accessories SUZUKI SX4 2006 1.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1320 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-1 Lighting Systems:

Body, Cab and Accessories

Lighting Systems

Precautions

Precautions for Discharge Headlight Service (If Equipped)S6RW0D9200001

WARNING!

• Do not touch igniter or ballast when lighting switch is at “HEAD” position to avoid possible electric

shock.

• Do not measure voltage or resistance with tester connected to output connector of ballast or igniter

to avoid possible electric shock.

• Do not perform work where exposed to water including rain or with wet hands to avoid possible

electric shock.

• Disassembling igniter or ballast is strictly prohibited as it may cause an electric shock.

• Before inspecting or repairing discharge headlight or its peripheral parts, make sure that lighting

switch is at OFF position and battery is disconnected at negative terminal to avoid possible

electrical shock.

• Do not set lighting switch to “HEAD” position with connector disconnected or any part removed to

avoid possible electric shock.

• Do not touch glass surface of headlight bulb. Oil or grease attached on it may not only make bulb

service life shorter but also cause bulb to burst when lighting switch is turned on.

• Mercury, metal iodide and xenon gas are sealed in discharge headlight bulb. Be sure to dispose of

used discharge headlight bulb properly according to applicable rules or regulations.

Precautions in Diagnosing Troubles (Headlight Auto Leveling System)S6RW0D9200002

• Be sure to read “Air Bag Warning in Section 00” before inspection and observe what is written there.

• Replacement of height sensor and headlight leveling control module. When height sensor and/or headlight leveling

control module is replaced with new one, perform initialization of headlight auto leveling system according to

“Initialization of Headlight Auto Leveling System”.

General Description

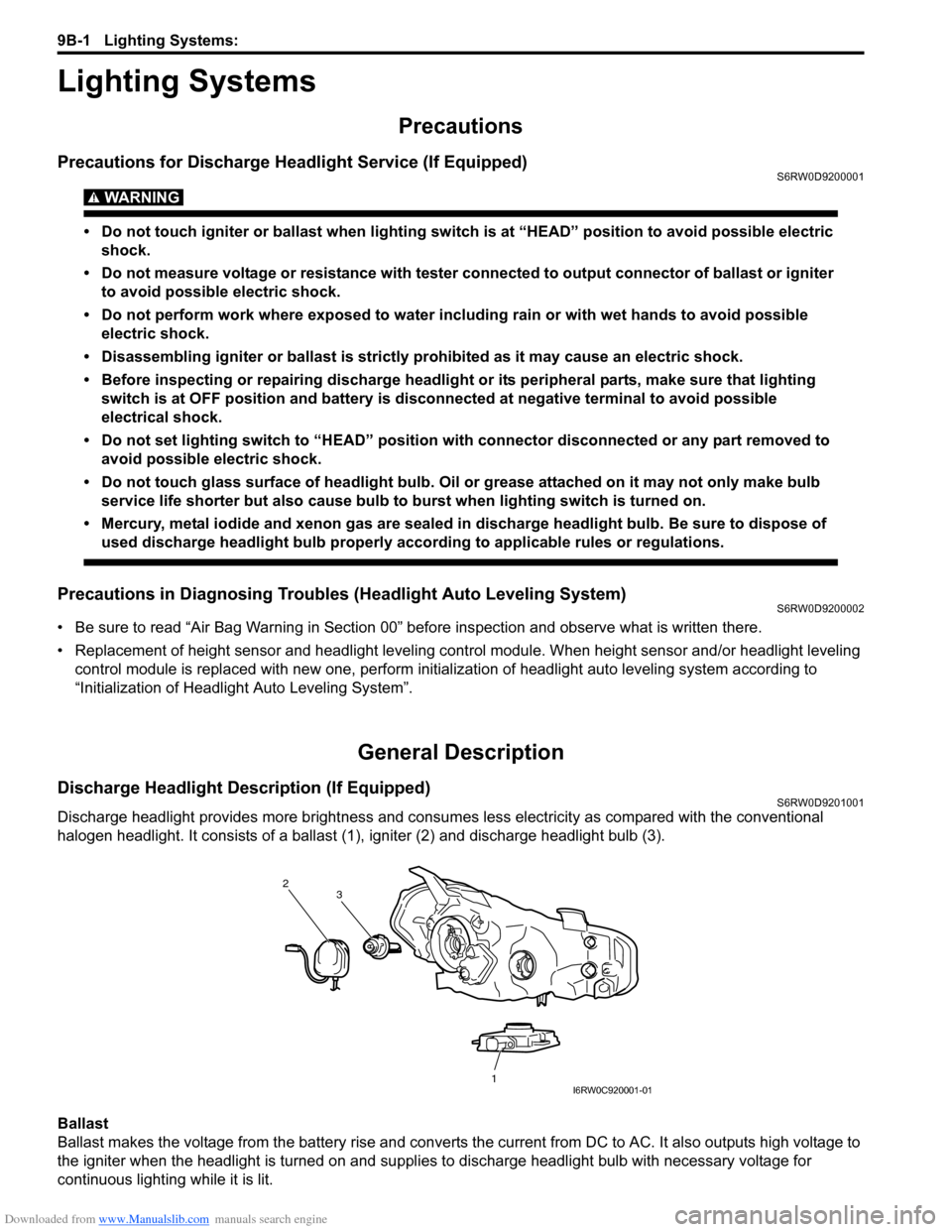

Discharge Headlight Description (If Equipped)S6RW0D9201001

Discharge headlight provides more brightness and consumes less electricity as compared with the conventional

halogen headlight. It consists of a ballast (1), igniter (2) and discharge headlight bulb (3).

