rear mirror SUZUKI SX4 2006 1.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1207 of 1556

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-40

Individual Circuit Fuse Box No. 2 (In J/B (Taiwan))S6RW0D910D005

19

25

20

26

34

21

27

35

22

28

36

23

29

37

24

30

38

31

39

32

40

33

41

42USE THE DESINGNATED FUSES AND RELAYS ONLY.

I7RW01910912-02

No. Fuse Description on the cover Protected circuit

15 A RR WIPRear wiper motor

Rear washer motor

15 A IG COILBCM

A/F

ECM

Fuel pump relay

Generator

Heated oxygen sensor #1

Heated oxygen sensor #2

VSS

ICM

IG coil #1

IG coil #2

IG coil #3

IG coil #4

10 A BACKBack-up light switch

Fresh / Recircle actuator

Mode control switch

Auto A/C unit

KLS ECM

Transaxle range sensor

10 A MTRCOMB meter

Flasher relay

15 A ACCBCM

Power mirror switch

ACC socket

15 A ACC 2Rear ACC socket

Audio

Multi information display

KLS ECM

30 A WIPCOMB switch

Windshield washer motor

Windshield wiper motor

Rear wiper relay

10 A IG1 SIGPower steering control module

A/T relay

15 A A/B A/B SDM

Page 1208 of 1556

Downloaded from www.Manualslib.com manuals search engine 9A-41 Wiring Systems:

10 A ABSABS control module

G sensor

BLANK BLANK BLANK

15 A STOP Brake light switch

20 A D/L BCM

BLANK BLANK BLANK

10 A ST SIG Starting motor relay

BLANK BLANK BLANK

10 A IG2 SIG Blower fan relay

10 A TAIL Tail light relay

15 A DOMEAudio

BCM

COMB meter

DLC

ECM

Interior light

ICM

TCM

Rear interior light

Luggage compartment light

Main switch (Key switch)

Multi information display

KLS ECM

30 A RR DEFRear defogger relay

Mirror motor (R)

Mirror motor (L)

15 A HORN-HAZHorn relay

Flasher relay

BLANK BLANK BLANK

BLANK BLANK BLANK

30 A P/WPower window main switch

Front power window sub switch

Rear power window sub switch (R)

Rear power window sub switch (L) No. Fuse Description on the cover Protected circuit

Page 1224 of 1556

Downloaded from www.Manualslib.com manuals search engine 9A-57 Wiring Systems:

System Circuit Diagram

System Circuit DiagramS6RW0D910E001

Refer to “A-1 Cranking System Circuit Diagram”.

Refer to “A-2 Charging System Circuit Diagram”.

Refer to “A-3 Ignition System Circuit Diagram (M15A engine, M16A engine)”.

Refer to “A-3 Ignition System Circuit Diagram (J20A engine)”.

Refer to “A-4 Cooling System Circuit Diagram (M15A engine, M16A engine)”.

Refer to “A-4 Cooling System Circuit Diagram (J20A engine)”.

Refer to “A-5 Engine and A/C Control System Circuit Diagram (M15A engine)”.

Refer to “A-5 Engine and A/C Control System Circuit Diagram (M16A engine)”.

Refer to “A-5 Engine and A/C Control System Circuit Diagram (J20A engine)”.

Refer to “A-6 A/T Control System Circuit Diagram”.

Refer to “A-7 Immobilizer System Circuit Diagram”.

Refer to “A-8 Body Control System Circuit Diagram (Except Taiwan)”.

Refer to “A-8 Body Control System Circuit Diagram (Taiwan)”.

Refer to “A-10 4WD Control System (Except Taiwan)”

Refer to “B-1 Windshield Wiper and Washer Circuit Diagram”.

Refer to “B-2 Rear Wiper and Washer Circuit Diagram (Except Taiwan)”.

Refer to “B-2 Rear Wiper and Washer Circuit Diagram (Taiwan)”.

Refer to “B-3 Rear Defogger Circuit Diagram (Except Taiwan)”.

Refer to “B-3 Rear Defogger Circuit Diagram (Taiwan)”.

