shift to P SUZUKI SWIFT 2017 5.G Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2017, Model line: SWIFT, Model: SUZUKI SWIFT 2017 5.GPages: 336, PDF Size: 6.24 MB

Page 184 of 336

6-1VEHICLE LOADING AND TOWING

74LH0-74E

Vehicle LoadingYour vehicle was designed for specific

weight capacities. The weight capacities of

your vehicle are indicated by the Gross

Vehicle Weight Rating (GVWR) and the

Gross Axle Weight Rating (GAWR, front

and rear). The GVWR and GAWR (front

and rear) are listed in the “SPECIFICA-

TIONS” section.

GVWR – Maximum permissible overall

weight of the fully loaded vehicle (including

all the occupants, accessories and cargo

plus the trailer nose weight if towing a

trailer).

GAWR – (Front and Rear) Maximum per-

missible weight on an individual axle.

Actual weight of the loaded vehicle and

actual loads at the front and rear axles can

only be determined by weighing the vehi-

cle. Compare these weights to the GVWR

and GAWR (front and rear). If the gross

vehicle weight or the load on either axle

exceeds these ratings, you must remove

enough weight to bring the load down to

the rated capacity.

Trailer TowingYour MARUTI SUZUKI was originally

designed to carry people and a normal

amount of cargo, not to tow a trailer.

MARUTI SUZUKI does not recommend

you use your vehicle to tow a trailer. Tow-

ing a trailer can adversely affect handling,

durability,

Some countries have regulations which

specifically allow trailer towing up to a

specified maximum trailer weight (regis-

tered or statutory towing capacity, which-

ever is smaller); vehicles sold in these

countries can be used to tow a light trailer,

provided the trailer does not exceed the

maximum trailer weight specified in the

country’s regulations.

If you use your MARUTI SUZUKI to tow a

trailer, you should always observe the

requirements and recommendations in this

section. If you intend to tow a trailer, it is

essential to select a trailer and trailer tow-

ing equipment which are compatible. A

reputable towing specialist can help you.

and fuel economy.

WA R N I N G

Never overload your vehicle. The

gross vehicle weight (sum of the

weights of the vehicle, all the occu-

pants, accessories, cargo plus trailer

nose weight if towing a trailer) must

never exceed the Gross Vehicle

Weight Rating (GVWR). In addition,

never distribute a load so that the

weight on either the front or rear axle

exceeds the Gross Axle Weight Rat-

ing (GAWR).

WA R N I N G

Always distribute cargo evenly. To

avoid personal injury or damage to

your vehicle, always secure cargo to

prevent it from shifting if the vehicle

moves suddenly. Place heavier

objects on the floor and as far for-

ward in the cargo area as possible.

Never pile cargo higher than the top

of the seat backs.

NOTICE

Trailer towing puts additional stress

on the engine, drive train, and brakes

of your vehicle. Never tow a trailer

during the first 960 km (600 miles) of

vehicle operation.

Vehicle Loading: 11

Trailer Towing: 5, 11

Page 187 of 336

6-4

VEHICLE LOADING AND TOWING

74LH0-74E

60A186

Towing Your VehicleYour vehicle may be towed behind another

vehicle (such as a motor-home), provided

your vehicle is 2 wheel drive (2WD) and

you use the proper towing method speci-

fied for your vehicle.

Use the towing instruction table to select

the proper towing method for your vehicle,and carefully follow the corresponding

instructions. Be sure to use proper towing

equipment designed for recreational tow-

ing and make sure that towing speed does

not exceed 90 km/h (55 mph)

TOWING INSTRUCTION TABLE

WA R N I N G

Be careful when overtaking other

vehicles. Be sure to allow enough

room for your trailer before you

change lanes, and signal well in

advance. Slow down and change into a lower

gear before you reach long or steep

downhill grades. It is hazardous to

attempt changing down while you

are descending a hill.

Avoid “riding” the brakes. This

could cause the brakes to overheat

resulting in reduced braking effi-

ciency. Use engine braking as

much as possible.

