terminal SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 522 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-25 Differential:

DTC C1254: 2WD/4WD Switch MalfunctionS6RW0D3204021

Wiring Diagram4Coupling assembly check

1) Check coupling assembly referring to “Coupling

Assembly Inspection”.

Is it in good condition?Substitute a known-

good 4WD control

module and recheck.Replace coupling

assembly.

5Coupling assembly circuit check

1) Disconnect connector from 4WD control module

connector “G26” with ignition switch turned OFF.

2) Check for proper connection to “G26-2” and “G26-3”

terminals of 4WD control module connector.

3) If connection is OK, measure resistance between “G26-

2” terminal of 4WD control module connector and

vehicle body ground.

Is resistance above 1 M

Ω?“YEL” wire is shorted to

ground circuit.Substitute a known-

good 4WD control

module and recheck.

6Coupling assembly circuit check

1) Disconnect connector from 4WD control module

connector “G26” with ignition switch turned OFF.

2) Check for proper connection to “G26-3” terminal of 4WD

control module connector.

3) If connection is OK, measure resistance between “G26-

3” terminal of 4WD control module connector and “L102-

1” terminal of coupling assembly connector.

Is resistance above 1 M

Ω?Substitute a known-

good 4WD control

module and recheck.“GRY” wire is shorted to

ground circuit. Step Action Yes No

G26-13

G26-14GRY/YEL

RED/WHT

12V

1

3

4

L174-1

L174-52L174-4BLK/ORN

1 2 3

4 5

6 7 8 9 10 11

12

13

14 15 16

17 18 19

20

21 22

23

24 25 26

[A]

2

64531

[B]

I7RW01320008-01

[A]: 4WD control module connector “G26” (viewed from harness side) 2. 2WD/4WD switch

[B]: 2WD/4WD switch connector “L174” (viewed from harness side) 3. “4WD” switch

1. 4WD control module 4. “4WD-lock” switch

Page 523 of 1556

Downloaded from www.Manualslib.com manuals search engine Differential: 3B-26

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Clear DTC using scan tool.

2) Select 2WD/4WD switch to “2WD” position and keep its position for 10 seconds. Similarly select 2WD/4WD switch

to “AUTO” and “LOCK” position.

3) Check DTC.

TroubleshootingDTC detecting condition Trouble area

2WD/4WD switch combination different from specification is

detected for more than 5 seconds.• 2WD/4WD switch

• 2WD/4WD switch circuit

• 4WD control module

Step Action Yes No

1Was “4WD control system check” performed?Go to Step 2. Go to “4WD Control

System Check”.

22WD/4WD switch circuit check

1) Disconnect 2WD/4WD switch connector “L174” with

ignition switch turned OFF.

2) Check for proper connection to “L174-1” and “L174-5”

terminals of 2WD/4WD switch connector.

3) If connection is OK, measure voltage between “L174-1”

terminal or “L174-5” terminal of 2WD/4WD switch

connector and vehicle body ground.

Is it 10 – 14 V?Go to Step 3. Go to Step 5.

32WD/4WD switch ground circuit check

1) Measure resistance between “L174-4” terminal of 2WD/

4WD switch connector and vehicle body ground with

ignition switch turned OFF.

Is resistance below 5

Ω?Go to Step 4. “BLK/ORN” wire is

shorted to ground.

42WD/4WD switch check

1) Check 2WD/4WD switch referring to “2WD/4WD Switch

Inspection”.

Is it in good condition?Substitute a known-

good 4WD control

module and recheck.Replace 2WD/4WD

switch.

52WD/4WD switch circuit check

1) Disconnect connector from 4WD control module

connector “G26” with ignition switch turned OFF.

2) Check for shorted to ground in related circuits.

• Between “G26-13” terminal of 4WD control module

connector and “L174-1” terminal of 2WD/4WD switch

connector.

• Between “G26-14” terminal of 4WD control module

connector and “L174-5” terminal of 2WD/4WD switch

connector.

Are they in good condition?Substitute a known-

good 4WD control

module and recheck.Repair circuit.

