Rear light SUZUKI SX4 2006 1.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 569 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 4- i

4

Section 4

CONTENTS

Brakes

Precautions ................................................. 4-1

Precautions............................................................. 4-1

Precautions for Brakes .......................................... 4-1

Brake Control System and Diagnosis ... 4A-1

Precautions........................................................... 4A-1

Precautions on Brake .......................................... 4A-1

General Description ............................................. 4A-1

Brakes Construction ............................................ 4A-1

Brake Pedal Foot Protection System

Construction (If Equipped) ................................ 4A-2

Front Brake Hose / Pipe Construction................. 4A-3

Rear Brake Hose / Pipe Construction ................. 4A-4

Diagnostic Information and Procedures ............ 4A-4

Brakes Diagnosis Note ....................................... 4A-4

Brakes Symptom Diagnosis ................................ 4A-5

Repair Instructions .............................................. 4A-7

Brake Pedal Components ................................... 4A-7

Brake Pedal Free Height Inspection ................... 4A-7

Brake Pedal Play Inspection ............................... 4A-7

Excessive Pedal Travel Inspection ..................... 4A-7

Brake Fluid Level Inspection ............................... 4A-8

Brake Light Switch Adjustment ........................... 4A-8

Air Bleeding of Brake System ............................. 4A-8

Front Brake Hose / Pipe Removal and

Installation ......................................................... 4A-9

Rear Brake Hose / Pipe Removal and

Installation ....................................................... 4A-10

Brake Hose and Pipe Inspection ....................... 4A-10

Master Cylinder and Brake Booster

Components.................................................... 4A-11

Master Cylinder Reservoir Removal and

Installation ....................................................... 4A-11

Master Cylinder Removal and Installation......... 4A-12

Master Cylinder Inspection ............................... 4A-13

Booster Operation Inspection ........................... 4A-14

Brake Booster Removal and Installation ........... 4A-15

Brake Booster Inspection .................................. 4A-15

Booster Push Clevis Rod Adjustment ............... 4A-16

Specifications..................................................... 4A-16

Tightening Torque Specifications ...................... 4A-16

Special Tools and Equipment ........................... 4A-16

Recommended Service Material ....................... 4A-16

Special Tool ...................................................... 4A-16

Front Brakes ............................................ 4B-1

Repair Instructions ..............................................4B-1

Front Disc Brake Components ............................ 4B-1

Front Disc Brake Pad On-Vehicle Inspection ...... 4B-2

Front Disc Brake Pad Removal and

Installation ......................................................... 4B-2

Front Disc Brake Pad Inspection......................... 4B-3

Front Disc Brake Caliper Removal and

Installation ......................................................... 4B-3

Front Disc Brake Caliper Disassembly and

Assembly........................................................... 4B-4

Front Disc Brake Caliper Inspection.................... 4B-6

Front Brake Disc Removal and Installation ......... 4B-6

Front Brake Disc Inspection ................................ 4B-7

Specifications .......................................................4B-8

Tightening Torque Specifications ........................ 4B-8

Special Tools and Equipment .............................4B-8

Recommended Service Material ......................... 4B-8

Special Tool ........................................................ 4B-8

Rear Brakes.............................................. 4C-1

Repair Instructions ..............................................4C-1

Rear Drum Brake Components ...........................4C-1

Rear Brake Drum Removal and Installation ........4C-2

Rear Brake Drum and Shoe Inspection ..............4C-2

Rear Brake Shoe On-Vehicle Inspection ............4C-3

Rear Brake Shoe Removal and Installation ........4C-3

Rear Brake Shoe Inspection ...............................4C-4

Wheel Cylinder Removal and Installation ...........4C-4

Wheel Cylinder Inspection ..................................4C-5

Brake Back Plate Removal and Installation ........4C-5

Specifications .......................................................4C-6

Tightening Torque Specifications ........................4C-6

Special Tools and Equipment .............................4C-6

Recommended Service Material .........................4C-6

Parking Brake .......................................... 4D-1

General Description .............................................4D-1

Parking Brake Cable Construction ......................4D-1

Repair Instructions ..............................................4D-2

Parking Brake Inspection and Adjustment ..........4D-2

Parking Brake Cable Removal and

Installation .........................................................4D-2

Parking Brake Lever Removal and Installation ....4D-3

Page 570 of 1556

Downloaded from www.Manualslib.com manuals search engine 4-ii Table of Contents

Specifications .......................................................4D-4

Tightening Torque Specifications ........................4D-4

ABS ............................................................4E-1

Precautions........................................................... 4E-1

Precautions in Diagnosing Troubles ................... 4E-1

Precautions in On-Vehicle Service...................... 4E-1

General Description ............................................. 4E-2

ABS Description .................................................. 4E-2

ABS Hydraulic Unit / Control Module

Assembly Description ....................................... 4E-3

CAN Communication System Description........... 4E-3

Schematic and Routing Diagram ........................ 4E-4

ABS Schematic ................................................... 4E-4

ABS Wiring Circuit Diagram ................................ 4E-5

Component Location ........................................... 4E-8

ABS Components Location ................................. 4E-8

Diagnostic Information and Procedures ............ 4E-8

ABS Check .......................................................... 4E-8

ABS Warning Light Check................................. 4E-10

EBD Warning Light (Brake Warning Light)

Check .............................................................. 4E-10

DTC Check........................................................ 4E-11

DTC Table ......................................................... 4E-11

DTC Clearance ................................................. 4E-11

Scan Tool Data ................................................. 4E-12

ABS Warning Light Does Not Come ON at

Ignition Switch ON .......................................... 4E-13

ABS Warning Light Comes ON Steady ............. 4E-15

EBD Warning Light (Brake Warning Light)

Comes ON Steady .......................................... 4E-16

Serial Data Link Circuit Check .......................... 4E-17

DTC C1013: Control Module Mismatch ............ 4E-20

DTC C1015: G Sensor Circuit (4WD Model)..... 4E-21

DTC 1016: Brake Light Switch .......................... 4E-22

DTC C1021 / C1022 / C1025 / C1026 / C1031

/ C1032 / C1035 / C1036: Wheel Speed

Sensor Circuit / Sensor or Encoder ................ 4E-23

DTC C1033: Wheel Speed Sensor Deviation ... 4E-25

DTC C1041 / C1042 / C1045 / C1046 / C1051

/ C1052 / C1055 / C1056: Inlet / Outlet

Solenoid .......................................................... 4E-26DTC C1057: Power Supply Voltage Too High

