ig coil SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 972 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-32 Air Conditioning System: Manual Type

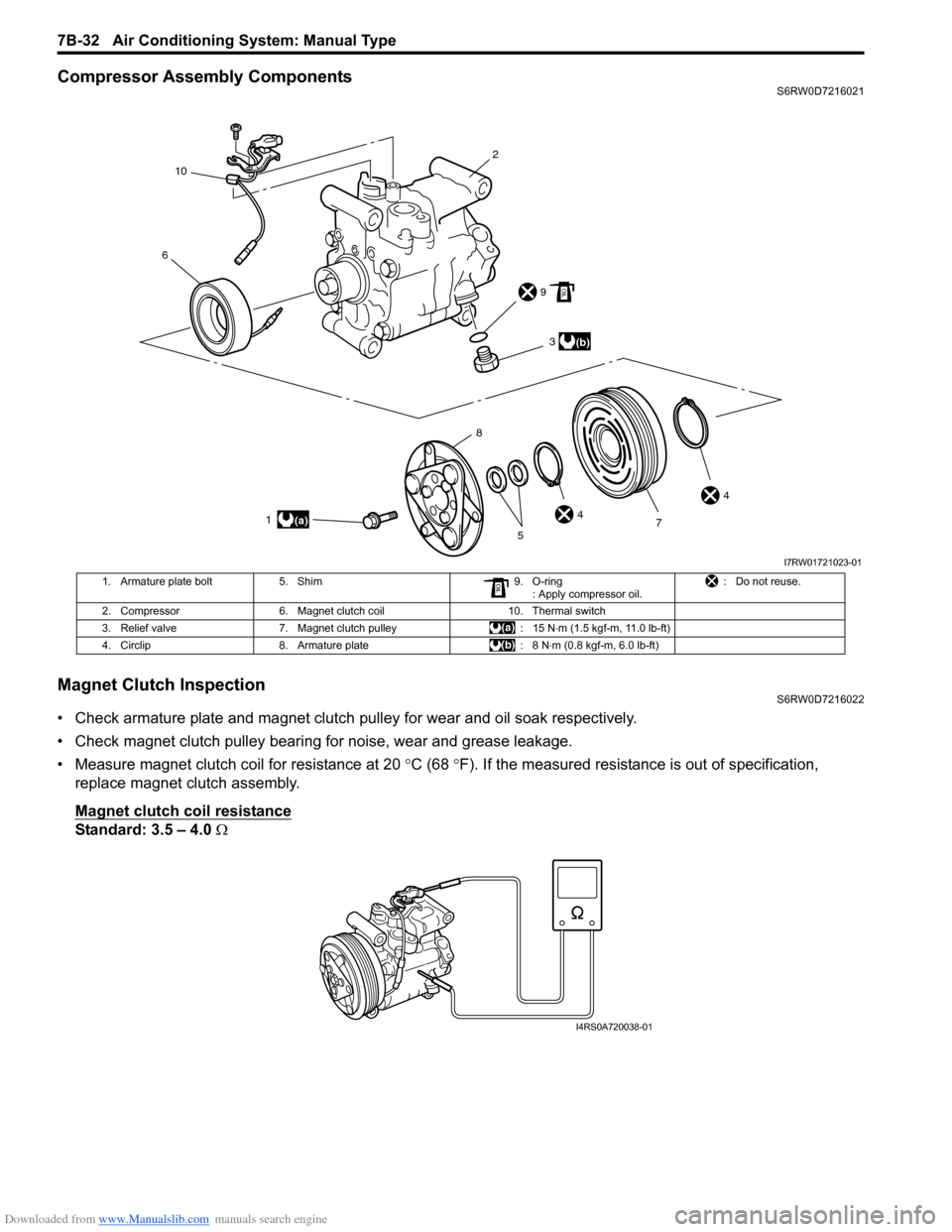

Compressor Assembly ComponentsS6RW0D7216021

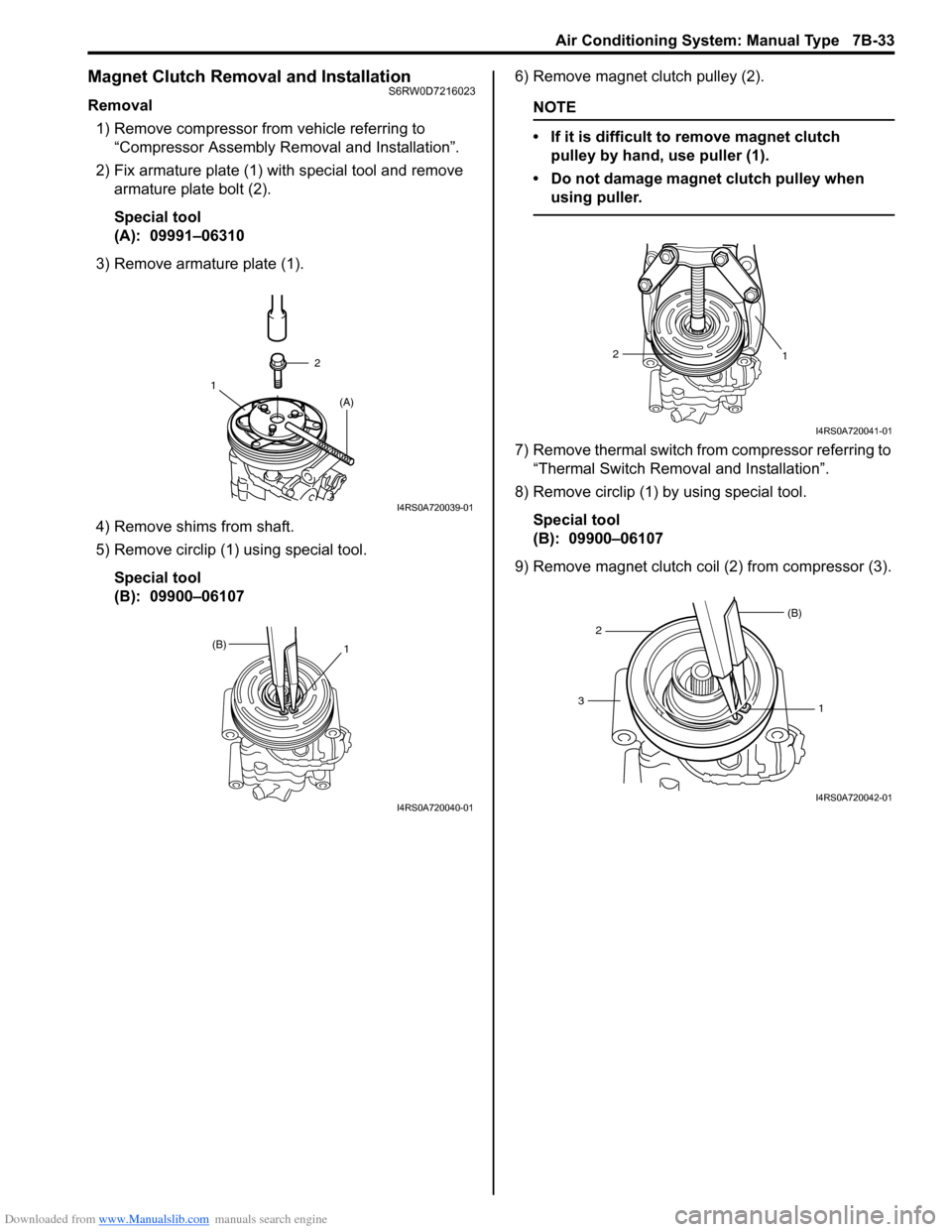

Magnet Clutch InspectionS6RW0D7216022

• Check armature plate and magnet clutch pulley for wear and oil soak respectively.

• Check magnet clutch pulley bearing for noise, wear and grease leakage.

• Measure magnet clutch coil for resistance at 20 °C (68 °F). If the measured resistance is out of specification,

replace magnet clutch assembly.

Magnet clutch coil resistance

Standard: 3.5 – 4.0 Ω

6

2

9

4

4 3

1

7

5 8(a)

(b)

10

I7RW01721023-01

1. Armature plate bolt 5. Shim 9. O-ring

: Apply compressor oil.: Do not reuse.