Page 524 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-27 Differential:

DTC U0073: Control Module Communication Bus OffS6RW0D3204022

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

DTC U0100: Lost Communication with ECMS6RW0D3204023

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

DTC U0121: Lost Communication with ABS / ESP® Control ModuleS6RW0D3204024

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

DTC U0155: Lost Communication with Instrument Panel Cluster (IPC) Control ModuleS6RW0D3204025

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

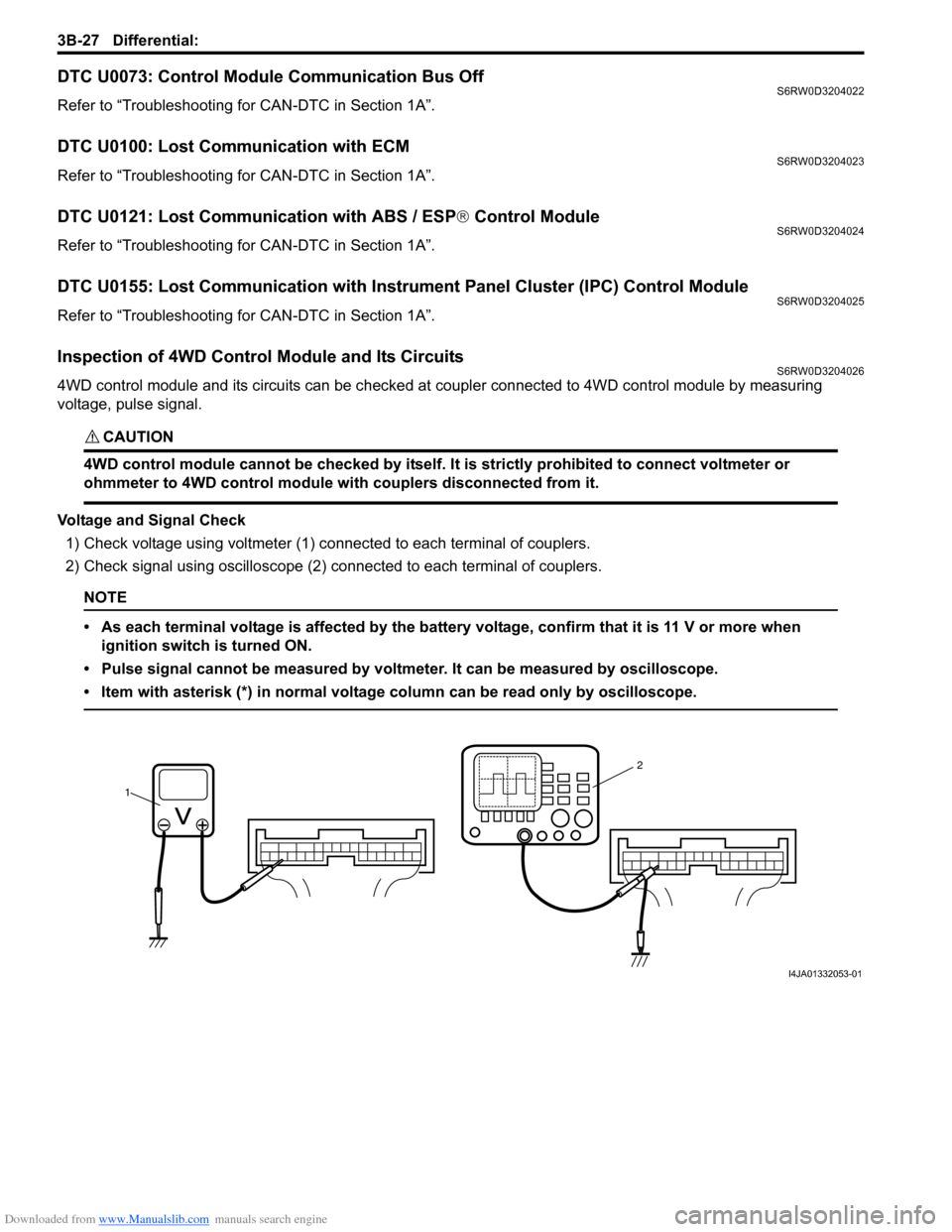

Inspection of 4WD Control Module and Its CircuitsS6RW0D3204026

4WD control module and its circuits can be checked at coupler connected to 4WD control module by measuring

voltage, pulse signal.

CAUTION!

4WD control module cannot be checked by itself. It is strictly prohibited to connect voltmeter or

ohmmeter to 4WD control module with couplers disconnected from it.

Voltage and Signal Check

1) Check voltage using voltmeter (1) connected to each terminal of couplers.

2) Check signal using oscilloscope (2) connected to each terminal of couplers.

NOTE

• As each terminal voltage is affected by the battery voltage, confirm that it is 11 V or more when

ignition switch is turned ON.

• Pulse signal cannot be measured by voltmeter. It can be measured by oscilloscope.

• Item with asterisk (*) in normal voltage column can be read only by oscilloscope.

