fuse SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1408 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-23 Glass / Windows / Mirrors:

Pulse Sensor and Its Circuit Inspection

(Pinching Prevention Function Model)

S6RW0D9506029

NOTE

After replacing or disconnecting the driver

side power window regulator (motor), power

window main switch, battery and/or fuse,

make sure to execute the initial setting, (to

have the door glass closed position learned)

refer to “Power Window Main Switch

Initialization (Pinching Prevention Function

Model)”.

Pulse Sensor Circuit Diagram1) Remove driver side door trim referring to Step 1) to

3) of “Front Door Glass Removal and Installation”.

2) Remove power window main switch from driver side

door trim, and them connect connector to power

window main switch.

3) Disconnect power window motor connector.

4) Turn ignition switch to ON position.

5) Check that “SV” wire terminal voltage of power

window motor connector is 10 – 14 V. If voltage is

not satisfied, check power window main switch

circuit for open, short and high resistance. If circuit is

OK, replace power window main switch.

6) Connect power window motor connector.

7) Connect oscilloscope to power window main switch

connector terminals.

8) Check pulse sensor signal by using oscilloscope. If

pulse sensor signal is not satisfied, check pulse

sensor 1 and 2 circuit. If circuit is OK, replace door

window regulator (motor).

Reference Waveform

[A]: Power window main switch connector

(viewed from harness side)

[B]: Driver side power window motor connector

(viewed from harness side)

1. Power window main switch

2. Driver side power window motor

3. Pulse sensor 1

4. Pulse sensor 2

SG

SV SB SA

SG SV SBSA

B IG

E

4 3

SG SV SBSA

SG SV SBSA

2 1

[A] [B]

I6RW0D950003-01

Measurement

terminalCH1: “SA” terminal to “SG” terminal

CH2: “SB” terminal to “SG” terminal

Oscilloscope

settingCH1: 5V/DIV, CH2: 5V/DIV

TIME: 10ms/DIV

Measurement

conditionIgnition switch is at ON position,

driver side power window operate

1. Normal operation

2. Something caught

I6RW0D950004-01

Page 1409 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-24

Power Window Main Switch Initialization

(Pinching Prevention Function Model)

S6RW0D9506030

CAUTION!

• After replacing or disconnecting the driver

side door window regulator (motor), power

window main switch, battery or fuse, be

sure to execute initial setting (to have door

glass completely closed position learned).

If initial setting is not executed, correct

automatic operation (including pinching

prevention operation) would not be

available.

• Make sure that no foreign matter is

pinched while executing initial setting.

1) Open driver side door glass fully.

2) Raise driver side door window switch (MANUAL UP

position) of power window main switch until door

glass is closed completely and hold the switch in that

state for 2 seconds or more.3) Use auto-down / auto-up function of power window

main switch and check that door glass opens fully /

closes completely.

4) Check pinching prevention function referring to

“Inspection of Pinching Prevention Function

(Pinching Prevention Function Model)”.

Door Mirror ComponentsS6RW0D9506023 1. AUTO UP position

2. MANUAL UP position

3. OFF position

1

2

3

I6RW0D950005-01

2

1

i

iiiii

3

I5RW0A950038-03

1. Door mirror

2. Door mirror mounting nut

:Tighten nuts in such order as indicated in the figure.

3. Door mirror trim

Page 1414 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-3 Security and Locks:

Diagnostic Information and Procedures

Power Door Lock System Symptom Diagnosis (If Equipped)S6RW0D9604001

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Power Door Lock System Operation Inspection (If Equipped)S6RW0D9604002

1) Check the following operation:

a) Turn the driver side key cylinder is turned LOCK once, check all doors lock.

b) Turn the driver side door key cylinder is turned UNLOCK position with door key twice, check all doors unlock.

c) With all doors unlocked, insert key in key cylinder of driver side door and turn it to lock side, turn it again to lock

side within 3 seconds and check that no door can be opened even when door lock knob is moved to unlock

side (dead lock function, if equipped).

If malfunction is found, go to “Power Door Lock System Symptom Diagnosis (If Equipped)”. Condition Possible cause Correction / Reference Item

All door can not be locked

/ unlocked by all of

switchesCircuit fuse blownReplace fuse and check for short circuit.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

All door can not be locked

/ unlocked by only power

door lock switchCircuit fuse blownReplace fuse and check for short circuit.

Power door lock switch faultyCheck power door lock switch referring to

“Power Door Lock Switch Inspection (If

Equipped)”.

Wiring harness connected to power door

lock switch faultyRepair.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

All door can not be locked

/ unlocked by only key

cylinder switchCircuit fuse blownReplace fuse and check for short circuit.