/ Too Low ........................................................ 4E-27

DTC C1061: Pump Motor Circuit ...................... 4E-28

DTC C1063: Solenoid Valve Power Supply

Driver Circuit ................................................... 4E-29

DTC C1071: Control Module Internal Defect .... 4E-30

ABS Hydraulic Unit / Control Module

Assembly Power and Ground Circuit Check ... 4E-30

Repair Instructions ............................................ 4E-31

ABS Hydraulic Unit Operation Check................ 4E-31

ABS Hydraulic Unit / Control Module

Assembly Components ................................... 4E-32

ABS Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4E-33

ABS Hydraulic Unit / Control Module

Assembly Removal and Installation ................ 4E-33

Front and Rear Wheel Speed Sensor On-

Vehicle Inspection ........................................... 4E-34

Front Wheel Speed Sensor Removal and

Installation ....................................................... 4E-35

Front and Rear Wheel Speed Sensor

Inspection ........................................................ 4E-36

Rear Wheel Speed Sensor Removal and

Installation (4WD Model) ................................. 4E-36

Rear Wheel Speed Sensor Removal and

Installation (2WD Model) ................................. 4E-36

Front Wheel Speed Sensor Encoder On-

Vehicle Inspection ........................................... 4E-37

Front Wheel Speed Sensor Encoder Removal

and Installation ................................................ 4E-37

Rear Wheel Speed Sensor Encoder On-

Vehicle Inspection ........................................... 4E-37

Rear Wheel Speed Sensor Encoder Removal

and Installation ................................................ 4E-37

G Sensor Removal and Installation (4WD

Model) ............................................................. 4E-38

G Sensor Inspection (4WD Model) ................... 4E-38

Specifications ..................................................... 4E-39

Tightening Torque Specifications ...................... 4E-39

Special Tools and Equipment ........................... 4E-39

Special Tool ...................................................... 4E-39

Page 575 of 1556

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-4

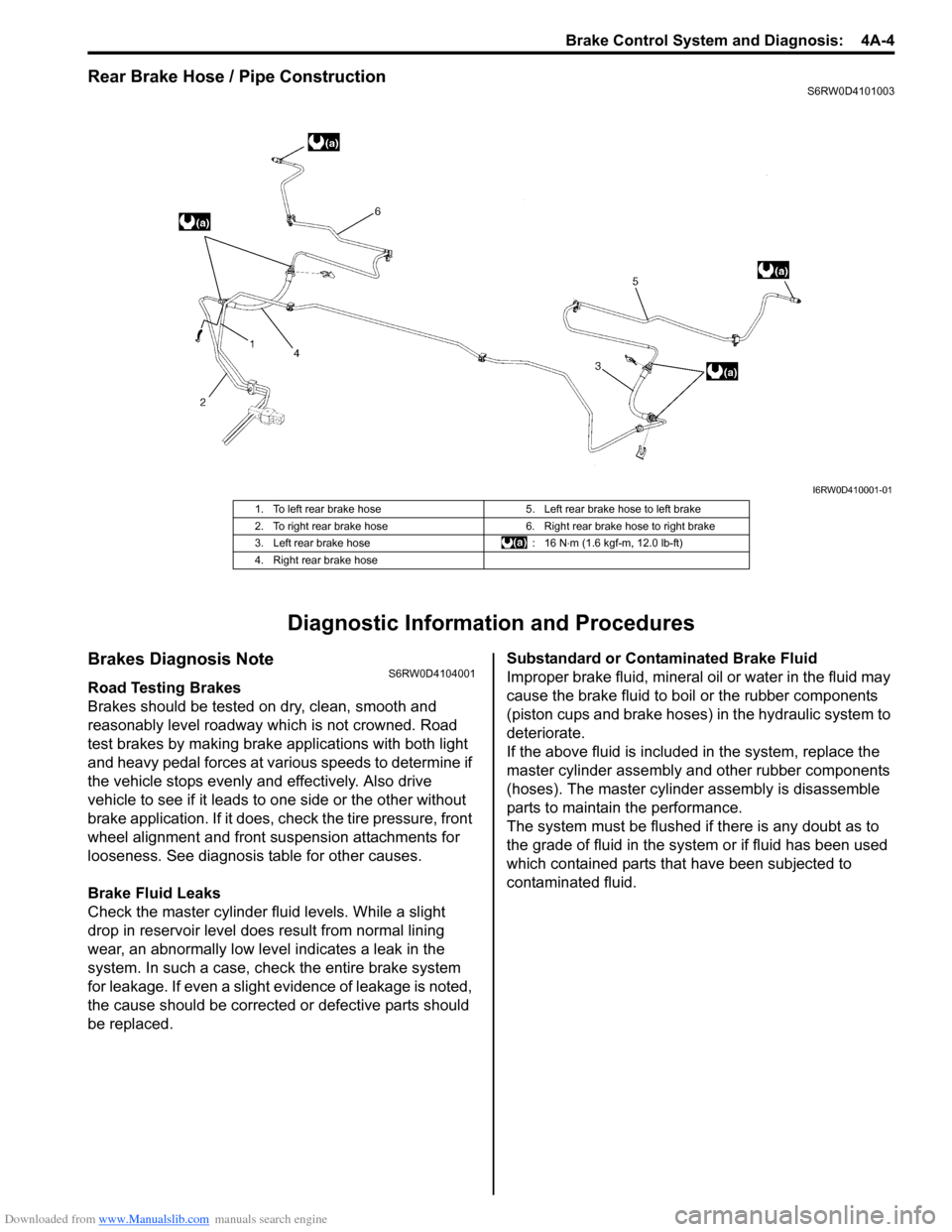

Rear Brake Hose / Pipe ConstructionS6RW0D4101003

Diagnostic Information and Procedures

Brakes Diagnosis NoteS6RW0D4104001

Road Testing Brakes

Brakes should be tested on dry, clean, smooth and

reasonably level roadway which is not crowned. Road

test brakes by making brake applications with both light

and heavy pedal forces at various speeds to determine if

the vehicle stops evenly and effectively. Also drive

vehicle to see if it leads to one side or the other without

brake application. If it does, check the tire pressure, front

wheel alignment and front suspension attachments for

looseness. See diagnosis table for other causes.

Brake Fluid Leaks

Check the master cylinder fluid levels. While a slight

drop in reservoir level does result from normal lining

wear, an abnormally low level indicates a leak in the

system. In such a case, check the entire brake system

for leakage. If even a slight evidence of leakage is noted,

the cause should be corrected or defective parts should

be replaced.Substandard or Contaminated Brake Fluid

Improper brake fluid, mineral oil or water in the fluid may

cause the brake fluid to boil or the rubber components

(piston cups and brake hoses) in the hydraulic system to

deteriorate.

If the above fluid is included in the system, replace the

master cylinder assembly and other rubber components

(hoses). The master cylinder assembly is disassemble

parts to maintain the performance.

The system must be flushed if there is any doubt as to

the grade of fluid in the system or if fluid has been used

which contained parts that have been subjected to

contaminated fluid.