Because of the added trailer

weight, your engine may overheat

on hot days when going up long or

steep hills. Pay attention to your

engine temperature gauge. If it indi-

cates overheating, pull off the road

and stop in a safe place. Refer to “If

the Engine Overheats” in “EMER-

GENCY SERVICE” section.

WA R N I N G

When parking your vehicle and con-

nected trailer, always use the follow-

ing procedure:

1) Apply the vehicle’s brakes firmly.

2) Have another person place wheel

chocks under the wheels of the

vehicle and the trailer while you

are holding the brakes.

3) Slowly release the brakes until the

wheel chocks absorb the load.

4) Fully engage the parking brake.

5) Change the manual transmission

into reverse or first gear and turn

off the engine.

When starting out after parking:

1) Depress the clutch and start the

engine.

2) Change into gear, release the

parking brake, and slowly pull

away from the chocks.

3) Stop, apply the brakes firmly and

hold them.

4) Have another person remove the

chocks.

WA R N I N G

When you tow your vehicle, follow

the instructions below to avoid acci-

dents and damage to your vehicle. In

addition, be sure to observe govern-

ment and local requirements regard-

ing vehicle lighting and trailer hitches

or tow bars.

DRIVE

TRAINTRANS

MISSIONTOWING

METHOD

2WD M/T

(MANUAL)A/B

2WD A/T

(AUTOMATIC)A

2WD AGS

(AUTO GEAR

SHIFT)A/B

Page 188 of 336

6-5VEHICLE LOADING AND TOWING

74LH0-74E

A: 2WD VEHICLES WITH MANUAL

TRANSAXLE OR AUTOMATIC

TRANSAXLE OR AUTO GEAR

SHIFT1) Secure the front wheels on a towing

dolly according to the instructions pro-

vided by the dolly manufacturer.

2) Release the parking brake.

NOTICE

The steering column is not strong

enough to withstand shocks trans-

mitted from the front wheels during

towing. Always unlock the steering

wheel before towing. TOWING METHOD AFROM THE FRONT:

FRONT WHEELS ON A DOLLY

AND REAR WHEELS ON THE GROUND

B: 2WD VEHICLES WITH MANUAL TRANSAXLE OR AUTO GEAR SHIFT1) Shift the manual transaxle lever into neutral.

2) Turn the ignition key to the “ACC” position or change the ignition mode to the “ACC” to

unlock the steering wheel.

3) Release the parking brake.

ACC

N

TOWING METHOD BFROM THE FRONT:

FRONT WHEELS ON THE GROUND

Page 189 of 336

6-6

VEHICLE LOADING AND TOWING

74LH0-74E

NOTICE

After shifting the Auto Gear Shift

lever to the “N” position, always

check the gear position indicator in

the instrument cluster shows the “N”

position to make sure that the

transaxle is disengaged.

If the transaxle cannot be put in neu-

tral, turn the key from the “LOCK” to

the “ON” position, and move the

Auto Gear Shift lever from “N” to “D”,

“M” or “R”, then back to “N” again.

Then turn the key from the “ON” to

the “LOCK” position.

These procedures may help put the

transaxle in neutral. If the transaxle

still cannot be put in neutral, you can-

not tow the vehicle without using a

towing dolly.