Key cylinder switch faultyCheck key cylinder switch referring to “Door

Key Cylinder Switch Inspection (If Equipped)”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Only one door can not be

locked / unlockedPower door lock actuator faultyCheck actuator referring to “Power Door Lock

Actuator Inspection (If Equipped)”.

Wiring harness connected to applicable

door lock actuator faultyRepair.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1416 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-5 Security and Locks:

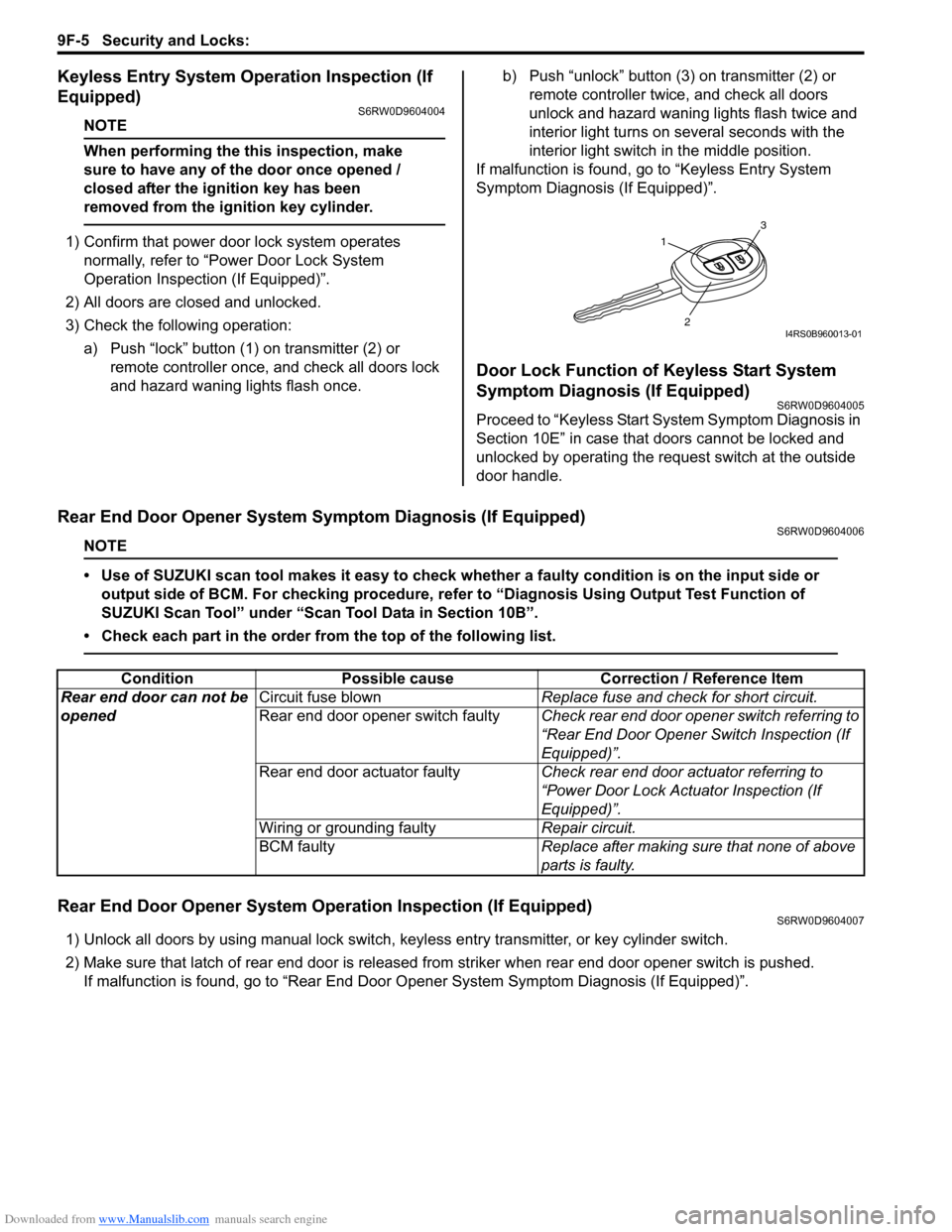

Keyless Entry System Operation Inspection (If

Equipped)

S6RW0D9604004

NOTE

When performing the this inspection, make

sure to have any of the door once opened /

closed after the ignition key has been

removed from the ignition key cylinder.

1) Confirm that power door lock system operates

normally, refer to “Power Door Lock System

Operation Inspection (If Equipped)”.