I6RW0D410001-01

1. To left rear brake hose 5. Left rear brake hose to left brake

2. To right rear brake hose 6. Right rear brake hose to right brake

3. Left rear brake hose : 16 N⋅m (1.6 kgf-m, 12.0 lb-ft)

4. Right rear brake hose

Page 577 of 1556

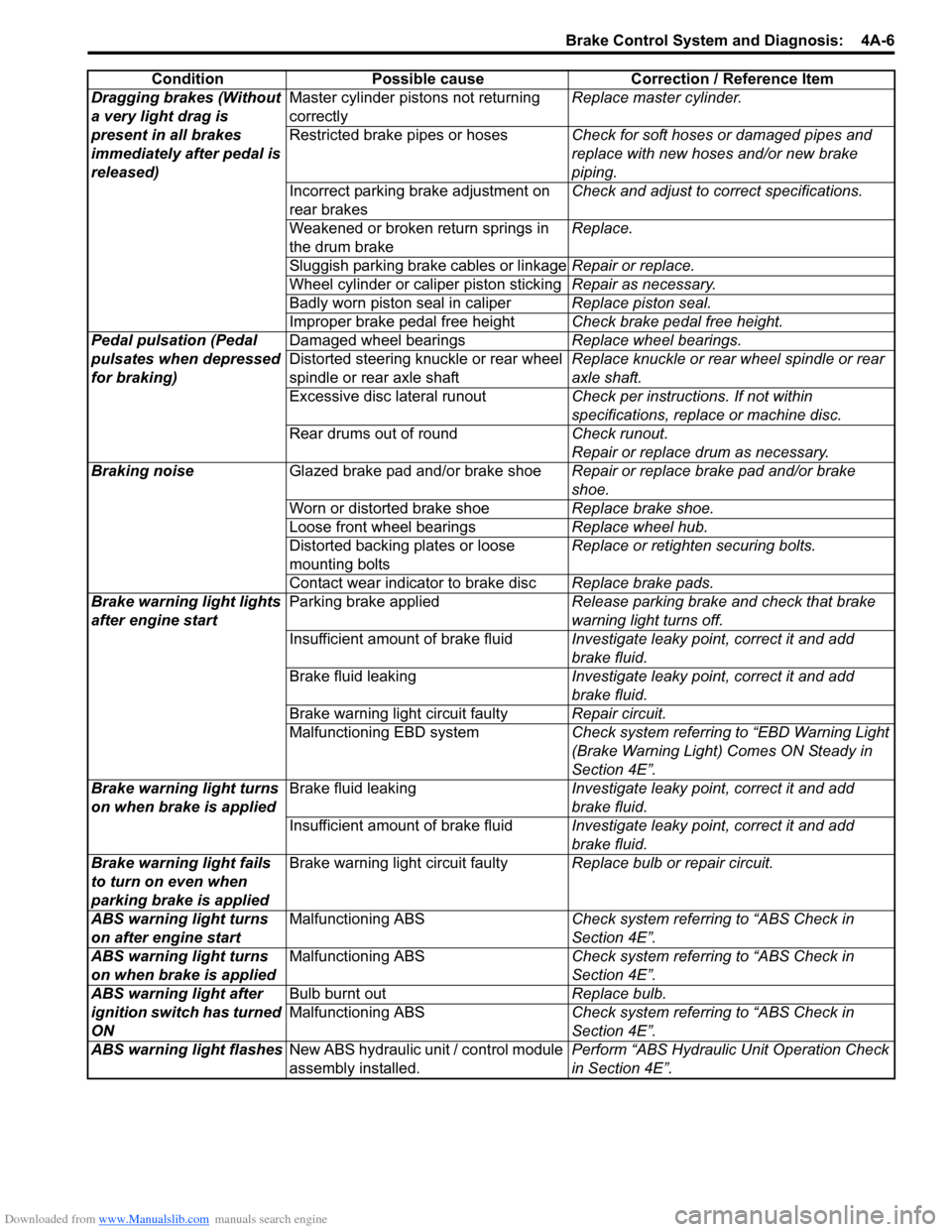

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-6

Dragging brakes (Without

a very light drag is

present in all brakes

immediately after pedal is

released)Master cylinder pistons not returning

correctlyReplace master cylinder.

Restricted brake pipes or hosesCheck for soft hoses or damaged pipes and

replace with new hoses and/or new brake

piping.

Incorrect parking brake adjustment on

rear brakesCheck and adjust to correct specifications.

Weakened or broken return springs in

the drum brakeReplace.

Sluggish parking brake cables or linkageRepair or replace.

Wheel cylinder or caliper piston stickingRepair as necessary.

Badly worn piston seal in caliperReplace piston seal.

Improper brake pedal free heightCheck brake pedal free height.

Pedal pulsation (Pedal

pulsates when depressed

for braking)Damaged wheel bearingsReplace wheel bearings.

Distorted steering knuckle or rear wheel

spindle or rear axle shaftReplace knuckle or rear wheel spindle or rear

axle shaft.

Excessive disc lateral runoutCheck per instructions. If not within

specifications, replace or machine disc.

Rear drums out of roundCheck runout.

Repair or replace drum as necessary.

Braking noiseGlazed brake pad and/or brake shoeRepair or replace brake pad and/or brake

shoe.

Worn or distorted brake shoeReplace brake shoe.

Loose front wheel bearingsReplace wheel hub.

Distorted backing plates or loose

mounting boltsReplace or retighten securing bolts.

Contact wear indicator to brake discReplace brake pads.

Brake warning light lights

after engine startParking brake appliedRelease parking brake and check that brake

warning light turns off.

Insufficient amount of brake fluidInvestigate leaky point, correct it and add

brake fluid.

Brake fluid leakingInvestigate leaky point, correct it and add

brake fluid.

Brake warning light circuit faultyRepair circuit.

Malfunctioning EBD systemCheck system referring to “EBD Warning Light

(Brake Warning Light) Comes ON Steady in

Section 4E”.

Brake warning light turns

on when brake is appliedBrake fluid leakingInvestigate leaky point, correct it and add

brake fluid.

Insufficient amount of brake fluidInvestigate leaky point, correct it and add

brake fluid.

Brake warning light fails

to turn on even when

parking brake is appliedBrake warning light circuit faultyReplace bulb or repair circuit.

ABS warning light turns

on after engine startMalfunctioning ABSCheck system referring to “ABS Check in

Section 4E”.

ABS warning light turns

on when brake is appliedMalfunctioning ABSCheck system referring to “ABS Check in

Section 4E”.

ABS warning light after

ignition switch has turned

ON Bulb burnt outReplace bulb.

Malfunctioning ABSCheck system referring to “ABS Check in

Section 4E”.

