Air flow sensor SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 118 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-68 Engine General Information and Diagnosis:

3) Start engine and run it for 10 sec.

4) Check DTC and pending DTC.

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2MAF sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and check MAF value displayed on scan

tool. (Refer to “Scan Tool Data” for normal value.)

Is normal value indicated?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 3.

3MAF sensor power supply voltage check

1) Disconnect connector from MAF and IAT sensor with

ignition switch tuned OFF.

2) Turn ON ignition switch, measure voltage between

engine ground and “BLK/RED” wire terminal of MAF and

IAT sensor connector.

Is voltage 10 – 14 V?Go to Step 4. “BLK/RED” wire is open

circuit.

4MAF sensor ground circuit check

1) Turn OFF ignition switch, measure resistance between

“GRY” wire terminal of MAF and IAT sensor connector

and engine ground.

Is resistance below 5

Ω?Go to Step 6. Go to Step 5.

5Ground circuit check

1) Remove ECM from its bracket with ECM connectors

connected.

2) Measure resistance between “C01-27” terminal of ECM

connector and engine ground.

Is resistance below 5

Ω?“GRY” wire is open or

high resistance circuit.ECM grounds “C01-58”,

“C01-15”, “C01-30” and/

or “E01-31” circuit are

open or high resistance.

If wires are OK,

substitute a known-

good ECM and recheck.

6MAF sensor signal circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure voltage between “GRY/BLK” wire terminal of

MAF and IAT sensor connector and engine ground.

Is voltage 0 V?Go to Step 7. “GRY/BLK” wire is

shorted to other circuit.

7MAF sensor output signal check

1) Connect connector to MAF and IAT sensor and ECM

with ignition switch turned OFF.

2) Measure voltage between “C01-26” and “C01-27”

terminal of ECM connector referring to “Mass Air Flow

(MAF) and Intake Air Temperature (IAT) Sensor On-

Vehicle Inspection in Section 1C”.

Is each value within specified range?Substitute a known-

good ECM and recheck.Faulty MAF and IAT

sensor.

Page 120 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-70 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

DTC P0107: Manifold Absolute Pressure Circuit Low InputS6RW0D1104021

Wiring Diagram

Refer to “DTC P0106: Manifold Absolute Pressure Range / Performance”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC using scan tool and warm up engine completely.

3) Run engine at idle speed for 1 min.

4) Check DTC and pending DTC. Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2MAP sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check DTC.

Is there DTC P0107 or DTC P0108?Go to applicable DTC

diag. flow.Go to Step 3.

3MAP sensor output signal check

1) Check MAP sensor according to “Manifold Absolute

Pressure (MAP) Sensor Inspection (If Equipped) in

Section 1C”.

Is it in good condition?Go to Step 4. Faulty MAP sensor.

4MAP sensor circuit check

1) Check MAP sensor circuit referring to Step 3 to 6 of

“DTC P0107: Manifold Absolute Pressure Circuit Low

Input” or Step 3 to 8 of “DTC P0108: Manifold Absolute

Pressure Circuit High Input”.

Is circuit in good condition?Go to Step 5. Repair or replace.

5Air intake system check

1) Check air intake system for clog or leak.

Is it in good condition?Substitute a known-

good ECM and recheck.Repair or replace.

DTC detecting condition Trouble area

Manifold absolute pressure sensor output voltage is lower

than specified value for specified time.

(1 driving cycle detection logic)• Manifold absolute pressure sensor circuit

• Manifold absolute pressure sensor

• A/C refrigerant pressure sensor (if equipped with A/C)

•ECM

Page 143 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-93

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions are satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 °F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temperature: 70 °C (158 °F) or more

• Altitude (barometric pressure): 2500 m, 8200 ft or less (560 mmHg, 74.4 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and warm up to normal operating temperature.

4) Drive vehicle at 40 mph (60 km/h) or higher. (engine speed: 2500 – 3000 r/min.)

5) Keep above vehicle speed for 6 min. or more. (Throttle valve opening is kept constant in this step.)