2) All doors are closed and unlocked.

3) Check the following operation:

a) Push “lock” button (1) on transmitter (2) or

remote controller once, and check all doors lock

and hazard waning lights flash once.b) Push “unlock” button (3) on transmitter (2) or

remote controller twice, and check all doors

unlock and hazard waning lights flash twice and

interior light turns on several seconds with the

interior light switch in the middle position.

If malfunction is found, go to “Keyless Entry System

Symptom Diagnosis (If Equipped)”.

Door Lock Function of Keyless Start System

Symptom Diagnosis (If Equipped)

S6RW0D9604005

Proceed to “Keyless Start System Symptom Diagnosis in

Section 10E” in case that doors cannot be locked and

unlocked by operating the request switch at the outside

door handle.

Rear End Door Opener System Symptom Diagnosis (If Equipped)S6RW0D9604006

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Rear End Door Opener System Operation Inspection (If Equipped)S6RW0D9604007

1) Unlock all doors by using manual lock switch, keyless entry transmitter, or key cylinder switch.

2) Make sure that latch of rear end door is released from striker when rear end door opener switch is pushed.

If malfunction is found, go to “Rear End Door Opener System Symptom Diagnosis (If Equipped)”.

1

3

2I4RS0B960013-01

Condition Possible cause Correction / Reference Item

Rear end door can not be

openedCircuit fuse blownReplace fuse and check for short circuit.

Rear end door opener switch faultyCheck rear end door opener switch referring to

“Rear End Door Opener Switch Inspection (If

Equipped)”.

Rear end door actuator faultyCheck rear end door actuator referring to

“Power Door Lock Actuator Inspection (If

Equipped)”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1428 of 1556

Downloaded from www.Manualslib.com manuals search engine 9G-1 Seats:

Body, Cab and Accessories

Seats

Diagnostic Information and Procedures

Front Seat Heater Symptom Diagnosis (If Equipped)S6RW0D9704001

Condition Possible cause Correction / Reference Item

Both seat back and

cushion do not become

hot although seat heater

switch is ON positionWiring or grounding faultyRepair.

“SEAT HTR” fuse blownReplace fuse to check for short.

Seat heater switch faultyReplace switch.

Seat heater circuit in seat back and/or

seat cushion faultyReplace heater front back and/or heater front

cushion.

Only seat back does not

become hot although seat

heater switch is ON

positionWiring faultyRepair.

Seat heater circuit in seat back and/or

seat cushion faultyReplace heater front back and/or heater front

cushion.

Only seat cushion does

not become hot although

seat heater switch is ON

positionWiring faultyRepair.

Seat heater circuit in seat cushion faultyReplace heater front cushion.

Page 1489 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-16

BCM Power Circuit and Ground Circuit CheckS6RW0DA204007

Wiring Diagram

Troubleshooting

+B

IG1

+BB

GRNG273-2BLKBLK/ORNG272-9

G271-3

BLK/ORNL314-4

BLU G273-5

WHTE324-22

3

1

E324 L314

1 2 4 53 6 7 8 9

10

11 12 13 14 15 16 17 181 21 2 4 53 61

2 4 53 6 7 8 9 10

7 8 9 10 11 12

11 12 13 14 15 16 17 18 19 20

G272 G271

1 2

4

65

G273[A] [A] [A]

3

[A]

I6RW0CA20006-02

[A]: Junction block connector viewed from harness side 2. Ignition switch

1. Junction block 3. Battery

Step Action Yes No

1Fuse check

1) Turn ignition switch to OFF position.

2) Check circuit fuses for condition.

Are circuit fuses in good condition?Go to Step 2. Replace fuse and check

for short circuit to

ground.

2Power supply circuit check

1) Disconnect connectors from junction block.

2) Check for proper connection to junction block connector

at terminal “E324-2”.

3) If OK, then measure voltage between “E324-2” terminal

of junction block connector and vehicle body ground.

Is voltage 10 – 14 V?Go to Step 3. Repair power supply

circuit.

3Power supply circuit check

1) Check for proper connection to junction block connector

at terminals “G273-2” and “G273-5”.

2) If OK, turn ignition switch to ON position.

3) Measure voltage between following terminals.

• Between “G273-2” terminal of junction block

connector and vehicle body ground

• Between “G273-5” terminal of junction block

connector and vehicle body ground

Is each voltage 10 – 14 V?Go to Step 4. Repair power supply

circuit.

Page 1503 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-1

Control Systems

Immobilizer Control System

Precautions

Precautions in Diagnosing TroublesS6RW0DA300001

• Before confirming the diagnostic trouble code (DTC),

do not disconnect connector from ECM, battery cable

from battery, ground wire harness, or main fuse. Such

disconnection will erase DTC stored in ECM.