12

I4JA01332053-01

Page 525 of 1556

Downloaded from www.Manualslib.com manuals search engine Differential: 3B-28

Terminal arrangement of 4WD control module connector (Viewed from harness side)

1 2 3 4 5 6 7 8 9 10 11 12

13 14 15 16 17 18 19 20 21 22 23 24 25 26

I4JA01332054-01

Terminal

NumberWire Color CircuitNormal

Vo l ta g eCondition

G26-1 — — — —

G26-2 GRNCoupling assembly

(ground)About 5 V Ignition switch turned ON position

G26-3 YELCoupling assembly

(power)10 – 12 V• Run engine at idle speed and 2WD/4WD switch at

4WD lock position

• Selector lever at “P” or “N” range (A/T model)

*0 – 12 V

(“Reference

waveform

No.1: ”)• Run engine at idle speed and 2WD/4WD switch at

4WD lock position

• Selector lever at other than “P” or “N” range (A/T

model) or depress accelerator pedal (M/T model)

About 5 V Above-mentioned condition

G26-4 — — — —

G26-5 — — — —

G26-6 — — — —

G26-7 — — — —

G26-8 — — — —

G26-9 — — — —

G26-10 BLK Ground 0 – 1 V —

G26-11 WHT/REDPower source for

internal memory10 – 14 V —

G26-12 RED/BLK Power source 10 – 14 V Ignition switch turned ON position

G26-13 RED/WHT 4WD switch0 – 1 VIgnition switch turned ON position and 2WD/4WD

switch at 4WD auto or 4WD lock position

10 – 14 VIgnition switch turned ON position and 2WD/4WD

switch at 2WD position

G26-14 GRN/YEL 4WD lock switch0 – 1 VIgnition switch turned ON position and 2WD/4WD

switch kept pushing at 4WD lock position

10 – 14 VIgnition switch turned ON position and 2WD/4WD

switch released at 4WD lock position

G26-15 — — — —

G26-16 — — — —

G26-17 — — — —

G26-18 — — — —

G26-19 — — — —

G26-20 — — — —

G26-21 BLUData link connector

(DLC)10 – 14 V Ignition switch turned ON position

G26-22 REDCAN communication

line (High)*2.5 – 3.6 V

(“Reference

waveform

No.2: ”)Ignition switch turned ON position

G26-23 WHTCAN communication

line (Low)*1.6 – 2.5 V

(“Reference

waveform

No.2: ”)Ignition switch turned ON position

Page 526 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-29 Differential:

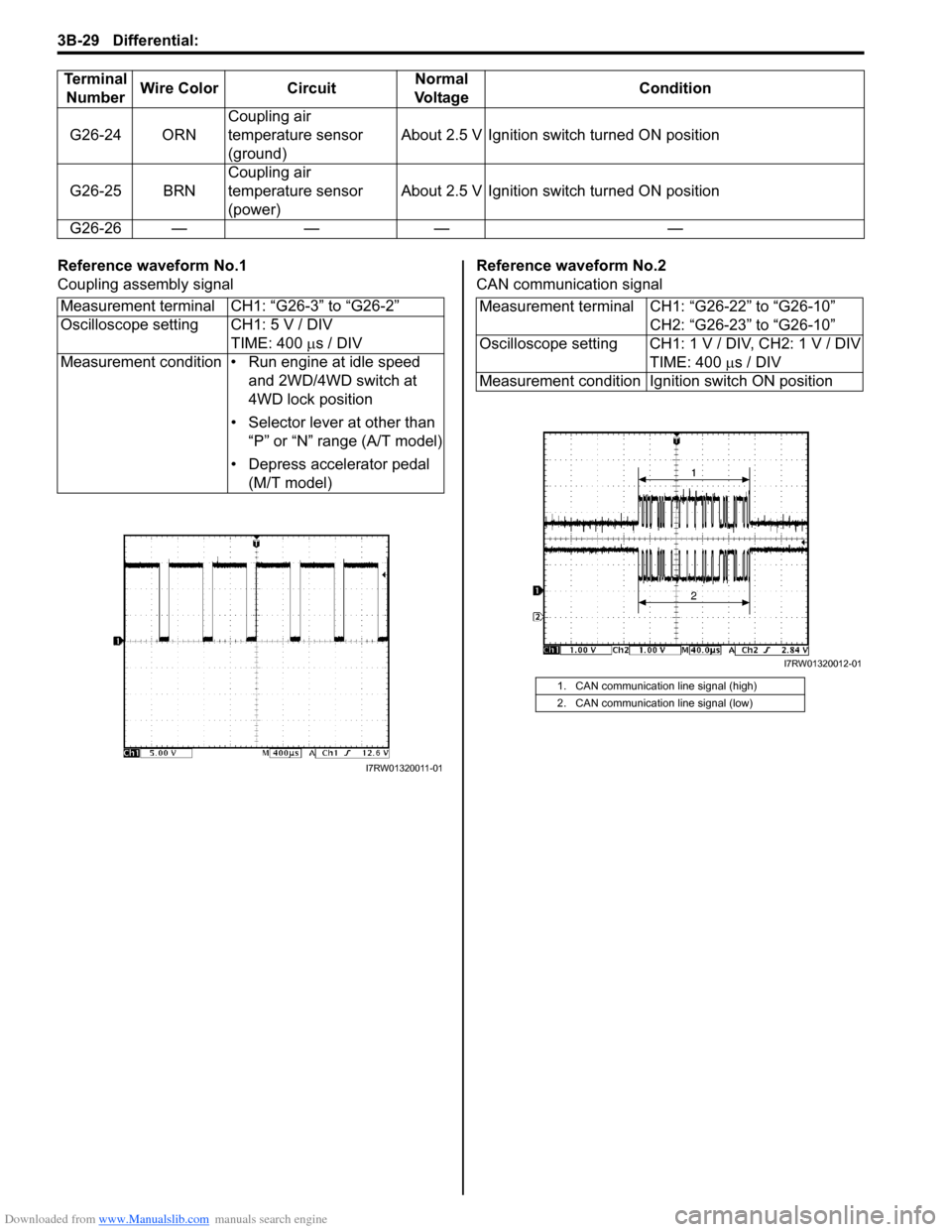

Reference waveform No.1

Coupling assembly signalReference waveform No.2

CAN communication signal G26-24 ORNCoupling air

temperature sensor

(ground)About 2.5 V Ignition switch turned ON position

G26-25 BRNCoupling air

temperature sensor

(power)About 2.5 V Ignition switch turned ON position

G26-26 — — — — Terminal

NumberWire Color CircuitNormal

Vo l ta g eCondition

Measurement terminal CH1: “G26-3” to “G26-2”

Oscilloscope setting CH1: 5 V / DIV

TIME: 400 µs / DIV

Measurement condition • Run engine at idle speed

and 2WD/4WD switch at

4WD lock position

• Selector lever at other than

“P” or “N” range (A/T model)

• Depress accelerator pedal

(M/T model)

I7RW01320011-01

Measurement terminal CH1: “G26-22” to “G26-10”

CH2: “G26-23” to “G26-10”

Oscilloscope setting CH1: 1 V / DIV, CH2: 1 V / DIV

TIME: 400 µs / DIV

Measurement condition Ignition switch ON position

1. CAN communication line signal (high)

2. CAN communication line signal (low)

I7RW01320012-01

Page 528 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-31 Differential:

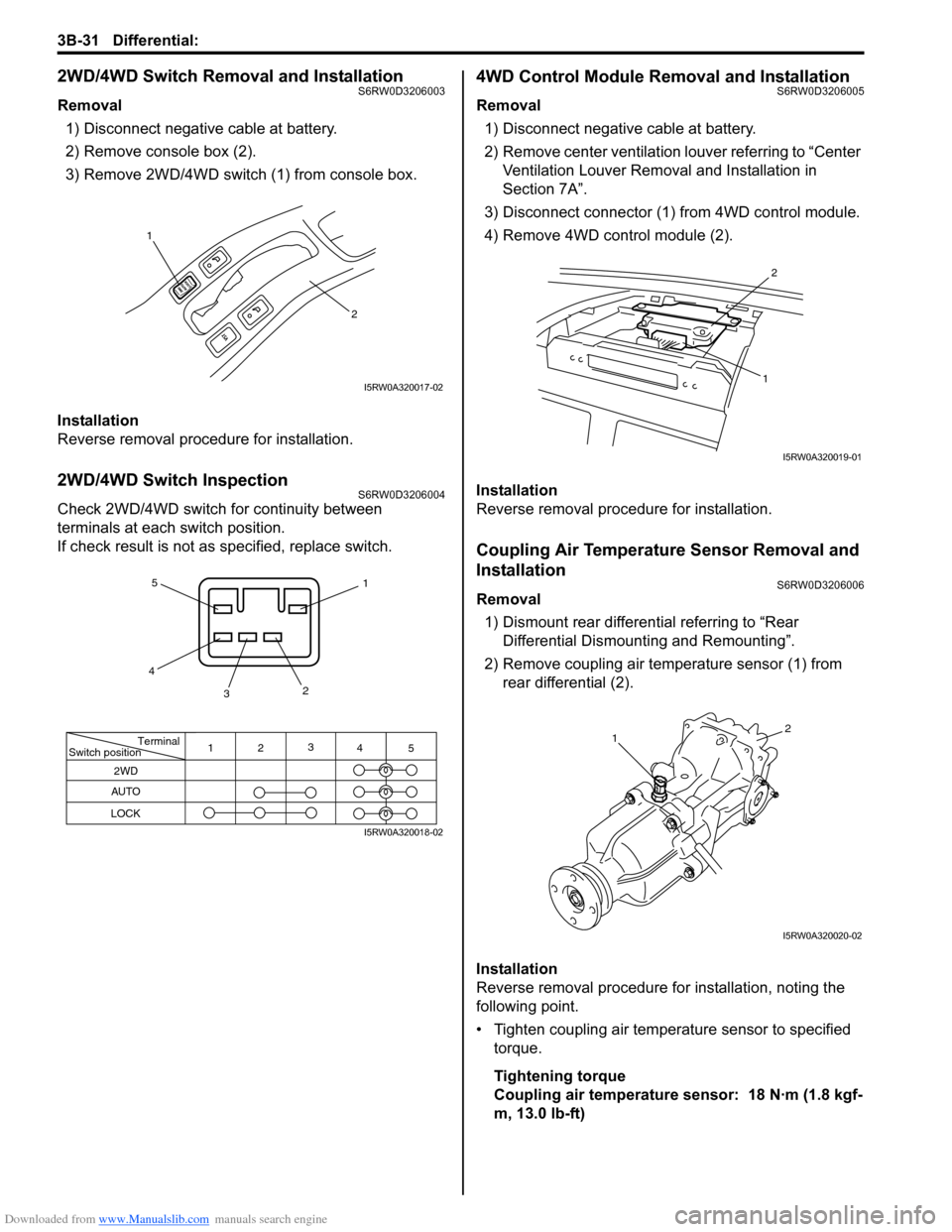

2WD/4WD Switch Removal and InstallationS6RW0D3206003

Removal

1) Disconnect negative cable at battery.

2) Remove console box (2).

3) Remove 2WD/4WD switch (1) from console box.

Installation

Reverse removal procedure for installation.

2WD/4WD Switch InspectionS6RW0D3206004

Check 2WD/4WD switch for continuity between

terminals at each switch position.

If check result is not as specified, replace switch.

4WD Control Module Removal and InstallationS6RW0D3206005

Removal

1) Disconnect negative cable at battery.

2) Remove center ventilation louver referring to “Center

Ventilation Louver Removal and Installation in

Section 7A”.

3) Disconnect connector (1) from 4WD control module.

4) Remove 4WD control module (2).

Installation

Reverse removal procedure for installation.

Coupling Air Temperature Sensor Removal and

Installation

S6RW0D3206006

Removal

1) Dismount rear differential referring to “Rear

Differential Dismounting and Remounting”.

2) Remove coupling air temperature sensor (1) from

rear differential (2).

Installation

Reverse removal procedure for installation, noting the

following point.

• Tighten coupling air temperature sensor to specified

torque.

Tightening torque

Coupling air temperature sensor: 18 N·m (1.8 kgf-

m, 13.0 lb-ft)

1

2

I5RW0A320017-02

Terminal

Switch position

2WD

AUTO

LOCK

11

22

3 3

4 4

5 5

I5RW0A320018-02

2

1

I5RW0A320019-01

12

I5RW0A320020-02

Page 529 of 1556

Downloaded from www.Manualslib.com manuals search engine Differential: 3B-32

Coupling Air Temperature Sensor InspectionS6RW0D3206007

CAUTION!

Do not heat up coupling air temperature

sensor more than 100 °C (212 °F). Otherwise,

coupling air temperature sensor will be

damaged.

• Blow hot air to temperature sensing part (2) of

coupling air temperature sensor (3) using hot air drier

(4) and measure resistance between sensor terminals

while heating air gradually.

If measured resistance does not show such

characteristic as shown, replace air temperature

sensor.

Coupling Assembly InspectionS6RW0D3206008

• Check coupling assembly for oil leakage. If leakage

exists, replace it.

• Measure resistance between “a” terminal and “b”

terminal of coupling connector (1).

If measured resistance is out of specification, check

harness for open or short.

If OK, replace coupling assembly.

