Service wire SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1043 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-4

• Never attempt to disassemble the seat belt

pretensioners (retractor assembly).

• If any abnormality is found, be sure to replace it with

new one as an assembly.

• When an abnormality is noted as existing in the live

(inactivated) seat belt pretensioner, be sure to activate

it before discarding it.

• When grease, cleaning agent oil, water, etc., got on

the seat belt pretensioners (retractor assembly), wipe

it off immediately with a dry cloth.

• If seat belt pretensioner was dropped from a height of

30 cm (1 ft) or more, it should be replaced with a new

one as an assembly.

WARNING!

• For handling and storage of a live seat belt

pretensioner, select a place where the

ambient temperature below 65 °C (150 °F),

without high humidity and away from

electric noise.

• Never carry the seat belt pretensioner by

webbing.

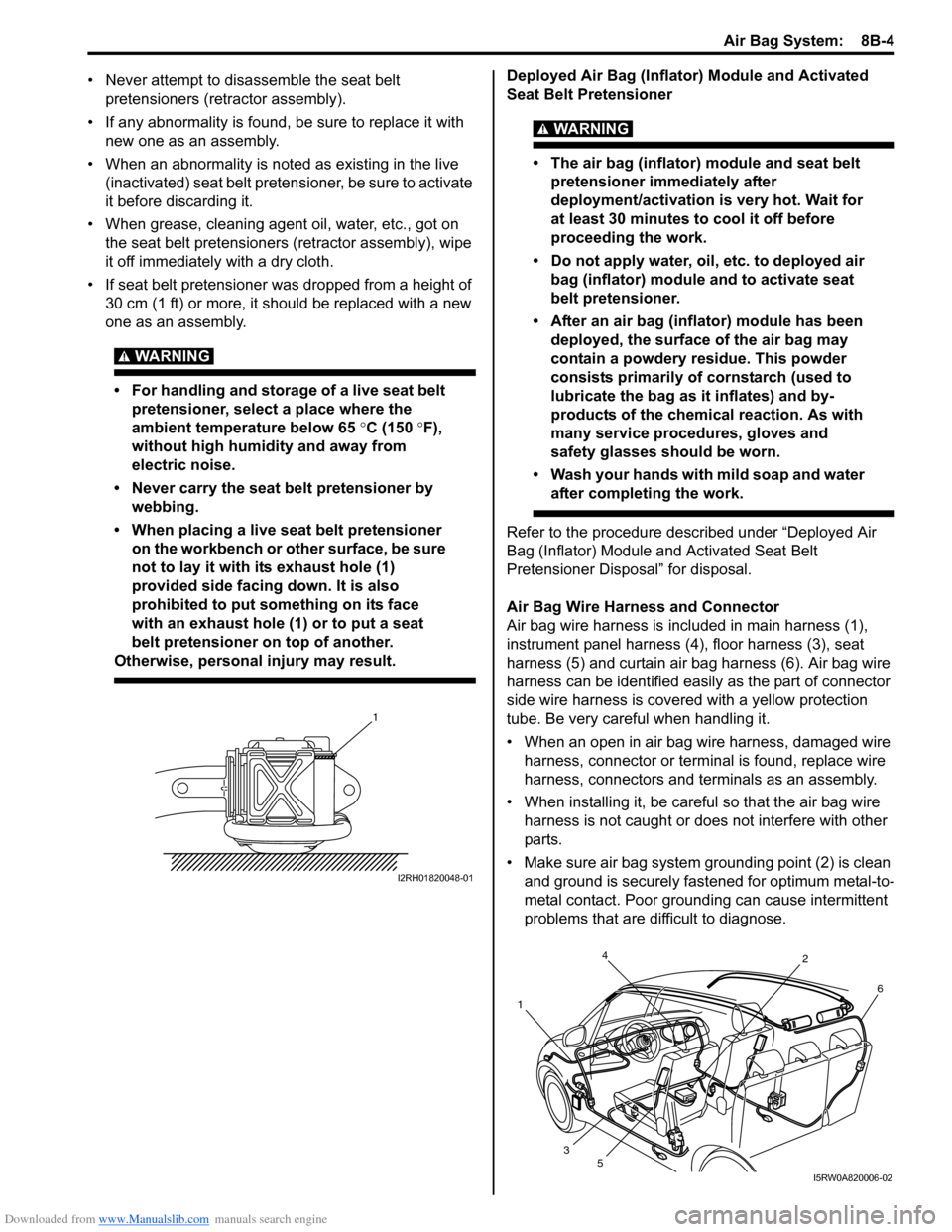

• When placing a live seat belt pretensioner

on the workbench or other surface, be sure

not to lay it with its exhaust hole (1)

provided side facing down. It is also

prohibited to put something on its face

with an exhaust hole (1) or to put a seat

belt pretensioner on top of another.

Otherwise, personal injury may result.

Deployed Air Bag (Inflator) Module and Activated

Seat Belt Pretensioner

WARNING!

• The air bag (inflator) module and seat belt

pretensioner immediately after

deployment/activation is very hot. Wait for

at least 30 minutes to cool it off before

proceeding the work.

• Do not apply water, oil, etc. to deployed air

bag (inflator) module and to activate seat

belt pretensioner.

• After an air bag (inflator) module has been

deployed, the surface of the air bag may

contain a powdery residue. This powder

consists primarily of cornstarch (used to

lubricate the bag as it inflates) and by-

products of the chemical reaction. As with

many service procedures, gloves and

safety glasses should be worn.