6) Release accelerator pedal and with engine brake applied, keep vehicle coasting (with fuel cut for 3 sec. or more)

and then stop vehicle.

7) For european market model, check whether O2 sensor readiness/monitoring test has completed or not by using

scan tool.

If O2 sensor readiness/monitoring test has not completed, check vehicle conditions (environmental) and repeat

Step 3) through 6).

8) Check DTC and pending DTC.

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2Is there DTC(s) other than HO2S-1?Go to applicable DTC

diag. flow.Go to Step 3.

3HO2S-1 signal check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Warm up engine to normal operating temperature and

keep it at 2000 r/min. for 60 sec.

3) Repeat racing engine (Repeat depressing accelerator

pedal 5 to 6 times continuously to enrich A/F mixture and

take foot off from pedal to enlean it).

Does HO2S-1 output voltage deflect between below 0.3 V

and over 0.6 V repeatedly?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”. If check result is

OK, go to Step 9.Go to Step 4.

Page 145 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-95

DTC P0133: O2 Sensor (HO2S) Circuit Slow Response (Sensor-1)S6RW0D1104032

Wiring Diagram

Refer to “DTC P0131 / P0132: O2 Sensor (HO2S) Circuit Low Voltage / High Voltage (Sensor-1)”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions are satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 °F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temperature: 70 °C (158 °F) or more

• Altitude (barometric pressure): 2500 m, 8200 ft or less (560 mmHg, 74.4 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and warm up to normal operating temperature.

4) Drive vehicle at 40 mph (60 km/h) or higher. (engine speed: 2500 – 3000 r/min.)

5) Keep above vehicle speed for 6 min. or more. (Throttle valve opening is kept constant in this step.)

6) Release accelerator pedal and with engine brake applied, keep vehicle coasting (with fuel cut for 3 sec. or more)

and then stop vehicle.

7) For european market model, check whether O2 sensor readiness/monitoring test has completed or not by using

scan tool.

If O2 sensor readiness/monitoring test has not completed, check vehicle conditions (environmental) and repeat

Step 3) through 6).

8) Check DTC and pending DTC.

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

DTC detecting condition Trouble area

Response time (time to change from lean to rich or from rich to lean) of HO2S-1 output

voltage is about 1 sec. at minimum or average time of 1 cycle is 5 sec. at minimum.

(2 driving cycle detection logic, monitoring once / 1 driving)Heated oxygen sensor-1

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2Is there DTC(s) other than HO2S-1 (DTC P0133)?Go to applicable DTC

diag. flow.Replace HO2S-1.

Page 154 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-104 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2Is there DTC(s) other than fuel system (DTC P0171 /

P0172)?Go to applicable DTC

diag. flow.Go to Step 3.

3Intake system and exhaust system for leakage check

Are intake system and exhaust system in good condition?Go to Step 4. Repair or replace

defective part.

4Fuel pressure check

1) Check fuel pressure referring to “Fuel Pressure Check”.

Is check result satisfactory?Go to Step 5. Repair or replace

defective part.

5Fuel injectors and its circuit check

1) Check fuel injectors referring to “Fuel Injector Inspection

in Section 1G”.

Is check result satisfactory?Go to Step 6. Faulty injector(s) or its

circuit.

6Visual inspection

1) Check MAF sensor and air intake system.

• Objects which block measuring duct and resistor of

MAF sensor.

• Other air flow which does not pass MAF sensor.

Are they in good condition?Go to Step 7. Repair or replace

defective part.

7MAF sensor for performance check

1) With ignition switch turned OFF, install scan tool.

2) Start engine and warm up to normal operating

temperature.

3) Check MAF value using scan tool (Refer to “Scan Tool

Data” for normal value.).

Is each value within specified range?Go to Step 8. Go to “DTC P0101:

Mass Air Flow Circuit

Range / Performance”.

8ECT sensor for performance check

1) Check ECT sensor referring to Step 3 and 4 of “DTC

P0118: Engine Coolant Temperature Circuit High”.

Is check result satisfactory?Go to Step 9. Faulty ECT sensor or its

circuit.