Page 195 of 336

7-4

INSPECTION AND MAINTENANCE

74LH0-74E

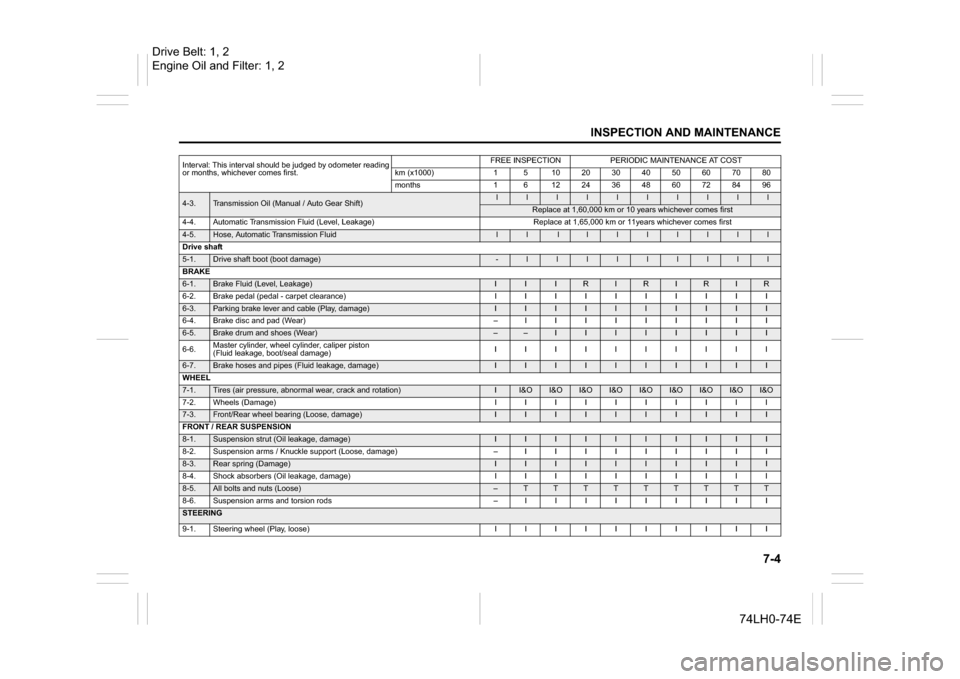

4-3.

Transmission Oil (Manual / Auto Gear Shift)

l

l

l

l

l

l

l

l

l

l

Replace at 1,60,000 km or 10 years whichever comes first

4-4. Automatic Transmission Fluid (Level, Leakage) Replace at 1,65,000 km or 11years whichever comes first

4-5.

Hose, Automatic Transmission Fluid

l

l

l

l

l

l

l

l

l

l

Drive shaft

5-1.

Drive shaft boot (boot damage)

-

l

l

l

l

l

l

l

l

l

BRAKE

6-1.

Brake Fluid (Level, Leakage)

I

I

I

R

I

R

I

R

I

R

6-2. Brake pedal (pedal - carpet clearance) I I I I I I I I I I

6-3.

Parking brake lever and cable (Play, damage)

I

I

I

I

I

I

I

I

I

I

6-4. Brake disc and pad (Wear) – I I I I I I I I I

6-5.

Brake drum and shoes (Wear)

–

–

I

I

I

I

I

I

I

I

6-6.Master cylinder, wheel cylinder, caliper piston

(Fluid leakage, boot/seal damage)IIIIIIIIII

6-7.

Brake hoses and pipes (Fluid leakage, damage)

I

I

I

I

I

I

I

I

I

I

WHEEL

7-1.

Tires (air pressure, abnormal wear, crack and rotation)

I

I&O

I&O

I&O

I&O

I&O

I&O

I&O

I&O

I&O

7-2. Wheels (Damage) I I I I I I I I I I

7-3.

Front/Rear wheel bearing (Loose, damage)

I

I

I

I

I

I

I

I

I

I

FRONT / REAR SUSPENSION

8-1.

Suspension strut (Oil leakage, damage)

I

I

I

I

I

I

I

I

I

I

8-2. Suspension arms / Knuckle support (Loose, damage) – I I I I I I I I I

8-3.

Rear spring (Damage)

I

I

I

I

I

I

I

I

I

I

8-4. Shock absorbers (Oil leakage, damage) I I I I I I I I I I

8-5.

All bolts and nuts (Loose)