• DTC stored in ECM memory can be checked as well

as cleared by using SUZUKI scan tool. Before using

SUZUKI scan tool, read its operator’s manual

carefully to know how to use it and what functions are

available.

• Be sure to read “Precautions for Electrical Circuit

Service in Section 00” before inspection.

• Communication of ECM, BCM, ABS control module,

TCM (if equipped), 4WD control module (if equipped),

keyless start control module (if equipped),

combination meter and DLC is established by CAN

(Controller Area Network). Therefore, handle CAN

communication lines with care referring to “Precaution

for CAN Communication System in Section 00”.

For CAN communication system, refer to description

on “CAN Communication System Description in

Section 1A”.

Precaution in Replacing ECMS6RW0DA300002

• If ECM is replaced with new or used one without

Immobilizer control function, the engine will not be

started. In case of the above, check if the newly

installed ECM has Immobilizer control function.

• After ECM is replaced with new one or used one, the

transponder code in the transponder built in the

ignition key has to be registered with ECM. Or, the

engine cannot be started up. For the registration

procedure, refer to “Procedure after ECM

Replacement”.

Precaution in Replacing Ignition KeyS6RW0DA300003

To register ignition key in case of replacing key(s) and/or

making spare key(s), the transponder code in the ignition

key is registered with ECM. Or the engine can not be

started up. For the registration procedure, refer to

“Registration of the Ignition Key”.

