Lower bracket SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 809 of 1556

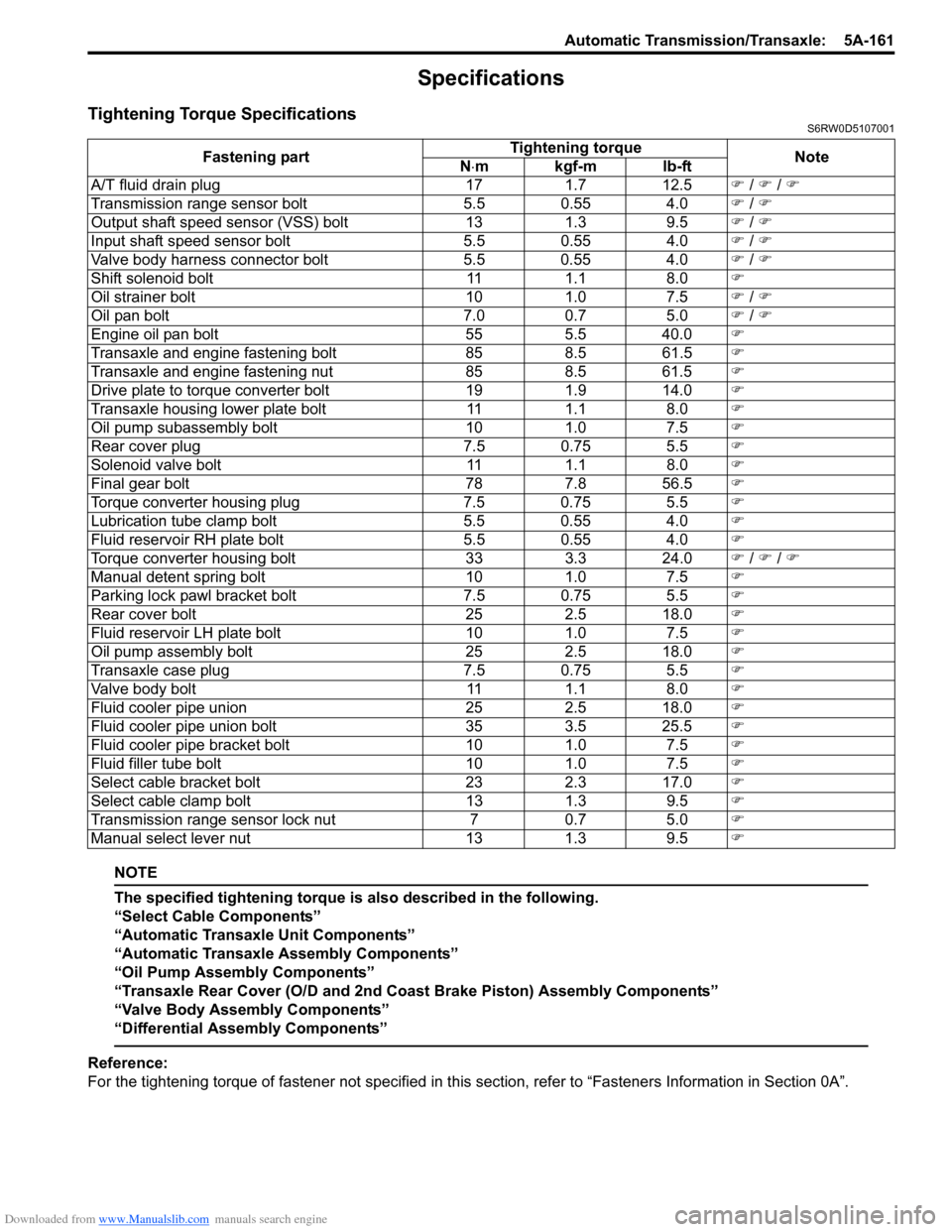

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-161

Specifications

Tightening Torque SpecificationsS6RW0D5107001

NOTE

The specified tightening torque is also described in the following.

“Select Cable Components”

“Automatic Transaxle Unit Components”

“Automatic Transaxle Assembly Components”

“Oil Pump Assembly Components”

“Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Components”

“Valve Body Assembly Components”

“Differential Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”. Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

A/T fluid drain plug 17 1.7 12.5�) / �) / �)

Transmission range sensor bolt 5.5 0.55 4.0�) / �)

Output shaft speed sensor (VSS) bolt 13 1.3 9.5�) / �)

Input shaft speed sensor bolt 5.5 0.55 4.0�) / �)

Valve body harness connector bolt 5.5 0.55 4.0�) / �)

Shift solenoid bolt 11 1.1 8.0�)

Oil strainer bolt 10 1.0 7.5�) / �)

Oil pan bolt 7.0 0.7 5.0�) / �)

Engine oil pan bolt 55 5.5 40.0�)

Transaxle and engine fastening bolt 85 8.5 61.5�)

Transaxle and engine fastening nut 85 8.5 61.5�)

Drive plate to torque converter bolt 19 1.9 14.0�)

Transaxle housing lower plate bolt 11 1.1 8.0�)

Oil pump subassembly bolt 10 1.0 7.5�)

Rear cover plug 7.5 0.75 5.5�)

Solenoid valve bolt 11 1.1 8.0�)

Final gear bolt 78 7.8 56.5�)

Torque converter housing plug 7.5 0.75 5.5�)

Lubrication tube clamp bolt 5.5 0.55 4.0�)

Fluid reservoir RH plate bolt 5.5 0.55 4.0�)

Torque converter housing bolt 33 3.3 24.0�) / �) / �)

Manual detent spring bolt 10 1.0 7.5�)

Parking lock pawl bracket bolt 7.5 0.75 5.5�)

Rear cover bolt 25 2.5 18.0�)

Fluid reservoir LH plate bolt 10 1.0 7.5�)

Oil pump assembly bolt 25 2.5 18.0�)