• Wash your hands with mild soap and water

after completing the work.

Refer to the procedure described under “Deployed Air

Bag (Inflator) Module and Activated Seat Belt

Pretensioner Disposal” for disposal.

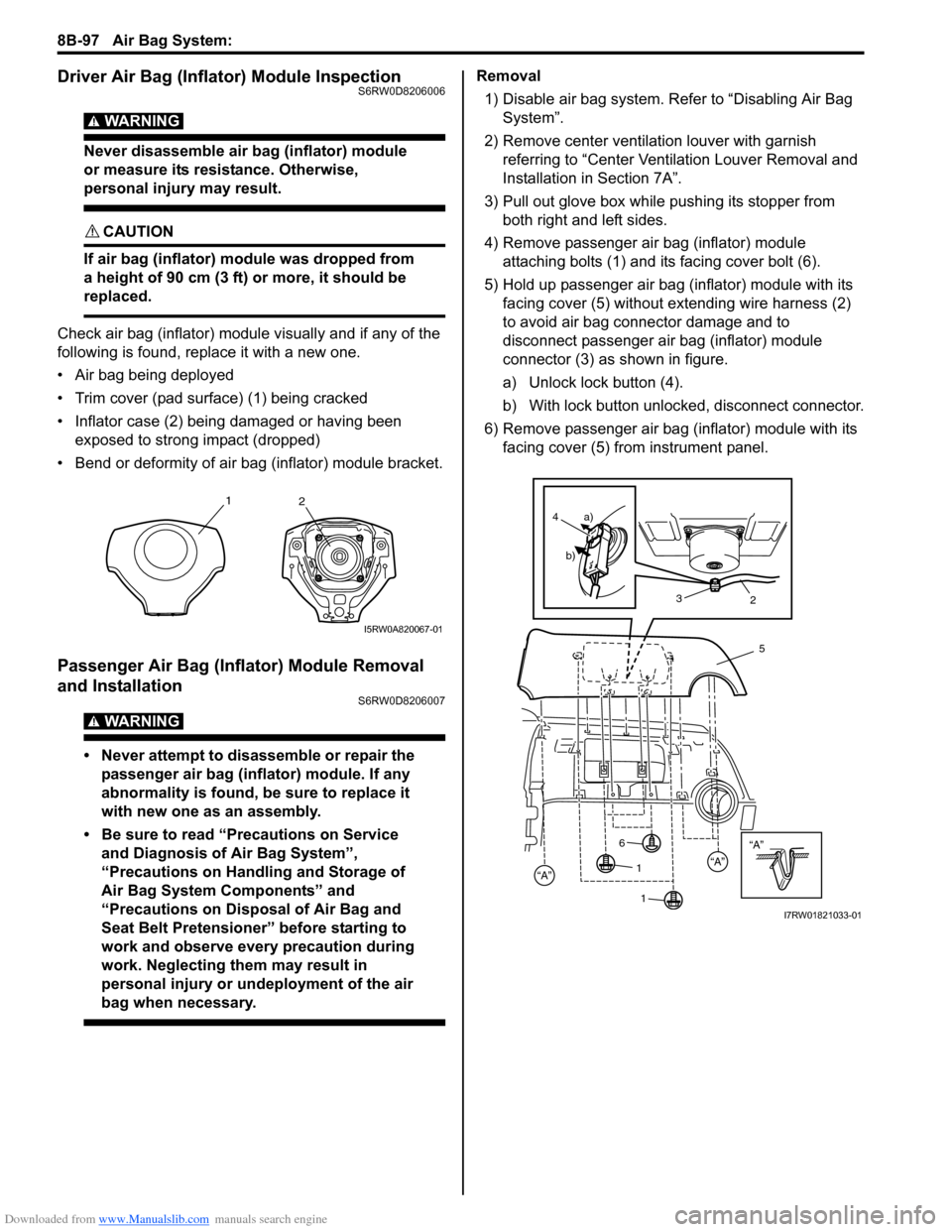

Air Bag Wire Harness and Connector

Air bag wire harness is included in main harness (1),

instrument panel harness (4), floor harness (3), seat

harness (5) and curtain air bag harness (6). Air bag wire

harness can be identified easily as the part of connector

side wire harness is covered with a yellow protection

tube. Be very careful when handling it.

• When an open in air bag wire harness, damaged wire

harness, connector or terminal is found, replace wire

harness, connectors and terminals as an assembly.

• When installing it, be careful so that the air bag wire

harness is not caught or does not interfere with other

parts.

• Make sure air bag system grounding point (2) is clean

and ground is securely fastened for optimum metal-to-

metal contact. Poor grounding can cause intermittent

problems that are difficult to diagnose.

1

I2RH01820048-01

4

12

6

3

5

I5RW0A820006-02

Page 1129 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-90

• Improperly formed or damaged terminals.

Check each connector terminal in problem circuits

carefully to ensure good contact tension by using the

corresponding mating terminal included in the

connector test adapter kit (special tool).

If contact tension is not enough, reform the terminal to

increase contact tension or replace it.

Special tool

(A): 09932–76010 Connector test adapter kit

• Poor terminal-to-wire connection.

Check each wire harness in problem circuits for poor

connection by shaking it by hand lightly. If any

abnormal condition is found, change the wire harness

assembly or component parts with new ones.

