intake SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 401 of 1556

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-6

Ignition Spark TestS6RW0D1804004

1) Remove air cleaner assembly with air intake pipe.

2) Disconnect all injector couplers from injectors.

WARNING!

Without disconnection of injector couplers,

combustible gas may come out from spark

plug holes during this test and may get

ignited in engine room.

3) Remove spark plug and check it for condition and

type referring to “Spark Plug Inspection”.

4) If OK, connect ignition coil coupler to ignition coil

assembly and connect spark plug to ignition coil

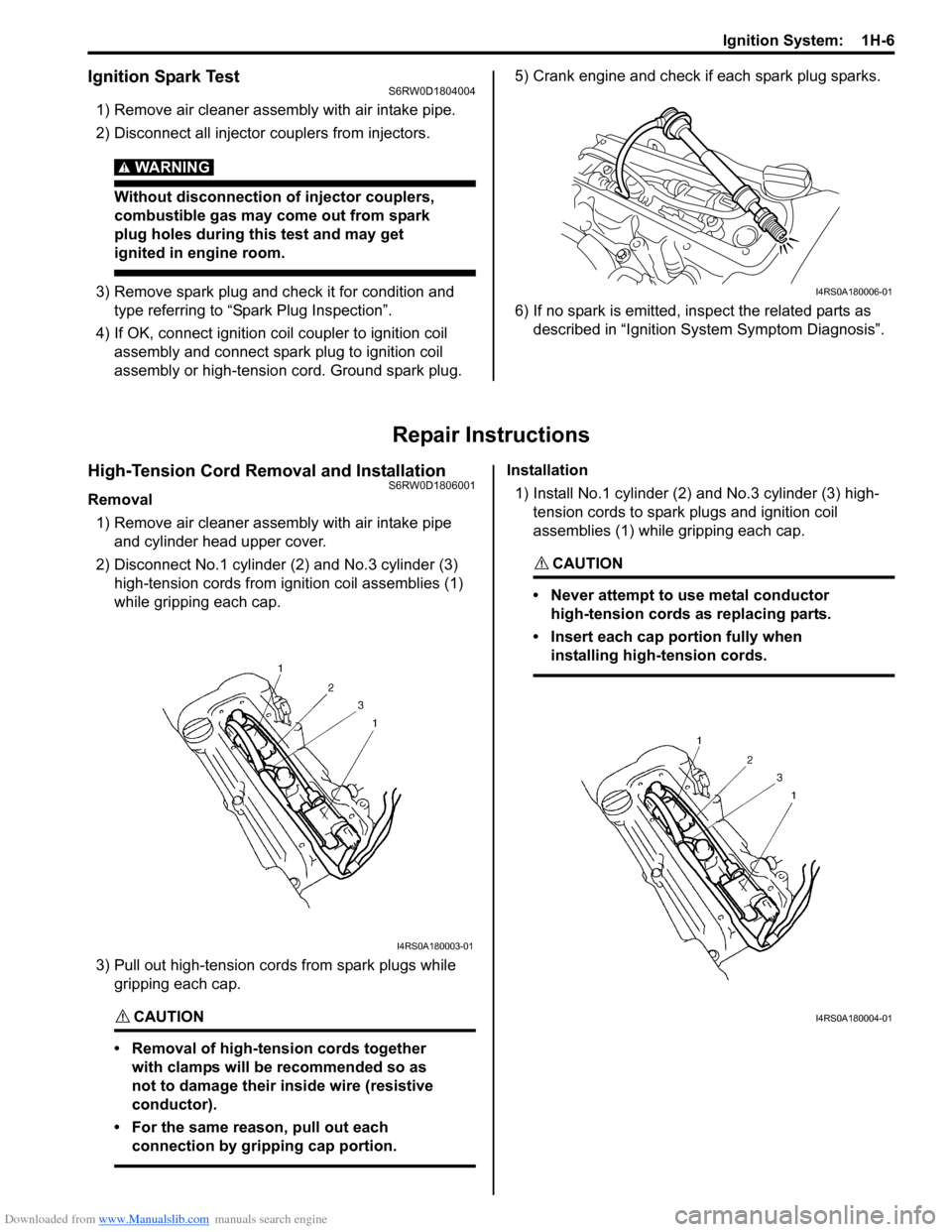

assembly or high-tension cord. Ground spark plug.5) Crank engine and check if each spark plug sparks.

6) If no spark is emitted, inspect the related parts as

described in “Ignition System Symptom Diagnosis”.

Repair Instructions

High-Tension Cord Removal and InstallationS6RW0D1806001

Removal

1) Remove air cleaner assembly with air intake pipe

and cylinder head upper cover.