Transaxle case plug 7.5 0.75 5.5�)

Valve body bolt 11 1.1 8.0�)

Fluid cooler pipe union 25 2.5 18.0�)

Fluid cooler pipe union bolt 35 3.5 25.5�)

Fluid cooler pipe bracket bolt 10 1.0 7.5�)

Fluid filler tube bolt 10 1.0 7.5�)

Select cable bracket bolt 23 2.3 17.0�)

Select cable clamp bolt 13 1.3 9.5�)

Transmission range sensor lock nut 7 0.7 5.0�)

Manual select lever nut 13 1.3 9.5�)

Page 824 of 1556

Downloaded from www.Manualslib.com manuals search engine 5B-12 Manual Transmission/Transaxle:

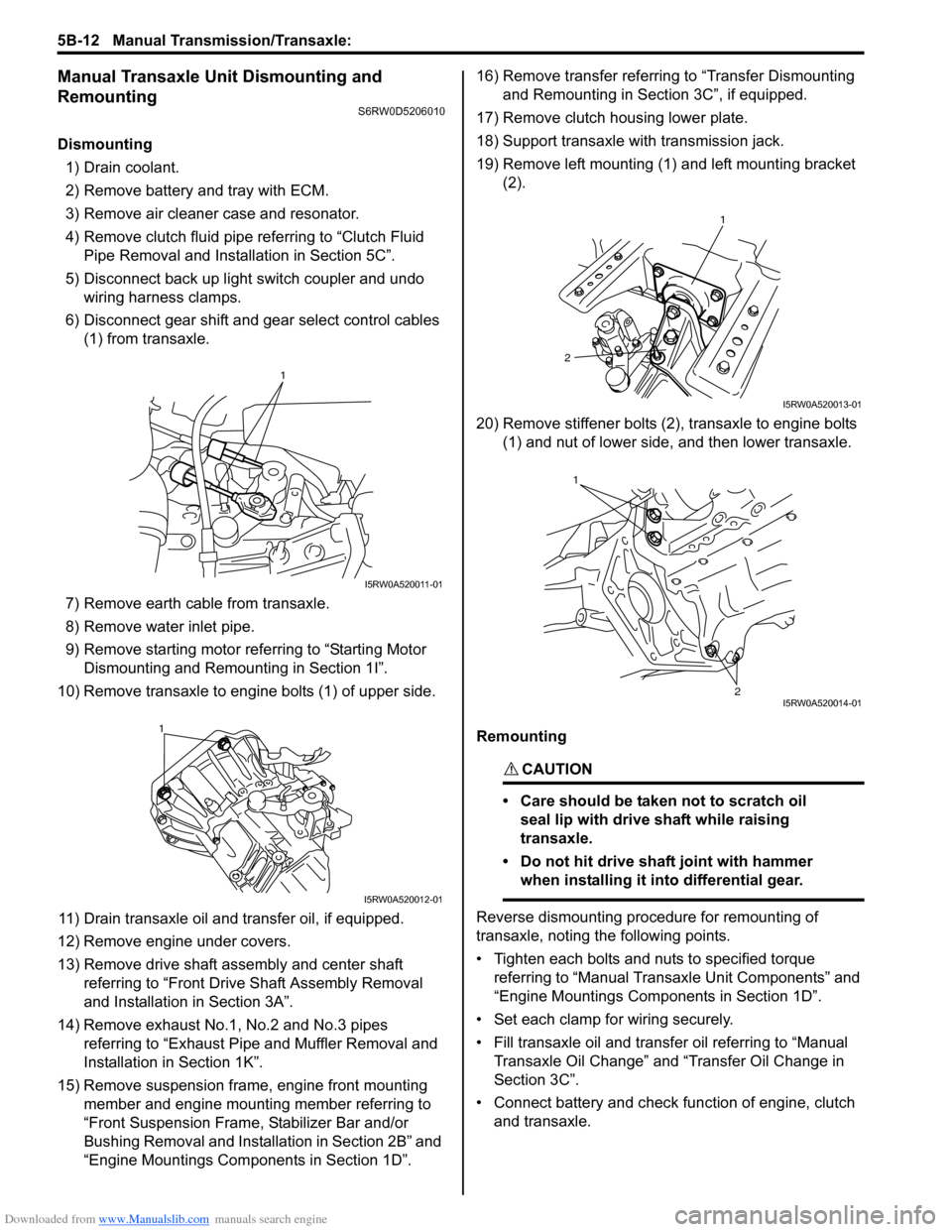

Manual Transaxle Unit Dismounting and

Remounting

S6RW0D5206010

Dismounting

1) Drain coolant.

2) Remove battery and tray with ECM.

3) Remove air cleaner case and resonator.

4) Remove clutch fluid pipe referring to “Clutch Fluid

Pipe Removal and Installation in Section 5C”.

5) Disconnect back up light switch coupler and undo

wiring harness clamps.

6) Disconnect gear shift and gear select control cables

(1) from transaxle.

7) Remove earth cable from transaxle.

8) Remove water inlet pipe.

9) Remove starting motor referring to “Starting Motor

Dismounting and Remounting in Section 1I”.

10) Remove transaxle to engine bolts (1) of upper side.

11) Drain transaxle oil and transfer oil, if equipped.

12) Remove engine under covers.

13) Remove drive shaft assembly and center shaft

referring to “Front Drive Shaft Assembly Removal

and Installation in Section 3A”.

14) Remove exhaust No.1, No.2 and No.3 pipes

referring to “Exhaust Pipe and Muffler Removal and

Installation in Section 1K”.

15) Remove suspension frame, engine front mounting

member and engine mounting member referring to

“Front Suspension Frame, Stabilizer Bar and/or

Bushing Removal and Installation in Section 2B” and

“Engine Mountings Components in Section 1D”.16) Remove transfer referring to “Transfer Dismounting

and Remounting in Section 3C”, if equipped.