–

T

T

T

T

T

T

T

T

T

8-6. Suspension arms and torsion rods – I I I I I I I I I

STEERING

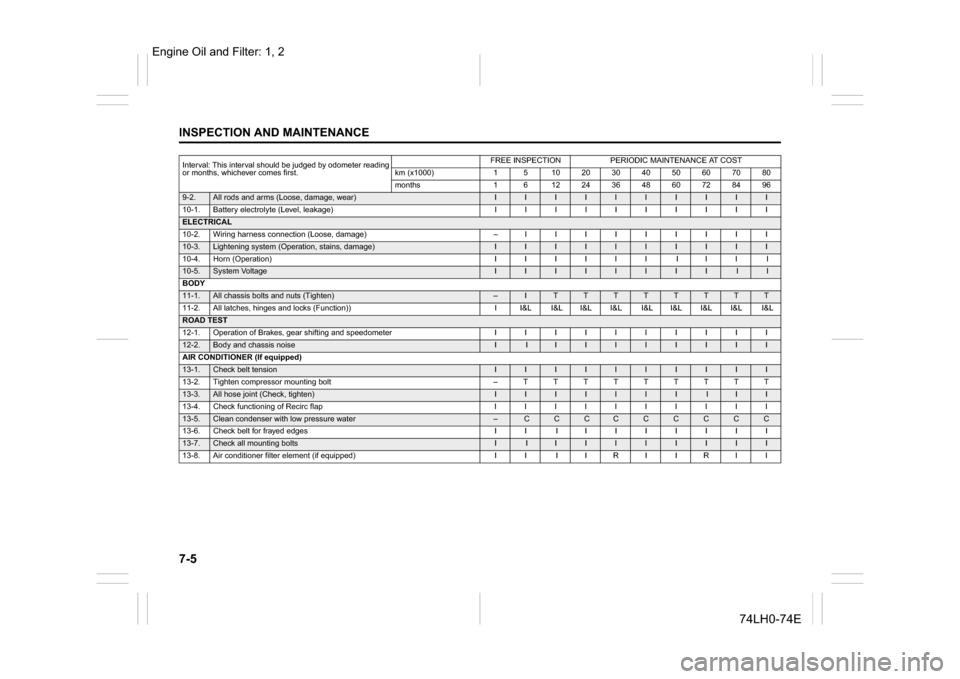

9-1. Steering wheel (Play, loose) I I I I I I I I I IInterval: This interval should be judged by odometer reading

or months, whichever comes first.

FREE INSPECTION

PERIODIC MAINTENANCE AT COST

km (x1000)

1

5

10

20

30

40

50

60

70

80

months

1

6

12

24

36

48

60

72

84

96

Drive Belt: 1, 2

Engine Oil and Filter: 1, 2

Page 196 of 336

7-5INSPECTION AND MAINTENANCE

74LH0-74E

9-2.

All rods and arms (Loose, damage, wear)

I

I

I

I

I

I

I

I

I

I

10-1. Battery electrolyte (Level, leakage) I I I I I I I I I I

ELECTRICAL

10-2. Wiring harness connection (Loose, damage)

–

I I I I I I I I I10-3.

Lightening system (Operation, stains, damage)

I

I

I

I

I

I

I

I

I

I

10-4. Horn (Operation) I I I I I I I I I I

10-5.

System Voltage

I

I

I

I

I

I

I

I

I

I

BODY

11-1.

All chassis bolts and nuts (Tighten)

–

I

T

T

T

T

T

T

T

T

11-2. All latches, hinges and locks (Function)) I I&L I&L I&L I&L I&L I&L I&L I&L I&L

ROAD TEST12-1.

Operation of Brakes, gear shifting and speedometer

I

I

I

I

I

I

I

I

I

I

12-2.

Body and chassis noise

I

I

I

I

I

I

I

I

I

I

AIR CONDITIONER (If equipped)

13-1.

Check belt tension

I

I

I

I

I

I

I

I

I

I

13-2. Tighten compressor mounting bolt

–

T T T T T T T T T

13-3.

All hose joint (Check, tighten)

I

I

I

I

I

I

I

I

I

I

13-4. Check functioning of Recirc flap I I I I I I I I I I

13-5.

Clean condenser with low pressure water

–

C

C

C

C

C

C

C

C

C

13-6. Check belt for frayed edges I I I I I I I I I I

13-7.

Check all mounting bolts

I

I

I

I

I

I

I

I

I

I

13-8. Air conditioner filter element (if equipped) I I I I R I I R I I

Interval: This interval should be judged by odometer reading

or months, whichever comes first.