9HO2S-1 for performance check

1) Check HO2S-1 referring to Step 3 of “DTC P0131 /

P0132: O2 Sensor (HO2S) Circuit Low Voltage / High

Voltage (Sensor-1)”.

Is check result satisfactory?Substitute a known-

good ECM and recheck.Faulty HO2S-1 or its

circuit.

Page 169 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-119

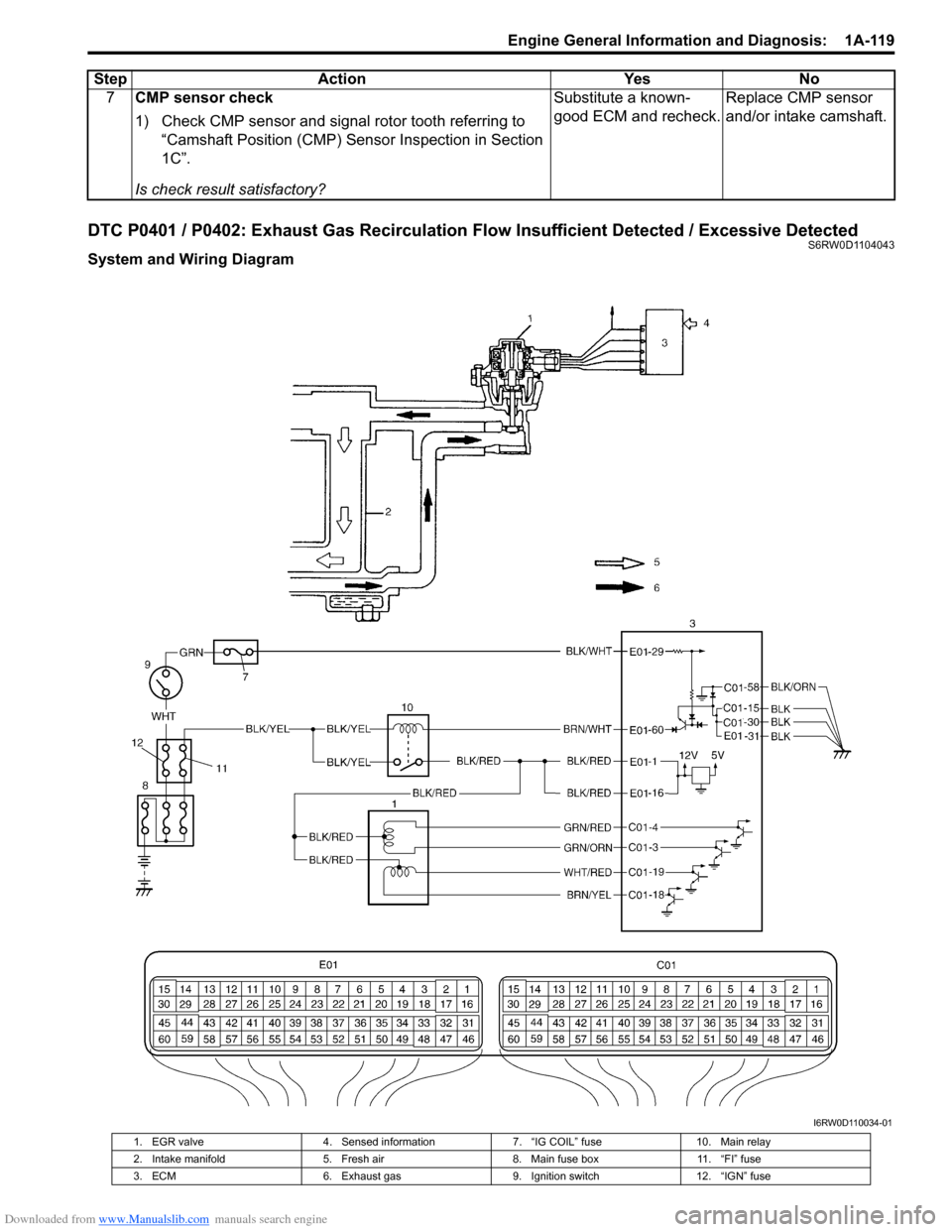

DTC P0401 / P0402: Exhaust Gas Recirculation Flow Insufficient Detected / Excessive DetectedS6RW0D1104043

System and Wiring Diagram7CMP sensor check

1) Check CMP sensor and signal rotor tooth referring to

“Camshaft Position (CMP) Sensor Inspection in Section

1C”.

