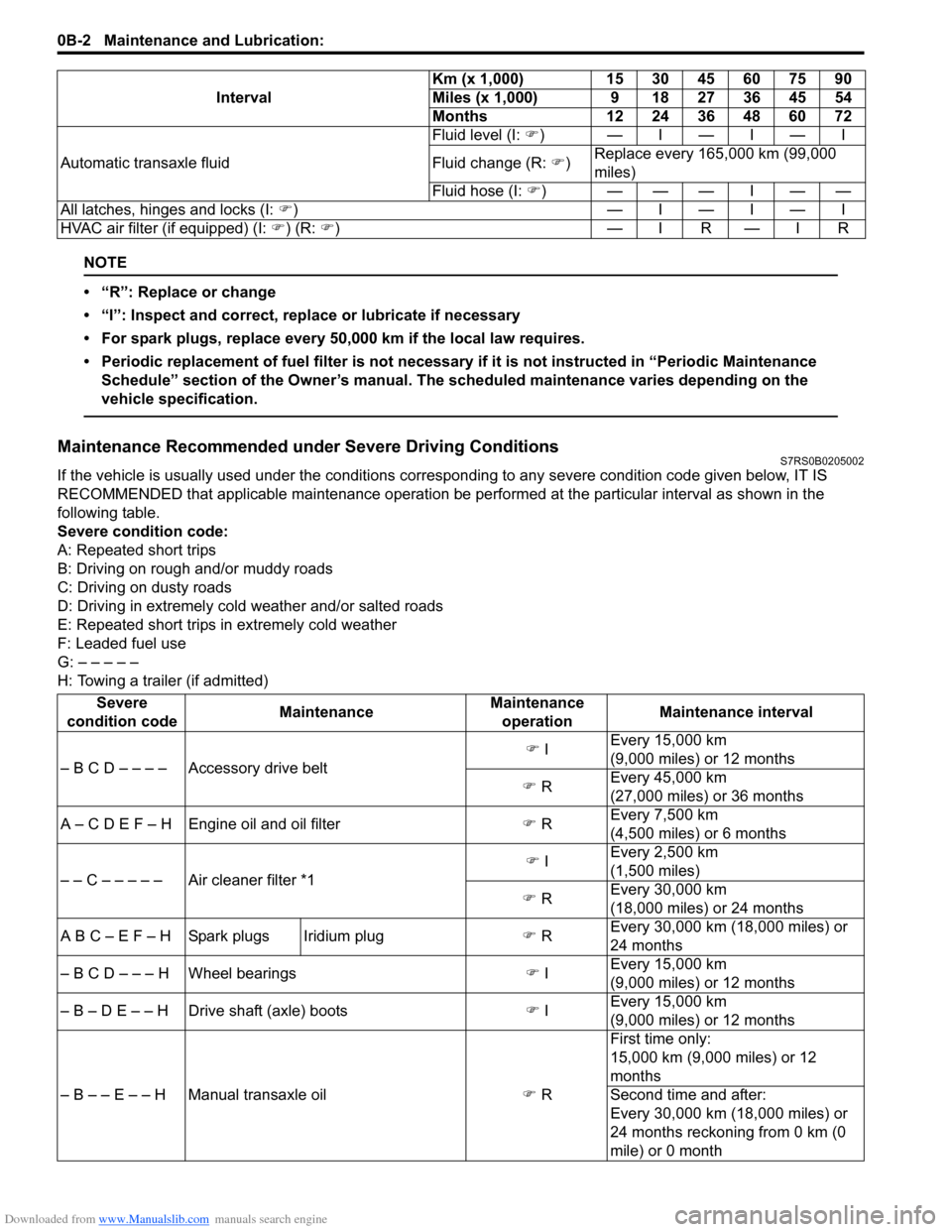

Fluid level (I:

�)) —I—I—I

Fluid change (R: �)) Replace every 165,000 km (99,000

miles)