Coupling assembly resistance

: 2 – 3 Ω

[A]: Lower limit [D]: Resistance

[B]: Normal [E]: Temperature

[C]: Upper limit 1. Temperature gauge

020

32 68 17680 (6.00)

(0.34) (2.56)

1

4

23

[D]

[C]

[B]

[A]

[E]

I5RW0A320021-01

1

“a” “b”I5RW0A320064-01

Page 611 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-6

17+BB

18BLU

WHT12VGRN/ORN 34

30E08-9

RED

WHT 1226

WHT/RED

12V

E08-7

19GRN

GRN

E08-16

12V

5

76

21REDRED/BLK

12V

BLKWHTE08-22 E08-11

23BLKWHTLT GRN/BLKLT GRN

12V

E08-10 E08-21

E08-23

E08-26

E08-1E08-12

24BLKWHT

12V

YELBRNE08-19 E08-20

27

1 2

RED/BLK

WHTRED

WHTRED

WHTRED9

E08-2E08-13WHT

E08-6

RED

9

9

11

9

9

9

REDWHT

WHTRED

12VE08-25

M

BLK

BLK

WHT/BLUWHT/RED

WHT/BLUE08-24

WHT

E08 [A]

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26

GRN/WHT

22

12V

BLKWHTWHTWHT/BLKE08-17 E08-18

GRN/ORN28

2033

31

29

25

15

32

GRN/YELE08-3GRN/BLK

8

12V

12V

13

14RED/BLK

RED/BLU

WHTRED6

16

10

BLK [B]

I6RW0D450001-02

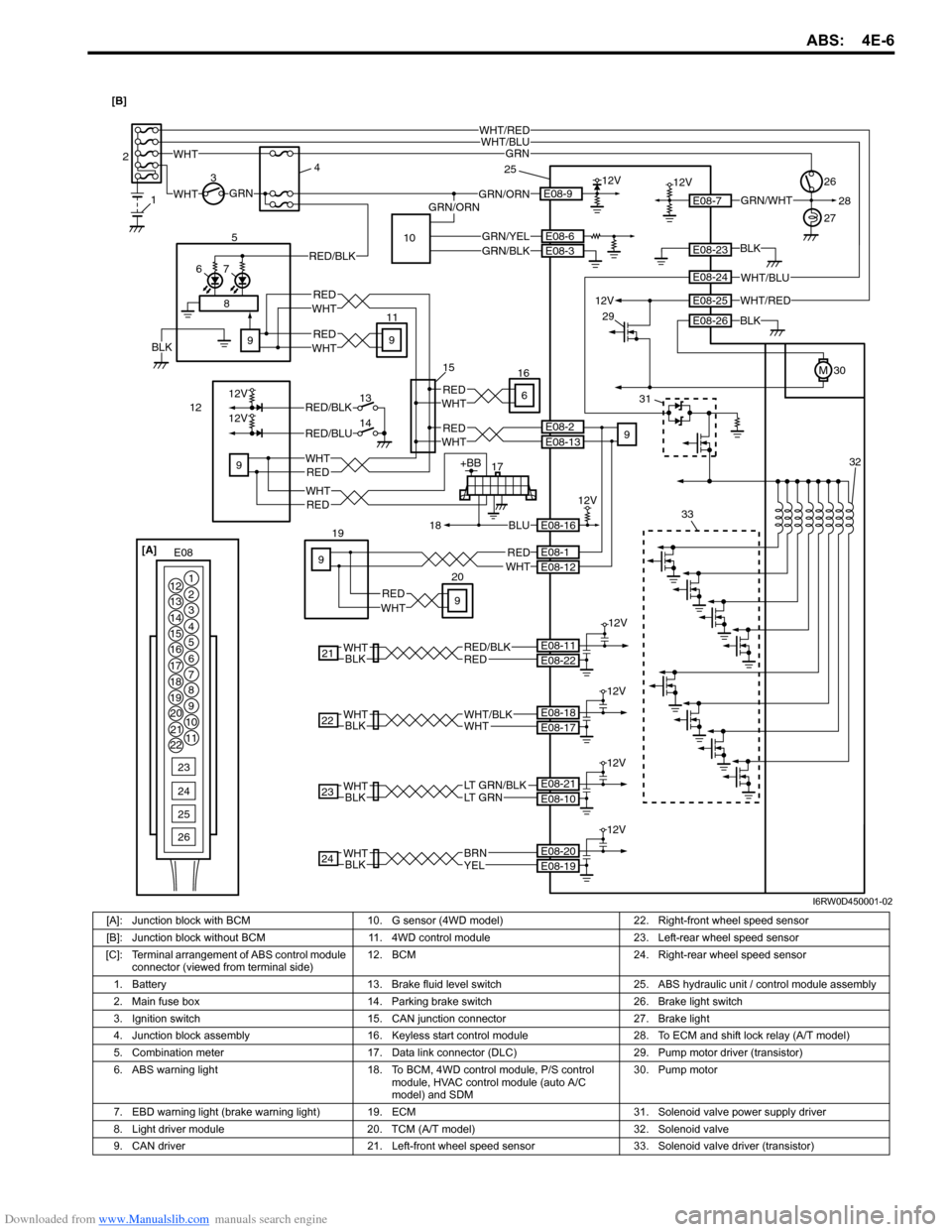

[A]: Junction block with BCM 10. G sensor (4WD model) 22. Right-front wheel speed sensor