Refer to “B-4 Power Window Circuit Diagram”.

Refer to “B-5 Power Door Lock Circuit Diagram (Except Taiwan)”.

Refer to “B-5 Power Door Lock Circuit Diagram (Taiwan)”.

Refer to “B-6 Power Mirror Circuit Diagram (Except Taiwan)”.

Refer to “B-6 Power Mirror Circuit Diagram (Taiwan)”.

Refer to “B-7 Horn Circuit Diagram”.

Refer to “B-8 Seat Heater Circuit Diagram”.

Refer to “B-9 Keyless Start System Circuit Diagram”

Refer to “C-1 Combination Meter Circuit Diagram (Meter)”.

Refer to “C-2 Combination Meter Circuit Diagram (Indicator)”.

Refer to “C-3 Combination Meter Circuit Diagram (Warning Light)”.

Refer to “D-1 Headlight System Circuit Diagram (Except Taiwan)”.

Refer to “D-1 Headlight System Circuit Diagram (Taiwan)”.

Refer to “D-2 Position, Tail and Licence Plate Light System Circuit Diagram (Except Taiwan)”.

Refer to “D-2 Position, Tail and Licence Plate Light System Circuit Diagram (Taiwan)”.

Refer to “D-3 Front Fog Light System Circuit Diagram (Except Taiwan)”.

Refer to “D-3 Front Fog Light System Circuit Diagram (Taiwan)”.

Refer to “D-4 Illumination Light System Circuit Diagram (Except Taiwan)”.

Refer to “D-4 Illumination Light System Circuit Diagram (Taiwan)”.

Refer to “D-5 Interior Light System Circuit Diagram (Except Taiwan)”.

Refer to “D-5 Interior Light System Circuit Diagram (Taiwan)”.

Refer to “D-6 Turn Signal and Hazard Warning Light System Circuit Diagram (Except Taiwan)”.

Refer to “D-6 Turn Signal and Hazard Warning Light System Circuit Diagram (Taiwan)”.

Refer to “D-7 Brake Light System Circuit Diagram”.

Refer to “D-8 Back-Up Light System Circuit Diagram”.

Refer to “D-9 Headlight Beam Leveling System Circuit Diagram (Manual Leveling)”.

Refer to “D-10 Rear Fog Light Circuit Diagram”.

Refer to “E-1 Heater System Circuit Diagram”.

Refer to “E-2 Auto A/C System Circuit Diagram”.

Refer to “F-1 Air-Bag System Circuit Diagram (4ch)”.

Refer to “F-1 Air-Bag System Circuit Diagram (8ch)”.

Refer to “F-2 Anti-Lock Brake System Circuit Diagram”.

Refer to “F-4 Power Steering System Circuit Diagram”.

Refer to “G-1 Audio System Circuit Diagram”.

Refer to “G-2 Multi Information Display / Accessory Socket System Circuit Diagram”.

Refer to “G-4 Navigation System Circuit Diagram”.

Page 1386 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-1 Glass / Windows / Mirrors:

Body, Cab and Accessories

Glass / Windows / Mirrors

Precautions

Precautions for Power Window Service (Pinching Prevention Function Model)S6RW0D9500001

WARNING!

When checking the pinching prevention function, never attempt intentionally to have your hand, arm

or any other part of the body pinched. Also, use full care not to have your body caught.

• Do not drop the power window regulator (motor) or expose it to a strong impact in any other way.

• Do not operate the motor unless the power window regulator (motor) is installed and ready to operate door glass.

• If any peripheral part has bean damaged, replace regulator (motor) as well depending on the damage condition.

• After replacing or disconnecting the driver side power window regulator (motor), power window main switch, battery

and/or fuse, make sure to execute the initial setting, (to have the door glass closed position learned) refer to “Power

Window Main Switch Initialization (Pinching Prevention Function Model)”.

General Description

Rear End Door Window Defogger System DescriptionS6RW0D9501001

The rear end door window defogger is controlled by BCM. For the BCM description refer to “BCM General Description

in Section 10B”.