Ballast

Ballast makes the voltage from the battery rise and converts the current from DC to AC. It also outputs high voltage to

the igniter when the headlight is turned on and supplies to discharge headlight bulb with necessary voltage for

continuous lighting while it is lit.

2

1 3

I6RW0C920001-01

Page 1353 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-1

Body, Cab and Accessories

Instrumentation / Driver Info. / Horn

Precautions

Precautions in Diagnosing Troubles for Combination MeterS6RW0D9300001

Combination meter uses signals (information) from each control module by CAN communication to control

speedometer, tachometer, fuel meter, engine coolant temp meter, warning light and indicator light (other than air bag

warning light, EPS warning light, headlight leveling warning light (if equipped), rear fog light indicator light (if

equipped), high beam indicator light and turn signal indicator light). Therefor, check that no DTC is detected in each

module before performing combination meter symptom diagnosis. If any DTC is detected, correct trouble indicated by

that DTC troubleshooting first.

General Description

CAN Communication System DescriptionS6RW0D9301001

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description.

Combination meter communicates control data with each control module as follows.

Combination Meter Transmission Data

BCM

Combination

meterDATA

TransmitCombination meter spec signal

I5RW0A930001-02

Page 1375 of 1556

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-1

Body, Cab and Accessories

Wipers / Washers

Diagnostic Information and Procedures

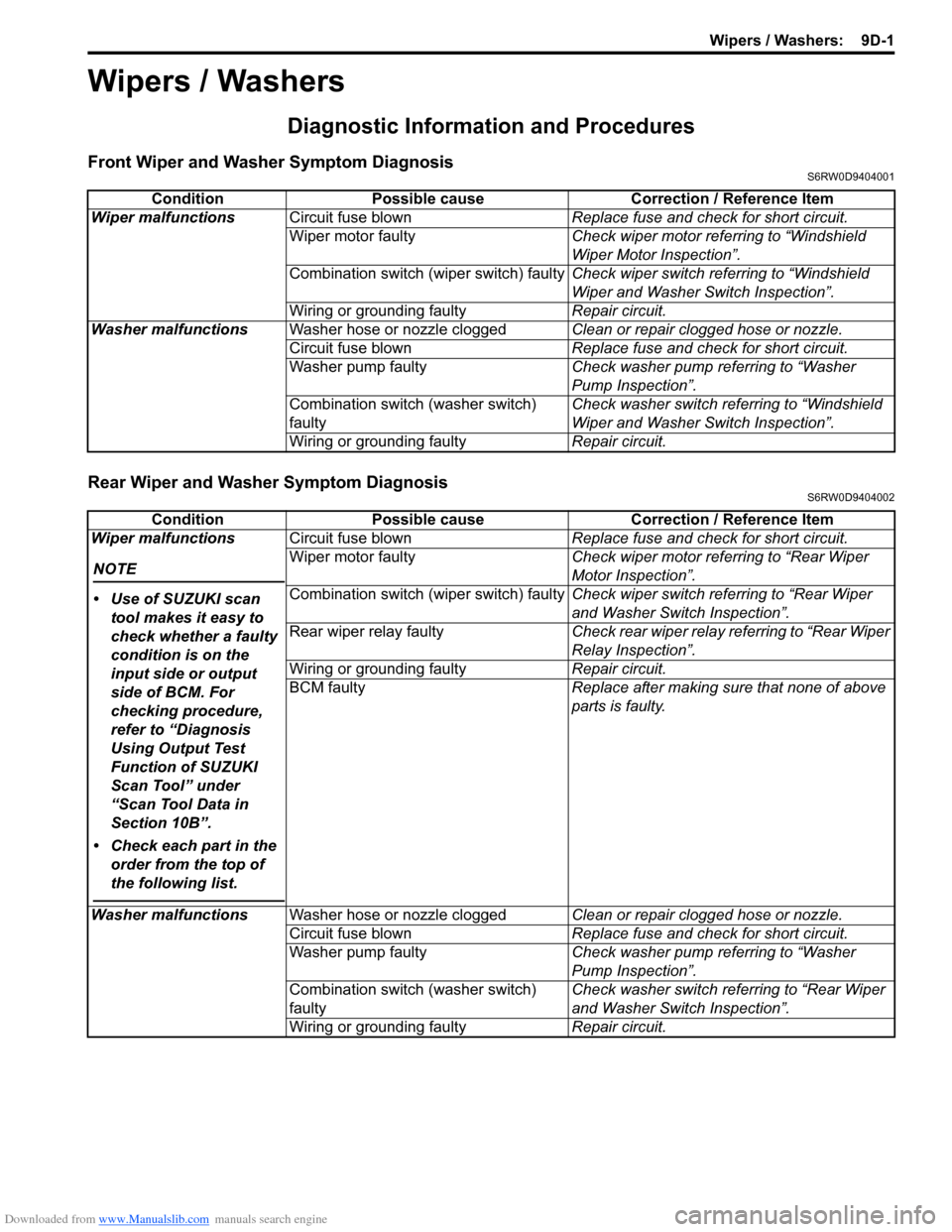

Front Wiper and Washer Symptom DiagnosisS6RW0D9404001

Rear Wiper and Washer Symptom DiagnosisS6RW0D9404002

Condition Possible cause Correction / Reference Item

Wiper malfunctionsCircuit fuse blownReplace fuse and check for short circuit.