2. Compressor 6. Magnet clutch coil 10. Thermal switch

3. Relief valve 7. Magnet clutch pulley : 15 N⋅m (1.5 kgf-m, 11.0 lb-ft)

4. Circlip 8. Armature plate : 8 N⋅m (0.8 kgf-m, 6.0 lb-ft)

I4RS0A720038-01

Page 973 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-33

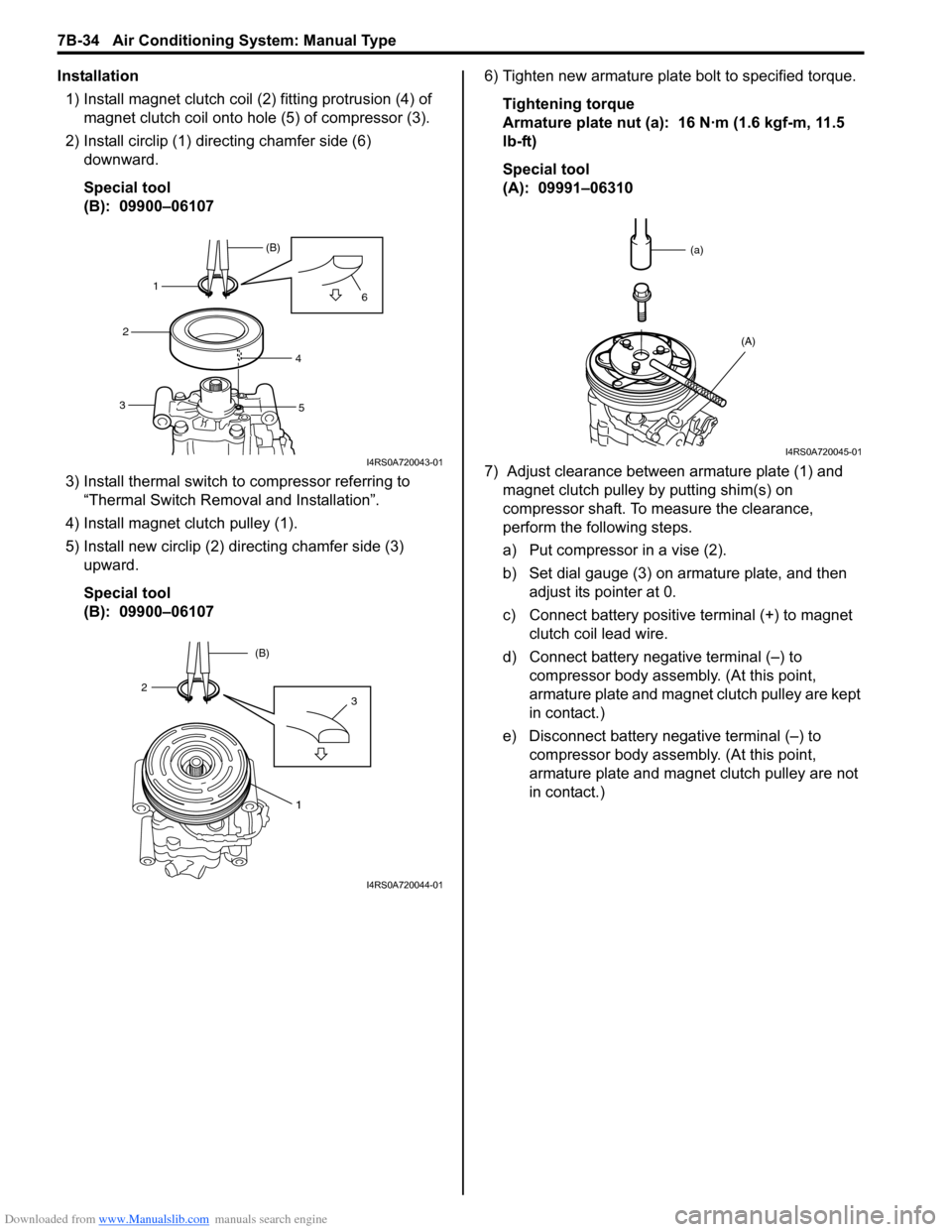

Magnet Clutch Removal and InstallationS6RW0D7216023

Removal

1) Remove compressor from vehicle referring to

“Compressor Assembly Removal and Installation”.

2) Fix armature plate (1) with special tool and remove

armature plate bolt (2).

Special tool

(A): 09991–06310

3) Remove armature plate (1).

4) Remove shims from shaft.

5) Remove circlip (1) using special tool.

Special tool

(B): 09900–061076) Remove magnet clutch pulley (2).NOTE

• If it is difficult to remove magnet clutch

pulley by hand, use puller (1).

• Do not damage magnet clutch pulley when

using puller.

7) Remove thermal switch from compressor referring to

“Thermal Switch Removal and Installation”.

8) Remove circlip (1) by using special tool.

Special tool

(B): 09900–06107

9) Remove magnet clutch coil (2) from compressor (3).

2

1

(A)

I4RS0A720039-01

(B)

1

I4RS0A720040-01

1 2

I4RS0A720041-01

1 (B)

23

I4RS0A720042-01

Page 974 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-34 Air Conditioning System: Manual Type

Installation

1) Install magnet clutch coil (2) fitting protrusion (4) of

magnet clutch coil onto hole (5) of compressor (3).

2) Install circlip (1) directing chamfer side (6)

downward.

Special tool

(B): 09900–06107

3) Install thermal switch to compressor referring to

“Thermal Switch Removal and Installation”.

4) Install magnet clutch pulley (1).

5) Install new circlip (2) directing chamfer side (3)

upward.

Special tool

(B): 09900–061076) Tighten new armature plate bolt to specified torque.

Tightening torque

Armature plate nut (a): 16 N·m (1.6 kgf-m, 11.5

lb-ft)

Special tool

(A): 09991–06310

7) Adjust clearance between armature plate (1) and

magnet clutch pulley by putting shim(s) on

compressor shaft. To measure the clearance,

perform the following steps.

a) Put compressor in a vise (2).

b) Set dial gauge (3) on armature plate, and then

adjust its pointer at 0.

c) Connect battery positive terminal (+) to magnet

clutch coil lead wire.

d) Connect battery negative terminal (–) to

compressor body assembly. (At this point,

armature plate and magnet clutch pulley are kept

in contact.)

e) Disconnect battery negative terminal (–) to

compressor body assembly. (At this point,

armature plate and magnet clutch pulley are not

in contact.)

1(B)

2

34

56

I4RS0A720043-01

1

32(B)

I4RS0A720044-01

(a)

(A)