Page 1387 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-2

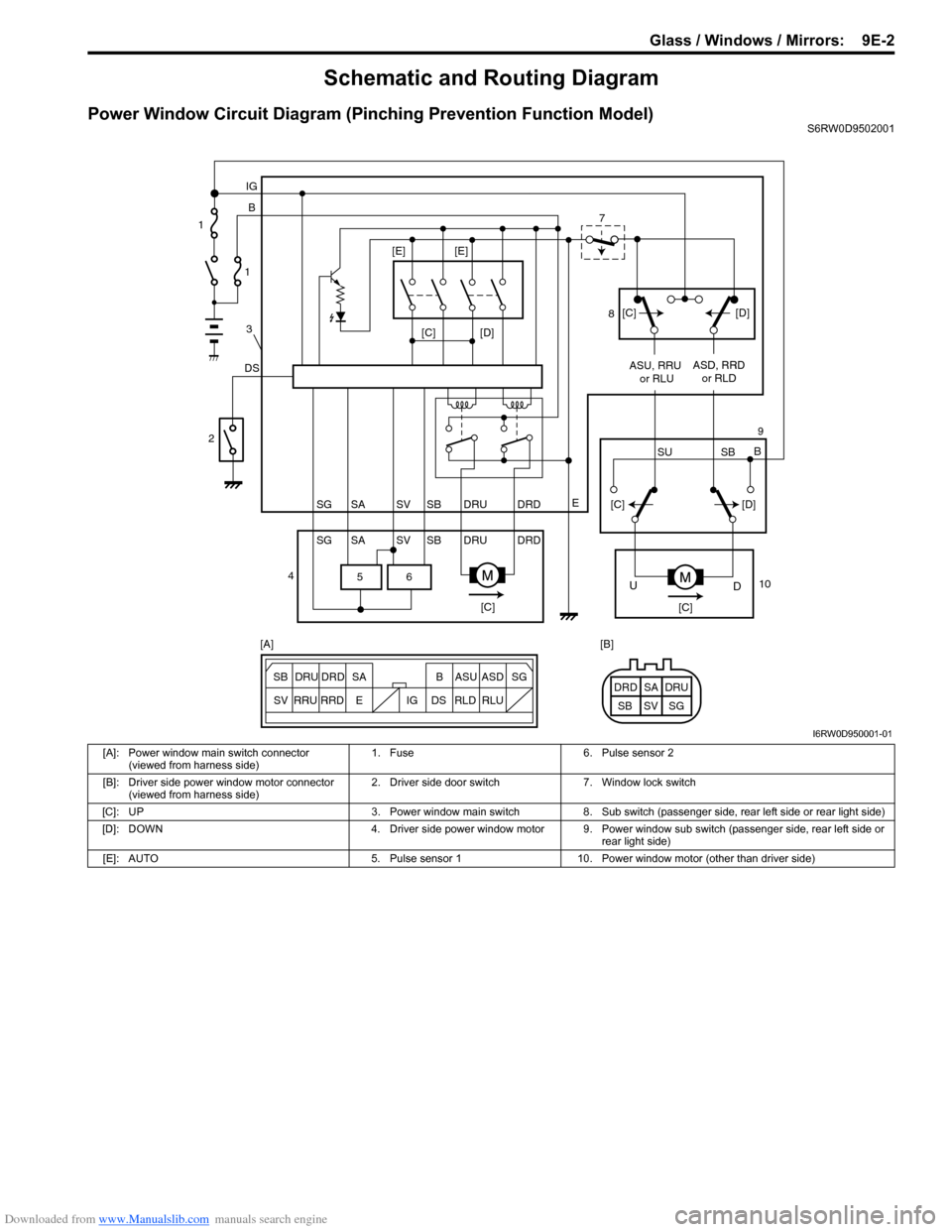

Schematic and Routing Diagram

Power Window Circuit Diagram (Pinching Prevention Function Model)S6RW0D9502001

6 5

[C][D]

DSB IG

E

SG SV SBSA DRU DRD

SG SV SBSA DRU DRDASU, RRU

or RLUASD, RRD

or RLD

[C][C]

