Fuel System SUZUKI SX4 2006 1.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 47 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 1-iii

EGR Valve Removal and Installation (If

Equipped).......................................................... 1B-4

EGR Valve Inspection (If Equipped) ................... 1B-4

PCV Hose Inspection .......................................... 1B-5

PCV Valve Inspection ......................................... 1B-5

Special Tools and Equipment ............................. 1B-5

Special Tool ........................................................ 1B-5

Engine Electrical Devices ....................... 1C-1

Repair Instructions .............................................. 1C-1

Engine Control Module (ECM) Removal and

Installation ......................................................... 1C-1

Manifold Absolute Pressure (MAP) Sensor

Inspection (If Equipped) .................................... 1C-2

Electric Throttle Body Assembly On-Vehicle

Inspection.......................................................... 1C-2

Electric Throttle Body System Calibration ........... 1C-5

Accelerator Pedal Position (APP) Sensor

Assembly On-Vehicle Inspection ...................... 1C-5

Accelerator Pedal Position (APP) Sensor

Assembly Removal and Installation .................. 1C-5

Accelerator Pedal Position (APP) Sensor

Assembly Inspection ......................................... 1C-6

Engine Coolant Temperature (ECT) Sensor

Removal and Installation................................... 1C-7

Engine Coolant Temperature (ECT) Sensor

Inspection.......................................................... 1C-7

Heated Oxygen Sensor (HO2S-1 and HO2S-

2) Heater On-Vehicle Inspection (If

Equipped).......................................................... 1C-8

Heated Oxygen Sensor (HO2S-1 and HO2S-

2) Removal and Installation (If Equipped) ......... 1C-8

Camshaft Position (CMP) Sensor Removal

and Installation .................................................. 1C-9

Camshaft Position (CMP) Sensor Inspection ...... 1C-9

Crankshaft Position (CKP) Sensor Removal

and Installation ................................................ 1C-10

Crankshaft Position (CKP) Sensor Inspection .. 1C-11

Knock Sensor Removal and Installation ........... 1C-11

Main Relay, Fuel Pump Relay, Starting Motor

Control Relay, Throttle Actuator Control

Relay and Radiator Cooling Fan Relay

Inspection........................................................ 1C-12

Mass Air Flow (MAF) and Intake Air

Temperature (IAT) Sensor On-Vehicle

Inspection........................................................ 1C-12

Mass Air Flow (MAF) and Intake Air

Temperature (IAT) Sensor Removal and

Installation ....................................................... 1C-13

Intake Air Temperature (IAT) Sensor

Inspection........................................................ 1C-13

Specifications..................................................... 1C-14

Tightening Torque Specifications ...................... 1C-14

Engine Mechanical .................................. 1D-1

General Description ............................................. 1D-1

Engine Construction Description ......................... 1D-1

Camshaft Position Control (VVT Variable

Valve Timing) System Description .................... 1D-3Diagnostic Information and Procedures ............1D-5

Compression Check ............................................1D-5

Engine Vacuum Check........................................1D-6

Valve Lash (Clearance) Inspection .....................1D-7

Repair Instructions ............................................1D-10

Air Intake System Components.........................1D-10

Air Cleaner Filter Removal and Installation .......1D-10

Air Cleaner Filter Inspection and Cleaning........1D-10

Air Cleaner Assembly Removal and

Installation .......................................................1D-11

Cylinder Head Cover Removal and

Installation .......................................................1D-11

Throttle Body and Intake Manifold

Components ....................................................1D-13

Throttle Body On-Vehicle Inspection.................1D-14

Electric Throttle Body Assembly Removal and

Installation .......................................................1D-14

Throttle Body Cleaning......................................1D-14

Intake Manifold Removal and Installation .........1D-15

Engine Mountings Components ........................1D-16

Engine Assembly Removal and Installation ......1D-17

Timing Chain Cover Components .....................1D-22

Timing Chain Cover Removal and Installation ..1D-23

Timing Chain Cover Inspection .........................1D-25

Oil Control Valve Removal and Installation

(For Engine with VVT) .....................................1D-26

Oil Control Valve Inspection (For Engine with

VVT) ................................................................1D-26

Timing Chain and Chain Tensioner

Components ....................................................1D-27

Timing Chain and Chain Tensioner Removal

and Installation ................................................1D-27

Timing Chain and Chain Tensioner Inspection ..1D-31

Camshaft, Tappet and Shim Components ........1D-32

Camshaft, Tappet and Shim Removal and

Installation .......................................................1D-33

Camshaft, Tappet and Shim Inspection ............1D-36

Valves and Cylinder Head Components ...........1D-39

Valves and Cylinder Head Removal and

Installation .......................................................1D-40

Valves and Cylinder Head Disassembly and

Assembly.........................................................1D-42

Valves and Valve Guides Inspection.................1D-45

Cylinder Head Inspection ..................................1D-47

Valve Spring Inspection ....................................1D-48

Pistons, Piston Rings, Connecting Rods and

Cylinders Components ....................................1D-49

Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation .................1D-49