I4RS0A720045-01

Page 1030 of 1556

Downloaded from www.Manualslib.com manuals search engine 8-ii Table of Contents

DTC B1062 / B1066: Side-Air Bag Circuit Low

Resistance ...................................................... 8B-59

DTC B1063 / B1067: Side-Air Bag Circuit

Shorted to Ground .......................................... 8B-61

DTC B1064 / B1068: Side-Air Bag Circuit

Shorted to Power Supply ................................ 8B-64

DTC B1071: Driver Forward Impact-Sensor

Communication Data Inconsistent .................. 8B-66

DTC B1072: Driver Forward Impact-Sensor

Communication Data Invalid ........................... 8B-66

DTC B1073: Driver Forward Impact-Sensor

Circuit Shorted to Ground ............................... 8B-67

DTC B1074: Driver Forward Impact-Sensor

Circuit Open .................................................... 8B-68

DTC B1081 / B1091: Side Impact-Sensor No

Response ........................................................ 8B-70

DTC B1082 / B1092: Side Impact-Sensor

Communication DATA Invalid ......................... 8B-70

DTC B1083 / B1093: Side Impact-Sensor

Circuit Shorted to Ground ............................... 8B-71

DTC B1084 / B1094: Side Impact-Sensor

Circuit Open .................................................... 8B-73

DTC B1085 / B1095: Side Impact-Sensor

Communication DATA Inconsistent ................ 8B-74

DTC B1361 / B1365: Curtain-Air Bag Circuit

High Resistance .............................................. 8B-75

DTC B1362 / B1366: Curtain-Air Bag Circuit

Low Resistance ............................................... 8B-79

DTC B1363 / B1367: Curtain-Air Bag Circuit

Shorted to Ground .......................................... 8B-81

DTC B1364 / B1368: Curtain-Air Bag Circuit

Shorted to Power Supply ................................ 8B-83

SDM Power Supply and Ground Circuit

Check .............................................................. 8B-85

Contact Coil Cable and Its Circuit Check .......... 8B-87

Inspection of Intermittent and Poor

Connections .................................................... 8B-89Repair and Inspection Required after

Accident .......................................................... 8B-90

Repair Instructions ............................................8B-93

Disabling Air Bag System.................................. 8B-93

Enabling Air Bag System .................................. 8B-93

SDM Removal and Installation .......................... 8B-94

SDM Inspection ................................................. 8B-95

Driver Air Bag (Inflator) Module Removal and

Installation ....................................................... 8B-95

Driver Air Bag (Inflator) Module Inspection ....... 8B-97

Passenger Air Bag (Inflator) Module Removal

and Installation ................................................ 8B-97

Passenger Air Bag (Inflator) Module

Inspection ........................................................ 8B-99

Side-Air Bag (Inflator) Module Removal and

Installation ....................................................... 8B-99

Side-Air Bag (Inflator) Inspection .................... 8B-101

Side Curtain-Air Bag (Inflator) Module

Removal and Installation ............................... 8B-102

Side Curtain-Air Bag (Inflator) Module

Inspection ...................................................... 8B-103

Forward Impact-Sensor Removal and

Installation ..................................................... 8B-103

Forward Impact-Sensor Inspection ................. 8B-104

Side Impact-Sensor Removal and Installation 8B-105

Side Impact-Sensor Inspection ....................... 8B-105

Passenger Air Bag (Inflator) Module Repair

Harness Installation....................................... 8B-106

Air Bag (Inflator) Module and Seat Belt

Pretensioner Disposal ................................... 8B-107

Deployed Air Bag (Inflator) Module and

Activated Seat Belt Pretensioner Disposal.... 8B-117

Specifications ...................................................8B-118

Tightening Torque Specifications .................... 8B-118

Special Tools and Equipment .........................8B-118

Use of Special Tools ....................................... 8B-118

Special Tool .................................................... 8B-120

Page 1048 of 1556

![SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 8B-9 Air Bag System:

Terminal arrangement of SDM (viewed from harness side)

[A]: Shorting bar 11. BCM 25. Driver seat belt pretensioner

[B]: C SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 8B-9 Air Bag System:

Terminal arrangement of SDM (viewed from harness side)

[A]: Shorting bar 11. BCM 25. Driver seat belt pretensioner

[B]: C](/img/20/7612/w960_7612-1047.png)

Downloaded from www.Manualslib.com manuals search engine 8B-9 Air Bag System:

Terminal arrangement of SDM (viewed from harness side)

[A]: Shorting bar 11. BCM 25. Driver seat belt pretensioner

[B]: Connector 12. Combination meter 26. Passenger seat belt pretensioner

[C]: Junction block with BCM model 13. “AIR BAG” warning light27. Driver side-air bag (inflator) module (8-channel system)

[D]: Junction block without BCM model 14. Light driver 28. Passenger side-air bag (inflator) module (8-channel system)

1. Battery 15. SDM 29. Driver side curtain-air bag (inflator) module (8-channel

system)

2. Main fuse 16. To HVAC control module (auto A/C model) 30. Passenger side curtain-air bag (inflator) module (8-channel

system)

3. Fuse 17. Data link connector (DLC) 31. Safing power driver

4. Individual circuit fuse box No.1 18. Forward impact-sensor 32. X-Y-G (longitudinal / lateral acceleration)

5. “IGN” fuse 19. Driver side impact-sensor (8-channel

system)33. DC / DC converter

6. Ignition switch 20. Passenger side impact-sensor (8-channel

system)34. Mechanical longitudinal G sensor (switch)

7. Junction block assembly 21. Ground for air bag system 35. Back up capacitor

8. “DOME” fuse 22. Contact coil assembly

9. “METER” fuse 23. Driver air bag (inflator) module

10. “A/B” fuse 24. Passenger air bag (inflator) module

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

1

I7RW01822003-02

1. SDM Connector “L04”

Page 1051 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-12

Diagnostic Information and Procedures

Air Bag Diagnostic System CheckS6RW0D8204001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified in this manual. Do not use a non-

powered probe type tester.

Instructions in this manual must be followed

carefully, otherwise personal injury may

result.

CAUTION!