[B]: Junction block without BCM 11. 4WD control module 23. Left-rear wheel speed sensor

[C]: Terminal arrangement of ABS control module

connector (viewed from terminal side)12. BCM 24. Right-rear wheel speed sensor

1. Battery 13. Brake fluid level switch 25. ABS hydraulic unit / control module assembly

2. Main fuse box 14. Parking brake switch 26. Brake light switch

3. Ignition switch 15. CAN junction connector 27. Brake light

4. Junction block assembly 16. Keyless start control module 28. To ECM and shift lock relay (A/T model)

5. Combination meter 17. Data link connector (DLC) 29. Pump motor driver (transistor)

6. ABS warning light 18. To BCM, 4WD control module, P/S control

module, HVAC control module (auto A/C

model) and SDM30. Pump motor

7. EBD warning light (brake warning light)19. ECM 31. Solenoid valve power supply driver

8. Light driver module 20. TCM (A/T model) 32. Solenoid valve

9. CAN driver 21. Left-front wheel speed sensor 33. Solenoid valve driver (transistor)

Page 619 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-14

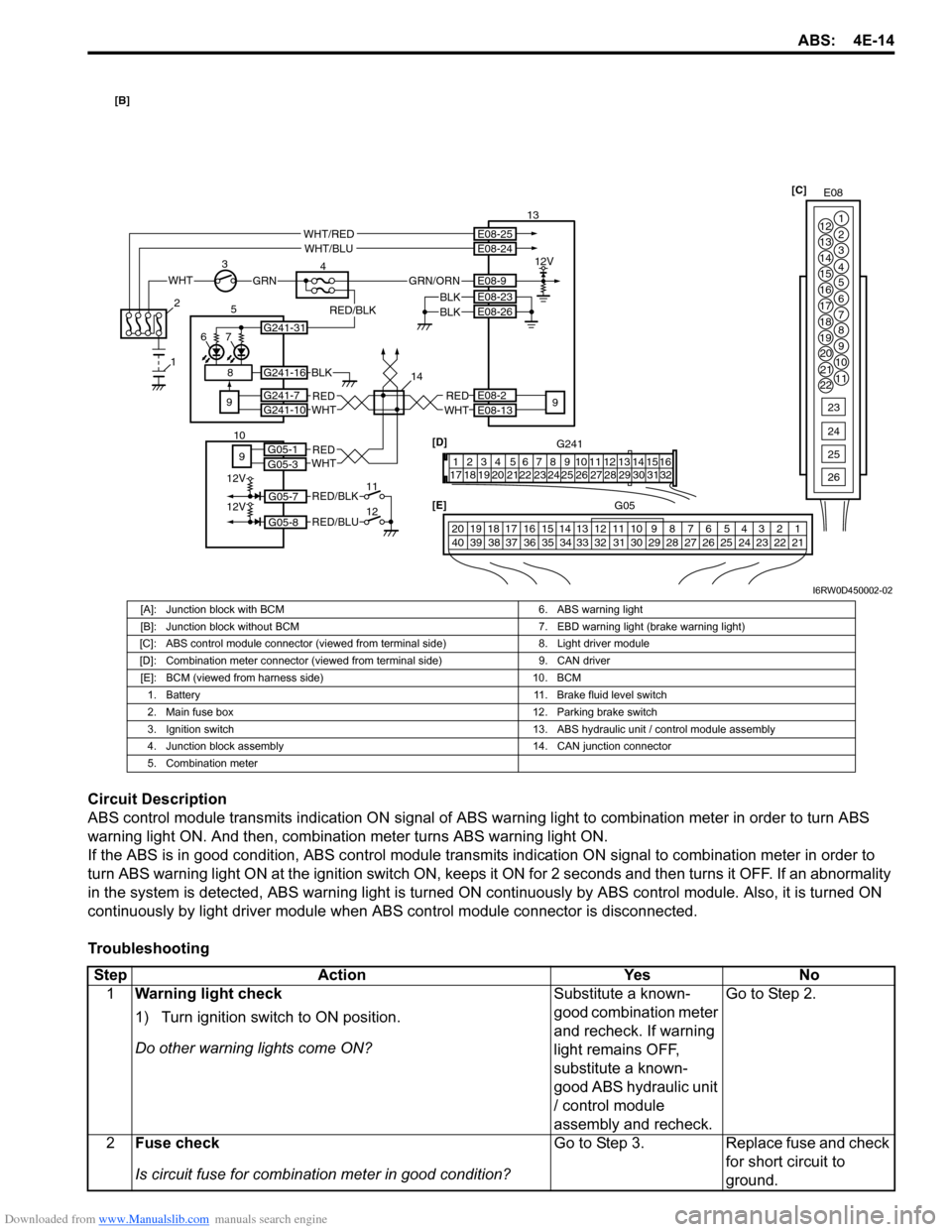

Circuit Description

ABS control module transmits indication ON signal of ABS warning light to combination meter in order to turn ABS

warning light ON. And then, combination meter turns ABS warning light ON.

If the ABS is in good condition, ABS control module transmits indication ON signal to combination meter in order to

turn ABS warning light ON at the ignition switch ON, keeps it ON for 2 seconds and then turns it OFF. If an abnormality

in the system is detected, ABS warning light is turned ON continuously by ABS control module. Also, it is turned ON

continuously by light driver module when ABS control module connector is disconnected.

Troubleshooting

G241 [D]

132 4 5 6 7 8 9 10111213141516

17 1918 20 2122 23 24 25 26 27 28 29 30 31 32E08 [C]

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26

G05 [E]

1 2 3 4 765 8 9 10 11 14 15 16

36 34 33 32 3135 24 23 2122 28 27 2526 37 39 38 4018 17 13 12 19 20

30 29

WHTGRN

3

E08-2

E08-13REDWHT 5

4 13

9

E08-23

E08-26BLKBLK

67

BLK

REDWHTG241-7G241-10

G241-16

12V

E08-25E08-24

E08-9

WHT/REDWHT/BLU

GRN/ORN

9

2

1

14

G241-31

RED/BLK

8

REDWHT9

12V

12V

11

12G05-7

G05-1G05-3

G05-8

RED/BLK

RED/BLU