Is check result satisfactory?Substitute a known-

good ECM and recheck.Replace CMP sensor

and/or intake camshaft. Step Action Yes No

I6RW0D110034-01

1. EGR valve 4. Sensed information 7. “IG COIL” fuse 10. Main relay

2. Intake manifold 5. Fresh air 8. Main fuse box 11. “FI” fuse

3. ECM 6. Exhaust gas 9. Ignition switch 12. “IGN” fuse

Page 225 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-175

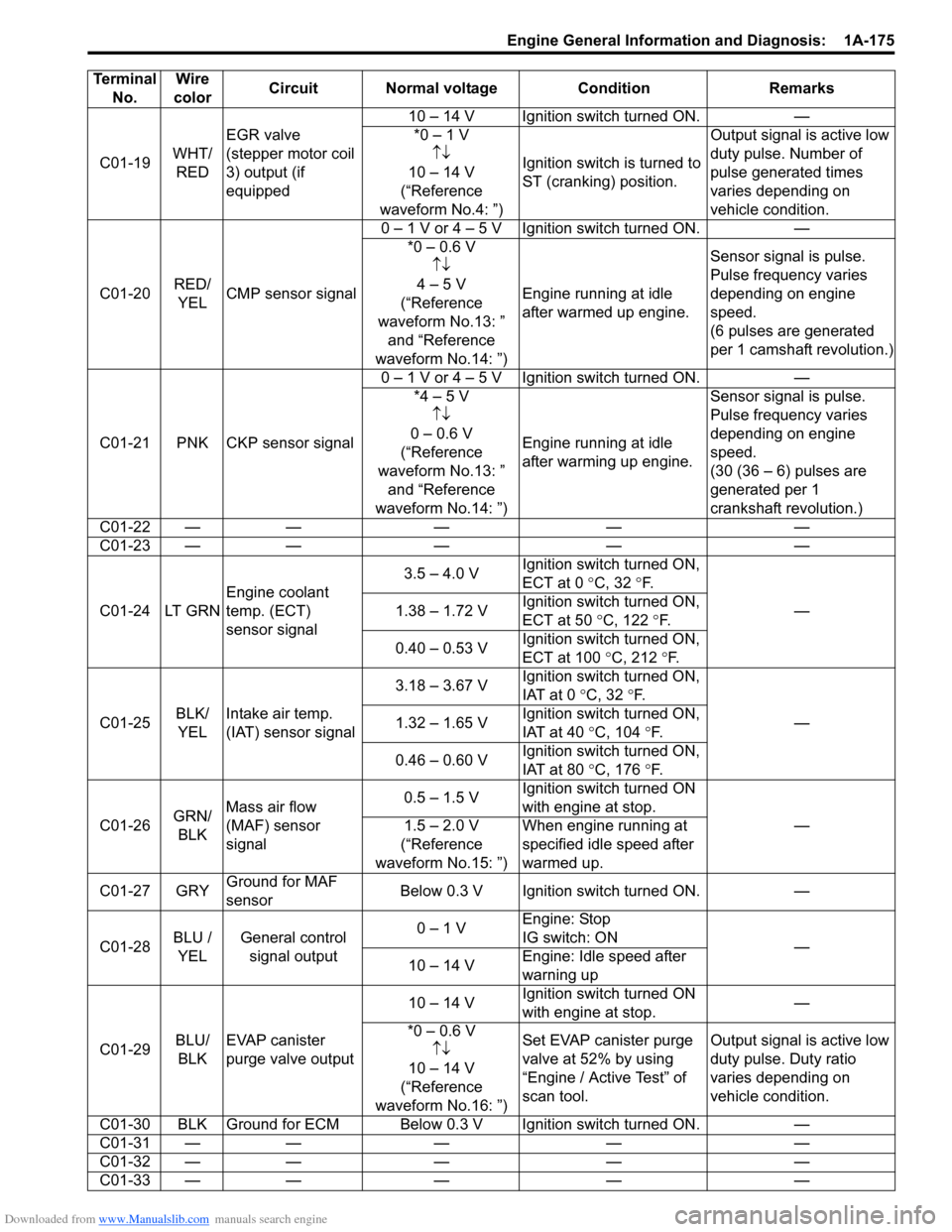

C01-19WHT/

REDEGR valve

(stepper motor coil

3) output (if

equipped10 – 14 V Ignition switch turned ON. —

*0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.4: ”)Ignition switch is turned to

ST (cranking) position.Output signal is active low

duty pulse. Number of

pulse generated times

varies depending on

vehicle condition.

C01-20RED/

YELCMP sensor signal0 – 1 V or 4 – 5 V Ignition switch turned ON. —

*0 – 0.6 V

↑↓

4 – 5 V

(“Reference

waveform No.13: ”

and “Reference

waveform No.14: ”)Engine running at idle

after warmed up engine.Sensor signal is pulse.

Pulse frequency varies

depending on engine

speed.

(6 pulses are generated

per 1 camshaft revolution.)

C01-21 PNK CKP sensor signal0 – 1 V or 4 – 5 V Ignition switch turned ON. —

*4 – 5 V

↑↓

0 – 0.6 V

(“Reference

waveform No.13: ”

and “Reference

waveform No.14: ”)Engine running at idle

after warming up engine.Sensor signal is pulse.

Pulse frequency varies