Wiper motor faultyCheck wiper motor referring to “Windshield

Wiper Motor Inspection”.

Combination switch (wiper switch) faultyCheck wiper switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faultyRepair circuit.

Washer malfunctionsWasher hose or nozzle cloggedClean or repair clogged hose or nozzle.

Circuit fuse blownReplace fuse and check for short circuit.

Washer pump faultyCheck washer pump referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faultyCheck washer switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faultyRepair circuit.

Condition Possible cause Correction / Reference Item

Wiper malfunctions

NOTE

• Use of SUZUKI scan

tool makes it easy to

check whether a faulty

condition is on the

input side or output

side of BCM. For

checking procedure,

refer to “Diagnosis

Using Output Test

Function of SUZUKI

Scan Tool” under

“Scan Tool Data in

Section 10B”.

• Check each part in the

order from the top of

the following list.

Circuit fuse blownReplace fuse and check for short circuit.

Wiper motor faultyCheck wiper motor referring to “Rear Wiper

Motor Inspection”.

Combination switch (wiper switch) faultyCheck wiper switch referring to “Rear Wiper

and Washer Switch Inspection”.

Rear wiper relay faultyCheck rear wiper relay referring to “Rear Wiper

Relay Inspection”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Washer malfunctionsWasher hose or nozzle cloggedClean or repair clogged hose or nozzle.

Circuit fuse blownReplace fuse and check for short circuit.

Washer pump faultyCheck washer pump referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faultyCheck washer switch referring to “Rear Wiper

and Washer Switch Inspection”.

Wiring or grounding faultyRepair circuit.

Page 1386 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-1 Glass / Windows / Mirrors:

Body, Cab and Accessories

Glass / Windows / Mirrors

Precautions

Precautions for Power Window Service (Pinching Prevention Function Model)S6RW0D9500001

WARNING!

When checking the pinching prevention function, never attempt intentionally to have your hand, arm

or any other part of the body pinched. Also, use full care not to have your body caught.

• Do not drop the power window regulator (motor) or expose it to a strong impact in any other way.

• Do not operate the motor unless the power window regulator (motor) is installed and ready to operate door glass.

• If any peripheral part has bean damaged, replace regulator (motor) as well depending on the damage condition.

• After replacing or disconnecting the driver side power window regulator (motor), power window main switch, battery

and/or fuse, make sure to execute the initial setting, (to have the door glass closed position learned) refer to “Power

Window Main Switch Initialization (Pinching Prevention Function Model)”.

General Description

Rear End Door Window Defogger System DescriptionS6RW0D9501001

The rear end door window defogger is controlled by BCM. For the BCM description refer to “BCM General Description

in Section 10B”.

Page 1412 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-1 Security and Locks:

Body, Cab and Accessories

Security and Locks

General Description

Key Coding ConstructionS6RW0D9601001

Key Usage and Identification

Key is used for ignition and door lock cylinders. Key is cut on both edges to make them reversible.

Key identification is obtained from five character key code stamped on key code tag. Using this key code, key code

cutting combination can be determined from a code list (available to owners of key cutting equipment from suppliers).