10

[B]

I6RW0D450002-02

[A]: Junction block with BCM 6. ABS warning light

[B]: Junction block without BCM 7. EBD warning light (brake warning light)

[C]: ABS control module connector (viewed from terminal side) 8. Light driver module

[D]: Combination meter connector (viewed from terminal side) 9. CAN driver

[E]: BCM (viewed from harness side) 10. BCM

1. Battery 11. Brake fluid level switch

2. Main fuse box 12. Parking brake switch

3. Ignition switch 13. ABS hydraulic unit / control module assembly

4. Junction block assembly 14. CAN junction connector

5. Combination meter

Step Action Yes No

1Warning light check

1) Turn ignition switch to ON position.

Do other warning lights come ON?Substitute a known-

good combination meter

and recheck. If warning

light remains OFF,

substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.Go to Step 2.

2Fuse check

Is circuit fuse for combination meter in good condition?Go to Step 3. Replace fuse and check

for short circuit to

ground.

Page 623 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-18

WHTGRN

3

E08-2

E08-13REDWHT 5

4 12

9

E08-23

E08-26BLKBLK

76

BLK

REDWHTG241-7G241-10

G241-16

12V

E08-25E08-24

E08-9

WHT/REDWHT/BLU

GRN/ORN

9

REDWHTG05-1G05-3

REDWHTG05-4G05-2

9

2

1

13

G241-31

RED/BLK

8

11+BBBG

G1

12V

E08-1614BLU 10

[C]E08

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26

G05 [E]

1 2 3 4 765 8 9 10 11 14 15 16

36 34 33 32 3135 24 23 2122 28 27 2526 37 39 38 4018 17 13 12 19 20

30 29

G241 [D]

132 4 5 6 7 8 9 10111213141516

17 1918 20 2122 23 24 25 26 27 28 29 30 31 32 [B]

I6RW0D450003-02

[A]: Junction block with BCM 3. Ignition switch 10. BCM

[B]: Junction block without BCM 4. Junction block assembly 11. Data link connector (DLC)

[C]: ABS control module connector (viewed from

terminal side)5. Combination meter 12. ABS hydraulic unit / control module assembly

[D]: BCM connector (viewed from harness side) 6.ABS warning light 13. CAN junction connector

[E]: Combination meter connector (viewed from

terminal side)7. EBD warning light (brake

warning light)14. To TCM (A/T model), BCM, 4WD control module, P/S control

module (electric P/S model), HVAC control module (auto A/C

model) and SDM

1. Battery 8. Light driver module

2. Main fuse box 9. CAN driver