D U

[C][D]

SU SBB [C][D] [E] [E]

ESG

SV SB SADRU DRD B ASU ASD

RRU

RRDDS IG RLD RLUSG SV SBSA DRU DRD [A] [B] 1

1

3

2

47

8

9

10

I6RW0D950001-01

[A]: Power window main switch connector

(viewed from harness side)1. Fuse 6. Pulse sensor 2

[B]: Driver side power window motor connector

(viewed from harness side)2. Driver side door switch 7. Window lock switch

[C]: UP 3. Power window main switch 8. Sub switch (passenger side, rear left side or rear light side)

[D]: DOWN 4. Driver side power window motor 9. Power window sub switch (passenger side, rear left side or

rear light side)

[E]: AUTO 5. Pulse sensor 1 10. Power window motor (other than driver side)

Page 1388 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-3 Glass / Windows / Mirrors:

Diagnostic Information and Procedures

Rear End door Window Defogger Symptom DiagnosisS6RW0D9504001

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Power Window Control System Symptom DiagnosisS6RW0D9504002

Condition Possible cause Correction / Reference Item

Rear end door window

defogger does not

operateCircuit fuse blownReplace fuse and check for short circuit.

Rear end door window defogger switch

faultyCheck rear end door window defogger switch

referring to “Rear End Door Window Defogger

Switch Inspection”.

Rear end door window defogger relay

faultyCheck rear end door window defogger relay

referring to “Rear End Door Window Defogger

Relay Inspection”.

Defogger wire faultyCheck defogger wire referring to “Rear End

Door Window Defogger Wire Inspection”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

All power windows do not

operateCircuit fuse blownReplace fuse and check for short circuit.

Power window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Ignition switch faultyCheck ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faultyRepair circuit.

Only one power window

does not operatePower window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Power window sub switch faultyCheck power window sub switch referring to

“Power Window Sub Switch Inspection”.

Wiring and/or coupler faultyCheck wiring and/or coupler.

Power window regulator faultyCheck window regulator.

Power window motor faultyCheck power window motor.

Wiring or grounding faultyRepair circuit.

Driver side door glass

fails to perform auto-up /

auto-down function

(Pinching Prevention

Function Model)Power window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Power window motor faultyCheck power window motor referring to “Pulse

Sensor and Its Circuit Inspection (Pinching

Prevention Function Model)”.

Wiring or grounding faultyRepair circuit.

Driver side door glass

fails to lower back even

when a foreign matter is

pinched (Pinching

Prevention Function

Model)Power window main switch has not been

initializedExecute the initial setting of power window

main switch referring to “Power Window Main

Switch Initialization (Pinching Prevention

Function Model)”.

Power window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Power window motor faultyCheck power window motor referring to “Pulse

Sensor and Its Circuit Inspection (Pinching

Prevention Function Model)”.

Page 1390 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-5 Glass / Windows / Mirrors:

Door Mirror Heater Symptom Diagnosis (If Equipped)S6RW0D9504004

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Repair Instructions

Windshield ComponentsS6RW0D9506001

Condition Possible cause Correction / Reference Item

All door mirror heaters

does not operateCircuit fuse blownReplace fuse and check for short circuit.

Rear end door window defogger switch

faultyCheck rear end door window defogger switch

referring to “Rear End Door Window Defogger

Switch Inspection”.

Rear end door window defogger relay

faultyCheck rear end door window defogger relay

referring to “Rear End Door Window Defogger

Relay Inspection”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Only one door mirror

heater does not operateDoor mirror heater faultyCheck door mirror heater refiring to “Door

Mirror Heater Inspection (If Equipped)”.

Wiring or grounding faultyRepair circuit.