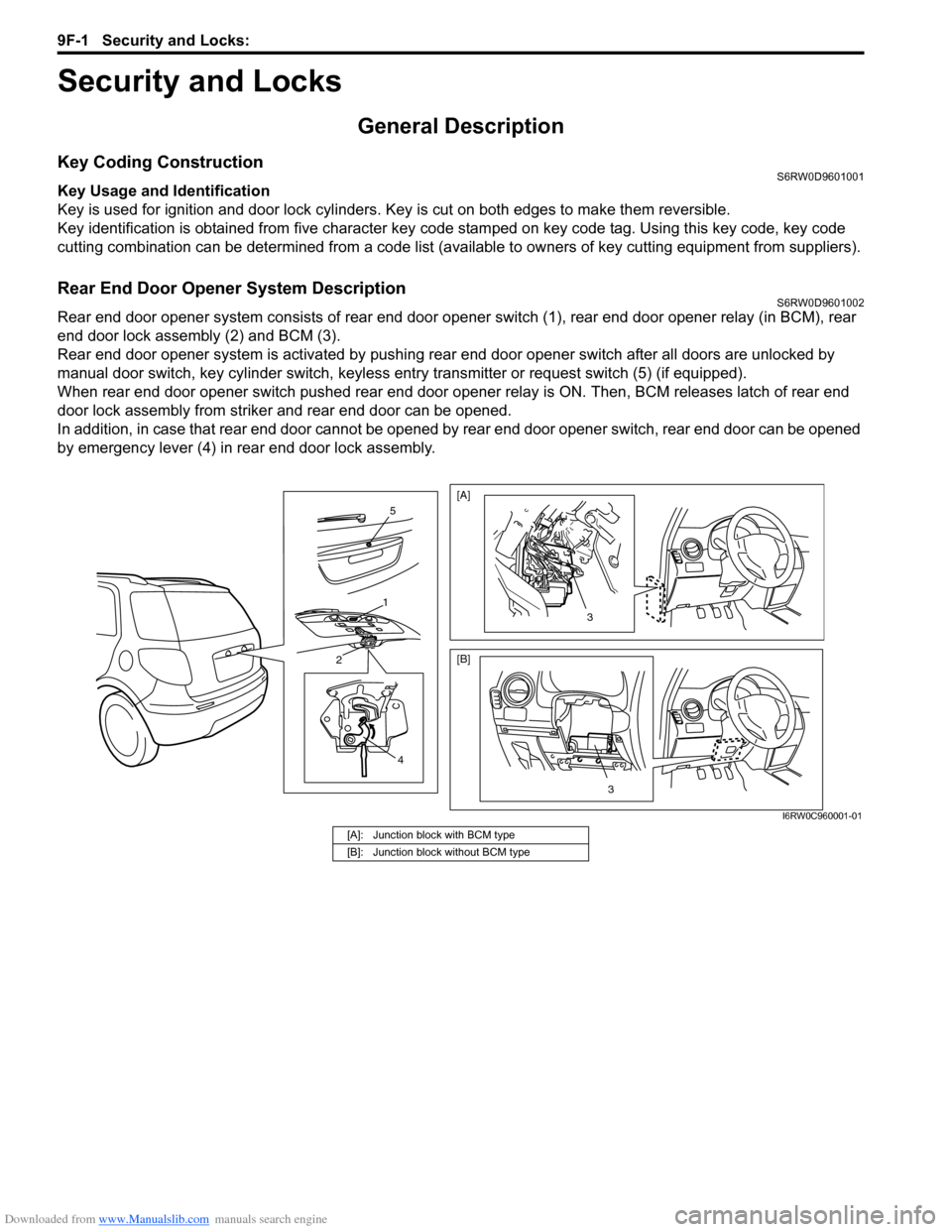

Rear End Door Opener System DescriptionS6RW0D9601002

Rear end door opener system consists of rear end door opener switch (1), rear end door opener relay (in BCM), rear

end door lock assembly (2) and BCM (3).

Rear end door opener system is activated by pushing rear end door opener switch after all doors are unlocked by

manual door switch, key cylinder switch, keyless entry transmitter or request switch (5) (if equipped).

When rear end door opener switch pushed rear end door opener relay is ON. Then, BCM releases latch of rear end

door lock assembly from striker and rear end door can be opened.

In addition, in case that rear end door cannot be opened by rear end door opener switch, rear end door can be opened

by emergency lever (4) in rear end door lock assembly.

4

2

1

5

3

[A]

[B]

3

I6RW0C960001-01

[A]: Junction block with BCM type

[B]: Junction block without BCM type

Page 1428 of 1556

Downloaded from www.Manualslib.com manuals search engine 9G-1 Seats:

Body, Cab and Accessories

Seats

Diagnostic Information and Procedures

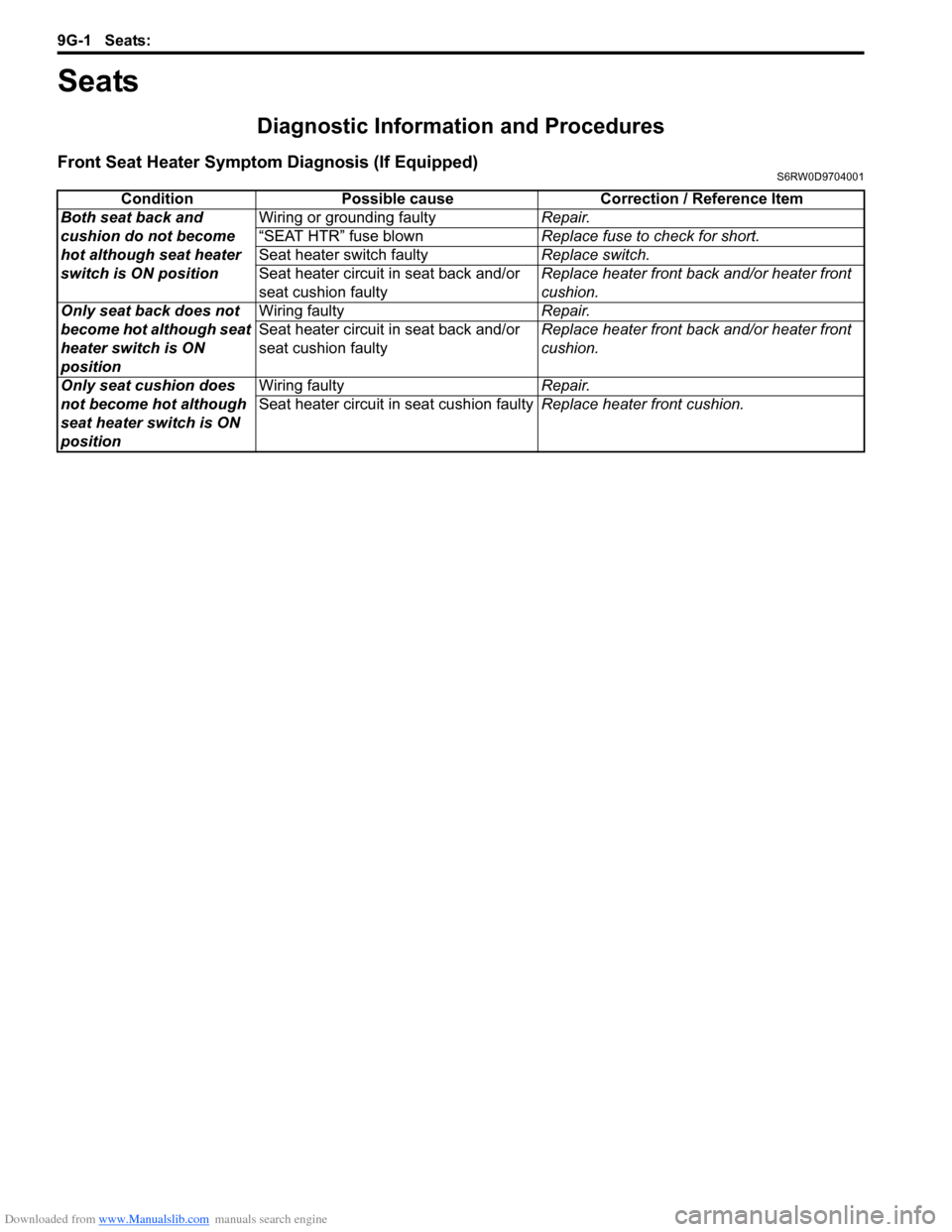

Front Seat Heater Symptom Diagnosis (If Equipped)S6RW0D9704001

Condition Possible cause Correction / Reference Item

Both seat back and

cushion do not become

hot although seat heater

switch is ON positionWiring or grounding faultyRepair.

“SEAT HTR” fuse blownReplace fuse to check for short.

Seat heater switch faultyReplace switch.

Seat heater circuit in seat back and/or

seat cushion faultyReplace heater front back and/or heater front

cushion.

Only seat back does not

become hot although seat

heater switch is ON

positionWiring faultyRepair.

Seat heater circuit in seat back and/or

seat cushion faultyReplace heater front back and/or heater front

cushion.

Only seat cushion does

not become hot although

seat heater switch is ON

positionWiring faultyRepair.

Seat heater circuit in seat cushion faultyReplace heater front cushion.