• Wire insulation which is rubbed through, causing an

intermittent short as the bare area touches other

wiring or parts of the vehicle.

• Wire broken inside the insulation. This condition could

cause a continuity check to show a good circuit, but if

only 1 or 2 strands of a multi-strand-type wire are

intact, resistance could be far too high.

Repair and Inspection Required after AccidentS6RW0D8204048

CAUTION!

• All air bag system components, including

the electrical harness (component

mounting points), must be inspected after

an accident. If any components are

damaged or bent, they must be replaced

even if air bag system activation did not

occur.

• Never use air bag system parts from

another vehicle.

• Do not attempt to service the parts below.

Service of these parts is by replacement

only.

– Driver / Passenger air bag (inflator)

modules

– Driver / Passenger side-air bag (inflator)

modules

– Driver / Passenger side curtain-air bag

(inflator) modules

– Driver / Passenger seat belt

pretensioners

– Forward impact-sensor

– Driver / Passenger side impact-sensors

–SDM

– Contact coil and combination switch

assembly

– Air bag wire harness in main harness,

instrument panel harness, floor harness,

passenger air bag harness, side-air bag

harness and side curtain-air bag

harness.

• Proper operation of the sensors and air

bag system requires that any repairs to the

vehicle structure return it to its original

production configuration.

(A)

I4RS0A820045-01

IYSQ01010028-01

IYSQ01820025-01

Page 1136 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-97 Air Bag System:

Driver Air Bag (Inflator) Module InspectionS6RW0D8206006

WARNING!

Never disassemble air bag (inflator) module

or measure its resistance. Otherwise,

personal injury may result.

CAUTION!

If air bag (inflator) module was dropped from

a height of 90 cm (3 ft) or more, it should be

replaced.

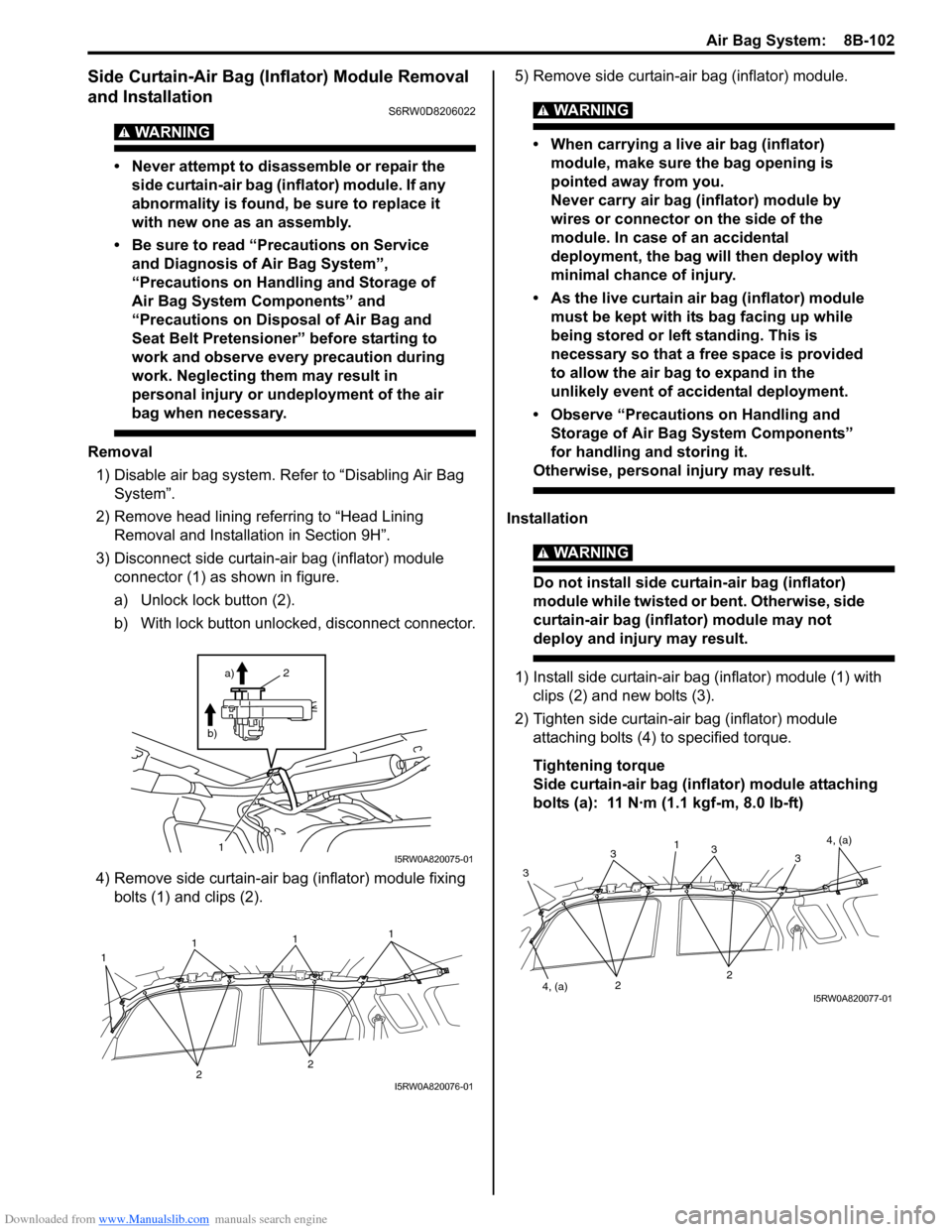

Check air bag (inflator) module visually and if any of the

following is found, replace it with a new one.