ABS warning light flashesNew ABS hydraulic unit / control module

assembly installed.Perform “ABS Hydraulic Unit Operation Check

in Section 4E”. Condition Possible cause Correction / Reference Item

Page 579 of 1556

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-8

Brake Fluid Level InspectionS6RW0D4106004

CAUTION!

Do not use shock absorber fluid or any other

fluid which contains mineral oil. Do not use a

container which has been used for mineral oil

or a container which is wet from water.

Mineral oil will cause swelling and distortion

of rubber parts in hydraulic brake system and

water mixed into brake fluid will lower fluid

boiling point. Keep all fluid containers

capped to prevent contamination.

NOTE

Be sure to use particular brake fluid either as

indicated on reservoir cap of that vehicle or

recommended in owner’s manual which

comes along with that vehicle. Use of any

other fluid is strictly prohibited.

Fluid level should be between MIN and MAX

lines marked on reservoir.

When brake warning light lights sometimes

during driving, replenish fluid to MAX level.

When fluid decreases quickly, inspect brake

system for leakage. Correct leaky points and

then refill to specified level.

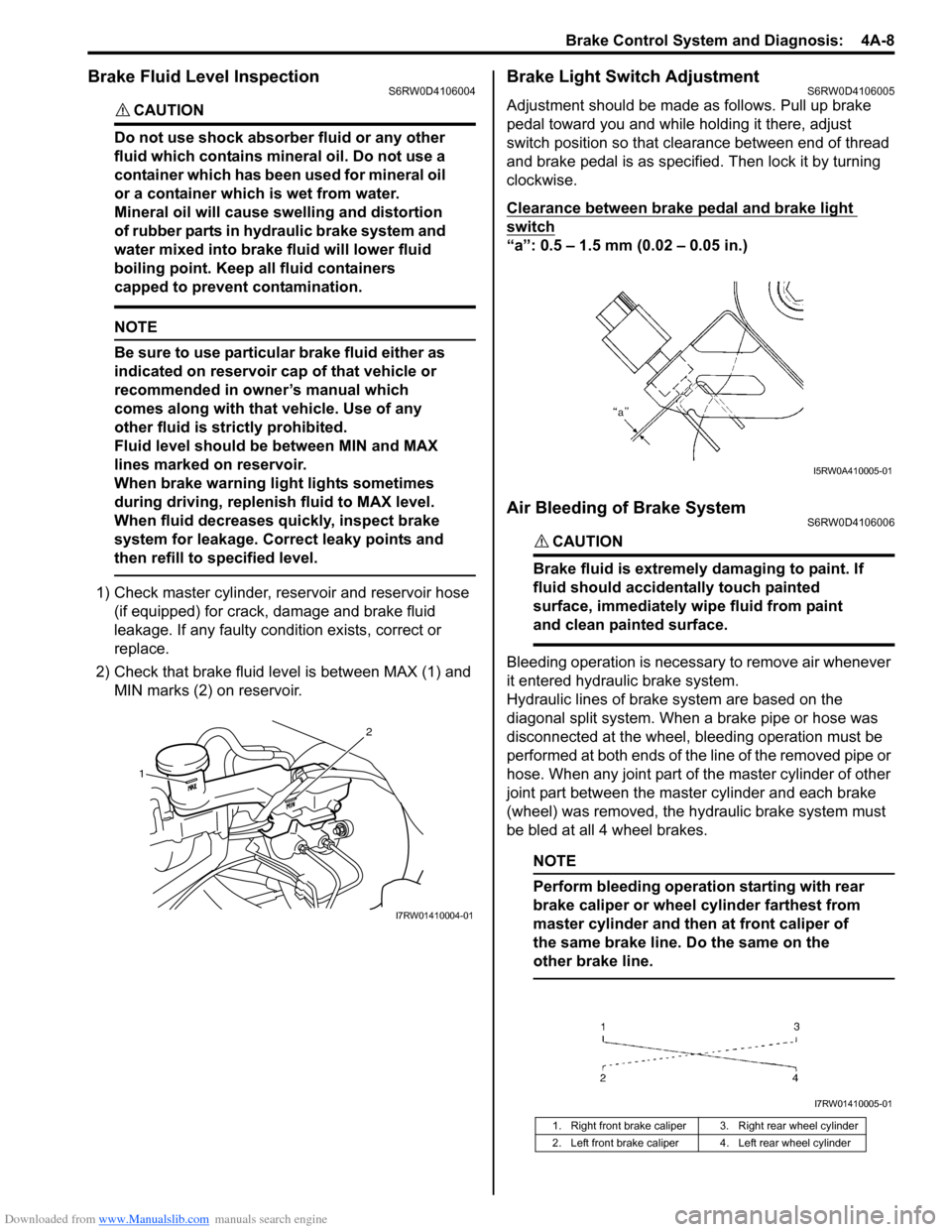

1) Check master cylinder, reservoir and reservoir hose

(if equipped) for crack, damage and brake fluid

leakage. If any faulty condition exists, correct or

replace.

2) Check that brake fluid level is between MAX (1) and

MIN marks (2) on reservoir.

Brake Light Switch AdjustmentS6RW0D4106005

Adjustment should be made as follows. Pull up brake

pedal toward you and while holding it there, adjust

switch position so that clearance between end of thread

and brake pedal is as specified. Then lock it by turning

clockwise.

Clearance between brake pedal and brake light

switch

“a”: 0.5 – 1.5 mm (0.02 – 0.05 in.)

Air Bleeding of Brake SystemS6RW0D4106006

CAUTION!

Brake fluid is extremely damaging to paint. If

fluid should accidentally touch painted

surface, immediately wipe fluid from paint

and clean painted surface.

Bleeding operation is necessary to remove air whenever

it entered hydraulic brake system.

Hydraulic lines of brake system are based on the

diagonal split system. When a brake pipe or hose was

disconnected at the wheel, bleeding operation must be

performed at both ends of the line of the removed pipe or

hose. When any joint part of the master cylinder of other

joint part between the master cylinder and each brake

(wheel) was removed, the hydraulic brake system must

be bled at all 4 wheel brakes.

NOTE

Perform bleeding operation starting with rear

brake caliper or wheel cylinder farthest from

master cylinder and then at front caliper of

the same brake line. Do the same on the

other brake line.

