remove seat SUZUKI SX4 2006 1.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 463 of 1556

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-4

Rear Coil Spring Removal and InstallationS6RW0D2306005

CAUTION!

Removal and Installation both coil springs

(right and left) at the same time to avoid rear

axle twisting and other damage.

Removal

1) Hoist vehicle and remove rear wheels.

2) Dismount rear differential (4WD model) referring to

“Rear Differential Dismounting and Remounting in

Section 3B”.

3) Remove rear fender lining (1) and then loosen rear

axle bolt (2) a little.

CAUTION!

Do not reuse rear axle bolt. Otherwise, bolt

may loosen.

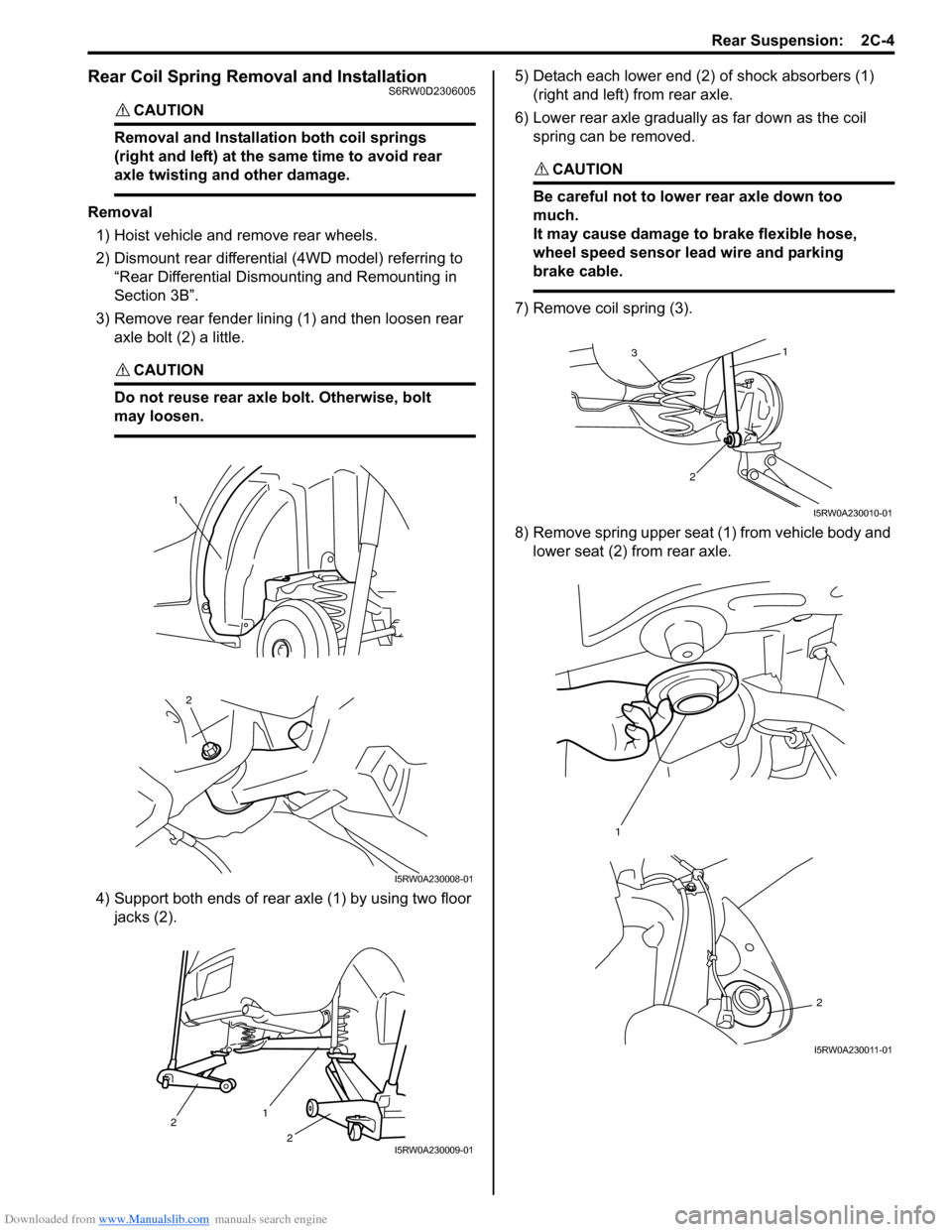

4) Support both ends of rear axle (1) by using two floor

jacks (2).5) Detach each lower end (2) of shock absorbers (1)

(right and left) from rear axle.

6) Lower rear axle gradually as far down as the coil

spring can be removed.

CAUTION!

Be careful not to lower rear axle down too

much.

It may cause damage to brake flexible hose,

wheel speed sensor lead wire and parking

brake cable.

7) Remove coil spring (3).

8) Remove spring upper seat (1) from vehicle body and

lower seat (2) from rear axle.

2

1

I5RW0A230008-01

1

2

2

I5RW0A230009-01

1

2

3

I5RW0A230010-01

1

2

I5RW0A230011-01

Page 464 of 1556

Downloaded from www.Manualslib.com manuals search engine 2C-5 Rear Suspension:

Installation

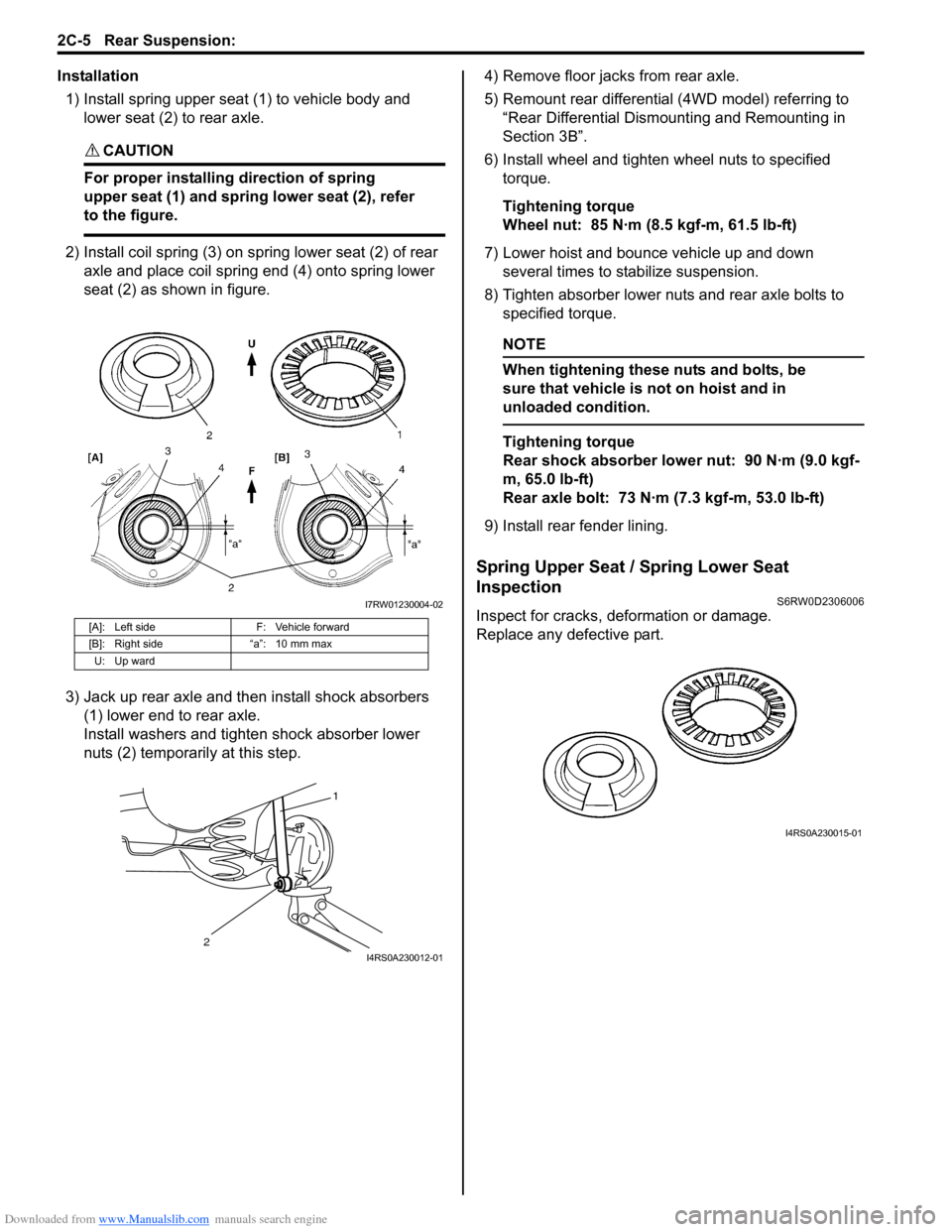

1) Install spring upper seat (1) to vehicle body and

lower seat (2) to rear axle.

CAUTION!

For proper installing direction of spring

upper seat (1) and spring lower seat (2), refer

to the figure.

2) Install coil spring (3) on spring lower seat (2) of rear

axle and place coil spring end (4) onto spring lower

seat (2) as shown in figure.

3) Jack up rear axle and then install shock absorbers

(1) lower end to rear axle.

Install washers and tighten shock absorber lower

nuts (2) temporarily at this step.4) Remove floor jacks from rear axle.

5) Remount rear differential (4WD model) referring to

“Rear Differential Dismounting and Remounting in

Section 3B”.

6) Install wheel and tighten wheel nuts to specified

torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

7) Lower hoist and bounce vehicle up and down

several times to stabilize suspension.

8) Tighten absorber lower nuts and rear axle bolts to

specified torque.

NOTE

When tightening these nuts and bolts, be

sure that vehicle is not on hoist and in

unloaded condition.

Tightening torque

Rear shock absorber lower nut: 90 N·m (9.0 kgf-

m, 65.0 lb-ft)

Rear axle bolt: 73 N·m (7.3 kgf-m, 53.0 lb-ft)

9) Install rear fender lining.

Spring Upper Seat / Spring Lower Seat

Inspection

S6RW0D2306006

Inspect for cracks, deformation or damage.

Replace any defective part.[A]: Left side F: Vehicle forward

[B]: Right side “a”: 10 mm max

U: Up ward

I7RW01230004-02

1

2I4RS0A230012-01

I4RS0A230015-01

Page 475 of 1556

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-6

Wheel (with Tire) Removal and InstallationS6RW0D2406003

Removal

CAUTION!

Never use heat to loosen tight wheel because

the application of heat to wheel causes the

wheel life shorter and the wheel bearing

damage.

1) Loosen wheel nuts by approximately 180° (half a

rotation).

2) Hoist vehicle.

3) Make sure that the vehicle will not fall off by trying to

move vehicle body in both ways.

4) Remove wheel nuts except one.

5) Support the wheel and/or tire not to drop the wheel

and then remove the nut left with the wheel.