Fluid hose (I: �))———I——

All latches, hinges and locks (I: �)) —I—I—I

HVAC air filter (if equipped) (I: �) ) (R: �))— IR — IR

Interval

Km (x 1,000)

15 30 45 60 75 90

Miles (x 1,000) 9 18 27 36 45 54

Months 12 24 36 48 60 72

Severe

condition code MaintenanceMaintenance

operation Maintenance interval

– B C D – – – – Accessory drive belt �)

I Every 15,000 km

(9,000 miles) or 12 months

�) R Every 45,000 km

(27,000 miles) or 36 months

A – C D E F – H Engine oil and oil filter �) R Every 7,500 km

(4,500 miles) or 6 months

– – C – – – – – Air cleaner filter *1 �)

I Every 2,500 km

(1,500 miles)

�) R Every 30,000 km

(18,000 miles) or 24 months

A B C – E F – H Spark plugs Iridium plug �) R Every 30,000 km (18,000 miles) or

24 months

– B C D – – – H Wheel bearings �) I Every 15,000 km

(9,000 miles) or 12 months

– B – D E – – H Drive shaft (axle) boots �) I Every 15,000 km

(9,000 miles) or 12 months

– B – – E – – H Manual transaxle oil �) R First time only:

15,000 km (9,000 miles) or 12

months

Second time and after:

Every 30,000 km (18,000 miles) or

24 months reckoning from 0 km (0

mile) or 0 month

Page 733 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-89

A/T Fluid Level CheckS7RS0B5106002

CAUTION!

Do not use any fluid other than the specified

ATF. Use of any fluid other than the specified

ATF may cause juddering or some other

faulty condition to occur.