depending on engine

speed.

(30 (36 – 6) pulses are

generated per 1

crankshaft revolution.)

C01-22 — — — — —

C01-23 — — — — —

C01-24 LT GRNEngine coolant

temp. (ECT)

sensor signal3.5 – 4.0 VIgnition switch turned ON,

ECT at 0 °C, 32 °F.

— 1.38 – 1.72 VIgnition switch turned ON,

ECT at 50 °C, 122 °F.

0.40 – 0.53 VIgnition switch turned ON,

ECT at 100 °C, 212 °F.

C01-25BLK/

YELIntake air temp.

(IAT) sensor signal3.18 – 3.67 VIgnition switch turned ON,

IAT at 0 °C, 32 °F.

— 1.32 – 1.65 VIgnition switch turned ON,

IAT at 40 °C, 104 °F.

0.46 – 0.60 VIgnition switch turned ON,

IAT at 80 °C, 176 °F.

C01-26GRN/

BLKMass air flow

(MAF) sensor

signal0.5 – 1.5 VIgnition switch turned ON

with engine at stop.

— 1.5 – 2.0 V

(“Reference

waveform No.15: ”)When engine running at

specified idle speed after

warmed up.

C01-27 GRYGround for MAF

sensorBelow 0.3 V Ignition switch turned ON. —

C01-28BLU /

YELGeneral control

signal output0 – 1 VEngine: Stop

IG switch: ON

—

10 – 14 VEngine: Idle speed after

warning up

C01-29BLU/

BLKEVAP canister

purge valve output10 – 14 VIgnition switch turned ON

with engine at stop.—

*0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform No.16: ”)Set EVAP canister purge

valve at 52% by using

“Engine / Active Test” of

scan tool.Output signal is active low

duty pulse. Duty ratio

varies depending on

vehicle condition.