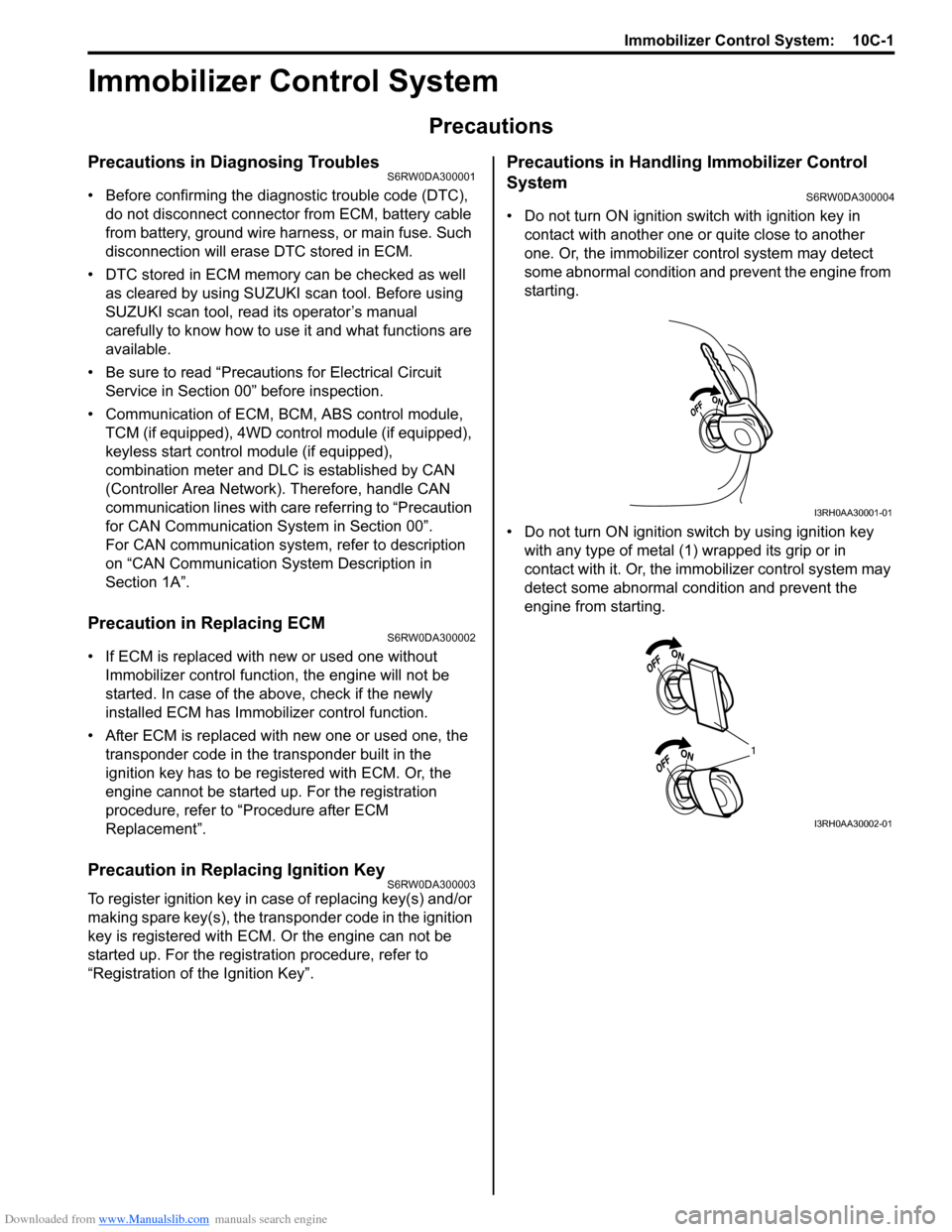

Precautions in Handling Immobilizer Control

System

S6RW0DA300004

• Do not turn ON ignition switch with ignition key in

contact with another one or quite close to another

one. Or, the immobilizer control system may detect

some abnormal condition and prevent the engine from

starting.

• Do not turn ON ignition switch by using ignition key