Pistons, Piston Rings, Connecting Rods and

Cylinders Disassembly and Assembly ............1D-51

Cylinders, Pistons and Piston Rings

Inspection ........................................................1D-52

Piston Pins and Connecting Rods Inspection ...1D-54

Crank Pin and Connecting Rod Bearings

Inspection ........................................................1D-55

Main Bearings, Crankshaft and Cylinder

Block Components ..........................................1D-59

Main Bearings, Crankshaft and Cylinder

Block Removal and Installation .......................1D-60

Page 48 of 1556

Downloaded from www.Manualslib.com manuals search engine 1-iv Table of Contents

Crankshaft Inspection .......................................1D-63

Main Bearings Inspection ..................................1D-65

Sensor Plate Inspection ....................................1D-70

Rear Oil Seal Inspection ...................................1D-70

Flywheel Inspection...........................................1D-70

Cylinder Block Inspection ..................................1D-70

Specifications .....................................................1D-71

Tightening Torque Specifications ......................1D-71

Special Tools and Equipment ...........................1D-73

Recommended Service Material .......................1D-73

Special Tool ......................................................1D-73

Engine Lubrication System.....................1E-1

General Description ............................................. 1E-1

Engine Lubrication Description ........................... 1E-1

Diagnostic Information and Procedures ............ 1E-2

Oil Pressure Check ............................................. 1E-2

Repair Instructions .............................................. 1E-3

Oil Pan and Oil Pump Strainer Components....... 1E-3

Oil Pan and Oil Pump Strainer Removal and

Installation ......................................................... 1E-4

Oil Pan and Oil Pump Strainer Cleaning ............. 1E-5

Oil Pump Components ........................................ 1E-6

Oil Pump Removal and Installation ..................... 1E-6

Oil Pump Disassembly and Reassembly ............ 1E-6

Oil Pump Inspection ............................................ 1E-7

Specifications ....................................................... 1E-9

Tightening Torque Specifications ........................ 1E-9

Special Tools and Equipment ............................. 1E-9

Recommended Service Material ......................... 1E-9

Special Tool ........................................................ 1E-9

Engine Cooling System ........................... 1F-1

General Description ............................................. 1F-1

Cooling System Description ................................ 1F-1

Coolant Description ............................................. 1F-1

Schematic and Routing Diagram ........................ 1F-2

Coolant Circulation .............................................. 1F-2

Diagnostic Information and Procedures ............ 1F-3

Engine Cooling Symptom Diagnosis ................... 1F-3

Repair Instructions .............................................. 1F-4

Cooling System Components.............................. 1F-4

Coolant Level Check ........................................... 1F-5

Engine Cooling System Inspection and

Cleaning ............................................................ 1F-5

Cooling System Draining..................................... 1F-5

Cooling System Flush and Refill ......................... 1F-6

Cooling Water Pipes or Hoses Removal and

Installation ......................................................... 1F-6

Thermostat Removal and Installation.................. 1F-7

Thermostat Inspection......................................... 1F-7

Radiator Cooling Fan Assembly On-Vehicle

Inspection .......................................................... 1F-8

Radiator Cooling Fan Relay Inspection............... 1F-8

Radiator Cooling Fan Assembly Removal and

Installation ......................................................... 1F-8

Radiator Cooling Fan Disassembly and

Reassembly ...................................................... 1F-9

Radiator On-Vehicle Inspection and Cleaning .... 1F-9Radiator Removal and Installation ...................... 1F-9

Water Pump / Generator Drive Belt Tension

Inspection and Adjustment.............................. 1F-10

Water Pump / Generator Drive Belt Removal

and Installation ................................................ 1F-10

Water Pump Removal and Installation .............. 1F-11

Water Pump Inspection ..................................... 1F-12

Specifications ..................................................... 1F-12

Tightening Torque Specifications ...................... 1F-12

Special Tools and Equipment ........................... 1F-12

Recommended Service Material ....................... 1F-12

Fuel System ............................................. 1G-1

Precautions .......................................................... 1G-1

Precautions on Fuel System Service ................. 1G-1

General Description ............................................ 1G-2

Fuel System Description .................................... 1G-2

Fuel Delivery System Description ...................... 1G-2

Fuel Pump Description ....................................... 1G-2

Schematic and Routing Diagram ....................... 1G-3

Fuel Delivery System Diagram........................... 1G-3

Diagnostic Information and Procedures ........... 1G-3

Fuel Pressure Inspection ................................... 1G-3

Fuel Cut Operation Inspection ........................... 1G-4

Repair Instructions ............................................. 1G-5

Fuel System Components .................................. 1G-5

Fuel Hose Disconnecting and Reconnecting ..... 1G-6

Fuel Pressure Relief Procedure ......................... 1G-7

Fuel Leakage Check Procedure......................... 1G-8

Fuel Lines On-Vehicle Inspection ...................... 1G-8

Fuel Pipe Removal and Installation.................... 1G-8

Fuel Injector On-Vehicle Inspection ................... 1G-9

Fuel Injector Removal and Installation ............... 1G-9

Fuel Injector Inspection .................................... 1G-10

Fuel Filler Cap Inspection ................................ 1G-12

Fuel Tank Inlet Valve Removal and

Installation ...................................................... 1G-12

Fuel Tank Inlet Valve Inspection ...................... 1G-12

Fuel Tank Removal and Installation ................. 1G-13

Fuel Tank Inspection ........................................ 1G-14

Fuel Tank Purging Procedure .......................... 1G-15

Fuel Pump On-Vehicle Inspection.................... 1G-15

Fuel Pump Assembly Removal and

Installation ...................................................... 1G-15

Main Fuel Level Sensor Removal and

Installation ...................................................... 1G-16

Fuel Pump Inspection ...................................... 1G-17

Specifications .................................................... 1G-17

Tightening Torque Specifications ..................... 1G-17

Special Tools and Equipment .......................... 1G-18

Special Tool ..................................................... 1G-18

Ignition System ........................................ 1H-1

General Description .............................................1H-1

Ignition System Construction ..............................1H-1

Schematic and Routing Diagram ........................1H-2

Ignition System Wiring Circuit Diagram...............1H-2

Component Location ...........................................1H-3

Ignition System Components Location................1H-3

Page 50 of 1556

Downloaded from www.Manualslib.com manuals search engine 1-1 Precautions:

Engine

Precautions

Precautions

Precautions for EngineS6RW0D1000001

Air Bag Warning

Refer to “Air Bag Warning in Section 00”.

Precautions on Engine Service

Refer to “Precautions on Engine Service in Section 1A”.

Precautions in Diagnosing Trouble

Refer to “Precautions in Diagnosing Trouble in Section 1A”.

Precautions of ECM Circuit Inspection

Refer to “Precautions of ECM Circuit Inspection in Section 1A”.

Precautions on Fuel System Service

Refer to “Precautions on Fuel System Service in Section 1G”.

Precaution for CAN Communication System

Refer to “Precaution for CAN Communication System in Section 00”.

Precautions for Catalytic Converter

Refer to “Precautions for Catalytic Converter in Section 00”.

Precautions for Electrical Circuit Service

Refer to “Precautions for Electrical Circuit Service in Section 00”.

Page 52 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-2 Engine General Information and Diagnosis:

• When checking ECM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by ECM.

– CAN communication OBD generic scan tool

displays DTC detected by each of ECM and TCM

(for A/T model) simultaneously.

• Priorities for diagnosing troubles

If two or more DTCs are stored, proceed to the DTC

flow which has been detected earliest in the order and

follow the instruction in that flow.

If no instructions are given, troubleshoot DTCs

according to the following priorities.

a. DTCs other than DTC P0171 / P0172 (Fuel

system too lean / too rich), DTC P0300 / P0301 /

P0302 / P0303 / P0304 (Misfire detected) and

DTC P0401 / P0402 (EGR flow malfunction)

b. DTC P0171 / P0172 (Fuel system too lean / too

rich) and DTC P0401 / P0402 (EGR flow

malfunction)

c. DTC P0300 / P0301 / P0302 / P0303 / P0304

(Misfire detected)

• Be sure to read “Precautions for Electrical Circuit

Service in Section 00” before inspection and observe

what is written there.