FREE INSPECTION

PERIODIC MAINTENANCE AT COST

km (x1000)

1

5

10

20

30

40

50

60

70

80

months

1

6

12

24

36

48

60

72

84

96

Engine Oil and Filter: 1, 2

Page 204 of 336

7-13INSPECTION AND MAINTENANCE

74LH0-74E

60D204

NOTE:

If your engine is equipped with the high

tension cord type ignition wiring and you

experience some firing problem of spark

plugs, such as, hard engine-starting, mis-

fire etc., the cause may be located not only

on spark plugs but also on deteriorated

ignition wirings (generally, used for more

than 80,000 km or five years). If spark plug

replacement does not solve the problem,

have the ignition wiring and other ignition

system inspected by your MARUTI

SUZUKI dealer.Gear OilManual Transaxle Oil / Auto Gear

Shift OilWhen adding gear oil, use gear oil with the

appropriate viscosity and grade.

We highly recommend you use:

"MARUTI SUZUKI GEAR OIL 75W-80" for

manual transaxle gear oil or Auto Gear

Shift Oil.

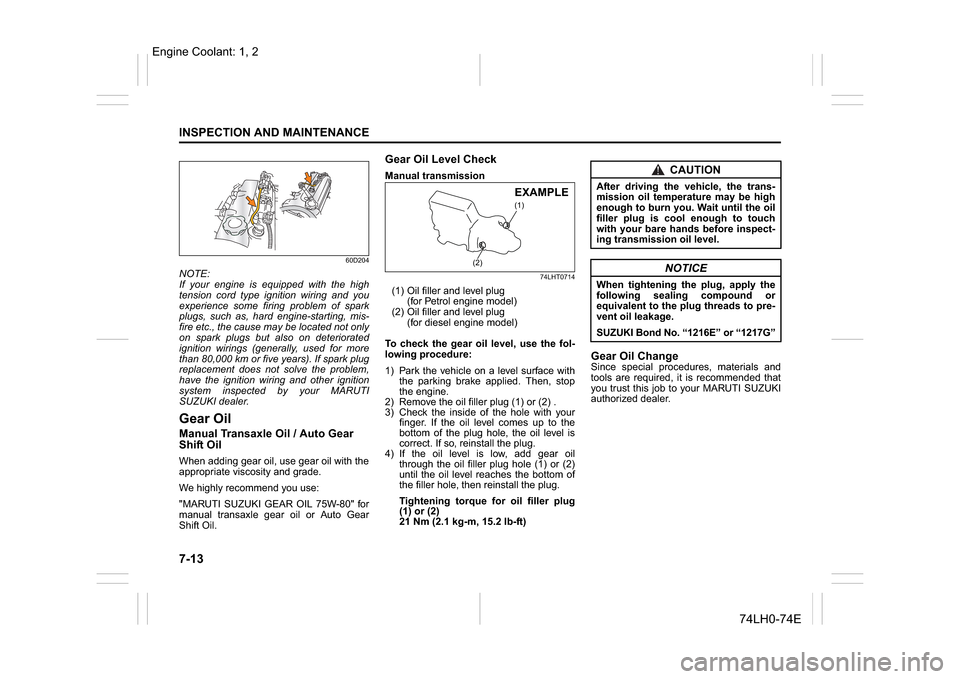

Gear Oil Level CheckManual transmission

74LHT0714

(1) Oil filler and level plug

(for Petrol engine model)

(2) Oil filler and level plug

(for diesel engine model)

To check the gear oil level, use the fol-

lowing procedure:

1) Park the vehicle on a level surface with

the parking brake applied. Then, stop

the engine.

2) Remove the oil filler plug (1) or (2) .

3) Check the inside of the hole with your

finger. If the oil level comes up to the

bottom of the plug hole, the oil level is

correct. If so, reinstall the plug.

4) If the oil level is low, add gear oil

through the oil filler plug hole (1) or (2)

until the oil level reaches the bottom of

the filler hole, then reinstall the plug.

Tightening torque for oil filler plug

(1) or (2)

21 Nm (2.1 kg-m, 15.2 lb-ft)

Gear Oil ChangeSince special procedures, materials and

tools are required, it is recommended that

you trust this job to your MARUTI SUZUKI

authorized dealer.

(1)

(2)

EXAMPLE

CAUTION

After driving the vehicle, the trans-

mission oil temperature may be high

enough to burn you. Wait until the oil

filler plug is cool enough to touch

with your bare hands before inspect-

ing transmission oil level.