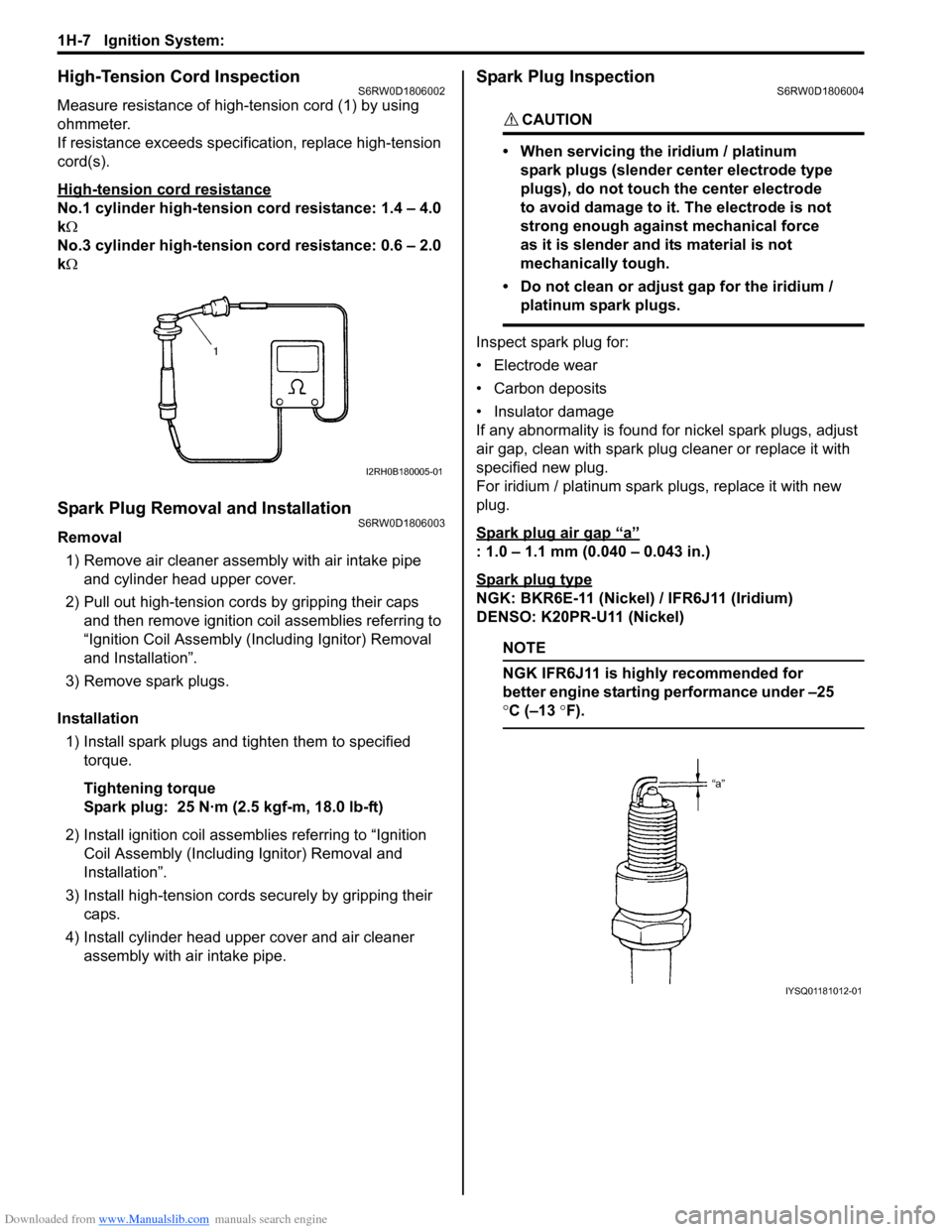

2) Disconnect No.1 cylinder (2) and No.3 cylinder (3)

high-tension cords from ignition coil assemblies (1)

while gripping each cap.

3) Pull out high-tension cords from spark plugs while

gripping each cap.

CAUTION!

• Removal of high-tension cords together

with clamps will be recommended so as

not to damage their inside wire (resistive

conductor).

• For the same reason, pull out each

connection by gripping cap portion.

Installation

1) Install No.1 cylinder (2) and No.3 cylinder (3) high-

tension cords to spark plugs and ignition coil

assemblies (1) while gripping each cap.

CAUTION!

• Never attempt to use metal conductor

high-tension cords as replacing parts.

• Insert each cap portion fully when

installing high-tension cords.

I4RS0A180006-01

I4RS0A180003-01

I4RS0A180004-01

Page 402 of 1556

Downloaded from www.Manualslib.com manuals search engine 1H-7 Ignition System:

High-Tension Cord InspectionS6RW0D1806002

Measure resistance of high-tension cord (1) by using

ohmmeter.

If resistance exceeds specification, replace high-tension

cord(s).

High-tension cord resistance

No.1 cylinder high-tension cord resistance: 1.4 – 4.0

kΩ

No.3 cylinder high-tension cord resistance: 0.6 – 2.0

kΩ

Spark Plug Removal and InstallationS6RW0D1806003

Removal

1) Remove air cleaner assembly with air intake pipe

and cylinder head upper cover.

2) Pull out high-tension cords by gripping their caps

and then remove ignition coil assemblies referring to

“Ignition Coil Assembly (Including Ignitor) Removal

and Installation”.

3) Remove spark plugs.

Installation

1) Install spark plugs and tighten them to specified

torque.

Tightening torque

Spark plug: 25 N·m (2.5 kgf-m, 18.0 lb-ft)

2) Install ignition coil assemblies referring to “Ignition

Coil Assembly (Including Ignitor) Removal and

Installation”.

3) Install high-tension cords securely by gripping their

caps.

4) Install cylinder head upper cover and air cleaner

assembly with air intake pipe.

Spark Plug InspectionS6RW0D1806004

CAUTION!

• When servicing the iridium / platinum

spark plugs (slender center electrode type

plugs), do not touch the center electrode

to avoid damage to it. The electrode is not

strong enough against mechanical force

as it is slender and its material is not

mechanically tough.

• Do not clean or adjust gap for the iridium /

platinum spark plugs.

Inspect spark plug for:

• Electrode wear

• Carbon deposits

• Insulator damage

If any abnormality is found for nickel spark plugs, adjust

air gap, clean with spark plug cleaner or replace it with

specified new plug.

For iridium / platinum spark plugs, replace it with new

plug.

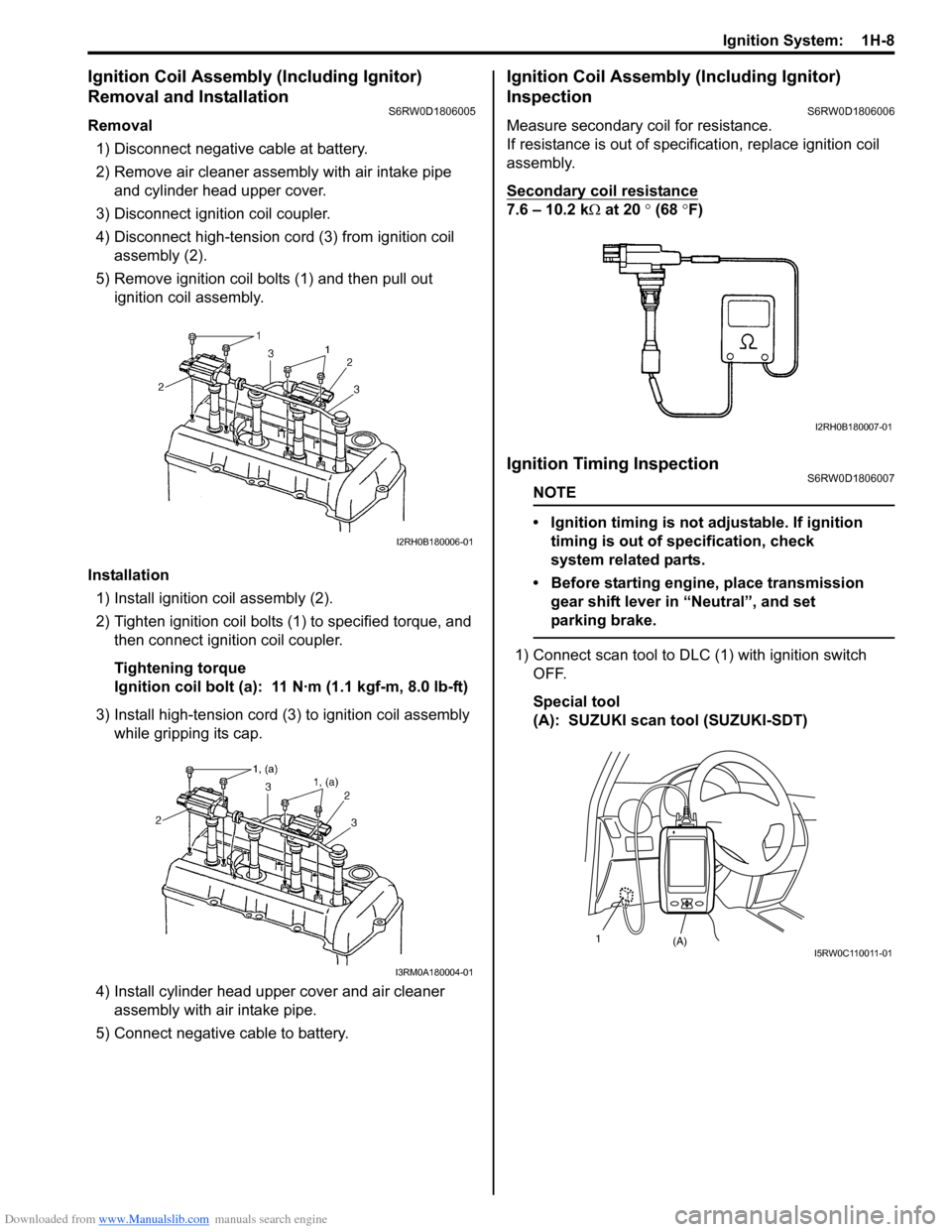

Spark plug air gap

“a”

: 1.0 – 1.1 mm (0.040 – 0.043 in.)