• ECM replacement:

When substituting a known-good ECM, check for the

following conditions. Neglecting this check may cause

damage to a known-good ECM.

– Resistance value of all relays, actuators is as

specified respectively.

– MAP sensor, A/C refrigerant pressure sensor (if

equipped with A/C), accelerator pedal position

(APP) sensor and TP sensor are in good condition

and none of power circuits of these sensors is

shorted to ground.

• Communication of ECM, BCM, combination meter,

keyless start control module (if equipped with keyless

start control system), 4WD control module (if

equipped), TCM (for A/T model) and ABS control

module, is established by CAN (Controller Area

Network). (For more detail of CAN communication for

ECM, refer to “CAN Communication System

Description”). Therefore, handle CAN communication

line with care referring to “Precaution for CAN

Communication System in Section 00”.

• Immobilizer transponder code registration after

replacing ECM (Immobilizer model)

When ECM is replaced with new one or with another

one, make sure to register immobilizer transponder

code to ECM correctly according to “Procedure after

ECM Replacement in Section 10C”.Precautions for DTC TroubleshootingS6RW0D1100003

• Before performed trouble shooting, be sure to read

the “Precautions of ECM Circuit Inspection”.

• When measuring circuit voltage, resistance and/or

pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referring to

“Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work,

perform “DTC Confirmation Procedure” and confirm

that the trouble has been corrected.

Precautions of ECM Circuit InspectionS6RW0D1100004

• ECM connectors are waterproofed. Each terminal of

the ECM connectors is sealed up with the grommet.

Therefore, when measuring circuit voltage, resistance

and/or pulse signal at ECM connector, do not insert

the tester’s probe into the sealed terminal at the

harness side. When measuring circuit voltage,

resistance and/or pulse signal at ECM connector,

connect the special tool to the ECM connectors. And,

insert the tester’s probe into the special tool’s

connectors at the harness side, and then measure

voltage, resistance and/or pulse signal. Or, ECM and

its circuits may be damaged by water.

• Wire colors of the special tool’s connectors are

different from the ones of the ECM connectors.

However, the circuit arrangement of the special tool’s

connectors is same as the one of the ECM

connectors. Therefore, measure circuit voltage and

resistance by identifying the terminal location subject

to the measurement.

Precautions of Electric Throttle Body System

Calibration

S6RW0D1100005

After performing one of works described below, it is

necessary to re-register the completely closed throttle

valve reference position stored in memory of ECM. (For

detailed information, refer to “Description of Electric

Throttle Body System Calibration”.) For the procedure to

register such data in ECM, refer to “Electric Throttle

Body System Calibration in Section 1C”.

• To shut off backup power of ECM for such purposes of

battery replacement or “DOME” fuse removal

• To erase DTCs P0122, P0123, P0222, P0223, P2101,

P2102, P2103, P2111, P2112, P2119 and/or P2135

• To replace ECM

• To replace throttle body and/or accelerator pedal

position (APP) sensor assembly

Page 56 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-6 Engine General Information and Diagnosis:

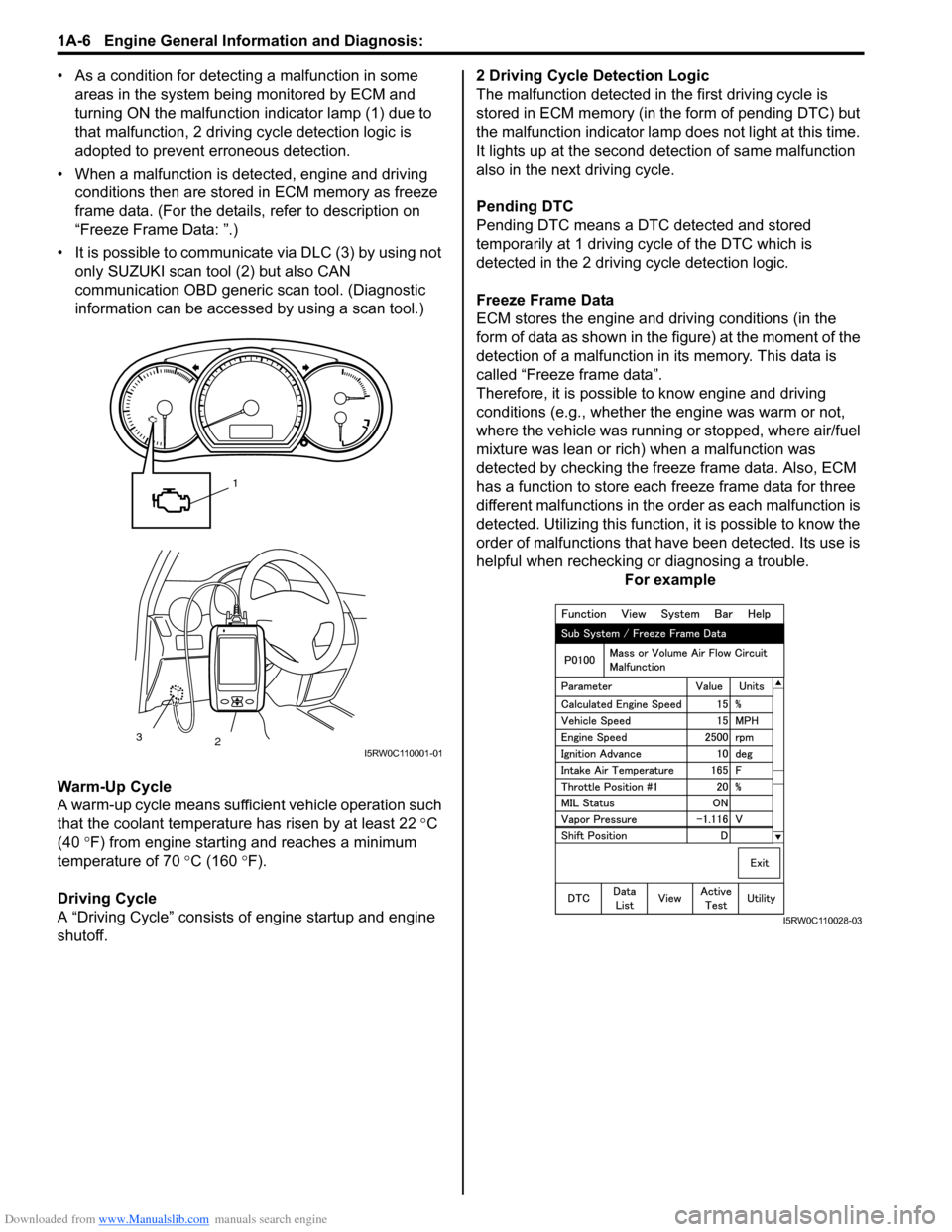

• As a condition for detecting a malfunction in some

areas in the system being monitored by ECM and

turning ON the malfunction indicator lamp (1) due to

that malfunction, 2 driving cycle detection logic is

adopted to prevent erroneous detection.