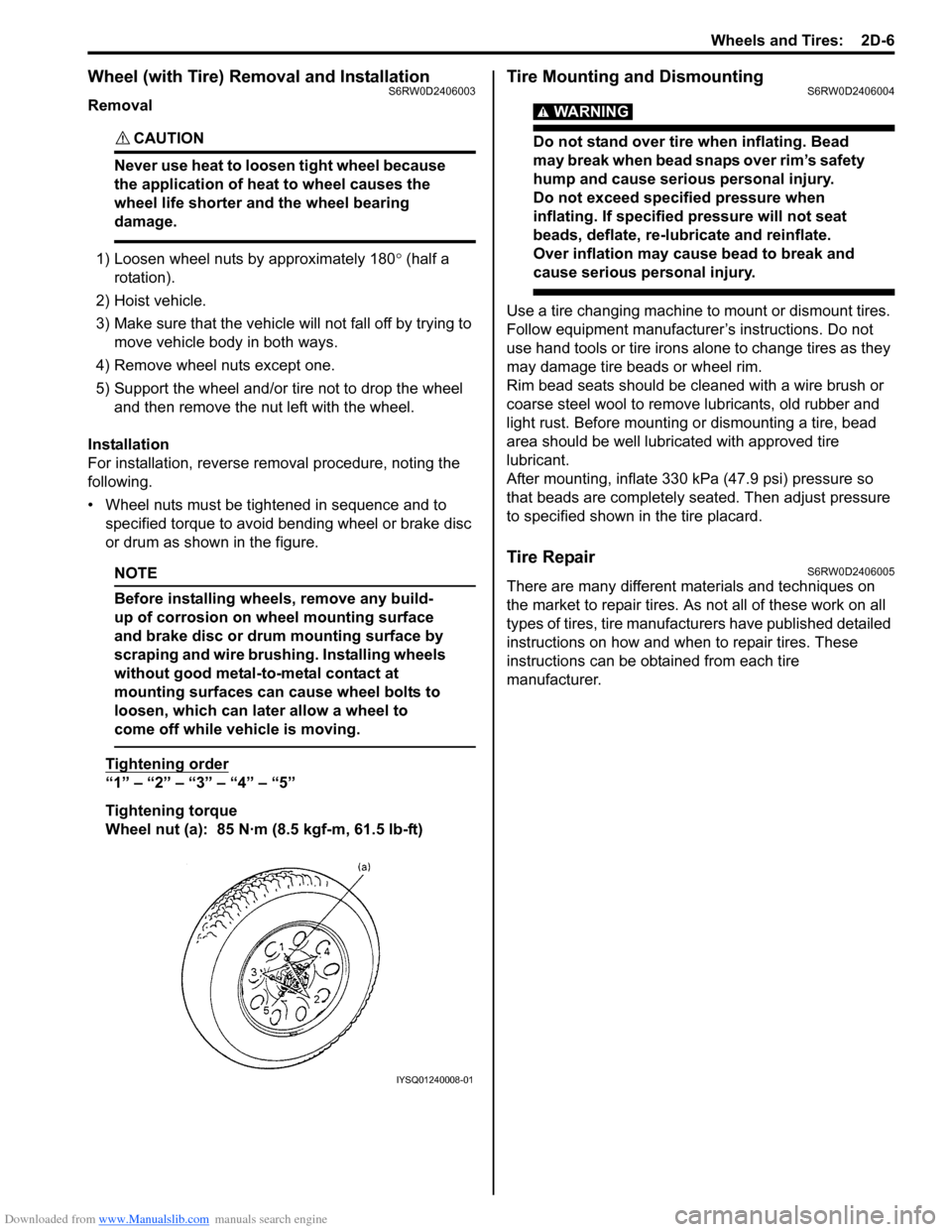

Installation

For installation, reverse removal procedure, noting the

following.

• Wheel nuts must be tightened in sequence and to

specified torque to avoid bending wheel or brake disc

or drum as shown in the figure.

NOTE

Before installing wheels, remove any build-

up of corrosion on wheel mounting surface

and brake disc or drum mounting surface by

scraping and wire brushing. Installing wheels

without good metal-to-metal contact at

mounting surfaces can cause wheel bolts to

loosen, which can later allow a wheel to

come off while vehicle is moving.

Tightening order

“1” – “2” – “3” – “4” – “5”

Tightening torque

Wheel nut (a): 85 N·m (8.5 kgf-m, 61.5 lb-ft)

Tire Mounting and DismountingS6RW0D2406004

WARNING!

Do not stand over tire when inflating. Bead

may break when bead snaps over rim’s safety

hump and cause serious personal injury.

Do not exceed specified pressure when

inflating. If specified pressure will not seat

beads, deflate, re-lubricate and reinflate.

Over inflation may cause bead to break and

cause serious personal injury.

Use a tire changing machine to mount or dismount tires.

Follow equipment manufacturer’s instructions. Do not

use hand tools or tire irons alone to change tires as they

may damage tire beads or wheel rim.

Rim bead seats should be cleaned with a wire brush or

coarse steel wool to remove lubricants, old rubber and

light rust. Before mounting or dismounting a tire, bead

area should be well lubricated with approved tire

lubricant.

After mounting, inflate 330 kPa (47.9 psi) pressure so

that beads are completely seated. Then adjust pressure

to specified shown in the tire placard.

Tire RepairS6RW0D2406005

There are many different materials and techniques on

the market to repair tires. As not all of these work on all

types of tires, tire manufacturers have published detailed

instructions on how and when to repair tires. These

instructions can be obtained from each tire

manufacturer.