• Air bag being deployed

• Trim cover (pad surface) (1) being cracked

• Inflator case (2) being damaged or having been

exposed to strong impact (dropped)

• Bend or deformity of air bag (inflator) module bracket.

Passenger Air Bag (Inflator) Module Removal

and Installation

S6RW0D8206007

WARNING!

• Never attempt to disassemble or repair the

passenger air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service

and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

Removal

1) Disable air bag system. Refer to “Disabling Air Bag

System”.

2) Remove center ventilation louver with garnish

referring to “Center Ventilation Louver Removal and

Installation in Section 7A”.

3) Pull out glove box while pushing its stopper from

both right and left sides.

4) Remove passenger air bag (inflator) module

attaching bolts (1) and its facing cover bolt (6).

5) Hold up passenger air bag (inflator) module with its

facing cover (5) without extending wire harness (2)

to avoid air bag connector damage and to

disconnect passenger air bag (inflator) module

connector (3) as shown in figure.

a) Unlock lock button (4).

b) With lock button unlocked, disconnect connector.

6) Remove passenger air bag (inflator) module with its

facing cover (5) from instrument panel.

1

2

I5RW0A820067-01

“A”

5

“A”“A”

3

4a)

b)

2

6

1 1

I7RW01821033-01

Page 1138 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-99 Air Bag System:

Passenger Air Bag (Inflator) Module InspectionS6RW0D8206008

WARNING!

• Never measure resistance of passenger air

bag (inflator) module or disassemble it.

Otherwise personal injury may result.

• Never attempt to disassemble or repair the

passenger air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service

and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

CAUTION!

If air bag (Inflator) module was dropped from

a height of 90 cm (3 ft) or more, it should be

replaced.

Check air bag (inflator) module appearance visually for

the following symptoms and if any one of them is found,

replace with a new one.

• Air bag has deployed.

• Wire harness or connector is damaged.

• Air bag (inflator) module is damaged or a strong

impact was applied to it.

• Bend or deformity of air bag (inflator) module bracket.

Side-Air Bag (Inflator) Module Removal and

Installation

S6RW0D8206020

WARNING!

• Never attempt to disassemble or repair the

side-air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service

and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

I5RW0A820072-03

1. Side-air bag (inflator) module 6. Sleeve

2. Seat back frame bracket 7. Sleeve lock nut

3. Side-air bag (inflator) module

connector8. Fastener

4. Seat back : 2.5 N⋅m (0.25 kgf-m, 2.0

lb-ft)

5. Air bag harness in floor harness : Do not reuse.

12

3

4

5

(a)7 6

8

2

1

I7RW01822144-01

Page 1140 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-101 Air Bag System:

2) Install new sleeve (1) and sleeve lock nut (2) to side-

air bag (inflator) module, then tighten nut to specified

torque.

Tightening torque

Sleeve lock nut (a): 2.5 N·m (0.25 kgf-m, 2.0 lb-

ft)

3) Connect side-air bag (inflator) module connector (1)

securely as shown in the figure.

a) Connect connector.

b) Lock connector with lock button (2).

4) Insert claw (1) of side-air bag (inflator) module on

installation hole (2).

5) Install side-air bag (inflator) module by pushing it into

fastener (3) securely.

6) Roll down backside seat back surface and fix seat

back surface fastener securely.Side-Air Bag (Inflator) InspectionS6RW0D8206021

WARNING!

• Never attempt to disassemble or repair the

side-air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service

and Diagnosis of Air Bag System” before

starting to work and observe every

precaution during work. Neglecting them

may result in personal injury or

undeployment of the air bag when

necessary.

CAUTION!

If air bag (inflator) module was dropped from

a height of 90 cm (3 ft) or more, it should be

replaced.

Check air bag (inflator) module appearance visually for

the following symptoms and if any one of them is found,

replace with a new one.

• Air bag has deployed.

• There is a crack in trim cover (pad surface).

• Wire harness or connector is damaged.

• Air bag (inflator) module is damaged or a strong

impact was applied to it.

• Bend or deformity of air bag (inflator) module bracket.

12, (a)

I4RS0A820073-02

1

2

a) b)

I4RS0A820070-01

1

2

3

I4RS0A820074-02

I4RS0A820075-02

Page 1141 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-102

Side Curtain-Air Bag (Inflator) Module Removal

and Installation

S6RW0D8206022

WARNING!