3 31

2

44

4

I5RW0A950001-02

1. Windshield glass 3. Windshield glass stopper : Do not reuse.

2. Windshield molding 4. Spacer

Page 1391 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-6

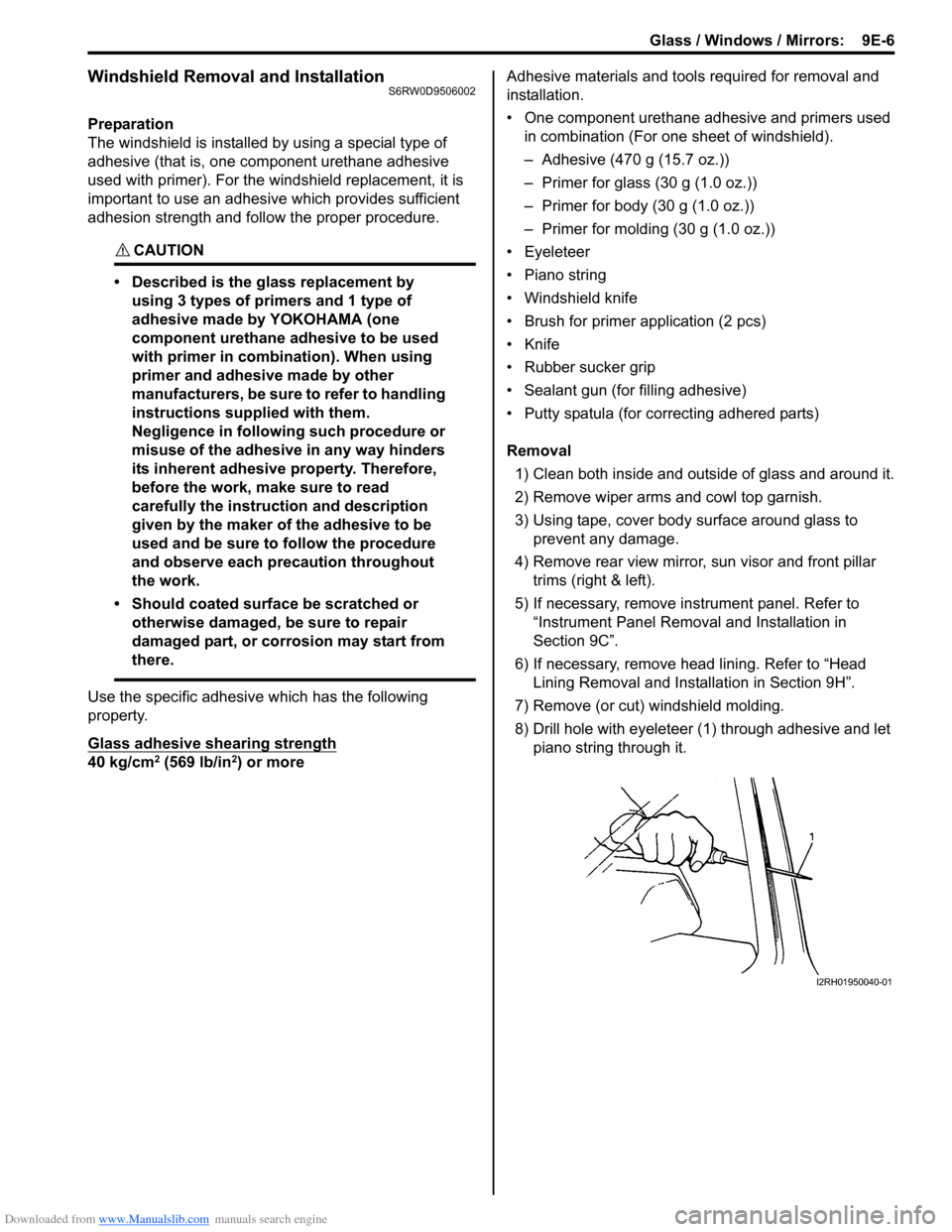

Windshield Removal and InstallationS6RW0D9506002

Preparation

The windshield is installed by using a special type of

adhesive (that is, one component urethane adhesive

used with primer). For the windshield replacement, it is

important to use an adhesive which provides sufficient

adhesion strength and follow the proper procedure.

CAUTION!