IYSQ01240008-01

Page 483 of 1556

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: Front 3A-4

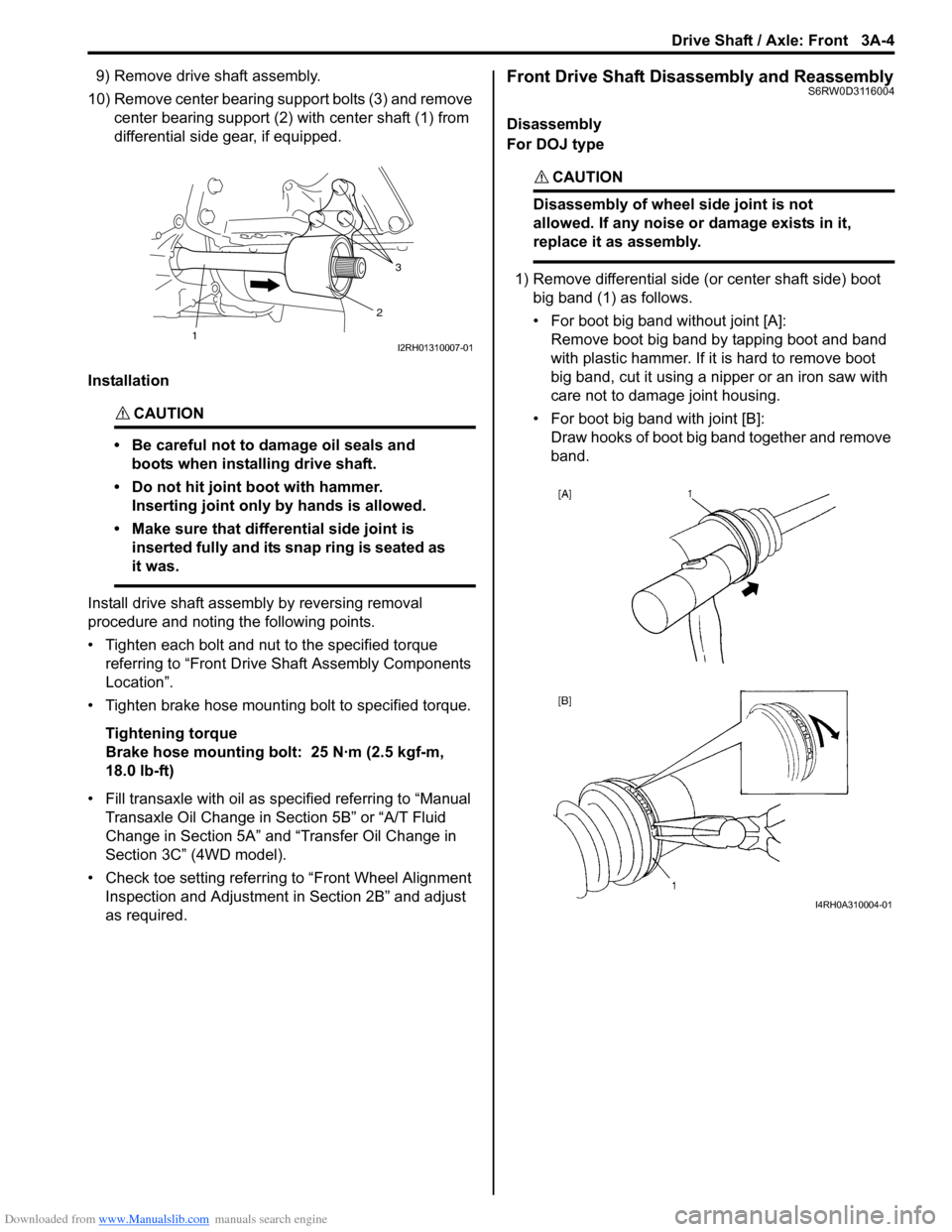

9) Remove drive shaft assembly.

10) Remove center bearing support bolts (3) and remove

center bearing support (2) with center shaft (1) from

differential side gear, if equipped.

Installation

CAUTION!

• Be careful not to damage oil seals and

boots when installing drive shaft.

• Do not hit joint boot with hammer.

Inserting joint only by hands is allowed.

• Make sure that differential side joint is

inserted fully and its snap ring is seated as

it was.

Install drive shaft assembly by reversing removal

procedure and noting the following points.

• Tighten each bolt and nut to the specified torque

referring to “Front Drive Shaft Assembly Components

Location”.

• Tighten brake hose mounting bolt to specified torque.

Tightening torque

Brake hose mounting bolt: 25 N·m (2.5 kgf-m,

18.0 lb-ft)

• Fill transaxle with oil as specified referring to “Manual

Transaxle Oil Change in Section 5B” or “A/T Fluid

Change in Section 5A” and “Transfer Oil Change in

Section 3C” (4WD model).

• Check toe setting referring to “Front Wheel Alignment

Inspection and Adjustment in Section 2B” and adjust

as required.

Front Drive Shaft Disassembly and ReassemblyS6RW0D3116004

Disassembly

For DOJ type

CAUTION!

Disassembly of wheel side joint is not

allowed. If any noise or damage exists in it,

replace it as assembly.

1) Remove differential side (or center shaft side) boot

big band (1) as follows.

• For boot big band without joint [A]:

Remove boot big band by tapping boot and band

with plastic hammer. If it is hard to remove boot

big band, cut it using a nipper or an iron saw with

care not to damage joint housing.

• For boot big band with joint [B]:

Draw hooks of boot big band together and remove

band.3

2

1I2RH01310007-01

I4RH0A310004-01

Page 870 of 1556

Downloaded from www.Manualslib.com manuals search engine 6B-1 Steering Wheel and Column:

Ste eri ng

Steering Wheel and Column

Precautions

Service Precautions of Steering Wheel and ColumnS6RW0D6200001

For service precautions, refer to “Precautions on Service and Diagnosis of Air Bag System in Section 8B”.

Service and Diagnosis

For diagnosis and servicing, refer to “Precautions on Service and Diagnosis of Air Bag System in Section 8B”.

Disabling Air Bag System

For disabling air bag system, refer to “Disabling Air Bag System in Section 8B”.

Enabling Air Bag System

For enabling air bag system, refer to “Enabling Air Bag System in Section 8B”.

Handling and Storage

For handling and storage, refer to “Precautions on Handling and Storage of Air Bag System Components in Section

8B”.

Disposal

For disposal, refer to “Precautions on Disposal of Air Bag and Seat Belt Pretensioner in Section 8B”.

General Description

Steering Wheel and Column ConstructionS6RW0D6201001

This double tube type steering column has the following three important features in addition to the steering function:

• The column is energy absorbing, designed to compress in a front-end collision.

• The ignition switch and lock are mounted conveniently on this column.

• With the column mounted lock, the ignition and steering operations can be locked to inhibit theft of the vehicle.

To insure the energy absorbing action, it is important that only the specified screws, bolts and nuts be used as

designated, and that they are tightened to the specified torque. When the column assembly is removed from the

vehicle, special care must be taken in handling it. Use of a steering wheel puller other than the recommended puller in

this manual or a sharp blow on the end of the steering shaft, leaning on the assembly, or dropping the assembly could

shear the plastic shear pins which maintain column length and position.

The driver air bag (inflator) module is one of the supplemental restraint (air bag) system components and is mounted

to the center of the steering wheel. During certain frontal crashes, the air bag system supplements the restraint of the

driver’s and passenger’s seat belts by deploying the air bags. The air bag (inflator) module should be handled with

care to prevent accidental deployment. When servicing, be sure to observe “Precautions on Service and Diagnosis of

Air Bag System in Section 8B”.