• Never attempt to disassemble or repair the

side curtain-air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service

and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

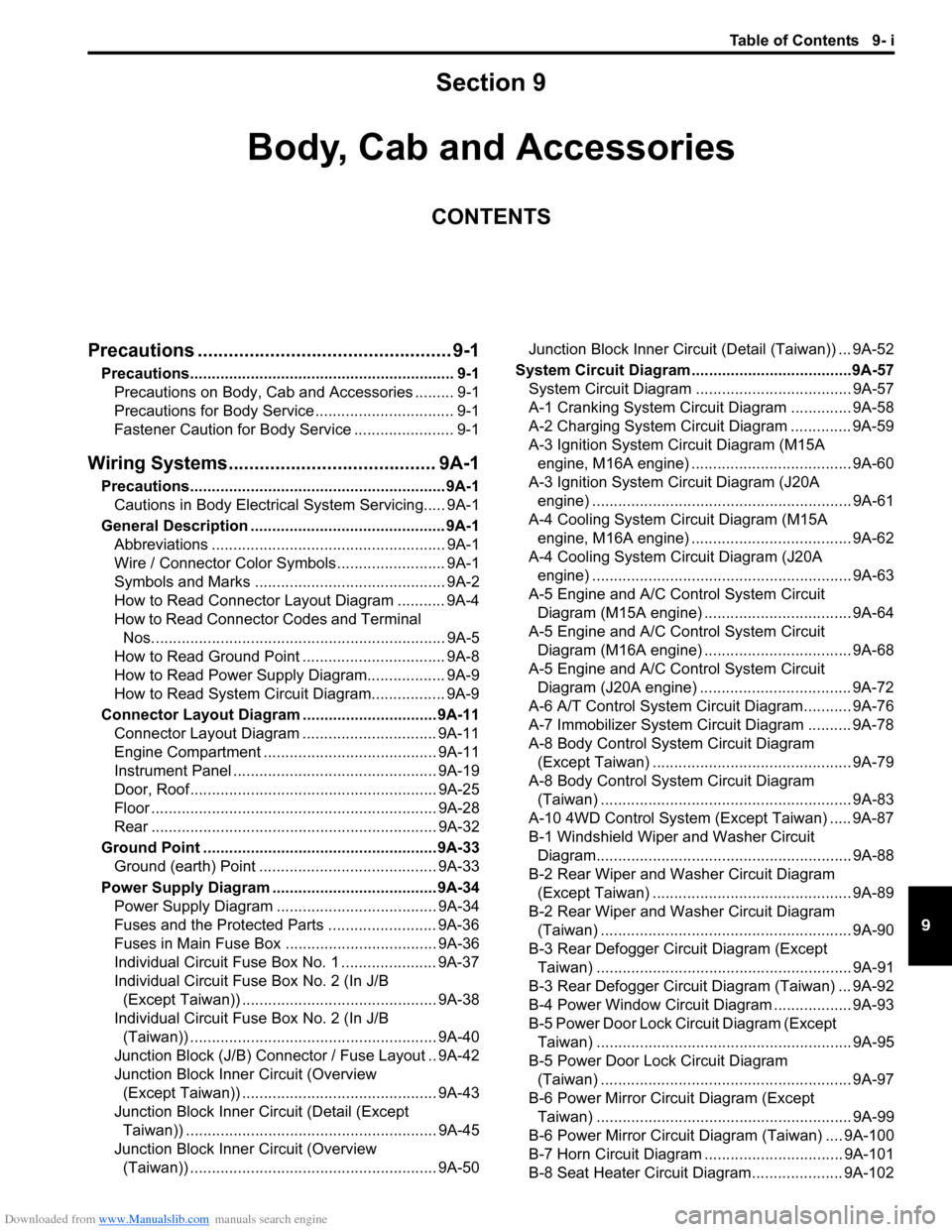

Removal

1) Disable air bag system. Refer to “Disabling Air Bag

System”.

2) Remove head lining referring to “Head Lining

Removal and Installation in Section 9H”.

3) Disconnect side curtain-air bag (inflator) module

connector (1) as shown in figure.

a) Unlock lock button (2).

b) With lock button unlocked, disconnect connector.

4) Remove side curtain-air bag (inflator) module fixing

bolts (1) and clips (2).5) Remove side curtain-air bag (inflator) module.

WARNING!

• When carrying a live air bag (inflator)

module, make sure the bag opening is

pointed away from you.

Never carry air bag (inflator) module by

wires or connector on the side of the

module. In case of an accidental

deployment, the bag will then deploy with

minimal chance of injury.

• As the live curtain air bag (inflator) module

must be kept with its bag facing up while

being stored or left standing. This is

necessary so that a free space is provided

to allow the air bag to expand in the

unlikely event of accidental deployment.

• Observe “Precautions on Handling and

Storage of Air Bag System Components”

for handling and storing it.

Otherwise, personal injury may result.

Installation

WARNING!

Do not install side curtain-air bag (inflator)

module while twisted or bent. Otherwise, side

curtain-air bag (inflator) module may not

deploy and injury may result.

1) Install side curtain-air bag (inflator) module (1) with

clips (2) and new bolts (3).

2) Tighten side curtain-air bag (inflator) module

attaching bolts (4) to specified torque.

Tightening torque

Side curtain-air bag (inflator) module attaching

bolts (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

1

2

a)

b)

I5RW0A820075-01

1111

22I5RW0A820076-01

4, (a)

333

34, (a)

1

22

I5RW0A820077-01

Page 1144 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-105 Air Bag System:

Side Impact-Sensor Removal and InstallationS6RW0D8206024

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor bolt must be carefully torqued to

assure proper operation. Under loose

connection, it could cause improper

operation of the air bag system.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Refer to “Disabling Air Bag

System”.

3) Remove center pillar lower trim.

4) Turn up floor carpet at front seat side.

5) Disconnect side impact-sensor connector (1) sliding

connector outer (2) as shown.

6) Remove side impact-sensor bolts (3), and side

impact-sensor (4) from side sill inner panel (5).

Installation

CAUTION!

Proper operation of side impact-sensor

requires that sensor is rigidly attached to

specified position.

1) Check that none of following faulty conditions exists.

• Bend, deformity or rust of under body.

• Foreign matter on mating surface of sensor.2) Install side impact-sensor (1) to side sill inner panel

(2) and tighten side impact-sensor bolt (3) to

specified torque.