NOTICE

When tightening the plug, apply the

following sealing compound or

equivalent to the plug threads to pre-

vent oil leakage.

SUZUKI Bond No. “1216E” or “1217G”

Engine Coolant: 1, 2

Page 205 of 336

7-14

INSPECTION AND MAINTENANCE

74LH0-74E

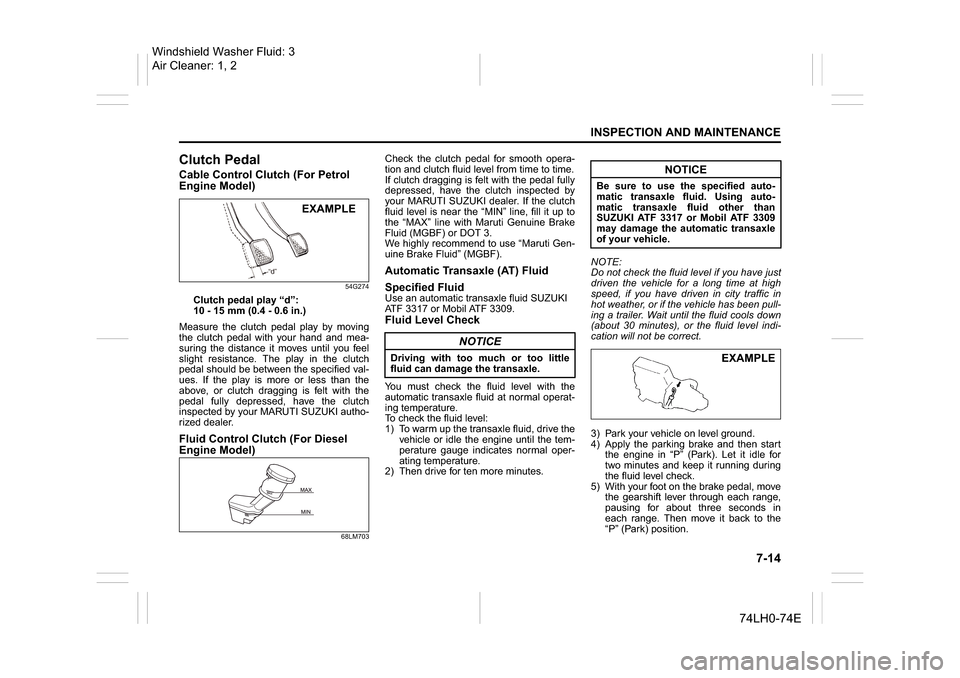

Clutch Pedal

Cable Control Clutch (For Petrol

Engine Model)

54G274

Clutch pedal play “d”:

10 - 15 mm (0.4 - 0.6 in.)

Measure the clutch pedal play by moving

the clutch pedal with your hand and mea-

suring the distance it moves until you feel

slight resistance. The play in the clutch

pedal should be between the specified val-

ues. If the play is more or less than the

above, or clutch dragging is felt with the

pedal fully depressed, have the clutch

inspected by your MARUTI SUZUKI autho-

rized dealer.

Fluid Control Clutch (For Diesel

Engine Model)

68LM703

Check the clutch pedal for smooth opera-

tion and clutch fluid level from time to time.

If clutch dragging is felt with the pedal fully

depressed, have the clutch inspected by

your MARUTI SUZUKI dealer. If the clutch

fluid level is near the “MIN” line, fill it up to

the “MAX” line with Maruti Genuine Brake

Fluid (MGBF) or DOT 3.

We highly recommend to use “Maruti Gen-

uine Brake Fluid” (MGBF).

Automatic Transaxle (AT) Fluid

Specified Fluid

Use an automatic transaxle fluid SUZUKI

ATF 3317 or Mobil ATF 3309.

Fluid Level Check

You must check the fluid level with the

automatic transaxle fluid at normal operat-

ing temperature.

To check the fluid level:

1) To warm up the transaxle fluid, drive the

vehicle or idle the engine until the tem-

perature gauge indicates normal oper-

ating temperature.