1

2

I7RW01410004-01

1. Right front brake caliper 3. Right rear wheel cylinder

2. Left front brake caliper 4. Left rear wheel cylinder

I5RW0A410005-01

I7RW01410005-01

Page 581 of 1556

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-10

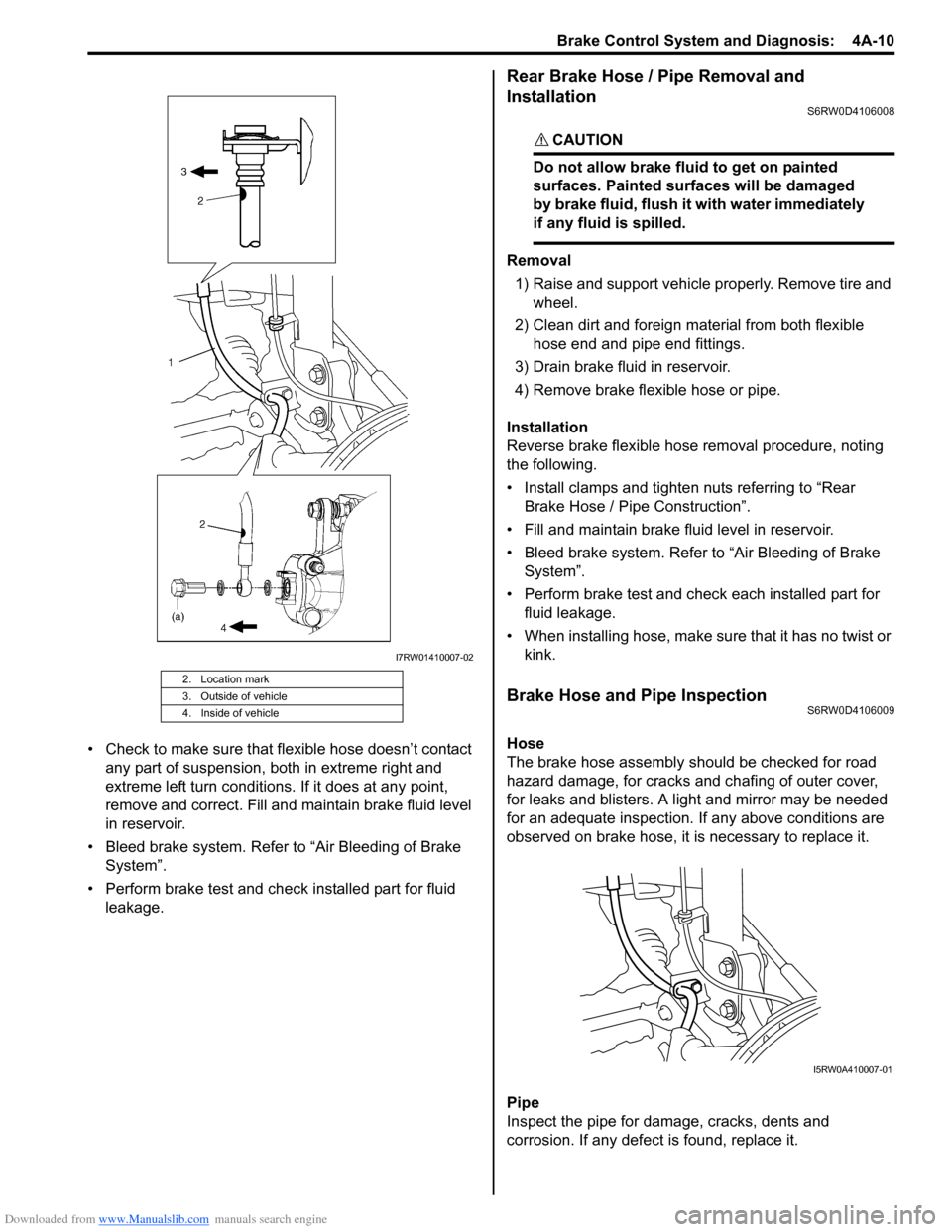

• Check to make sure that flexible hose doesn’t contact

any part of suspension, both in extreme right and

extreme left turn conditions. If it does at any point,

remove and correct. Fill and maintain brake fluid level

in reservoir.

• Bleed brake system. Refer to “Air Bleeding of Brake

System”.

• Perform brake test and check installed part for fluid

leakage.

Rear Brake Hose / Pipe Removal and

Installation

S6RW0D4106008

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Raise and support vehicle properly. Remove tire and

wheel.

2) Clean dirt and foreign material from both flexible

hose end and pipe end fittings.

3) Drain brake fluid in reservoir.

4) Remove brake flexible hose or pipe.

Installation

Reverse brake flexible hose removal procedure, noting

the following.

• Install clamps and tighten nuts referring to “Rear

Brake Hose / Pipe Construction”.

• Fill and maintain brake fluid level in reservoir.

• Bleed brake system. Refer to “Air Bleeding of Brake

System”.

• Perform brake test and check each installed part for

fluid leakage.

• When installing hose, make sure that it has no twist or

kink.

Brake Hose and Pipe InspectionS6RW0D4106009

Hose

The brake hose assembly should be checked for road

hazard damage, for cracks and chafing of outer cover,

for leaks and blisters. A light and mirror may be needed

for an adequate inspection. If any above conditions are

observed on brake hose, it is necessary to replace it.

Pipe

Inspect the pipe for damage, cracks, dents and

corrosion. If any defect is found, replace it.

2. Location mark

3. Outside of vehicle

4. Inside of vehicle

I7RW01410007-02

I5RW0A410007-01

Page 598 of 1556

Downloaded from www.Manualslib.com manuals search engine 4C-3 Rear Brakes:

Cracked, Scored or Grooved Drum

A cracked drum is unsafe for further service and must be

replaced. Do not attempt to weld a cracked drum.

Smooth up any slight scores. Heavy or extensive scoring

will cause excessive brake lining wear and it will

probably be necessary to resurface drum braking

surface.

If brake linings are slightly worn and drum is grooved,

drum should be polished with fine emery cloth in the

direction of drum depth but not circumferentially along

drum inner.

NOTE

When drum is removed, visually inspect

wheel cylinder for brake fluid leakage.

Correct leaky point, if any.