with any type of metal (1) wrapped its grip or in

contact with it. Or, the immobilizer control system may

detect some abnormal condition and prevent the

engine from starting.

I3RH0AA30001-01

1

I3RH0AA30002-01

Page 1506 of 1556

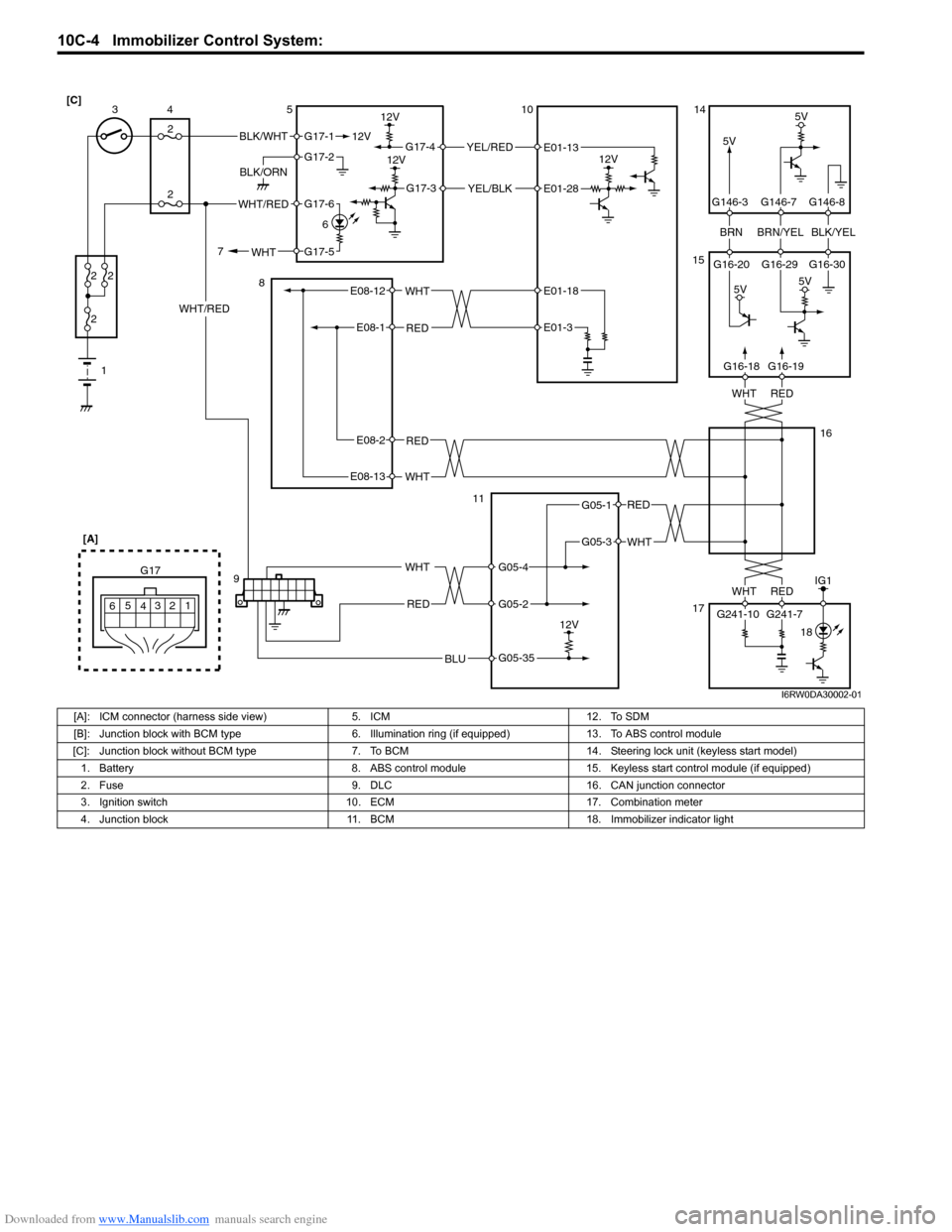

Downloaded from www.Manualslib.com manuals search engine 10C-4 Immobilizer Control System:

BLK/WHT

BLK/ORN12V

G17-1

G17-2

12V

5V

12V

12VYEL/RED

YEL/BLK

G17-4

G17-3

5V

BRNBRN/YELBLK/YEL

1 2

22

2 34

251014

15

1 2 3

4 G17

[A]

5

6

G16-20 G16-29 G16-30 G146-3 G146-7 G146-8

WHT/RED

5V

5V

9

G16-18G16-19 E01-13

E01-28

BLU

RED

WHTE08-12

E08-1E01-18

E01-3

RED

WHTE08-13

E08-2

WHT

RED

G05-4

G05-2

12V

G05-35 8

11

G17-5WHT 76

G17-6WHT/RED

17

REDWHT

REDWHT

G241-10 G241-7

IG1

18

WHT

REDG05-1

G05-3

16 [C]

I6RW0DA30002-01

[A]: ICM connector (harness side view) 5. ICM 12. To SDM

[B]: Junction block with BCM type 6. Illumination ring (if equipped) 13. To ABS control module

[C]: Junction block without BCM type 7. To BCM 14. Steering lock unit (keyless start model)

1. Battery 8. ABS control module 15. Keyless start control module (if equipped)

2. Fuse 9. DLC 16. CAN junction connector

3. Ignition switch 10. ECM 17. Combination meter

4. Junction block 11. BCM 18. Immobilizer indicator light

Page 1511 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-9

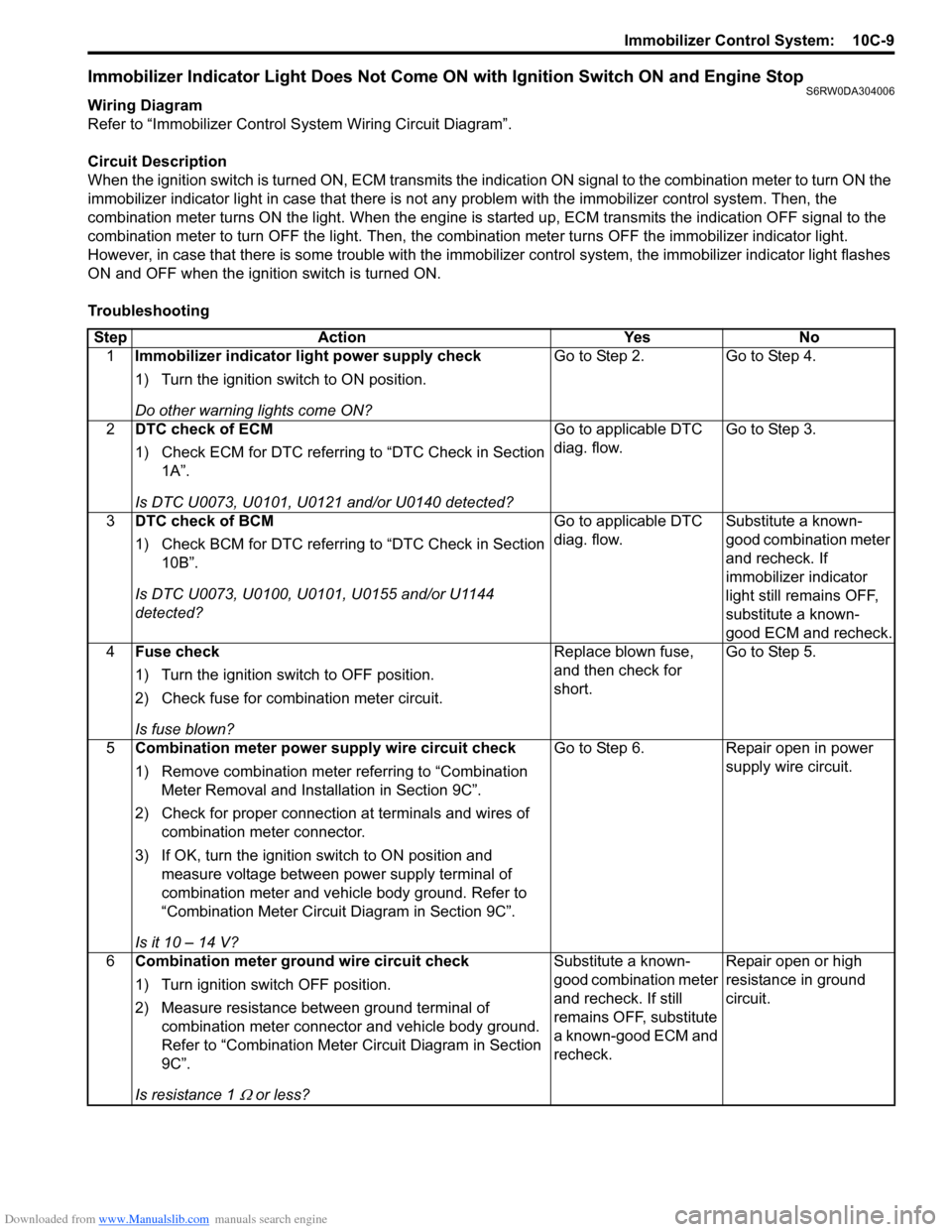

Immobilizer Indicator Light Does Not Come ON with Ignition Switch ON and Engine StopS6RW0DA304006

Wiring Diagram

Refer to “Immobilizer Control System Wiring Circuit Diagram”.

Circuit Description

When the ignition switch is turned ON, ECM transmits the indication ON signal to the combination meter to turn ON the

immobilizer indicator light in case that there is not any problem with the immobilizer control system. Then, the

combination meter turns ON the light. When the engine is started up, ECM transmits the indication OFF signal to the

combination meter to turn OFF the light. Then, the combination meter turns OFF the immobilizer indicator light.

However, in case that there is some trouble with the immobilizer control system, the immobilizer indicator light flashes

ON and OFF when the ignition switch is turned ON.

Troubleshooting

Step Action Yes No

1Immobilizer indicator light power supply check

1) Turn the ignition switch to ON position.

Do other warning lights come ON?Go to Step 2. Go to Step 4.

2DTC check of ECM

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is DTC U0073, U0101, U0121 and/or U0140 detected?Go to applicable DTC

diag. flow.Go to Step 3.

3DTC check of BCM

1) Check BCM for DTC referring to “DTC Check in Section

10B”.

Is DTC U0073, U0100, U0101, U0155 and/or U1144

detected?Go to applicable DTC

diag. flow.Substitute a known-

good combination meter

and recheck. If

immobilizer indicator

light still remains OFF,

substitute a known-

good ECM and recheck.

4Fuse check

1) Turn the ignition switch to OFF position.

2) Check fuse for combination meter circuit.

Is fuse blown?Replace blown fuse,

and then check for

short.Go to Step 5.

5Combination meter power supply wire circuit check

1) Remove combination meter referring to “Combination

Meter Removal and Installation in Section 9C”.

2) Check for proper connection at terminals and wires of

combination meter connector.

3) If OK, turn the ignition switch to ON position and

measure voltage between power supply terminal of

combination meter and vehicle body ground. Refer to

“Combination Meter Circuit Diagram in Section 9C”.

Is it 10 – 14 V?Go to Step 6. Repair open in power

supply wire circuit.

6Combination meter ground wire circuit check

1) Turn ignition switch OFF position.

2) Measure resistance between ground terminal of

combination meter connector and vehicle body ground.

Refer to “Combination Meter Circuit Diagram in Section

9C”.

Is resistance 1

Ω or less?Substitute a known-

good combination meter

and recheck. If still

remains OFF, substitute

a known-good ECM and

recheck.Repair open or high

resistance in ground

circuit.