Page 1433 of 1556

Downloaded from www.Manualslib.com manuals search engine Interior Trim: 9H-1

Body, Cab and Accessories

Interior Trim

Repair Instructions

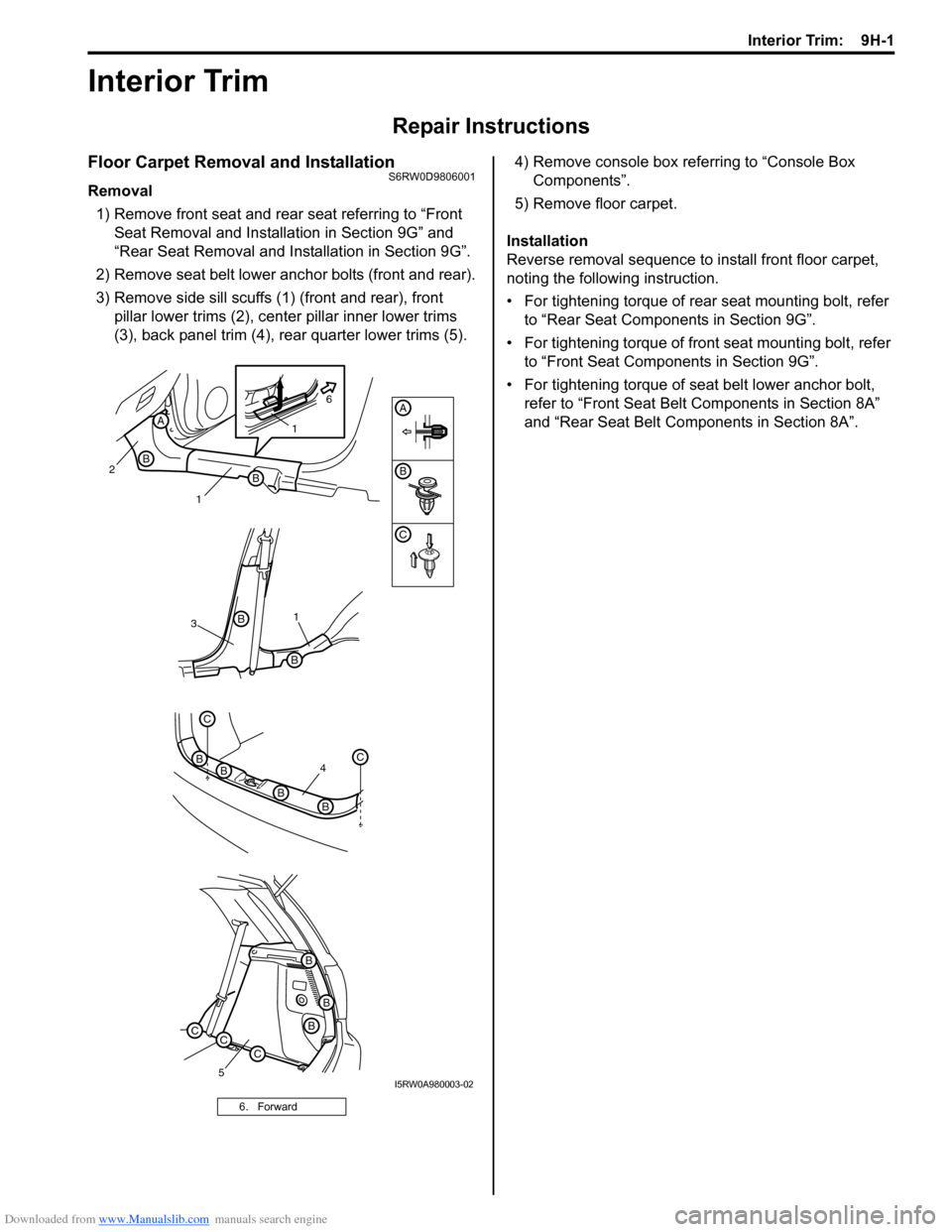

Floor Carpet Removal and InstallationS6RW0D9806001

Removal

1) Remove front seat and rear seat referring to “Front

Seat Removal and Installation in Section 9G” and

“Rear Seat Removal and Installation in Section 9G”.

2) Remove seat belt lower anchor bolts (front and rear).

3) Remove side sill scuffs (1) (front and rear), front

pillar lower trims (2), center pillar inner lower trims

(3), back panel trim (4), rear quarter lower trims (5).4) Remove console box referring to “Console Box

Components”.

5) Remove floor carpet.

Installation

Reverse removal sequence to install front floor carpet,

noting the following instruction.

• For tightening torque of rear seat mounting bolt, refer

to “Rear Seat Components in Section 9G”.

• For tightening torque of front seat mounting bolt, refer

to “Front Seat Components in Section 9G”.

• For tightening torque of seat belt lower anchor bolt,

refer to “Front Seat Belt Components in Section 8A”

and “Rear Seat Belt Components in Section 8A”.

6. Forward

B

C

A

4

C

BC

BB

B

31

B

B

5

B

B

B

CCC

2

1B

B

A1

6

I5RW0A980003-02

Page 1437 of 1556

Downloaded from www.Manualslib.com manuals search engine Hood / Fenders / Doors: 9J-1