Page 940 of 1556

Downloaded from www.Manualslib.com manuals search engine 7A-12 Heater and Ventilation:

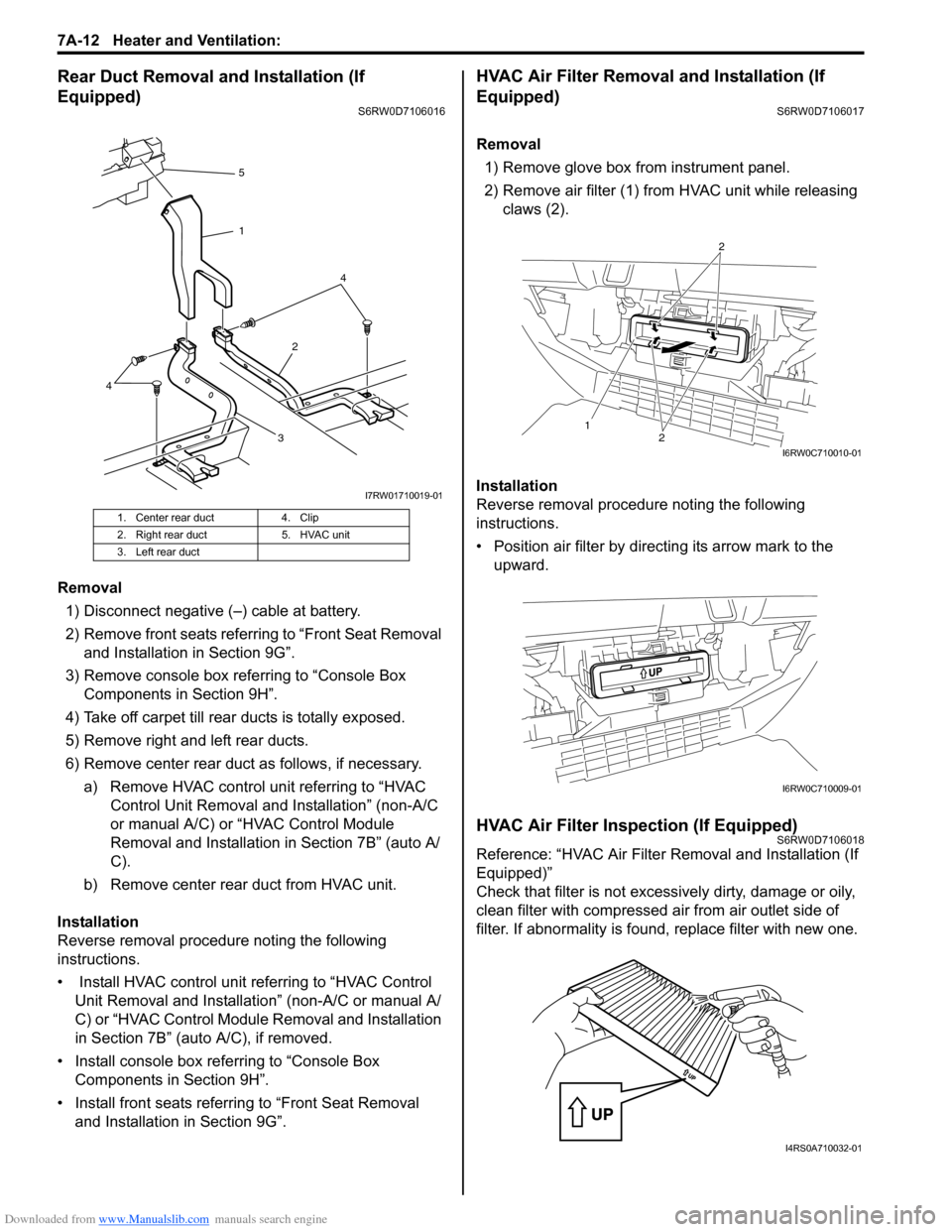

Rear Duct Removal and Installation (If

Equipped)

S6RW0D7106016

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front seats referring to “Front Seat Removal

and Installation in Section 9G”.

3) Remove console box referring to “Console Box

Components in Section 9H”.

4) Take off carpet till rear ducts is totally exposed.

5) Remove right and left rear ducts.

6) Remove center rear duct as follows, if necessary.

a) Remove HVAC control unit referring to “HVAC

Control Unit Removal and Installation” (non-A/C

or manual A/C) or “HVAC Control Module

Removal and Installation in Section 7B” (auto A/

C).

b) Remove center rear duct from HVAC unit.

Installation

Reverse removal procedure noting the following

instructions.

• Install HVAC control unit referring to “HVAC Control

Unit Removal and Installation” (non-A/C or manual A/

C) or “HVAC Control Module Removal and Installation

in Section 7B” (auto A/C), if removed.

• Install console box referring to “Console Box

Components in Section 9H”.

• Install front seats referring to “Front Seat Removal

and Installation in Section 9G”.

HVAC Air Filter Removal and Installation (If

Equipped)

S6RW0D7106017

Removal

1) Remove glove box from instrument panel.

2) Remove air filter (1) from HVAC unit while releasing

claws (2).

Installation

Reverse removal procedure noting the following

instructions.

• Position air filter by directing its arrow mark to the

upward.

HVAC Air Filter Inspection (If Equipped)S6RW0D7106018

Reference: “HVAC Air Filter Removal and Installation (If

Equipped)”

Check that filter is not excessively dirty, damage or oily,

clean filter with compressed air from air outlet side of

filter. If abnormality is found, replace filter with new one.