• Described is the glass replacement by

using 3 types of primers and 1 type of

adhesive made by YOKOHAMA (one

component urethane adhesive to be used

with primer in combination). When using

primer and adhesive made by other

manufacturers, be sure to refer to handling

instructions supplied with them.

Negligence in following such procedure or

misuse of the adhesive in any way hinders

its inherent adhesive property. Therefore,

before the work, make sure to read

carefully the instruction and description

given by the maker of the adhesive to be

used and be sure to follow the procedure

and observe each precaution throughout

the work.

• Should coated surface be scratched or

otherwise damaged, be sure to repair

damaged part, or corrosion may start from

there.

Use the specific adhesive which has the following

property.

Glass adhesive shearing strength

40 kg/cm2 (569 lb/in2) or moreAdhesive materials and tools required for removal and

installation.

• One component urethane adhesive and primers used

in combination (For one sheet of windshield).

– Adhesive (470 g (15.7 oz.))

– Primer for glass (30 g (1.0 oz.))

– Primer for body (30 g (1.0 oz.))

– Primer for molding (30 g (1.0 oz.))

• Eyeleteer

•Piano string

• Windshield knife

• Brush for primer application (2 pcs)

•Knife

• Rubber sucker grip

• Sealant gun (for filling adhesive)

• Putty spatula (for correcting adhered parts)

Removal

1) Clean both inside and outside of glass and around it.

2) Remove wiper arms and cowl top garnish.

3) Using tape, cover body surface around glass to

prevent any damage.

4) Remove rear view mirror, sun visor and front pillar

trims (right & left).

5) If necessary, remove instrument panel. Refer to

“Instrument Panel Removal and Installation in

Section 9C”.

6) If necessary, remove head lining. Refer to “Head

Lining Removal and Installation in Section 9H”.

7) Remove (or cut) windshield molding.

8) Drill hole with eyeleteer (1) through adhesive and let

piano string through it.

I2RH01950040-01

Page 1396 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-11 Glass / Windows / Mirrors:

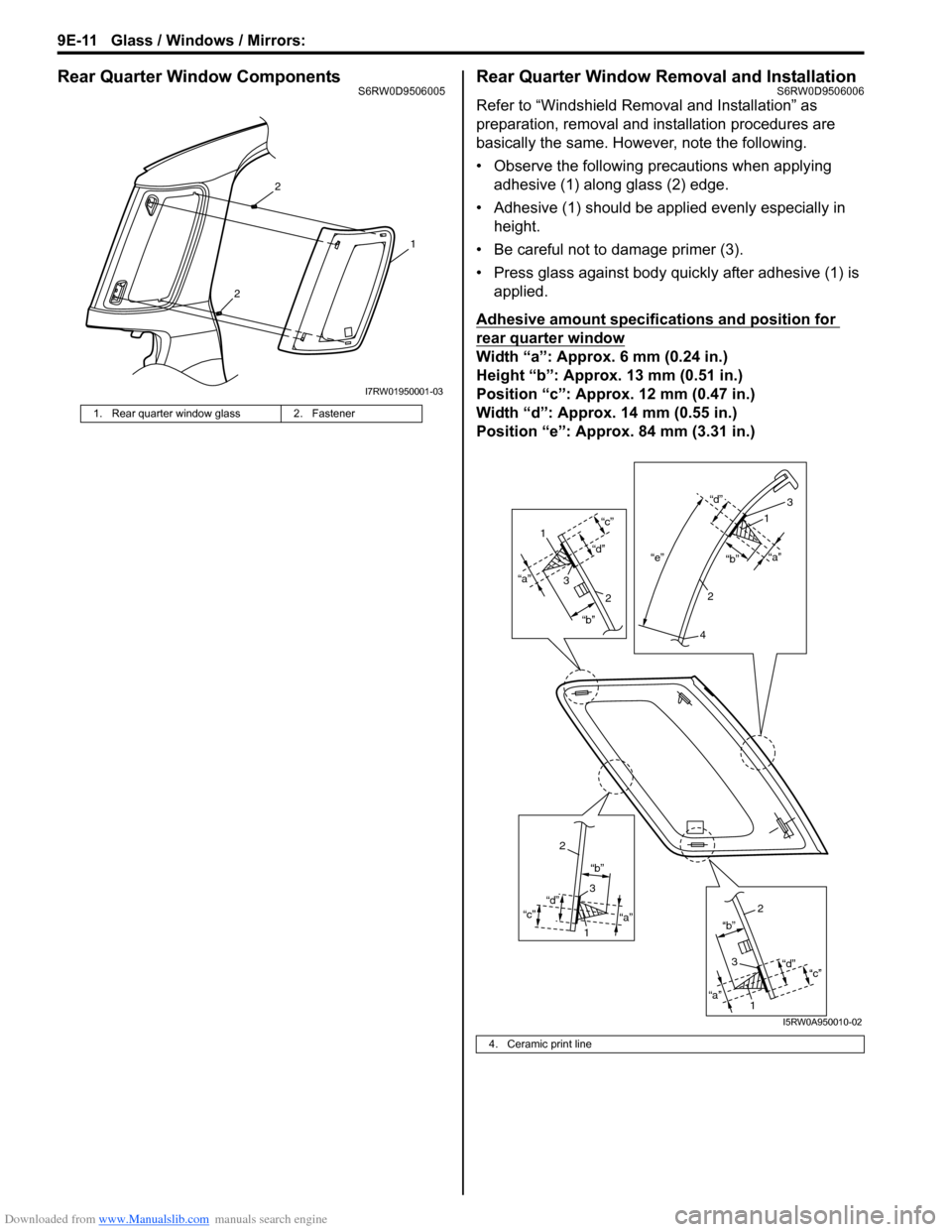

Rear Quarter Window ComponentsS6RW0D9506005Rear Quarter Window Removal and InstallationS6RW0D9506006

Refer to “Windshield Removal and Installation” as

preparation, removal and installation procedures are

basically the same. However, note the following.

• Observe the following precautions when applying

adhesive (1) along glass (2) edge.

• Adhesive (1) should be applied evenly especially in

height.

• Be careful not to damage primer (3).

• Press glass against body quickly after adhesive (1) is

applied.

Adhesive amount specifications and position for

rear quarter window

Width “a”: Approx. 6 mm (0.24 in.)

Height “b”: Approx. 13 mm (0.51 in.)

Position “c”: Approx. 12 mm (0.47 in.)

Width “d”: Approx. 14 mm (0.55 in.)

Position “e”: Approx. 84 mm (3.31 in.)

1. Rear quarter window glass 2. Fastener

2

2

1

I7RW01950001-03

4. Ceramic print line

“a”

“b”

“d”“c”“e”“a”

“b” “d”

“a” “b”

“d”

“c”

“a”“b”

“d”

“c”