Body, Cab and Accessories

Hood / Fenders / Doors

Repair Instructions

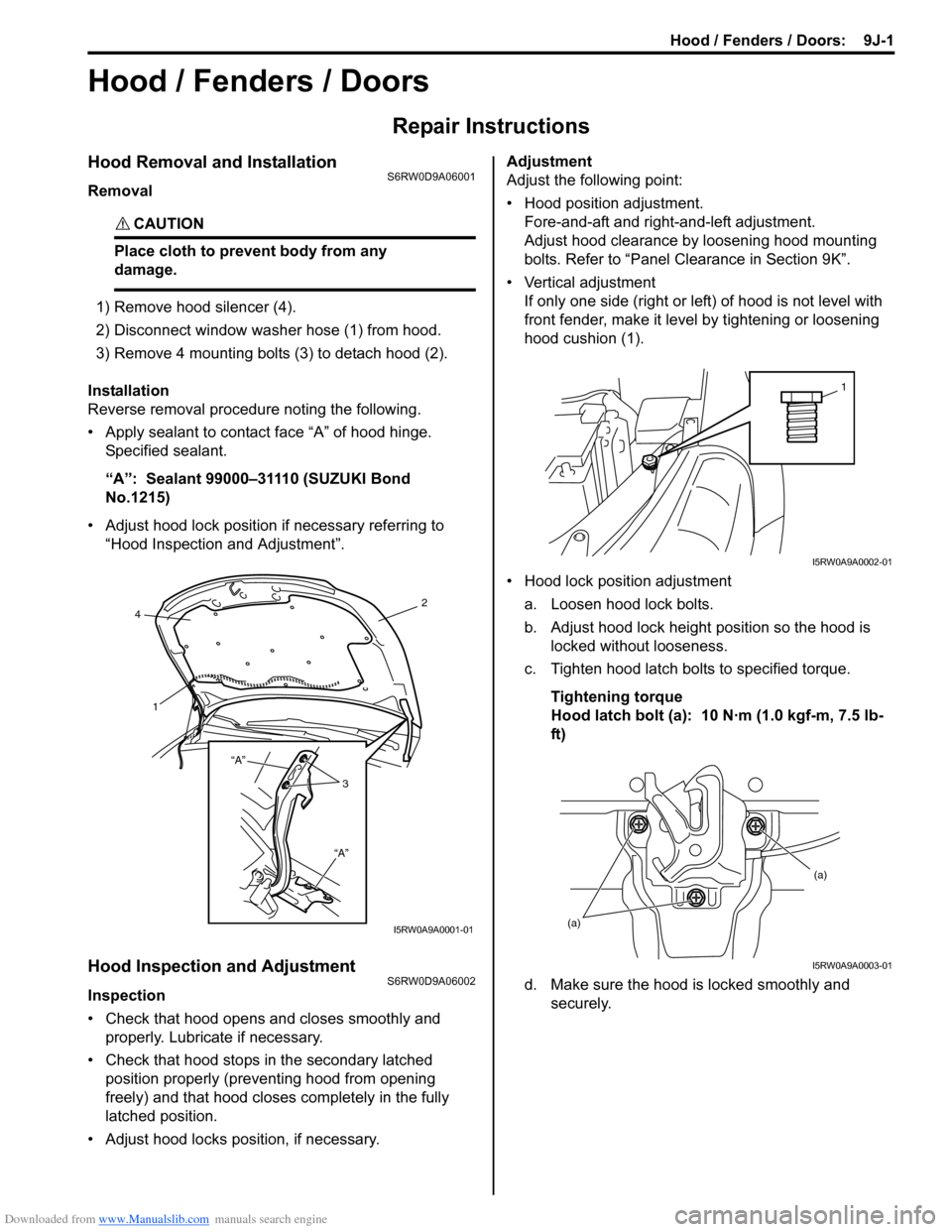

Hood Removal and InstallationS6RW0D9A06001

Removal

CAUTION!

Place cloth to prevent body from any

damage.

1) Remove hood silencer (4).

2) Disconnect window washer hose (1) from hood.

3) Remove 4 mounting bolts (3) to detach hood (2).

Installation

Reverse removal procedure noting the following.

• Apply sealant to contact face “A” of hood hinge.

Specified sealant.

“A”: Sealant 99000–31110 (SUZUKI Bond

No.1215)

• Adjust hood lock position if necessary referring to

“Hood Inspection and Adjustment”.

Hood Inspection and AdjustmentS6RW0D9A06002

Inspection

• Check that hood opens and closes smoothly and

properly. Lubricate if necessary.

• Check that hood stops in the secondary latched

position properly (preventing hood from opening

freely) and that hood closes completely in the fully

latched position.

• Adjust hood locks position, if necessary.Adjustment

Adjust the following point:

• Hood position adjustment.

Fore-and-aft and right-and-left adjustment.

Adjust hood clearance by loosening hood mounting

bolts. Refer to “Panel Clearance in Section 9K”.

• Vertical adjustment

If only one side (right or left) of hood is not level with

front fender, make it level by tightening or loosening

hood cushion (1).

• Hood lock position adjustment

a. Loosen hood lock bolts.

b. Adjust hood lock height position so the hood is

locked without looseness.

c. Tighten hood latch bolts to specified torque.

Tightening torque

Hood latch bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-

ft)

d. Make sure the hood is locked smoothly and

securely.

2

4

1

3 “A”

“A”

I5RW0A9A0001-01

1

I5RW0A9A0002-01

(a)(a)