2) Then drive for ten more minutes.NOTE:

Do not check the fluid level if you have just

driven the vehicle for a long time at high

speed, if you have driven in city traffic in

hot weather, or if the vehicle has been pull-

ing a trailer. Wait until the fluid cools down

(about 30 minutes), or the fluid level indi-

cation will not be correct.

3) Park your vehicle on level ground.

4) Apply the parking brake and then start

the engine in “P” (Park). Let it idle for

two minutes and keep it running during

the fluid level check.

5) With your foot on the brake pedal, move

the gearshift lever through each range,

pausing for about three seconds in

each range. Then move it back to the

“P” (Park) position.

EXAMPLE

NOTICE

Driving with too much or too little

fluid can damage the transaxle.

NOTICE

Be sure to use the specified auto-

matic transaxle fluid. Using auto-

matic transaxle fluid other than

SUZUKI ATF 3317 or Mobil ATF 3309

may damage the automatic transaxle

of your vehicle.

EXAMPLE

Windshield Washer Fluid: 3

Air Cleaner: 1, 2

Page 206 of 336

7-15

INSPECTION AND MAINTENANCE

74LH0-74E

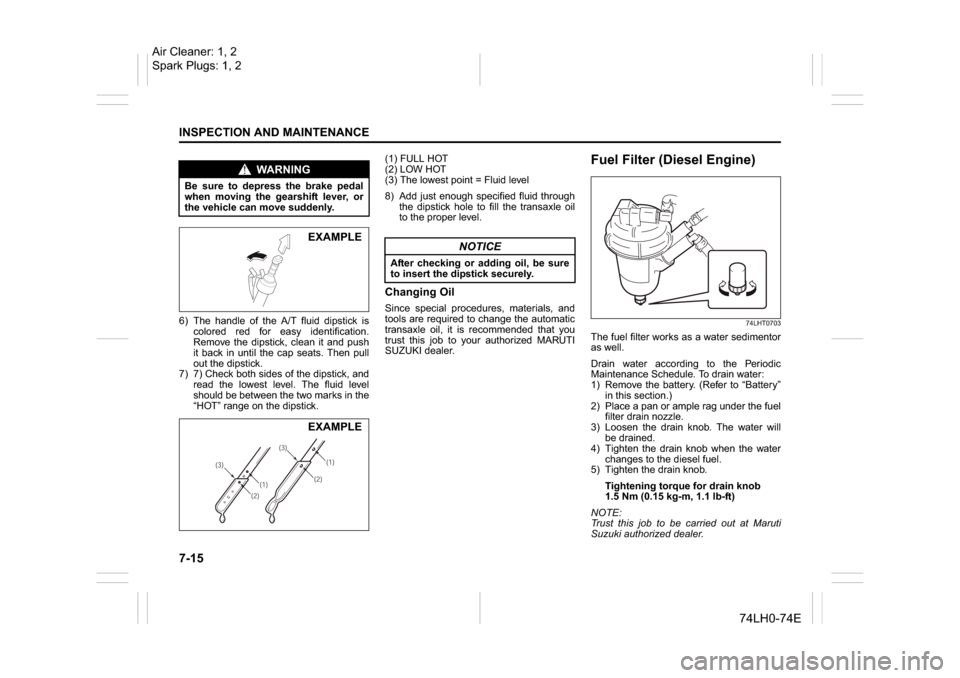

6) The handle of the A/T fluid dipstick is

colored red for easy identification.

Remove the dipstick, clean it and push

it back in until the cap seats. Then pull

out the dipstick.

7) 7) Check both sides of the dipstick, and

read the lowest level. The fluid level

should be between the two marks in the

“HOT” range on the dipstick.(1) FULL HOT

(2) LOW HOT

(3) The lowest point = Fluid level

8) Add just enough specified fluid through

the dipstick hole to fill the transaxle oil

to the proper level.

Changing Oil

Since special procedures, materials, and

tools are required to change the automatic

transaxle oil, it is recommended that you

trust this job to your authorized MARUTI

SUZUKI dealer.

Fuel Filter (Diesel Engine)

74LHT0703

The fuel filter works as a water sedimentor

as well.

Drain water according to the Periodic

Maintenance Schedule. To drain water:

1) Remove the battery. (Refer to “Battery”

in this section.)