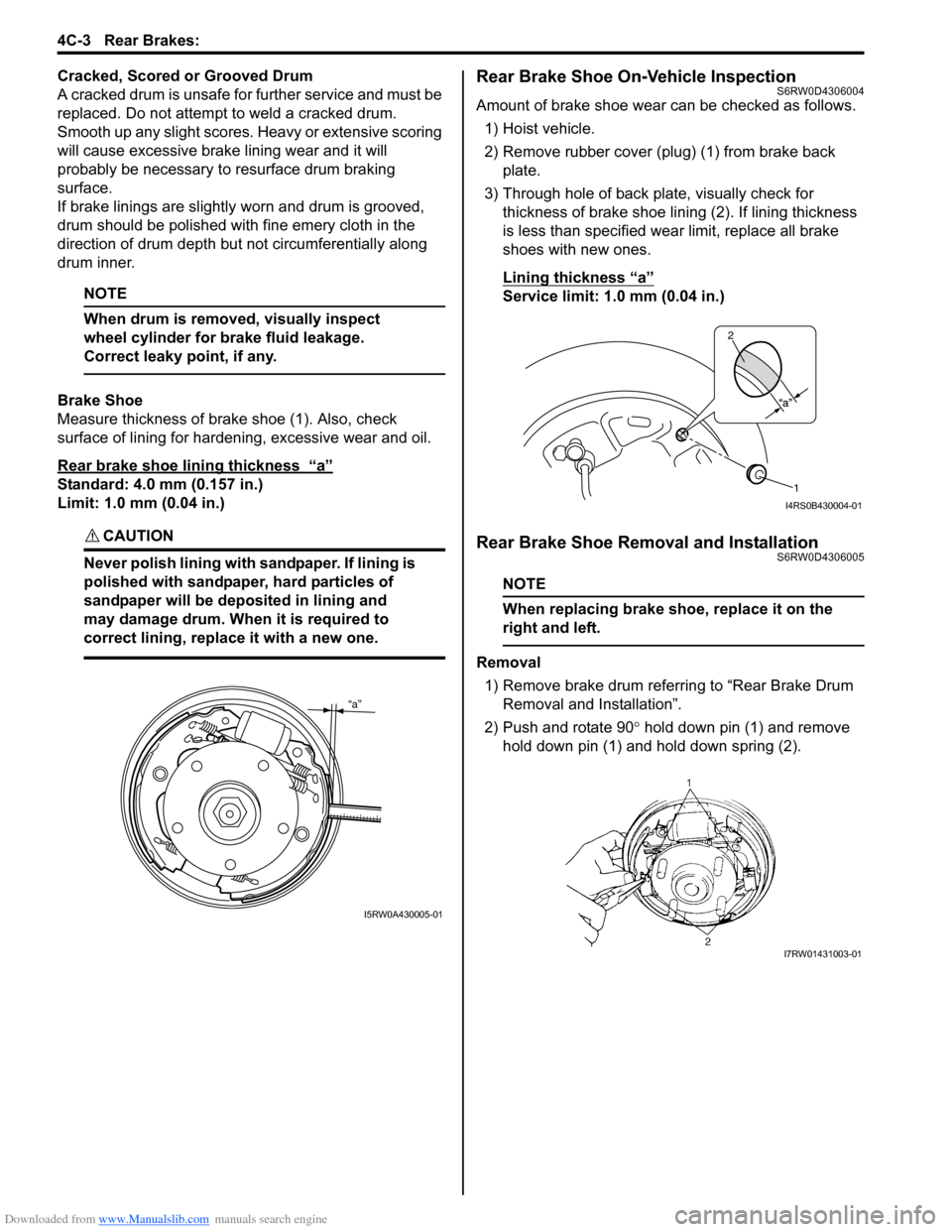

Brake Shoe

Measure thickness of brake shoe (1). Also, check

surface of lining for hardening, excessive wear and oil.

Rear brake shoe lining thickness

“a”

Standard: 4.0 mm (0.157 in.)

Limit: 1.0 mm (0.04 in.)

CAUTION!

Never polish lining with sandpaper. If lining is

polished with sandpaper, hard particles of

sandpaper will be deposited in lining and

may damage drum. When it is required to

correct lining, replace it with a new one.

Rear Brake Shoe On-Vehicle InspectionS6RW0D4306004

Amount of brake shoe wear can be checked as follows.

1) Hoist vehicle.

2) Remove rubber cover (plug) (1) from brake back

plate.

3) Through hole of back plate, visually check for

thickness of brake shoe lining (2). If lining thickness

is less than specified wear limit, replace all brake

shoes with new ones.

Lining thickness “a”

Service limit: 1.0 mm (0.04 in.)

Rear Brake Shoe Removal and InstallationS6RW0D4306005

NOTE

When replacing brake shoe, replace it on the

right and left.

Removal

1) Remove brake drum referring to “Rear Brake Drum

Removal and Installation”.

2) Push and rotate 90° hold down pin (1) and remove

hold down pin (1) and hold down spring (2).

“a”