17) Remove clutch housing lower plate.

18) Support transaxle with transmission jack.

19) Remove left mounting (1) and left mounting bracket

(2).

20) Remove stiffener bolts (2), transaxle to engine bolts

(1) and nut of lower side, and then lower transaxle.

Remounting

CAUTION!

• Care should be taken not to scratch oil

seal lip with drive shaft while raising

transaxle.

• Do not hit drive shaft joint with hammer

when installing it into differential gear.

Reverse dismounting procedure for remounting of

transaxle, noting the following points.

• Tighten each bolts and nuts to specified torque

referring to “Manual Transaxle Unit Components” and

“Engine Mountings Components in Section 1D”.

• Set each clamp for wiring securely.

• Fill transaxle oil and transfer oil referring to “Manual

Transaxle Oil Change” and “Transfer Oil Change in

Section 3C”.

• Connect battery and check function of engine, clutch

and transaxle.

1

I5RW0A520011-01

1

I5RW0A520012-01

1

2

I5RW0A520013-01

1

2I5RW0A520014-01

Page 871 of 1556

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-2

Diagnostic Information and Procedures

Checking Steering Column for Accident

Damage

S6RW0D6204001

NOTE

Vehicles involved in accidents resulting in

body damage, where steering column has

been impacted or air bag deployed may have

a damaged or misaligned steering column.

• Check that two capsules (1) are attached to steering

column bracket securely. If found loose, replace

steering column assembly.

• Take measurement “a”, “b” and “c” as follows.

If it is shorter than specified length, replace steering

column assembly or steering lower shaft with new

one.

Steering column length

“a”: 339 ± 2 mm (13.3 ± 0.08 in.)

“b”: 59.5 ± 2.1 mm (2.4 ± 0.08 in.)

Steering lower shaft length

“c”: 348 ± 1 mm (13.7 ± 0.04 in.)• Check that there is no axial looseness “d” and no

axially-vertical looseness “e” for steering column

shaft.

If found defective, replace steering column assembly

with new one.

• Check steering shaft joints and shaft for any damages

such as crack, breakage, malfunction or excessive

play.

If anything is found faulty, replace as lower shaft

assembly or steering column assembly.

• Check steering shaft for smooth rotation.

If found defective, replace as steering column

assembly.

• Check steering shaft and steering column for bend,

cracks or deformation.

If found defective, replace.

1

1

I4RS0A620001-01

“a”

“d”

“e”“b”

“c”

I7RW01620002-01

I4RS0A620003-01

Page 876 of 1556

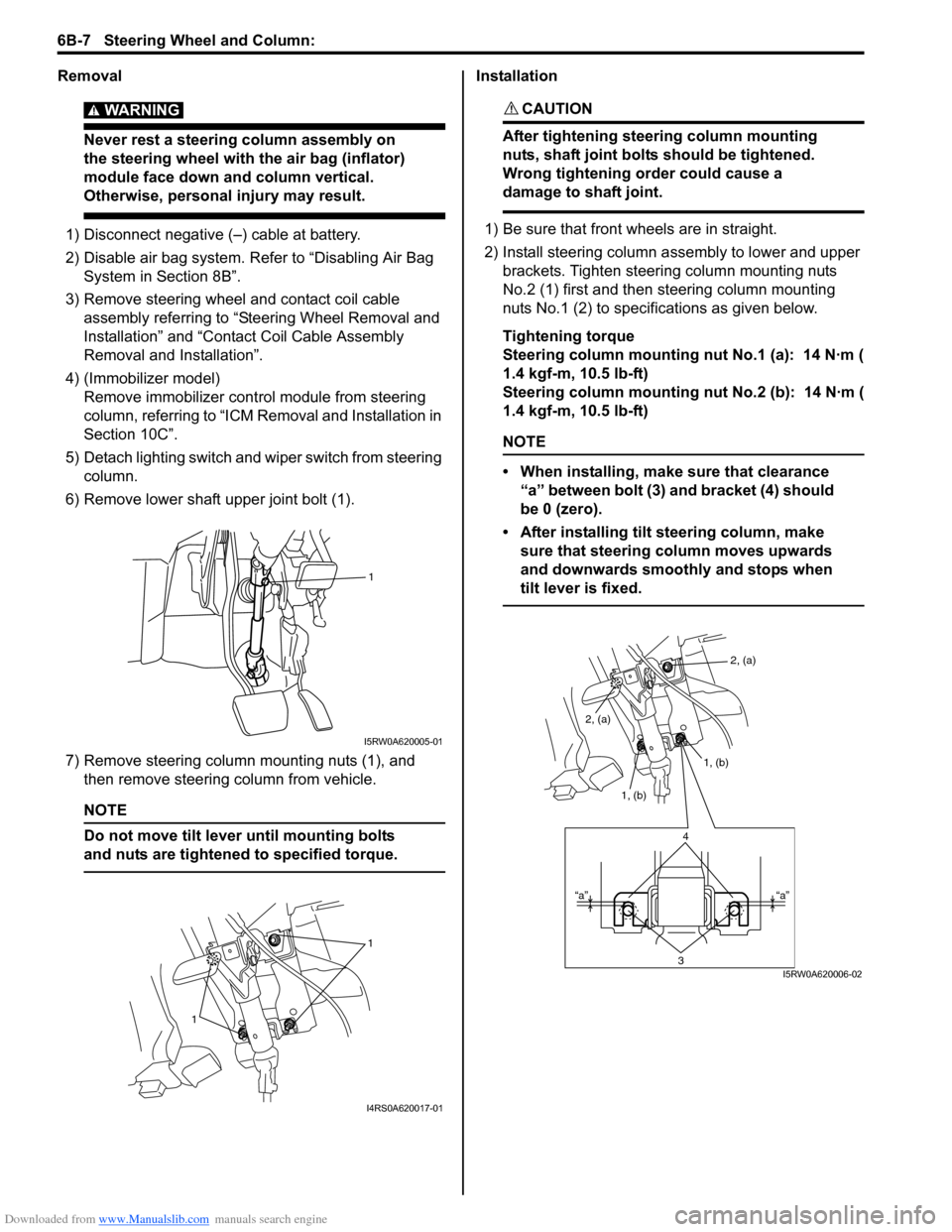

Downloaded from www.Manualslib.com manuals search engine 6B-7 Steering Wheel and Column:

Removal

WARNING!