• When a malfunction is detected, engine and driving

conditions then are stored in ECM memory as freeze

frame data. (For the details, refer to description on

“Freeze Frame Data: ”.)

• It is possible to communicate via DLC (3) by using not

only SUZUKI scan tool (2) but also CAN

communication OBD generic scan tool. (Diagnostic

information can be accessed by using a scan tool.)

Warm-Up Cycle

A warm-up cycle means sufficient vehicle operation such

that the coolant temperature has risen by at least 22 °C

(40 °F) from engine starting and reaches a minimum

temperature of 70 °C (160 °F).

Driving Cycle

A “Driving Cycle” consists of engine startup and engine

shutoff.2 Driving Cycle Detection Logic

The malfunction detected in the first driving cycle is

stored in ECM memory (in the form of pending DTC) but

the malfunction indicator lamp does not light at this time.

It lights up at the second detection of same malfunction

also in the next driving cycle.

Pending DTC

Pending DTC means a DTC detected and stored

temporarily at 1 driving cycle of the DTC which is

detected in the 2 driving cycle detection logic.

Freeze Frame Data

ECM stores the engine and driving conditions (in the

form of data as shown in the figure) at the moment of the

detection of a malfunction in its memory. This data is

called “Freeze frame data”.

Therefore, it is possible to know engine and driving

conditions (e.g., whether the engine was warm or not,

where the vehicle was running or stopped, where air/fuel

mixture was lean or rich) when a malfunction was

detected by checking the freeze frame data. Also, ECM

has a function to store each freeze frame data for three

different malfunctions in the order as each malfunction is

detected. Utilizing this function, it is possible to know the

order of malfunctions that have been detected. Its use is

helpful when rechecking or diagnosing a trouble.

For example

1

2 3

I5RW0C110001-01

I5RW0C110028-03

Page 57 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-7

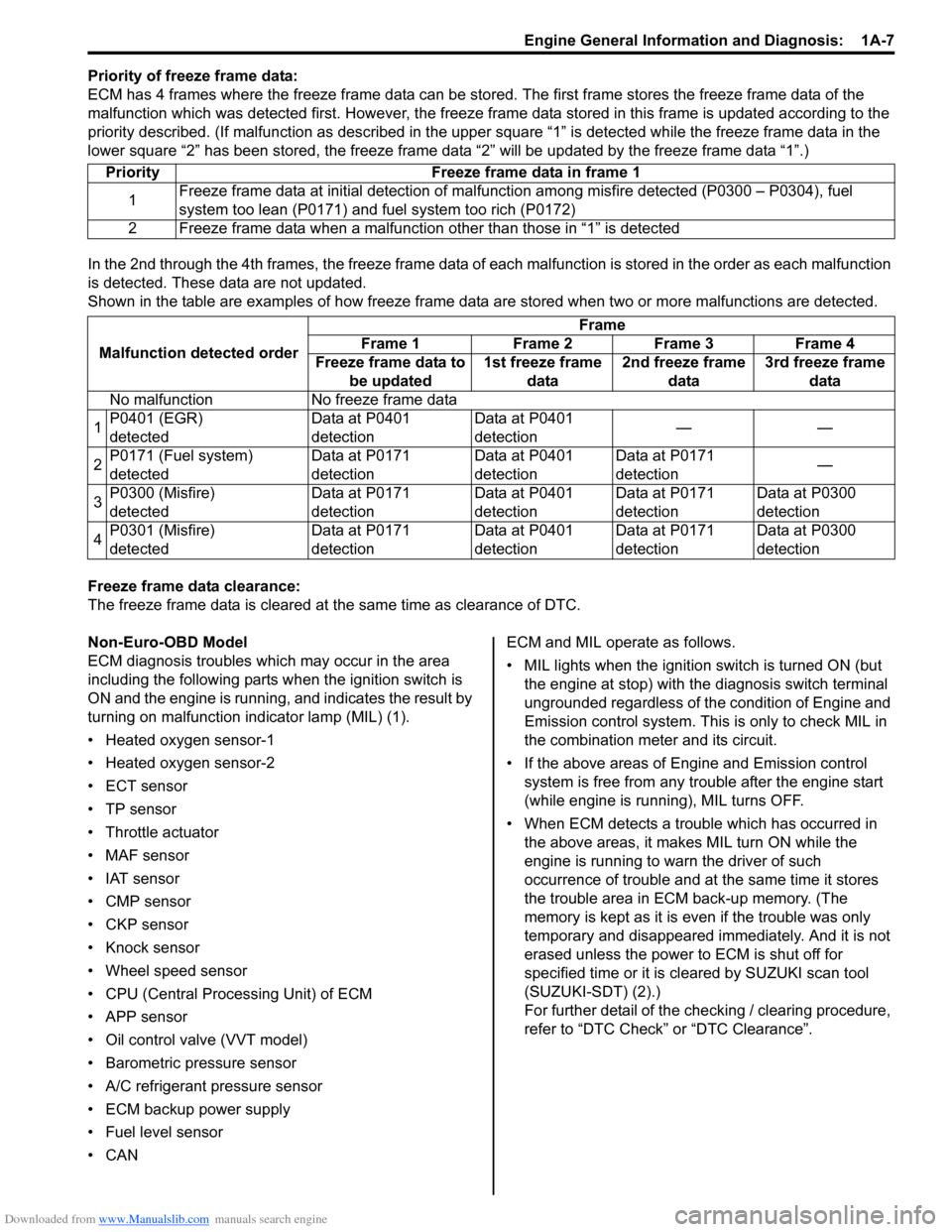

Priority of freeze frame data:

ECM has 4 frames where the freeze frame data can be stored. The first frame stores the freeze frame data of the

malfunction which was detected first. However, the freeze frame data stored in this frame is updated according to the

priority described. (If malfunction as described in the upper square “1” is detected while the freeze frame data in the

lower square “2” has been stored, the freeze frame data “2” will be updated by the freeze frame data “1”.)

In the 2nd through the 4th frames, the freeze frame data of each malfunction is stored in the order as each malfunction

is detected. These data are not updated.