I5RW0A430005-01

2

1

I4RS0B430004-01

I7RW01431003-01

Page 607 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-2

General Description

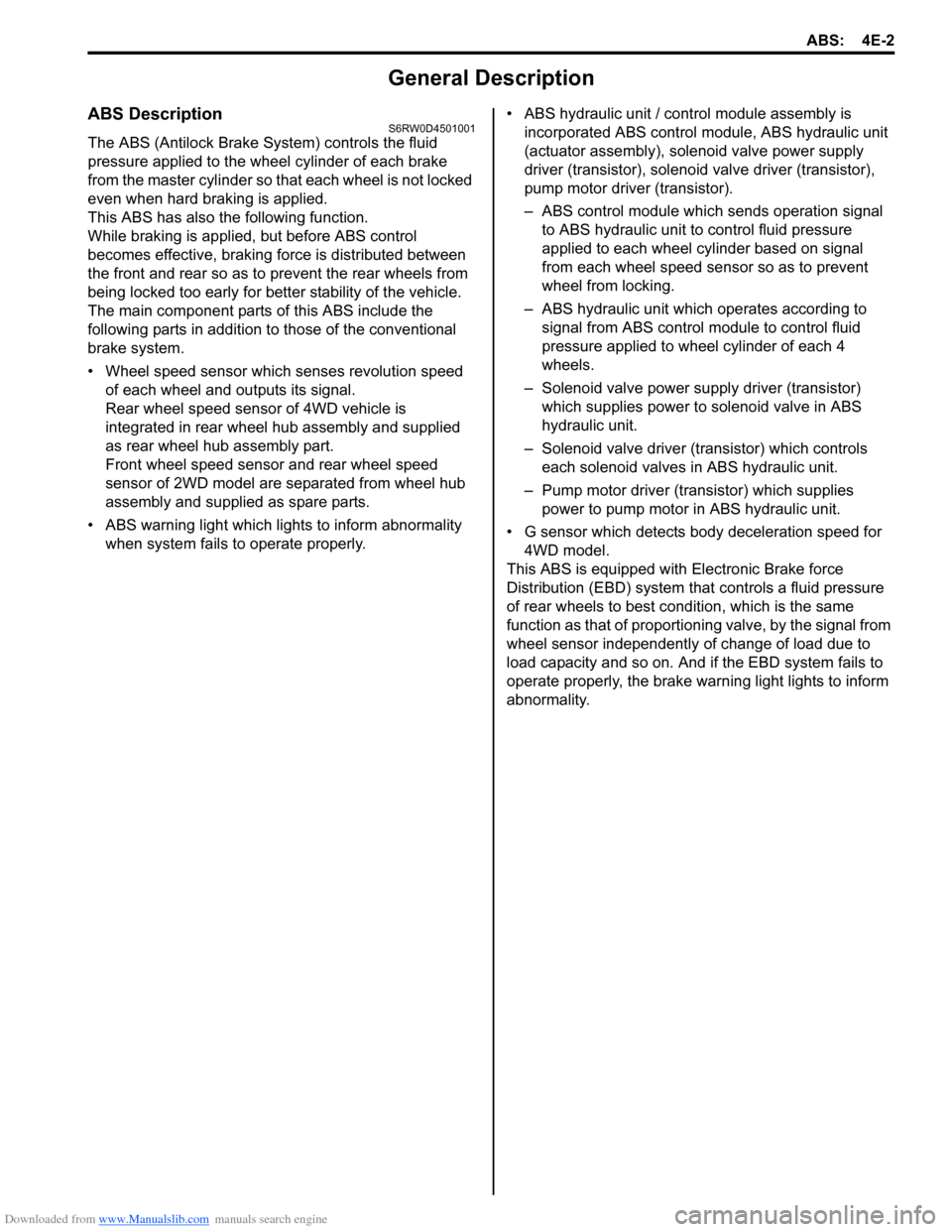

ABS DescriptionS6RW0D4501001

The ABS (Antilock Brake System) controls the fluid

pressure applied to the wheel cylinder of each brake

from the master cylinder so that each wheel is not locked

even when hard braking is applied.

This ABS has also the following function.

While braking is applied, but before ABS control

becomes effective, braking force is distributed between

the front and rear so as to prevent the rear wheels from

being locked too early for better stability of the vehicle.

The main component parts of this ABS include the

following parts in addition to those of the conventional

brake system.

• Wheel speed sensor which senses revolution speed

of each wheel and outputs its signal.

Rear wheel speed sensor of 4WD vehicle is

integrated in rear wheel hub assembly and supplied

as rear wheel hub assembly part.

Front wheel speed sensor and rear wheel speed

sensor of 2WD model are separated from wheel hub

assembly and supplied as spare parts.

• ABS warning light which lights to inform abnormality

when system fails to operate properly.• ABS hydraulic unit / control module assembly is

incorporated ABS control module, ABS hydraulic unit

(actuator assembly), solenoid valve power supply

driver (transistor), solenoid valve driver (transistor),

pump motor driver (transistor).

– ABS control module which sends operation signal

to ABS hydraulic unit to control fluid pressure

applied to each wheel cylinder based on signal

from each wheel speed sensor so as to prevent

wheel from locking.

– ABS hydraulic unit which operates according to

signal from ABS control module to control fluid

pressure applied to wheel cylinder of each 4

wheels.

– Solenoid valve power supply driver (transistor)

which supplies power to solenoid valve in ABS

hydraulic unit.

– Solenoid valve driver (transistor) which controls

each solenoid valves in ABS hydraulic unit.

– Pump motor driver (transistor) which supplies

power to pump motor in ABS hydraulic unit.

• G sensor which detects body deceleration speed for

4WD model.

This ABS is equipped with Electronic Brake force

Distribution (EBD) system that controls a fluid pressure

of rear wheels to best condition, which is the same

function as that of proportioning valve, by the signal from

wheel sensor independently of change of load due to

load capacity and so on. And if the EBD system fails to

operate properly, the brake warning light lights to inform

abnormality.

Page 608 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-3 ABS:

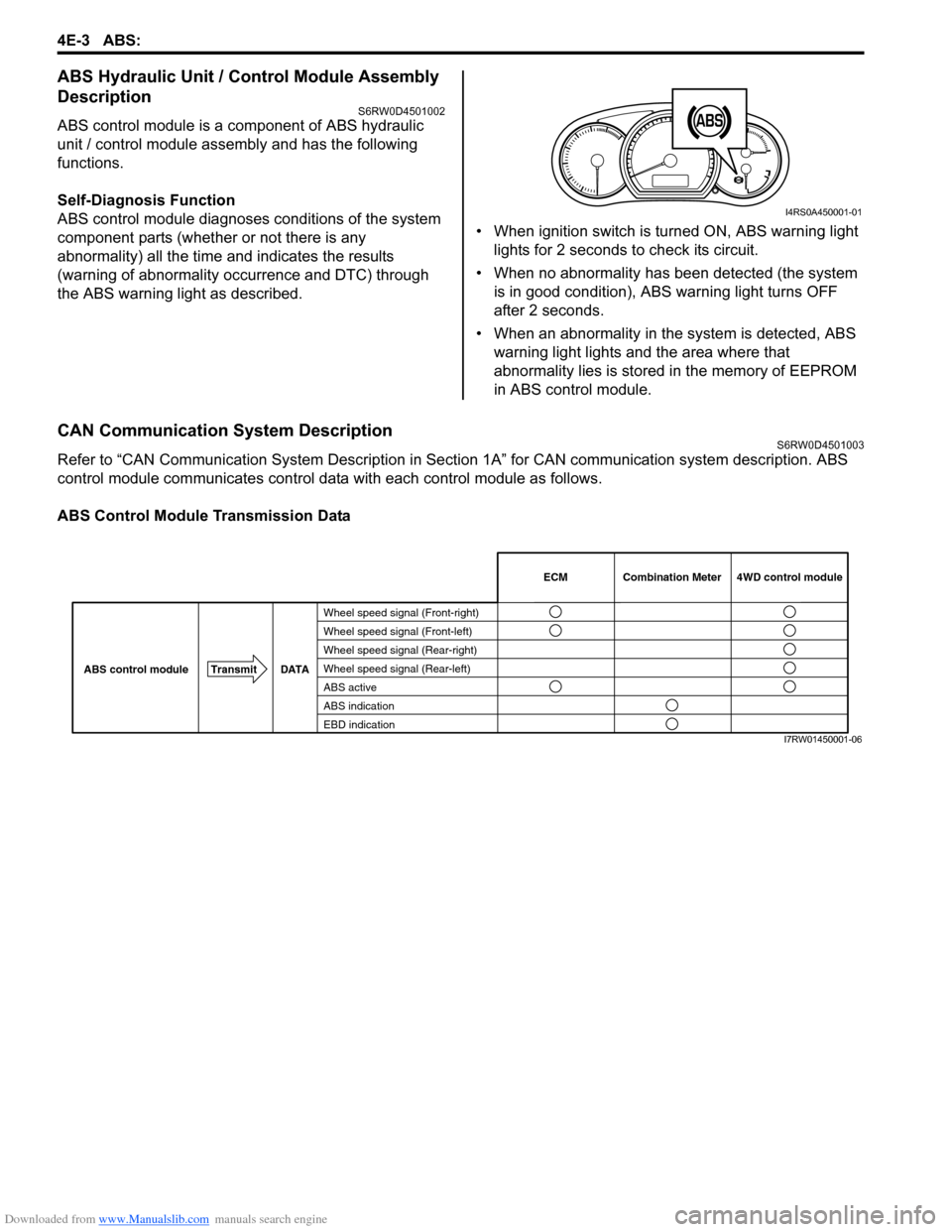

ABS Hydraulic Unit / Control Module Assembly

Description

S6RW0D4501002

ABS control module is a component of ABS hydraulic

unit / control module assembly and has the following

functions.