C01-30 BLK Ground for ECM Below 0.3 V Ignition switch turned ON. —

C01-31 — — — — —

C01-32 — — — — —

C01-33 — — — — — Terminal

No.Wire

colorCircuit Normal voltage Condition Remarks

Page 237 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-187

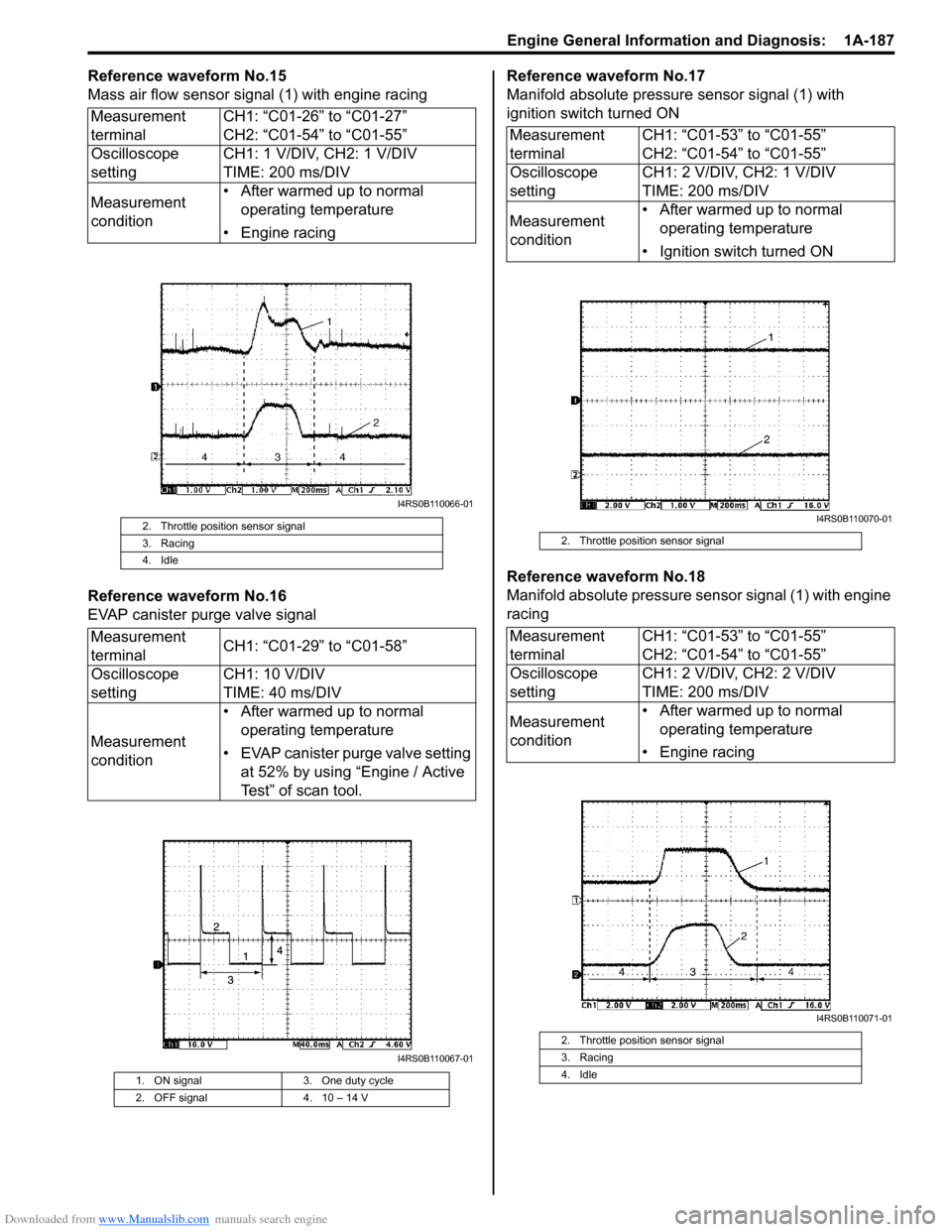

Reference waveform No.15

Mass air flow sensor signal (1) with engine racing

Reference waveform No.16

EVAP canister purge valve signalReference waveform No.17

Manifold absolute pressure sensor signal (1) with

ignition switch turned ON

Reference waveform No.18

Manifold absolute pressure sensor signal (1) with engine

racing Measurement

terminalCH1: “C01-26” to “C01-27”

CH2: “C01-54” to “C01-55”

Oscilloscope

settingCH1: 1 V/DIV, CH2: 1 V/DIV

TIME: 200 ms/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Engine racing

2. Throttle position sensor signal

3. Racing

4. Idle

Measurement

terminalCH1: “C01-29” to “C01-58”

Oscilloscope

settingCH1: 10 V/DIV

TIME: 40 ms/DIV

Measurement

condition• After warmed up to normal

operating temperature

• EVAP canister purge valve setting

at 52% by using “Engine / Active

Test” of scan tool.