Spark plug type

NGK: BKR6E-11 (Nickel) / IFR6J11 (Iridium)

DENSO: K20PR-U11 (Nickel)

NOTE

NGK IFR6J11 is highly recommended for

better engine starting performance under –25

°C (–13 °F).

I2RH0B180005-01

IYSQ01181012-01

Page 403 of 1556

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-8

Ignition Coil Assembly (Including Ignitor)

Removal and Installation

S6RW0D1806005

Removal

1) Disconnect negative cable at battery.

2) Remove air cleaner assembly with air intake pipe

and cylinder head upper cover.

3) Disconnect ignition coil coupler.

4) Disconnect high-tension cord (3) from ignition coil

assembly (2).

5) Remove ignition coil bolts (1) and then pull out

ignition coil assembly.

Installation

1) Install ignition coil assembly (2).

2) Tighten ignition coil bolts (1) to specified torque, and

then connect ignition coil coupler.

Tightening torque

Ignition coil bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Install high-tension cord (3) to ignition coil assembly

while gripping its cap.

4) Install cylinder head upper cover and air cleaner

assembly with air intake pipe.

5) Connect negative cable to battery.

Ignition Coil Assembly (Including Ignitor)

Inspection

S6RW0D1806006

Measure secondary coil for resistance.

If resistance is out of specification, replace ignition coil

assembly.

Secondary coil resistance

7.6 – 10.2 kΩ at 20 ° (68 °F)

Ignition Timing InspectionS6RW0D1806007

NOTE

• Ignition timing is not adjustable. If ignition

timing is out of specification, check

system related parts.

• Before starting engine, place transmission

gear shift lever in “Neutral”, and set

parking brake.

1) Connect scan tool to DLC (1) with ignition switch

OFF.

Special tool

(A): SUZUKI scan tool (SUZUKI-SDT)