1

3

2

3

1

2

4

2

3

1

2

3

1

I5RW0A950010-02

Page 1397 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-12

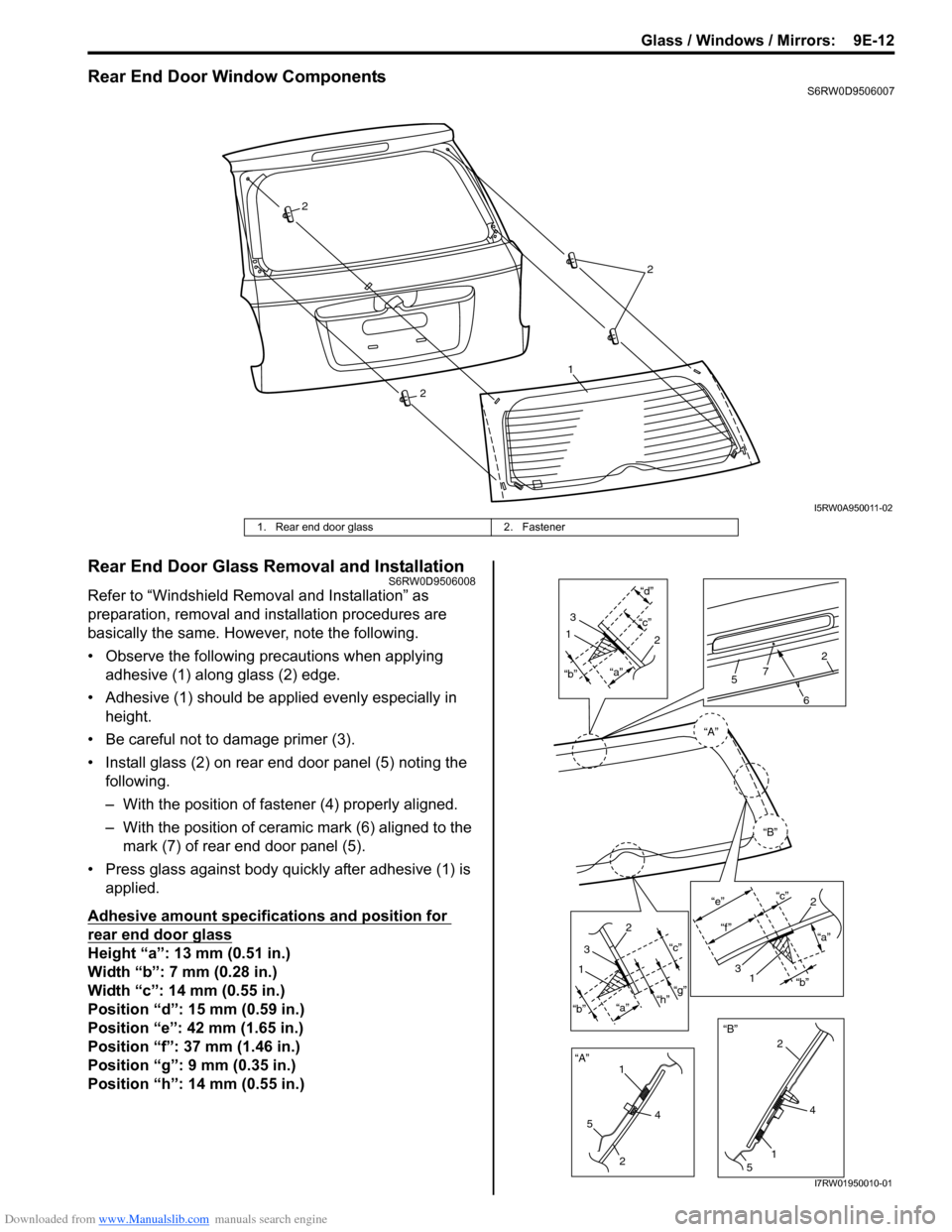

Rear End Door Window ComponentsS6RW0D9506007

Rear End Door Glass Removal and InstallationS6RW0D9506008

Refer to “Windshield Removal and Installation” as

preparation, removal and installation procedures are

basically the same. However, note the following.

• Observe the following precautions when applying

adhesive (1) along glass (2) edge.

• Adhesive (1) should be applied evenly especially in

height.

• Be careful not to damage primer (3).

• Install glass (2) on rear end door panel (5) noting the

following.

– With the position of fastener (4) properly aligned.

– With the position of ceramic mark (6) aligned to the

mark (7) of rear end door panel (5).

• Press glass against body quickly after adhesive (1) is

applied.

Adhesive amount specifications and position for

rear end door glass

Height “a”: 13 mm (0.51 in.)

Width “b”: 7 mm (0.28 in.)

Width “c”: 14 mm (0.55 in.)

Position “d”: 15 mm (0.59 in.)

Position “e”: 42 mm (1.65 in.)

Position “f”: 37 mm (1.46 in.)

Position “g”: 9 mm (0.35 in.)

Position “h”: 14 mm (0.55 in.)

2

2

1

2

I5RW0A950011-02

1. Rear end door glass 2. Fastener

“A”“a”“c”“d”1

3

12

“a”

“b”“c”

“g”

“h”

1

2

3

“A”

“B”“B” “b”

5

24

15

4 2

6

572

“a” “c”

“e”

“f ”

2

31“b”

I7RW01950010-01