Never rest a steering column assembly on

the steering wheel with the air bag (inflator)

module face down and column vertical.

Otherwise, personal injury may result.

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Refer to “Disabling Air Bag

System in Section 8B”.

3) Remove steering wheel and contact coil cable

assembly referring to “Steering Wheel Removal and

Installation” and “Contact Coil Cable Assembly

Removal and Installation”.

4) (Immobilizer model)

Remove immobilizer control module from steering

column, referring to “ICM Removal and Installation in

Section 10C”.

5) Detach lighting switch and wiper switch from steering

column.

6) Remove lower shaft upper joint bolt (1).

7) Remove steering column mounting nuts (1), and

then remove steering column from vehicle.

NOTE

Do not move tilt lever until mounting bolts

and nuts are tightened to specified torque.

Installation

CAUTION!

After tightening steering column mounting

nuts, shaft joint bolts should be tightened.

Wrong tightening order could cause a

damage to shaft joint.

1) Be sure that front wheels are in straight.

2) Install steering column assembly to lower and upper

brackets. Tighten steering column mounting nuts

No.2 (1) first and then steering column mounting

nuts No.1 (2) to specifications as given below.

Tightening torque

Steering column mounting nut No.1 (a): 14 N·m (

1.4 kgf-m, 10.5 lb-ft)

Steering column mounting nut No.2 (b): 14 N·m (

1.4 kgf-m, 10.5 lb-ft)

NOTE

• When installing, make sure that clearance

“a” between bolt (3) and bracket (4) should

be 0 (zero).

• After installing tilt steering column, make

sure that steering column moves upwards

and downwards smoothly and stops when

tilt lever is fixed.

1

I5RW0A620005-01

1

1

I4RS0A620017-01

2, (a)

1, (b)

1, (b) 2, (a)

4

3“a” “a”

I5RW0A620006-02

Page 918 of 1556

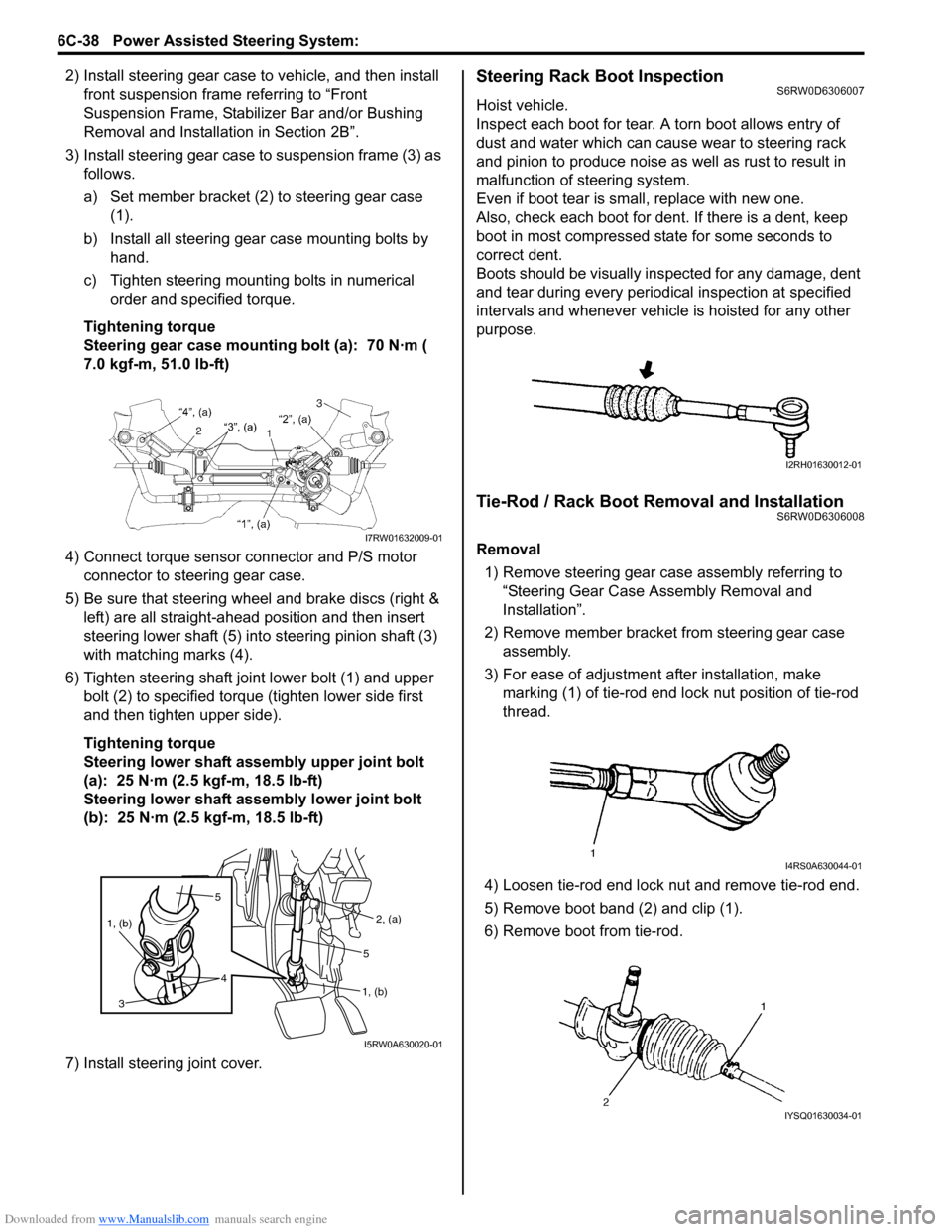

Downloaded from www.Manualslib.com manuals search engine 6C-38 Power Assisted Steering System:

2) Install steering gear case to vehicle, and then install

front suspension frame referring to “Front

Suspension Frame, Stabilizer Bar and/or Bushing

Removal and Installation in Section 2B”.