I2RH0B180006-01

I3RM0A180004-01

I2RH0B180007-01

(A) 1I 5 R W 0 C 11 0 0 11 - 0 1

Page 925 of 1556

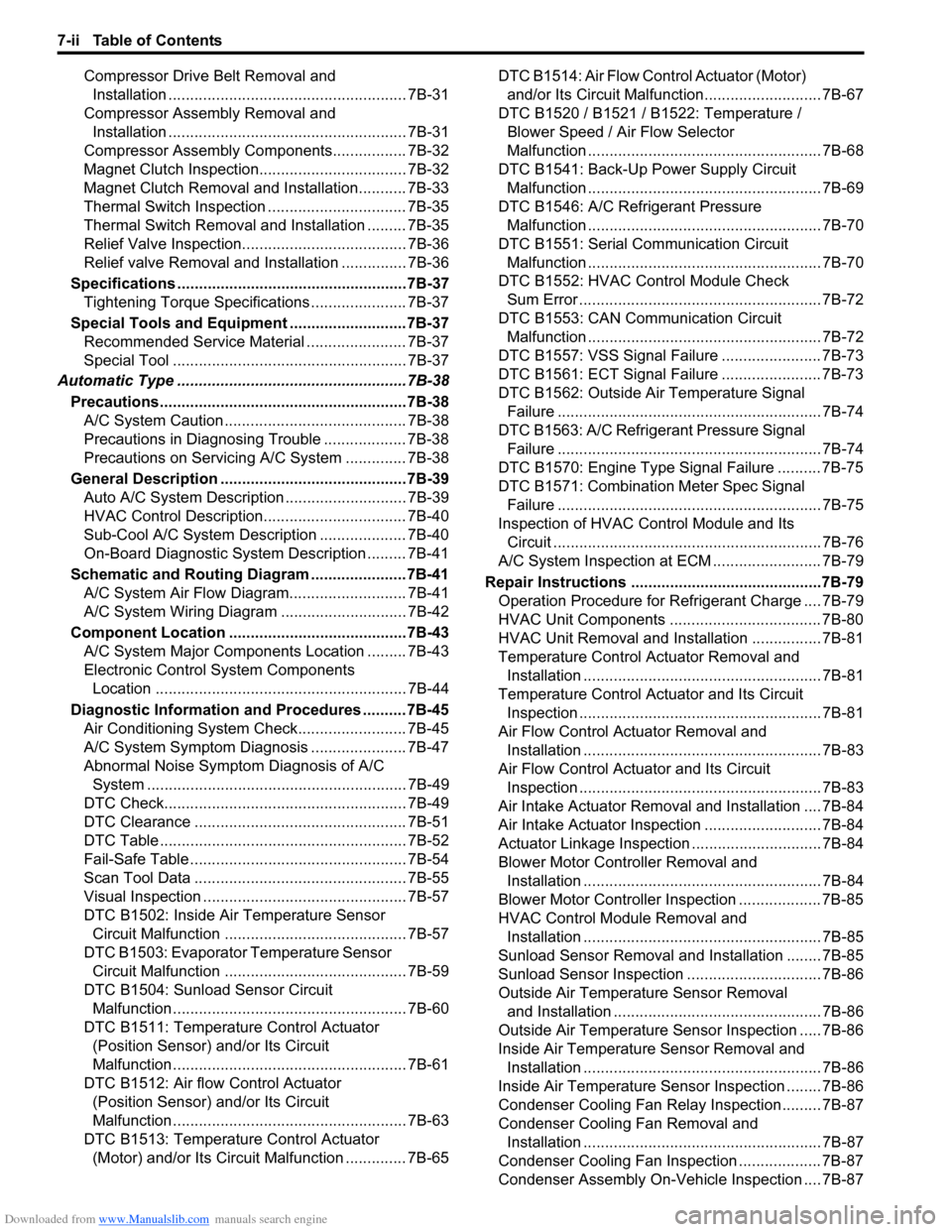

Downloaded from www.Manualslib.com manuals search engine Table of Contents 7- i

7

Section 7

CONTENTS

HVAC

Precautions ................................................. 7-1

Precautions............................................................. 7-1

Precautions on HVAC ........................................... 7-1

Heater and Ventilation............................. 7A-1

General Description ............................................. 7A-1

Heater and Ventilation Construction ................... 7A-1

Schematic and Routing Diagram ........................ 7A-2

Heater and Ventilation Wiring Circuit Diagram .... 7A-2

Component Location ........................................... 7A-2

Electronic Control System Components

Location ............................................................ 7A-2

Diagnostic Information and Procedures ............ 7A-3

Heater and Ventilation Symptom Diagnosis........ 7A-3

Repair Instructions .............................................. 7A-4

HVAC Unit Components ..................................... 7A-4

HVAC Unit Removal and Installation (Non-A/

C) ...................................................................... 7A-4

Blower Motor Removal and Installation............... 7A-4

Blower Motor Inspection ..................................... 7A-4

Blower Motor Resistor Removal and

Installation ......................................................... 7A-5

Blower Motor Resistor Inspection ....................... 7A-5

Blower Motor Relay Inspection ........................... 7A-6

HVAC Control Unit Components ......................... 7A-6

HVAC Control Unit Removal and Installation ...... 7A-7

Blower Speed Selector Inspection ...................... 7A-9

Air Intake Selector Inspection ............................. 7A-9

Air Intake Control Actuator Removal and

Installation ......................................................... 7A-9

Air Intake Control Actuator Inspection .............. 7A-10

Center Ventilation Louver Removal and

Installation ....................................................... 7A-11

Side Ventilation Louver Removal and

Installation ....................................................... 7A-11

Rear Duct Removal and Installation (If

Equipped)........................................................ 7A-12

HVAC Air Filter Removal and Installation (If

Equipped)........................................................ 7A-12

HVAC Air Filter Inspection (If Equipped) ........... 7A-12

Air Conditioning System......................... 7B-1

Manual Type ............................................................ 7B-1

Precautions........................................................... 7B-1A/C System Caution ............................................ 7B-1

Precautions on Servicing A/C System ................ 7B-1

General Description .............................................7B-2

Sub-Cool A/C System Description ...................... 7B-2

Manual A/C Electronic Input Output Table .......... 7B-3

A/C Operation Description at ECM ..................... 7B-3

Schematic and Routing Diagram ........................7B-4

A/C System Air Flow Diagram............................. 7B-4

A/C System Wiring Diagram ............................... 7B-5

Component Location ...........................................7B-6

A/C System Major Components Location ........... 7B-6

Electronic Control System Components

Location............................................................. 7B-7

Diagnostic Information and Procedures ............7B-8

A/C System Performance Inspection .................. 7B-8

Trouble Diagnosis for Abnormal Pressure ........ 7B-11

A/C System Inspection at ECM ......................... 7B-12

A/C System Symptom Diagnosis ...................... 7B-13

Abnormal Noise Symptom Diagnosis of A/C

System ............................................................ 7B-15

Repair Instructions ............................................7B-17

Operation Procedure for Refrigerant Charge .... 7B-17

Condenser Cooling Fan Removal and

Installation ....................................................... 7B-22

Condenser Cooling Fan Inspection ................... 7B-23

Condenser Assembly On-Vehicle Inspection .... 7B-23

Condenser Assembly Removal and

Installation ....................................................... 7B-23

Desiccant Removal and Installation .................. 7B-24

HVAC Unit Components ................................... 7B-25

HVAC Unit Removal and Installation ................ 7B-26

Evaporator Inspection ....................................... 7B-27

Evaporator Temperature Sensor Removal

and Installation ................................................ 7B-27

Evaporator Temperature Sensor Inspection ..... 7B-28

Expansion Valve Removal and Installation ....... 7B-28

Expansion Valve Inspection .............................. 7B-28

A/C Refrigerant Pressure Sensor and Its

Circuit Inspection............................................. 7B-29

A/C Refrigerant Pressure Sensor Removal

and Installation ................................................ 7B-29

A/C Switch Inspection ....................................... 7B-29

A/C System Relay Inspection............................ 7B-30

Compressor Drive Belt Inspection and

Adjustment ...................................................... 7B-30

Page 926 of 1556

Downloaded from www.Manualslib.com manuals search engine 7-ii Table of Contents

Compressor Drive Belt Removal and

Installation ....................................................... 7B-31

Compressor Assembly Removal and

Installation ....................................................... 7B-31

Compressor Assembly Components................. 7B-32

Magnet Clutch Inspection.................................. 7B-32

Magnet Clutch Removal and Installation........... 7B-33

Thermal Switch Inspection ................................ 7B-35

Thermal Switch Removal and Installation ......... 7B-35

Relief Valve Inspection...................................... 7B-36

Relief valve Removal and Installation ............... 7B-36

Specifications .....................................................7B-37

Tightening Torque Specifications ...................... 7B-37

Special Tools and Equipment ...........................7B-37

Recommended Service Material ....................... 7B-37

Special Tool ...................................................... 7B-37

Automatic Type .....................................................7B-38

Precautions.........................................................7B-38

A/C System Caution .......................................... 7B-38

Precautions in Diagnosing Trouble ................... 7B-38

Precautions on Servicing A/C System .............. 7B-38

General Description ...........................................7B-39

Auto A/C System Description ............................ 7B-39

HVAC Control Description................................. 7B-40

Sub-Cool A/C System Description .................... 7B-40

On-Board Diagnostic System Description ......... 7B-41

Schematic and Routing Diagram ......................7B-41

A/C System Air Flow Diagram........................... 7B-41

A/C System Wiring Diagram ............................. 7B-42

Component Location .........................................7B-43

A/C System Major Components Location ......... 7B-43

Electronic Control System Components

Location .......................................................... 7B-44

Diagnostic Information and Procedures ..........7B-45

Air Conditioning System Check......................... 7B-45

A/C System Symptom Diagnosis ...................... 7B-47

Abnormal Noise Symptom Diagnosis of A/C

System ............................................................ 7B-49

DTC Check........................................................ 7B-49

DTC Clearance ................................................. 7B-51

DTC Table ......................................................... 7B-52

Fail-Safe Table .................................................. 7B-54

Scan Tool Data ................................................. 7B-55

Visual Inspection ............................................... 7B-57

DTC B1502: Inside Air Temperature Sensor

Circuit Malfunction .......................................... 7B-57

DTC B1503: Evaporator Temperature Sensor

Circuit Malfunction .......................................... 7B-59

DTC B1504: Sunload Sensor Circuit

Malfunction ...................................................... 7B-60

DTC B1511: Temperature Control Actuator

(Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-61

DTC B1512: Air flow Control Actuator

(Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-63

DTC B1513: Temperature Control Actuator

(Motor) and/or Its Circuit Malfunction .............. 7B-65DTC B1514: Air Flow Control Actuator (Motor)