Shown in the table are examples of how freeze frame data are stored when two or more malfunctions are detected.

Freeze frame data clearance:

The freeze frame data is cleared at the same time as clearance of DTC.

Non-Euro-OBD Model

ECM diagnosis troubles which may occur in the area

including the following parts when the ignition switch is

ON and the engine is running, and indicates the result by

turning on malfunction indicator lamp (MIL) (1).

• Heated oxygen sensor-1

• Heated oxygen sensor-2

• ECT sensor

•TP sensor

• Throttle actuator

• MAF sensor

• IAT sensor

• CMP sensor

• CKP sensor

• Knock sensor

• Wheel speed sensor

• CPU (Central Processing Unit) of ECM

• APP sensor

• Oil control valve (VVT model)

• Barometric pressure sensor

• A/C refrigerant pressure sensor

• ECM backup power supply

• Fuel level sensor

•CANECM and MIL operate as follows.

• MIL lights when the ignition switch is turned ON (but

the engine at stop) with the diagnosis switch terminal

ungrounded regardless of the condition of Engine and

Emission control system. This is only to check MIL in

the combination meter and its circuit.

• If the above areas of Engine and Emission control

system is free from any trouble after the engine start

(while engine is running), MIL turns OFF.

• When ECM detects a trouble which has occurred in

the above areas, it makes MIL turn ON while the

engine is running to warn the driver of such

occurrence of trouble and at the same time it stores

the trouble area in ECM back-up memory. (The

memory is kept as it is even if the trouble was only

temporary and disappeared immediately. And it is not

erased unless the power to ECM is shut off for

specified time or it is cleared by SUZUKI scan tool

(SUZUKI-SDT) (2).)

For further detail of the checking / clearing procedure,

refer to “DTC Check” or “DTC Clearance”. Priority Freeze frame data in frame 1

1Freeze frame data at initial detection of malfunction among misfire detected (P0300 – P0304), fuel

system too lean (P0171) and fuel system too rich (P0172)

2 Freeze frame data when a malfunction other than those in “1” is detected

Malfunction detected orderFrame

Frame 1 Frame 2 Frame 3 Frame 4

Freeze frame data to

be updated1st freeze frame

data2nd freeze frame

data3rd freeze frame

data

No malfunction No freeze frame data

1P0401 (EGR)

detectedData at P0401

detectionData at P0401

detection——

2P0171 (Fuel system)

detectedData at P0171

detectionData at P0401

detectionData at P0171

detection—

3P0300 (Misfire)

detectedData at P0171

detectionData at P0401

detectionData at P0171

detectionData at P0300

detection

4P0301 (Misfire)

detectedData at P0171

detectionData at P0401

detectionData at P0171

detectionData at P0300

detection

Page 58 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-8 Engine General Information and Diagnosis:

For information about the following items, refer to “Euro

OBD model: ”.

• Warm-up cycle

• Driving cycle

• 2 driving cycle detection logic

• Pending DTC

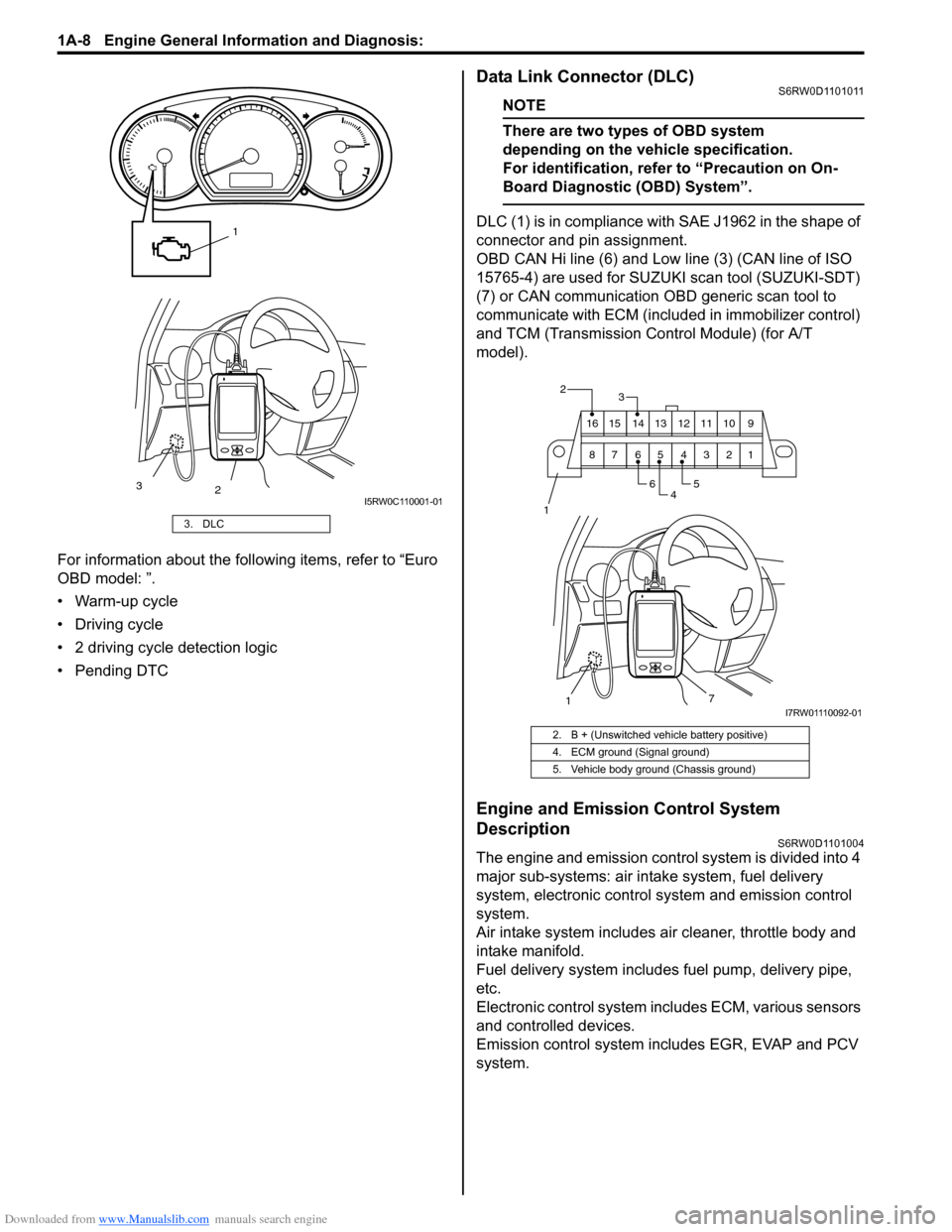

Data Link Connector (DLC)S6RW0D1101011

NOTE

There are two types of OBD system

depending on the vehicle specification.