1. ON signal 3. One duty cycle

2. OFF signal 4. 10 – 14 V

I4RS0B110066-01

I4RS0B110067-01

Measurement

terminalCH1: “C01-53” to “C01-55”

CH2: “C01-54” to “C01-55”

Oscilloscope

settingCH1: 2 V/DIV, CH2: 1 V/DIV

TIME: 200 ms/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Ignition switch turned ON

2. Throttle position sensor signal

Measurement

terminalCH1: “C01-53” to “C01-55”

CH2: “C01-54” to “C01-55”

Oscilloscope

settingCH1: 2 V/DIV, CH2: 2 V/DIV

TIME: 200 ms/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Engine racing

2. Throttle position sensor signal

3. Racing

4. Idle

I4RS0B110070-01

I4RS0B110071-01

Page 256 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-206 Engine General Information and Diagnosis:

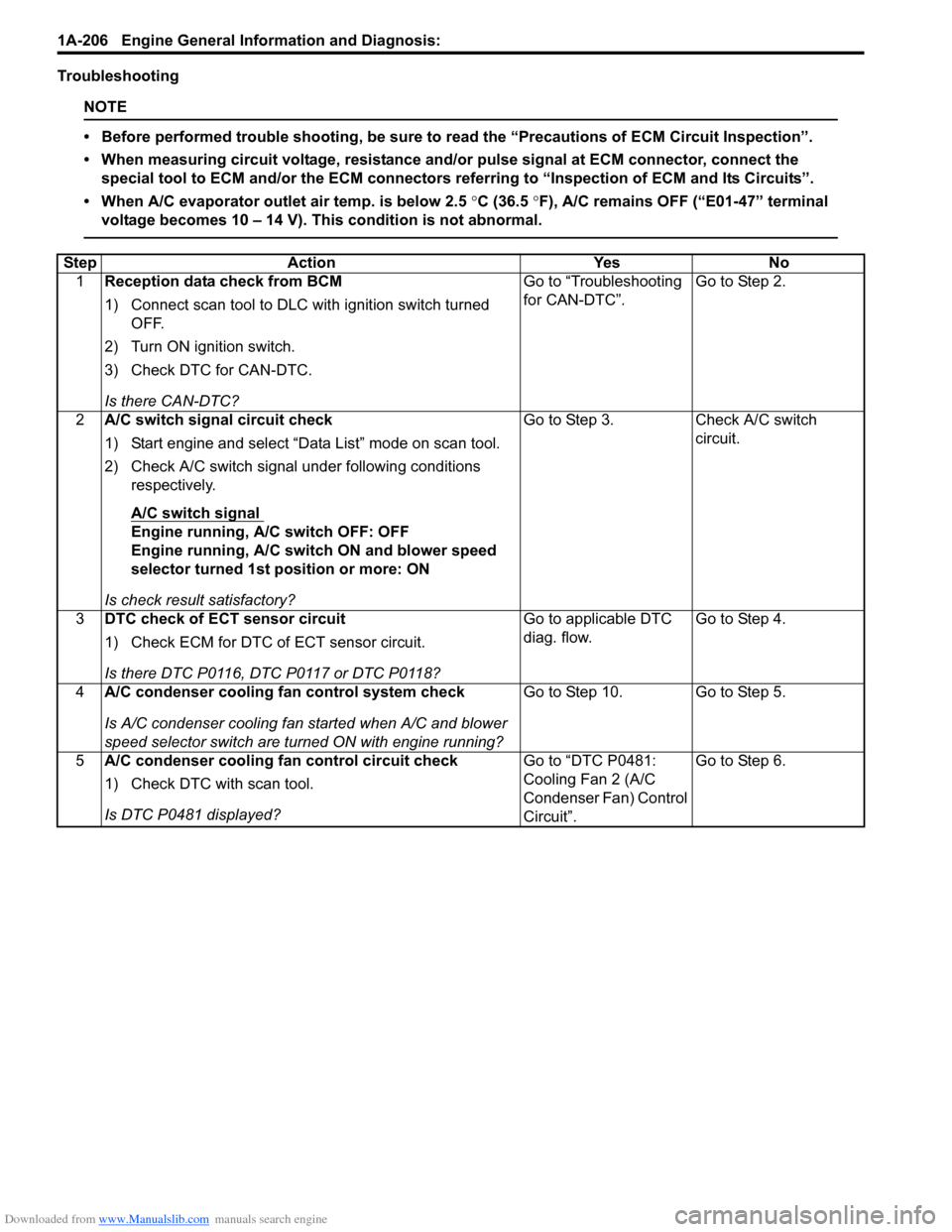

Troubleshooting

NOTE

• Before performed trouble shooting, be sure to read the “Precautions of ECM Circuit Inspection”.

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors referring to “Inspection of ECM and Its Circuits”.

• When A/C evaporator outlet air temp. is below 2.5 °C (36.5 °F), A/C remains OFF (“E01-47” terminal

voltage becomes 10 – 14 V). This condition is not abnormal.

Step Action Yes No

1Reception data check from BCM

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check DTC for CAN-DTC.

Is there CAN-DTC?Go to “Troubleshooting

for CAN-DTC”.Go to Step 2.

2A/C switch signal circuit check

1) Start engine and select “Data List” mode on scan tool.

2) Check A/C switch signal under following conditions

respectively.

A/C switch signal

Engine running, A/C switch OFF: OFF

Engine running, A/C switch ON and blower speed

selector turned 1st position or more: ON

Is check result satisfactory?Go to Step 3. Check A/C switch

circuit.

3DTC check of ECT sensor circuit

1) Check ECM for DTC of ECT sensor circuit.

Is there DTC P0116, DTC P0117 or DTC P0118?Go to applicable DTC

diag. flow.Go to Step 4.

4A/C condenser cooling fan control system check