1. Center rear duct 4. Clip

2. Right rear duct 5. HVAC unit

3. Left rear duct

324 5

1

4

I7RW01710019-01

12

2

I6RW0C710010-01

I6RW0C710009-01

I4RS0A710032-01

Page 1036 of 1556

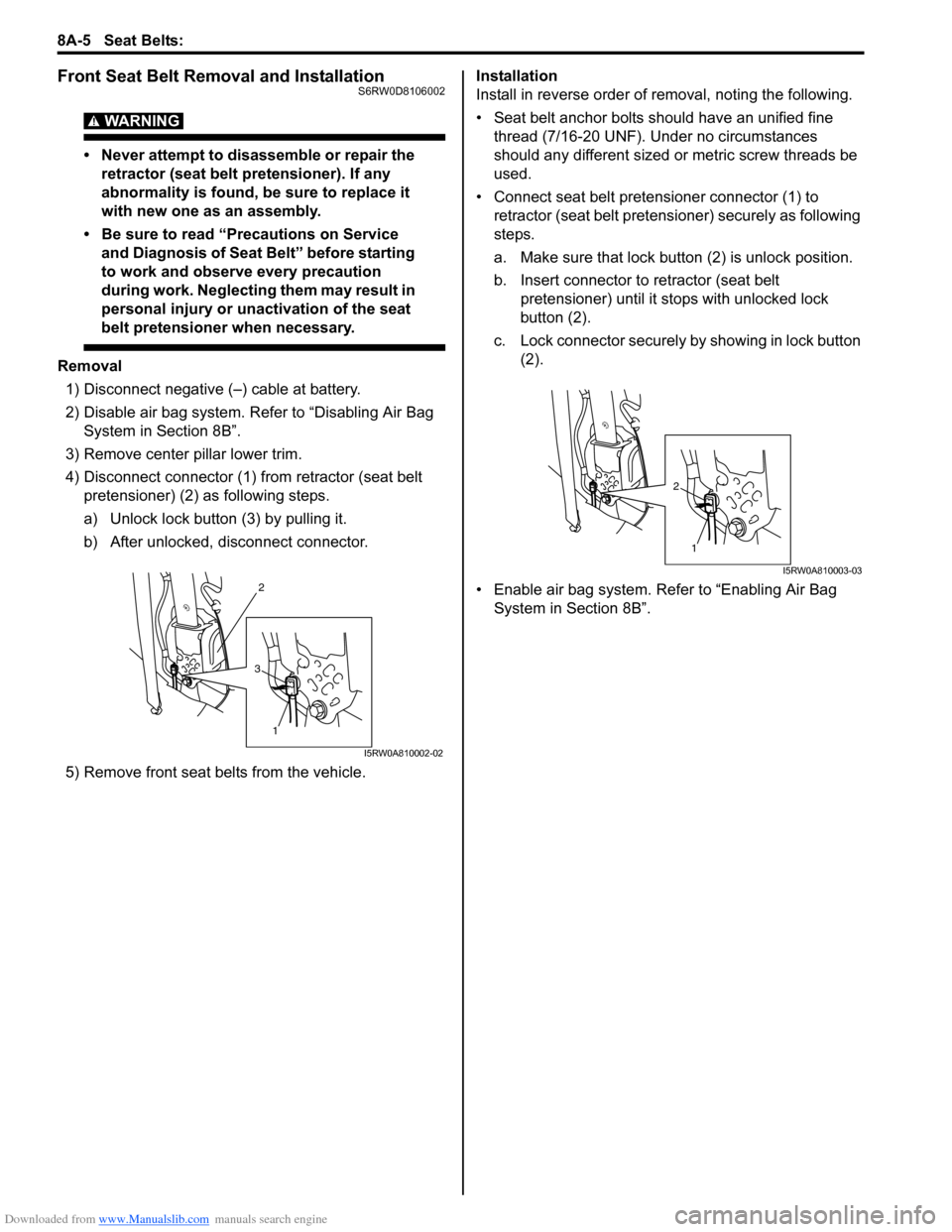

Downloaded from www.Manualslib.com manuals search engine 8A-5 Seat Belts:

Front Seat Belt Removal and InstallationS6RW0D8106002

WARNING!

• Never attempt to disassemble or repair the

retractor (seat belt pretensioner). If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service

and Diagnosis of Seat Belt” before starting

to work and observe every precaution

during work. Neglecting them may result in

personal injury or unactivation of the seat

belt pretensioner when necessary.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Refer to “Disabling Air Bag

System in Section 8B”.

3) Remove center pillar lower trim.

4) Disconnect connector (1) from retractor (seat belt

pretensioner) (2) as following steps.

a) Unlock lock button (3) by pulling it.

b) After unlocked, disconnect connector.

5) Remove front seat belts from the vehicle.Installation

Install in reverse order of removal, noting the following.

• Seat belt anchor bolts should have an unified fine

thread (7/16-20 UNF). Under no circumstances

should any different sized or metric screw threads be

used.

• Connect seat belt pretensioner connector (1) to

retractor (seat belt pretensioner) securely as following

steps.

a. Make sure that lock button (2) is unlock position.

b. Insert connector to retractor (seat belt

pretensioner) until it stops with unlocked lock

button (2).

c. Lock connector securely by showing in lock button

(2).

• Enable air bag system. Refer to “Enabling Air Bag

System in Section 8B”.