• The order in which DTCs are diagnosed is

very important. Failure to diagnose the

DTCs in the order specified may result in

extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.

• When measurement of resistance or

voltage is required in the flow, use a tester

along with a correct terminal adapter from

special tool (Connector test adapter kit).

• When a check for proper connection is

required, refer to “Inspection of

Intermittent and Poor Connections”.

• If an open circuit in the air bag wire

harness damaged, connector or terminal is

found, replace the wire harness,

connectors and terminals as an assembly.

The diagnostic procedures used are designed to find

and repair air bag system malfunctions.

To get the best results, it is important to use the

diagnostic flow and follow the sequence in the following.

1) Perform the “Air Bag Diagnostic System Check

Flow”.

(The “Air Bag Diagnostic System Check Flow” must

be the starting point of any air bag system diagnosis.

The “Air Bag Diagnostic System Check Flow” checks

for proper “AIR BAG” warning light operation through

“AIR BAG” warning light and whether air bag DTCs

exist.)

2) Refer to the proper diagnostic flow as directed by the

“Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” will

lead you to the correct flow to diagnose any air bag

system malfunctions. Bypassing these procedures

may result in extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.)

3) Repeat the “Air Bag Diagnostic System Check Flow”

after any repair or diagnostic procedures have been

performed.

(Performing the “Air Bag Diagnostic System Check

Flow” after all repair or diagnostic procedures will

ensure that the repair has been made correctly and

that no other malfunctions exist.)

A: Combination meter 6. Side curtain-air bag (inflator) module (8-

channel system)14. “A/B” fuse in junction block assembly

B: Steering wheel 7. Contact coil assembly 15. Air bag harness in main harness

C: Seat 8. Forward impact-sensor 16. Air bag harness in instrument panel harness

1. “AIR BAG” warning light 9. Apron-side-member (driver side) 17. Air bag harness in floor harness

2. Driver air bag (inflator) module 10. Side impact-sensor (8-channel system) 18. Side-air bag harness (8-channel system)

3. Passenger air bag facing cover 11. Side sill inner panel 19. Side curtain-air bag harness (8-channel

system)

4. Passenger air bag (inflator) module 12. SDM 20. Ground for air bag system

5. Side-air bag (inflator) module (8-channel

system)13. Seat belt pretensioner

Page 1054 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-15 Air Bag System:

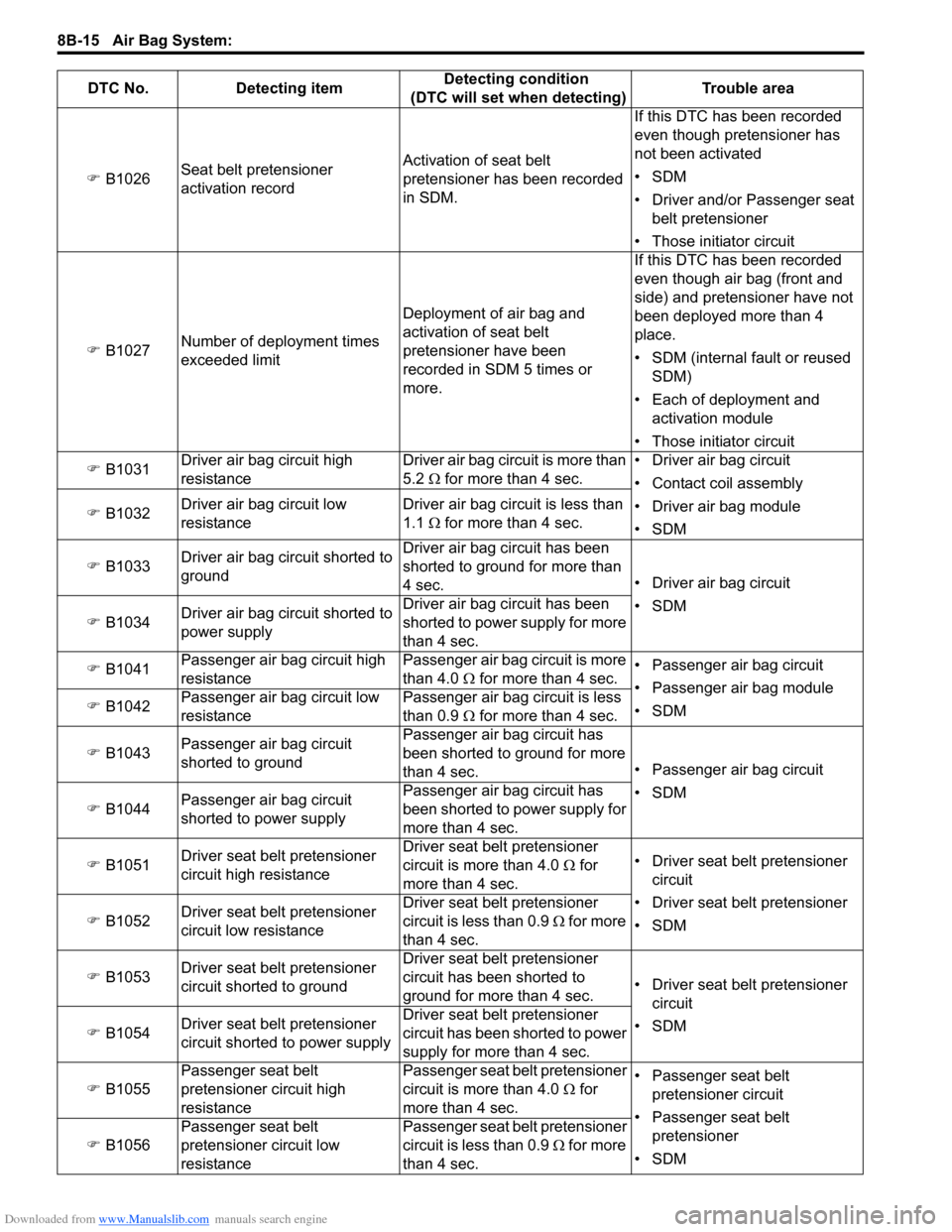

�) B1026Seat belt pretensioner

activation recordActivation of seat belt

pretensioner has been recorded

in SDM.If this DTC has been recorded

even though pretensioner has

not been activated

•SDM

• Driver and/or Passenger seat

belt pretensioner

• Those initiator circuit

�) B1027Number of deployment times

exceeded limitDeployment of air bag and

activation of seat belt

pretensioner have been

recorded in SDM 5 times or

more.If this DTC has been recorded

even though air bag (front and

side) and pretensioner have not

been deployed more than 4

place.

• SDM (internal fault or reused

SDM)

• Each of deployment and

activation module

• Those initiator circuit

�) B1031Driver air bag circuit high

resistanceDriver air bag circuit is more than

5.2 Ω for more than 4 sec.• Driver air bag circuit

• Contact coil assembly

• Driver air bag module

•SDM �) B1032Driver air bag circuit low

resistanceDriver air bag circuit is less than

1.1 Ω for more than 4 sec.

�) B1033Driver air bag circuit shorted to

groundDriver air bag circuit has been

shorted to ground for more than

4 sec.• Driver air bag circuit

•SDM

�) B1034Driver air bag circuit shorted to

power supplyDriver air bag circuit has been

shorted to power supply for more

than 4 sec.

�) B1041Passenger air bag circuit high

resistancePassenger air bag circuit is more

than 4.0 Ω for more than 4 sec.• Passenger air bag circuit

• Passenger air bag module

•SDM �) B1042Passenger air bag circuit low

resistancePassenger air bag circuit is less

than 0.9 Ω for more than 4 sec.

�) B1043Passenger air bag circuit

shorted to groundPassenger air bag circuit has

been shorted to ground for more

than 4 sec.• Passenger air bag circuit

•SDM

�) B1044Passenger air bag circuit

shorted to power supplyPassenger air bag circuit has

been shorted to power supply for

more than 4 sec.

�) B1051Driver seat belt pretensioner

circuit high resistance Driver seat belt pretensioner

circuit is more than 4.0 Ω for

more than 4 sec.• Driver seat belt pretensioner

circuit

• Driver seat belt pretensioner

•SDM �) B1052Driver seat belt pretensioner

circuit low resistance Driver seat belt pretensioner

circuit is less than 0.9 Ω for more

than 4 sec.

�) B1053Driver seat belt pretensioner

circuit shorted to groundDriver seat belt pretensioner

circuit has been shorted to

ground for more than 4 sec.• Driver seat belt pretensioner

circuit

•SDM

�) B1054Driver seat belt pretensioner

circuit shorted to power supplyDriver seat belt pretensioner

circuit has been shorted to power

supply for more than 4 sec.

�) B1055Passenger seat belt

pretensioner circuit high

resistance Passenger seat belt pretensioner

circuit is more than 4.0 Ω for

more than 4 sec.• Passenger seat belt

pretensioner circuit

• Passenger seat belt

pretensioner

•SDM �) B1056Passenger seat belt

pretensioner circuit low

resistancePassenger seat belt pretensioner

circuit is less than 0.9 Ω for more

than 4 sec. DTC No. Detecting itemDetecting condition

(DTC will set when detecting)Trouble area

Page 1070 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-31 Air Bag System:

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

• Clear DTC B1157 (air bag deployed) of BCM referring to “DTC Clearance in Section 10B”, if any.