3) Install steering gear case to suspension frame (3) as

follows.

a) Set member bracket (2) to steering gear case

(1).

b) Install all steering gear case mounting bolts by

hand.

c) Tighten steering mounting bolts in numerical

order and specified torque.

Tightening torque

Steering gear case mounting bolt (a): 70 N·m (

7.0 kgf-m, 51.0 lb-ft)

4) Connect torque sensor connector and P/S motor

connector to steering gear case.

5) Be sure that steering wheel and brake discs (right &

left) are all straight-ahead position and then insert

steering lower shaft (5) into steering pinion shaft (3)

with matching marks (4).

6) Tighten steering shaft joint lower bolt (1) and upper

bolt (2) to specified torque (tighten lower side first

and then tighten upper side).

Tightening torque

Steering lower shaft assembly upper joint bolt

(a): 25 N·m (2.5 kgf-m, 18.5 lb-ft)

Steering lower shaft assembly lower joint bolt

(b): 25 N·m (2.5 kgf-m, 18.5 lb-ft)

7) Install steering joint cover.Steering Rack Boot InspectionS6RW0D6306007

Hoist vehicle.

Inspect each boot for tear. A torn boot allows entry of

dust and water which can cause wear to steering rack

and pinion to produce noise as well as rust to result in

malfunction of steering system.

Even if boot tear is small, replace with new one.

Also, check each boot for dent. If there is a dent, keep

boot in most compressed state for some seconds to

correct dent.

Boots should be visually inspected for any damage, dent

and tear during every periodical inspection at specified

intervals and whenever vehicle is hoisted for any other

purpose.

Tie-Rod / Rack Boot Removal and InstallationS6RW0D6306008

Removal

1) Remove steering gear case assembly referring to

“Steering Gear Case Assembly Removal and

Installation”.

2) Remove member bracket from steering gear case

assembly.

3) For ease of adjustment after installation, make

marking (1) of tie-rod end lock nut position of tie-rod

thread.

4) Loosen tie-rod end lock nut and remove tie-rod end.

5) Remove boot band (2) and clip (1).

6) Remove boot from tie-rod.I7RW01632009-01

5

4 1, (b)

3

2, (a)