I5RW0A9A0003-01

Page 1445 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Structure: 9K-1

Body, Cab and Accessories

Body Structure

Repair Instructions

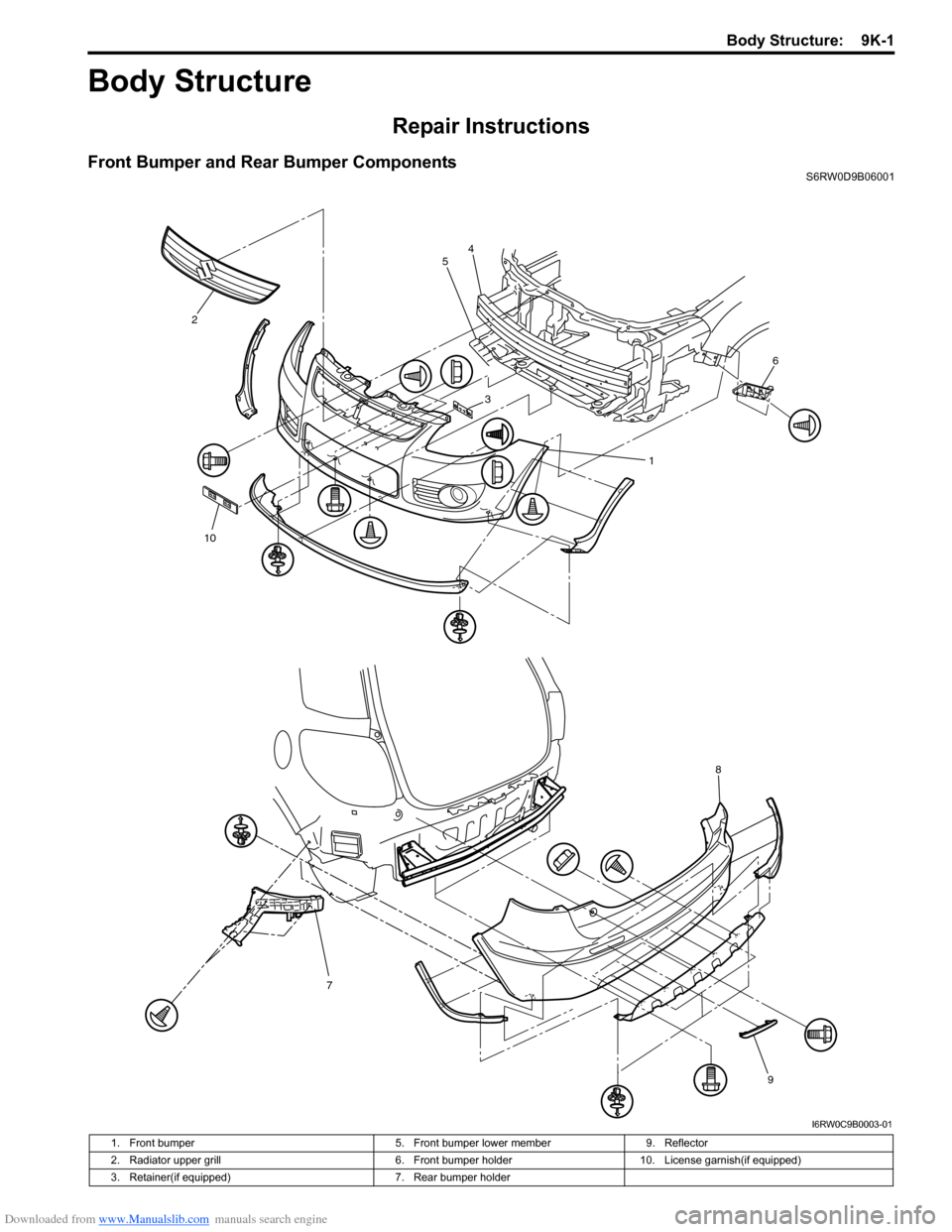

Front Bumper and Rear Bumper ComponentsS6RW0D9B06001

1 24

5

6

3

78

9

10

I6RW0C9B0003-01

1. Front bumper 5. Front bumper lower member 9. Reflector

2. Radiator upper grill 6. Front bumper holder 10. License garnish(if equipped)

3. Retainer(if equipped) 7. Rear bumper holder

Page 1455 of 1556

Downloaded from www.Manualslib.com manuals search engine Paint / Coatings: 9L-1

Body, Cab and Accessories

Paint / Coatings

General Description

Anti-Corrosion Treatment ConstructionS6RW0D9C01001

WARNING!

Standard shop practices, particularly eye protection, should be followed during the performance of the

following operations to avoid personal injury.

As rust proof treatment, steel sheets are given corrosion resistance on the interior and/or exterior.

These corrosion resistance steel sheet materials are called one of two-side galvanized steel sheets.

It is for the sake of rust protection that these materials are selected and given a variety of treatments as described

blow.

• Steel sheets are treated with cathodic electro primer which is excellent in corrosion resistance.

• Rust proof wax coatings are applied to door and side sill insides where moisture is liable to stay.

• Vinyl coating is applied to body underside and wheel housing inside.

• Sealer is applied to door hem, engine compartment steel sheet-to-steel sheet joint, and the like portions to prevent

water penetration and resulting in rust occurrence.

In panel replacement or collision damage repair, leaving the relevant area untreated as it is in any operation which

does disturb the rust proof treatment will cause corrosion to that area. Therefore, it is the essential function of any

repair operation to correctly recoat the related surfaces of the relevant area.

All the metal panels are coated with metal conditioners and primer coating during vehicle production. Following the

repair and/or replacement parts installation, every accessible bare metal surface should be cleaned and coated with

rust proof primer. Perform this operation prior to the application of sealer and rust proof wax coating.

Sealer is applied to the specific joints of a vehicle during production. The sealer is intended to prevent dust from

entering the vehicle and serves also as an anticorrosion barrier. The sealer is applied to the door and hood hem areas

and between panels. Correct and reseal the originally sealed joints if damaged. Reseal the attaching joints of a new

replacement panel and reseal the hem area of a replacement door or hood.

Use a quality sealer to seal the flanged joints, overlap joints and seams. The sealer must have flexible characteristics

and paint ability after it’s applied to repair areas.

For the sealer to fill open joints, use caulking material. Select a sealer in conformance with the place and purpose of a

specific use. Observe the manufacturer’s label-stand instructions when using the sealer.

In many cases, repaired places require color painting. When this is required, follow the ordinary techniques specified

for the finish preparation, color painting and undercoating build-up.

Rust proof wax, a penetrative compound, is applied to the metal-to-metal surfaces (door and side sill insides) where it

is difficult to use ordinary undercoating material for coating. Therefore, when selecting the rust proof wax, it may be the

penetrative type.

During the undercoating (vinyl coating) application, care should be taken that sealer is not applied to the engine-

related parts and shock absorber mounting or rotating parts. Following the under coating, make sure that body drain

holes are kept open.

The sequence of the application steps of the anti-corrosion materials are as follows:

1) Clean and prepare the metal surface.

2) Apply primer.

3) Apply sealer (all joints sealed originally).

4) Apply color in areas where color is required such as hem flanges, exposed joints and under body components.

5) Apply anticorrosion compound (penetrative wax).

6) Apply undercoating (rust proof material).