2

1

3

I5RW0A810002-02

1

2

I5RW0A810003-03

Page 1039 of 1556

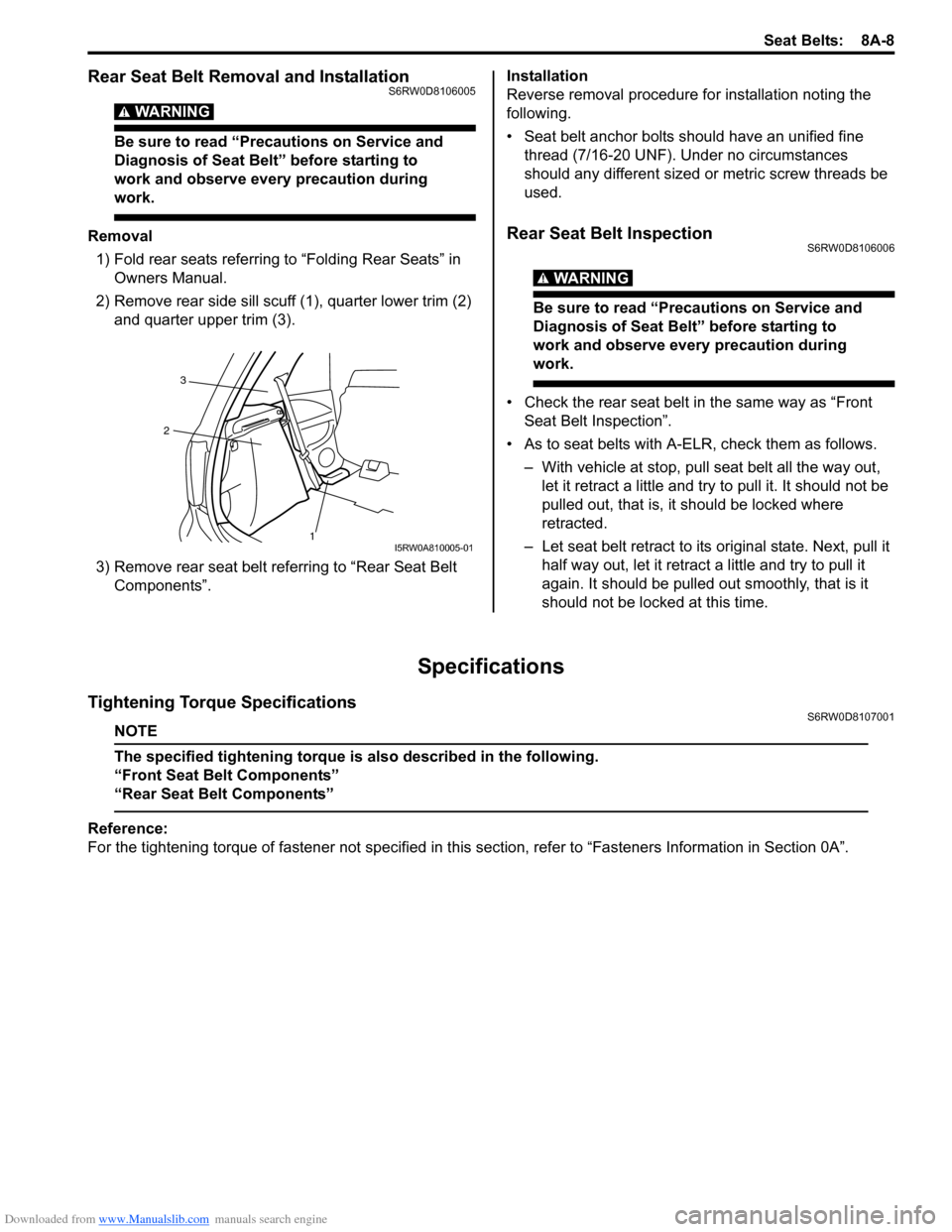

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-8

Rear Seat Belt Removal and InstallationS6RW0D8106005

WARNING!

Be sure to read “Precautions on Service and

Diagnosis of Seat Belt” before starting to

work and observe every precaution during

work.

Removal

1) Fold rear seats referring to “Folding Rear Seats” in

Owners Manual.

2) Remove rear side sill scuff (1), quarter lower trim (2)

and quarter upper trim (3).

3) Remove rear seat belt referring to “Rear Seat Belt

Components”.Installation

Reverse removal procedure for installation noting the

following.

• Seat belt anchor bolts should have an unified fine

thread (7/16-20 UNF). Under no circumstances

should any different sized or metric screw threads be

used.Rear Seat Belt InspectionS6RW0D8106006

WARNING!

Be sure to read “Precautions on Service and

Diagnosis of Seat Belt” before starting to

work and observe every precaution during

work.

• Check the rear seat belt in the same way as “Front

Seat Belt Inspection”.

• As to seat belts with A-ELR, check them as follows.

– With vehicle at stop, pull seat belt all the way out,

let it retract a little and try to pull it. It should not be

pulled out, that is, it should be locked where

retracted.

– Let seat belt retract to its original state. Next, pull it

half way out, let it retract a little and try to pull it

again. It should be pulled out smoothly, that is it

should not be locked at this time.

Specifications

Tightening Torque SpecificationsS6RW0D8107001

NOTE

The specified tightening torque is also described in the following.

“Front Seat Belt Components”

“Rear Seat Belt Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

1 23I5RW0A810005-01

Page 1040 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-1 Air Bag System:

Restraint

Air Bag System

Precautions

Precautions on Service and Diagnosis of Air

Bag System

S6RW0D8200004

WARNING!

• If the air bag system and another vehicle

system both need repair, SUZUKI

recommends that the air bag system be

repaired first, to help avoid unintended air

bag system activation.

• Do not modify the steering wheel,

dashboard, both front seat or any other on

or around air bag system components.

Modifications can adversely affect air bag

system performance and lead to injury.

• Be sure to follow the procedures described

in this section. Failure to follow

procedures could result in possible air bag

system activation, personal injury or

unneeded air bag system repairs.

• WARNING / CAUTION labels are attached on each

part of air bag system components (SDM, air bag

(inflator) modules and seat belt pretensioners). Be

sure to follow the instructions.

• Many of service procedures require disconnection of

“A/B” fuse and air bag (inflator) module(s) (driver

module, passenger module, side modules and curtain

modules) from initiator circuit to avoid an accidental

deployment.

• Do not apply power to the air bag system unless all

components are connected or a diagnostic flow

requests it, as this will set a DTC.

• The “Air Bag Diagnostic System Check” must be the

starting point of any air bag diagnostics. The “Air Bag

Diagnostic System Check” will verify proper “AIR

BAG” warning light operation and will lead you to the

correct flow to diagnose any air bag malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacements.

• Never use air bag component parts from another

vehicle.