Is A/C condenser cooling fan started when A/C and blower

speed selector switch are turned ON with engine running?Go to Step 10. Go to Step 5.

5A/C condenser cooling fan control circuit check

1) Check DTC with scan tool.

Is DTC P0481 displayed?Go to “DTC P0481:

Cooling Fan 2 (A/C

Condenser Fan) Control

Circuit”.Go to Step 6.

Page 257 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-207

6A/C evaporator outlet air temp. sensor check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection to “E01-57” and “E01-54”

wire terminals of ECM connector.

3) If OK, measure resistance between “E01-57” and “E01-

54” wire terminals of ECM connector.

Evaporator temp. sensor resistance

At 0 °C: 6.3 – 6.9 kΩ

At 25 °C: 1.8 – 2.2 kΩ

Is resistance within specification?Go to Step 7. Faulty A/C evaporator

outlet air temp. sensor

or its circuit.

7DTC check of A/C refrigerant pressure sensor circuit

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check ECM for DTC of A/C refrigerant pressure sensor

circuit.

Is there DTC P0532 or DTC P0533?Go to applicable DTC

diag. flow.Go to Step 8.

8A/C refrigerant pressure sensor voltage check

1) Check A/C refrigerant pressure sensor voltage referring

to “Inspection of ECM and Its Circuits”.

Is voltage within specified value?Go to Step 9. Check amount of

refrigerant. If OK,

replace A/C refrigerant

pressure sensor.

9A/C condenser cooling fan check

1) Check A/C condenser cooling fan referring to

“Condenser Cooling Fan Inspection in Section 7B”.

Is check result satisfactory?A/C condenser cooling

fan drive circuit

malfunction. If circuit is

OK, go to Step 6.Replace A/C condenser

cooling fan motor.

10A/C compressor control system check

Is A/C compressor started when A/C and blower speed

selector switch are turned ON with engine running?A/C system is in good

condition.Go to Step 11. Step Action Yes No

7

6

5

4

3

2

1

10

20

30

4050 010

2030

60 70

80 ResistanceTemperatureI3RB0A110053-01