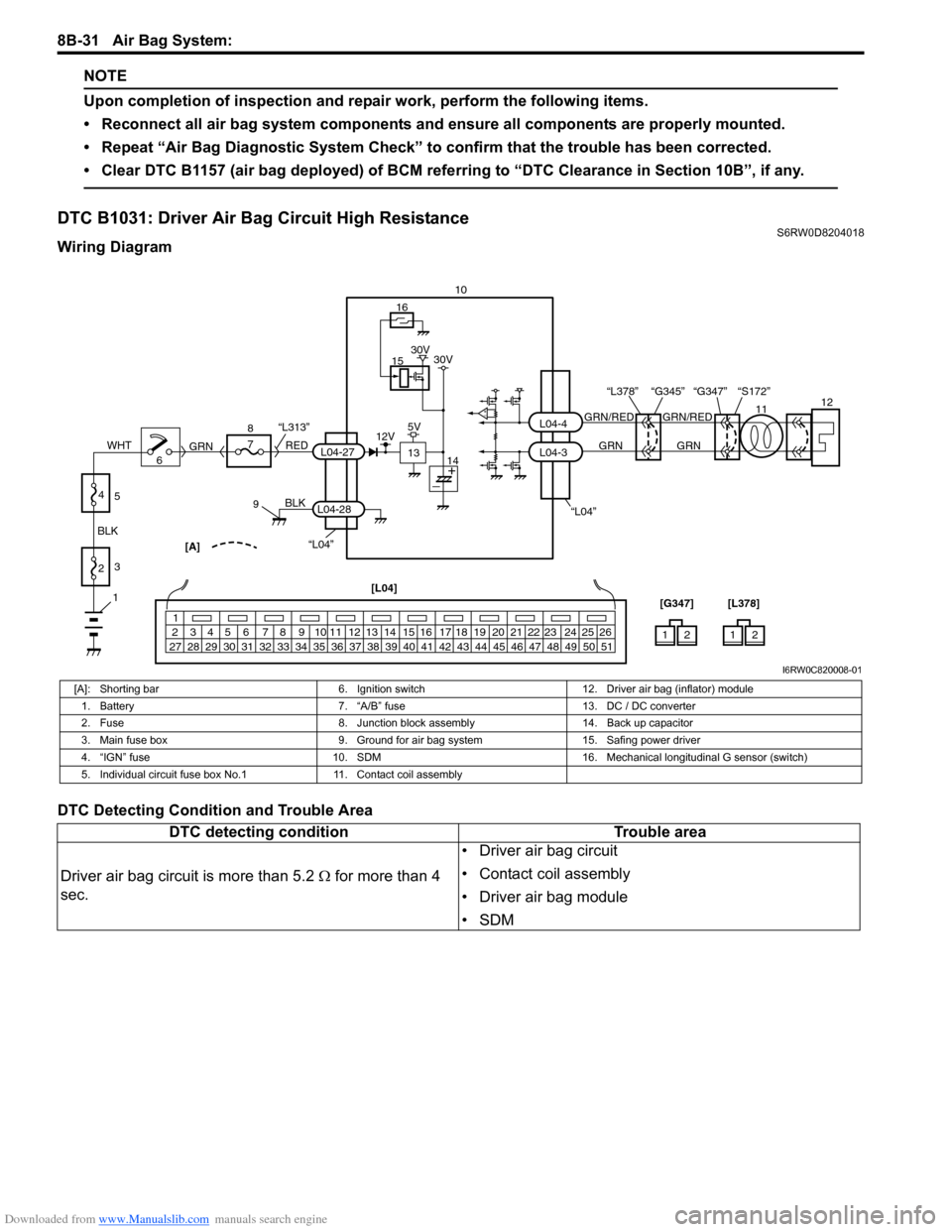

DTC B1031: Driver Air Bag Circuit High Resistance S6RW0D8204018

Wiring Diagram

DTC Detecting Condition and Trouble Area

“L04”“L04”[A]

BLK

L04-28

6 8

7

RED

GRN“L313”L04-27

910

L04-3 L04-4

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

12 [L04]

[G347]12 [L378]

15

13

16

12V5V30V 30V

141112

GRN/RED GRN/RED

GRN GRN

“G347” “S172” “L378” “G345”

1

2 BLKWHT3

4

5

I6RW0C820008-01

[A]: Shorting bar 6. Ignition switch 12. Driver air bag (inflator) module

1. Battery 7. “A/B” fuse 13. DC / DC converter

2. Fuse 8. Junction block assembly 14. Back up capacitor

3. Main fuse box 9. Ground for air bag system 15. Safing power driver

4. “IGN” fuse 10. SDM 16. Mechanical longitudinal G sensor (switch)

5. Individual circuit fuse box No.1 11. Contact coil assembly

DTC detecting condition Trouble area

Driver air bag circuit is more than 5.2 Ω for more than 4

sec.• Driver air bag circuit

• Contact coil assembly

• Driver air bag module

•SDM

Page 1071 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-32

DTC Troubleshooting

Step Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2Drive air bag circuit check

1) With ignition switch turned OFF, disconnect contact coil

connector located under the steering column.

2) Check for proper connection to contact coil at terminal in

“G347” connector.

3) If OK, then connect special tools (A) and (B) to “G347”

connector disconnected in Step 1).

Special tool

(A): 09932–75010

(B): 09932–78340

4) Check SDM for DTC.

With ignition switch turned ON, is DTC B1031 indicated?Go to Step 3. Go to Step 5.

3Driver air bag circuit check

1) Disconnect SDM connector “L04”.

2) Check for proper connection to SDM connector at

terminal “L04-3” and “L04-4”.

3) If OK, release shorting bar in SDM connector inserting

release tool (1) included in special tool (A).

Special tool

(A): 09932–76010

4) Measure resistance between “L04-3” and “G347-2”

terminals.

5) Measure resistance between “L04-4” and “G347-1”

terminals.

Is each measured resistance 1

Ω or less?Substitute a known-

good SDM and recheck.Go to Step 4.

BASE OF COLUMNBASE OF COLUMN

“G347”

(A)(B)

DRIVERPASSENGER

I7RW01821018-02

“L04-4” “L04-3”

1,(A)

(A)

I7RW01821019-01

Page 1072 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-33 Air Bag System:

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1032: Driver Air Bag Circuit Low ResistanceS6RW0D8204019

Wiring Diagram

Refer to “DTC B1031: Driver Air Bag Circuit High Resistance”.