Self-Diagnosis Function

ABS control module diagnoses conditions of the system

component parts (whether or not there is any

abnormality) all the time and indicates the results

(warning of abnormality occurrence and DTC) through

the ABS warning light as described.• When ignition switch is turned ON, ABS warning light

lights for 2 seconds to check its circuit.

• When no abnormality has been detected (the system

is in good condition), ABS warning light turns OFF

after 2 seconds.

• When an abnormality in the system is detected, ABS

warning light lights and the area where that

abnormality lies is stored in the memory of EEPROM

in ABS control module.

CAN Communication System DescriptionS6RW0D4501003

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description. ABS

control module communicates control data with each control module as follows.

ABS Control Module Transmission Data

1

I4RS0A450001-01

Wheel speed signal (Front-right)

Wheel speed signal (Front-left)

Wheel speed signal (Rear-right)

Wheel speed signal (Rear-left)

ABS active

ABS indication

EBD indicationCombination Meter

TransmitDATA

ABS control module ECM 4WD control module

I7RW01450001-06

Page 610 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-5 ABS:

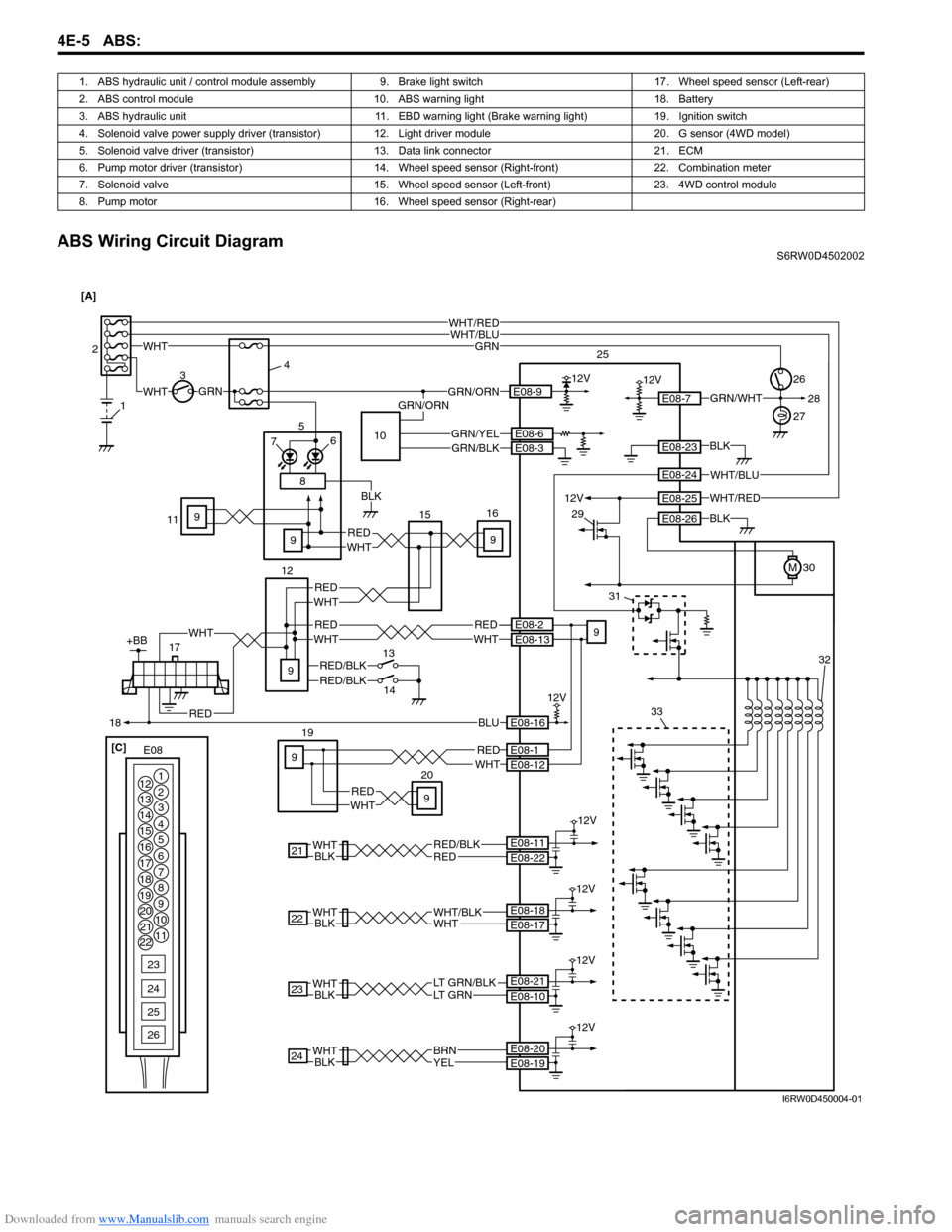

ABS Wiring Circuit DiagramS6RW0D4502002 1. ABS hydraulic unit / control module assembly 9. Brake light switch 17. Wheel speed sensor (Left-rear)

2. ABS control module 10. ABS warning light 18. Battery

3. ABS hydraulic unit 11. EBD warning light (Brake warning light) 19. Ignition switch

4. Solenoid valve power supply driver (transistor)12. Light driver module 20. G sensor (4WD model)

5. Solenoid valve driver (transistor) 13. Data link connector 21. ECM

6. Pump motor driver (transistor) 14. Wheel speed sensor (Right-front) 22. Combination meter

7. Solenoid valve 15. Wheel speed sensor (Left-front) 23. 4WD control module

8. Pump motor 16. Wheel speed sensor (Right-rear)

BLU

WHT12VGRN/ORN 34

30E08-9

RED

WHT26

WHT/RED

12V

E08-7

19GRN

GRN

E08-16

12V

21REDRED/BLK

12V

BLKWHTE08-22 E08-11

23BLKWHTLT GRN/BLKLT GRN

12V

E08-10 E08-21

E08-23

E08-26

E08-1E08-12

24BLKWHT

12V

YELBRNE08-19 E08-2027

1 2

E08-6

9

9

9

WHTRED

12VE08-25

M

BLK

BLK

WHT/BLUWHT/RED

WHT/BLUE08-24

WHT

E08 [C] [A]

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26

GRN/WHT

22

12V

BLKWHTWHTWHT/BLKE08-17 E08-18

GRN/ORN28

2033

31

29

25

32

GRN/YELE08-3GRN/BLK10

8

17

18

+BB

RED/BLKRED/BLK

REDWHTREDWHT

RED

BLK

WHT

14 13 12 76 5

1516

REDWHT

11

RED

WHT

9 9

E08-13E08-2

99

I6RW0D450004-01