1, (b)5

I5RW0A630020-01

I2RH01630012-01

I4RS0A630044-01

IYSQ01630034-01

Page 956 of 1556

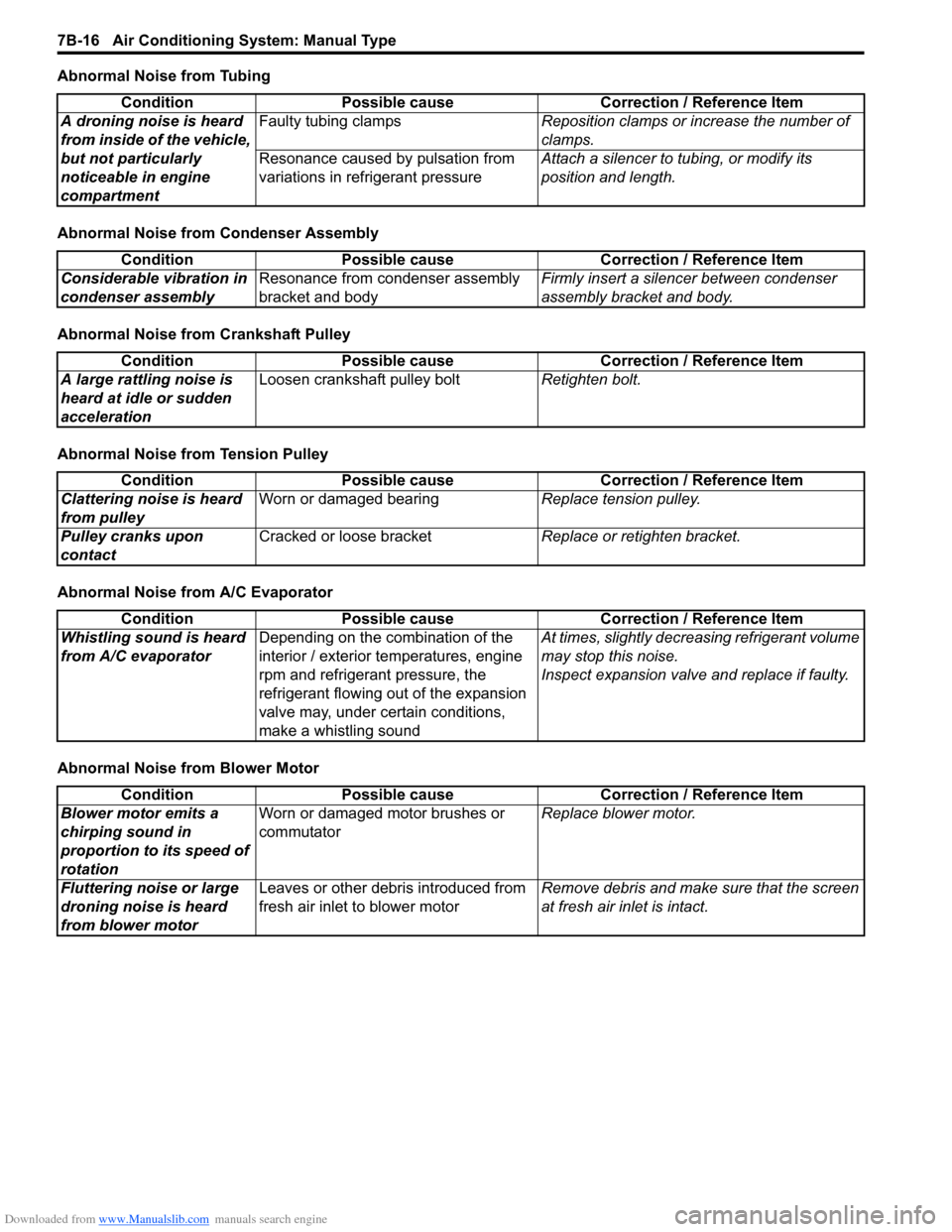

Downloaded from www.Manualslib.com manuals search engine 7B-16 Air Conditioning System: Manual Type

Abnormal Noise from Tubing

Abnormal Noise from Condenser Assembly

Abnormal Noise from Crankshaft Pulley

Abnormal Noise from Tension Pulley

Abnormal Noise from A/C Evaporator

Abnormal Noise from Blower MotorCondition Possible cause Correction / Reference Item

A droning noise is heard

from inside of the vehicle,

but not particularly

noticeable in engine

compartmentFaulty tubing clampsReposition clamps or increase the number of

clamps.

Resonance caused by pulsation from

variations in refrigerant pressureAttach a silencer to tubing, or modify its

position and length.

Condition Possible cause Correction / Reference Item

Considerable vibration in

condenser assemblyResonance from condenser assembly

bracket and bodyFirmly insert a silencer between condenser

assembly bracket and body.

Condition Possible cause Correction / Reference Item

A large rattling noise is

heard at idle or sudden

accelerationLoosen crankshaft pulley boltRetighten bolt.

Condition Possible cause Correction / Reference Item

Clattering noise is heard

from pulleyWorn or damaged bearingReplace tension pulley.

Pulley cranks upon

contactCracked or loose bracketReplace or retighten bracket.

Condition Possible cause Correction / Reference Item

Whistling sound is heard

from A/C evaporatorDepending on the combination of the

interior / exterior temperatures, engine

rpm and refrigerant pressure, the

refrigerant flowing out of the expansion

valve may, under certain conditions,

make a whistling soundAt times, slightly decreasing refrigerant volume

may stop this noise.

Inspect expansion valve and replace if faulty.

Condition Possible cause Correction / Reference Item

Blower motor emits a

chirping sound in

proportion to its speed of

rotationWorn or damaged motor brushes or

commutatorReplace blower motor.

Fluttering noise or large

droning noise is heard

from blower motorLeaves or other debris introduced from

fresh air inlet to blower motorRemove debris and make sure that the screen

at fresh air inlet is intact.

Page 1133 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-94

5) Install driver and passenger side front pillar lower

trim.

6) Side-air bag (inflator) model:

Connect yellow connector (1) of side-air bag

(inflator) module by pushing connector till click is

heard from it.

7) Side curtain-air bag (inflator) model:

Connect yellow connector (1) of side curtain-air bag

(inflator) module by pushing connector till click is

heard from it.

8) Install right-side rear quarter lower trim.

9) Install “A/B” fuse to fuse box.

10) Connect negative (–) cable at battery.

11) Turn ignition switch to ON position and verify that

“AIR BAG” warning light flashes 6 times and then

turns OFF. If it does not operate as described,

perform “Air Bag Diagnostic System Check”.

SDM Removal and InstallationS6RW0D8206003

WARNING!

During service procedures, be very careful

when handling a Sensing and Diagnostic

Module (SDM).

Be sure to read “Precautions on Service and

Diagnosis of Air Bag System” before starting

to work and observe every precaution during

work. Neglecting them may result in personal

injury or inactivation of the air bag system

when necessary.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air

Bag System”.

3) Remove console box referring to “Console Box

Components in Section 9H”.

4) Remove G sensor referring to “G Sensor Removal

and Installation (4WD Model) in Section 4E” and its

bracket (1).

5) Disconnect SDM connector (1) from SDM (2).

6) Remove SDM (2) from vehicle.

1

I5JB0A820070-01

1

I5RW0A820063-01

2. SDM

A: Forward

1

2

I5RW0A820064-01

2

1

A

I4RS0A820056-01

Page 1144 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-105 Air Bag System:

Side Impact-Sensor Removal and InstallationS6RW0D8206024

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor bolt must be carefully torqued to

assure proper operation. Under loose

connection, it could cause improper

operation of the air bag system.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Refer to “Disabling Air Bag

System”.

3) Remove center pillar lower trim.

4) Turn up floor carpet at front seat side.

5) Disconnect side impact-sensor connector (1) sliding

connector outer (2) as shown.

6) Remove side impact-sensor bolts (3), and side

impact-sensor (4) from side sill inner panel (5).

Installation

CAUTION!

Proper operation of side impact-sensor

requires that sensor is rigidly attached to

specified position.

1) Check that none of following faulty conditions exists.

• Bend, deformity or rust of under body.

• Foreign matter on mating surface of sensor.2) Install side impact-sensor (1) to side sill inner panel

(2) and tighten side impact-sensor bolt (3) to

specified torque.

Tightening torque

Side impact-sensor bolt (a): 9 N·m (0.9 kgf-m,

6.5 lb-ft)

3) Connect side impact-sensor connector (4) by

pushing connector till click is heard from it.

4) Return the carpet, and install center pillar lower trim.

5) Enable air bag system. Refer to “Enabling Air Bag

System”.

6) Connect negative (–) cable at battery.

Side Impact-Sensor InspectionS6RW0D8206025

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor and mounting bracket bolts must

be carefully torqued to assure proper

operation. Under loose connection, it

could cause improper operation of the air

bag system.

CAUTION!