and/or Its Circuit Malfunction........................... 7B-67

DTC B1520 / B1521 / B1522: Temperature /

Blower Speed / Air Flow Selector

Malfunction ...................................................... 7B-68

DTC B1541: Back-Up Power Supply Circuit

Malfunction ...................................................... 7B-69

DTC B1546: A/C Refrigerant Pressure

Malfunction ...................................................... 7B-70

DTC B1551: Serial Communication Circuit

Malfunction ...................................................... 7B-70

DTC B1552: HVAC Control Module Check

Sum Error ........................................................ 7B-72

DTC B1553: CAN Communication Circuit

Malfunction ...................................................... 7B-72

DTC B1557: VSS Signal Failure ....................... 7B-73

DTC B1561: ECT Signal Failure ....................... 7B-73

DTC B1562: Outside Air Temperature Signal

Failure ............................................................. 7B-74

DTC B1563: A/C Refrigerant Pressure Signal

Failure ............................................................. 7B-74

DTC B1570: Engine Type Signal Failure .......... 7B-75

DTC B1571: Combination Meter Spec Signal

Failure ............................................................. 7B-75

Inspection of HVAC Control Module and Its

Circuit .............................................................. 7B-76

A/C System Inspection at ECM ......................... 7B-79

Repair Instructions ............................................7B-79

Operation Procedure for Refrigerant Charge .... 7B-79

HVAC Unit Components ................................... 7B-80

HVAC Unit Removal and Installation ................ 7B-81

Temperature Control Actuator Removal and

Installation ....................................................... 7B-81

Temperature Control Actuator and Its Circuit

Inspection ........................................................ 7B-81

Air Flow Control Actuator Removal and

Installation ....................................................... 7B-83

Air Flow Control Actuator and Its Circuit

Inspection ........................................................ 7B-83

Air Intake Actuator Removal and Installation .... 7B-84

Air Intake Actuator Inspection ........................... 7B-84

Actuator Linkage Inspection.............................. 7B-84

Blower Motor Controller Removal and

Installation ....................................................... 7B-84

Blower Motor Controller Inspection ................... 7B-85

HVAC Control Module Removal and

Installation ....................................................... 7B-85

Sunload Sensor Removal and Installation ........ 7B-85

Sunload Sensor Inspection ............................... 7B-86

Outside Air Temperature Sensor Removal

and Installation ................................................ 7B-86

Outside Air Temperature Sensor Inspection ..... 7B-86

Inside Air Temperature Sensor Removal and

Installation ....................................................... 7B-86

Inside Air Temperature Sensor Inspection ........ 7B-86

Condenser Cooling Fan Relay Inspection......... 7B-87

Condenser Cooling Fan Removal and

Installation ....................................................... 7B-87

Condenser Cooling Fan Inspection ................... 7B-87

Condenser Assembly On-Vehicle Inspection .... 7B-87

Page 929 of 1556

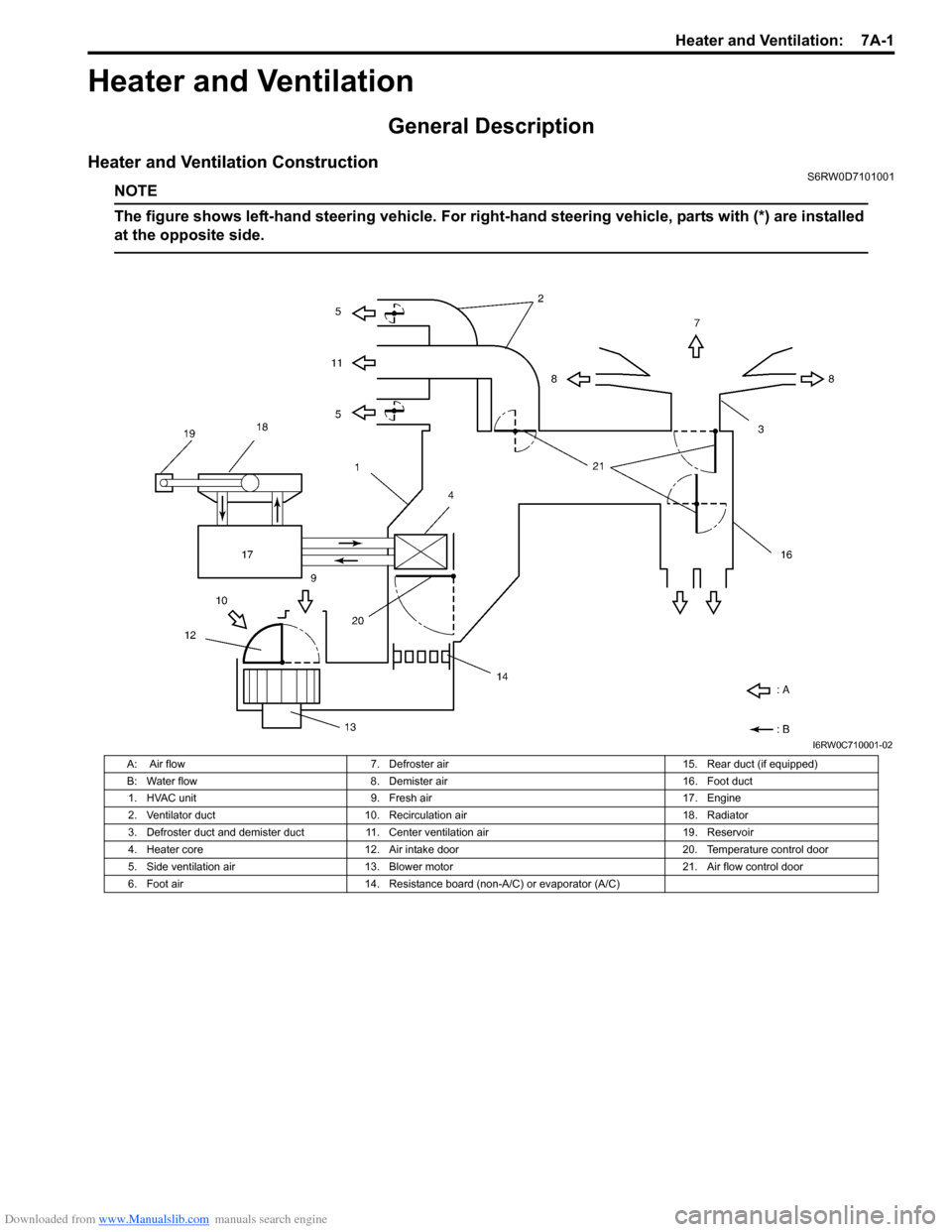

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-1

HVAC

Heater and Ventilation

General Description

Heater and Ventilation ConstructionS6RW0D7101001

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

I6RW0C710001-02

A: Air flow 7. Defroster air 15. Rear duct (if equipped)

B: Water flow 8. Demister air 16. Foot duct

1. HVAC unit 9. Fresh air 17. Engine

2. Ventilator duct 10. Recirculation air 18. Radiator

3. Defroster duct and demister duct 11. Center ventilation air 19. Reservoir

4. Heater core 12. Air intake door 20. Temperature control door

5. Side ventilation air 13. Blower motor 21. Air flow control door

6. Foot air 14. Resistance board (non-A/C) or evaporator (A/C)

Page 930 of 1556

Downloaded from www.Manualslib.com manuals search engine 7A-2 Heater and Ventilation:

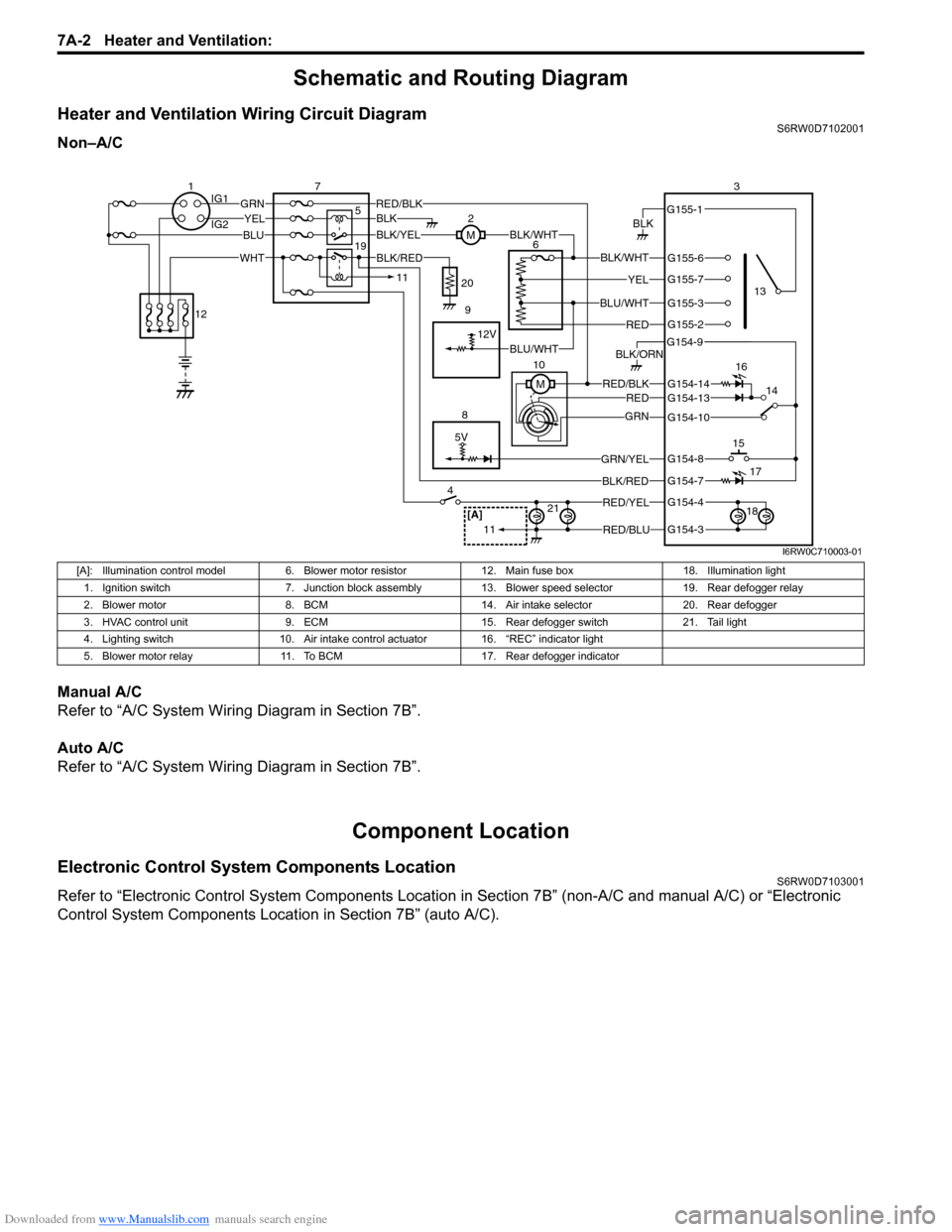

Schematic and Routing Diagram

Heater and Ventilation Wiring Circuit DiagramS6RW0D7102001

Non–A/C

Manual A/C

Refer to “A/C System Wiring Diagram in Section 7B”.

Auto A/C

Refer to “A/C System Wiring Diagram in Section 7B”.

Component Location

Electronic Control System Components LocationS6RW0D7103001

Refer to “Electronic Control System Components Location in Section 7B” (non-A/C and manual A/C) or “Electronic

Control System Components Location in Section 7B” (auto A/C).

5V

BLK

RED/BLK3

5 72

G154-3

G154-4

G154-7

G154-8

G154-10

G154-13

G155-2

G155-3

G155-7

G155-6

G155-1

G154-9

G154-14

BLK/WHT

YEL

BLU/WHT

RED

RED/BLKRED

GRN

GRN/YEL

RED/YEL

RED/BLU

BLK/ORN

46

8

BLU

YELGRN

WHT

13

1514

[A]21

BLK/RED

12V

BLK/YELBLK/WHTM

BLK

1IG1

IG2

12

BLK/RED

M 10

11

11

BLU/WHT 19

16

17

18 9 20

I6RW0C710003-01

[A]: Illumination control model 6. Blower motor resistor 12. Main fuse box 18. Illumination light