For identification, refer to “Precaution on On-

Board Diagnostic (OBD) System”.

DLC (1) is in compliance with SAE J1962 in the shape of

connector and pin assignment.

OBD CAN Hi line (6) and Low line (3) (CAN line of ISO

15765-4) are used for SUZUKI scan tool (SUZUKI-SDT)

(7) or CAN communication OBD generic scan tool to

communicate with ECM (included in immobilizer control)

and TCM (Transmission Control Module) (for A/T

model).

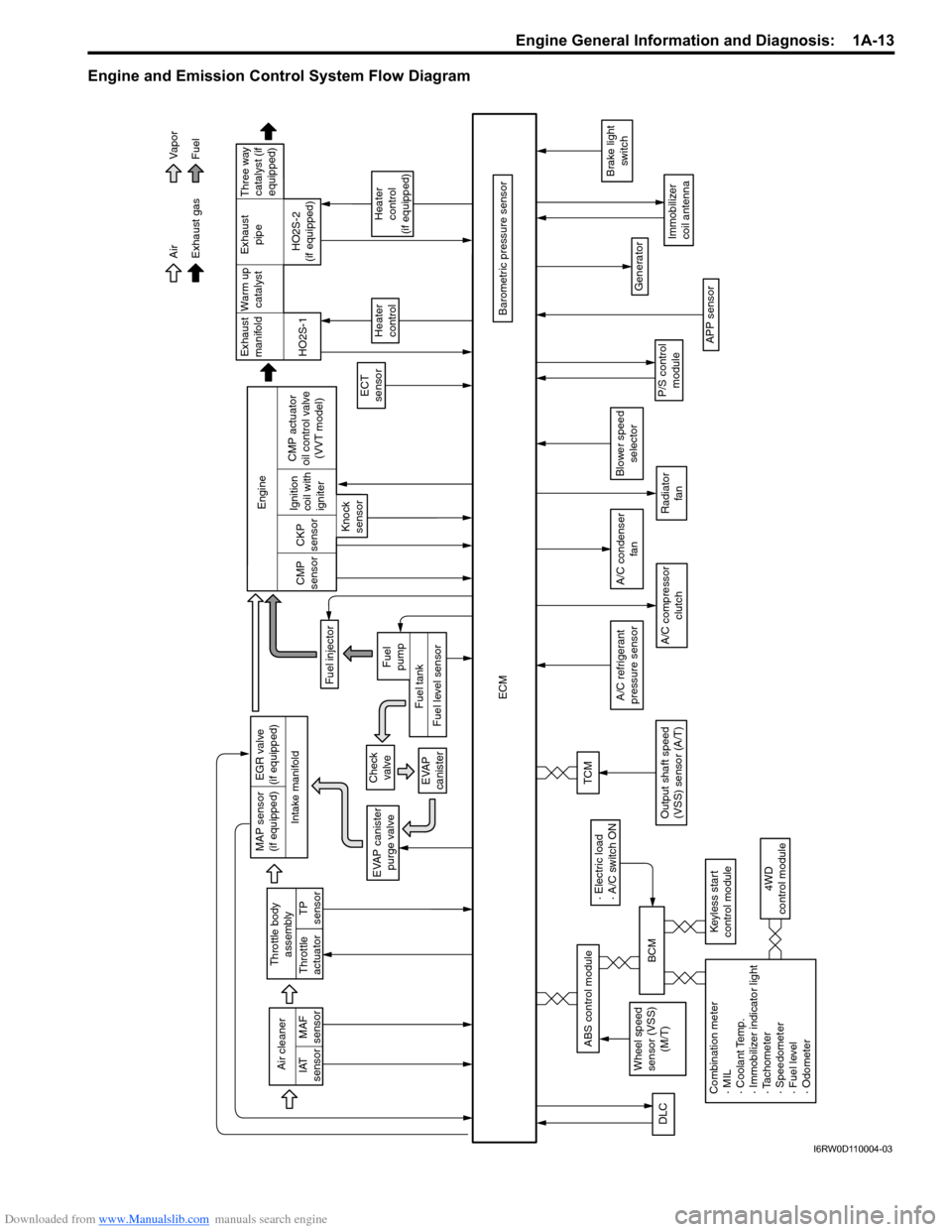

Engine and Emission Control System

Description

S6RW0D1101004

The engine and emission control system is divided into 4

major sub-systems: air intake system, fuel delivery

system, electronic control system and emission control

system.

Air intake system includes air cleaner, throttle body and

intake manifold.

Fuel delivery system includes fuel pump, delivery pipe,

etc.

Electronic control system includes ECM, various sensors

and controlled devices.

Emission control system includes EGR, EVAP and PCV

system.

3. DLC

1

2 3

I5RW0C110001-01

2. B + (Unswitched vehicle battery positive)

4. ECM ground (Signal ground)

5. Vehicle body ground (Chassis ground)

2

45 6

1

9 10 11 12 13 14 15 16

1 2 3 4 5 6 7 8

7

3

1I7RW01110092-01

Page 62 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-12 Engine General Information and Diagnosis:

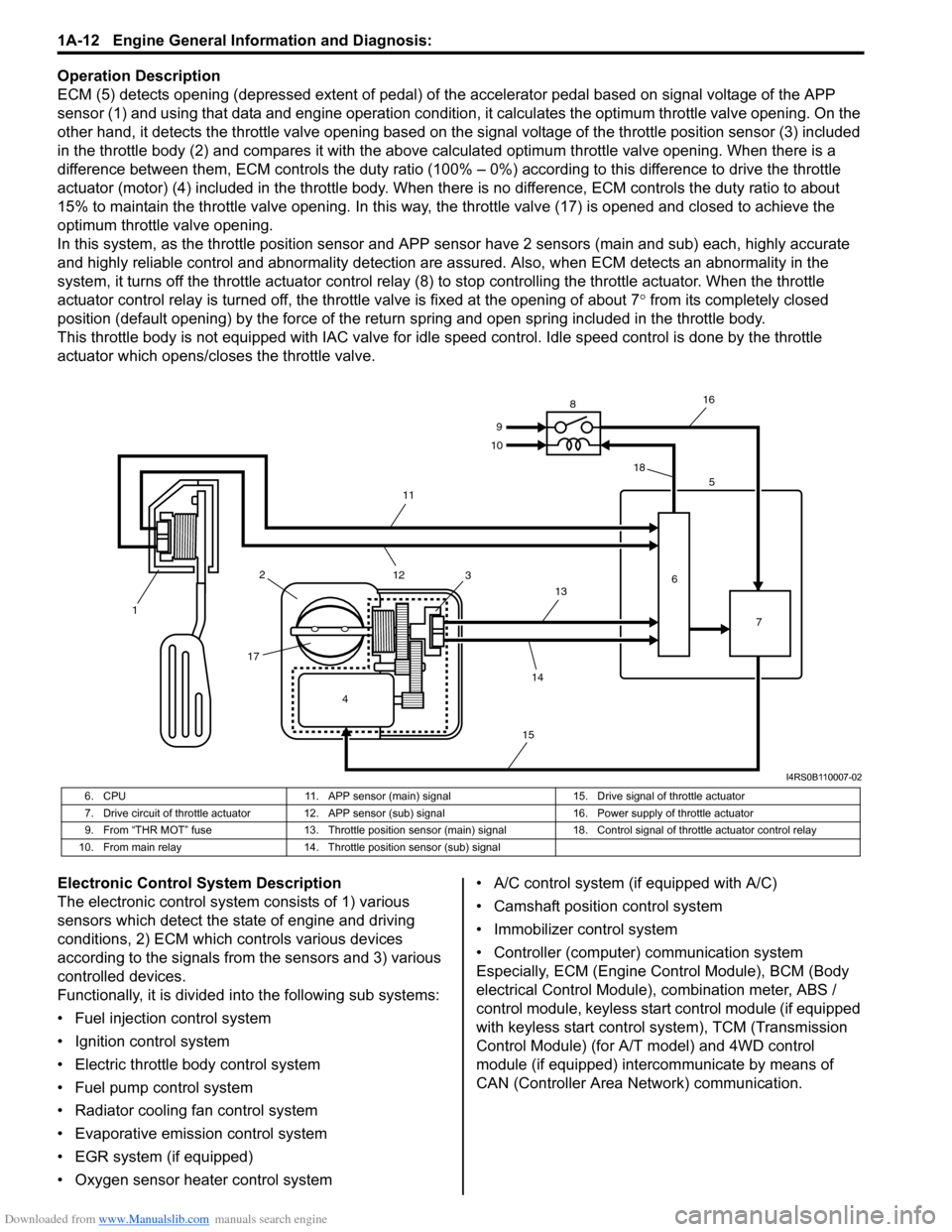

Operation Description

ECM (5) detects opening (depressed extent of pedal) of the accelerator pedal based on signal voltage of the APP

sensor (1) and using that data and engine operation condition, it calculates the optimum throttle valve opening. On the

other hand, it detects the throttle valve opening based on the signal voltage of the throttle position sensor (3) included

in the throttle body (2) and compares it with the above calculated optimum throttle valve opening. When there is a

difference between them, ECM controls the duty ratio (100% – 0%) according to this difference to drive the throttle

actuator (motor) (4) included in the throttle body. When there is no difference, ECM controls the duty ratio to about

15% to maintain the throttle valve opening. In this way, the throttle valve (17) is opened and closed to achieve the

optimum throttle valve opening.

In this system, as the throttle position sensor and APP sensor have 2 sensors (main and sub) each, highly accurate

and highly reliable control and abnormality detection are assured. Also, when ECM detects an abnormality in the

system, it turns off the throttle actuator control relay (8) to stop controlling the throttle actuator. When the throttle

actuator control relay is turned off, the throttle valve is fixed at the opening of about 7° from its completely closed

position (default opening) by the force of the return spring and open spring included in the throttle body.

This throttle body is not equipped with IAC valve for idle speed control. Idle speed control is done by the throttle

actuator which opens/closes the throttle valve.

Electronic Control System Description

The electronic control system consists of 1) various

sensors which detect the state of engine and driving

conditions, 2) ECM which controls various devices

according to the signals from the sensors and 3) various

controlled devices.

Functionally, it is divided into the following sub systems:

• Fuel injection control system

• Ignition control system

• Electric throttle body control system

• Fuel pump control system

• Radiator cooling fan control system

• Evaporative emission control system

• EGR system (if equipped)

• Oxygen sensor heater control system• A/C control system (if equipped with A/C)

• Camshaft position control system

• Immobilizer control system

• Controller (computer) communication system

Especially, ECM (Engine Control Module), BCM (Body

electrical Control Module), combination meter, ABS /

control module, keyless start control module (if equipped

with keyless start control system), TCM (Transmission

Control Module) (for A/T model) and 4WD control

module (if equipped) intercommunicate by means of

CAN (Controller Area Network) communication.

4 12

1735

6

7 8

9

10

11

12

13

14

1516

18

I4RS0B110007-02

6. CPU 11. APP sensor (main) signal 15. Drive signal of throttle actuator

7. Drive circuit of throttle actuator 12. APP sensor (sub) signal 16. Power supply of throttle actuator

9. From “THR MOT” fuse 13. Throttle position sensor (main) signal 18. Control signal of throttle actuator control relay

10. From main relay 14. Throttle position sensor (sub) signal

Page 63 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-13

Engine and Emission Control System Flow Diagram

Intake manifoldExhaust

manifold

Exhaust gas Air

Fuel Vapor

War m up

catalystExhaust

pipe

EVAP canister

purge valve

Fuel injector

ECT

sensor

ECM

Heater

control

Heater

control

(if equipped)

Barometric pressure sensor HO2S-1HO2S-2

(if equipped) Engine

CMP

sensorCKP

sensor

Knock

sensorIgnition

coil with

igniter

APP sensor

A/C compressor

clutch

Generator

Immobilizer

coil antenna

P/S control

module

Brake light

switch

Air cleaner

IAT

sensorMAF

sensor

A/C refrigerant

pressure sensor

TP

sensor Throttle body

assembly

Throttle

actuator

A/C condenser

fan

DLC

Radiator

fan

Combination meter

· MIL

· Coolant Temp.