Page 1515 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-13

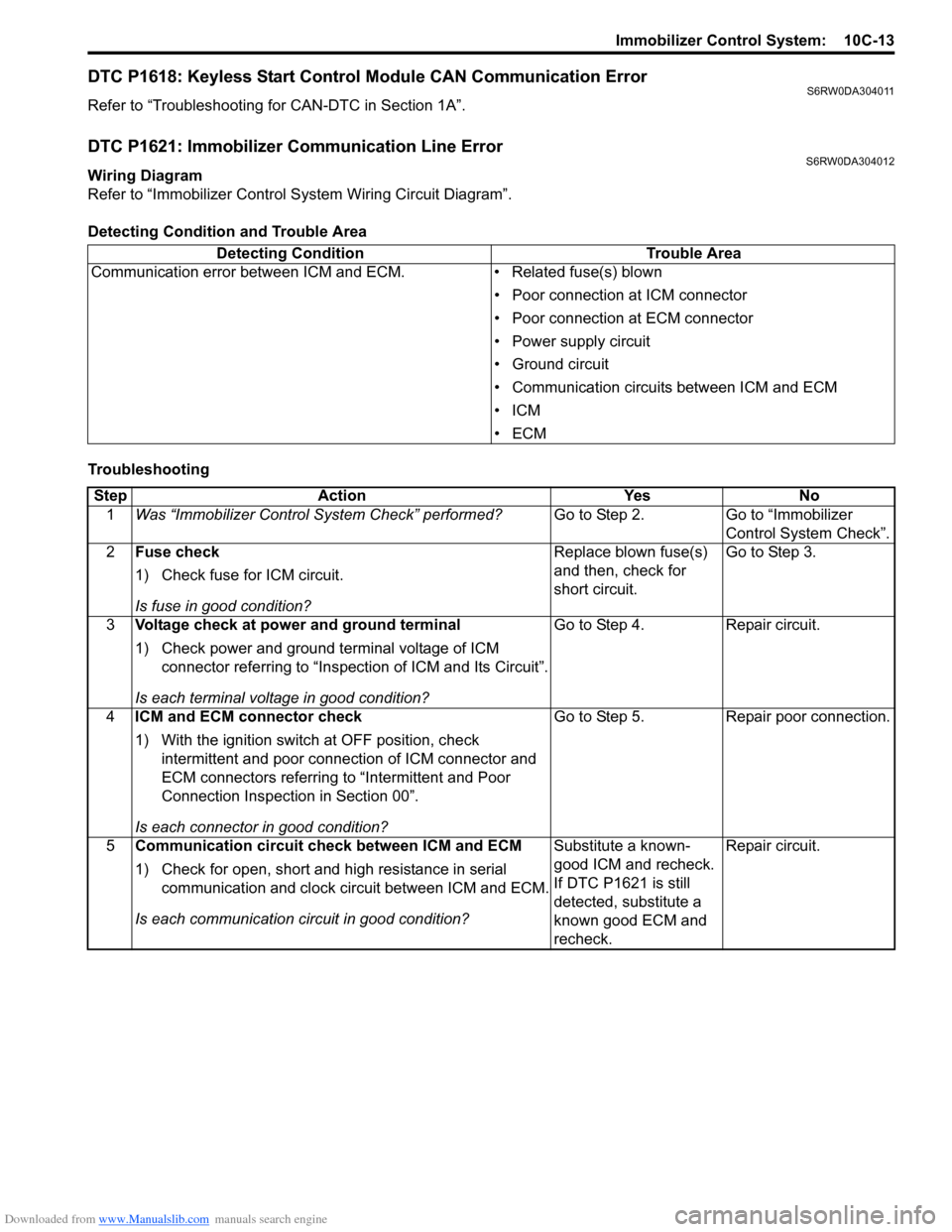

DTC P1618: Keyless Start Control Module CAN Communication ErrorS6RW0DA304011

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

DTC P1621: Immobilizer Communication Line ErrorS6RW0DA304012

Wiring Diagram

Refer to “Immobilizer Control System Wiring Circuit Diagram”.

Detecting Condition and Trouble Area

TroubleshootingDetecting Condition Trouble Area

Communication error between ICM and ECM. • Related fuse(s) blown

• Poor connection at ICM connector

• Poor connection at ECM connector

• Power supply circuit

• Ground circuit

• Communication circuits between ICM and ECM

•ICM

•ECM

Step Action Yes No

1Was “Immobilizer Control System Check” performed?Go to Step 2. Go to “Immobilizer

Control System Check”.

2Fuse check

1) Check fuse for ICM circuit.

Is fuse in good condition?Replace blown fuse(s)

and then, check for

short circuit.Go to Step 3.

3Voltage check at power and ground terminal

1) Check power and ground terminal voltage of ICM

connector referring to “Inspection of ICM and Its Circuit”.

Is each terminal voltage in good condition?Go to Step 4. Repair circuit.

4ICM and ECM connector check

1) With the ignition switch at OFF position, check

intermittent and poor connection of ICM connector and

ECM connectors referring to “Intermittent and Poor

Connection Inspection in Section 00”.

Is each connector in good condition?Go to Step 5. Repair poor connection.

5Communication circuit check between ICM and ECM

1) Check for open, short and high resistance in serial

communication and clock circuit between ICM and ECM.

Is each communication circuit in good condition?Substitute a known-

good ICM and recheck.

If DTC P1621 is still

detected, substitute a

known good ECM and

recheck.Repair circuit.