• Never disassemble side impact-sensor.

• Sensor should be replaced when it was

dropped from a height of 90 cm (3 ft) or

more.

• Check sensor for dents, crack, deformation.

• Check sensor connector (sensor side and harness

side), lock mechanism or sensor lead wire for

damage, crack, scorching or melting.

• Check connector terminals for bent, corrosion or rust.

If any faulty condition is found in above checks,

replace.

5

4

3

2

1I7RW01822149-01

2

1

3, (a)

4I7RW01822150-01

Page 1348 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-29 Lighting Systems:

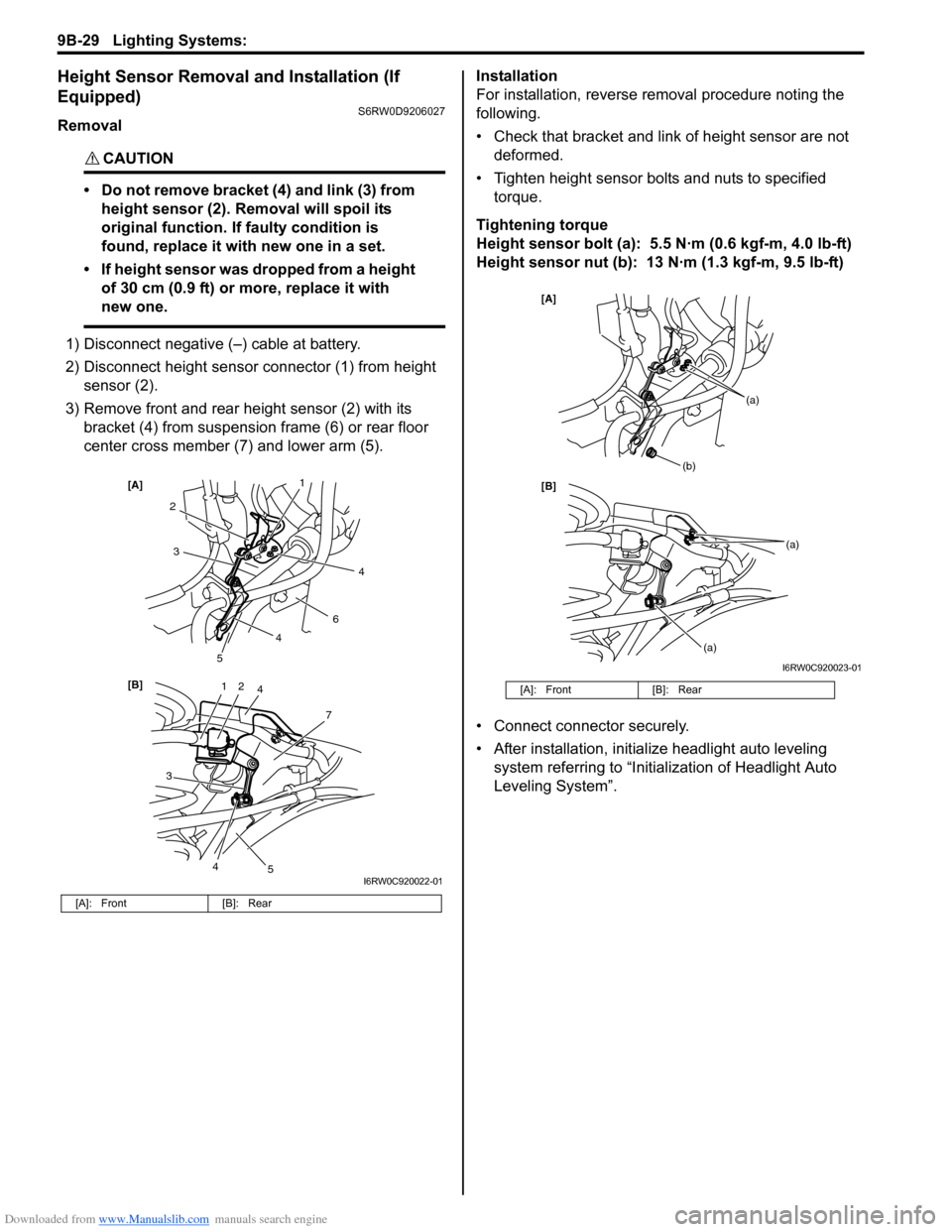

Height Sensor Removal and Installation (If

Equipped)

S6RW0D9206027

Removal

CAUTION!

• Do not remove bracket (4) and link (3) from

height sensor (2). Removal will spoil its

original function. If faulty condition is

found, replace it with new one in a set.

• If height sensor was dropped from a height

of 30 cm (0.9 ft) or more, replace it with

new one.

1) Disconnect negative (–) cable at battery.

2) Disconnect height sensor connector (1) from height

sensor (2).

3) Remove front and rear height sensor (2) with its

bracket (4) from suspension frame (6) or rear floor

center cross member (7) and lower arm (5).Installation

For installation, reverse removal procedure noting the

following.

• Check that bracket and link of height sensor are not

deformed.

• Tighten height sensor bolts and nuts to specified

torque.

Tightening torque

Height sensor bolt (a): 5.5 N·m (0.6 kgf-m, 4.0 lb-ft)

Height sensor nut (b): 13 N·m (1.3 kgf-m, 9.5 lb-ft)

• Connect connector securely.

• After installation, initialize headlight auto leveling

system referring to “Initialization of Headlight Auto

Leveling System”.