· Immobilizer indicator light

· Tachometer

· Speedometer

· Fuel level

· Odometer4WD

control module

Wheel speed

sensor (VSS)

(M/T)

· Electric load

· A/C switch ON

BCM

Keyless start

control module

ABS control module

Blower speed

selector

MAP sensor

(if equipped)EGR valve

(if equipped)

Check

valve

EVAP

canister

Fuel level sensorFuel tankFuel

pump

CMP actuator

oil control valve

(VVT model)

TCM

Output shaft speed

(VSS) sensor (A/T)

Three way

catalyst (if

equipped)

I6RW0D110004-03

Page 66 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-16 Engine General Information and Diagnosis:

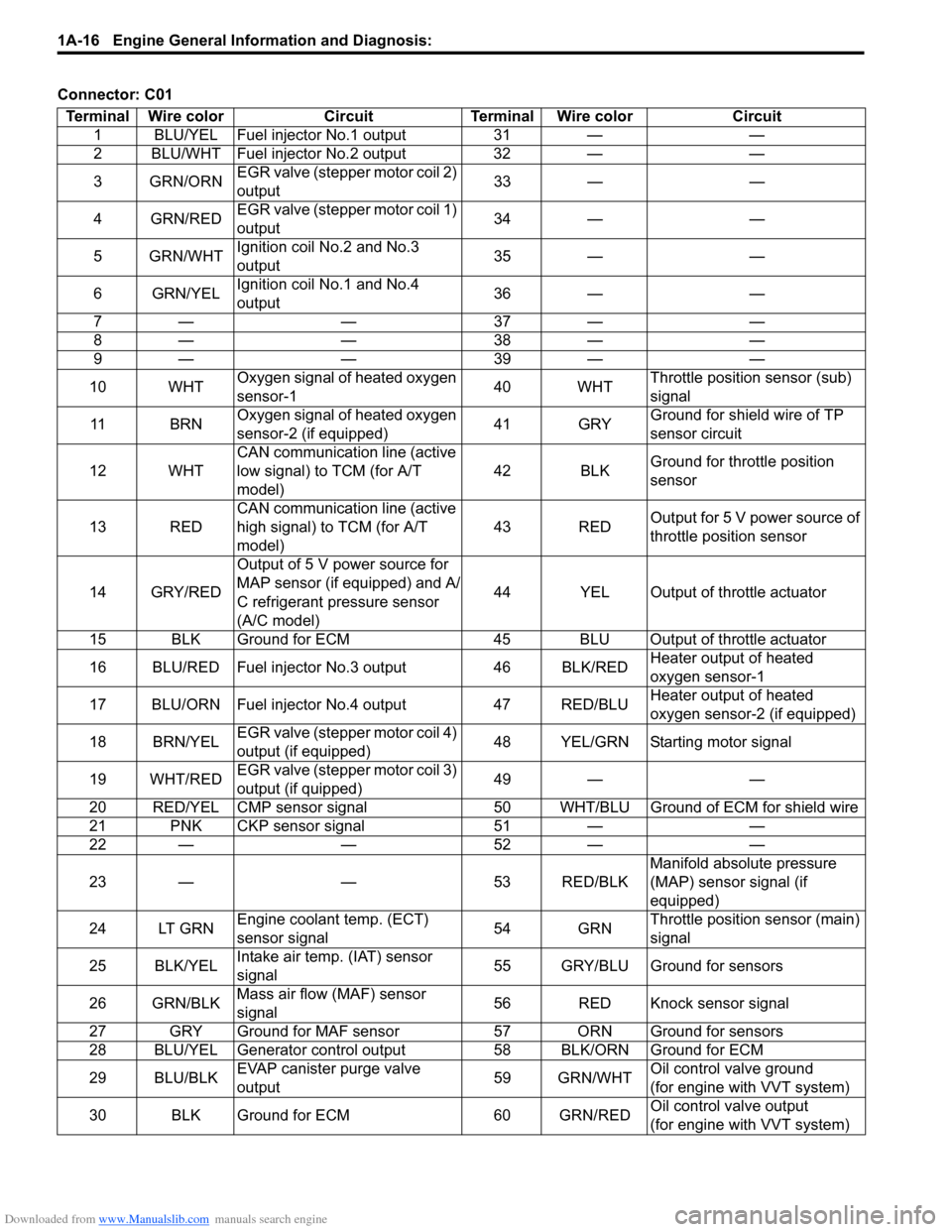

Connector: C01

Terminal Wire color Circuit Terminal Wire color Circuit

1 BLU/YEL Fuel injector No.1 output 31 — —

2 BLU/WHT Fuel injector No.2 output 32 — —

3 GRN/ORNEGR valve (stepper motor coil 2)

output33 — —

4 GRN/REDEGR valve (stepper motor coil 1)

output34 — —

5 GRN/WHTIgnition coil No.2 and No.3

output35 — —

6 GRN/YELIgnition coil No.1 and No.4

output36 — —

7— — 37— —

8— — 38— —

9— — 39— —

10 WHTOxygen signal of heated oxygen

sensor-140 WHTThrottle position sensor (sub)

signal

11 B R NOxygen signal of heated oxygen

sensor-2 (if equipped)41 GRYGround for shield wire of TP

sensor circuit

12 WHTCAN communication line (active

low signal) to TCM (for A/T

model)42 BLKGround for throttle position

sensor

13 REDCAN communication line (active

high signal) to TCM (for A/T

model) 43 REDOutput for 5 V power source of

throttle position sensor

14 GRY/REDOutput of 5 V power source for

MAP sensor (if equipped) and A/

C refrigerant pressure sensor

(A/C model)44 YEL Output of throttle actuator

15 BLK Ground for ECM 45 BLU Output of throttle actuator

16 BLU/RED Fuel injector No.3 output 46 BLK/REDHeater output of heated

oxygen sensor-1

17 BLU/ORN Fuel injector No.4 output 47 RED/BLUHeater output of heated

oxygen sensor-2 (if equipped)

18 BRN/YELEGR valve (stepper motor coil 4)

output (if equipped)48 YEL/GRN Starting motor signal

19 WHT/REDEGR valve (stepper motor coil 3)

output (if quipped)49 — —

20 RED/YEL CMP sensor signal 50 WHT/BLU Ground of ECM for shield wire

21 PNK CKP sensor signal 51 — —

22 — — 52 — —

23 — — 53 RED/BLKManifold absolute pressure

(MAP) sensor signal (if

equipped)

24 LT GRNEngine coolant temp. (ECT)

sensor signal54 GRNThrottle position sensor (main)

signal

25 BLK/YELIntake air temp. (IAT) sensor

signal55 GRY/BLU Ground for sensors

26 GRN/BLKMass air flow (MAF) sensor

signal56 RED Knock sensor signal

27 GRY Ground for MAF sensor 57 ORN Ground for sensors

28 BLU/YEL Generator control output 58 BLK/ORN Ground for ECM

29 BLU/BLKEVAP canister purge valve

output59 GRN/WHTOil control valve ground

(for engine with VVT system)

30 BLK Ground for ECM 60 GRN/REDOil control valve output

(for engine with VVT system)