1. Ignition switch 7. Junction block assembly 13. Blower speed selector 19. Rear defogger relay

2. Blower motor 8. BCM 14. Air intake selector 20. Rear defogger

3. HVAC control unit 9. ECM 15. Rear defogger switch 21. Tail light

4. Lighting switch 10. Air intake control actuator 16. “REC” indicator light

5. Blower motor relay 11. To BCM 17. Rear defogger indicator

Page 931 of 1556

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-3

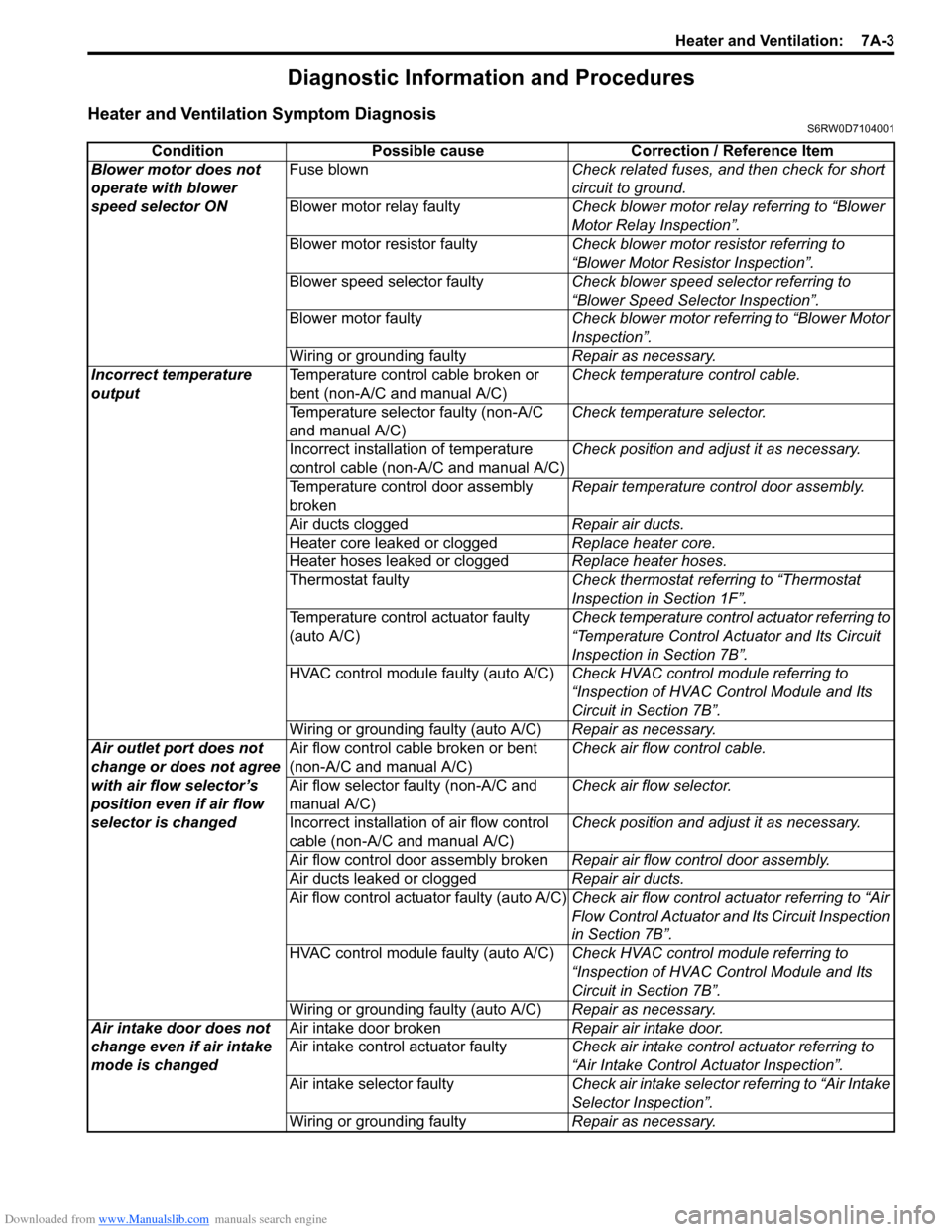

Diagnostic Information and Procedures

Heater and Ventilation Symptom DiagnosisS6RW0D7104001

Condition Possible cause Correction / Reference Item

Blower motor does not

operate with blower

speed selector ONFuse blownCheck related fuses, and then check for short

circuit to ground.

Blower motor relay faultyCheck blower motor relay referring to “Blower

Motor Relay Inspection”.

Blower motor resistor faultyCheck blower motor resistor referring to

“Blower Motor Resistor Inspection”.

Blower speed selector faultyCheck blower speed selector referring to

“Blower Speed Selector Inspection”.

Blower motor faultyCheck blower motor referring to “Blower Motor

Inspection”.

Wiring or grounding faultyRepair as necessary.

Incorrect temperature

outputTemperature control cable broken or

bent (non-A/C and manual A/C)Check temperature control cable.

Temperature selector faulty (non-A/C

and manual A/C)Check temperature selector.

Incorrect installation of temperature

control cable (non-A/C and manual A/C)Check position and adjust it as necessary.

Temperature control door assembly

brokenRepair temperature control door assembly.

Air ducts cloggedRepair air ducts.

Heater core leaked or cloggedReplace heater core.

Heater hoses leaked or cloggedReplace heater hoses.

Thermostat faultyCheck thermostat referring to “Thermostat

Inspection in Section 1F”.

Temperature control actuator faulty

(auto A/C)Check temperature control actuator referring to

“Temperature Control Actuator and Its Circuit

Inspection in Section 7B”.

HVAC control module faulty (auto A/C)Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit in Section 7B”.

Wiring or grounding faulty (auto A/C)Repair as necessary.

Air outlet port does not

change or does not agree

with air flow selector’s

position even if air flow

selector is changedAir flow control cable broken or bent

(non-A/C and manual A/C)Check air flow control cable.

Air flow selector faulty (non-A/C and

manual A/C)Check air flow selector.

Incorrect installation of air flow control

cable (non-A/C and manual A/C)Check position and adjust it as necessary.

Air flow control door assembly brokenRepair air flow control door assembly.

Air ducts leaked or cloggedRepair air ducts.

Air flow control actuator faulty (auto A/C)Check air flow control actuator referring to “Air

Flow Control Actuator and Its Circuit Inspection

in Section 7B”.

HVAC control module faulty (auto A/C)Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit in Section 7B”.

Wiring or grounding faulty (auto A/C)Repair as necessary.

Air intake door does not

change even if air intake

mode is changedAir intake door brokenRepair air intake door.

Air intake control actuator faultyCheck air intake control actuator referring to

“Air Intake Control Actuator Inspection”.

Air intake selector faultyCheck air intake selector referring to “Air Intake

Selector Inspection”.

Wiring or grounding faultyRepair as necessary.

Page 934 of 1556

Downloaded from www.Manualslib.com manuals search engine 7A-6 Heater and Ventilation:

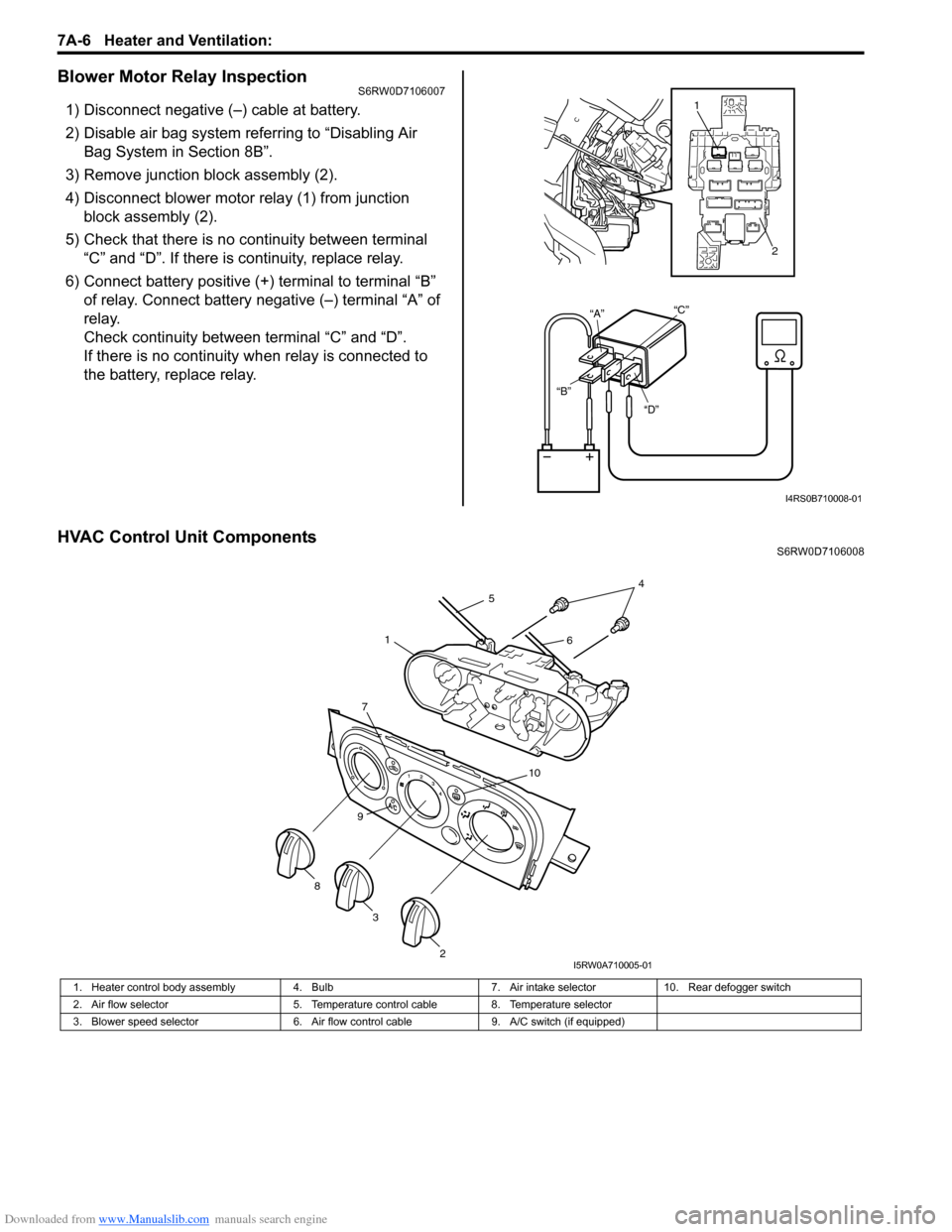

Blower Motor Relay InspectionS6RW0D7106007

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air

Bag System in Section 8B”.

3) Remove junction block assembly (2).

4) Disconnect blower motor relay (1) from junction

block assembly (2).

5) Check that there is no continuity between terminal

“C” and “D”. If there is continuity, replace relay.

6) Connect battery positive (+) terminal to terminal “B”

of relay. Connect battery negative (–) terminal “A” of

relay.

Check continuity between terminal “C” and “D”.

If there is no continuity when relay is connected to

the battery, replace relay.

HVAC Control Unit ComponentsS6RW0D7106008

“D” “B”“A”“C”

1

2

I4RS0B710008-01

1. Heater control body assembly 4. Bulb 7. Air intake selector 10. Rear defogger switch

2. Air flow selector 5. Temperature control cable 8. Temperature selector

3. Blower speed selector 6. Air flow control cable 9. A/C switch (if equipped)

7

10

9

2

3 8

45

61

I5RW0A710005-01

Page 937 of 1556

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-9

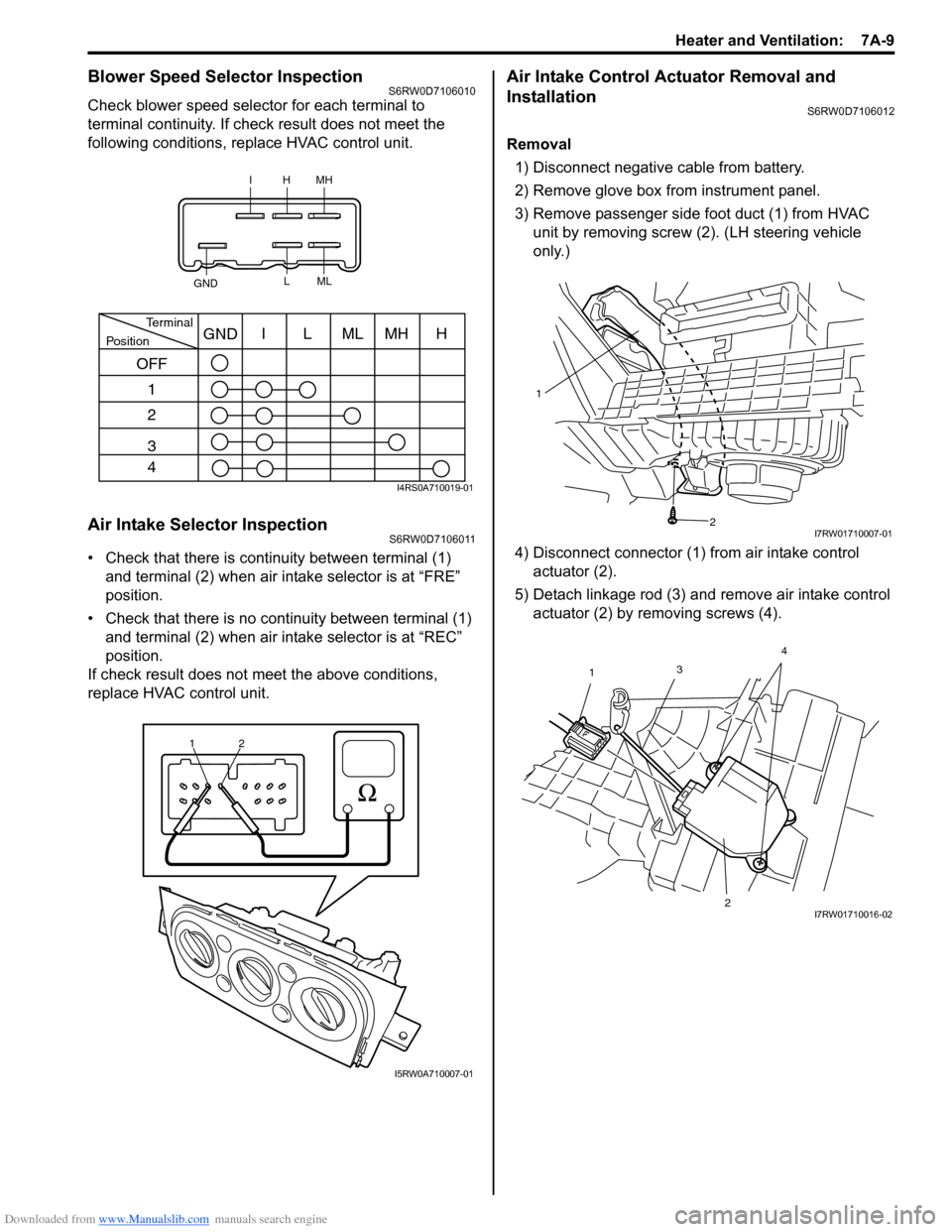

Blower Speed Selector InspectionS6RW0D7106010

Check blower speed selector for each terminal to

terminal continuity. If check result does not meet the

following conditions, replace HVAC control unit.

Air Intake Selector InspectionS6RW0D7106011

• Check that there is continuity between terminal (1)

and terminal (2) when air intake selector is at “FRE”

position.

• Check that there is no continuity between terminal (1)

and terminal (2) when air intake selector is at “REC”

position.

If check result does not meet the above conditions,

replace HVAC control unit.

Air Intake Control Actuator Removal and

Installation

S6RW0D7106012

Removal

1) Disconnect negative cable from battery.

2) Remove glove box from instrument panel.

3) Remove passenger side foot duct (1) from HVAC

unit by removing screw (2). (LH steering vehicle

only.)

4) Disconnect connector (1) from air intake control

actuator (2).

5) Detach linkage rod (3) and remove air intake control

actuator (2) by removing screws (4).

IHMH

GNDLML

PositionTerminalI

OFF

1

2

3

4LMLMHHGND

I4RS0A710019-01

1

2

I5RW0A710007-01

1

2

I7RW01710007-01

3

1

24I7RW01710016-02