2) Place a pan or ample rag under the fuel

filter drain nozzle.

3) Loosen the drain knob. The water will

be drained.

4) Tighten the drain knob when the water

changes to the diesel fuel.

5) Tighten the drain knob.

Tightening torque for drain knob

1.5 Nm (0.15 kg-m, 1.1 lb-ft)

NOTE:

Trust this job to be carried out at Maruti

Suzuki authorized dealer.

WA R N I N G

Be sure to depress the brake pedal

when moving the gearshift lever, or

the vehicle can move suddenly.

EXAMPLE

(1)(2) (3)(1)

(2)(3)

EXAMPLE

NOTICE

After checking or adding oil, be sure

to insert the dipstick securely.

Air Cleaner: 1, 2

Spark Plugs: 1, 2

Page 225 of 336

8-2

EMERGENCY SERVICE

74LH0-74E

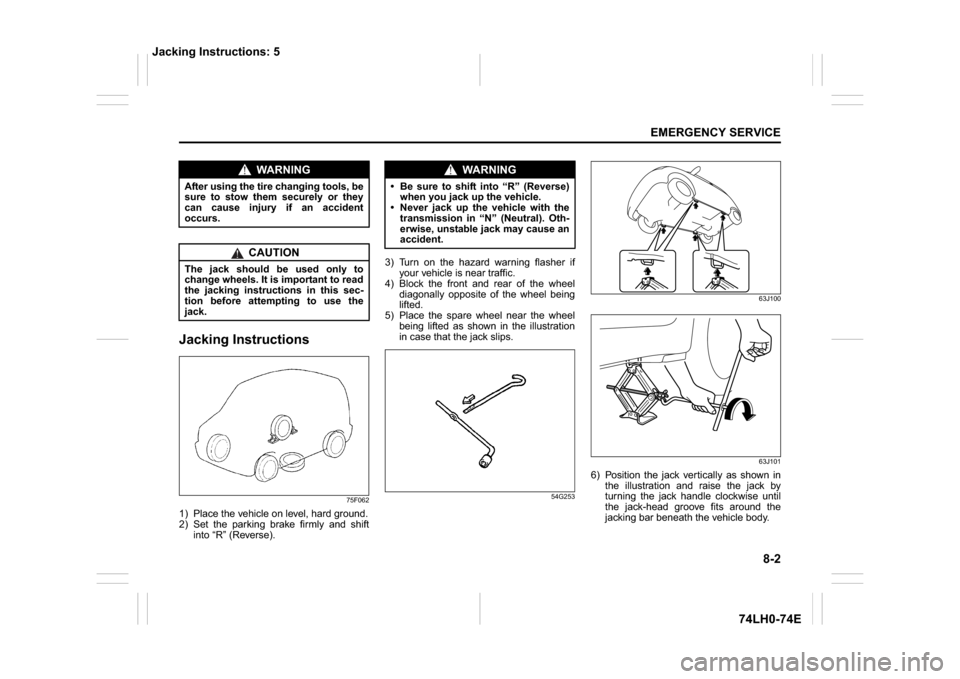

Jacking Instructions

75F062

1) Place the vehicle on level, hard ground.

2) Set the parking brake firmly and shift

into “R” (Reverse).3) Turn on the hazard warning flasher if

your vehicle is near traffic.

4) Block the front and rear of the wheel

diagonally opposite of the wheel being

lifted.

5) Place the spare wheel near the wheel

being lifted as shown in the illustration

in case that the jack slips.

54G25363J100

63J101

6) Position the jack vertically as shown in

the illustration and raise the jack by

turning the jack handle clockwise until

the jack-head groove fits around the

jacking bar beneath the vehicle body.

WA R N I N G

After using the tire changing tools, be

sure to stow them securely or they

can cause injury if an accident

occurs.

CAUTION

The jack should be used only to

change wheels. It is important to read

the jacking instructions in this sec-

tion before attempting to use the

jack.

WA R N I N G

Be sure to shift into “R” (Reverse)

when you jack up the vehicle.

Never jack up the vehicle with the

transmission in “N” (Neutral). Oth-

erwise, unstable jack may cause an

accident.

Jacking Instructions: 5