Tightening torque

Side impact-sensor bolt (a): 9 N·m (0.9 kgf-m,

6.5 lb-ft)

3) Connect side impact-sensor connector (4) by

pushing connector till click is heard from it.

4) Return the carpet, and install center pillar lower trim.

5) Enable air bag system. Refer to “Enabling Air Bag

System”.

6) Connect negative (–) cable at battery.

Side Impact-Sensor InspectionS6RW0D8206025

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor and mounting bracket bolts must

be carefully torqued to assure proper

operation. Under loose connection, it

could cause improper operation of the air

bag system.

CAUTION!

• Never disassemble side impact-sensor.

• Sensor should be replaced when it was

dropped from a height of 90 cm (3 ft) or

more.

• Check sensor for dents, crack, deformation.

• Check sensor connector (sensor side and harness

side), lock mechanism or sensor lead wire for

damage, crack, scorching or melting.

• Check connector terminals for bent, corrosion or rust.

If any faulty condition is found in above checks,

replace.

5

4

3

2

1I7RW01822149-01

2

1

3, (a)

4I7RW01822150-01

Page 1161 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9- i

9

Section 9

CONTENTS

Body, Cab and Accessories

Precautions ................................................. 9-1

Precautions............................................................. 9-1

Precautions on Body, Cab and Accessories ......... 9-1

Precautions for Body Service ................................ 9-1

Fastener Caution for Body Service ....................... 9-1

Wiring Systems........................................ 9A-1

Precautions........................................................... 9A-1

Cautions in Body Electrical System Servicing..... 9A-1

General Description ............................................. 9A-1

Abbreviations ...................................................... 9A-1

Wire / Connector Color Symbols ......................... 9A-1

Symbols and Marks ............................................ 9A-2

How to Read Connector Layout Diagram ........... 9A-4

How to Read Connector Codes and Terminal

Nos.................................................................... 9A-5

How to Read Ground Point ................................. 9A-8

How to Read Power Supply Diagram.................. 9A-9

How to Read System Circuit Diagram................. 9A-9

Connector Layout Diagram ............................... 9A-11

Connector Layout Diagram ............................... 9A-11

Engine Compartment ........................................ 9A-11

Instrument Panel ............................................... 9A-19

Door, Roof......................................................... 9A-25

Floor .................................................................. 9A-28

Rear .................................................................. 9A-32

Ground Point ...................................................... 9A-33

Ground (earth) Point ......................................... 9A-33

Power Supply Diagram ...................................... 9A-34

Power Supply Diagram ..................................... 9A-34

Fuses and the Protected Parts ......................... 9A-36

Fuses in Main Fuse Box ................................... 9A-36

Individual Circuit Fuse Box No. 1 ...................... 9A-37

Individual Circuit Fuse Box No. 2 (In J/B

(Except Taiwan)) ............................................. 9A-38

Individual Circuit Fuse Box No. 2 (In J/B

(Taiwan)) ......................................................... 9A-40

Junction Block (J/B) Connector / Fuse Layout .. 9A-42

Junction Block Inner Circuit (Overview

(Except Taiwan)) ............................................. 9A-43

Junction Block Inner Circuit (Detail (Except

Taiwan)) .......................................................... 9A-45

Junction Block Inner Circuit (Overview

(Taiwan)) ......................................................... 9A-50Junction Block Inner Circuit (Detail (Taiwan)) ... 9A-52