[A]: Front [B]: Rear

12

7

[B] [A]

4

3

2

6

3

5

5

1

4

4

4

I6RW0C920022-01

[A]: Front [B]: Rear

[B] [A]

(b)

(a)

(a)

(a)

I6RW0C920023-01

Page 1349 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-30

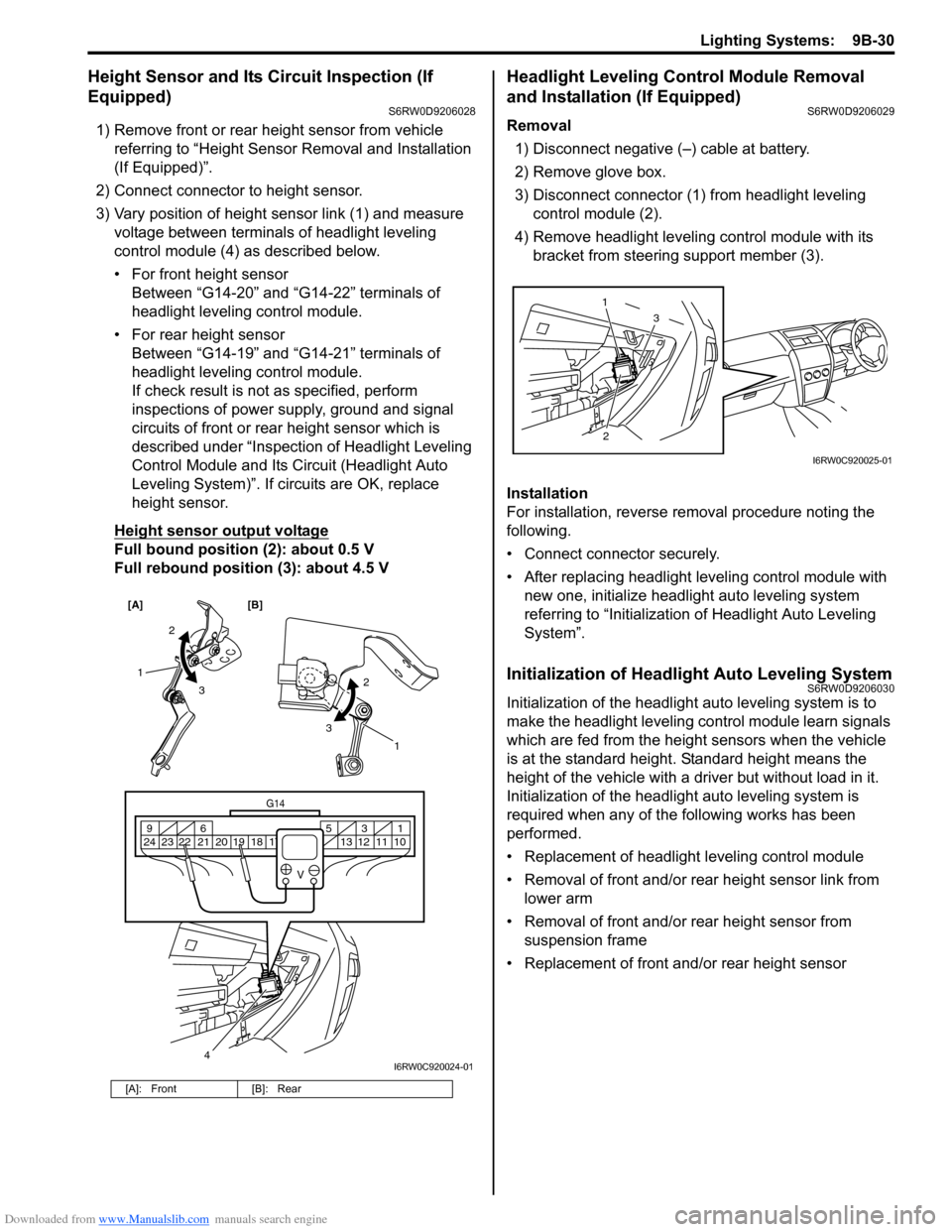

Height Sensor and Its Circuit Inspection (If

Equipped)

S6RW0D9206028

1) Remove front or rear height sensor from vehicle

referring to “Height Sensor Removal and Installation

(If Equipped)”.

2) Connect connector to height sensor.

3) Vary position of height sensor link (1) and measure

voltage between terminals of headlight leveling

control module (4) as described below.

• For front height sensor

Between “G14-20” and “G14-22” terminals of

headlight leveling control module.

• For rear height sensor

Between “G14-19” and “G14-21” terminals of

headlight leveling control module.

If check result is not as specified, perform

inspections of power supply, ground and signal

circuits of front or rear height sensor which is

described under “Inspection of Headlight Leveling

Control Module and Its Circuit (Headlight Auto

Leveling System)”. If circuits are OK, replace

height sensor.

Height sensor output voltage

Full bound position (2): about 0.5 V

Full rebound position (3): about 4.5 V

Headlight Leveling Control Module Removal

and Installation (If Equipped)

S6RW0D9206029

Removal

1) Disconnect negative (–) cable at battery.

2) Remove glove box.

3) Disconnect connector (1) from headlight leveling

control module (2).

4) Remove headlight leveling control module with its

bracket from steering support member (3).

Installation

For installation, reverse removal procedure noting the

following.

• Connect connector securely.

• After replacing headlight leveling control module with

new one, initialize headlight auto leveling system

referring to “Initialization of Headlight Auto Leveling

System”.

Initialization of Headlight Auto Leveling SystemS6RW0D9206030

Initialization of the headlight auto leveling system is to

make the headlight leveling control module learn signals

which are fed from the height sensors when the vehicle

is at the standard height. Standard height means the

height of the vehicle with a driver but without load in it.

Initialization of the headlight auto leveling system is

required when any of the following works has been

performed.

• Replacement of headlight leveling control module

• Removal of front and/or rear height sensor link from

lower arm

• Removal of front and/or rear height sensor from

suspension frame

• Replacement of front and/or rear height sensor

[A]: Front [B]: Rear

[A] [B]

4

G14

10 11 12 13 16 17 18 19 2031 5 6 9

21 22 23 24

V

2

3 1

2

3

1

I6RW0C920024-01

23 1

I6RW0C920025-01