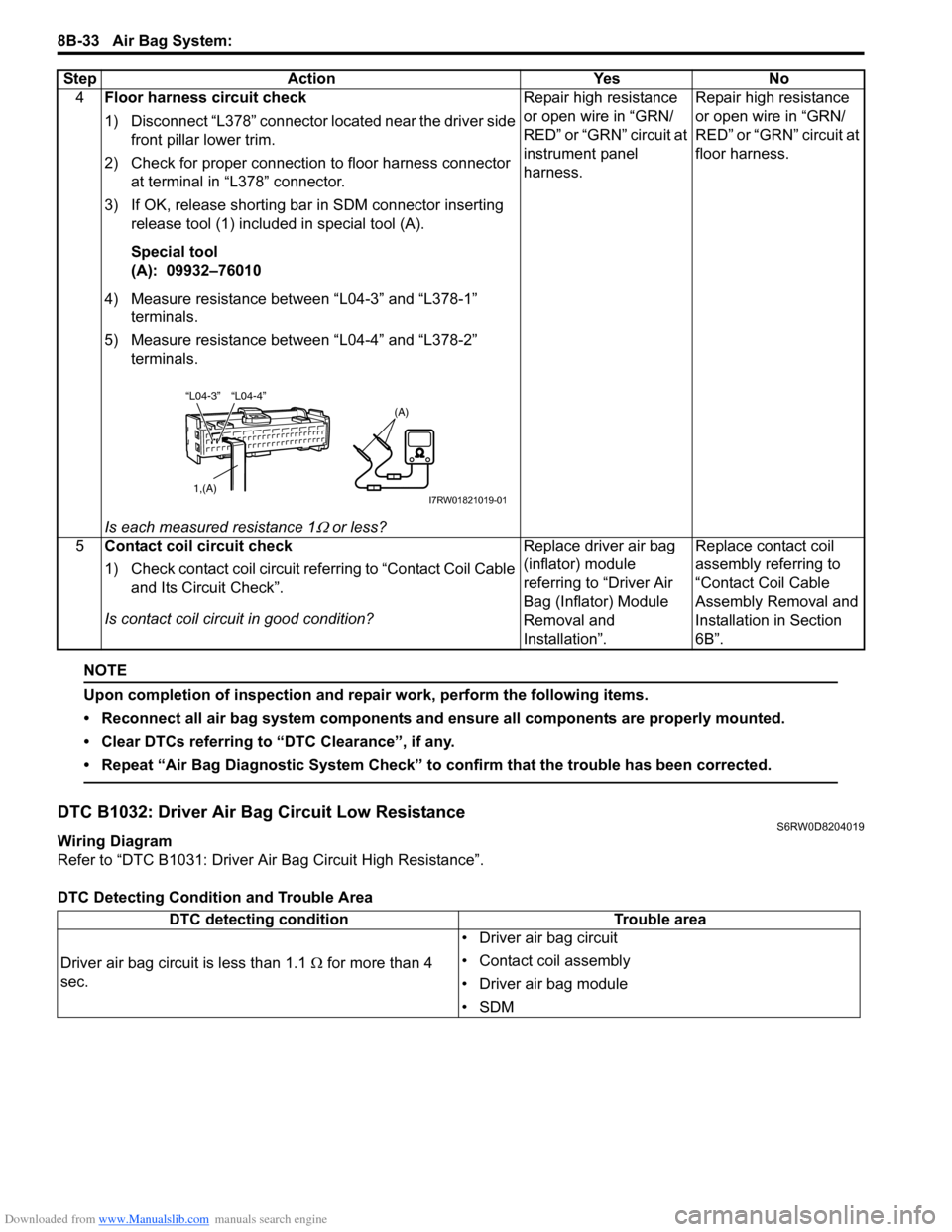

DTC Detecting Condition and Trouble Area4Floor harness circuit check

1) Disconnect “L378” connector located near the driver side

front pillar lower trim.

2) Check for proper connection to floor harness connector

at terminal in “L378” connector.

3) If OK, release shorting bar in SDM connector inserting

release tool (1) included in special tool (A).

Special tool

(A): 09932–76010

4) Measure resistance between “L04-3” and “L378-1”

terminals.

5) Measure resistance between “L04-4” and “L378-2”

terminals.

Is each measured resistance 1

Ω or less?Repair high resistance

or open wire in “GRN/

RED” or “GRN” circuit at

instrument panel

harness.Repair high resistance

or open wire in “GRN/

RED” or “GRN” circuit at

floor harness.

5Contact coil circuit check

1) Check contact coil circuit referring to “Contact Coil Cable

and Its Circuit Check”.

Is contact coil circuit in good condition?Replace driver air bag

(inflator) module

referring to “Driver Air

Bag (Inflator) Module

Removal and

Installation”.Replace contact coil

assembly referring to

“Contact Coil Cable

Assembly Removal and

Installation in Section

6B”. Step Action Yes No

“L04-4” “L04-3”

1,(A)

(A)

I7RW01821019-01

DTC detecting condition Trouble area

Driver air bag circuit is less than 1.1 Ω for more than 4

sec.• Driver air bag circuit

• Contact coil assembly

• Driver air bag module

•SDM