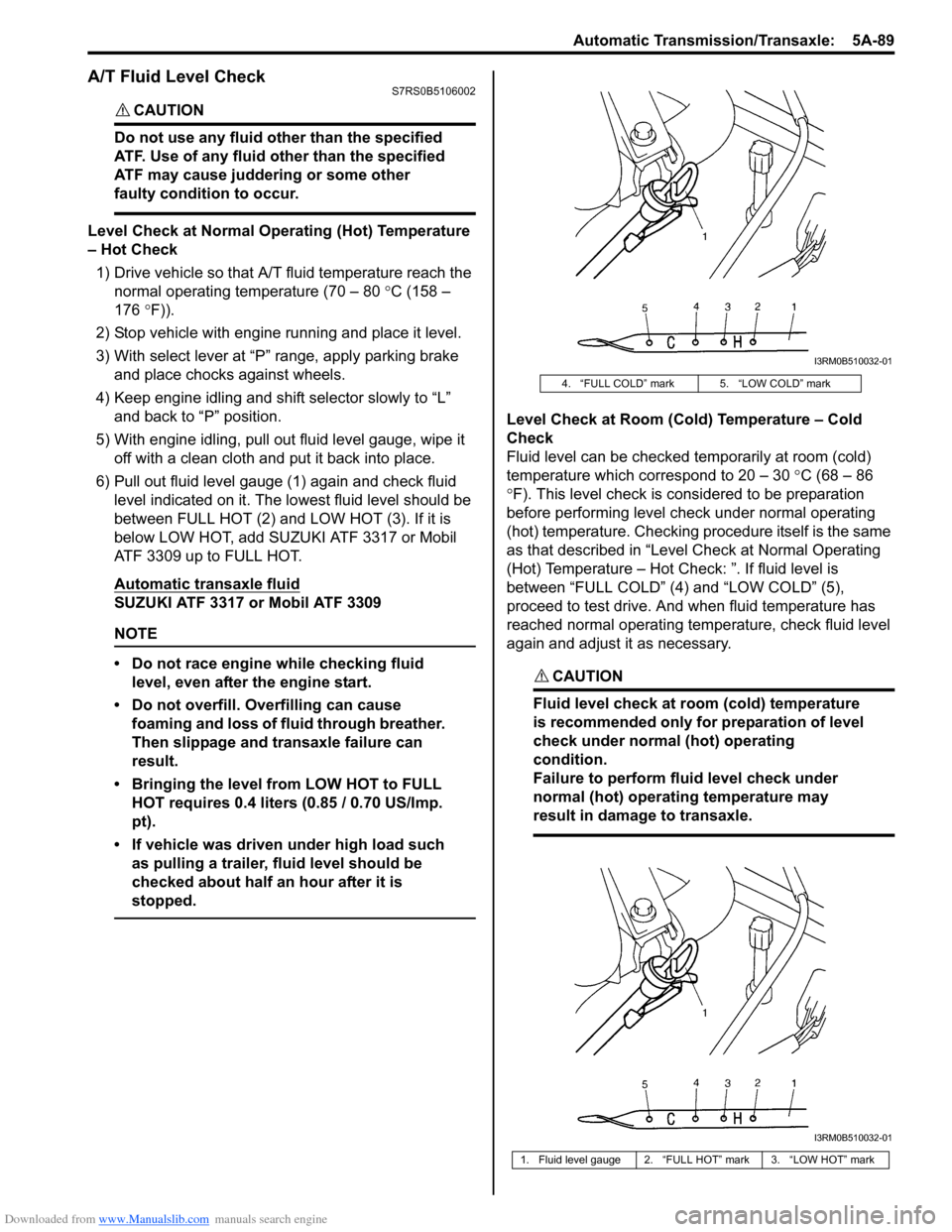

Level Check at Normal Operating (Hot) Temperature

– Hot Check1) Drive vehicle so that A/T fluid temperature reach the

normal operating temperature (70 – 80 °C (158 –

176 °F)).

2) Stop vehicle with engine running and place it level.

3) With select lever at “P” range, apply parking brake and place chocks against wheels.

4) Keep engine idling and shift selector slowly to “L” and back to “P” position.

5) With engine idling, pull out fluid level gauge, wipe it off with a clean cloth and put it back into place.

6) Pull out fluid level gauge (1) again and check fluid level indicated on it. The lo west fluid level should be

between FULL HOT (2) and LOW HOT (3). If it is

below LOW HOT, add SUZUKI ATF 3317 or Mobil

ATF 3309 up to FULL HOT.

Automatic transaxle fluid

SUZUKI ATF 3317 or Mobil ATF 3309

NOTE

• Do not race engine while checking fluid level, even after the engine start.

• Do not overfill. Overfilling can cause foaming and loss of fluid through breather.

Then slippage and transaxle failure can

result.

• Bringing the level from LOW HOT to FULL HOT requires 0.4 liters (0.85 / 0.70 US/Imp.

pt).

• If vehicle was driven under high load such as pulling a trailer, fluid level should be

checked about half an hour after it is

stopped.

Level Check at Room (Cold) Temperature – Cold

Check

Fluid level can be checked temporarily at room (cold)

temperature which correspond to 20 – 30 °C (68 – 86

° F). This level check is considered to be preparation

before performing level check under normal operating

(hot) temperature. Checking procedure itself is the same

as that described in “Level Check at Normal Operating

(Hot) Temperature – Hot Check: ”. If fluid level is

between “FULL COLD” (4) and “LOW COLD” (5),

proceed to test drive. And when fluid temperature has

reached normal operating temp erature, check fluid level

again and adjust it as necessary.

CAUTION!

Fluid level check at room (cold) temperature

is recommended only for preparation of level

check under normal (hot) operating

condition.

Failure to perform fluid level check under

normal (hot) operating temperature may

result in damage to transaxle.

4. “FULL COLD” mark 5. “LOW COLD” mark

1. Fluid level gauge 2. “FULL HOT” mark 3. “LOW HOT” mark

I3RM0B510032-01

I3RM0B510032-01