System Circuit Diagram.....................................9A-57

System Circuit Diagram .................................... 9A-57

A-1 Cranking System Circuit Diagram .............. 9A-58

A-2 Charging System Circuit Diagram .............. 9A-59

A-3 Ignition System Circuit Diagram (M15A

engine, M16A engine) ..................................... 9A-60

A-3 Ignition System Circuit Diagram (J20A

engine) ............................................................ 9A-61

A-4 Cooling System Circuit Diagram (M15A

engine, M16A engine) ..................................... 9A-62

A-4 Cooling System Circuit Diagram (J20A

engine) ............................................................ 9A-63

A-5 Engine and A/C Control System Circuit

Diagram (M15A engine) .................................. 9A-64

A-5 Engine and A/C Control System Circuit

Diagram (M16A engine) .................................. 9A-68

A-5 Engine and A/C Control System Circuit

Diagram (J20A engine) ................................... 9A-72

A-6 A/T Control System Circuit Diagram........... 9A-76

A-7 Immobilizer System Circuit Diagram .......... 9A-78

A-8 Body Control System Circuit Diagram

(Except Taiwan) .............................................. 9A-79

A-8 Body Control System Circuit Diagram

(Taiwan) .......................................................... 9A-83

A-10 4WD Control System (Except Taiwan) ..... 9A-87

B-1 Windshield Wiper and Washer Circuit

Diagram........................................................... 9A-88

B-2 Rear Wiper and Washer Circuit Diagram

(Except Taiwan) .............................................. 9A-89

B-2 Rear Wiper and Washer Circuit Diagram

(Taiwan) .......................................................... 9A-90

B-3 Rear Defogger Circuit Diagram (Except

Taiwan) ........................................................... 9A-91

B-3 Rear Defogger Circuit Diagram (Taiwan) ... 9A-92

B-4 Power Window Circuit Diagram .................. 9A-93

B-5 Power Door Lock Circuit Diagram (Except

Taiwan) ........................................................... 9A-95

B-5 Power Door Lock Circuit Diagram

(Taiwan) .......................................................... 9A-97

B-6 Power Mirror Circuit Diagram (Except

Taiwan) ........................................................... 9A-99

B-6 Power Mirror Circuit Diagram (Taiwan) .... 9A-100

B-7 Horn Circuit Diagram ................................ 9A-101

B-8 Seat Heater Circuit Diagram..................... 9A-102

Page 1164 of 1556

Downloaded from www.Manualslib.com manuals search engine 9-iv Table of Contents

Front Speaker Removal and Installation (If

Equipped) ........................................................9C-19

Rear Speaker Removal and Installation (If

Equipped) ........................................................9C-19

GPS Antenna Removal and Installation (If

Equipped) ........................................................9C-20

Horn Removal and Installation ..........................9C-20

Horn Inspection .................................................9C-20

Horn Relay Inspection .......................................9C-20

Antenna Base Removal and Installation ...........9C-21

Remote Audio Control Switch Removal and

Installation (If Equipped) .................................9C-21

Remote Audio Control Switch Inspection (If

Equipped) ........................................................9C-22

Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped) ...........................................9C-22

Specifications .....................................................9C-22

Tightening Torque Specifications ......................9C-22

Wipers / Washers .................................... 9D-1

Diagnostic Information and Procedures ............ 9D-1

Front Wiper and Washer Symptom Diagnosis ....9D-1

Rear Wiper and Washer Symptom Diagnosis..... 9D-1

Repair Instructions ..............................................9D-2

Wipers and Washers Components .....................9D-2

Washer Tank and Washer Pump Removal

and Installation ..................................................9D-3

Washer Pump Inspection ....................................9D-3

Windshield Wiper Removal and Installation ........9D-3

Windshield Wiper Motor Inspection.....................9D-4

Rear Wiper Removal and Installation.................. 9D-6

Rear Wiper Motor Inspection ..............................9D-7

Windshield Wiper and Washer Switch

Removal and Installation ................................... 9D-8

Windshield Wiper and Washer Switch

Inspection .......................................................... 9D-8

Rear Wiper and Washer Switch Removal and

Installation .......................................................9D-10

Rear Wiper and Washer Switch Inspection.......9D-10

Rear Wiper Relay Removal and Installation .....9D-10

Rear Wiper Relay Inspection ............................9D-10

Specifications .....................................................9D-11

Tightening Torque Specifications ......................9D-11

Glass / Windows / Mirrors .......................9E-1

Precautions........................................................... 9E-1

Precautions for Power Window Service

(Pinching Prevention Function Model) .............. 9E-1

General Description ............................................. 9E-1

Rear End Door Window Defogger System

Description ........................................................ 9E-1

Schematic and Routing Diagram ........................ 9E-2

Power Window Circuit Diagram (Pinching

Prevention Function Model) .............................. 9E-2

Diagnostic Information and Procedures ............ 9E-3

Rear End door Window Defogger Symptom

Diagnosis .......................................................... 9E-3

Power Window Control System Symptom

Diagnosis .......................................................... 9E-3Inspection of Pinching Prevention Function