• If the vehicle will be exposed to temperatures over 93

°C (200 °F) (for example, during a paint baking

process), remove the air bag system components

beforehand to avoid component damage or

unintended system activation.• When handling the air bag (inflator) modules (driver

module, passenger module, side modules and curtain

modules), seat belt pretensioners (driver module and

passenger module), SDM, forward impact-sensor or

side impact-sensor be careful not to drop it or apply

an impact to it. If an excessive impact was applied

(e.g., SDM, forward impact-sensor are dropped, air

bag (inflator) module is dropped from a height of 90

cm (3 ft) or more, seat belt pretensioner (retractor

assembly) is dropped from a height of 30 cm (1 ft) or

more), never attempt disassembly or repair but

replace it with a new one.

• When using electric welding, be sure to disconnect air

bag (inflator) module connectors (driver module,

passenger module, side modules and curtain

modules) and seat belt pretensioner connectors

(driver module and passenger module) respectively.

• When applying paint around the air bag system

related parts, use care so that the harness or

connector will not be exposed to the paint mist.

• Never expose air bag system component parts

directly to hot air (drying or baking the vehicle after

painting) or flames.

WARNING!

When performing service on or around air

bag system components or air bag wiring,

follow the procedures listed in “Disabling Air

Bag System” to temporarily disable the air

bag system.

Failure to follow procedures could result in

possible air bag system activation, personal

injury or unneeded air bag system repairs.

Precautions on Handling and Storage of Air Bag

System Components

S6RW0D8200002

SDM

WARNING!

Never power up air bag system when SDM is

not rigidly attached to the vehicle. Otherwise,

personal injury may result.

CAUTION!

After detecting one time of such collision as

to meet deployment conditions, SDM must

not be used. Refer to “Air Bag Diagnostic

System Check” when checking SDM.

Page 1088 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-49 Air Bag System:

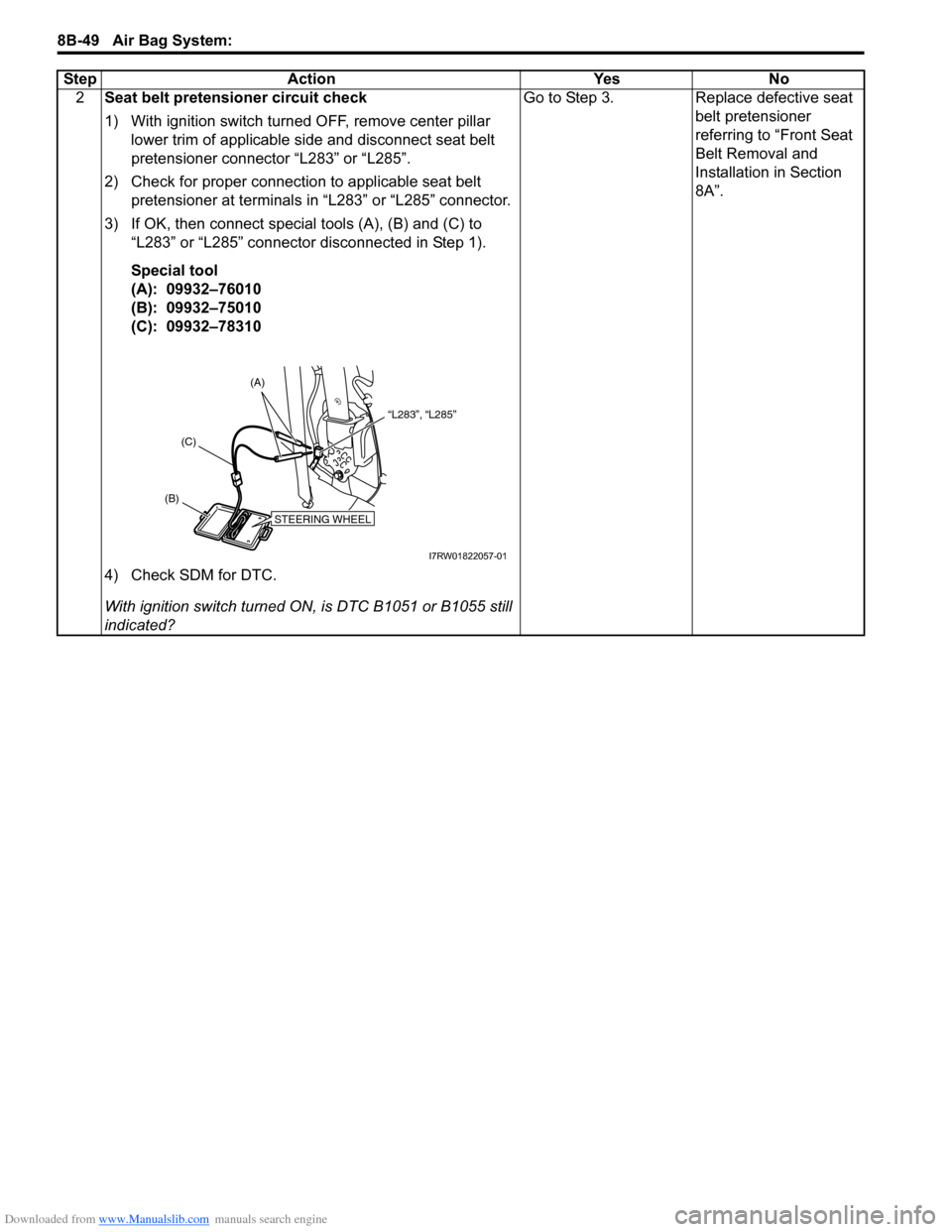

2Seat belt pretensioner circuit check

1) With ignition switch turned OFF, remove center pillar

lower trim of applicable side and disconnect seat belt

pretensioner connector “L283” or “L285”.

2) Check for proper connection to applicable seat belt

pretensioner at terminals in “L283” or “L285” connector.

3) If OK, then connect special tools (A), (B) and (C) to

“L283” or “L285” connector disconnected in Step 1).

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM for DTC.

With ignition switch turned ON, is DTC B1051 or B1055 still

indicated?Go to Step 3. Replace defective seat

belt pretensioner

referring to “Front Seat

Belt Removal and

Installation in Section

8A”. Step Action Yes No

STEERING WHEEL

(B)(C)(A)

“L283”, “L285”

I7RW01822057-01