(Pinching Prevention Function Model) .............. 9E-4

Power Door Mirror Control System Symptom

Diagnosis .......................................................... 9E-4

Door Mirror Heater Symptom Diagnosis (If

Equipped) .......................................................... 9E-5

Repair Instructions .............................................. 9E-5

Windshield Components ..................................... 9E-5

Windshield Removal and Installation .................. 9E-6

Front Pillar Window Components...................... 9E-10

Front Pillar Window Removal and Installation... 9E-10

Rear Quarter Window Components .................. 9E-11

Rear Quarter Window Removal and

Installation ....................................................... 9E-11

Rear End Door Window Components ............... 9E-12

Rear End Door Glass Removal and

Installation ....................................................... 9E-12

Front Door Window Components ...................... 9E-13

Front Door Glass Removal and Installation ...... 9E-14

Front Door Window Regulator Removal and

Installation ....................................................... 9E-15

Front Door Window Regulator Inspection ......... 9E-15

Rear Door Window Components ...................... 9E-16

Rear Door Glass Removal and Installation ....... 9E-16

Rear Door Window Regulator Removal and

Installation ....................................................... 9E-18

Rear Door Window Regulator Inspection .......... 9E-18

Rear End Door Window Defogger Switch

Inspection ........................................................ 9E-18

Rear End Door Window Defogger Relay

Inspection ........................................................ 9E-19

Rear End Door Window Defogger Wire

Inspection ........................................................ 9E-19

Rear End Door Window Defogger Wire

Repair.............................................................. 9E-20

Power Window Main Switch Inspection ............ 9E-20

Power Window Sub Switch Inspection .............. 9E-22

Pulse Sensor and Its Circuit Inspection

(Pinching Prevention Function Model) ............ 9E-23

Power Window Main Switch Initialization

(Pinching Prevention Function Model) ............ 9E-24

Door Mirror Components................................... 9E-24

Door Mirror Removal and Installation................ 9E-25

Power Door Mirror Switch Inspection ................ 9E-25

Power Door Mirror Actuator Inspection ............. 9E-25

Door Mirror Heater Inspection (If Equipped) ..... 9E-26

Door Mirror Heater Switch Inspection (If

Equipped) ........................................................ 9E-26

Special Tools and Equipment ........................... 9E-26

Recommended Service Material ....................... 9E-26

Security and Locks...................................9F-1

General Description ............................................. 9F-1

Key Coding Construction .................................... 9F-1

Rear End Door Opener System Description ....... 9F-1

Component Location ........................................... 9F-2

Power Door Lock and Keyless Entry System

Component Location (If Equipped) ................... 9F-2

Diagnostic Information and Procedures ............ 9F-3

Page 1165 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9-v

Power Door Lock System Symptom

Diagnosis (If Equipped)..................................... 9F-3

Power Door Lock System Operation

Inspection (If Equipped) .................................... 9F-3

Keyless Entry System Symptom Diagnosis (If

Equipped).......................................................... 9F-4

Keyless Entry System Operation Inspection

(If Equipped) ..................................................... 9F-5

Door Lock Function of Keyless Start System

Symptom Diagnosis (If Equipped) .................... 9F-5

Rear End Door Opener System Symptom

Diagnosis (If Equipped)..................................... 9F-5

Rear End Door Opener System Operation

Inspection (If Equipped) .................................... 9F-5

Repair Instructions .............................................. 9F-6

Front Door Lock Assembly Components ............ 9F-6

Front Door Lock Assembly Removal and

Installation ......................................................... 9F-6

Front Door Lock Assembly Inspection ................ 9F-8

Power Door Lock Switch Inspection (If

Equipped).......................................................... 9F-8

Door Key Cylinder Switch Inspection (If

Equipped).......................................................... 9F-8

Power Door Lock Actuator Inspection (If

Equipped).......................................................... 9F-9

Rear Door Lock Assembly Components ........... 9F-10

Rear Door Lock Assembly Removal and

Installation ....................................................... 9F-10

Rear Door Lock Assembly Inspection ............... 9F-10

Rear End Door Lock Assembly Components.... 9F-11

Rear End Door Lock Assembly Removal and

Installation ....................................................... 9F-12

Rear End Door Lock Assembly Inspection........ 9F-12

Rear End Door Opener Switch Inspection (If

Equipped)........................................................ 9F-12

Replacement of Transmitter Battery (Other

than Keyless Start Model) ............................... 9F-13

Programming Transmitter Code for Keyless

Entry System (Other than Keyless Start

Model) ............................................................. 9F-13

Keyless Entry Answer Back Function

Change-over Procedure (If Equipped) ............ 9F-14

Keyless Entry Receiver Removal and

Installation (If Equipped)................................. 9F-14

Keyless Entry Receiver and Its Circuit

Inspection (If Equipped) .................................. 9F-15

Specifications..................................................... 9F-16

Tightening Torque Specifications ...................... 9F-16

Special Tools and Equipment ........................... 9F-16

Recommended Service Material ....................... 9F-16

Seats ......................................................... 9G-1

Diagnostic Information and Procedures ............9G-1

Front Seat Heater Symptom Diagnosis (If

Equipped)..........................................................9G-1

Repair Instructions ..............................................9G-2

Front Seat Components ......................................9G-2

Front Seat Removal and Installation ...................9G-3Front Seat Heater Switch (Driver and

Passenger Side) Inspection (If Equipped)........ 9G-3

Front Seat Heater Wire Inspection (If

Equipped) ......................................................... 9G-3

Rear Seat Components...................................... 9G-4

Rear Seat Removal and Installation................... 9G-4

Specifications ...................................................... 9G-5

Tightening Torque Specifications ....................... 9G-5

Special Tools and Equipment ............................ 9G-5

Recommended Service Material ........................ 9G-5

Interior Trim ............................................. 9H-1

Repair Instructions ..............................................9H-1

Floor Carpet Removal and Installation ................9H-1

Head Lining Removal and Installation.................9H-2

Console Box Components ..................................9H-3

Specifications .......................................................9H-4

Tightening Torque Specifications ........................9H-4

Hood / Fenders / Doors ............................ 9J-1

Repair Instructions .............................................. 9J-1

Hood Removal and Installation ........................... 9J-1

Hood Inspection and Adjustment ........................ 9J-1

Front Fender Components .................................. 9J-2

Front Fender Removal and Installation ............... 9J-2

Front Door Assembly Components ..................... 9J-3

Front Door Assembly Removal and

Installation ......................................................... 9J-3

Rear Door Assembly Components...................... 9J-5

Rear Door Assembly Removal and

Installation ......................................................... 9J-5

Rear End Door Assembly Components .............. 9J-6

Rear End Door Assembly Removal and

Installation ......................................................... 9J-6

Specifications ....................................................... 9J-8

Tightening Torque Specifications ........................ 9J-8

Special Tools and Equipment ............................. 9J-8

Recommended Service Material ......................... 9J-8

Body Structure......................................... 9K-1

Repair Instructions ..............................................9K-1

Front Bumper and Rear Bumper Components .... 9K-1

Cowl Top and Front Lower Crossmember

Components ...................................................... 9K-2

Specifications .......................................................9K-3

Body Dimensions ................................................ 9K-3

Panel Clearance................................................ 9K-10

Tightening Torque Specifications ...................... 9K-10

Paint / Coatings ........................................9L-1

General Description ............................................. 9L-1

Anti-Corrosion Treatment Construction............... 9L-1

Plastic Parts Finishing ......................................... 9L-2

Component Location ........................................... 9L-3

Sealant Application Areas ................................... 9L-3

Under Coating Application Areas ...................... 9L-10

Anti-Corrosion Compound Application Area ..... 9L-12

Exterior Trim ............................................ 9M-1